A Rest Time-Based Prognostic Framework for State of Health Estimation of Lithium-Ion Batteries with Regeneration Phenomena

Abstract

:1. Introduction

2. Related Work

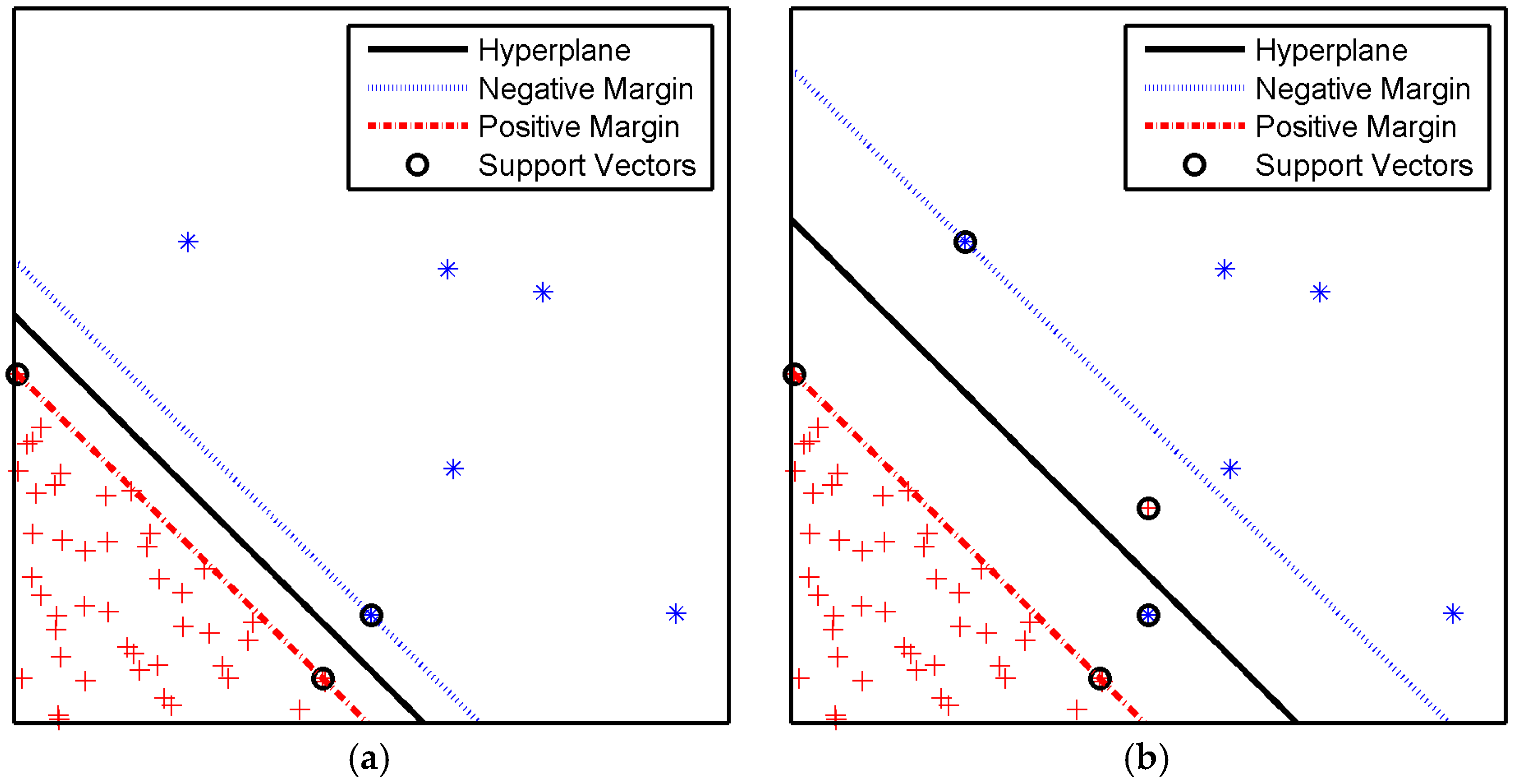

2.1. Support Vector Machine and Hyperplane Shift

2.1.1. Support Vector Machine

2.1.2. Hyperplane Shift

