Integrated Combined Heat and Power System Dispatch Considering Electrical and Thermal Energy Storage

Abstract

:1. Introduction

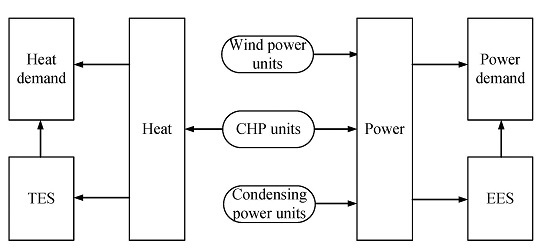

2. Integrated CHP System Model

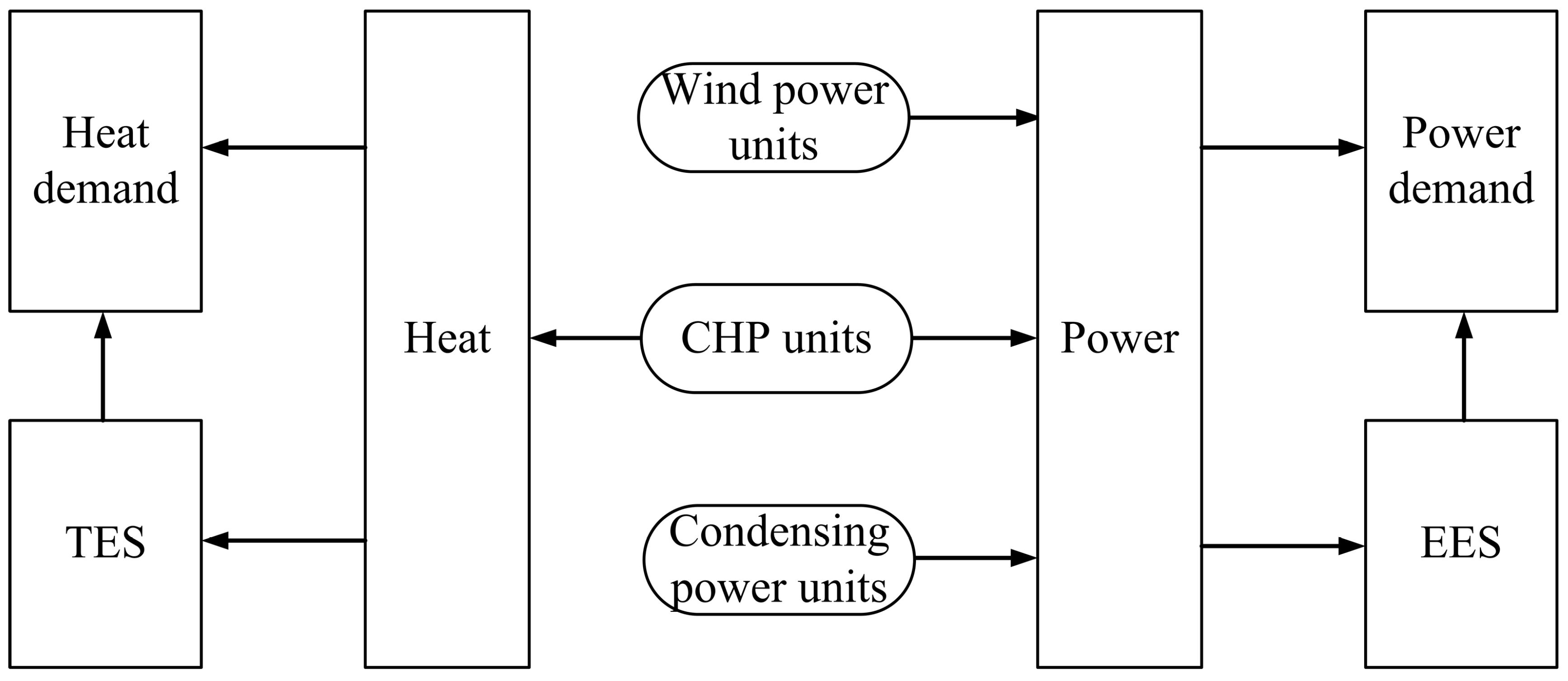

2.1. Electrical Energy Storage Model

2.1.1. Description of Hydrogen Storage System

2.1.2. Mathematical Model of Hydrogen Storage System

2.2. Thermal Energy Storage Model

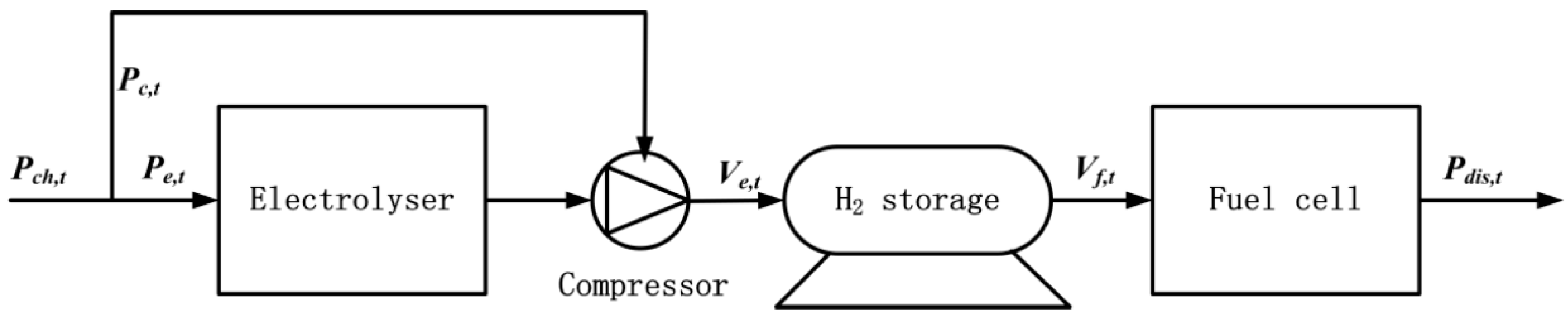

2.3. CHP Unit Model

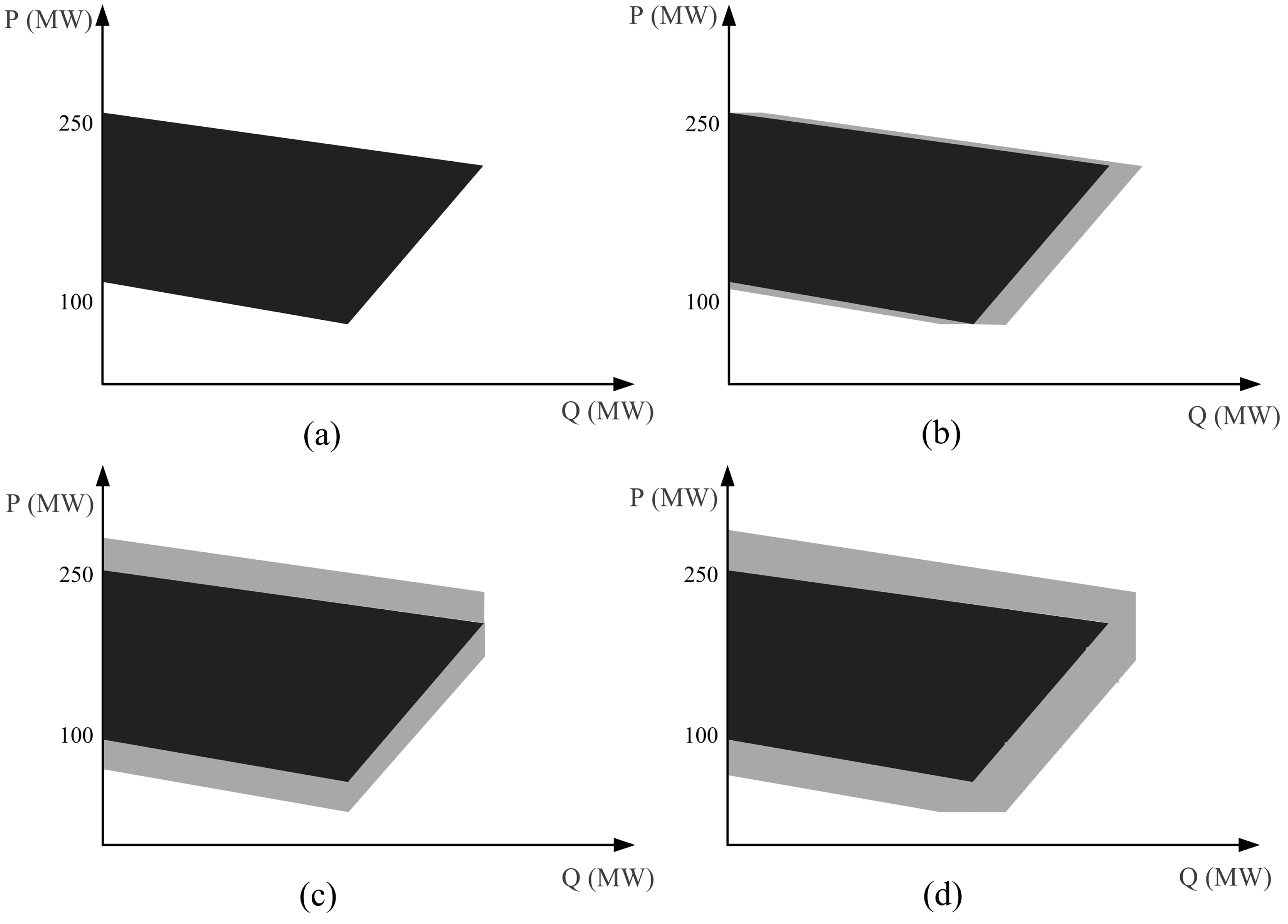

2.3.1. The Heat-Power Feasible Operation Region of CHP Unit

2.3.2. The Heat-Power Feasible Operation Region of CHP Unit when Introducing EES and TES

3. Integrated CHP System Dispatch (ICHPSD) Model

3.1. Decision Variables

3.2. The Objective Function of the Dispatch Model

3.3. Constraints for Energy Balances

3.4. Constraints for System Control and Operation

- (1)

- Constraints for thermal and electrical energy output of CHP plants are expressed in Equations (17)–(20).

- (2)

- Constraints for power ramping rate of CHP plants are expressed in Equations (28) and (29).

- (3)

- Constraints for power output of condensing power units are expressed in Equations (30).

- (4)

- Constraints for power ramping rate of condensing power units are expressed in Equations (31) and (32).

- (5)

- Constraint for power output of wind power in Equation (33) which means the power output should be smaller than the available wind power.where , , , are the ramp-up and ramp-down rates of i-th CHP unit and condensing power unit, respectively.

- (6)

- Constraints for EES device are described in Equations (6)–(11).

- (7)

- Constraints for TES device are described in Equations (12)–(17).

