Enhancement of Fire Safety of an Existing Green Building due to Natural Ventilation

Abstract

:1. Introduction

1.1. Energy-Saving Trend of Buildings

1.2. Fire Safety of Energy-Saving Buildings

1.3. Stack Effect Due to the Momentum Conservation in the Fluid

| F: force (N) | σij: fluid stress in x,y,z direction |

| ρ: density (kg/m3) | : normal vector |

| g: gravity vector (m/s2) |

2. Description of Study Case

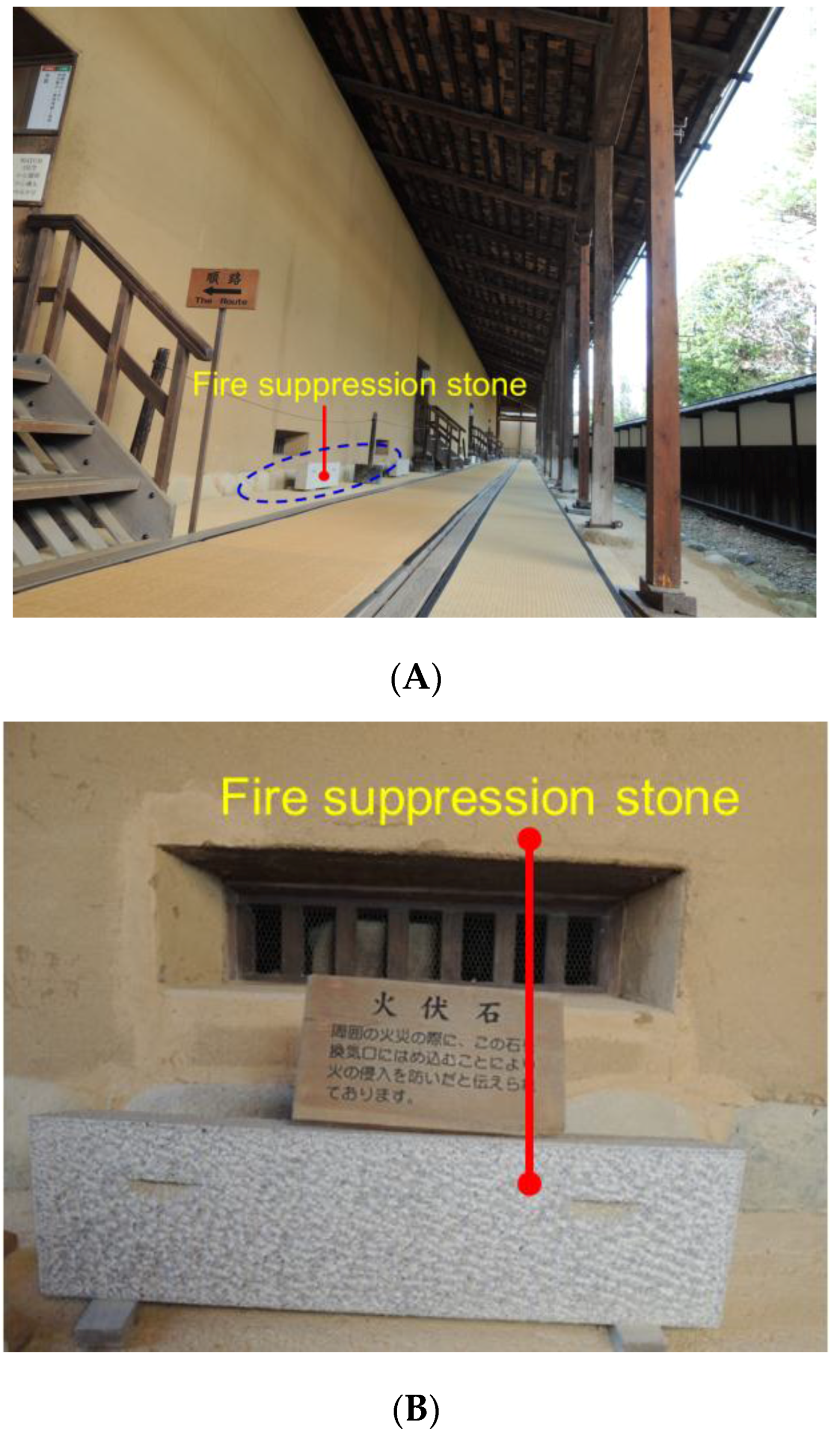

2.1. Building Characteristics

- Special opening design: three openings under the platform are created to allow natural wind into the room when the outside air temperature is not too high. There is an opening in the rear wall through which the imported air flows back outdoors. The planned air flow path is about 1 m above the ground, just above the seats. The gentle air flow helps keep the ambient air at a comfortable temperature.

- Metal ventilation tower: on the principle of the stack effect, the air discharged from the rear of room to the outside flows through a metal chimney. As the solar irradiation heats the periphery of the metal chimney, the air flow is heated and the velocity of the ascending air flow is accelerated. More outside air is imported to increase the indoor air change rate.

2.2. Regional Meteorology

3. Methodology

3.1. Research on Building Performance Simulation

- (1)

- Algebraic Equation [35]

- (2)

- Zone Model

- (3)

- Field Model

3.2. Features of FDS

- Conservation of Mass:

- Conservation of Momentum (Newton’s Second Law)

- Conservation of Energy (First Law of Thermodynamics)

- Equation of State for a Perfect Gas

| ρ | density (kg/m3) | mass production rate per unit volume (kg/s m3) | |

| fb | external force vector (N/m3) | heat release rate per unit volume (kg/s m3) | |