2.2. Gaussian Process Model

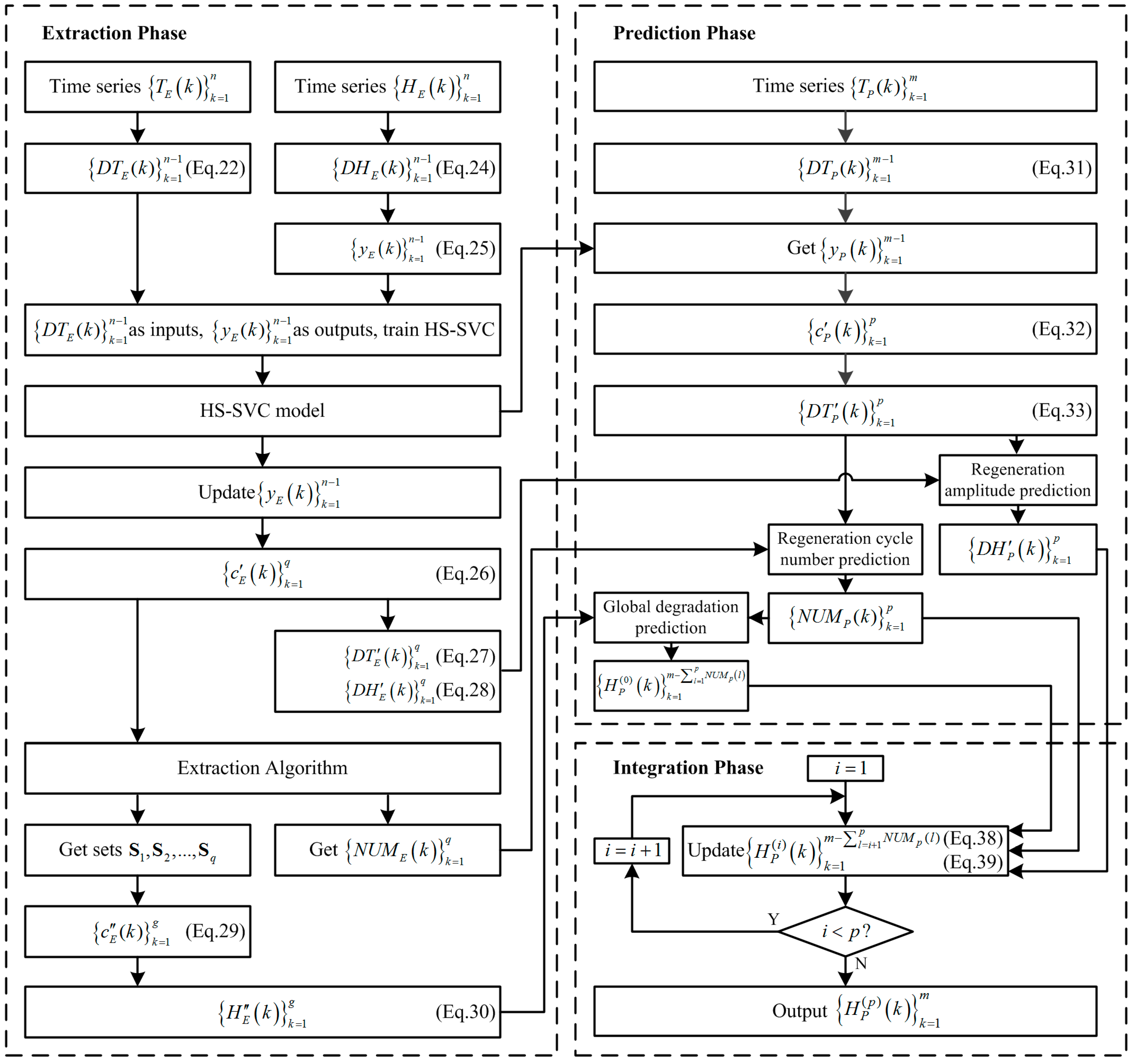

3. The Proposed Framework for Lithium-Battery State of Health Prognostics

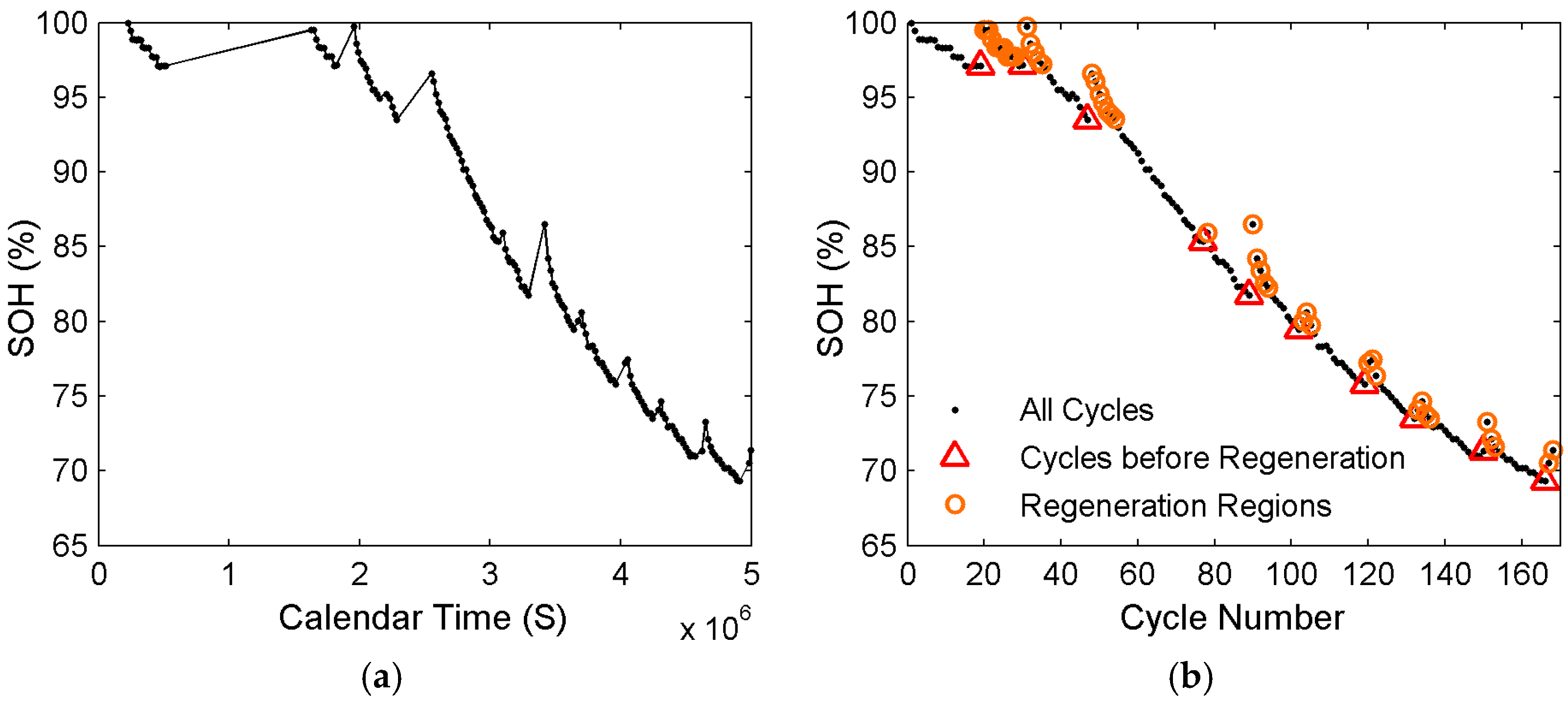

