A New Robust Decoupled Control of the Stator Active and Reactive Currents for Grid-Connected Doubly-Fed Induction Generators

Abstract

:1. Introduction

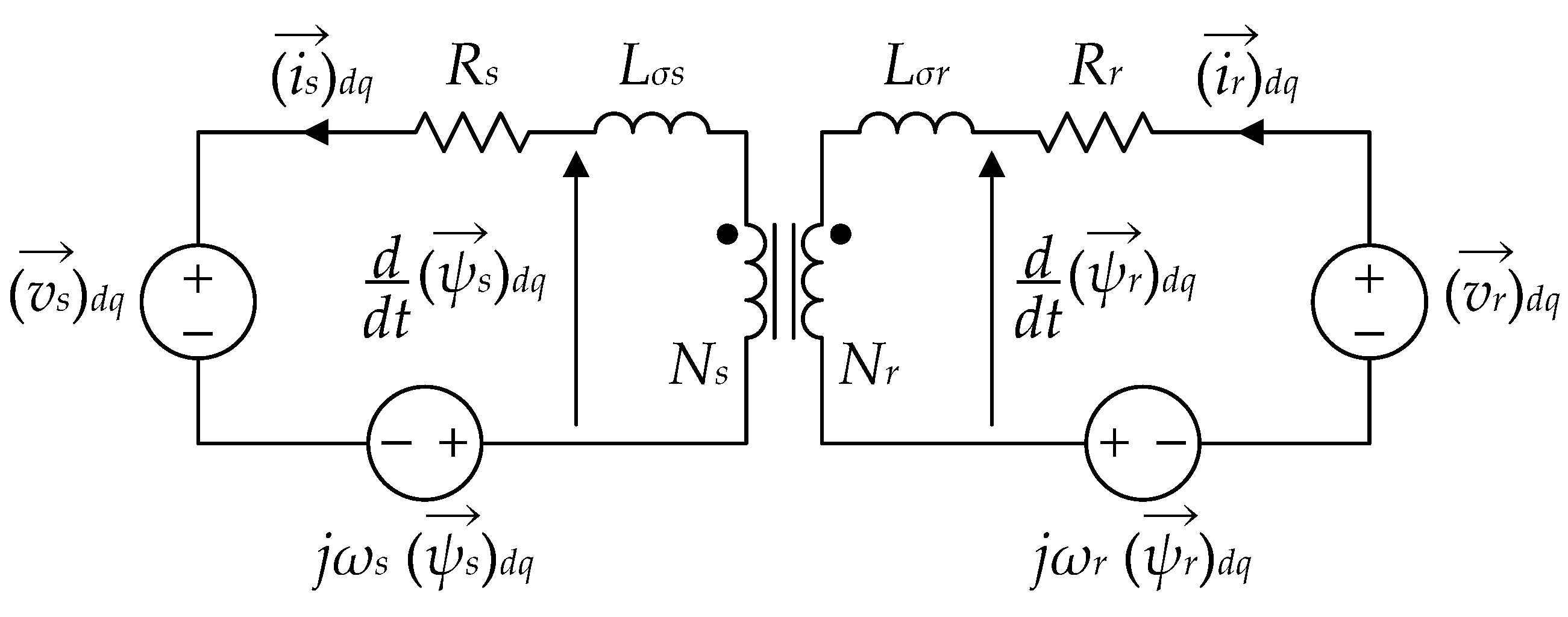

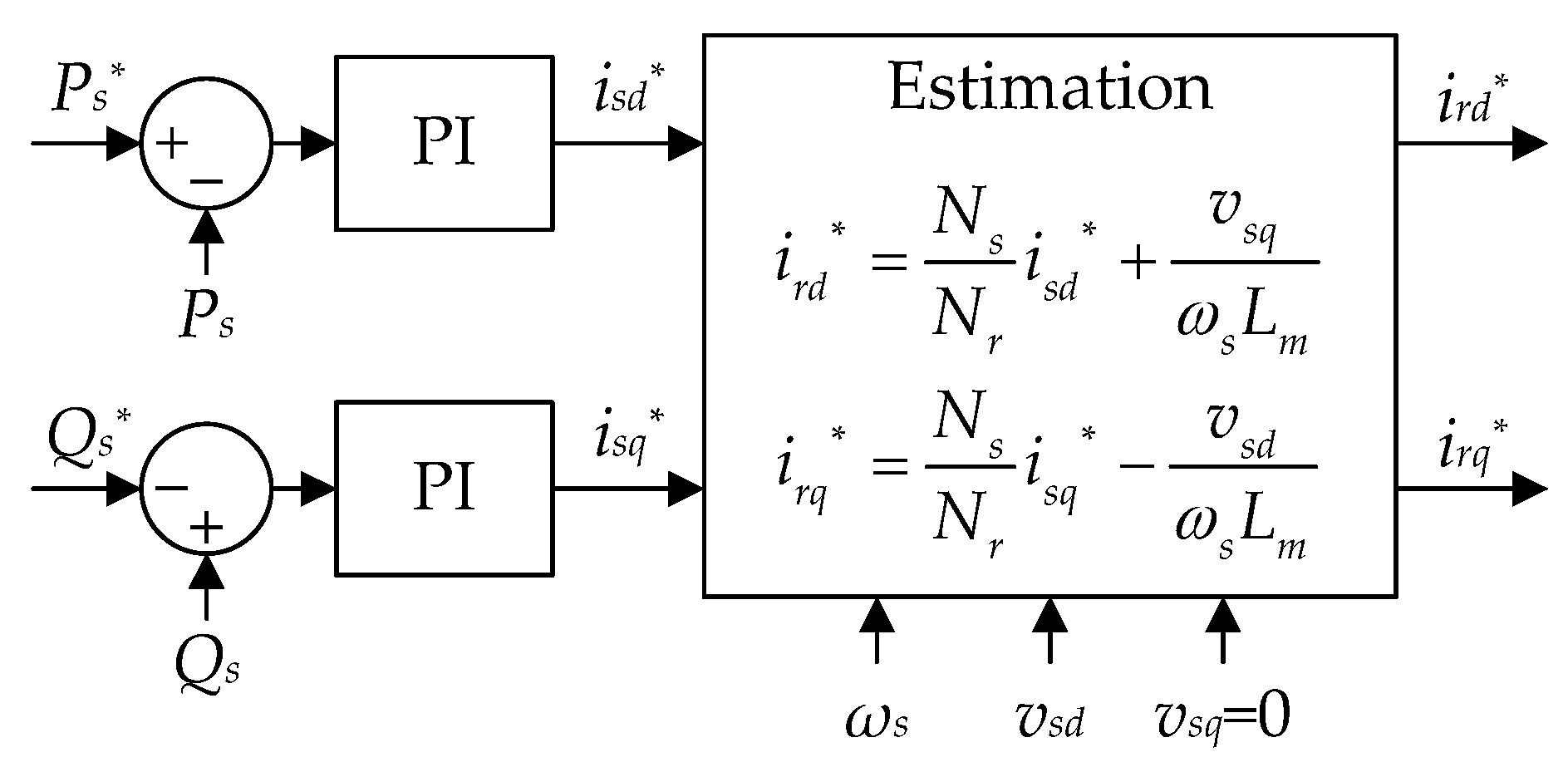

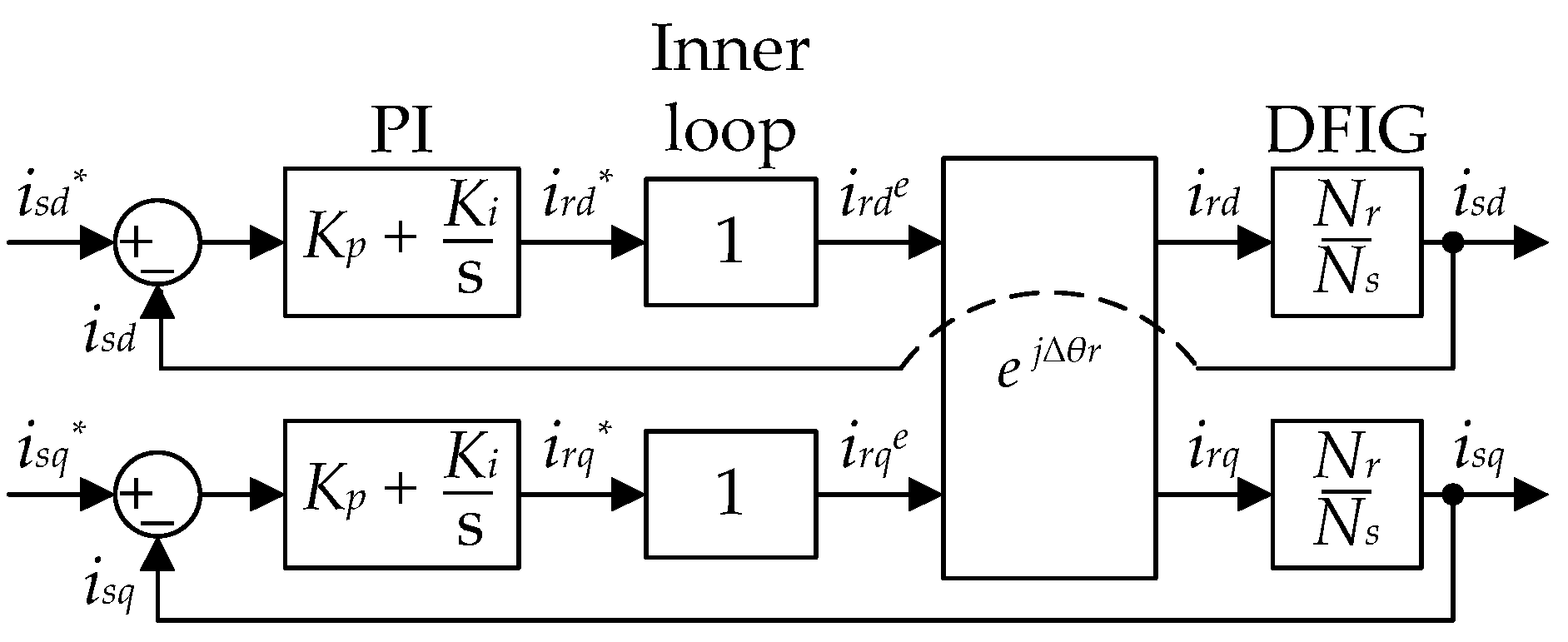

2. Conventional Decoupled P-Q Control

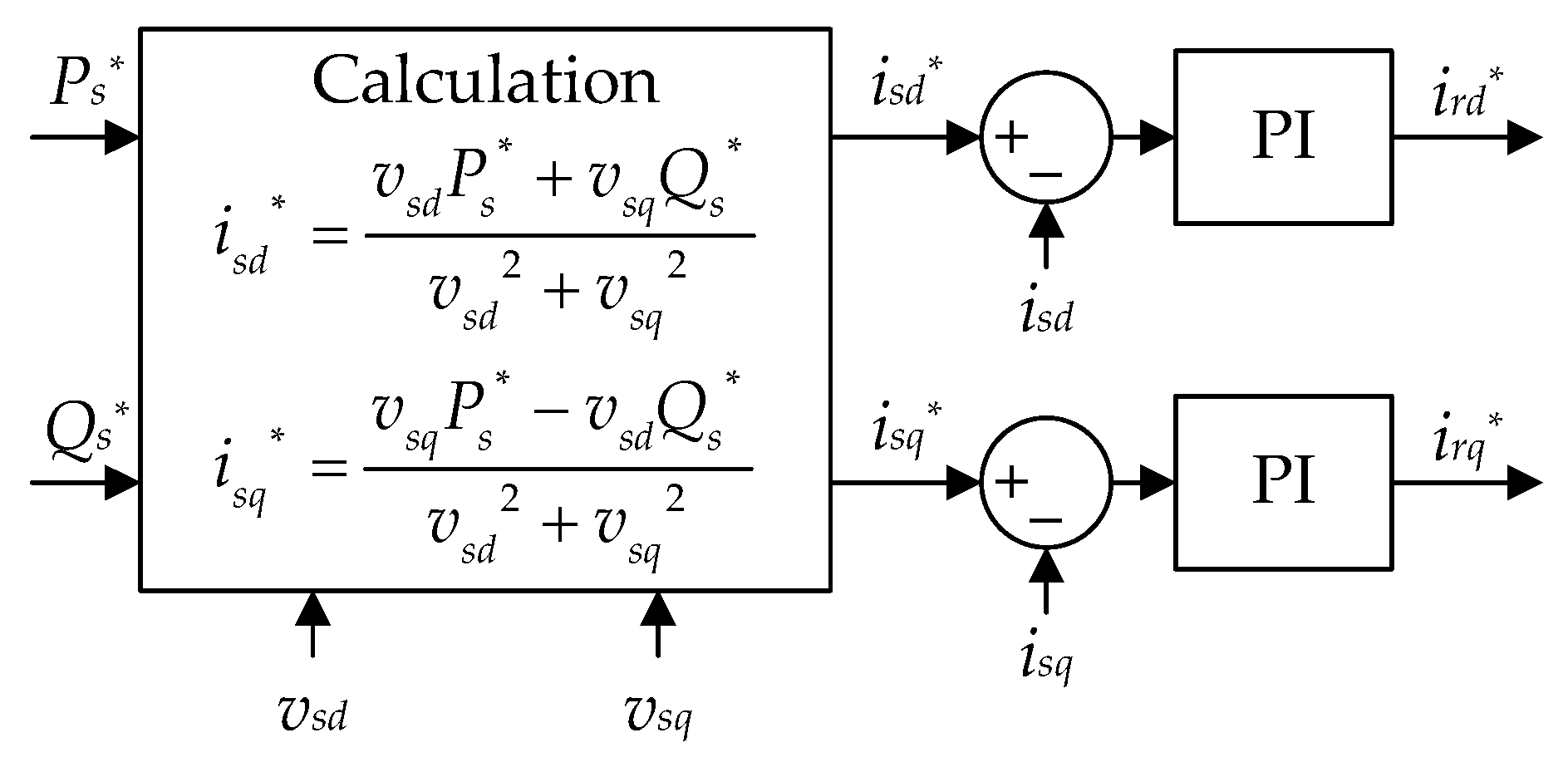

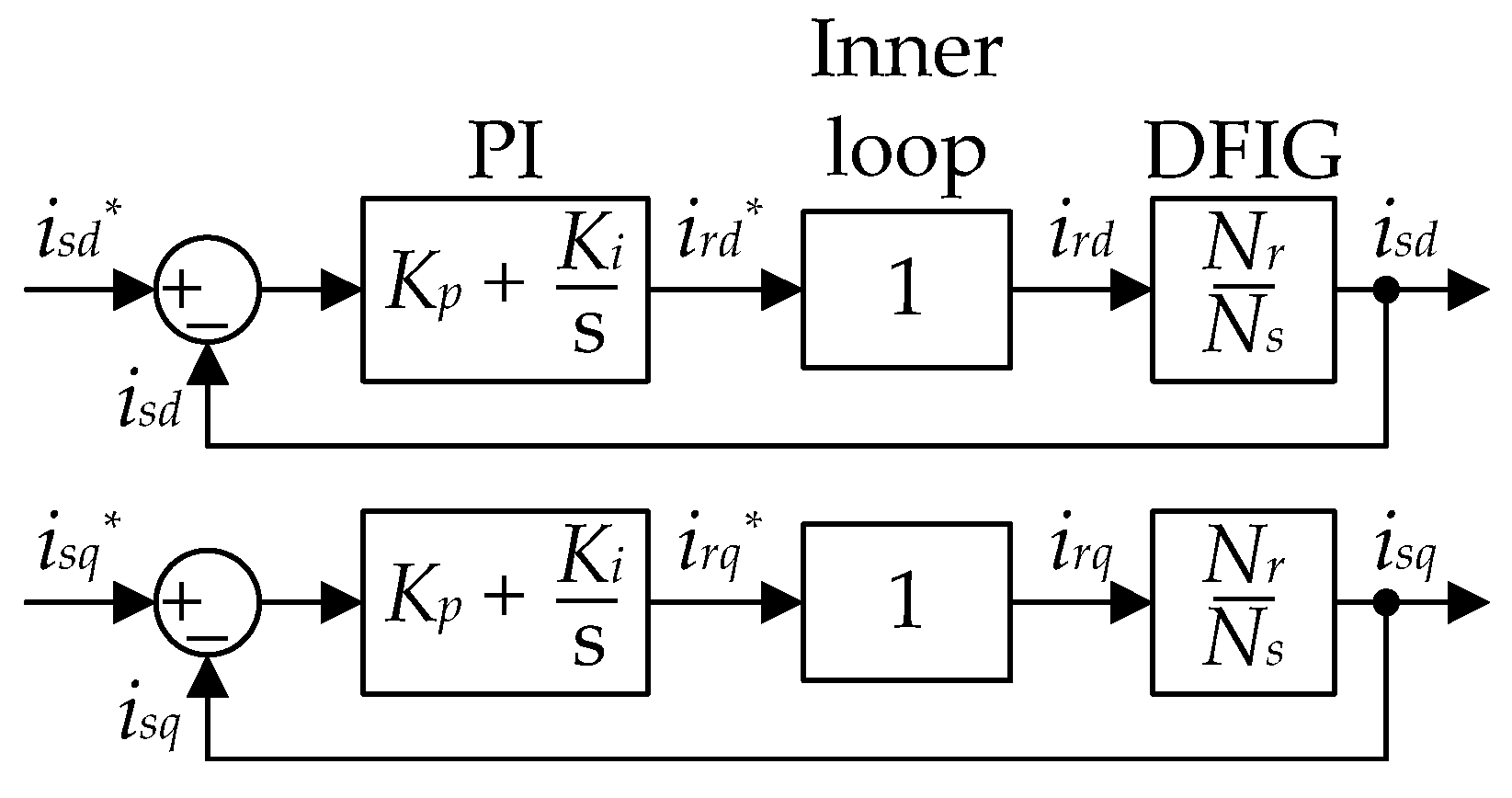

3. Proposed Decoupled Control

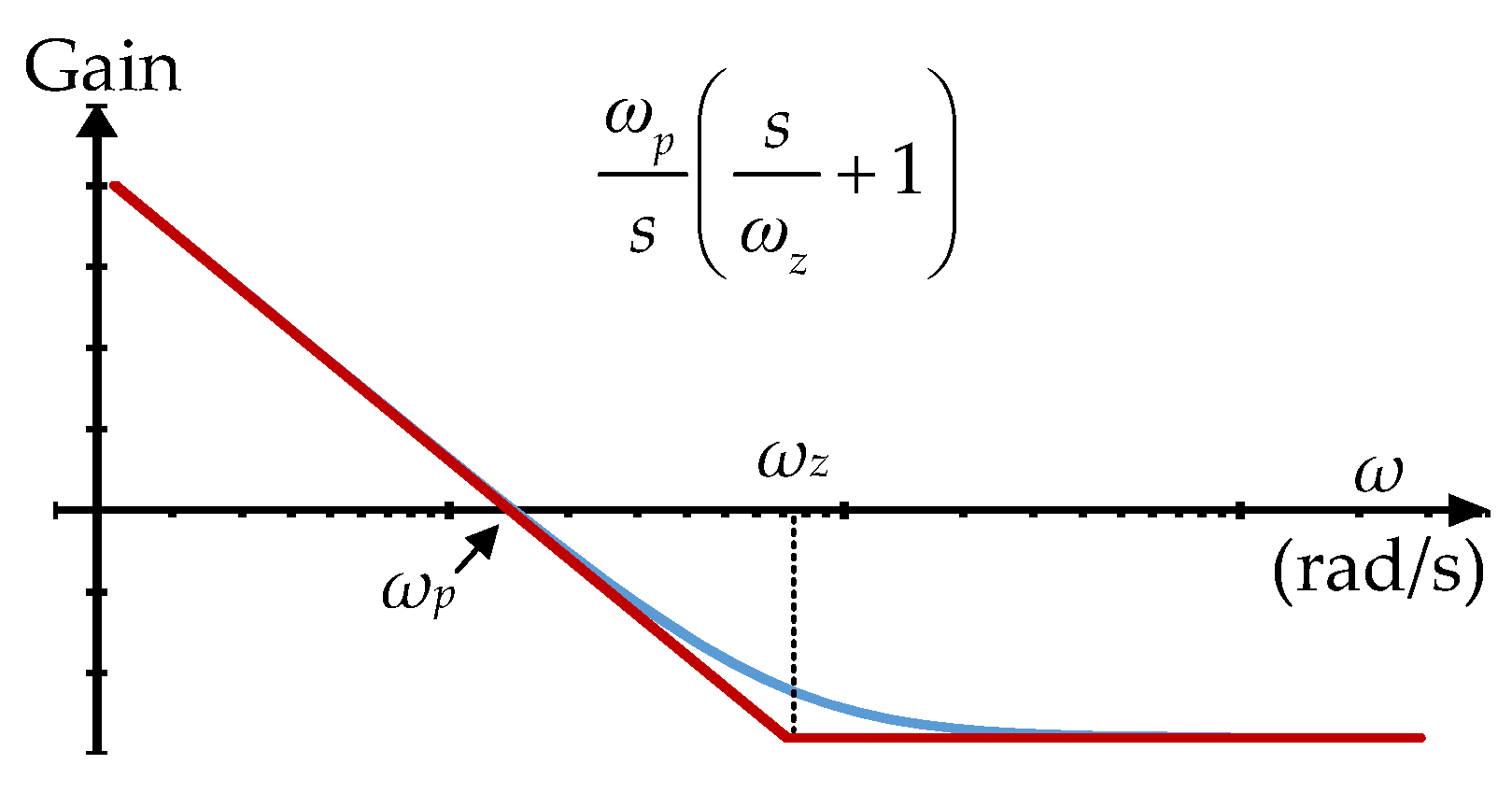

3.1. Concept

3.2. Controller Design

3.3. Sensitivity to Slip Angle Inaccuracy

4. Results

