1. Introduction

Mining presents a significant element of economic development in every state. It is also known that the biggest environmental pollutant is the mining sector [

1]. Mining is followed by a mass production of waste in the form of tailing on tailing ponds. They are often formed in areas which have other potential (agriculture, water supply, urban areas, water flows, etc.). In general, all material left after the extraction of minerals or after the process of exploitation is waste, which when dumped on the deposit spot creates the tailing pond [

2].

Vast areas are covered with mining tailings. For example, amounts of waste from mining in EU countries are around 400 Mt, and tailing waste is approximately 29% of total waste produced [

3]. According to the “2012 Minerals Yearbook, Mining and quarrying trends (advance release)” published by the U.S. Department of the Interior, U.S. Geological Survey, in the U.S. total waste from mining and ore processing in 2012 was around 5210 million tons [

4]. It is interesting that in the previous report, there was a conclusion of a “slight increase” of quantity of mining waste in 2012 compared to 2011.

According to the Environmental Protection Agency (2005) [

5] in the “Report of the State of the Environment in Republic of Serbia”, it is estimated that there are around 700 million tons of flotation and separation tailings, between 1.4 and 1.7 billion tons of tailing wastes from opening pits and around 170 million tons of ashes from thermal power plants on deposit spots and landfills in Serbia. Metallurgy in the Republic of Serbia contributes 10% to the total gross domestic product for production of basic metals and metal products [

6].

In mines with metallic mineral ores, concentration of heavy metals in tailing has increased. This is why the problem of environmental protection is severe in systems like Mining Metallurgy Chemical Combine (MMCC) “Trepča”.

The purpose of this paper is to rank the flotation tailings of MMCC “Trepča” in terms of negative environmental impact. For these purposes, selection of relevant parameters was undertaken and calculations were made through the application of multi-criteria analysis (MCA). This method has recently been used in a variety of studies by numerous researchers deliberating different problems. In the field of mining, such researchers include Bogdanović et al. 2012 and Ataei et al. 2008 and in the area of environmental protection, Kiker et al. 2005 among others [

7,

8,

9].

In this paper, analysis includes five non-remediated flotation tailings. On all five tailings, MMCC “Trepča” disposed their waste. Two flotation tailings are active (waste is still being disposed there) and three are passive, meaning there is no longer any dumping of waste.