| g | gravity vector (m/s2) | energy transferred (kg/s m3) | |

| h | sensible enthalpy (kJ) | heat flux vector (J/s m2) | |

| p | pressure (pa) | ε | dissipation rate (kg/s m3) |

| R | universal gas constant (J/K·mol) | viscous stress tensor (N/m2) | |

| T | temperature (°C) | molecular weight of the gas mixture (g/mol) | |

| u | velocity vector u(u,v,w) (m/s) | ||

4. Setting of Simulated Conditions

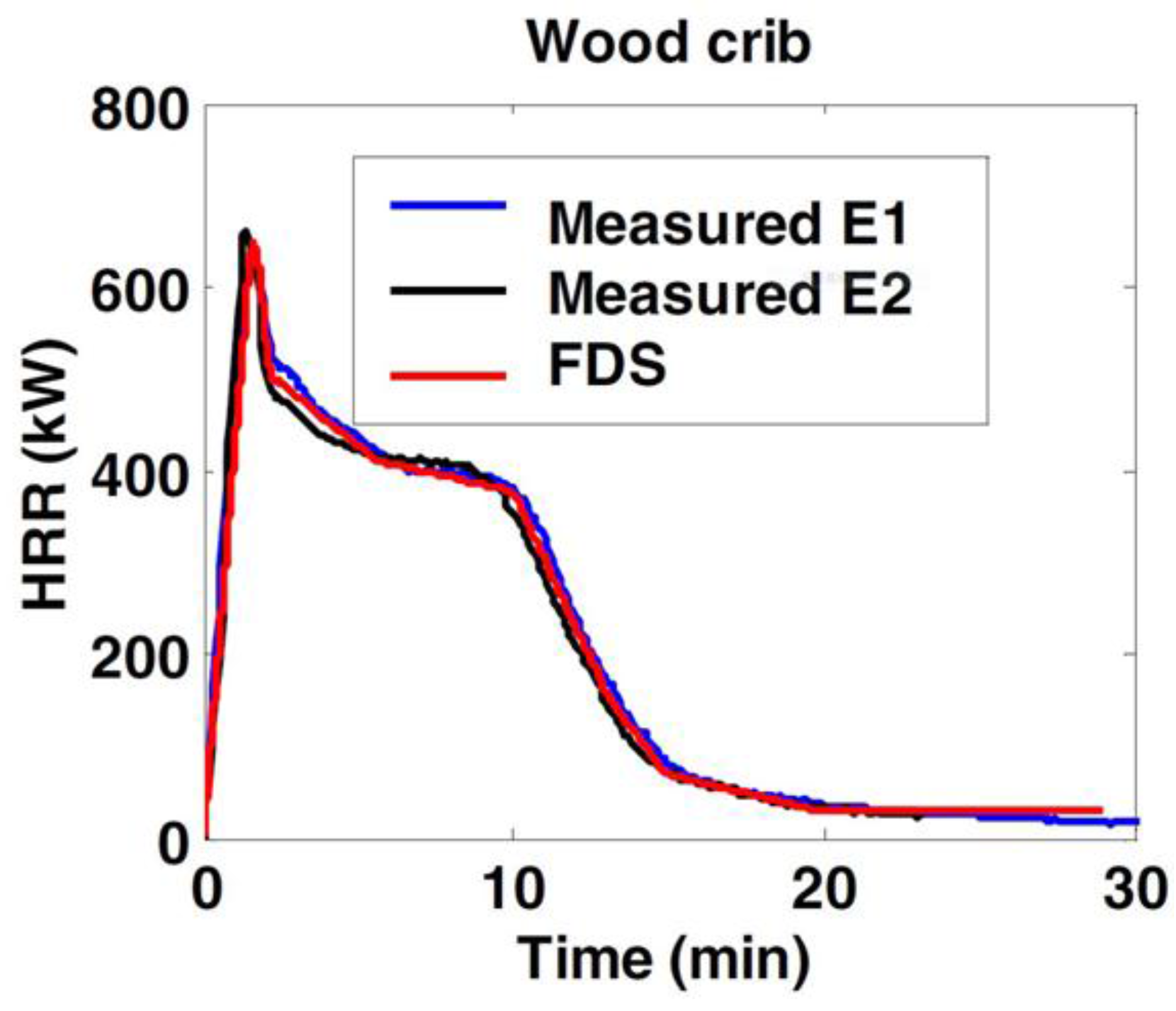

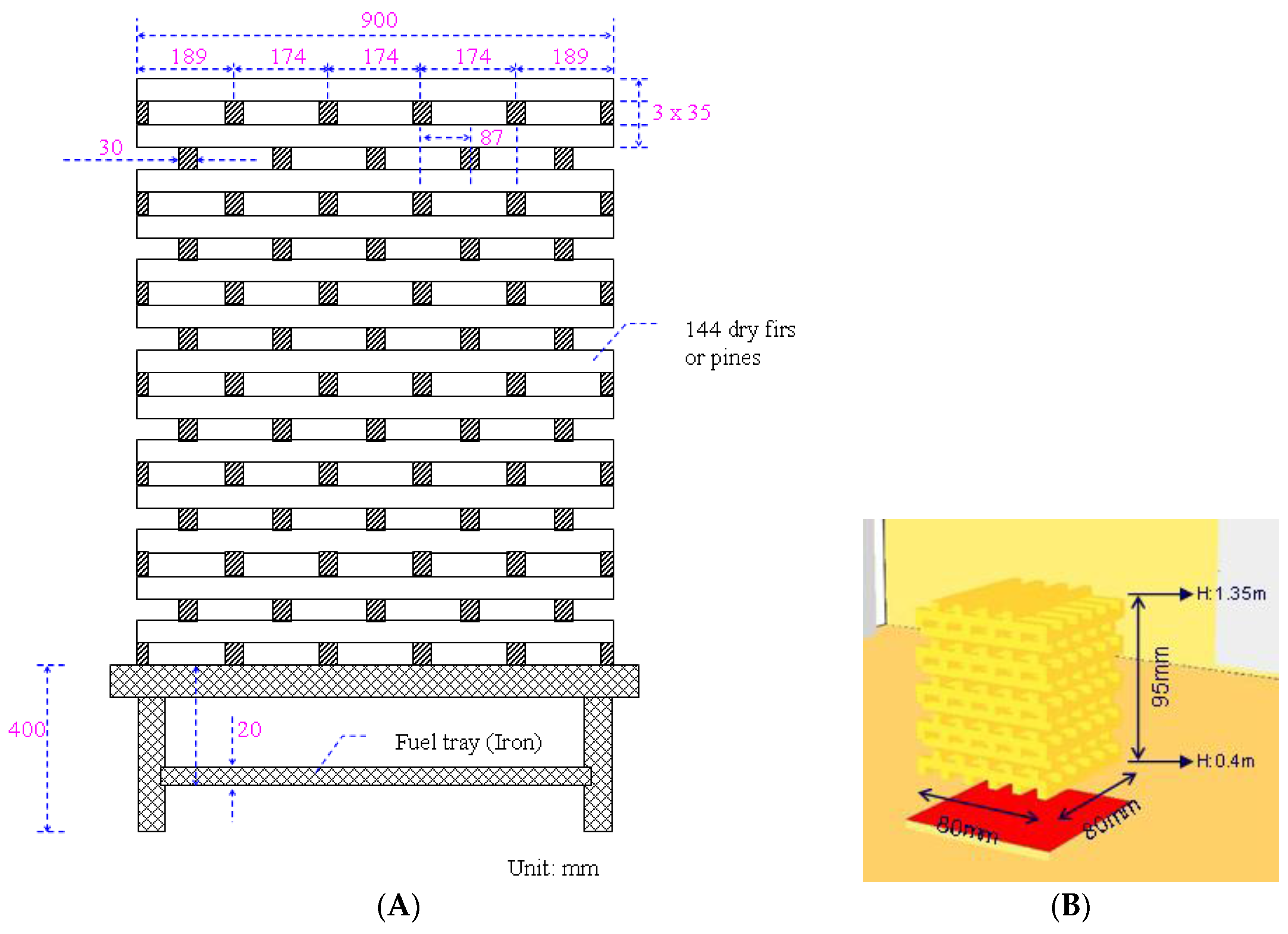

4.1. Woodpile Model in Numerical Simulation

4.2. Analysis of Grid Parameters

- Q: heat release rate (kW)

- ρ0: air density (kg/m3)

- Cp: specific heat (J/kg- °C)

- T0: ambient temperature (K)

- G: gravity (m/s2)

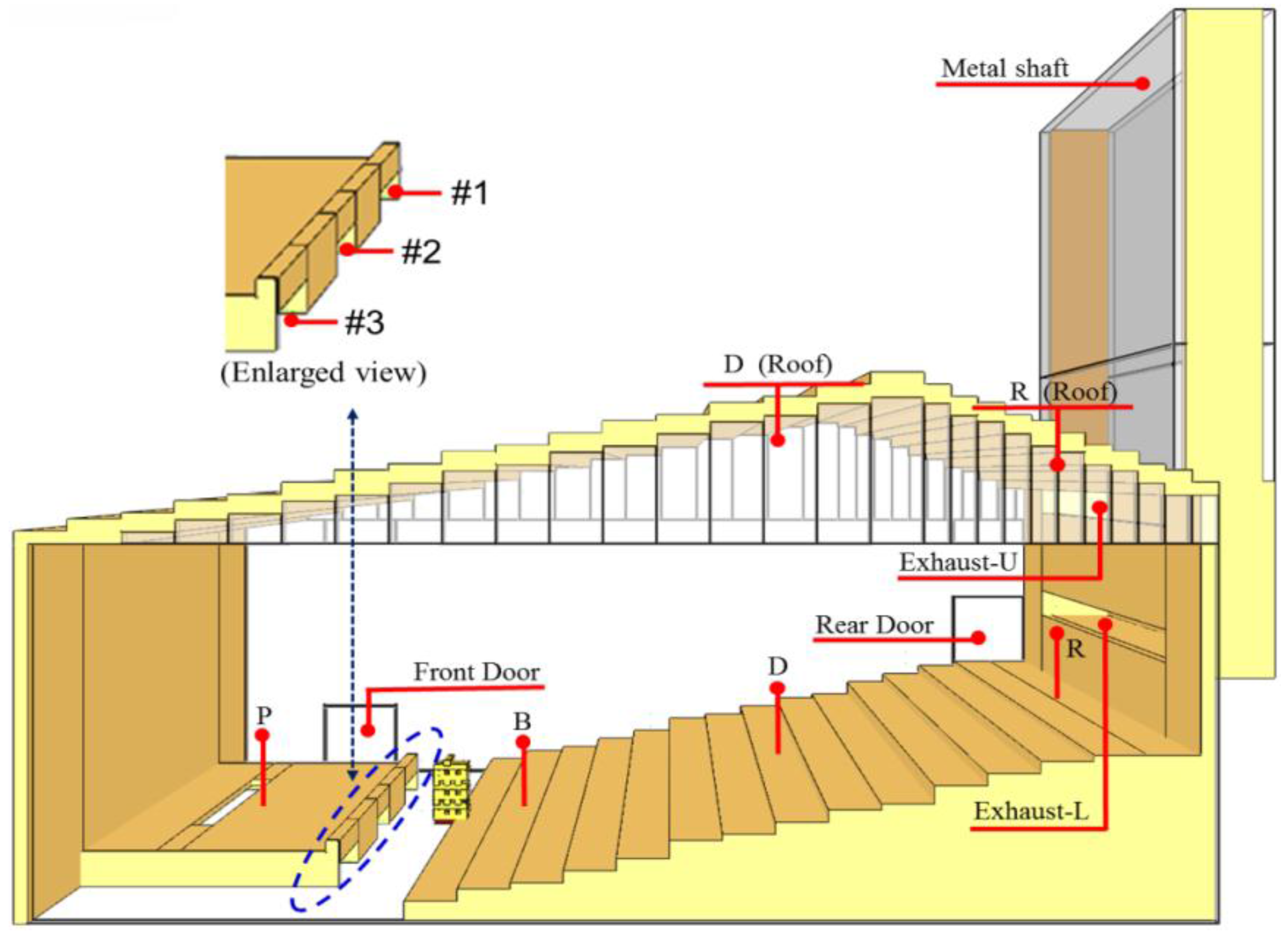

4.3. Description of Fire Scenario

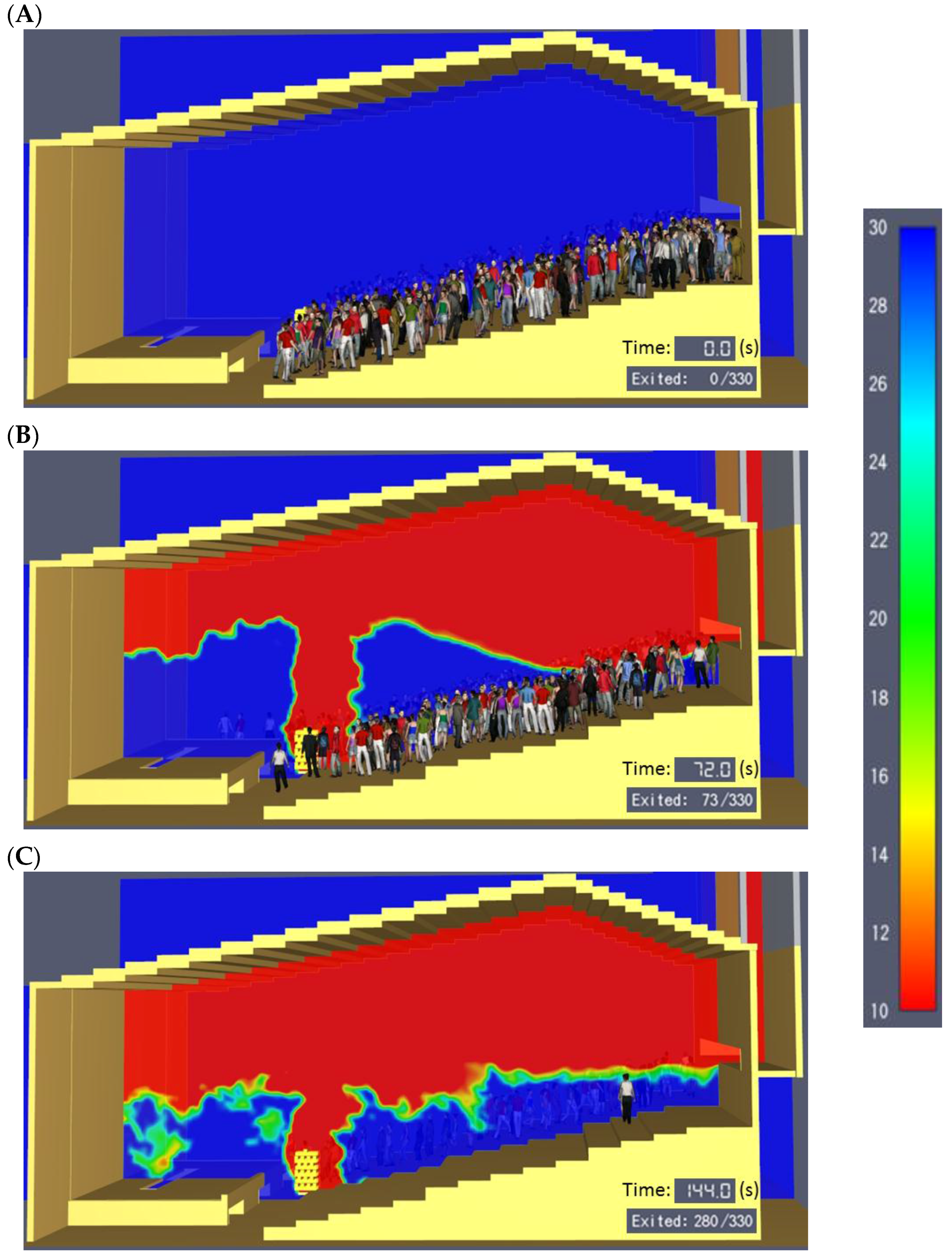

- The model size was 31.5 m (length) × 16 m (width) × 12 m (height); the number of grid points was about 7.5 million. Please refer to Figure 6A–C for the size marking. The size of each opening under the platform was 1.8 m (width) × 0.4 m (height); the calculated hydraulic diameter (Dh) was about 0.65 m. The hydraulic diameter is multiplied by 14, about 9 m as exterior space; the air flow field will be the fully-developed flow.