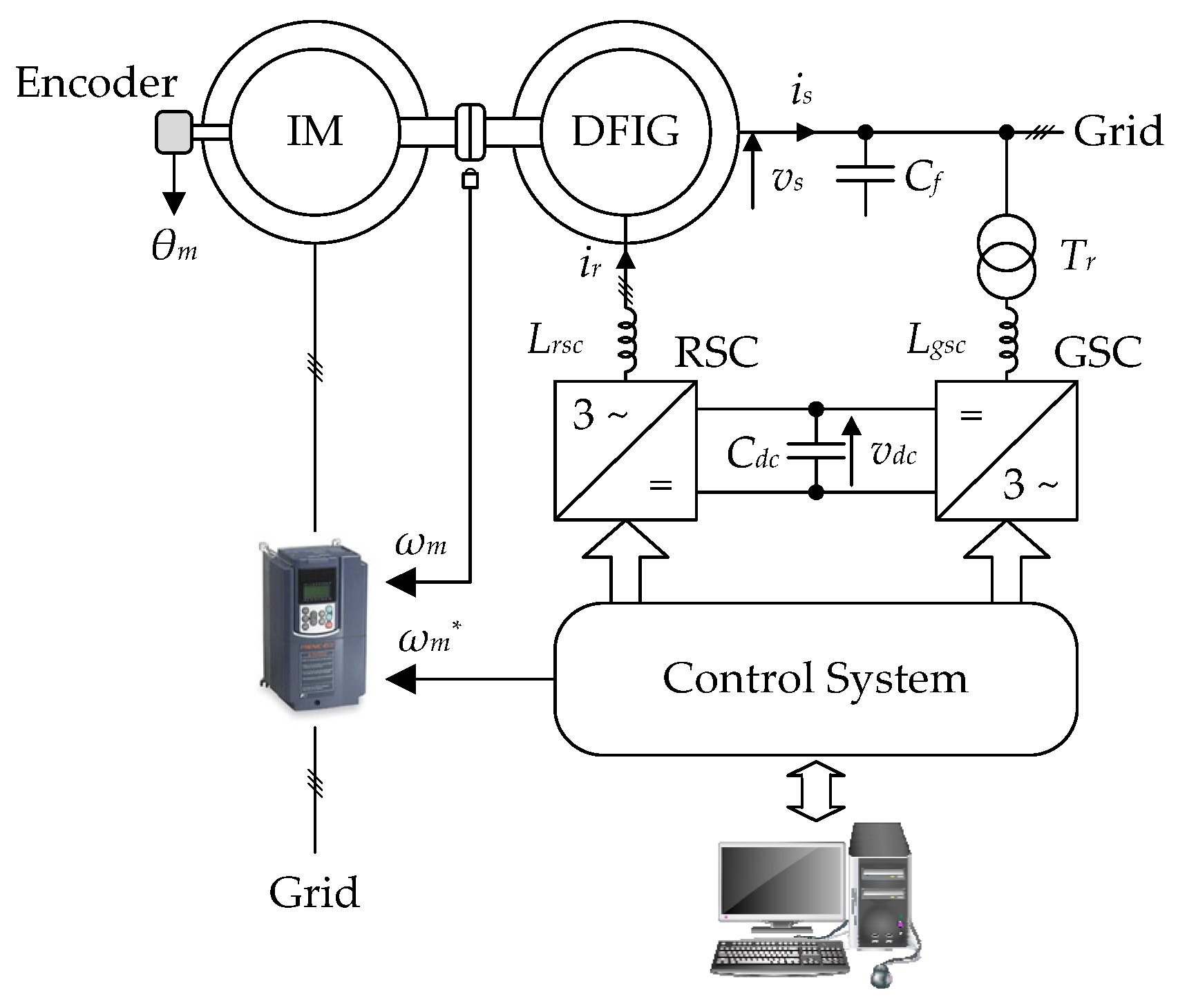

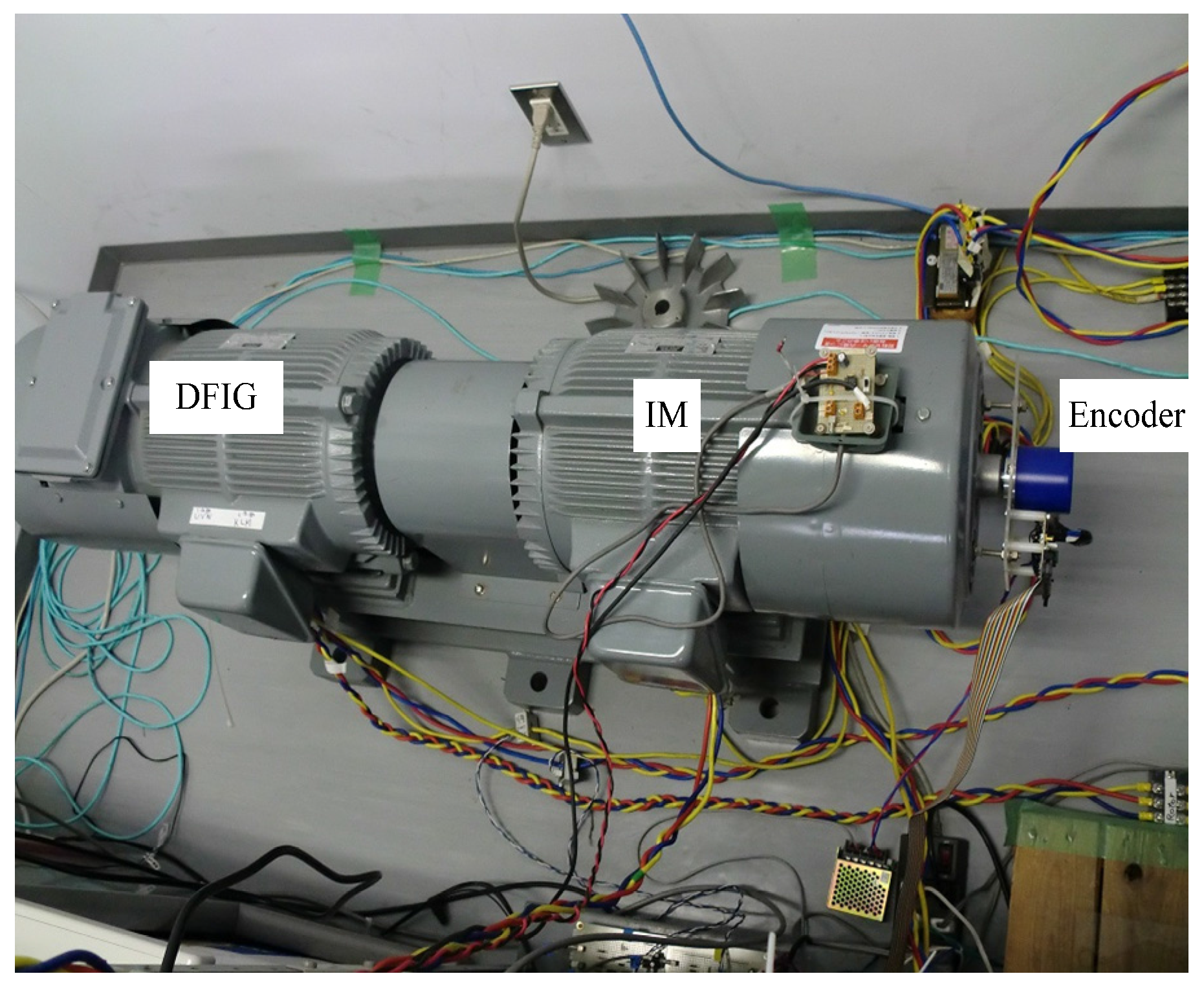

4.1. Experimental Setup

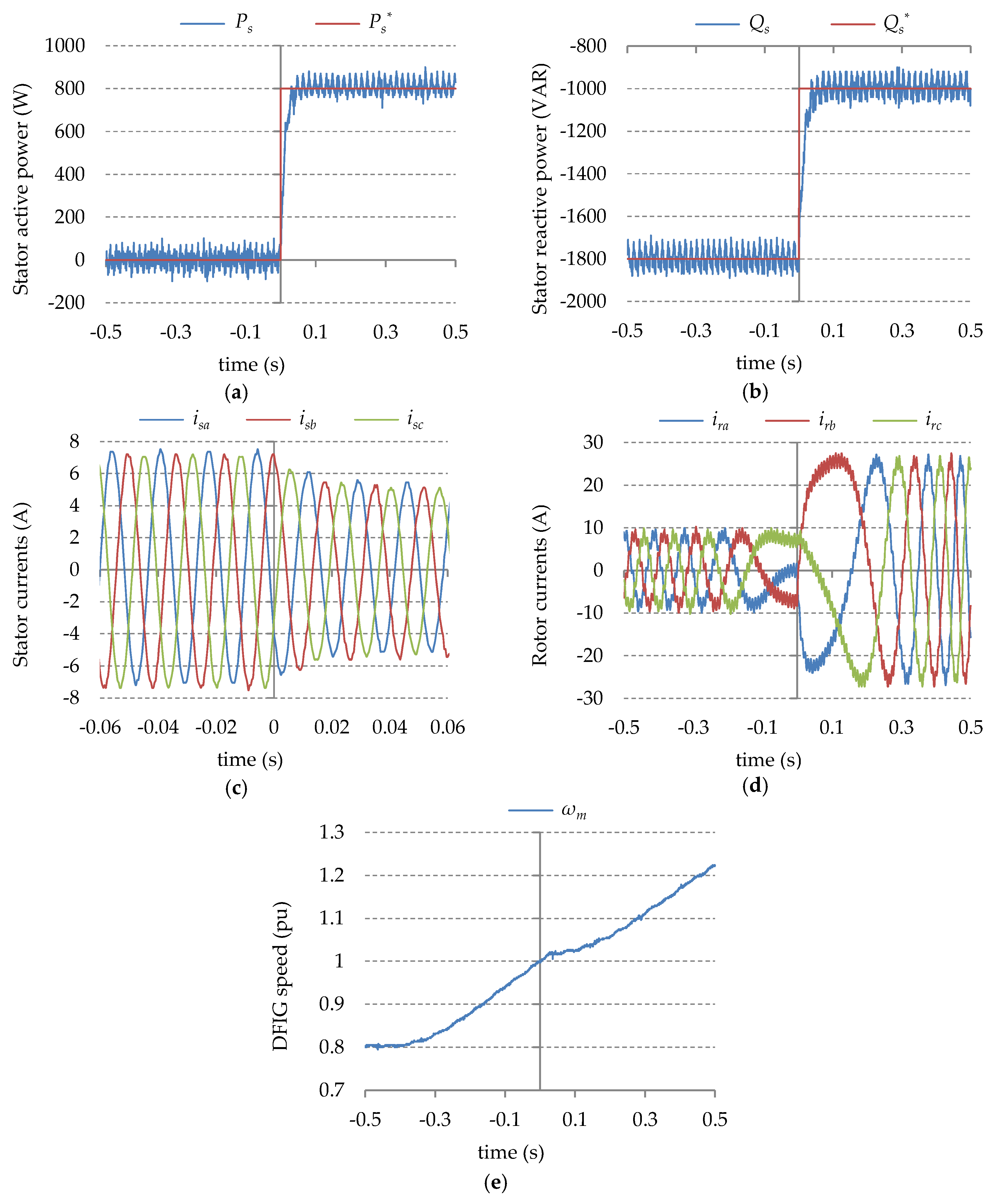

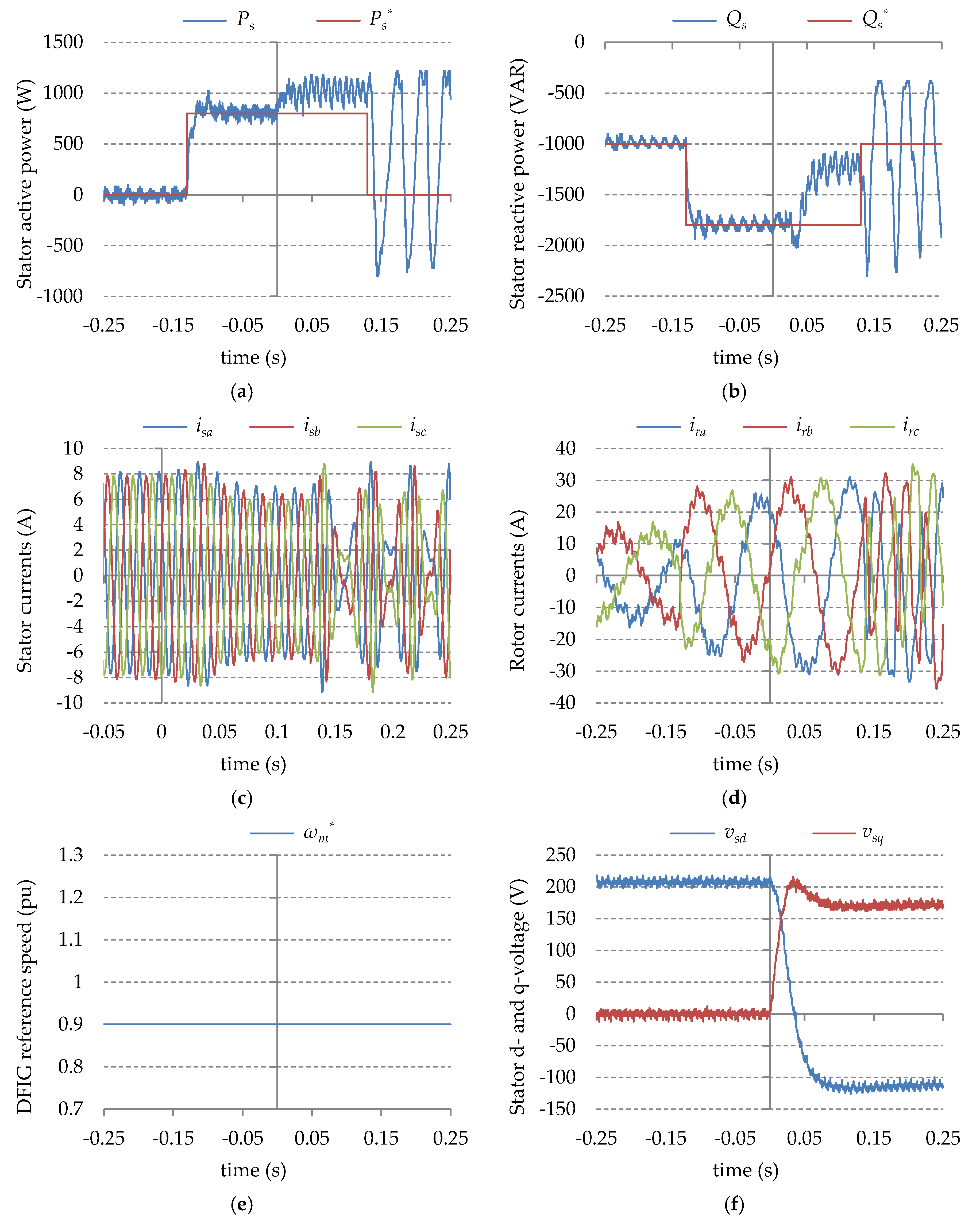

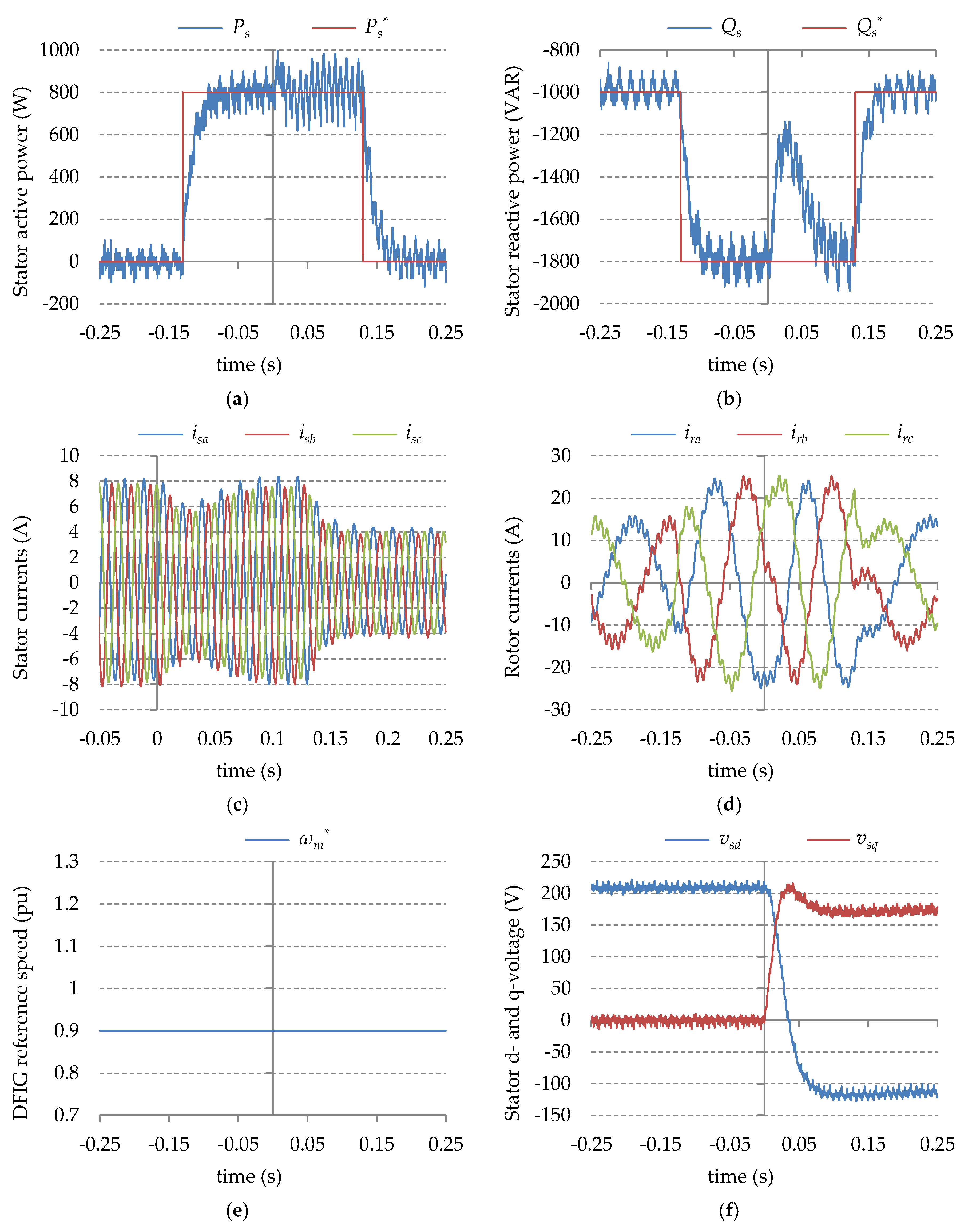

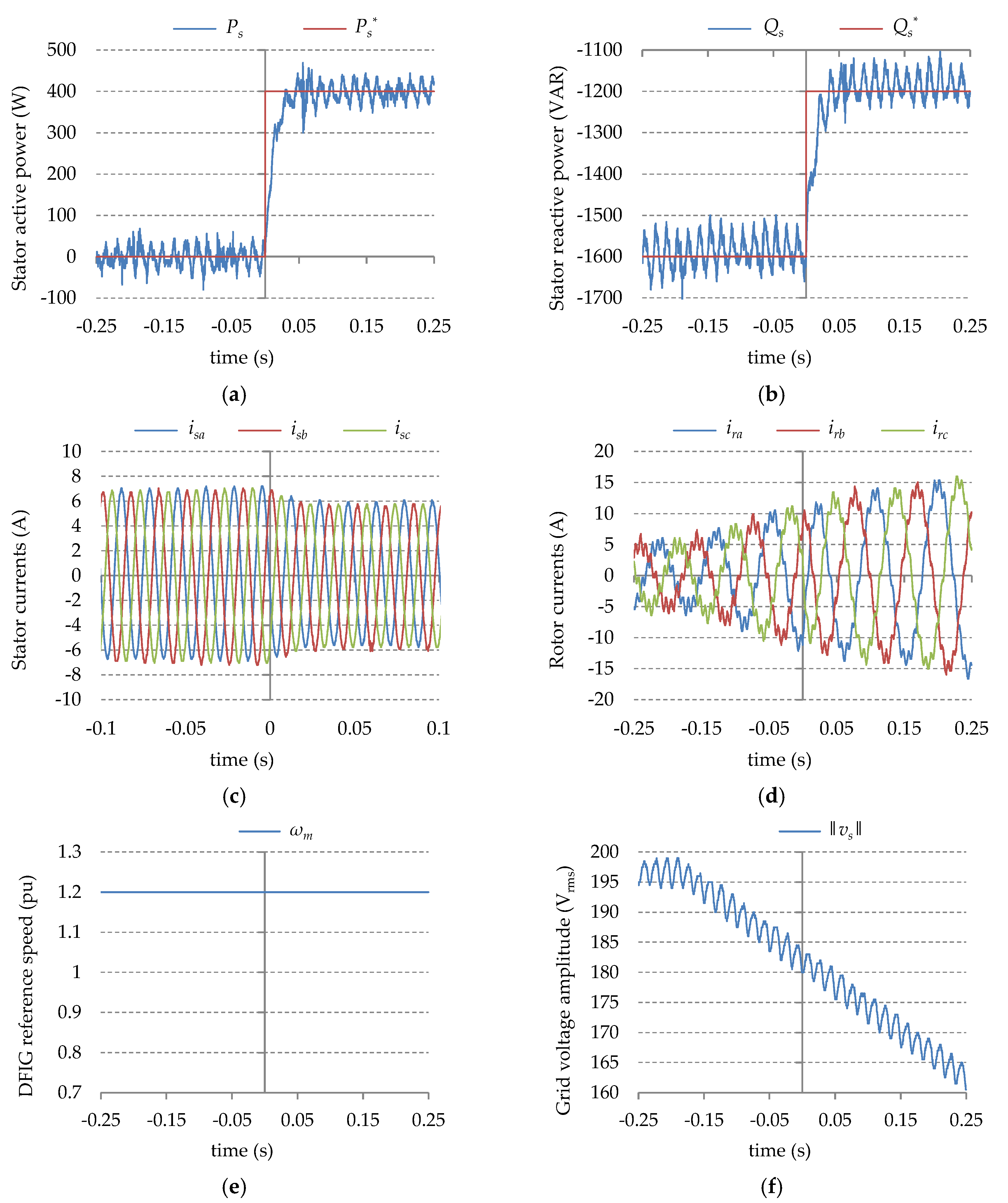

4.2. Experimental Results

5. Discussion

6. Conclusions

Author Contributions

Conflicts of Interest

Nomenclature

| ψs and ψr | Stator and rotor flux linkages |

| ωs and ωr | Synchronous and slip angular frequency (rad/s) |

| ωm | DFIG’s rotor speed (pu) |

| Ls and Lr | DFIG’s stator and rotor inductances |