2. Study Area

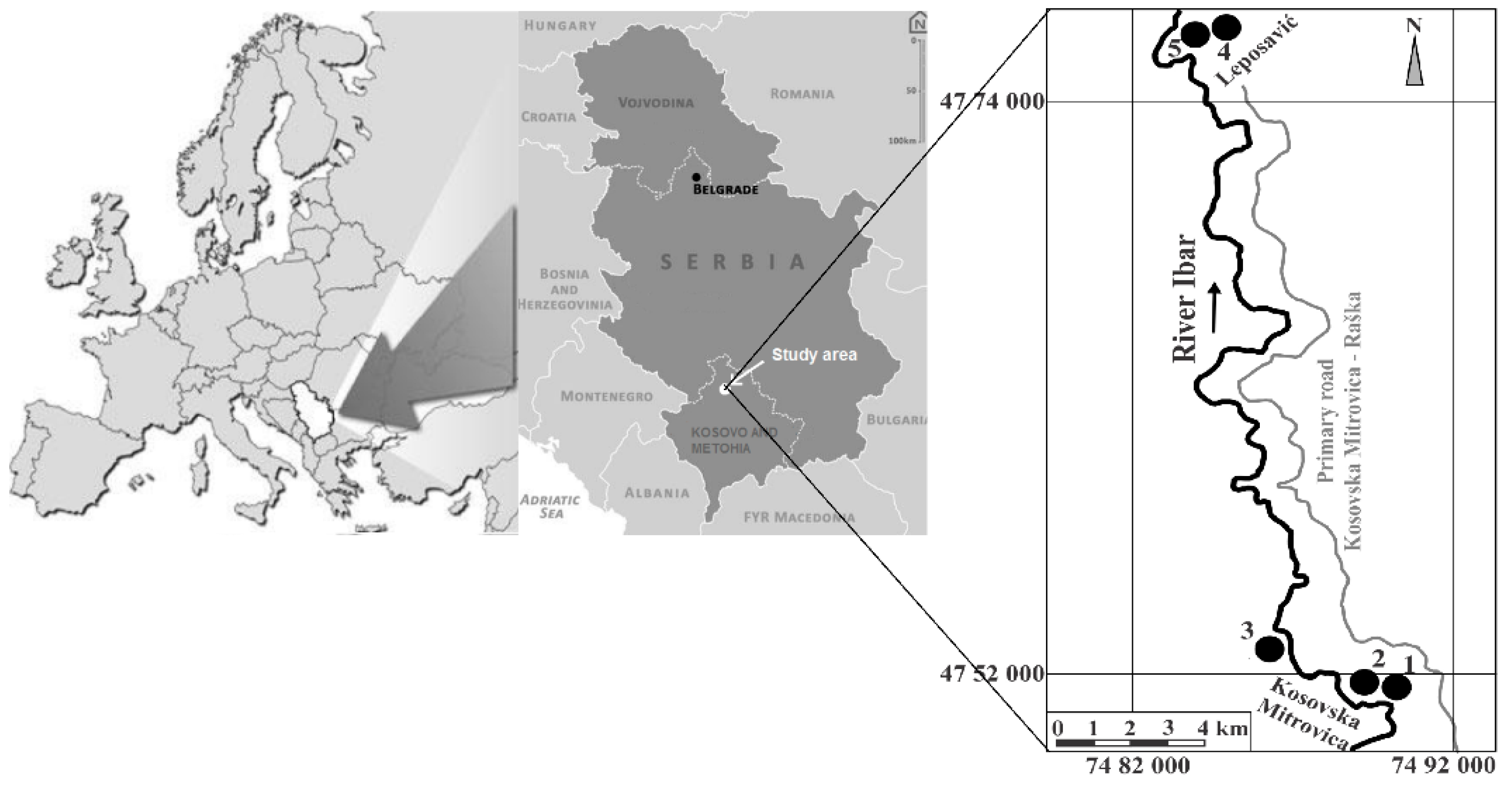

The study area is situated on the large highland Kosovo, to the north of the Autonomous Region Kosovo and Metohija (

Figure 1). Administratively, it belongs to the municipalities of Zvečan and Kosovska Mitrovica. The study area has the typical continental climate with long and hot summers and cold winters. According to the meteorological station Kosovska Mitrovica, the average precipitation from 1991−2013 was 637 mm, and average annual temperature 10.3 °C. Mean wind velocity for Kosovska Mitrovica is 1.9 m/s, and the most frequent blowing direction is north with an average velocity of 2.3 m/s and a northwesterly wind with an average velocity of 2.1 m/s. [

10]

MMCC “Trepča” has produced around 120,000 t of raw lead, 100,000 t refined lead, 100 t of silver, 80,000 t electrolyte zinc, 140,000 t artificial fertilizer, 50,000 t super phosphate, and 30,000 t accumulators, while daily production in mines was up to 10,000 t of mined ores. This was the case until two decades ago for this giant that was one of the biggest producers of lead, zinc, silver and gold in Europe in the period from 1965 to 1985. It had up to 20 facilities and employed up to 25,000 workers at one period of time [

11].

By mining in Kopaonik’s metallogenic zone and flotation processing of metallic minerals, MMCC “Trepča” established tailing ponds: Žarkov Potok, Gornje Polje, Žitkovac, Tvrđanski Do and Bostanište. All five tailings are in an administrative unit of the Kosovska Mitrovica area and in the municipalities of Zvečan and Mitrovica. The tailings are polymetallic and their mineral compositions are mostly heavy metals, as they were extracted from ore. In the process of creation and expansion of these five tailing ponds, material was transported hydraulically and deposed physically by hydrocyclone.