- As the combustible materials in the building were mostly wood, the fire occurred in front of the platform. The object on fire was a standard sized wood model; the extinguishment test refers to the Approval Directions for Fire Extinguisher released in Taiwan in July 2013.

- For the wood HRR combustion curve, the setup parameters refer to the test report of Valtion Teknillinen Tutkimuskeskus in 2007; the values are listed in Table 3.

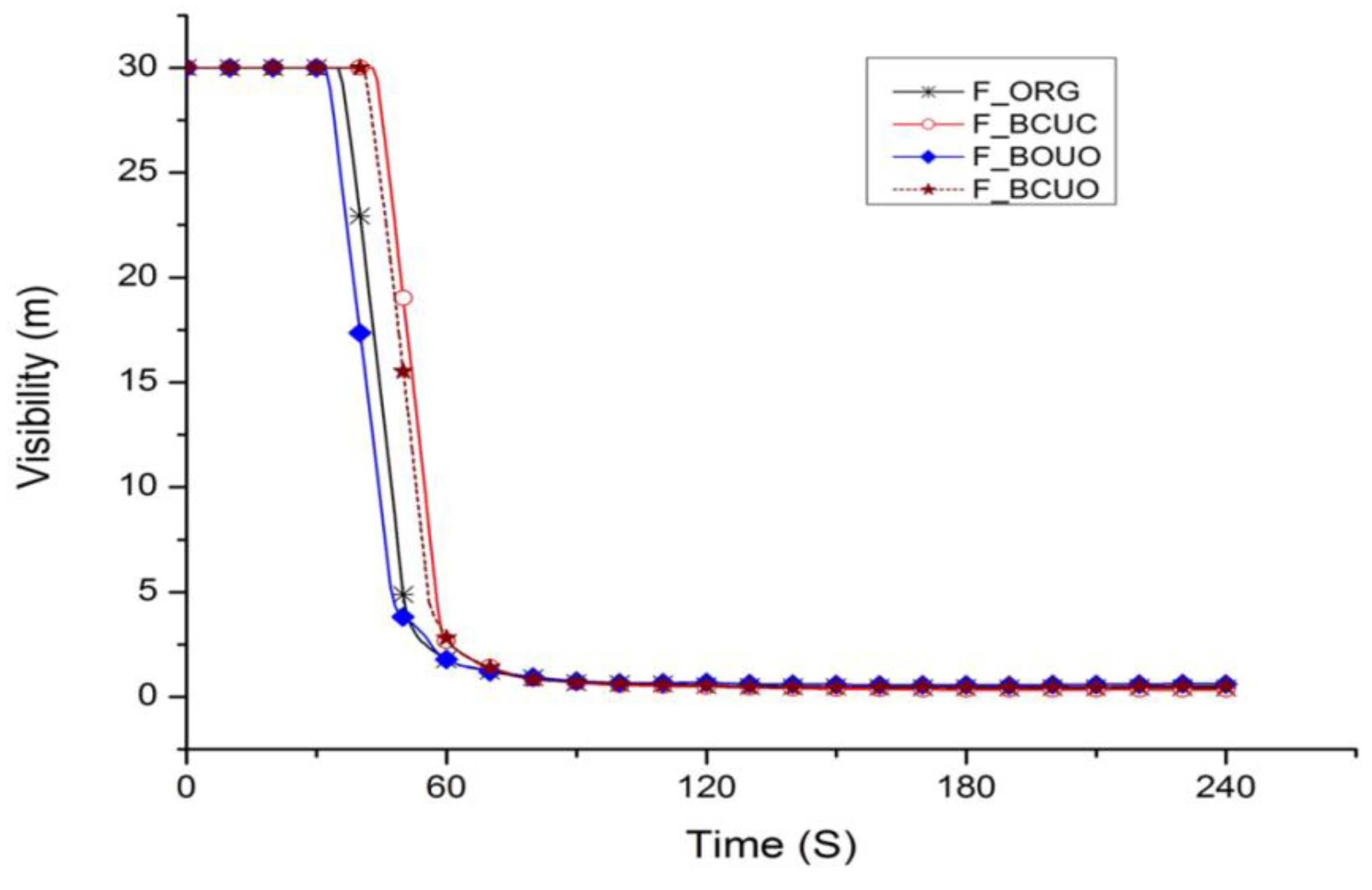

- Considering the actual breathing position of the people in the building, the visibility of the smoke layer was measured at 1.8 m above the ground.

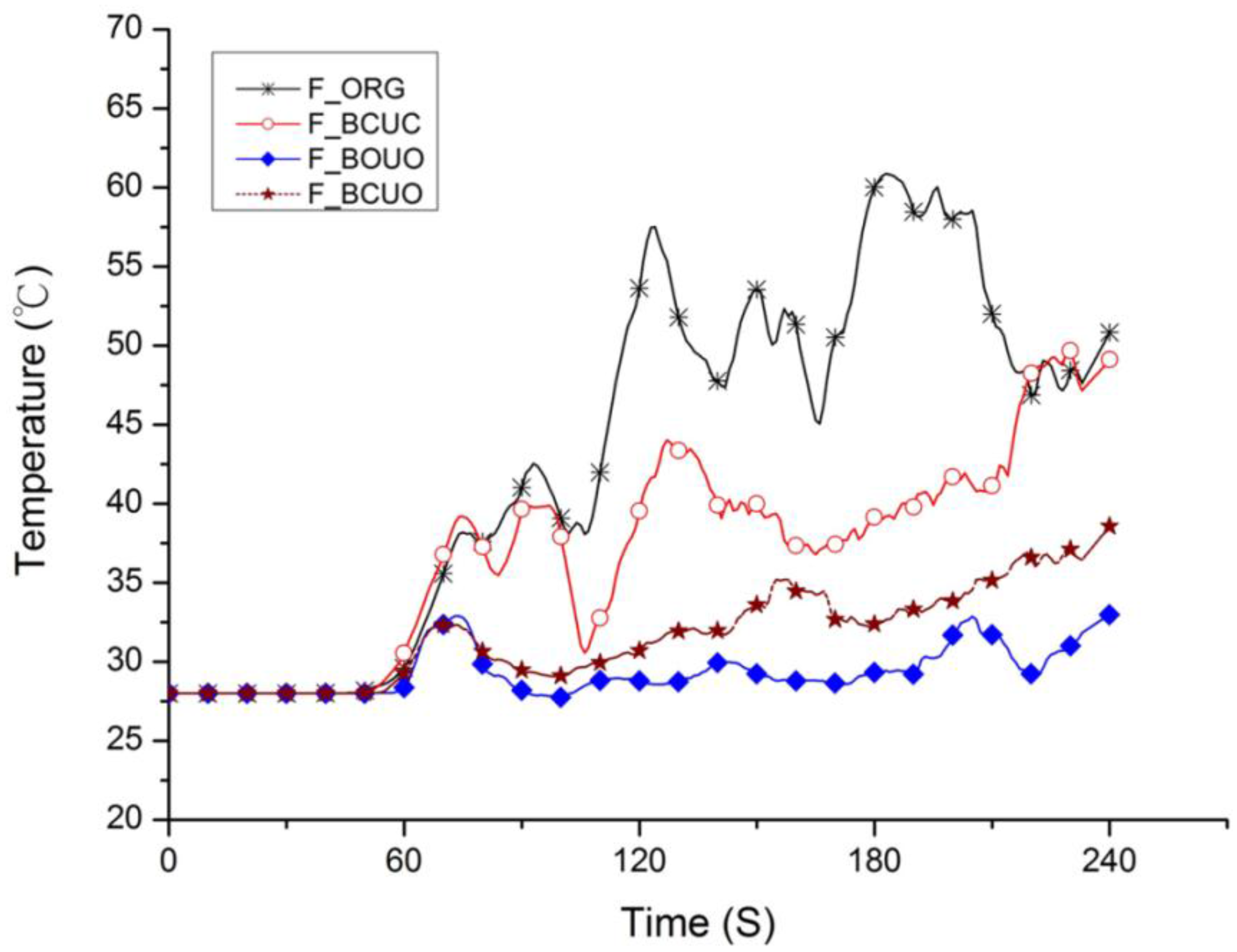

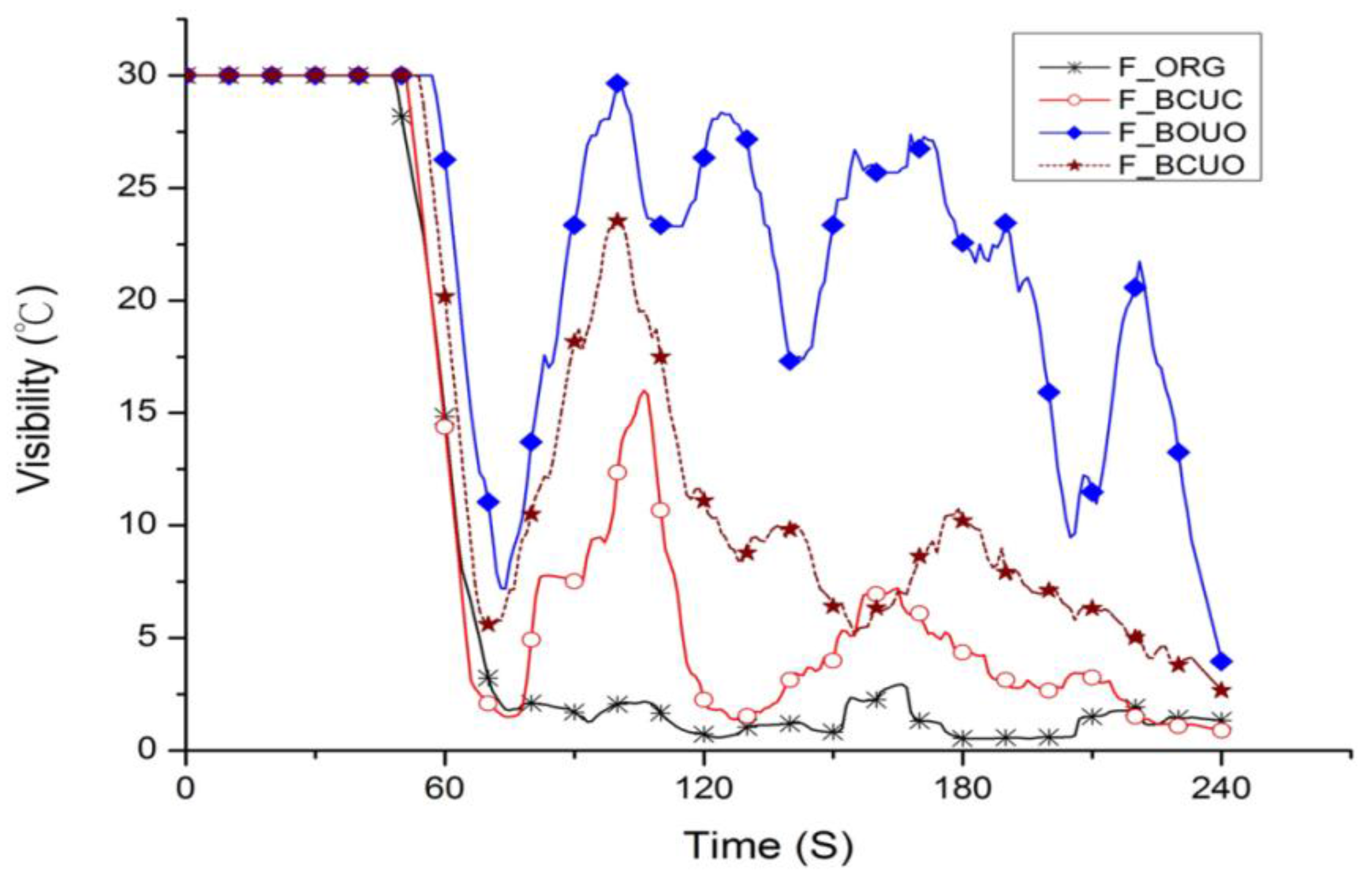

- The temperature and visibility changes in the monitoring positions and the air flow variation at the tower’s top air outlet were recorded, as shown in Figure 7.