4. Case Study

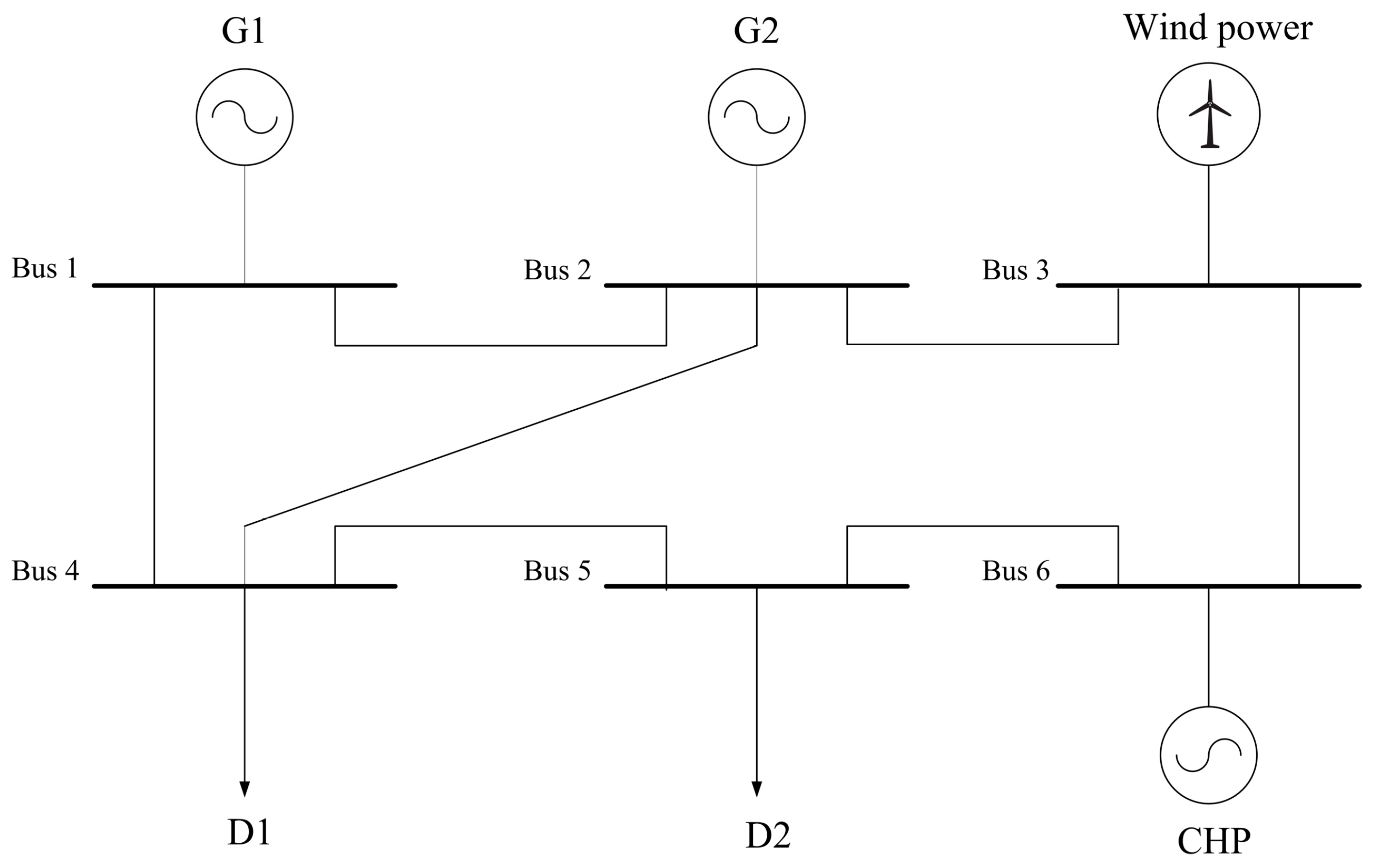

4.1. System Description

4.2. Model Input

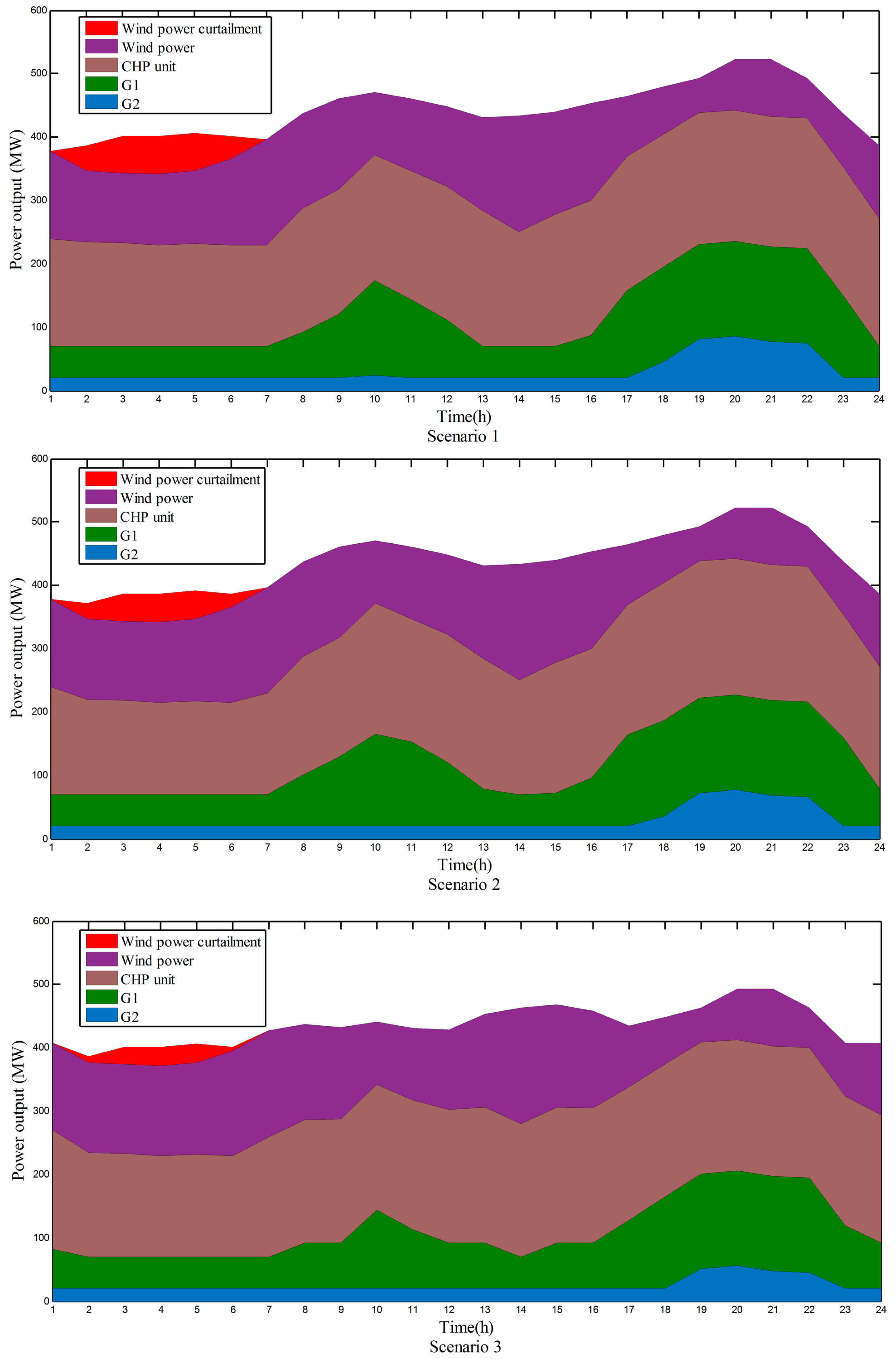

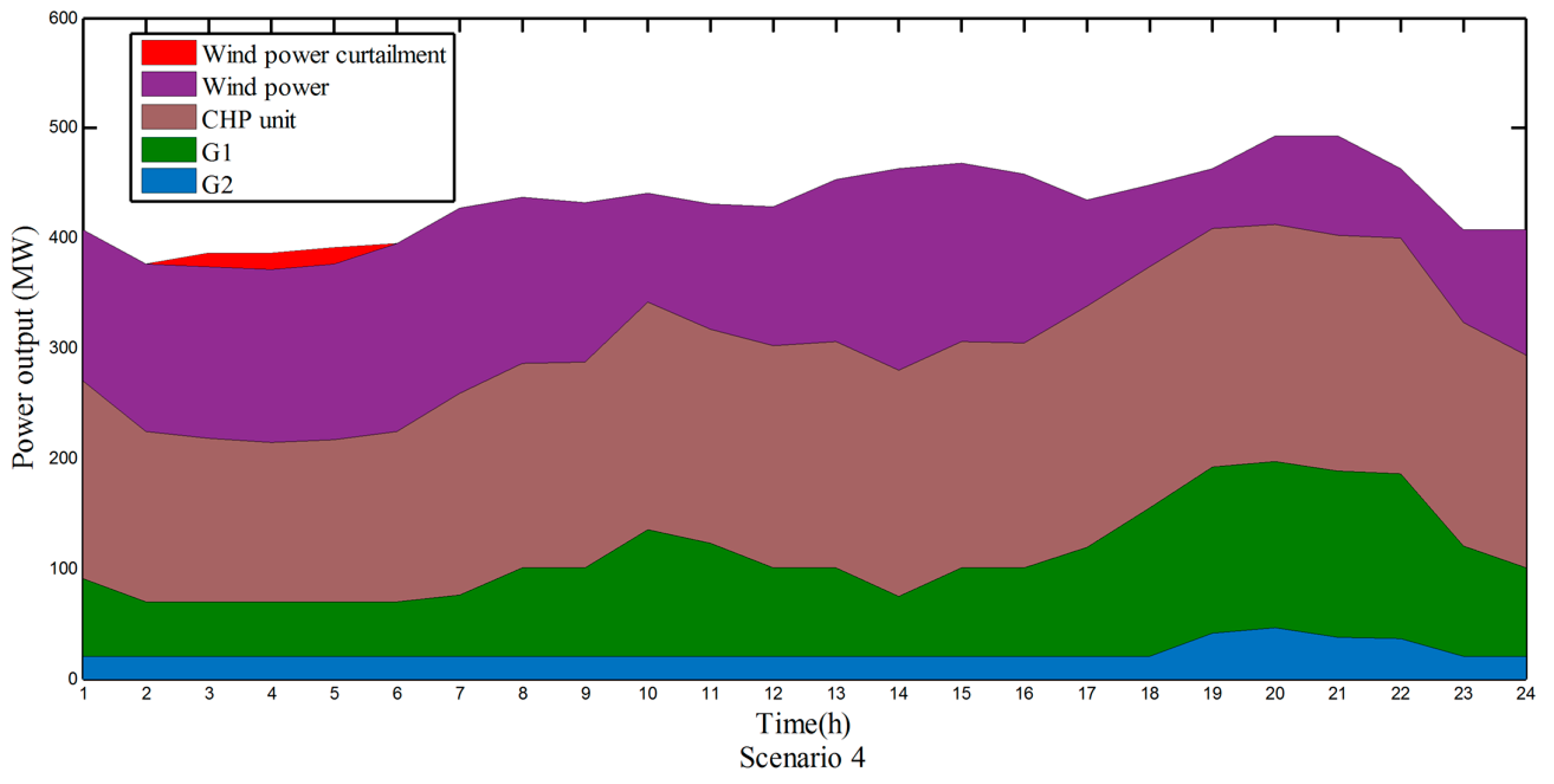

4.3. Results

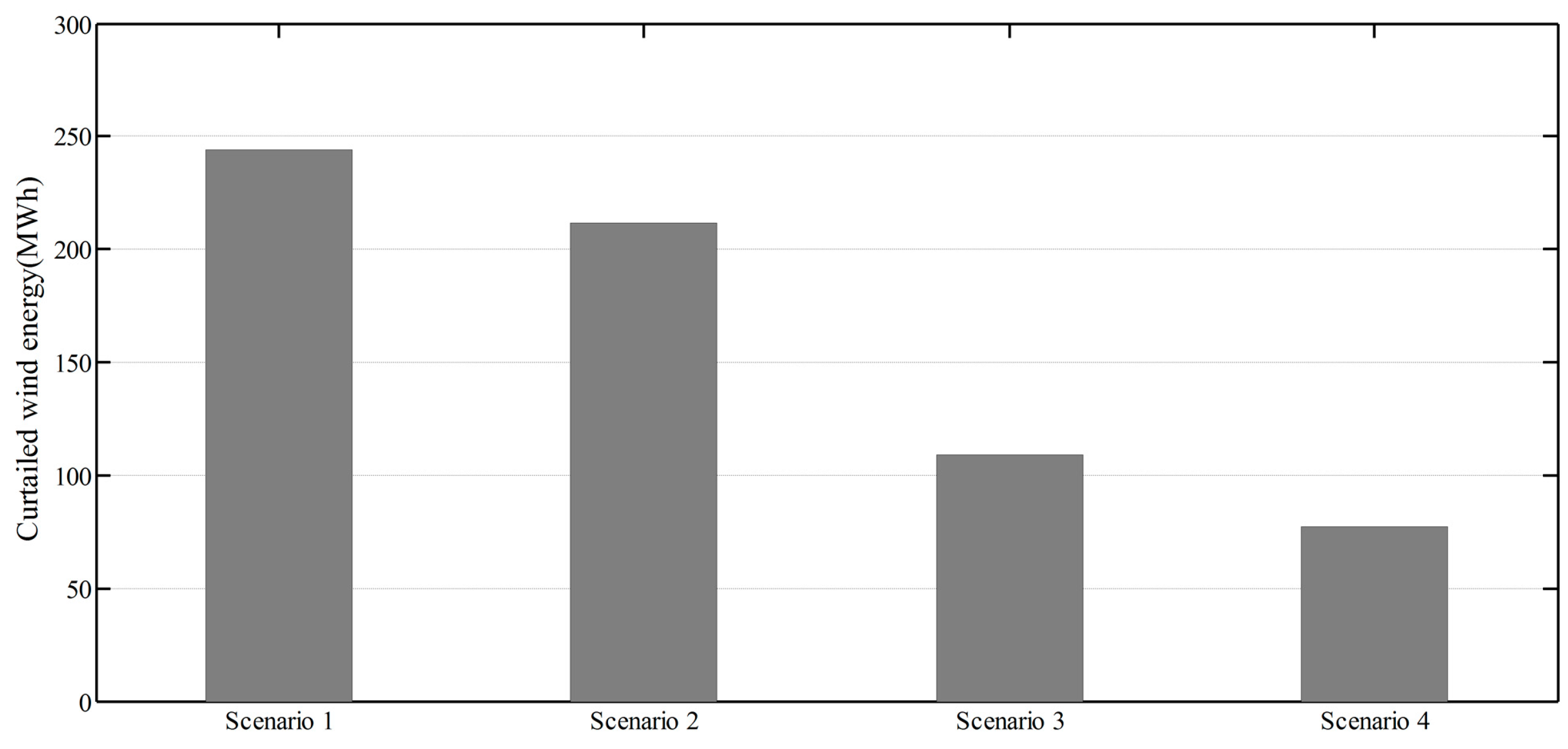

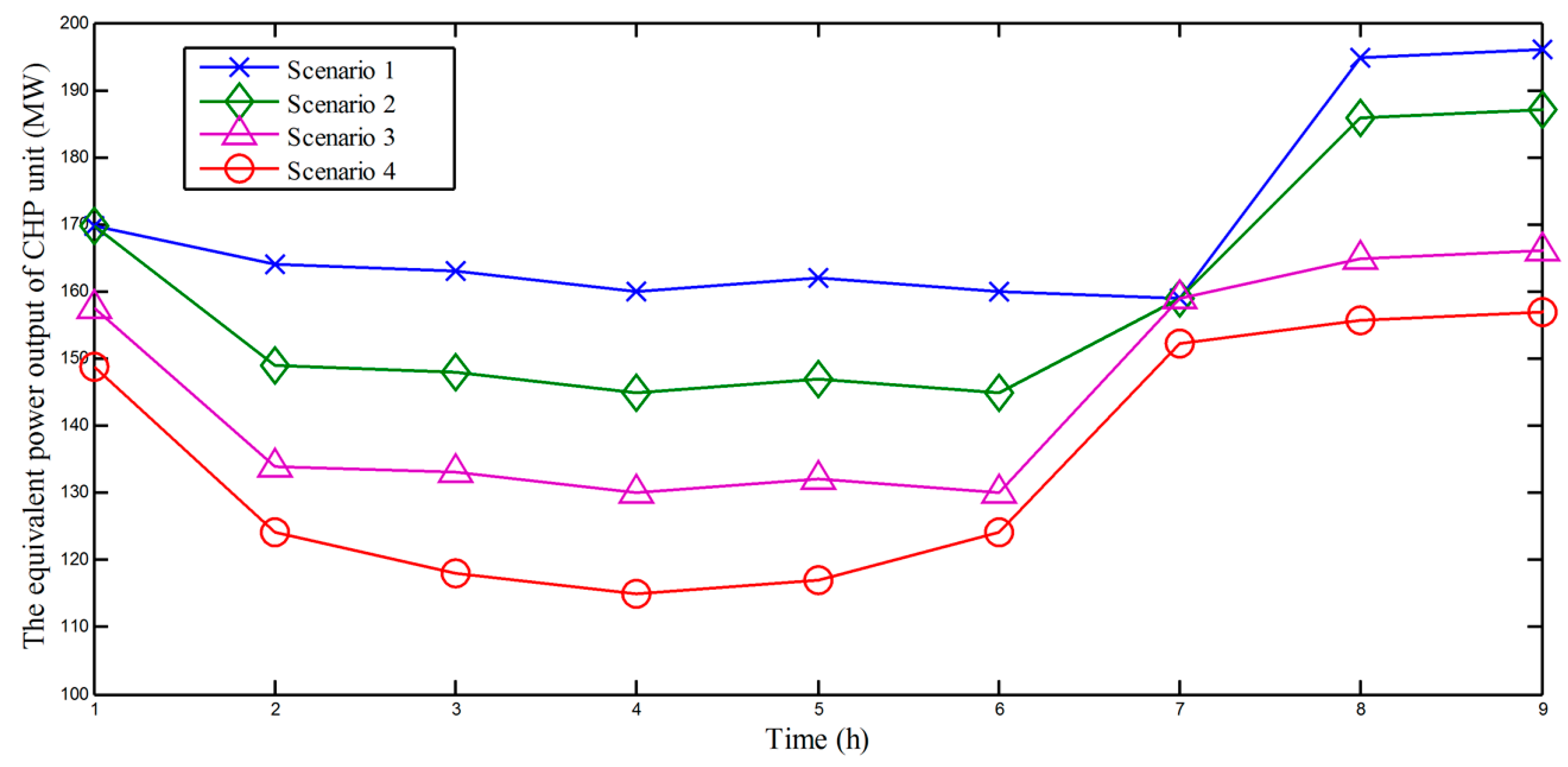

4.3.1. The Effect on Reducing Wind Curtailment

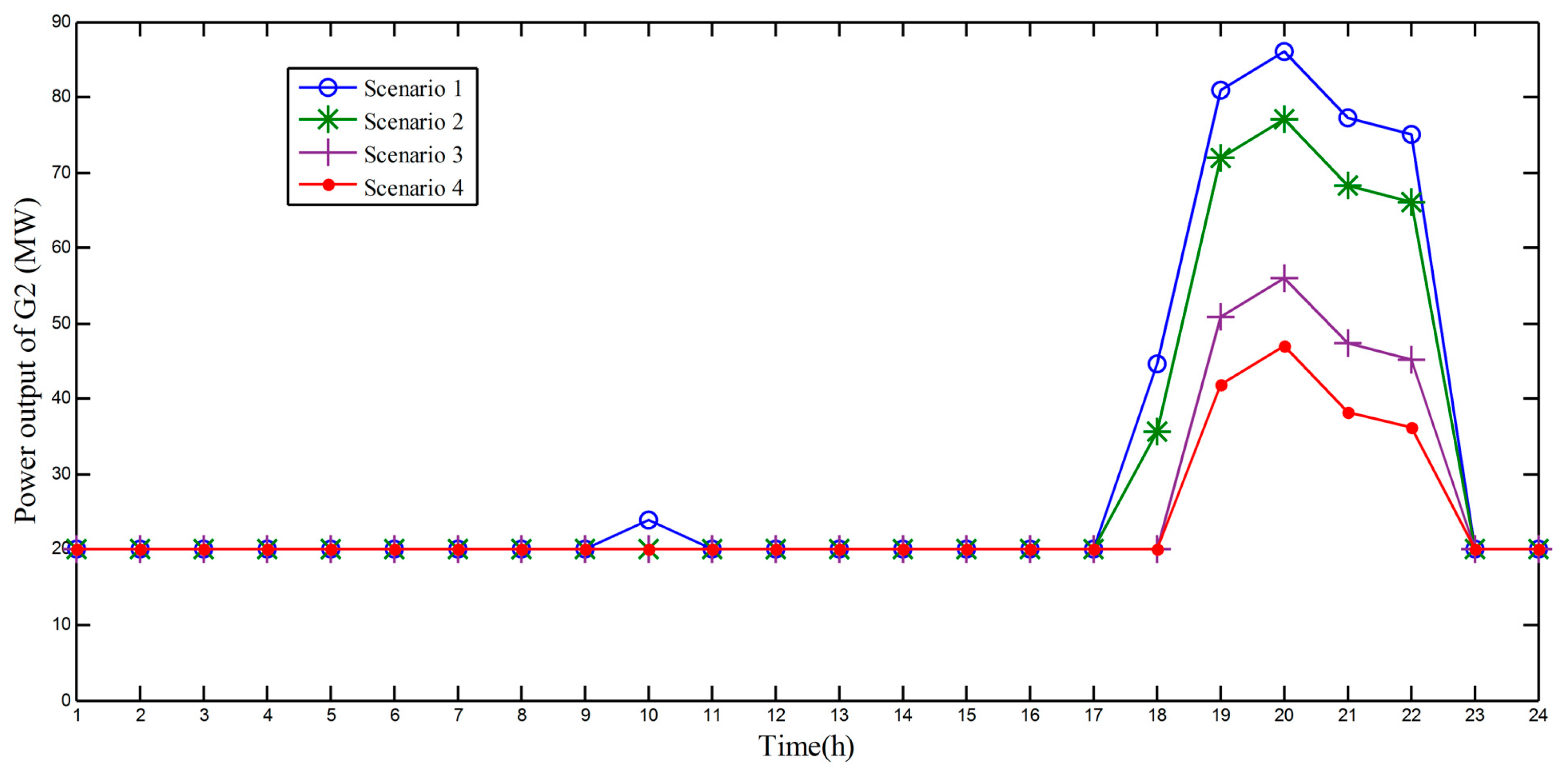

4.3.2. The Effect on Reducing Operation Cost

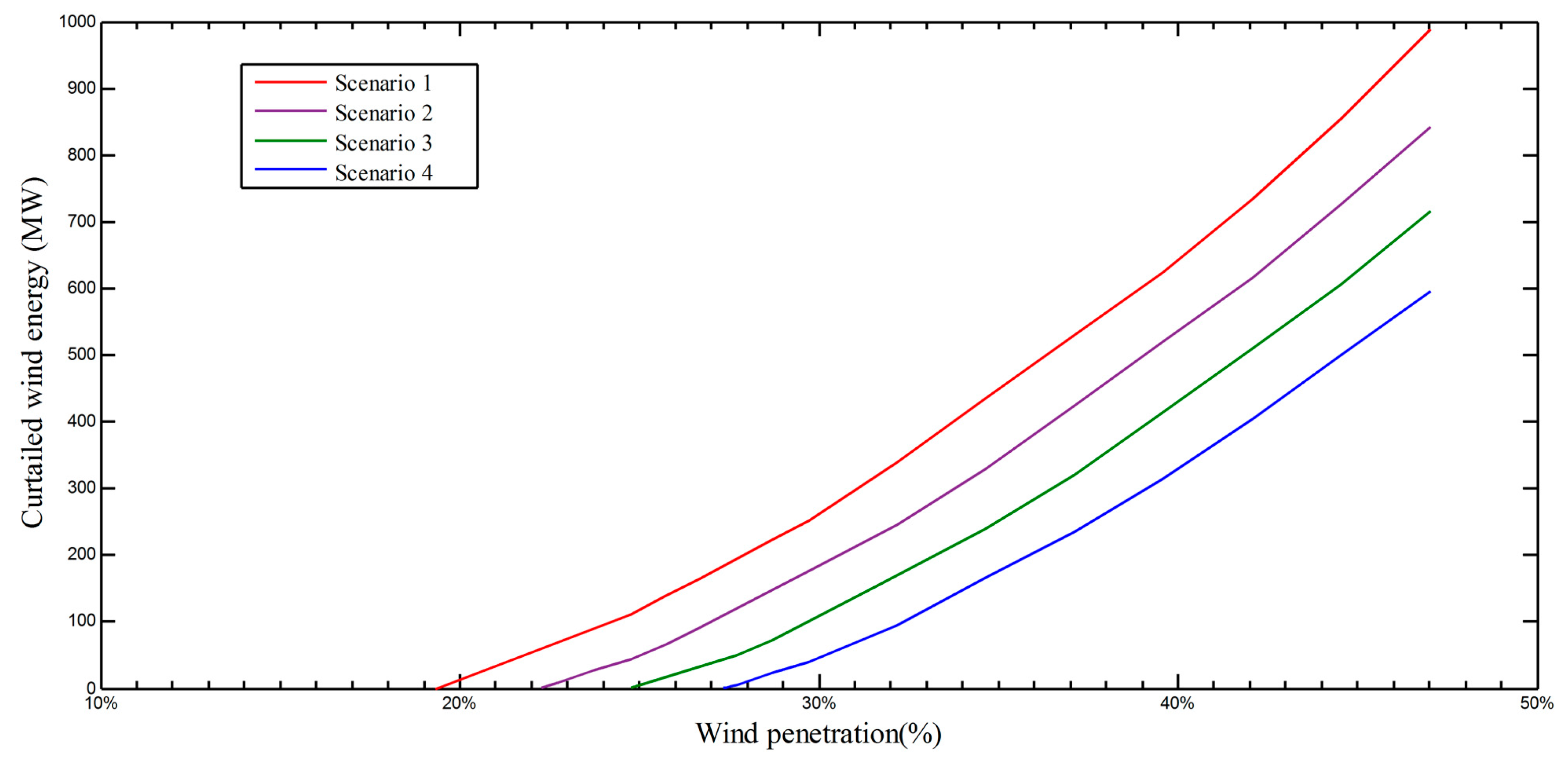

4.3.3. Sensitivity Analysis of Wind Penetration

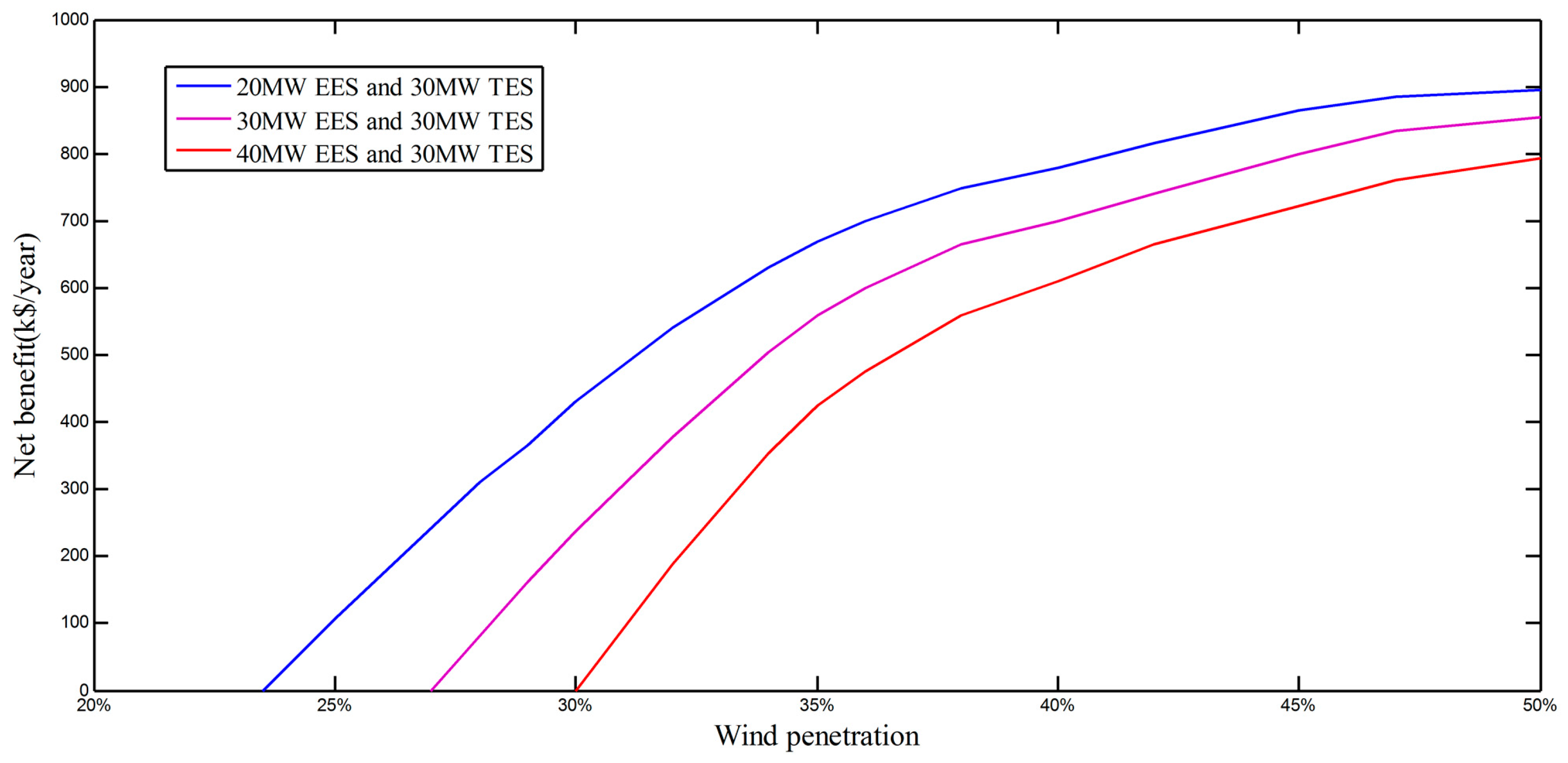

4.3.4. Cost-Benefit Analysis of EES and TES