The landscape where the tailings are situated is the Ibar River’s alluvial plain [

12]. Since the tailing deposits have not been rehabilitated, the material from the deposits have scattered over the years in the environment through the aeolian process, gravity and water flows. Tailing material from the analyzed deposits shows permanent toxic pollution of water and agricultural land [

13]. All atmospheric water and waters from tailing ponds are released into the Ibar River through drainage systems in the tailings. The water bodies from the area as well as those from remote areas are highly endangered by the leaching contamination from the tailings. The characteristics of the analyzed flotation tailing waste deposits are shown in

Table 1.

Flotation tailing pond Žarkov Potok is an active landfill site only 2 km northeast from Kosovska Mitrovica, in the basin of Žarkov Potok, right next to the Ibar River. It was formed in 1975 and contains tailings from flotation Prvi Tunel. The space for deposition was constructed by building a dam 87 m high and with a predicted capacity of 8.2 million cubic meters of tailings. Material from flotation to the tailing pond is transported through a hydraulic tunnel. The tailing pond is in the central part of the landfill. Reclamation of the landfill was never undertaken, so when there is windy weather, the effect of dust lifting occurs. There are two channels for drainage of atmospheric waters from the landfill, which are about 100 m and 200 m from the dam and which stop the breakthrough of water towards the dam and its erosion. The composition of the waste is changeable; depending on weather, there is separation of pyrite and pyrrhotite for sulphuric acid production. Cleared water from the tailing pond of the landfill through collectors was placed there when the landfill was constructed, releasing waste into the Ibar River. The tailings are still not managed properly [

11].