- The first mode involves the effect on the indoor fire scenario when the air inlet under the platform is closed.

- In the second mode, a 0.8 m (H) × 11.2 m (W) smoke exhaust port is opened above the back wall. The indoor smoke is exhausted through the rear metal shaft when the fire occurs. The area is 9.12 m2, accounting for about 2.5% of the total floor area. The bottom of the opening is within 80 cm of the top of the wall. The air inlet is designed with reference to Taiwan’s fire prevention code. According to specifications, if natural smoke extraction is used, the smoke exhaust port area should be at least 2% of the total floor area.

- In the third mode, the air inlet under the platform is closed, so the smoke emission effect of the upper smoke exhaust port and lower air outlet in the back wall can be analyzed.

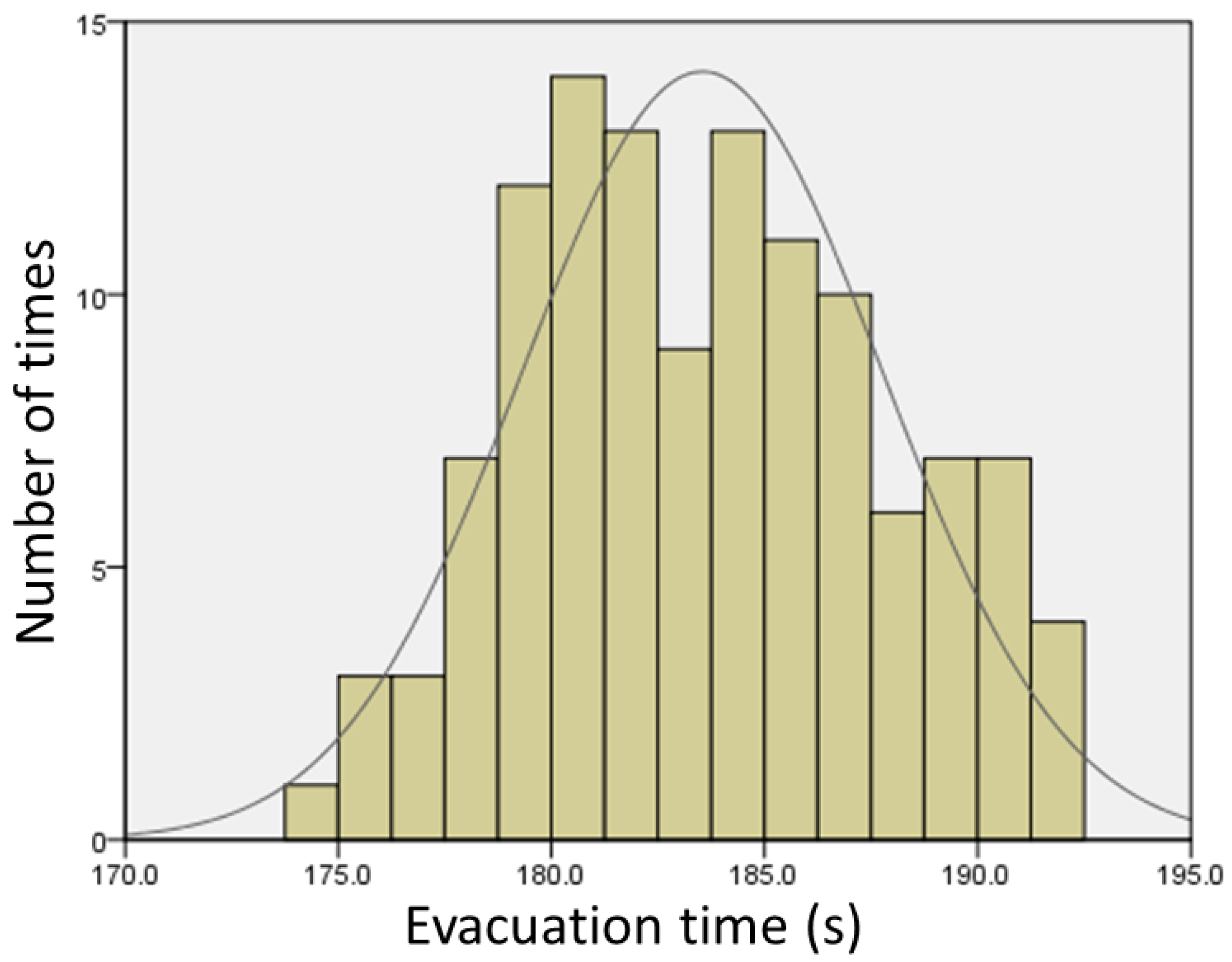

4.4. Evacuation Time under the Original Status of the Room

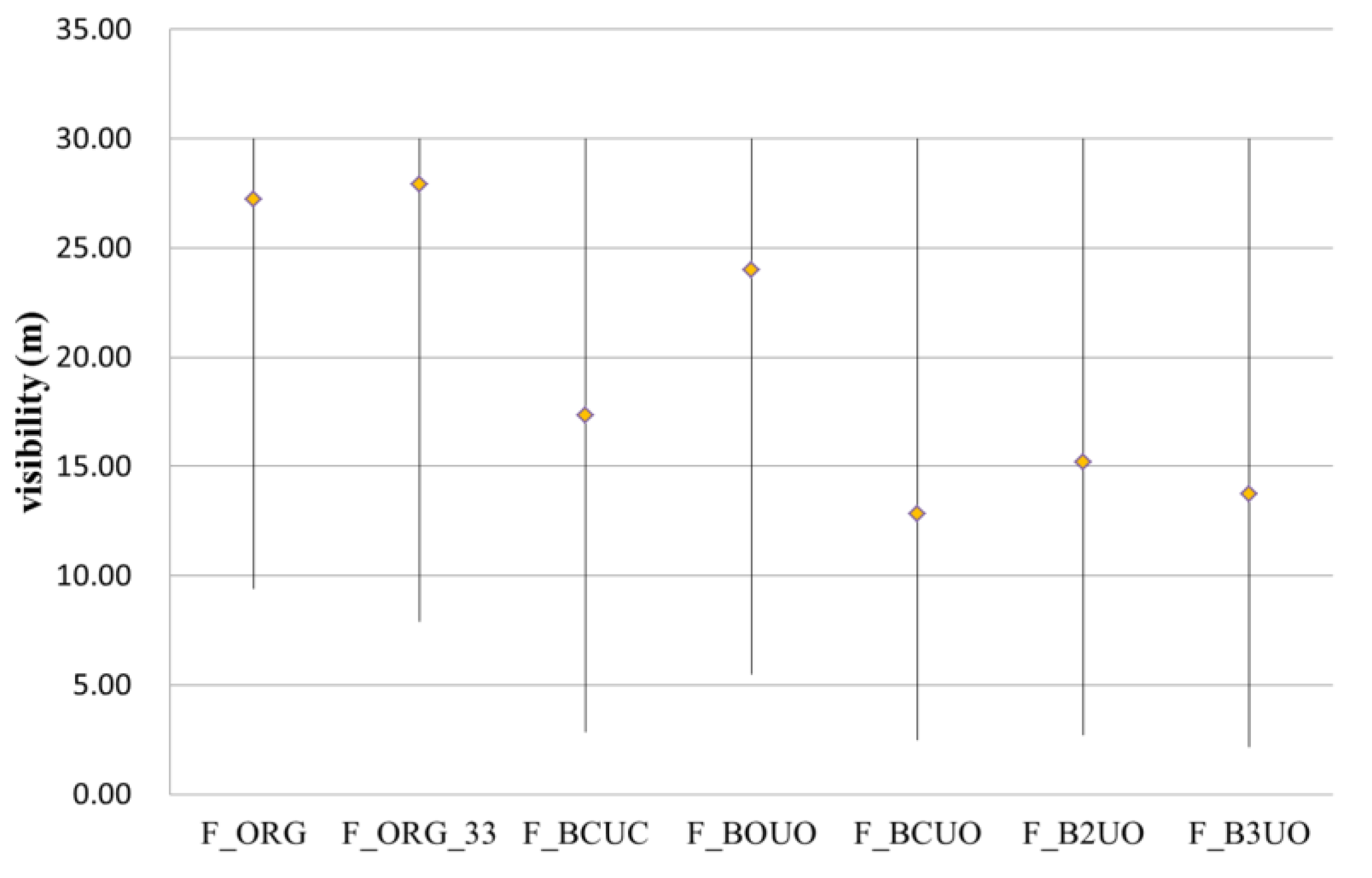

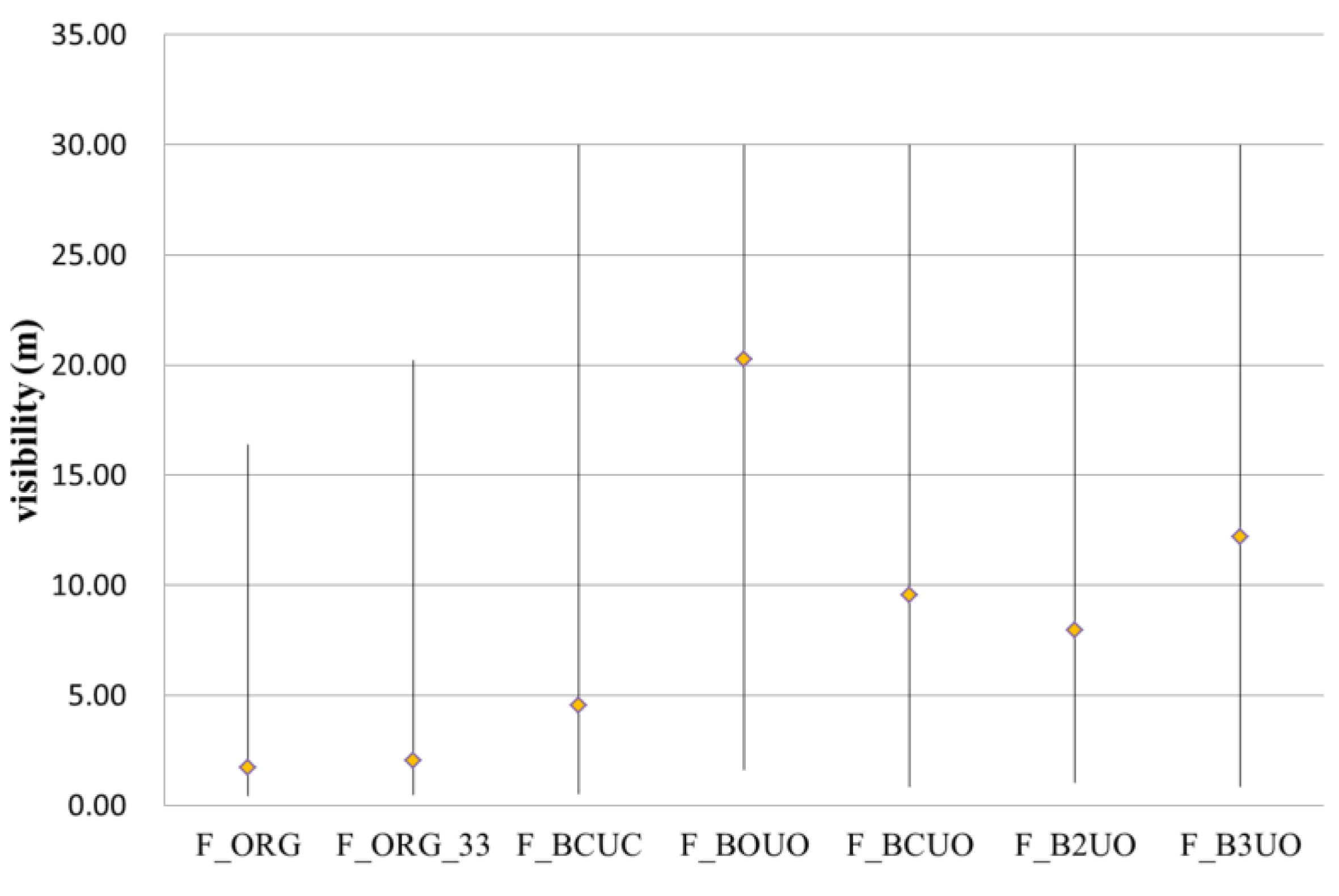

4.5. Measurement Points and Evaluated Period

5. Results and Discussion

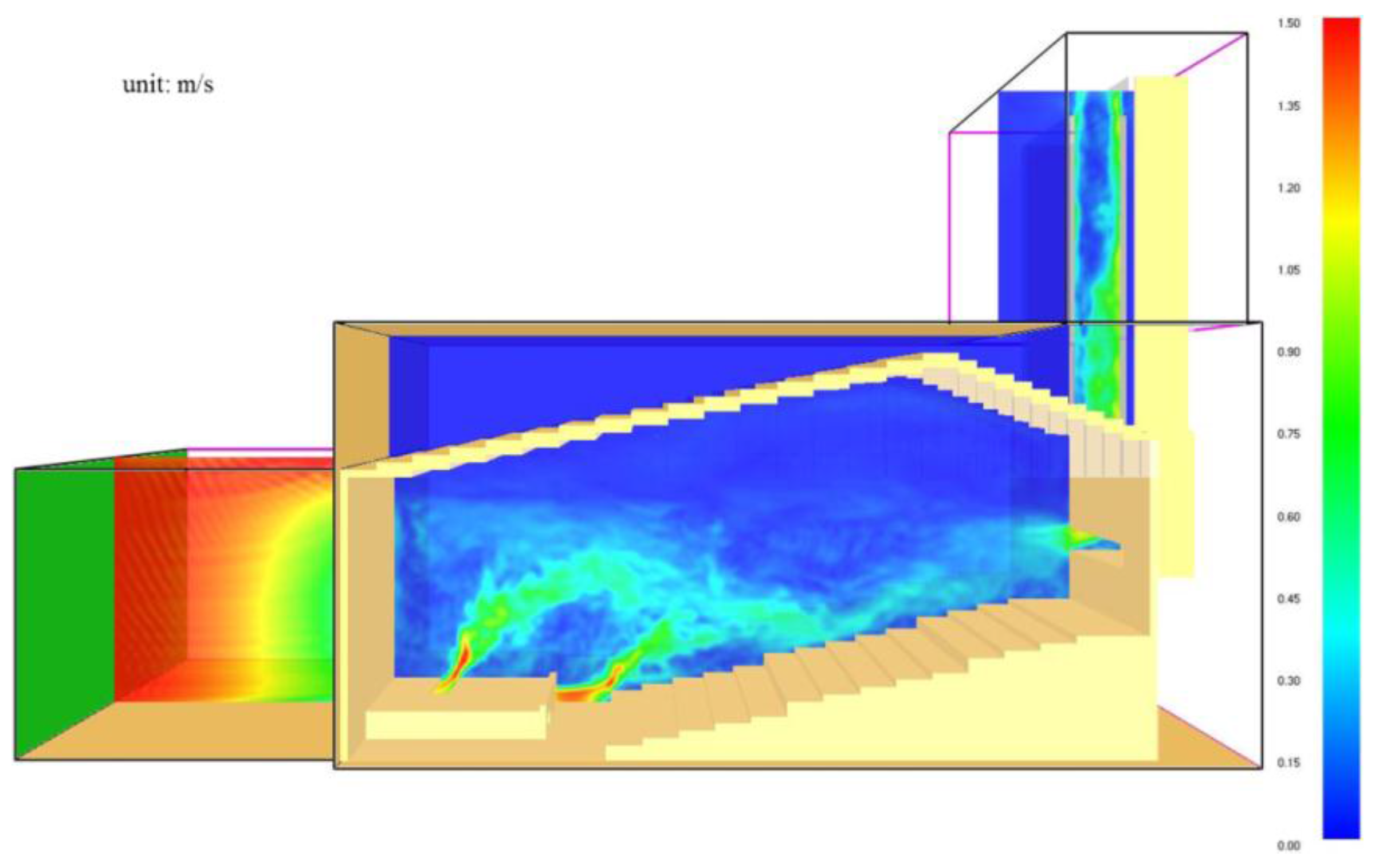

5.1. Natural Ventilation State

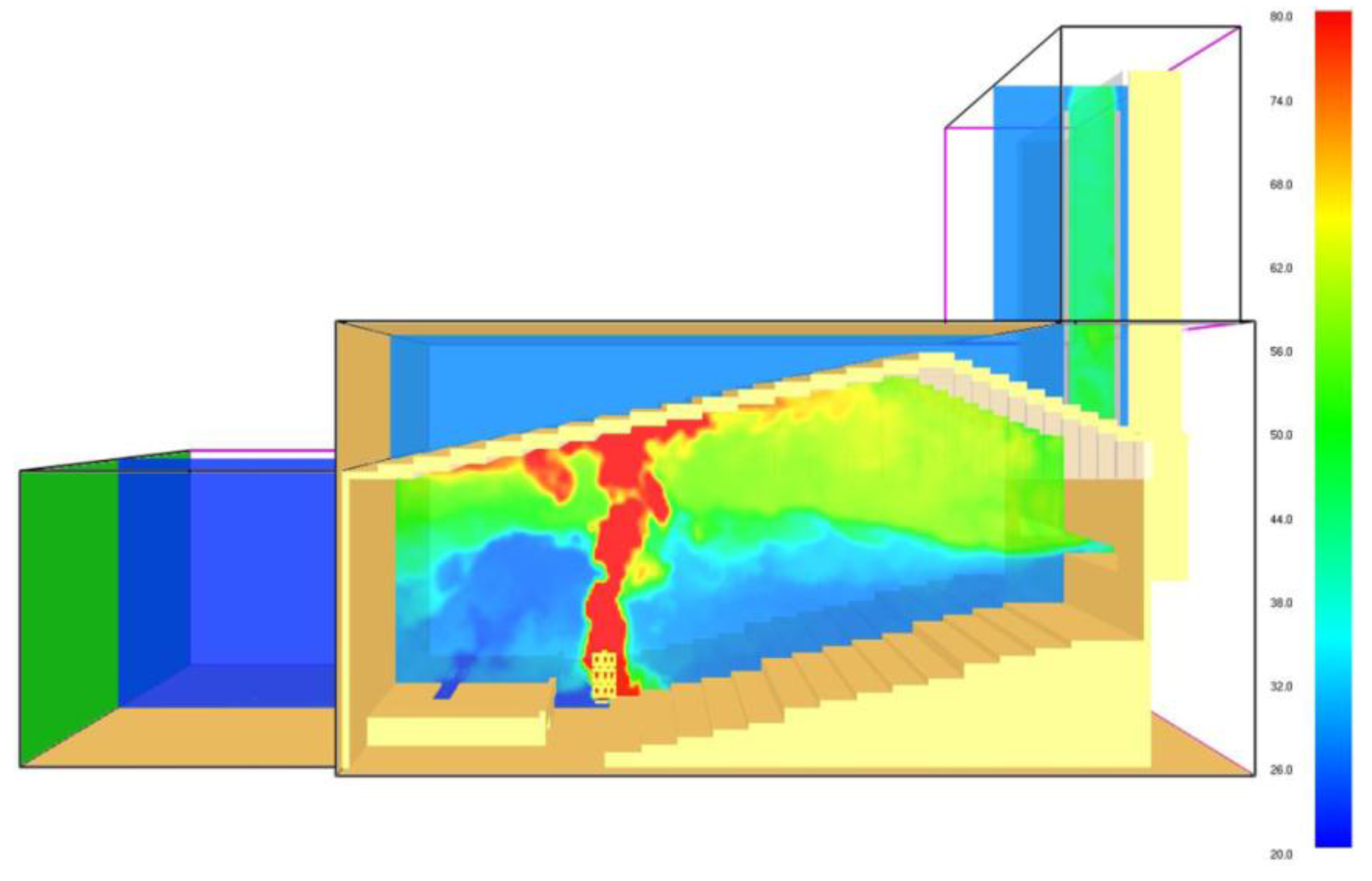

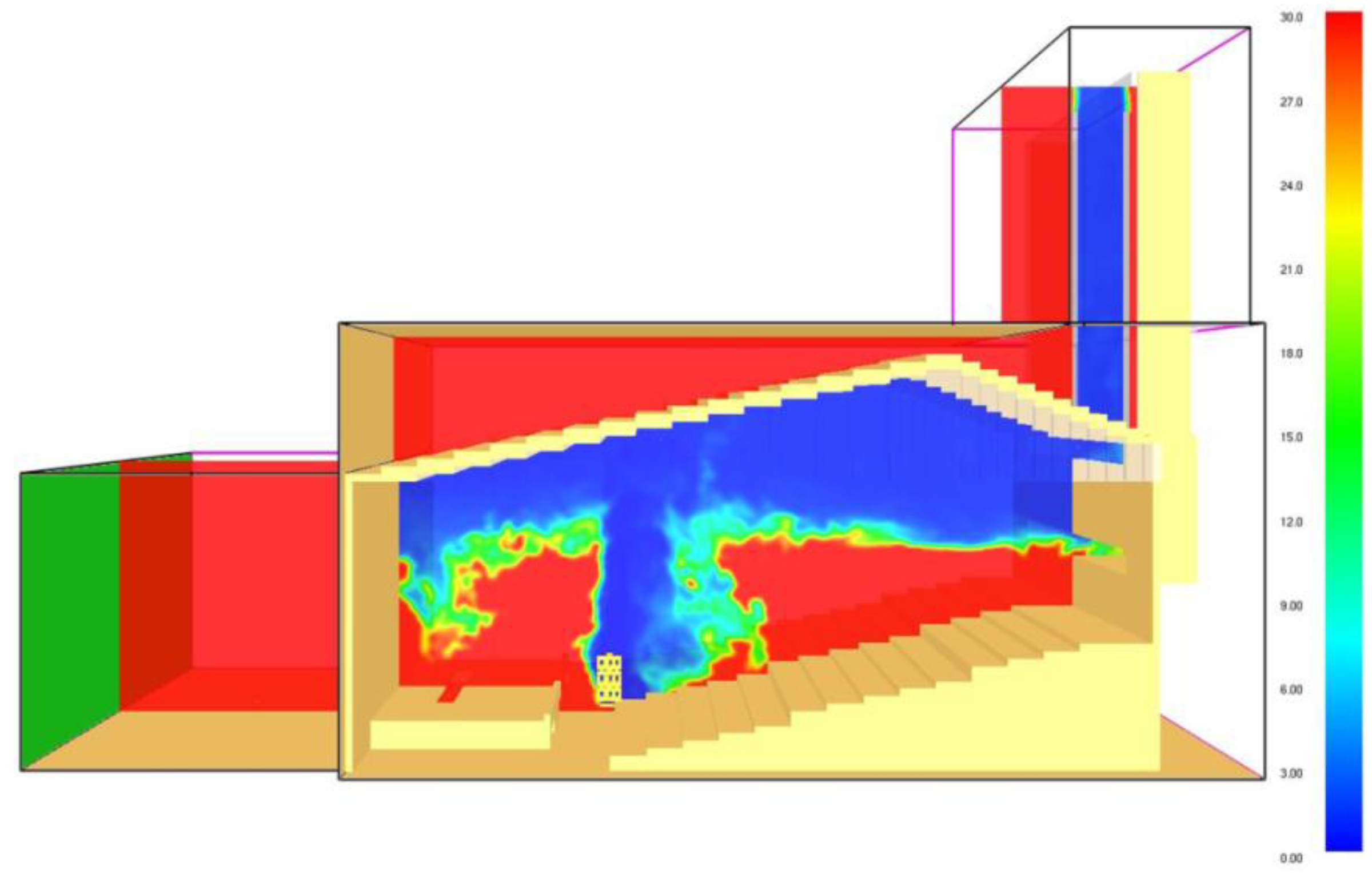

- Considering the indoor steady state, the state of the indoor center section was captured after 240 s of simulation to analyze the indoor condition. Figure 10 displays the temperature distribution. It was observed that the temperature