| Lσs and Lσr | DFIG’s stator and rotor leakage inductances |

| Lm | Mutual inductance between the DFIG’s stator and the rotor |

| Rs and Rr | DFIG’s stator and rotor winding resistances |

| Ns and Nr | DFIG’s stator and rotor number of winding’s turns |

| ( )dq | Representation in the synchronous reference frame |

References

- Jafarnejadsanil, H.; Pieper, J. Gain-scheduled l1-optimal control of variable-speed-variable-pitch wind turbines. IEEE Trans. Control Syst. Technol. 2015, 23, 372–379. [Google Scholar] [CrossRef]

- Singh, B.; Naidu, N.K.S. Direct power control of single VSC-based DFIG without rotor position sensor. IEEE Trans. Ind. Appl. 2014, 50, 4152–4163. [Google Scholar] [CrossRef]

- Pena, R.; Cardenas, R.; Proboste, J.; Clare, J.; Asher, G. Wind-diesel generation using doubly fed induction machines. IEEE Trans. Energy Convers. 2008, 23, 202–214. [Google Scholar] [CrossRef]

- Cardenas, R.; Clare, J.; Wheeler, P. 4-leg matrix converter interface for a variable-speed diesel generation system. In Proceedings of the 38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012.

- Iwanski, G.; Koczara, W. Power management in an autonomous adjustable speed large power diesel gensets. In Proceedings of the 13th Power Electronics and Motion Control Conference, Poznan, Poland, 1–3 September 2008.

- Fraile-Ardanuy, J.; Wilhelmi, J.R.; Fraile-Mora, J.J.; Perez, J.I. Variable-speed hydro generation: Operational aspects and control. IEEE Trans. Energy Convers. 2006, 21, 569–574. [Google Scholar] [CrossRef]

- Belhadji, L.; Bacha, S.; Munteanu, I.; Rumeau, A.; Roye, D. Adaptive MPPT applied to variable-speed microhydropower plant. IEEE Trans. Energy Convers. 2013, 28, 34–43. [Google Scholar] [CrossRef]