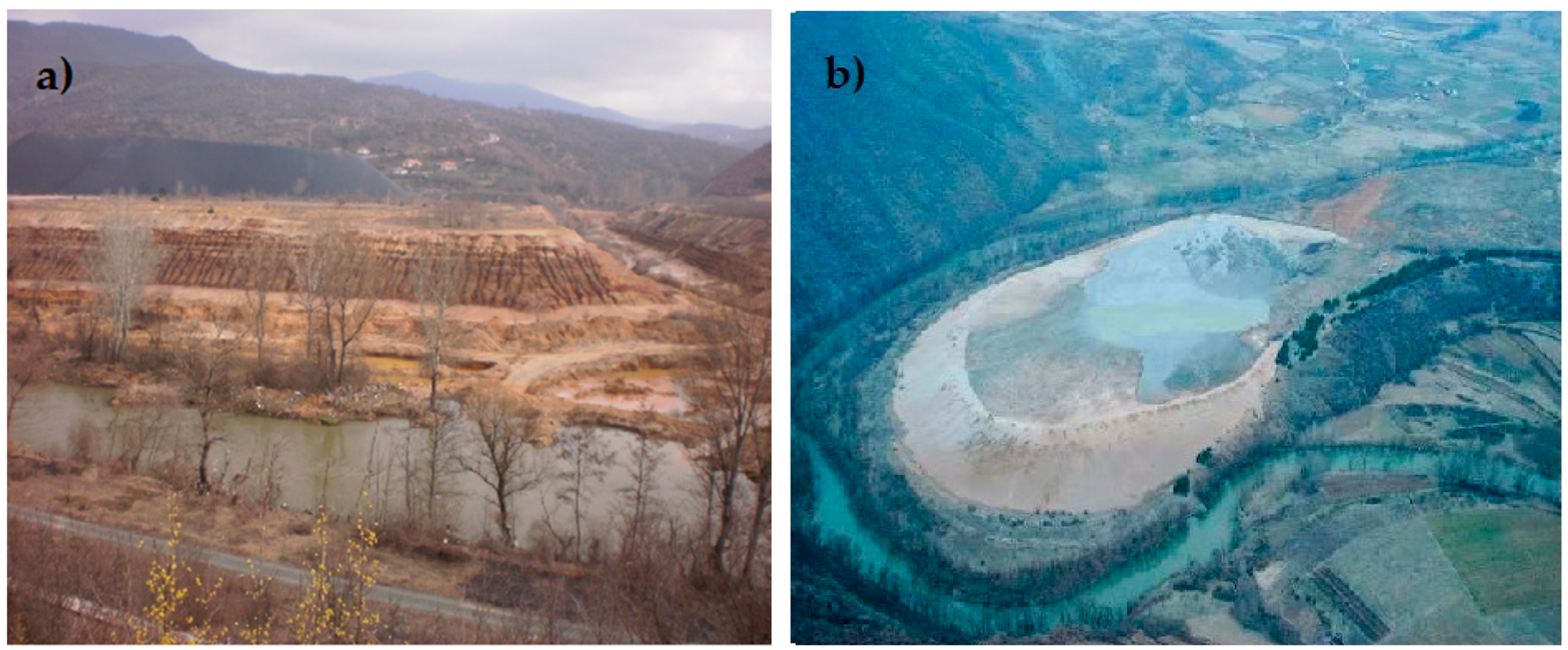

Flotation landfill Gornje Polje (

Figure 2a) is placed on the Ibar River bank, on the part of the terrain between Kosovska Mitrovica and Zvečan. On this landfill, flotation tailings from flotation in Zvečan have been deposed since the operation started in 1930 and lasted until it was closed in 1983. It is approximately 50 ha, and around 12 million cubic meters of tailings lie there. On the northern part of the landfill, tailings from the lead smelter have been disposed for a long time, so the landfill has taken on the form of a cone. Deep cuts have been created as a result of erosion on both sides of the dam, through which comes discharge of atmospheric waters from the landfill directly into the Ibar. Deposed flotation tailing is in general oxidized and solid [

1].

Flotation tailing Žitkovac is on the left side of the Ibar, in the village Žitkovac. Distance from tailings to settlement Zvečan is around 1 km, and to Kosovska Mitrovica around 4 km. The landfill was active from 1963 to 1974. Flotation tailings are transported by hydraulics from flotation in Zvečan, where there are concentrations of lead and zinc ore from Stari Trg ore. The landfill surface is approximately 26 ha, and it is estimated that the amount of tailings dumped there is 7,500,000 m3 or around 3 million tons.

Flotation landfill Tvrđanski Do is east of regional road Kraljevo-Kosovska Mitrovica, in close proximity to the settlement Leposavić, on the right bank of the Ibar River. Flotation tailings from mines Belo Brdo, Crnac, Koporić, Žuta Prlina and Jelakce were deposed there. Surface of the landfill is around 7 ha and on it are approximately 2,600,000 t of deposed tailings. The landfill dam has several steep slopes. Tailing is placed at the bottom of the slope, where there is a tree line next to the Ibar. The landfill was never reclaimed completely and, as a consequence, dust rises and endangers the Leposavić settlement whenever there is windy weather. Drainage water from the landfill is collected and taken directly into the Ibar. Surface of the tailing is oxidized and red. On the sides of the dam, solid parts are noticeable. Due to the fact that raising the upper level of the dam is no longer possible since its construction stability is in danger, there is further land filling with flotation tailing and a new tailing pond, Bostanište, has been established.

Landfill Bostanište (

Figure 2b) is south of the landfill Tvrđanski Do and they are practically one landfill as the north part of the dam of the Bostanište landfill leans on the end of the dam of the older Tvrđanski Do landfill. Most of the Bostanište landfill is comprised of1 km along Ibar River’s bank. It is characterized by the steep slopes of the dam and has surfaces covered with sand; part of the slopes are oxidized tailings with deep erosive cuts. Remediation of the landfill has not been done and there is no plant cover, which causes rising dust, endangering the Leposavić settlement and surrounding villages. The landfill surface is cracked as a result of lack of water. Between landfill dam and the Ibar is a tree line with ground vegetation. Steep slopes of the landfill ravine are present as a result of erosion. Drainage of atmospheric waters, fallen off the surface of the landfill, is done by drainage pipes from main collectors on peripheral parts of the tailings.

The chemical composition of the tailing waste is shown for the flotation tailing waste Gornje Polje. The chemical composition is analyzed by the atomic absorption spectroscopy (AAS) method and the distribution maps are determined by scanning electron microscopy (SEM). The obtained results are presented in the

Table 2 [

14]. Mineralogy composition is determined by using X-ray diffractometry whereby the presence of quartz ankerite, pyrite and clay minerals are recorded. The chemical and mineralogy compositions for the water of four tailing waste deposits are similar [

15].