stratification of the space was excellent. The upper part had a higher temperature of above 27.5 °C, while the lower seats, which were influenced by natural wind, had a temperature of 23 to 26 °C.

- The air flow distribution is shown in Figure 11. It was observed that the air flow pattern at the height of seats was that of air flowing in from the front platform and flowing out through the air outlet in the back wall. The air flow was obvious in the rear metal chimney, with a flow rate higher than 0.6 m/s.

5.2. Indoor Fire State

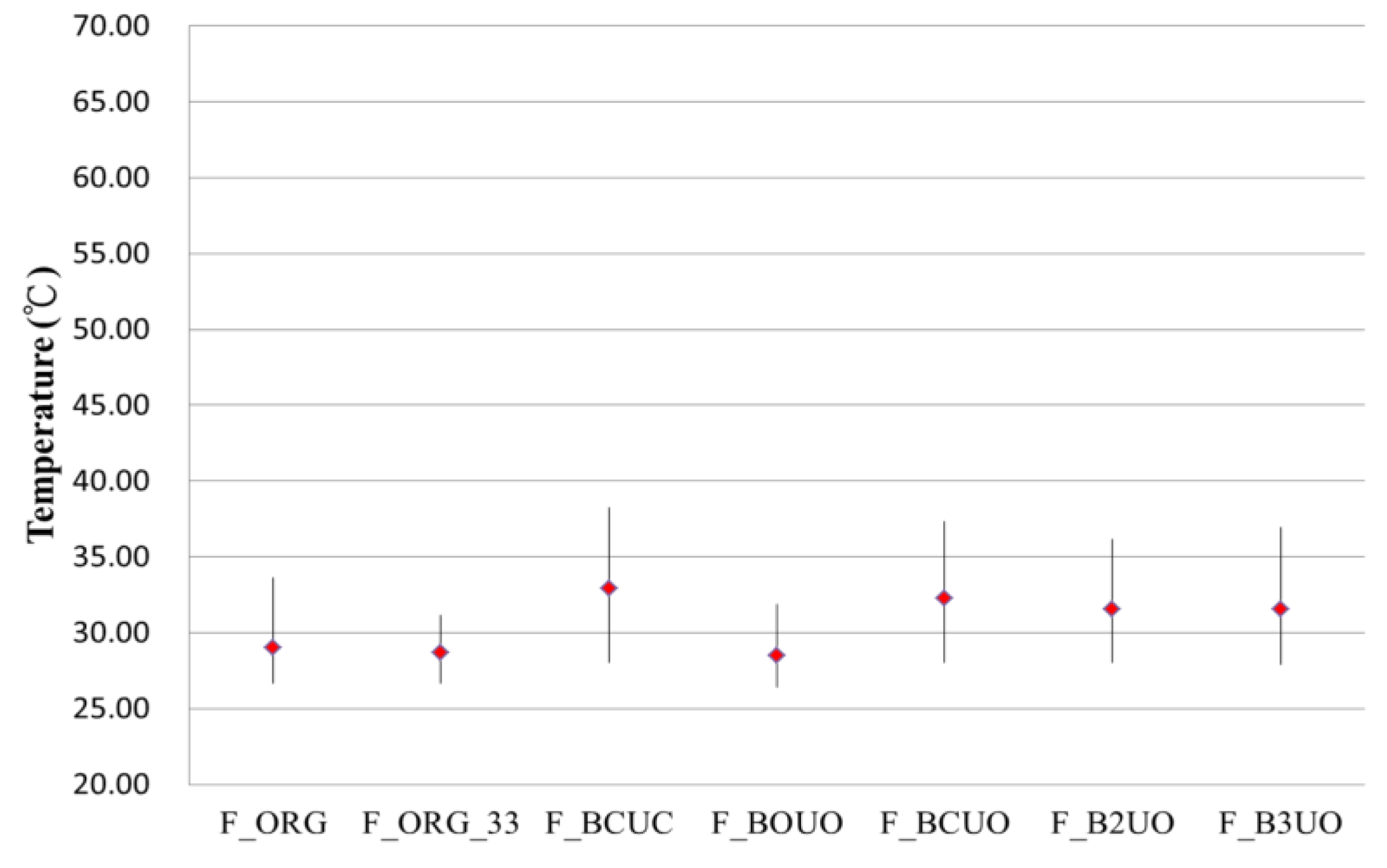

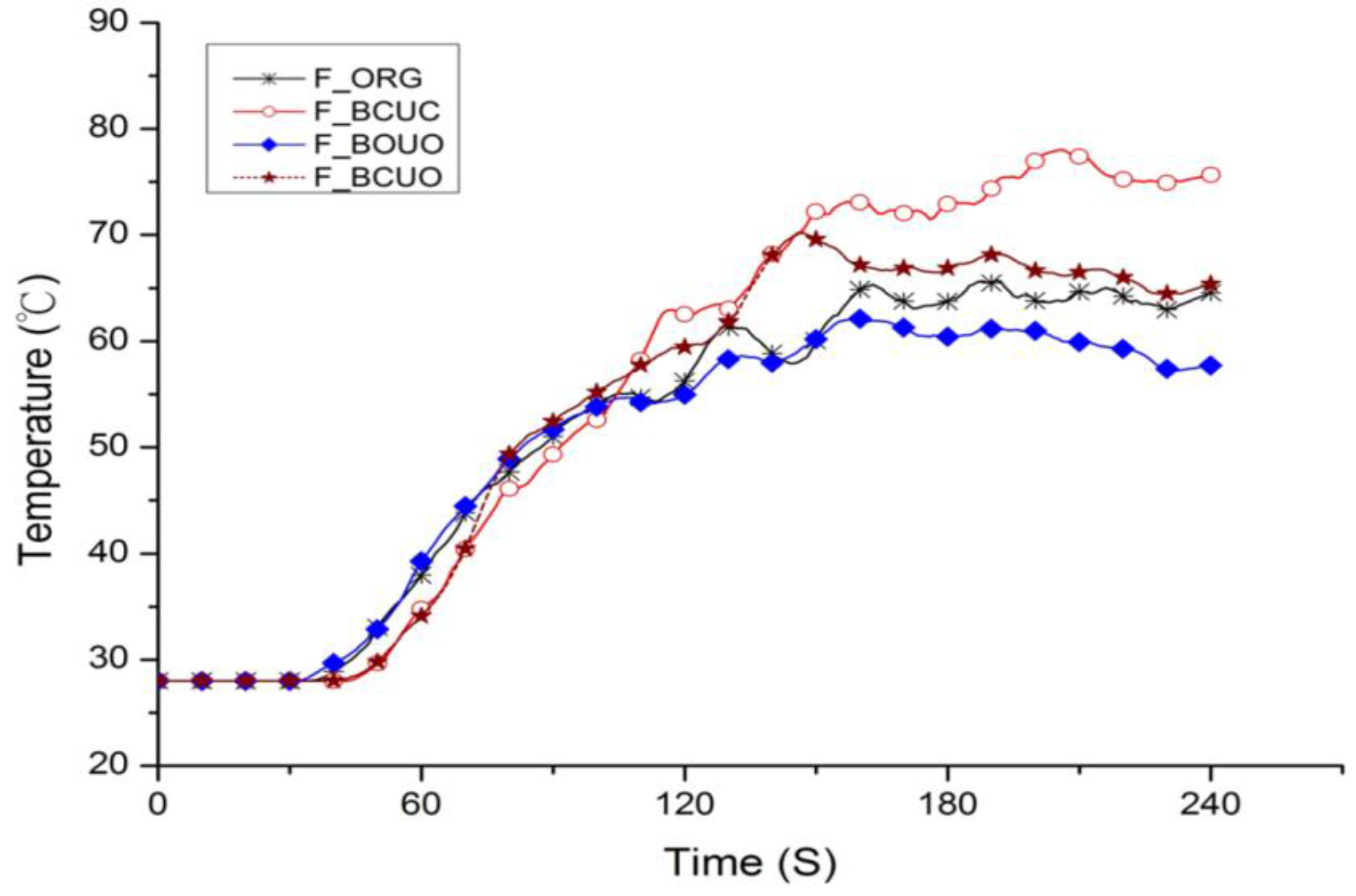

5.2.1. Temperature Variations

5.2.2. Variance in Visibility

5.3. Smoke Emission Improvement Strategies

- (A)