- Kanjiya, P.; Ambati, B.B.; Khadkikar, V. A novel fault-tolerant DFIG-based wind energy convers. System for seamless operation during grid faults. IEEE Trans. Power Syst. 2014, 29, 1296–1305. [Google Scholar] [CrossRef]

- Reigosa, D.D.; Briz, F.; Blanco, C.; Guerrero, J.M. Sensorless control of doubly fed induction generators based on stator high-frequency signal injection. IEEE Trans. Ind. Appl. 2014, 50, 3382–3391. [Google Scholar] [CrossRef]

- Nian, H.; Song, Y. Direct power control of doubly fed induction generator under distorted grid voltage. IEEE Trans. Power Electron. 2014, 29, 894–905. [Google Scholar] [CrossRef]

- Pena, R.; Clare, J.C.; Asher, G.M. Doubly fed induction generator using back-to-back PWM Converters and its Application to Variable-Speed Wind-Energy Generation. IEE Proc. Electric Power Appl. 1996, 143, 231–241. [Google Scholar] [CrossRef]

- Datta, R.; Ranganathan, V.T. Decoupled control of active and reactive power for a grid-connected doubly-fed wound rotor induction machine without position sensors. In Proceeding of the IEEE/IAS Annual Meeting, Phoenix, AZ, USA, 3–7 October 1999.

