Sliding Mode Variable Structure Control of a Bearingless Induction Motor Based on a Novel Reaching Law

Abstract

:1. Introduction

2. Design of the Adaptive Variable-Rated Exponential Reaching Law and ASMC

3. Design of the BIM Speed ASMC

3.1. The Dynamics Model of BIM

3.2. The Design of the Speed of the ASMC

4. Simulation and Experiment Research

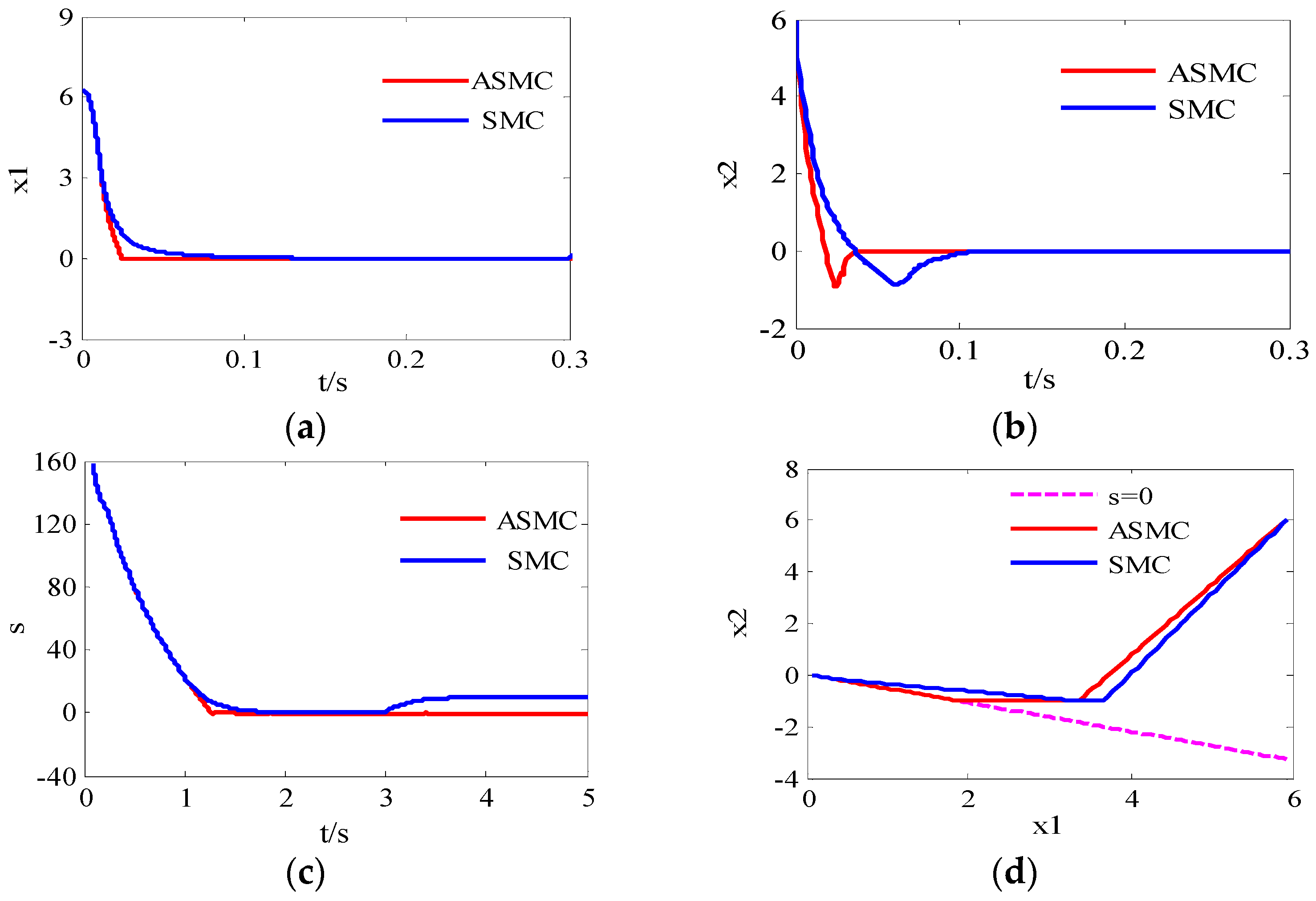

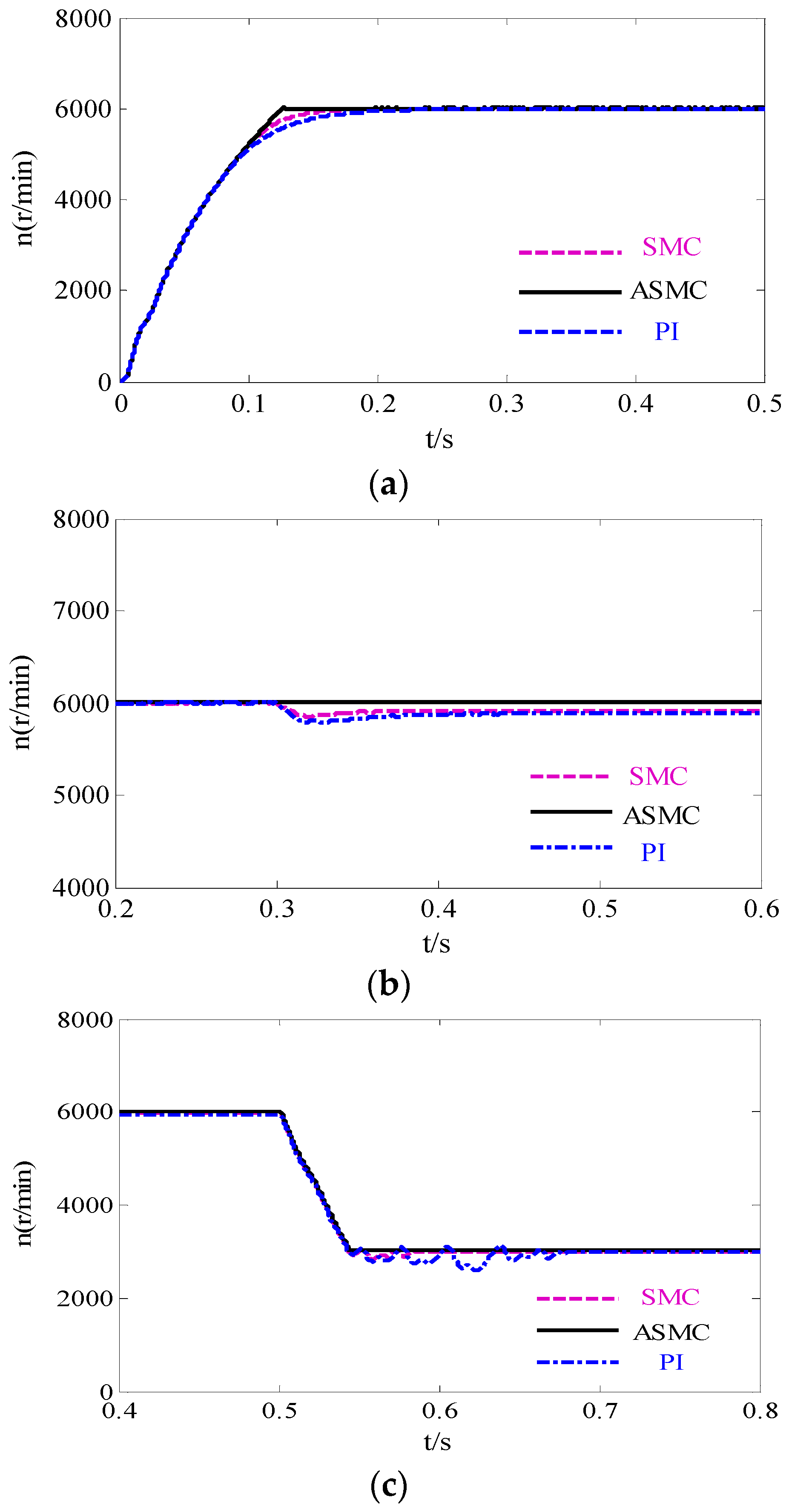

4.1. Results and Analysis of the Simulation