The Ibar’s water quality for 2008, on the sampling stations upstream and downstream from the flotation tailing waste deposit Bostanište, is presented in the following parameters: pH, total solid particles, soluble matter, non-soluble particles, SO

4, Pb, Zn, Cu, Cd, Fe, Ca. The increased values of the elements in comparison to the maximum allowed concentrations according to the administrative decision to limit concentration of the pollutive matter (RS Official Gazette, No. 50/2012) [

16] upstream from the deposit are determined only for lead in the range from 0.17 to 0.65 mg/L and iron from 0.15 to 4.12 mg/L. Downstream from the deposit the values above the maximum allowed concentrations are recorded for lead in the range from 0.20 to 0.58 mg/L, iron from 0.14 to 4.53 mg/L and copper from 0.02 to 0.12 mg/L. The rest of the parameters have concentrations below the maximum allowed concentrations [

17].

The heavy metal concentration in the top soil was examined in the area of the flotation tailing waste of Bostanište. The sampling was done to the north and the southeast of the deposit. In the northern direction, the top soil sampling was performed in the distances from the deposit of: 300 m, 600 m, and 800 m; in the southeastern direction, the distance range was 150 m, 250 m, 350 m and 1400 m. The analyses were conducted for the following heavy metals: Mo, Zr, Sr, Rb, Pb, Se, As, Hg, Zn, Cu, Mi, Co, Fe, Mn, Cr, Cd. Heavy metal concentration in the top soil in the area of Bostanište and their limited values according to the administrative decision on the soil quality (RS Official Gazette, No. 88/2010) [

18], are shown in

Table 3.

The mineral processing in MMCC “Trepča” is a metal concentration process. The ore is crushed, then milled to the average size of 0.1 mm in grain diameter. The grain-size distribution is of vital interest for the environmental impact assessment of the tailings. Based on the grain-size distribution investigation, done for the tailing waste Bostanište, the particles are sized between 0.1 mm and 0.2 mm diameter [

19]. These results point to the fact that the particles can be driven by the wind and water in both the close and remote sampled distances.

4. Results

Comparing the influence of certain criteria to the environment was based on relevant data obtained in the field. In

Table 1, analyzed criteria which were used as input data for matrix formatting and quantification for coupled comparison of criteria according to the Saaty scale are presented (

Table 7). Those data are than included into the calculations by AHP and PROMETHEE methods, by common steps in calculation process.

Based on results of the calculation done by AHP and PROMETHEE methods, final alternative rank was given—tailing ponds according to the their negative impact to the environment.

Matrix with double comparison is formed by AHP method based on previously set criteria (

Table 7). Weight coefficients for each criteria are calculated by mutual comparison and based on Saaty’s scale (

Table 5). Criteria are being added values by direct and inverted procedure in span from 1 to 9.

By valuing each criterion, coefficient weight of criteria was gained and are shown in

Table 8. For the purpose of control of gained results, calculations of the

CR are done. Results obtained confirmed that decision is consistent because its value is less than 0.1, or its value is 0.082062 (

Table 8).

For individual criteria, weight coefficient values, consistency index (

CI) and consistency rate (

CR) for all five tailings were obtained by the APH method (

Table 9). For criterion C1, the distance of water supply sources, the tailing A3 Žitkovac 0.4740 has the greatest value of weight coefficient, and A4 Tvrđanski Do 0.0715 has the minimum value. For criterion C2, vicinity of settlement, A5 Tvrđanski Do 0.4041 hasthe greatest value of weight coefficient, and A1 Žarkov Potok 0.05546 has the minimum value. For criterion C3—the vicinity of agricultural environments—tailing A4 Tvrđanski Do 0.30954 has the greatest value of weight coefficient, and A1 Žarkov Potok 0.0373 has the minimum value. For criterion C4—the vicinity of water stream—the tailing A4 Tvrđanski Do 0.3107 has the greatest value of weight coefficient and A1 Žarkov Potok 0.0837 has the minimum value. For criterion C5—the amount of deposited material—A2 Gornje Polje 0.4851 has the greatest value of weight coefficient, and A4 Tvrđanski Do 0.0420 has the minimum value. For criterion C6—the existence of torrential watercourses, the greatest value of weight coefficient has the tailing A2 Gornje Polje 0.4285, while the remaining tailings have the same value, 0.1428. For criterion C7, tailing activity, A1 Žarkov Potok and A5 Bostanište 0.3636 both have the greatest value of weight coefficient and the value of the remaining three tailings is 0.0909. For criterion C8, geology, all tailings have identical weight coefficient which is 0.2. For criterion C9, general slope of a region, A4 Tvrđanski Do and A5 Bostanište 0.2889 have the greatest value of weight coefficient, and the A2 Gornje Polje 0.0723 has the minimum value. For criterion C10—maintenance of tailings—all five tailings have identical value which is 0.2.