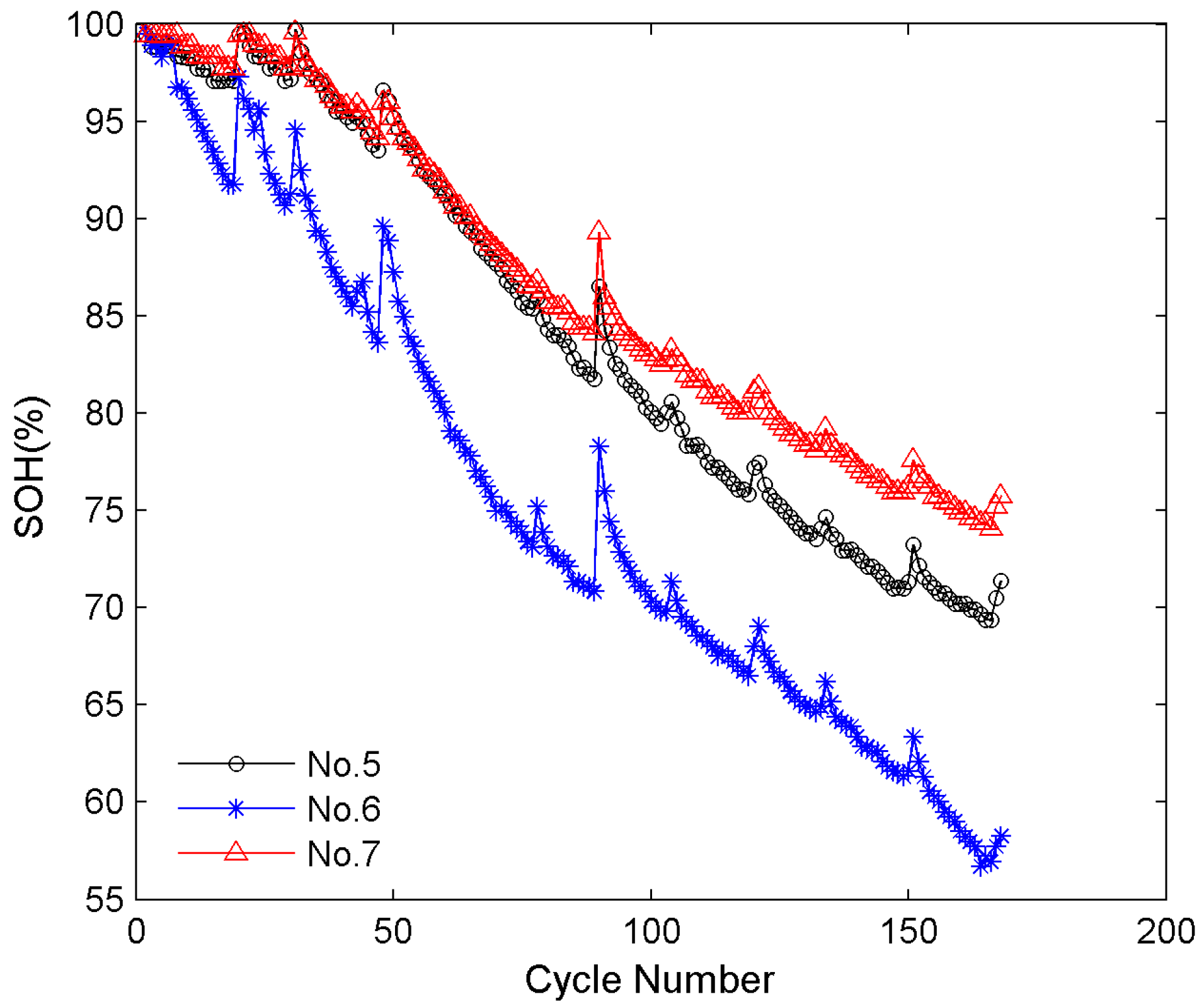

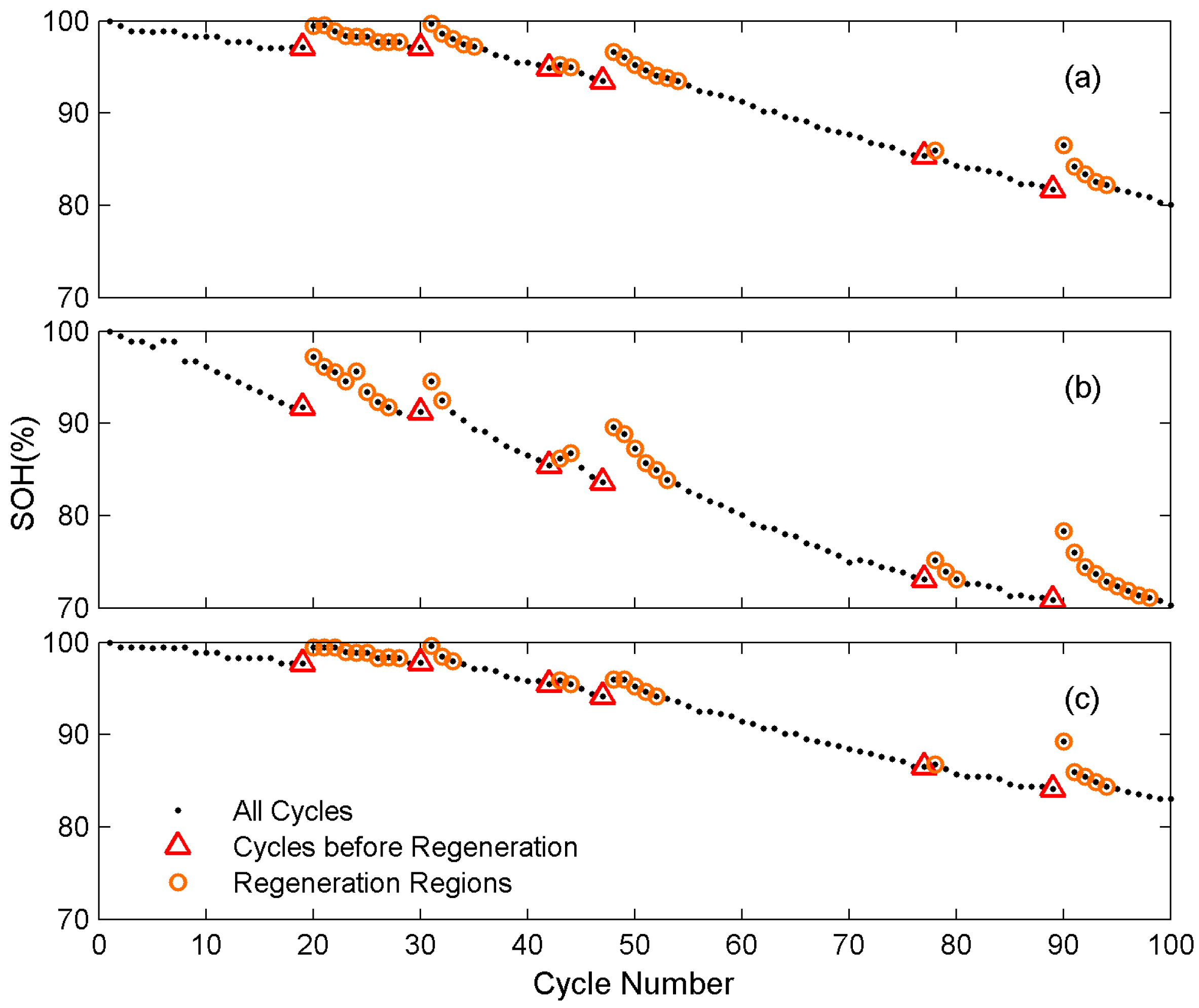

3.1. The Regeneration Phenomenon in Battery Degradation