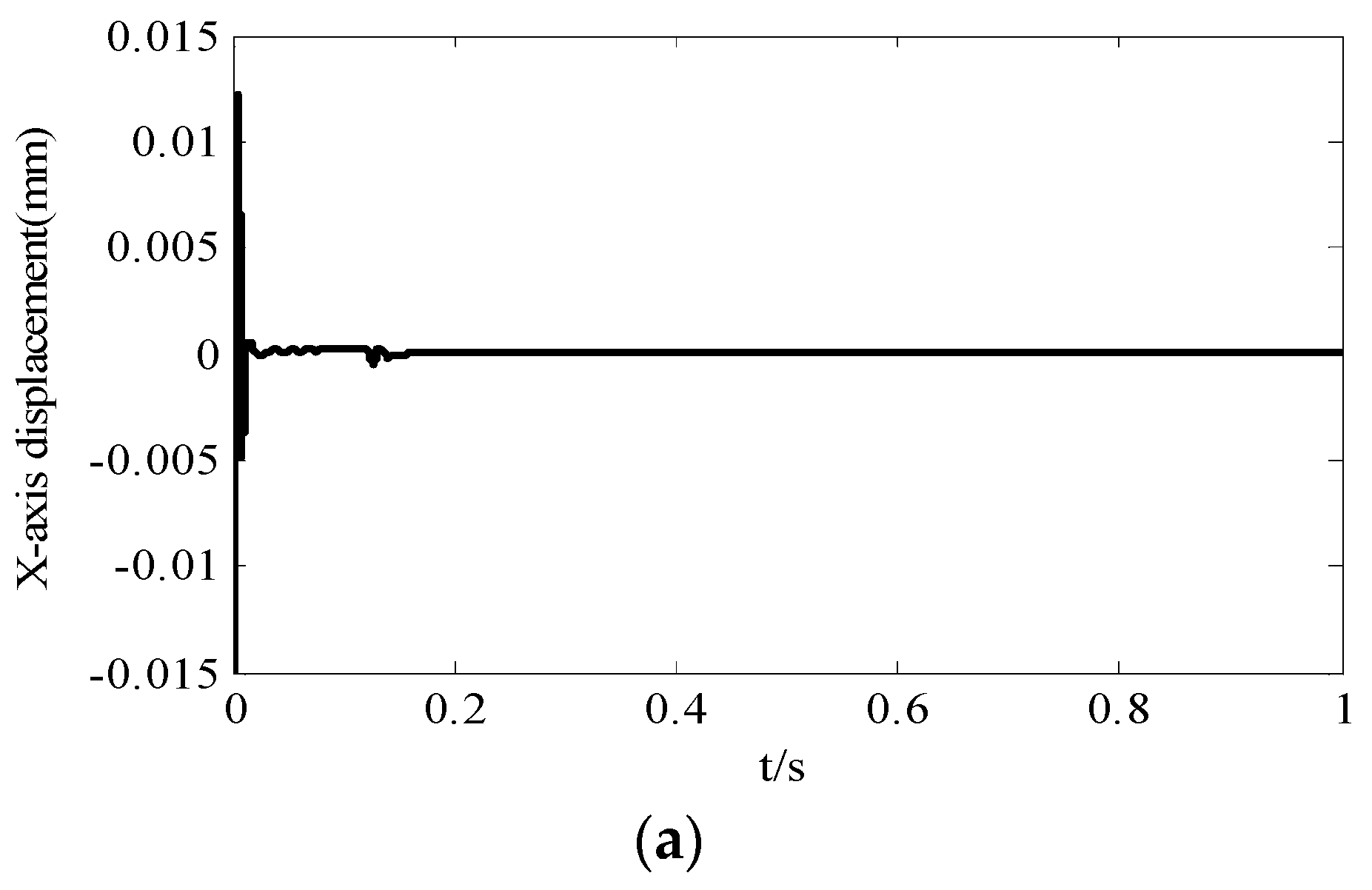

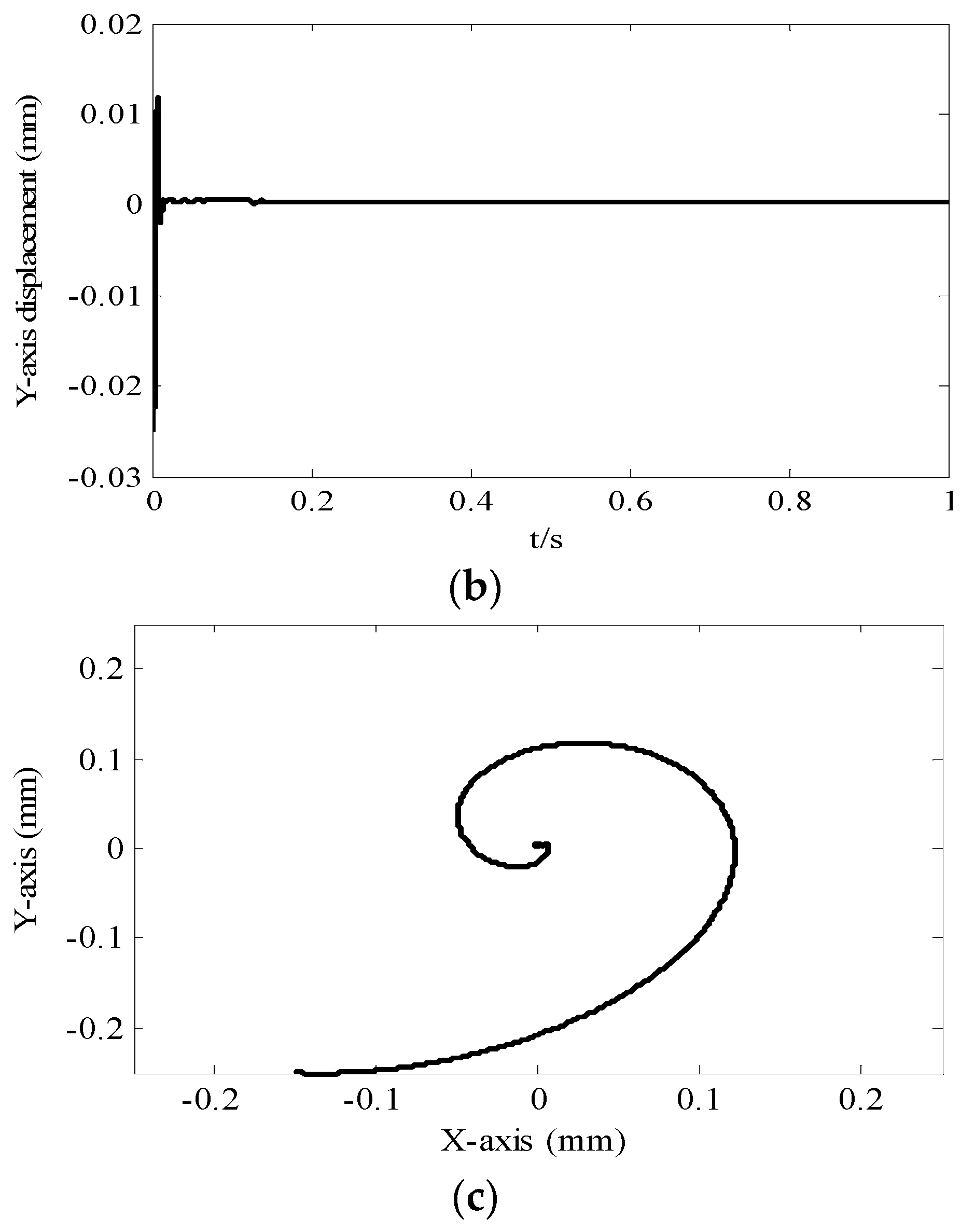

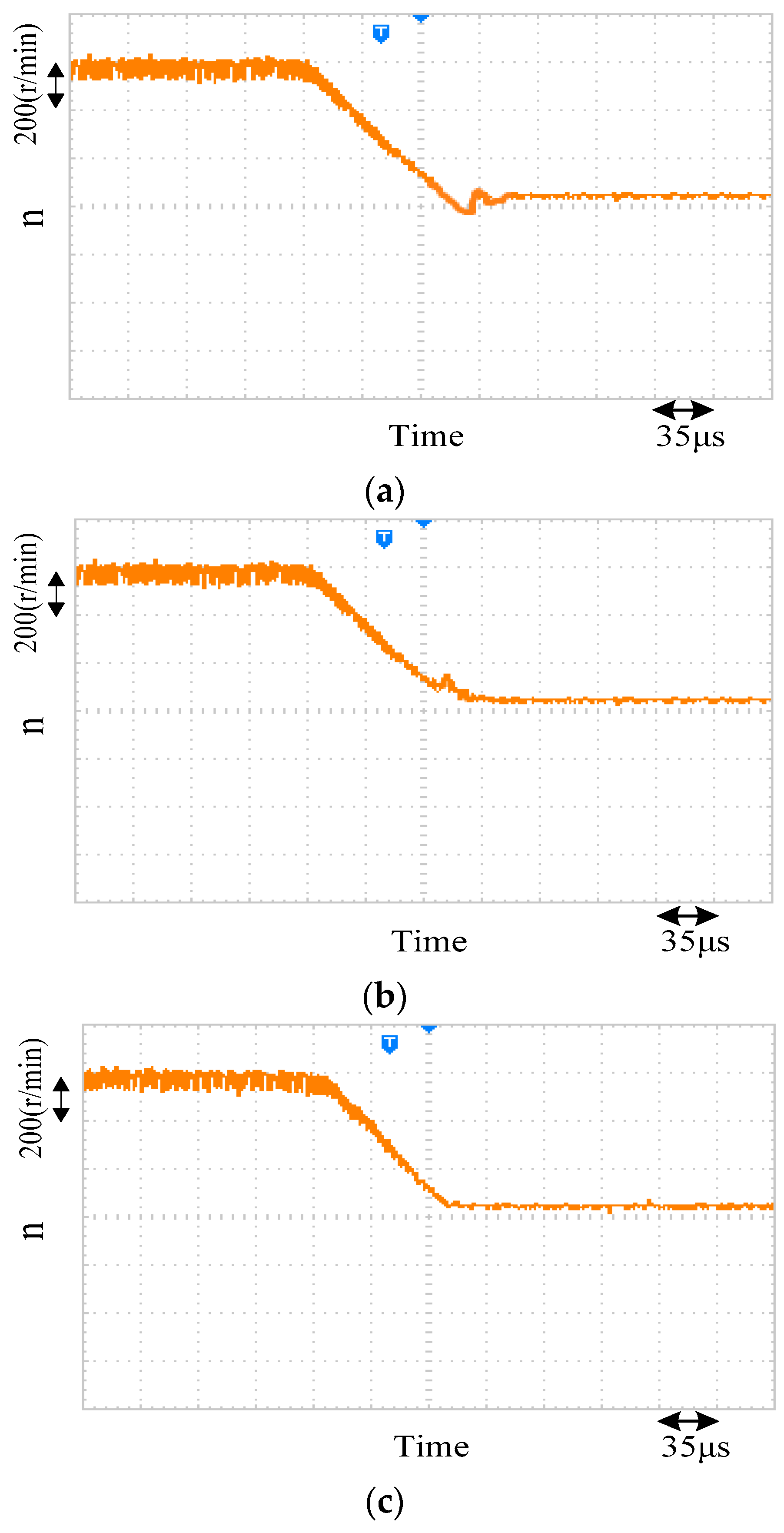

4.2. Results and Analysis of the Experiment

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| BIM | Bearingless Induction Motor. |

| ASMC | Adaptive variable-rated sliding mode controller. |

| PMSM | Permanent magnet synchronous motor. |

| SMC | Sliding mode controller. |

| DC | Direct current. |

| PI | Proportional-Integral |

References

- De Almeida, A.T.; Ferreira, F.J.T.E.; Quintino, D.A. Technical and Economical Considerations on Super High-Efficiency Three-Phase Motors. IEEE Trans. Ind. Appl. 2014, 50, 1274–1285. [Google Scholar] [CrossRef]