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhou, K.; Yang, S.; Shen, C.; Ding, S.; Sun, C. Energy conservation and emission reduction of China’s electric power industry. Renew. Sustain. Energy Rev. 2015, 45, 10–19. [Google Scholar] [CrossRef]

- Feng, Y.; Lin, H.Y.; Ho, S.L.; Yanc, J.H.; Dong, J.N.; Fang, S.H.; Huang, Y.K. Overview of wind power generation in China: Status and development. Renew. Sustain. Energy Rev. 2015, 50, 847–858. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Chang, R.D.; Chen, Y.L. What hinder the further development of wind power in China? A socio-technical barrier study. Energ Policy 2016, 88, 465–476. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, X.L.; He, J.K.; Chai, Q.M. Offshore wind energy development in China: Current status and future perspective. Renew. Sustain. Energy Rev. 2011, 15, 4673–4684. [Google Scholar] [CrossRef]

- Nuytten, T.; Claessens, B.; Paredis, K.; Van Bael, J.; Six, D. Flexibility of a combined heat and power system with thermal energy storage for district heating. Appl. Energy 2013, 104, 583–591. [Google Scholar] [CrossRef]

- Bianchi, M.; De Pascale, A.; Melino, F. Performance analysis of an integrated CHP system with thermal and Electric Energy Storage for residential application. Appl. Energy 2013, 112, 928–938. [Google Scholar] [CrossRef]