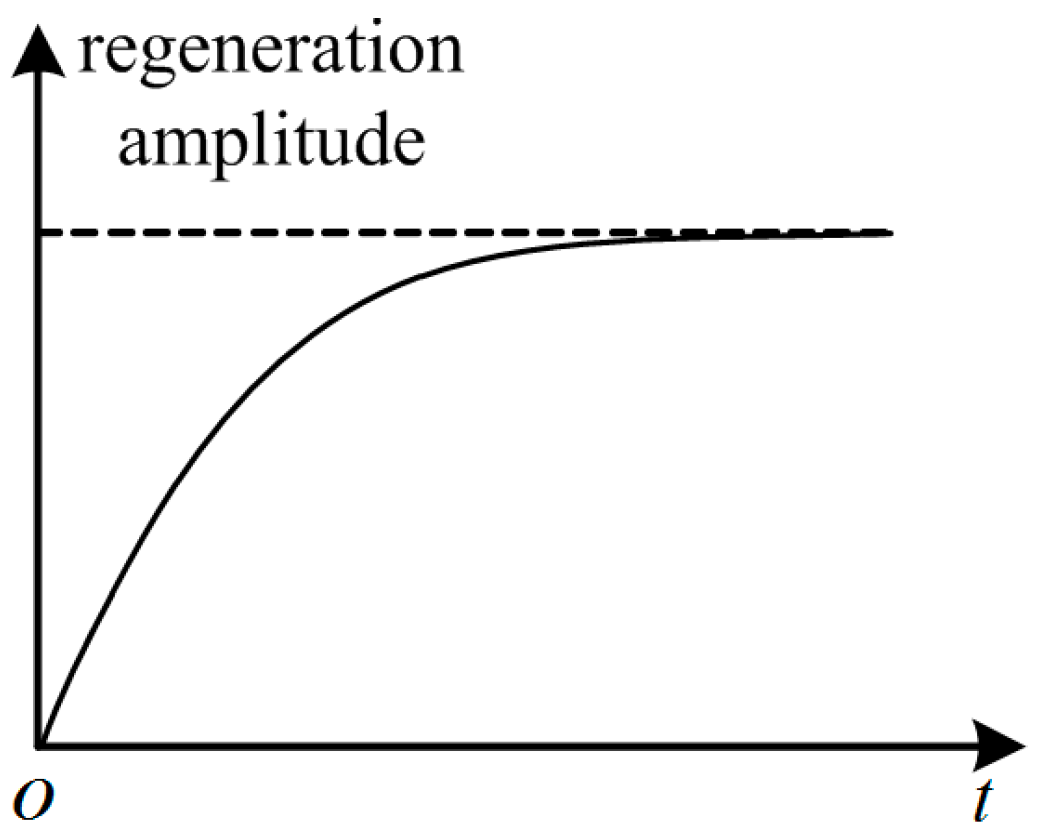

3.2. Rest Time-Based Prognostics Strategy

| Algorithm 1. Extraction of regeneration region sets and regeneration cycle number series. | |