- Sun, X.D.; Chen, L.; Yang, Z.B. Overview of bearingless permanent magnet synchronous motors. IEEE Trans. Ind. Electron. 2013, 60, 5528–5538. [Google Scholar] [CrossRef]

- Sinervo, A.; Arkkio, A. Rotor radial position control and its effect on the total efficiency of a bearingless induction motor with a cage rotor. IEEE Trans. Magn. 2014, 50, 1–9. [Google Scholar] [CrossRef]

- Yang, Z.B.; Dong, D.W.; Gao, H.Y.; Sun, X.D.; Fan, R.; Zhu, H.Q. Rotor mass eccentricity vibration compensation control in bearingless induction motor. Adv. Mech. Eng. 2015, 7. [Google Scholar] [CrossRef]

- Chiba, A.; Asama, J. Influence of rotor skew in induction type bearingless motor. IEEE Trans. Magn. 2012, 48, 4646–4649. [Google Scholar] [CrossRef]

- Hou, B.J.; Gao, J.S.; Li, X.Q.; Zhou, Y.F. Study on repetitive PID control of linear motor in wafer stage of lithography. Procedia Eng. 2012, 29, 3863–3867. [Google Scholar] [CrossRef]

- Sun, X.D.; Chen, L.; Yang, Z.B.; Zhu, H.Q. Speed-sensorless vector control of a bearingless induction motor with artificial neural network inverse speed observer. IEEE/ASME Trans. Mechatron. 2013, 18, 1357–1366. [Google Scholar] [CrossRef]

- Sun, X.D.; Chen, L.; Jiang, H.B.; Yang, Z.B.; Chen, J.C.; Zhang, W.Y. High-performance control for a bearingless permanent magnet synchronous motor using neural network inverse scheme plus internal model controllers. IEEE Trans. Ind. Electron. 2016, 63, 3479–3488. [Google Scholar] [CrossRef]

- Zhang, H.S.; Wang, P.; Han, B.C. Rotor Position Measurement for High-speed Permanent Magnet Synchronous Motors Based on Fuzzy PI MRAS. Proc. Chin. Soc. Electr. Eng. 2014, 34, 1889–1896. (In Chinese) [Google Scholar]

- Mercorelli, P. An Antisaturating Adaptive Preaction and a Slide Surface to Achieve Soft Landing Control for Electromagnetic Actuators. IEEE/ASME Trans. Mechatron. 2012, 17, 76–85. [Google Scholar] [CrossRef]

- Wang, X.D.; Liu, G. Sensorless Control of High Speed Permanent Magnet Synchronous Motor Based on Modified Sliding-Mode Observer. Adv. Mater. Res. 2014, 986–987, 1134–1137. [Google Scholar] [CrossRef]

- Shi, T.N.; Xiao, Z.X.; Xiao, Y.W.; Xia, C. A Position Sensorless Control Strategy for BLDCM Based on an Improved Sliding Mode Observer. Proc. Chin. Soc. Electr. Eng. 2015, 35, 2043–2051. [Google Scholar]

- Mercorelli, P. A Two-Stage Sliding-Mode High-Gain Observer to Reduce Uncertainties and Disturbances Effects for Sensorless Control in Automotive Applications. IEEE Trans. Ind. Electron. 2015, 62, 5929–5940. [Google Scholar] [CrossRef]

- Li, S.H.; Wu, C.; Sun, Z. Design and Implementation of Clutch Control for Automotive Transmissions Using Terminal-Sliding-Mode Control and Uncertainty Observer. IEEE Trans. Veh. Technol. 2016, 65, 1890–1898. [Google Scholar] [CrossRef]

- Serna-Garcés, S.I.; Gonzalez Montoya, D.; Ramos-Paja, C.A. Sliding-Mode Control of a Charger/Discharger DC/DC Converter for DC-Bus Regulation in Renewable Power Systems. Energies 2016, 9, 245. [Google Scholar] [CrossRef]