According to the conducted estimation with the application of the AHP method, the criterion C1, distance from the source of water supply, 0.2143, has the greatest value of weight coefficient and the criterion C10—maintenance of tailings, 0.0162—has the minimum value.

Alternatives have been evaluated and a quantified matrix of decision making has been formed (

Table 10) by application of the PROMETHEE method for evaluation of environmental influence of tailing ponds. In this process, certain criteria have a quantitative structure, while others are qualitative. Consequently, certain criteria (C1, C2, C3, C4, C5, C8, C9) are stated quantitatively, while others are stated qualitatively. The application of qualitative and quantitative scales provides confidence that all criteria are well arranged in the best manner possible.

After quantified matrix of decision making was provided, analyzed alternatives (tailing ponds) were evaluated using Visual PROMETHEE software. This resulted with a rank order of alternatives. Multi-criteria ranking method PROMETHEE introduces qualities of positive, negative and net flow [

29]. The results obtained from positive, negative and net flow are presented in

Table 11.

5. Discussion

In recent years, as a part of the numerous activities of MMCC “Trepča”, five tailing ponds were formed in this area, receiving a significant amount of disposed material from the category of pollutants that are potentially dangerous to the surrounding ecosystem. The tailing ponds are unsuitably placed and the current lack of maintenance in addition to the disposed materials can permanently endanger the living environment. At the same time, these ponds represent a potential danger which can reach the category of ecological disasters.

Numerous activities of the local population are taking place in relatively close proximity to these tailing ponds, despite the very precarious situation. Often, the local population has created facilities and taken part in activities, which are not safe so close to tailing ponds. For example, at about 50 m from some landfills there are wells used for irrigation and water supply, while some fields and streams are also only 50 m away from some landfills. Generally, all of the five treated tailings were formed in places that can have harmful effects on the surrounding ecosystem. The situation described here was meant to conduct an analysis and ranking of the tailings by the degree of potential danger to the living environment.