| 1: | for to do |

| 2: | set |

| 3: | while () and () do |

| 4: | put cycle number into set |

| 5: | |

| 6: | end while |

| 7: | end for |

| 8: | for to do |

| 9: | for to do |

| 10: | |

| 11: | end for |

| 12: | |

| 13: | end for |

| 14: | |

4. Experimental Section

4.1. Battery Data Set

4.2. Prediction and Comparison

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Abada, S.; Marlair, G.; Lecocq, A.; Petit, M.; Sauvant-Moynot, V.; Huet, F. Safety focused modeling of lithium-ion batteries: A review. J. Power Sources 2016, 306, 178–192. [Google Scholar] [CrossRef]

- Xing, Y.J.; Ma, E.W.M.; Tsui, K.L.; Pecht, M. An ensemble model for predicting the remaining useful performance of lithium-ion batteries. Microelectron. Reliab. 2013, 53, 811–820. [Google Scholar] [CrossRef]

- Liu, J.; Wang, W.; Golnaraghi, F. An enhanced diagnostic scheme for bearing condition monitoring. IEEE Trans. Instrum. Meas. 2010, 59, 309–321. [Google Scholar]

- Williard, N.; He, W.; Hendricks, C.; Pecht, M. Lessons learned from the 787 dreamliner issue on lithium-ion battery reliability. Energies 2013, 6, 4682–4695. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, L.; Su, X.; Ma, P. Prognostics of lithium-ion batteries based on battery performance analysis and flexible support vector regression. Energies 2014, 7, 6492–6508. [Google Scholar] [CrossRef]

- Zheng, X.J.; Fang, H.J. An integrated unscented kalman filter and relevance vector regression approach for lithium-ion battery remaining useful life and short-term capacity prediction. Reliab. Eng. Syst. Saf. 2015, 144, 74–82. [Google Scholar] [CrossRef]

- Rezvanizaniani, S.M.; Liu, Z.C.; Chen, Y.; Lee, J. Review and recent advances in battery health monitoring and prognostics technologies for electric vehicle (EV) safety and mobility. J. Power Sources 2014, 256, 110–124. [Google Scholar] [CrossRef]

- An, D.; Kim, N.H.; Choi, J.H. Practical options for selecting data-driven or physics-based prognostics algorithms with reviews. Reliab. Eng. Syst. Saf. 2015, 133, 223–236. [Google Scholar] [CrossRef]

- Hendricks, C.; Williard, N.; Mathew, S.; Pecht, M. A failure modes, mechanisms, and effects analysis (FMMEA) of lithium-ion batteries. J. Power Sources 2015, 297, 113–120. [Google Scholar] [CrossRef]

- Li, Y.; Yang, J.; Song, J. Microscale characterization of coupled degradation mechanism of graded materials in lithium batteries of electric vehicles. Renew. Sustain. Energy Rev. 2015, 50, 1445–1461. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; Van den Bossche, P. Critical review of state of health estimation methods of li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Long, B.; Xian, W.M.; Jiang, L.; Liu, Z. An improved autoregressive model by particle swarm optimization for prognostics of lithium-ion batteries. Microelectron. Reliab. 2013, 53, 821–831. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K.; Poll, S.; Christophersen, J. Prognostics methods for battery health monitoring using a bayesian framework. IEEE Trans. Instrum. Meas. 2009, 58, 291–296. [Google Scholar] [CrossRef]

- Miao, Q.; Xie, L.; Cui, H.J.; Liang, W.; Pecht, M. Remaining useful life prediction of lithium-ion battery with unscented particle filter technique. Microelectron. Reliab. 2013, 53, 805–810. [Google Scholar] [CrossRef]

- Liu, D.T.; Pang, J.Y.; Zhou, J.B.; Peng, Y.; Pecht, M. Prognostics for state of health estimation of lithium-ion batteries based on combination gaussian process functional regression. Microelectron. Reliab. 2013, 53, 832–839. [Google Scholar] [CrossRef]