- Hong, L.X.; Lund, H.; Moller, B. The importance of flexible power plant operation for Jiangsu’s wind integration. Energy 2012, 41, 499–507. [Google Scholar] [CrossRef]

- Tan, Z.F.; Li, H.H.; Ju, L.W.; Song, Y.H. An Optimization Model for Large-Scale Wind Power Grid Connection Considering Demand Response and Energy Storage Systems. Energies 2014, 7, 7282–7304. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, X.S.; Ju, P.; Qian, K.J.; Fu, Z.X. Applications of battery energy storage system for wind power dispatchability purpose. Electr. Power Syst. Res. 2012, 93, 54–60. [Google Scholar] [CrossRef]

- Ghofrani, M.; Arabali, A.; Etezadi-Amoli, M.; Fadali, M.S. Energy Storage Application for Performance Enhancement of Wind Integration. IEEE Trans. Power Syst. 2013, 28, 4803–4811. [Google Scholar] [CrossRef]

- Trifkovic, M.; Sheikhzadeh, M.; Nigim, K.; Daoutidis, P. Modeling and Control of a Renewable Hybrid Energy System With Hydrogen Storage. IEEE Trans. Contr. Syst. Tech. 2014, 22, 169–179. [Google Scholar] [CrossRef]

- Recalde Melo, D.F.; Chang-Chien, L.R. Synergistic Control Between Hydrogen Storage System and Offshore Wind Farm for Grid Operation. IEEE Trans. Sustain. Energy 2014, 5, 18–27. [Google Scholar] [CrossRef]