- Datta, R.; Ranganathan, V.T. A simple position-sensorless algorithm for rotor-side field-oriented control of wound-rotor induction machine. IEEE Trans. Ind. Electron. 2001, 48, 786–793. [Google Scholar] [CrossRef]

- Arnalite, S.; Burgos, J.C.; Rodriguez-Amendo, J.L. Direct torque control of a doubly-fed induction generator for variable speed wind turbines. Electric Power Compon. Syst. 2002, 30, 199–216. [Google Scholar] [CrossRef]

- Mahi, Z.; Serban, C.; Siguerdidjane, H. Direct torque control of a doubly-fed induction generator of a variable speed wind turbine power regulation. In Proceeding of the European Wind Energy Conference, Milan, Italy, 7–10 May 2007.

- Datta, R.; Ranganathan, V.T. Direct power control of grid-connected wound rotor induction machine without rotor position sensors. IEEE Trans. Power Electron. 2001, 16, 390–399. [Google Scholar] [CrossRef]

- Xu, L.; Cartwright, P. Direct active and reactive power control of dfig for wind energy generation. IEEE Trans. Energy Convers. 2006, 21, 750–758. [Google Scholar] [CrossRef]

- Zhi, D.; Xu, L.; Williams, B.W. Model-based predictive direct power control of doubly fed induction generators. IEEE Trans. Power Electron. 2010, 25, 341–351. [Google Scholar]

- Chen, S.Z.; Cheung, N.C.; Wong, K.C.; Wu, J. Integral sliding-mode direct torque control of doubly-fed induction generators under unbalanced grid voltage. IEEE Trans. Energy Convers. 2010, 25, 356–368. [Google Scholar] [CrossRef]

- Abad, G.; Rodriguez, M.A.; Poza, J. Two-level VSC based predictive direct torque control of the doubly fed induction machine with reduced torque and flux ripples at low constant switching frequency. IEEE Trans. Power Electron. 2008, 23, 1050–1061. [Google Scholar] [CrossRef]

- Abad, G.; Rodriguez, M.A.; Poza, J. Two-level VSC-based predictive direct power control of the doubly fed induction machine with reduced power ripple at low constant switching frequency. IEEE Trans. Energy Convers. 2008, 23, 570–580. [Google Scholar] [CrossRef]

- Filho, A.J.S.; Filho, E.R. Model-Based Predictive Control Applied to the Doubly-Fed Induction Generator Direct Power Control. IEEE Trans. Sustain. Energy 2012, 3, 398–406. [Google Scholar] [CrossRef]

- Mwinyiwiwa, B.; Zhang, Y.; Shen, B.; Ooi, B.T. Rotor position phase-locked loop for decoupled P-Q control of DFIG for wind power generation. IEEE Trans. Energy Convers. 2009, 24, 758–765. [Google Scholar] [CrossRef]

- Karthikeyan, A.; Nagamani, C.; Ilango, G.S. A versatile rotor position computation algorithm for the power control of a grid-connected doubly fed induction generator. IEEE Trans. Energy Convers. 2012, 27, 697–706. [Google Scholar] [CrossRef]

- Li, S.; Haskew, T.A.; Williams, K.A.; Swatloski, R.P. Control of DFIG wind turbine with direct-current vector control configuration. IEEE Trans. Sustain. Energy 2012, 3, 1–11. [Google Scholar] [CrossRef]

- Pena, R.; Cárdenas, R.; Proboste, J.; Asher, G.; Clare, J. Sensorless control of doubly-fed induction generators using a rotor-current based MRAS observer. IEEE Trans. Ind. Electron. 2008, 55, 330–339. [Google Scholar] [CrossRef]

- Shen, B.; Mwinyiwiwa, B.; Zhang, Y.; Ooi, B.T. Sensorless maximum power point tracking of wind by DFIG using rotor position phase locked loop (PLL). IEEE Trans. Power Electron. 2009, 24, 942–951. [Google Scholar] [CrossRef]

- Marques, G.D.; Sousa, D.M. New sensorless rotor position estimator of a DFIG based on torque calculations-stability study. IEEE Trans. Energy Convers. 2012, 27, 196–203. [Google Scholar] [CrossRef]

- Cárdenas, R.; Pena, R.; Clare, J.; Asher, G.; Proboste, J. MRAS observers for sensorless control of doubly-fed induction generators. IEEE Trans. Power Electron. 2008, 23, 1075–1084. [Google Scholar] [CrossRef]

- Prabhala, V.A.; Cespedes, M.; Sun, J. Implementation of DQ domain control in DSP and FPGA. In Proceedings of the 27th Annual IEEE Applied Power Electronics Conference and Exposition, Orlando, FL, USA, 5–9 February 2012.

- Ataji, A.B.; Miura, Y.; Ise, T.; Tanaka, H. Machine parameter independent control of a grid-connected variable speed doubly-fed induction generator for gas engine generation systems. In Proceedings of the IEEE ECCE Asia Downunder Conference, Melbourne, Australia, 3–6 June 2013.

- Petersson, A.; Harnefors, L.; Thiringer, T. Evaluation of current control methods for wind turbines using doubly-fed induction machines. IEEE Trans. Power Electron. 2005, 20, 227–235. [Google Scholar] [CrossRef]

- Morren, J.; De Haan, S.W.H. Ridethrough of wind turbines with doubly-fed induction generator during a voltage dip. IEEE Trans. Energy Convers. 2005, 20, 435–441. [Google Scholar] [CrossRef]

- Klaes, N.R. Parameter identification of an induction machine with regard to dependencies on saturation. IEEE Trans. Ind. Appl. 1993, 29, 1135–1140. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Power rating | 1.1 kW | Stator rated voltage | 210 Vrms |

| Stator rated current | 6.3 Arms | Rotor rated current | 20.3 Arms |

| Frequency | 60 Hz | Number of poles | 6 |

| Turns ratio Ns/Nr | 6.38 | Rs | 0.012 pu |

| Lσs and Lσr | 0.07 pu | Lm | 0.67 pu |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Grid voltage | 200 Vrms | Frequency | 60 Hz |

| Lrsc | 4 mH | Lgsc | 6 mH |

| Turns ratio of Tr | 0.5 | Cf | 30 μF |

| Block | Kp | Ki | ωcutoff(rad/s) |

|---|---|---|---|

| PI 1 | 0.5 | 500 | - |

| PI 2 | 20 | 1000 | - |

| PI 3 | 5 | 40 | - |

| PI 4 | 50 | 200 | - |

| LPF 1 | - | - | 12.5 |

| LPF 2 | - | - | 500 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ataji, A.B.; Miura, Y.; Ise, T.; Tanaka, H. A New Robust Decoupled Control of the Stator Active and Reactive Currents for Grid-Connected Doubly-Fed Induction Generators. Energies 2016, 9, 179. https://doi.org/10.3390/en9030179

Ataji AB, Miura Y, Ise T, Tanaka H. A New Robust Decoupled Control of the Stator Active and Reactive Currents for Grid-Connected Doubly-Fed Induction Generators. Energies. 2016; 9(3):179. https://doi.org/10.3390/en9030179

Chicago/Turabian StyleAtaji, Ahmad Bashar, Yushi Miura, Toshifumi Ise, and Hiroki Tanaka. 2016. "A New Robust Decoupled Control of the Stator Active and Reactive Currents for Grid-Connected Doubly-Fed Induction Generators" Energies 9, no. 3: 179. https://doi.org/10.3390/en9030179