- Tang, S.; Yu, C.; Wang, X.; Guo, X.; Si, X. Remaining useful life prediction of lithium-ion batteries based on the wiener process with measurement error. Energies 2014, 7, 520–547. [Google Scholar] [CrossRef]

- Widodo, A.; Shim, M.C.; Caesarendra, W.; Yang, B.S. Intelligent prognostics for battery health monitoring based on sample entropy. Expert Syst. Appl. 2011, 38, 11763–11769. [Google Scholar] [CrossRef]

- Guo, J.; Li, Z.J.; Pecht, M. A Bayesian approach for Li-ion battery capacity fade modeling and cycles to failure prognostics. J. Power Sources 2015, 281, 173–184. [Google Scholar] [CrossRef]

- Andre, D.; Appel, C.; Soczka-Guth, T.; Sauer, D.U. Advanced mathematical methods of SOC and SOH estimation for lithium-ion batteries. J. Power Sources 2013, 224, 20–27. [Google Scholar] [CrossRef]

- Liu, D.T.; Wang, H.; Peng, Y.; Xie, W.; Liao, H.T. Satellite lithium-ion battery remaining cycle life prediction with novel indirect health indicator extraction. Energies 2013, 6, 3654–3668. [Google Scholar] [CrossRef]

- Chen, C.C.; Zhang, B.; Vachtsevanos, G. Prediction of machine health condition using neuro-fuzzy and bayesian algorithms. IEEE Trans. Instrum. Meas. 2012, 61, 297–306. [Google Scholar] [CrossRef]

- Jin, G.; Matthews, D.E.; Zhou, Z. A Bayesian framework for on-line degradation assessment and residual life prediction of secondary batteries in spacecraft. Reliab. Eng. Syst. Saf. 2013, 113, 7–20. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K. Modeling Li-ion battery capacity depletion in a particle filtering framework. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, San Diego, CA, USA, 27 September–1 October 2009; pp. 1–10.

- Eddahech, A.; Briat, O.; Vinassa, J.-M. Lithium-ion battery performance improvement based on capacity recovery exploitation. Electrochim. Acta 2013, 114, 750–757. [Google Scholar] [CrossRef]

- He, Y.J.; Shen, J.N.; Shen, J.F.; Ma, Z.F. State of health estimation of lithium-ion batteries: A multiscale gaussian process regression modeling approach. AIChE J. 2015, 61, 1589–1600. [Google Scholar] [CrossRef]

- Olivares, B.E.; Munoz, M.A.C.; Orchard, M.E.; Silva, J.F. Particle-filtering-based prognosis framework for energy storage devices with a statistical characterization of state-of-health regeneration phenomena. IEEE Trans. Instrum. Meas. 2013, 62, 364–376. [Google Scholar] [CrossRef]

- Orchard, M.E.; Lacalle, M.S.; Olivares, B.E.; Silva, J.F.; Palma-Behnke, R.; Estevez, P.A.; Severino, B.; Calderon-Munoz, W.; Cortes-Carmona, M. Information-theoretic measures and sequential monte carlo methods for detection of regeneration phenomena in the degradation of lithium-ion battery cells. IEEE Trans. Reliab. 2015, 64, 701–709. [Google Scholar] [CrossRef]

- Qin, T.C.; Zeng, S.K.; Guo, J.B. Robust prognostics for state of health estimation of lithium-ion batteries based on an improved PSO-SVR model. Microelectron. Reliab. 2015, 55, 1280–1284. [Google Scholar] [CrossRef]

- Li, F.; Xu, J.P. A new prognostics method for state of health estimation of lithium-ion batteries based on a mixture of gaussian process models and particle filter. Microelectron. Reliab. 2015, 55, 1035–1045. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Osterman, M.; Pecht, M. Prognostics of lithium-ion batteries based on dempster-shafer theory and the bayesian monte carlo method. J. Power Sources 2011, 196, 10314–10321. [Google Scholar] [CrossRef]

- Schölkopf, B.; Smola, A.J. Learning with Kernels: Support Vector Machines, Regularization, Optimization, and Beyond; MIT Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Abu-Mostafa, Y.S.; Magdon-Ismail, M.; Lin, H.T. Learning from Data; AMLBook: Singapore, 2012. [Google Scholar]

- Vapnik, V.N. Statistical Learning Theory; John Wiley & Sons: Hoboken, NJ, USA, 1998. [Google Scholar]