- Zhao, H.R.; Wu, Q.W.; Hu, S.J.; Xu, H.H.; Rasmussen, C.N. Review of energy storage system for wind power integration support. Appl. Energy 2015, 137, 545–553. [Google Scholar] [CrossRef]

- Nuytten, T.; Moreno, P.; Vanhoudt, D.; Jespers, L.; Sole, A.; Cabeza, L.F. Comparative analysis of latent thermal energy storage tanks for micro-CHP systems. Appl. Therm. Eng. 2013, 59, 542–549. [Google Scholar] [CrossRef]

- Christidis, A.; Koch, C.; Pottel, L.; Tsatsaronis, G. The contribution of heat storage to the profitable operation of combined heat and power plants in liberalized electricity markets. Energy 2012, 41, 75–82. [Google Scholar] [CrossRef]

- Lund, H.; Mathiesen, B.V. Energy system analysis of 100% renewable energy systems—The case of Denmark in years 2030 and 2050. Energy 2009, 34, 524–531. [Google Scholar] [CrossRef]

- Yang, Y.L.; Wu, K.; Long, H.Y.; Gao, J.C.; Yan, X.; Kato, T.; Suzuoki, Y. Integrated electricity and heating demand-side management for wind power integration in China. Energy 2014, 78, 235–246. [Google Scholar] [CrossRef]

- Chen, X.Y.; Kang, C.Q.; O'Malley, M.; Xia, Q. Increasing the Flexibility of Combined Heat and Power for Wind Power Integration in China Modeling and Implications. IEEE Trans. Power Syst. 2015, 30, 1848–1857. [Google Scholar] [CrossRef]

- Li, Z.G.; Wu, W.C.; Shahidehpour, M.; Wang, J.H.; Zhang, B. Combined Heat and Power Dispatch Considering Pipeline Energy Storage of District Heating Network. IEEE Trans. Sustain. Energy 2016, 7, 12–22. [Google Scholar] [CrossRef]

- Hedegaard, K.; Mathiesen, B.V.; Lund, H.; Heiselberg, P. Wind power integration using individual heat pumps—Analysis of different heat storage options. Energy 2012, 47, 284–293. [Google Scholar] [CrossRef]

- Wang, H.C.; Yin, W.S.; Abdollahi, E.; Landelma, R.; Jiao, W.L. Modelling and optimization of CHP based district heating system with renewable energy production and energy storage. Appl. Energy 2015, 159, 401–421. [Google Scholar] [CrossRef]

- Agbossou, K.; Kolhe, M.; Hamelin, J.; Bose, T.K. Performance of a stand-alone renewable energy system based on energy storage as hydrogen. IEEE Trans. Energy Convers. 2004, 19, 633–640. [Google Scholar] [CrossRef]

- Korpas, K.; Holen, A.T. Operation planning of hydrogen storage connected to wind power operating in a power market. IEEE Trans. Energy Convers. 2006, 21, 742–749. [Google Scholar] [CrossRef]

- Garcia-Torres, F.; Bordons, C. Optimal Economical Schedule of Hydrogen-Based Microgrids With Hybrid Storage Using Model Predictive Control. IEEE Trans. Ind. Electron. 2015, 62, 5195–5207. [Google Scholar] [CrossRef]

- Bogdan, Z.; Kopjar, D. Improvement of the cogeneration plant economy by using heat accumulator. Energy 2006, 31, 2285–2292. [Google Scholar] [CrossRef]

- Rezaie, B.; Reddy, B.V.; Rosen, M.A. Energy analysis of thermal energy storages with grid configurations. Appl. Energy 2014, 117, 54–61. [Google Scholar] [CrossRef]

- Yazdani, A.; Jayabarathi, T.; Ramesh, V.; Raghunathan, T. Combined heat and power economic dispatch problem using firefly algorithm. Front. Energy 2013, 7, 133–139. [Google Scholar] [CrossRef]

- Khorram, E.; Jaberipour, M. Harmony search algorithm for solving combined heat and power economic dispatch problems. Energy Convers. Manag. 2011, 52, 1550–1554. [Google Scholar] [CrossRef]

- Jiang, R.W.; Wang, J.H.; Guan, Y.P. Robust Unit Commitment With Wind Power and Pumped Storage Hydro. IEEE Trans. Power Syst. 2012, 27, 800–810. [Google Scholar] [CrossRef]

- Barbieri, E.S.; Melino, F.; Morini, M. Influence of the thermal energy storage on the profitability of micro-CHP systems for residential building applications. Appl. Energy 2012, 97, 714–722. [Google Scholar] [CrossRef]

- Hedegaard, K.; Münster, M. Influence of individual heat pumps on wind power integration—Energy system investments and operation. Energ. Convers. Manag. 2013, 75, 673–684. [Google Scholar] [CrossRef] [Green Version]

- Danish Energy Agency. Energinet.dk. Technology Data for Energy Plants–Generation of Electricity and District Heating, Energy Storage and Carrier Generation and Conversion; Danish Energy Agency: Copenhagen, Denmark, 2012. [Google Scholar]

| Scenario | Condensing Power Units | CHP Unit | Wind Power Unit | EES | TES | |

|---|---|---|---|---|---|---|

| G1 | G2 | |||||

| 1 | • | • | • | • | × | × |

| 2 | • | • | • | • | • | × |

| 3 | • | • | • | • | × | • |

| 4 | • | • | • | • | • | • |

| Device | Investment Cost | O&M Cost (% of Investment Cost per Year) | Overall Efficiency | Lifetime (years) |

|---|---|---|---|---|

| Hydrogen storage | 1.6 M$/MW | 4% | 0.65 | 30 |

| Thermal storage | 0.004 M$/MWh | 1% | 0.99 | 40 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, R.; Ye, J.; Lei, J.; Li, T. Integrated Combined Heat and Power System Dispatch Considering Electrical and Thermal Energy Storage. Energies 2016, 9, 474. https://doi.org/10.3390/en9060474

Yuan R, Ye J, Lei J, Li T. Integrated Combined Heat and Power System Dispatch Considering Electrical and Thermal Energy Storage. Energies. 2016; 9(6):474. https://doi.org/10.3390/en9060474

Chicago/Turabian StyleYuan, Rongxiang, Jun Ye, Jiazhi Lei, and Timing Li. 2016. "Integrated Combined Heat and Power System Dispatch Considering Electrical and Thermal Energy Storage" Energies 9, no. 6: 474. https://doi.org/10.3390/en9060474