- Lin, F.-J.; Shen, P.-H. Robust Fuzzy Neural Network Sliding-Mode Control for Two-Axis Motion Control System. IEEE Trans. Ind. Electron. 2006, 53, 1209–1225. [Google Scholar] [CrossRef]

- Zhu, Y.; Cheng, M.; Hua, W.; Zhang, B.; Wang, W. Sensorless Control for Electrical Variable Transmission Based on Sliding Mode Model Reference Adaptive System. Diangong Jishu Xuebao 2015, 30, 64–72. (In Chinese) [Google Scholar]

- Zhang, X.G.; Sun, L.; Zhao, K. Sliding mode control of PMSM based on a novel load torque sliding mode observer. Proc. Chin. Soc. Electr. Eng. 2012, 32, 111–116. (In Chinese) [Google Scholar]

- Asad, M.; Bhatti, A.I.; Iqbal, S.; Asfia, Y. A smooth integral sliding mode controller and disturbance estimator design. Int. J. Control Autom. Syst. 2015, 13, 1326–1336. [Google Scholar] [CrossRef]

- Guo, J.G.; Jian, X.P.; Lin, G.Y. Performance Evaluation of an Anti-Lock Braking System for Electric Vehicles with a Fuzzy Sliding Mode Controller. Energies 2014, 7, 6459–6476. [Google Scholar] [CrossRef]

- Xu, B.; Zhu, H.Q. Adaptive nonsingular terminal sliding model control and its application to BPMSM. Control Decis. 2014, 29, 833–837. [Google Scholar]

- Yi, B.Y.; Kang, L.Y.; Tao, S.N.; Guo, H. Design of Robust High Order Sliding Mode Observer for Permanent Magnet Synchronous Motors. Diangong Jishu Xuebao 2014, 29, 132–140. (In Chinese) [Google Scholar]

- Gao, W.B. Variable Structure Control Theory; Science and Technology Press: Beijing, China, 1990; pp. 28–30. [Google Scholar]

- Kim, M.; Song, D. A robust control of Permanent magnet synchronous Motor using Load Torque Estimation. In Proceedings of the IEEE International Symposium on Industrial Electronics, Pusan, Korea, 12–16 June 2001; pp. 1157–1162.

- Yang, Z.B.; Sun, X.D.; Wang, M.T.; Zhu, H.Q. Decoupling control of bearingless induction motors based on least squares support vector machine inverse. J. Comput. Theor. Nanosci. 2014, 11, 1403–1409. [Google Scholar] [CrossRef]

| Parameters | Torque Winding | Suspension Winding |

|---|---|---|

| Rated power (Kw) | 1 | 0.5 |

| Rated current (A) | 2.86 | 2.86 |

| Stator resistance (Ω) | 2.01 | 1.03 |

| Rotor resistance (Ω) | 11.48 | 0.075 |

| Mutual inductance of stator and rotor (H) | 0.15856 | 0.00932 |

| Stator leakage inductance (H) | 0.16310 | 0.01199 |

| Rotor leakage inductance (H) | 0.16778 | 0.01474 |

| Rotational inertia (kg·m2) | 0.00769 | 0.00769 |

| Rotor mass (kg) | 2.85 | 2.85 |

| Stator inner diameter (mm) | 98 | 98 |

| Core length (mm) | 105 | 105 |

| Pole pairs | 1 | 2 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Wan, L.; Sun, X.; Li, F.; Chen, L. Sliding Mode Variable Structure Control of a Bearingless Induction Motor Based on a Novel Reaching Law. Energies 2016, 9, 452. https://doi.org/10.3390/en9060452

Yang Z, Wan L, Sun X, Li F, Chen L. Sliding Mode Variable Structure Control of a Bearingless Induction Motor Based on a Novel Reaching Law. Energies. 2016; 9(6):452. https://doi.org/10.3390/en9060452

Chicago/Turabian StyleYang, Zebin, Ling Wan, Xiaodong Sun, Fangli Li, and Lin Chen. 2016. "Sliding Mode Variable Structure Control of a Bearingless Induction Motor Based on a Novel Reaching Law" Energies 9, no. 6: 452. https://doi.org/10.3390/en9060452