- Brahim-Belhouari, S.; Bermak, A. Gaussian process for nonstationary time series prediction. Comput. Stat. Data Anal. 2004, 47, 705–712. [Google Scholar] [CrossRef]

- Murphy, K.P. Machine Learning: A Probabilistic Perspective; MIT Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Agubra, V.; Fergus, J. Lithium ion battery anode aging mechanisms. Materials 2013, 6, 1310–1325. [Google Scholar] [CrossRef]

- Wang, E.; Ofer, D.; Bowden, W.; Iltchev, N.; Moses, R.; Brandt, K. Stability of lithium ion spinel cells III. Improved life of charged cells. J. Electrochem. Soc. 2000, 147, 4023–4028. [Google Scholar] [CrossRef]

- Spotnitz, R. Simulation of capacity fade in lithium-ion batteries. J. Power Sources 2003, 113, 72–80. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Bertrand, N.; Delétage, J.-Y.; Vinassa, J.-M. Behavior and state-of-health monitoring of Li-ion batteries using impedance spectroscopy and recurrent neural networks. Int. J. Electr. Power Energy Syst. 2012, 42, 487–494. [Google Scholar] [CrossRef]

- Baghdadi, I.; Briat, O.; Gyan, P.; Vinassa, J.M. State of health assessment for lithium batteries based on voltage-time relaxation measure. Electrochim. Acta 2016, 194, 461–472. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K. Battery Data Set; National Aeronautics and Space Adminstration (NASA) Ames Prognostics Data Repository: Moffett Field, CA, USA, 2007.

| k | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| 102 | 119 | 132 | 149 | 166 | |

| 10.33 | 20.97 | 12.12 | 15.22 | 19.53 |

| k | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| No. 5 | 3 | 5 | 4 | 4 | 5 |

| No. 6 | 4 | 5 | 4 | 5 | 5 |

| No. 7 | 3 | 4 | 3 | 4 | 4 |

| k | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| No. 5 | 1.07 | 1.85 | 1.23 | 1.48 | 1.77 |

| No. 6 | 2.15 | 3.73 | 2.47 | 2.98 | 3.56 |

| No. 7 | 0.87 | 1.51 | 1.00 | 1.21 | 1.44 |

| Battery No. | 5 | 6 | 7 | |||

|---|---|---|---|---|---|---|

| Error Criteria | MAPE (%) | RMSE | MAPE (%) | RMSE | MAPE (%) | RMSE |

| LGPFR 1 | 23.0 | 1.71 | 10.30 | 6.90 | 1.90 | 1.59 |

| QGPFR 1 | 1.90 | 1.50 | 7.70 | 5.12 | 5.40 | 5.52 |

| C-LGPFR 1 | 1.60 | 1.36 | 10.20 | 6.86 | 1.70 | 1.73 |

| C-QGPFR 1 | 2.10 | 1.80 | 29.0 | 20.44 | 2.60 | 2.69 |

| SMK-GPR 2 | 1.65 | 1.38 | 10.60 | 7.08 | 1.91 | 1.88 |

| P-MGPR 2 | 1.55 | 1.36 | 2.96 | 2.12 | 1.09 | 1.14 |

| SE-MGPR 2 | 1.38 | 1.20 | 2.93 | 2.11 | 1.02 | 1.07 |

| IPSO-SVR 3 | 0.82 | 0.75 | 2.28 | 1.66 | 1.02 | 0.97 |

| RTPF | 0.76 | 0.68 | 1.25 | 0.93 | 0.43 | 0.44 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, T.; Zeng, S.; Guo, J.; Skaf, Z. A Rest Time-Based Prognostic Framework for State of Health Estimation of Lithium-Ion Batteries with Regeneration Phenomena. Energies 2016, 9, 896. https://doi.org/10.3390/en9110896

Qin T, Zeng S, Guo J, Skaf Z. A Rest Time-Based Prognostic Framework for State of Health Estimation of Lithium-Ion Batteries with Regeneration Phenomena. Energies. 2016; 9(11):896. https://doi.org/10.3390/en9110896

Chicago/Turabian StyleQin, Taichun, Shengkui Zeng, Jianbin Guo, and Zakwan Skaf. 2016. "A Rest Time-Based Prognostic Framework for State of Health Estimation of Lithium-Ion Batteries with Regeneration Phenomena" Energies 9, no. 11: 896. https://doi.org/10.3390/en9110896