- Improvement strategy 1: Case F_BCUC

- (B)

- Improvement strategy 2: Case F_BOUO

- (C)

- Improvement strategy 3: Case F_BCUO

5.4. Effect of Natural Draught

5.5. Evaluation of Make-up Effect

5.6. Effect of Smoke Extraction

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dall’O, G.; Bruni, E.; Panza, A. Improvement of the Sustainability of Existing School Buildings According to the Leadership in Energy and Environmental Design (LEED)® Protocol: A Case Study in Italy. Energies 2013, 6, 6487–6507. [Google Scholar] [CrossRef] [Green Version]

- GhaffarianHoseini, A.; Dahlan, N.D.; Berardi, U.; GhaffarianHoseini, A.; Makaremi, N.; GhaffarianHoseini, M. Sustainable energy performances of green buildings: A review of current theories, implementations and challenges. Renew. Sustain. Energy Rev. 2013, 25, 1–17. [Google Scholar] [CrossRef]

- Huang, K.T.; Huang, W.P.; Lin, T.P.; Hwang, R.L. Implementation of green building specification credits for better thermal conditions in naturally ventilated school buildings. Build. Environ. 2015, 86, 141–150. [Google Scholar] [CrossRef]

- Xiaoping, M.; Huimin, L.; Qiming, L. A comparison study of mainstream sustainable/green building rating tools in the world. In Proceedings of the MASS’09. International Conference on Management and Service Science, Wuhan, China, 20–22 September 2009; pp. 1–5.

- Alyami, S.H.; Rezgui, Y. Sustainable building assessment tool development approach. Sustain. Cities Soc. 2012, 5, 52–62. [Google Scholar] [CrossRef]

- Kibert, C.J. Chapter 4: Green Building Assessment. In Sustainable Construction: Green Building Design and Delivery; John Wiley & Sons, Inc: New York, NY, USA, 2012. [Google Scholar]

- Lin, H.T.; Zhuang, H.W.; Chang, C.Y.; Chen, C.N. Green Building Assessment Handbook; Basic, ABRI: Taipei, Taiwan, 2012. (In Chinese) [Google Scholar]

- Lin, H.T. Policy and Evaluation System for Green Building in Subtropical Taiwan. In Tropical Sustainable Architecture: Social and Environmental Dimensions; Bay, J.-H., Ong, B.L., Eds.; Architectural Press: Oxford, UK, 2006; pp. 101–124. [Google Scholar]

- Yang, K.H.; Hwang, R.L. An improved assessment model of variable frequency-driven direct expansion air-conditioning system in commercial buildings for Taiwan green building rating system. Build. Environ. 2007, 42, 3582–3588. [Google Scholar] [CrossRef]

- Chow, W.K. Fire safety in green or sustainable buildings: Application of the fire engineering approach in Hong Kong. Archit. Sci. Rev. 2003, 46, 297–303. [Google Scholar] [CrossRef]

- Tidwell, J.; Murphy, J.J. Bridging the Gap: Fire Safety and Green Buildings. National Association of State Fire Marshals, 2010; Available online: http://www.firemarshalsarchives.org/pdf/FireSafetyGreenBuildingHiResFINALv3sec.pdf (accessed on 10 December 2015).

- Meacham, B.; Poole, B.; Echeverria, J.; Cheng, R. Fire Safety Challenges of Green Buildings. Springer Science and Business Media. Final Report. 2013. Available online: file:///D:/Administrator/Downloads/rffiresafetygreenbuildings.pdf (accessed on 10 December 2015).

- Yau, A.; Ho, S.K. Fire Risk Analysis and Optimization of Fire Prevention Management for Green Building Design and High Rise Buildings: Hong Kong Experience. Nang Yan Bus. J. 2014, 3, 41–54. [Google Scholar]

- Chow, W.K. Performance-based approach to determining fire safety provisions for buildings in the Asia-Oceania regions. Build. Environ. 2015, 91, 127–137. [Google Scholar] [CrossRef]

- Ding, W.; Minegishi, Y.; Hasemi, Y.; Yamada, T. Smoke control based on a solar-assisted natural ventilation system. Build. Environ. 2004, 39, 775–782. [Google Scholar] [CrossRef]

- Chow, W.K.; Zhao, J.H. Scale modeling studies on stack effect in tall vertical shafts. J. Fire Sci. 2011, 29, 531–542. [Google Scholar] [CrossRef]

- Su, C.H.; Lin, Y.C.; Shu, C.M.; Hsu, M.C. Stack effect of smoke for an old-style apartment in Taiwan. Build. Environ. 2011, 46, 2425–2433. [Google Scholar] [CrossRef]

- Schulze, T.; Eicker, U. Controlled natural ventilation for energy efficient buildings. Energy Build. 2013, 56, 221–232. [Google Scholar] [CrossRef]

- Asdrubali, F.; Buratti, C.; Cotana, F.; Baldinelli, G.; Goretti, M.; Moretti, E.; Vergoni, M. Evaluation of green buildings’ overall performance through in situ monitoring and simulations. Energies 2013, 6, 6525–6547. [Google Scholar] [CrossRef]

- Su, C.H.; Huang, H.S.; Lin, C.C.; Lin, C.Y. Numerical Simulation of The Impact of Natural Ventilation on Fire Safety in Green Buildings. In the 2nd Asia conference of International Building Performance Simulation Association (ASim2014), Nagoya, Japan, 28–29 November 2014; 2014; pp. 115–122. [Google Scholar]

- Munson, B.R.; Young, D.F.; Okiishi, T.H.; Huebsch, W.W. Chapter 5: Finite Control Volume Analysis. In Fundamentals of Fluid Mechanics; John Wiley & Sons, Inc: New York, NY, USA, 2010. [Google Scholar]

- Ding, W.; Hasemi, Y.; Yamada, T. Natural ventilation performance of a double-skin façade with a solar chimney. Energy Build. 2005, 37, 411–418. [Google Scholar] [CrossRef]

- Wu, Y.T. Ventilation Efficiency Analysis of Passive Solar Chimney—A Case Study of the Exhibition Room in the Magic School of Green Technology. M.Sc. Thesis, Department of Architecture, National Cheng Kung University, Tainan, Taiwan, 2010. [Google Scholar]

- Chien, C.H.; Lin, H.T.; Chou, J.H.; Su, T.C. Buoyancy Ventilation Efficiency Analysis of a Conference Hall. Appl. Mech. Mater. 2011, 71, 2442–2446. [Google Scholar] [CrossRef]

- Milke, J.A.; Hugue, D.E.; Hoskins, B.L.; Carroll, J.P. Tenability Analyses in Performance-Based Design Methods for appraising the effects of exposure to smoke or heat from a fire. Fire Prot. Eng. 2005, 28, 50. [Google Scholar]

- Chang, B.L.; Tang, C.H. The Simulating Situation and the Escaping Strategy for Disabilities in the Huge Underground Space; Project Report; Ministry of the Interior, Building Research Institute, 2012; Available online: http://ir.lib.pccu.edu.tw/retrieve/46616/RRPG10101–0478–2732835[1].pdf (accessed on 10 December 2015). (In Chinese)

- Wang, Y.C.; Lin, H.T. Energy-Saving Techniques of Full-Scale Green Building Analysis Research-Taiwan’s First Zero-Carbon Green Building. Appl. Mech. Mater. 2012, 121, 3058–3066. [Google Scholar] [CrossRef]

- Zhaia, Z.Q.; Chen, Q.Y. Solution characters of iterative coupling between energy simulation and CFD programs. Energy Build. 2003, 35, 493–505. [Google Scholar] [CrossRef]

- Goldsworthy, M. Dynamic coupling of the transient system simulation and fire dynamics simulation programs. J. Build. Perform. Simul. 2012, 5, 105–114. [Google Scholar] [CrossRef]

- Arendt, K.; Krzaczek, M. Co-simulation strategy of transient CFD and heat transfer in building thermal envelope based on calibrated heat transfer coefficients. Int. J. Therm Sci. 2014, 85, 1–11. [Google Scholar] [CrossRef]

- Su, C.H.; Tsai, K.C.; Xu, M.Y. Computational analysis on the performance of smoke exhaust systems in small vestibules of high-rise buildings. J. Build. Perform. Simul. 2015, 8, 239–252. [Google Scholar] [CrossRef]

- Xiao, B. Comparison of Numerical and Experimental Results of Fire Induced Doorway Flows. Fire Technol. 2012, 48, 595–614. [Google Scholar] [CrossRef]

- Doheim, R.M.; Yohanis, Y.G.; Nadjai, A.; Elkadi, H. The impact of atrium shape on natural smoke ventilation. Fire Saf. J. 2014, 63, 9–16. [Google Scholar] [CrossRef]

- Suard, S.; Koched, A.; Pretrel, H.; Audouin, L. Numerical simulations of fire-induced doorway flows in a small scale enclosure. Int. J. Heat Mass Transf. 2015, 81, 578–590. [Google Scholar] [CrossRef]

- Yi, L.; Chow, W.K.; Li, Y.Z.; Huo, R. A simple two-layer zone model on mechanical exhaust in an atrium. Building and environment. 2005, 40, 869–880. [Google Scholar] [CrossRef]

- Klote, J.H.; Ferreira, M.J.; Kashef, A.; Turnbull, P.G.; Milke, J.A. Chapter20: Computational Fluid Dynamics. In Handbook of Smoke Control Engineering; American Society of Heating Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2012; pp. 405–416. [Google Scholar]

- McGrattan, K.; McDermott, R.; Weinschenk, C.; Overholt, K. Fire dynamics simulator (Version 6); User’s Guide. NIST Special Publication 1019 (6); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015. [Google Scholar]

- Grandison, A.J.; Patel, M.K.; Galea, E.R. Development of Standards for Fire Field Models. Report on SMARTFIRE Phase 2 Simulations; Research Report 1/2003; Office of the Deputy Prime Minister, Fire Research Division: London, UK, 2003. [Google Scholar]

- Wang, Y.; Chatterjee, P.; de Ris, J.L. Large eddy simulation of fire plumes. Proc. Combust. Inst. 2011, 33, 2473–2480. [Google Scholar] [CrossRef]

- Rinne, T.; Hietaniemi, J.; Hostikka, S. Experimental Validation of the FDS Simulations of Smoke and Toxic gas Concentrations. VTT: Finlan, 2007; Available online: http://www.vtt.fi/inf/pdf/workingpapers/2007/W66.pdf (accessed on 10 December 2015).