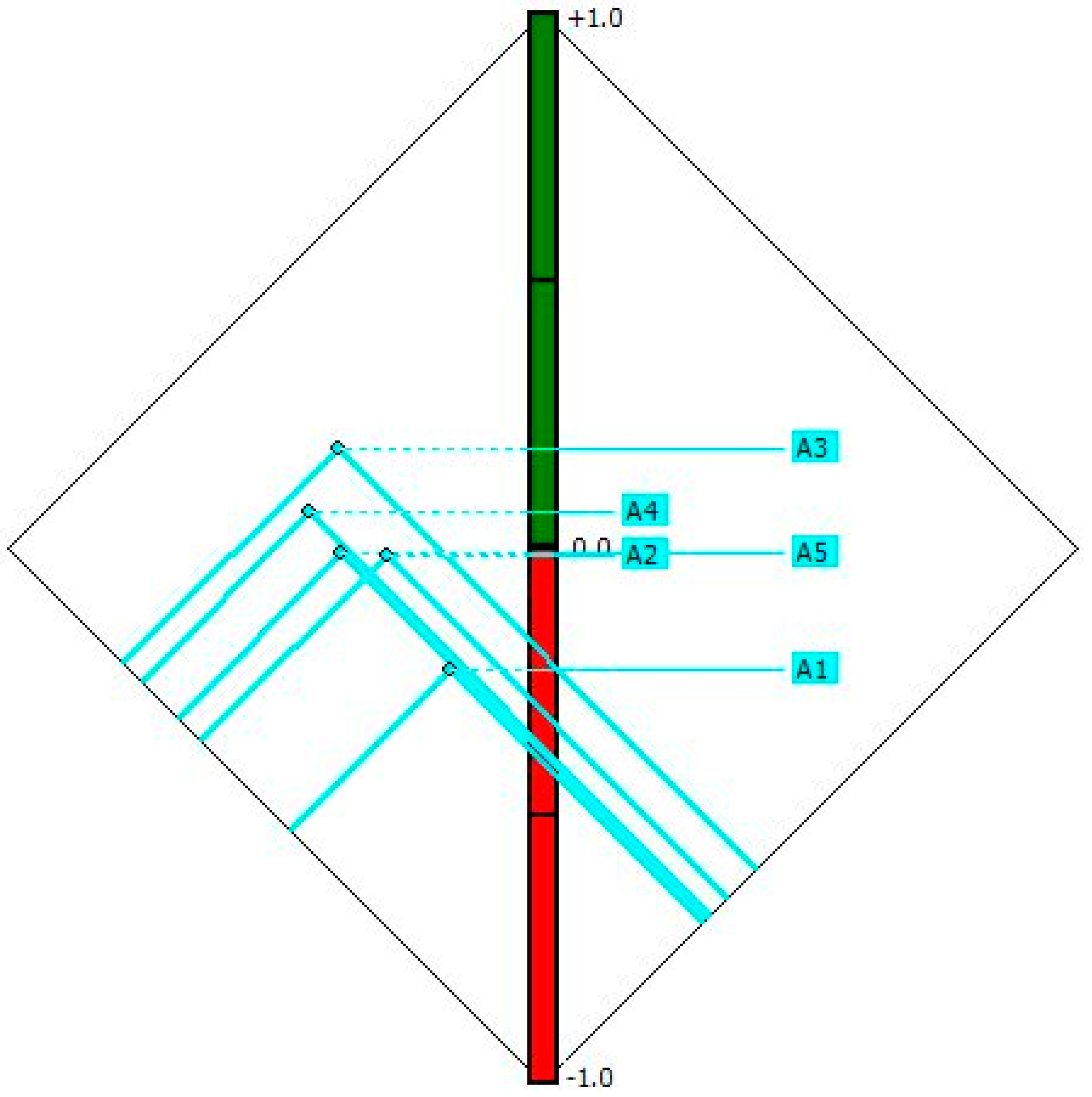

In

Figure 3, the final ranking of analyzed tailing ponds is given. This figure is based on net flow Phi. The upper half of the given scale (colored in green) represents positive Phi value, and the lower half (red) represents negative Phi value. Alternative A3 (Žitkovac) is at the top of the analyzed alternatives, preceding A4 (Tvrđanski Do), while A2 (Gornje Polje) and A5 (Bostanište) are about the same negative Phi values. At the bottom of the list is the alternative A1 (Žarkov Potok). Values of the Phi flow for these alternatives are given in

Figure 3.

Figure 4 shows a diamond PROMETHEE solution. This solution shows partial PROMETHEE I and final ranking PROMETHEE II in a two-dimensional model. The PROMETHEE diamond solution is presented with the dot on (Phi+,Phi−) flat. The flat is at an angle of 45° so that the vertical dimension (red-green axis) corresponds to Phi net flow. A cone is drawn for every alternative. Cones A2 and A5 overlap, which indicates that these two alternatives are closely congruent, while the alternative A2 has the advantage in partial ranking PROMETHEE I. The highest priority alternative is A3 (Žitkovac), and the lowest is alternative A1 (Žarkov Potok).

In

Figure 5, the GAIA plan is shown (Geometrical Analysis for Interactive Assistance), which is a descriptive addition to the PROMETHEE ranking. Every alternative is presented with a dot found on the GAIA plan. The position of these alternatives is connected with the marks of a set of criteria. Each criterion is presented with the axis from the center of the GAIA plan. The orientation of these axes shows how these criteria are interrelated. Alternative A4 and A5 are similar because they are closer to each other, whereas the other alternatives are completely dissimilar. Criteria with similar preferences are C5, C1 and C2 and C3, conflicting criteria are C9 and C4. The determination axis (red axis) suggests the alternative A3 tailing Žitkovac has the least favourable impact on the surrounding ecosystem.

With implementation of estimation by using the AHP and PROMETHEE methods, with the aim of ranking the impact on the environment, the ranks are obtained according to their negative impact (

Table 12). The comparative analysis of the negative impact on the surrounding ecosystem shows that the least favorable tailing pond is A3 Žitkovac, and that the least negative impact has the alternative A1 Žarkov Potok. Three remaining tailings have the following order of unfavorable impact on the environment: A4 Tvrđanski Do, A5 Bostanište and A2 Gornje Polje.

It should be noted that other methods of multi-criteria analysis (VIKOR, TOPSIS, ELECTRE) also should be used to verify the results and the final decision.

Finally, it should be emphasized that the legal regulations relevant for MMCC “Trepča” in terms of environmental protection can be classified into three levels: (1) Constitution (RS Official Gazette, No. 98/2006) [

31], International Conventions (Directive 98/83/EC: Quality of water intended for human consumption, Directive Drinking Water [

32]; Directive 80/68/EEC: Protection of groundwater against pollution caused by certain dangerous substances [

33]; Directive 93/67/EEC: Risk Assessment for new notified substances [

34]; Directive 86/278/EEC: Protection of the environment, and in particular of the soil, when sewage sludge is used in agriculture [

35]) and Recommendations; (2) By-Laws on Environmental Protection (RS Official Gazette, No. 36/2009) [

36]; Law on Nature Protection (RS Official Gazette, No. 88/2010) [

37]; Law on Mining and Geological Surveys (RS Official Gazette, No. 101/2015) (In Serbian) [

38], Water Law (RS Official Gazette, No. 93/2012) [

39]; (3) By-laws, regulations, instructions, directives regulation on the threshold values of pollutants in surface waters, groundwater and sediment and deadlines for their achievement (2012) (RS Official Gazette, No. 50/2012) [

40]. Unanimous compliance with the Constitution of the Republic of Serbia is mandatory; the application of the International Conventions and Recommendations relevant to the mining industry and environmental protection should enable the fulfilment of the requirements related to the environmental protection valid for all members of the EU.

6. Conclusions

This paper analyzed and ranked the impact on the surrounding ecosystem of five flotation tailings which are in the MMCC “Trepča,” located to the north of Kosovo and Metohija. The analysis was conducted for the following tailings: Žarkov Potok, Gornje Polje, Žitkovac, Tvrđanski Do and Bostanište. Tailings have a very strong impact on the surrounding ecosystem, considering the chemical composition of the deposited tailings, as well as where the tailings that are not repaired are located. These tailings are a major source of pollution in these areas of natural beauty and historical significance.

The result obtained using multi-criteria analysis ranking the impact on the environment of five analyzed tailing ponds with the application of the AHP and PROMETHEE methods showed a certain reality, which is in accordance with the situation on the terrain. According to this analysis, the most problematic tailing pond is Žitkovac, and then Tvrđanski Do, Bostanište, Gornje Polje and finally Žarkov Potok. Application of the results can be used in the decision-making process for prioritizing the rehabilitation of the tailings.

The application of the method for the multi-criteria analysis of the impact of pollutants on the environment should be an integral part of the overall management system to the highest level as the enforcement of environmental protection is an interactive process. In the case of the MMCC “Trepča,” the possibility of a method for multi-criteria analysis is demonstrated in the field of analysis and ranking of the influence tailing ponds have on the surrounding ecosystem.

Because of its primary purpose which is excavation and processing of mineral resources, MMCC “Trepča” should be more focused on increased concern about environmental protection. MMCC “Trepca” is required to identify and to abide legal requirements of its activity concerning environmental protection. This also applies to international laws, as well as national, regional, provincial and municipal. Where laws and regulations are not sufficient to meet the needs, MMCC “Trepča” can establish its own internal criteria.