- Ministry of the Interior of Taiwan. Approval Directions for Fire Extinguisher. National Fire Agency: Taipei, Taiwan, 2013; pp. 3–5. (In Chinese) [Google Scholar]

- Chen, Y.H.; Su, C.H.; Tseng, J.M.; Li, W.J. Experimental and numerical analysis of the cooling performance of water spraying systems during a fire. PLoS ONE 2015, 10, e0118306. [Google Scholar] [CrossRef] [PubMed]

- Baum, H.R.; MaCaffery, K.B. Fire Induced Flow Field-Theory and Experiment. Fire Saf. Sci. 1989, 129–148. [Google Scholar] [CrossRef]

- Averill, J.D. Pedestrian and Evacuation Dynamics. In Five Grand Challenges in Pedestrian and Evacuation Dynamics; Springer US: New York, NY, USA, 2011; pp. 1–11. [Google Scholar]

- Purser, D. Comparisons of Evacuation Efficiency and Pre-Travel Activity Times in reSponse to a Sounder and Two Different Voice Alarm Messages. In Pedestrian and Evacuation Dynamics; Springer: Berlin, Germany, 2008; pp. 121–134. [Google Scholar]

- Fraser, S.A.; Wood, N.J.; Johnston, D.M.; Leonard, G.S.; Greening, P.D.; Rossetto, T. Variable population exposure and distributed travel speeds in least-cost tsunami evacuation modelling. Nat. Hazard. Earth Syst. Sci. 2014, 14, 2975–2991. [Google Scholar] [CrossRef]

- Korhonen, T.; Hostikka, S. Fire Dynamics Simulator with Evacuation: FDS+ Evac. Technical Reference and User’s Guide; VTT Technical Research Centre of Finland: Helsinki, Finland, 2009; p. 119. [Google Scholar]

- Kuligowski, E.D. Computer Evacuation Models for Buildings. In SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 2152–2180. [Google Scholar]

| Country | Assessment Index | Country | Assessment Index |

|---|---|---|---|

| Australia | Green Star | Mexico | SICES |

| Canada | LEED-Canada | New Zealand | Green Star NZ |

| China | GBAS | Russia | LEED-Russia |

| Denmark | BEAT | South Africa | Green Star |

| Holland | EcoQuantum | Taiwan | EEWH |

| Japan | CASBEE | UK | BREEAM |

| Korea | CBCS | USA | LEED |

| Physical Factor | Critical Level |

|---|---|

| Environmental temperature | lower than 60 °C |

| Visibility | less than 10 m |

| Parameters | Numerical Simulation | Entity |

|---|---|---|

| Size | 50 mm × 50 mm × 800 mm | 30 mm × 35 mm × 900 mm |

| Heat Release Rate Per Unit Area (HRRPUA) | 175 kW/m2 | - |

| Density | 369.6 kg/m3 | - |

| Combustion heat | 17,900 kJ/kg | - |

| Ignition temperature | 384 °C | - |

| Volume | 0.002 m3/each | 0.000945 m3/each |

| Surface Area | 0.165 m2/each | 0.1191 m2/each |

| The total number | 104 sticks | 144 sticks |

| The total surface Area | 17.16 m2 | 17.1504 m2 |

| Case No. | Description | ||

|---|---|---|---|

| F_ORG | original status under light air (1.5 m/s)* | ||

| F_ORG33 | original status under light breeze (3.3 m/s)** | ||

| Openings Beneath the podium | Upper opening on the rear wall | ||

| F_BCUC | All (No. 1, 2, 3) close | close | |

| F_BOUO | All open | open | |

| F_BCUO | All close | open | |

| F_B2UO | No. 2 open | open | |

| F_B3UO | No. 3 open | open | |

| Case Codings | F_: | in Fire situation | |

| ORG: | ORiGinal status (natural wind speed is 1.5 m/s) | ||

| _33: | ORiGinal status in 3.3 m/s wind speed | ||

| B: | openings Beneath the podium | ||

| U: | Upper opening on the rear wall | ||

| C/O: | Close/Open | ||

| 2/3: | No. 2/3 inlet opened below the podium | ||

| Simulation Parameters | Value |

|---|---|

| Occupancy | 330 persons*(Referring to official information) |

| Dimensions of the front and rear door | 2 m (W) × 2 m (H) |

| Area of the room | 22.5 m (L) × 16 m (W) |

| Pre-movement time | from 32 to 60 s [45] |

| Walking speed | from 0.8 ± 0.3 to 1.35 ± 0.20 m/s [47,48] |

| Shoulder breadth | from 0.21 ± 0.015 to 0.27 ± 0.02 m [47] |

| Time (s) | Case No. | Point D | Point R | ||

|---|---|---|---|---|---|

| Temperature (°C) | Visibility (m) | Temperature (°C) | Visibility (m) | ||

| 60 | F_ORG | 26.7 | 30.0 | 29.3 | 13.3 |

| F_ORG33 | 26.7 | 30.0 | 29.3 | 13.1 | |

| F_BCUC | 28.0 | 30.0 | 30.9 | 5.0 | |

| F_BOUO | 26.8 | 30.0 | 28.0 | 30.0 | |

| F_BCUO | 28.0 | 30.0 | 28.0 | 30.0 | |

| F_B2UO | 28.0 | 30.0 | 29.8 | 10.7 | |

| F_B3UO | 28.0 | 30.0 | 28.1 | 30.0 | |

| 120 | F_ORG | 27.9 | 30.0 | 50.4 | 0.6 |

| F_ORG33 | 28.2 | 30.0 | 44.1 | 1.1 | |

| F_BCUC | 31.0 | 17.9 | 41.0 | 1.5 | |

| F_BOUO | 28.0 | 30.0 | 28.3 | 30.0 | |

| F_BCUO | 31.5 | 19.1 | 29.5 | 17.2 | |

| F_B2UO | 30.2 | 30.0 | 33.2 | 5.4 | |

| F_B3UO | 30.8 | 22.2 | 33.2 | 6.2 | |

| 183 | F_ORG | 30.4 | 27.1 | 63.8 | 0.5 |

| F_ORG33 | 30.8 | 23.8 | 38.2 | 2.5 | |

| F_BCUC | 34.8 | 7.1 | 34.8 | 6.2 | |

| F_BOUO | 28.0 | 29.6 | 31.6 | 12.1 | |

| F_BCUO | 33.3 | 5.9 | 31.5 | 14.0 | |

| F_B2UO | 34.0 | 4.1 | 34.5 | 4.8 | |

| F_B3UO | 32.1 | 5.7 | 35.1 | 2.6 | |

| Time (s) | Flow Rate (m3/s) | ||||||

|---|---|---|---|---|---|---|---|

| F_ORG | F_ORG_33 | F_BCUC | F_BCUO | F_BOUO | F_B2UO | F_B3UO | |

| 120 | 11.09 | 10.82 (−2.4%) * | - | - | 13.73 (+23.8%) | 9.43 (−15.0%) | 10.01 (−9.7%) |

| 180 | 12.20 | 12.26 (+0.5%) | - | - | 14.32 (+17.4%) | 10.39 (−14.8%) | 11.50 (−5.7%) |

| 240 | 12.51 | 12.45 (−0.5%) | - | - | 14.45 (+15.5%) | 10.28 (−17.8%) | 11.46 (−8.4%) |

| Time (s) | Flow Rate (m3/s) | ||||||

|---|---|---|---|---|---|---|---|

| F_ORG | F_ORG_33 | F_BCUC | F_BCUO | F_BOUO | F_B2UO | F_B3UO | |

| 120 | 20.93 | 19.89 (−5.0%) * | 18.23 (−12.9%) | 26.02 (+24.3%) | 29.54 (+41.1%) | 26.56 (+26.9%) | 27.25 (+30.2%) |

| 180 | 23.56 | 23.93 (+1.6%) | 22.70 (−3.7%) | 29.24 (+24.1%) | 30.32 (+28.7%) | 29.04 (+23.3%) | 31.61 (+34.2%) |

| 240 | 24.15 | 24.09 (−0.2%) | 24.10 (−0.2%) | 28.78 (+19.2%) | 30.25 (+25.3%) | 28.75 (+19.0%) | 30.65 (+26.9%) |

| Time (s) | Flow Rate (m3/s) | ||||||

|---|---|---|---|---|---|---|---|

| F_ORG | F_ORG_33 | F_BCUC | F_BCUO | F_BOUO | F_B2UO | F_B3UO | |

| 120 | 20.84 | 19.80 (−5.0%) | 18.14 (−13.0%) | 10.05 (−51.8%) | 11.99 (−42.5%) | 10.61 (−49.1%) | 10.64 (−48.9%) |

| 180 | 23.51 | 23.89 (+1.6%) | 22.67 (-3.6%) | 11.85 (−49.6%) | 12.68 (−46.1%) | 12.40 (−47.3%) | 12.50 (−46.8%) |

| 240 | 24.12 | 24.05 (−0.3%) | 24.11 (−0.0%) | 11.68 (−51.6%) | 12.78 (−47.0%) | 12.01 (−50.2%) | 12.18 (−49.5%) |

| Time (s) | Flow Rate (m3/s) | ||||||

|---|---|---|---|---|---|---|---|

| F_ORG | F_ORG_33 | F_BCUC | F_BCUO | F_BOUO | F_B2UO | F_B3UO | |

| 120 | - | - | - | 15.87 (−9.0%) | 17.43 | 15.85 (−9.1%) | 16.51 (−5.3%) |

| 180 | - | - | - | 17.33 (−1.2%) | 17.54 | 16.56 (−5.6%) | 19.05 (+8.6%) |

| 240 | - | - | - | 17.02 (−2.0%) | 17.36 | 16.65 (−4.1%) | 18.40 (+6.0%) |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.S.; Su, C.H.; Li, C.B.; Lin, C.Y.; Lin, C.C. Enhancement of Fire Safety of an Existing Green Building due to Natural Ventilation. Energies 2016, 9, 192. https://doi.org/10.3390/en9030192

Huang HS, Su CH, Li CB, Lin CY, Lin CC. Enhancement of Fire Safety of an Existing Green Building due to Natural Ventilation. Energies. 2016; 9(3):192. https://doi.org/10.3390/en9030192

Chicago/Turabian StyleHuang, Hong Sheng, Chung Hwei Su, Cheng Bang Li, Ching Yuan Lin, and Chun Chou Lin. 2016. "Enhancement of Fire Safety of an Existing Green Building due to Natural Ventilation" Energies 9, no. 3: 192. https://doi.org/10.3390/en9030192