Enhanced Thermoelectric Properties of Cu3SbSe3-Based Composites with Inclusion Phases

Abstract

:1. Introduction

2. Experimental Section

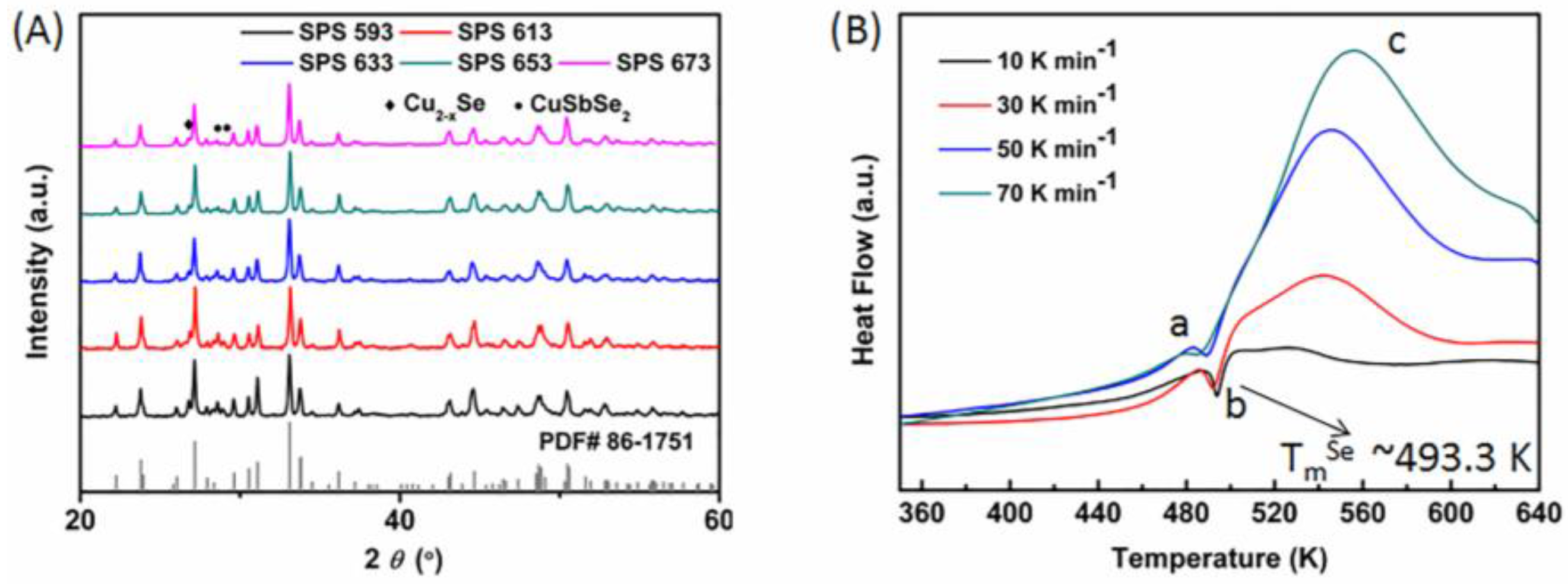

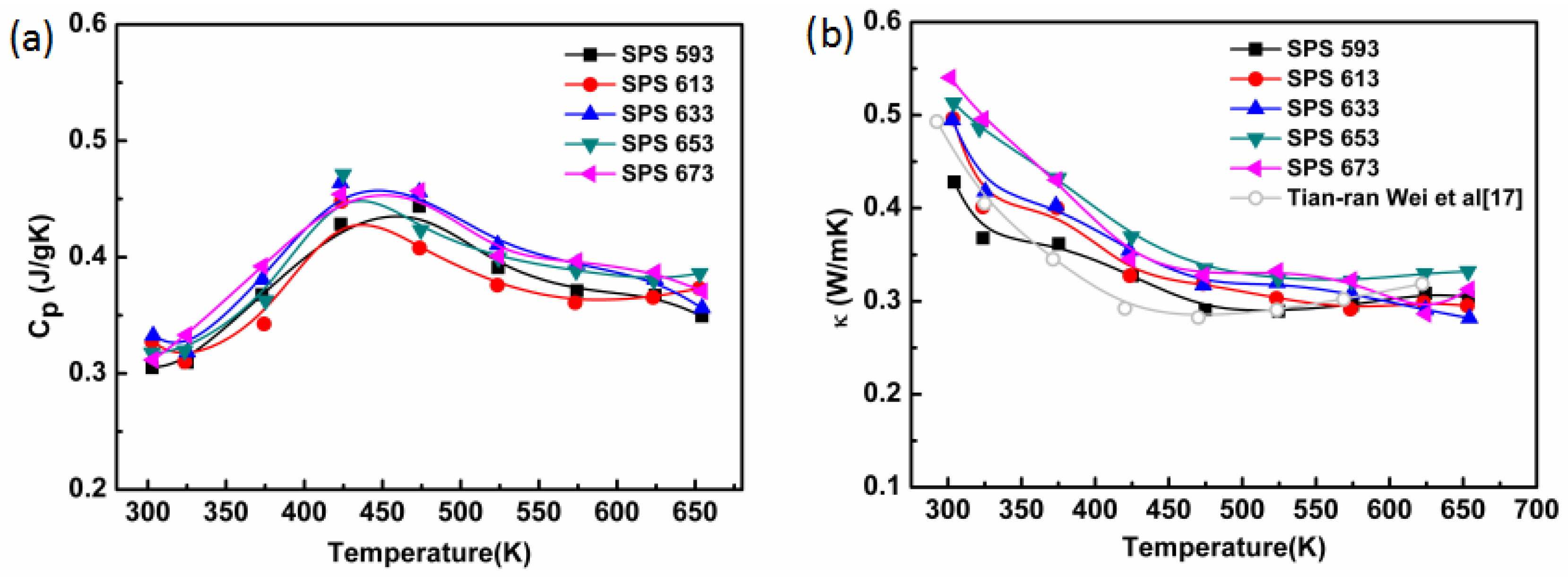

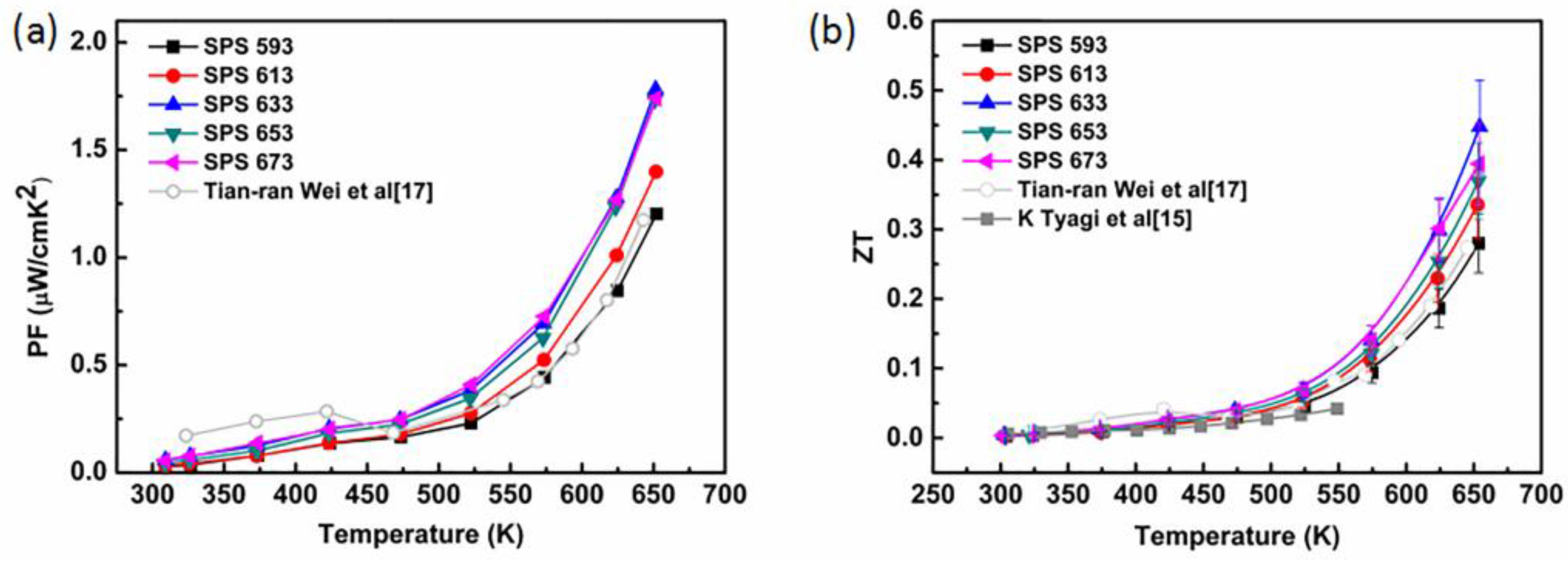

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Bell, L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.D.; Dravid, V.P.; Kanatzidis, M.G. The panoscopic approach to high performance thermoelectrics. Energy Environ. Sci. 2014, 7, 251–268. [Google Scholar] [CrossRef]

- Wan, C.; Wang, Y.; Wang, N.; Norimatsu, W.; Kusunoki, M.; Koumoto, K. Development of novel thermoelectric materials by reduction of lattice thermal conductivity. Sci. Technol. Adv. Mater. 2010, 11. [Google Scholar] [CrossRef]

- Zhao, L.D.; He, J.; Berardan, D.; Lin, Y.; Li, J.; Nan, C.; Dragoe, N. BiCuSeO oxyselenides: New promising thermoelectric materials. Energy Environ. Sci. 2014, 7, 2900–2924. [Google Scholar] [CrossRef]

- Liu, H.L.; Shi, X.; Xu, F.F.; Zhang, L.L.; Zhang, W.Q.; Chen, L.D.; Li, Q.; Uher, C.; Day, T.; Snyder, G.J. Copper ion in liquid-like thermoelectrics. Nat. Mater. 2012, 11, 422–425. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.D.; Lo, S.H.; Zhang, Y.; Sun, H.; Tan, G.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 2014, 508, 373–377. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.D.; Wang, H.; Chen, Y.Y.; Day, T.; Snyder, G.J. Thermoelectric properties of p-type polycrystalline SnSe doped with Ag. J. Mater. Chem. A 2014, 2, 11171–11176. [Google Scholar] [CrossRef]

- Wei, T.R.; Wang, H.; Gibbs, Z.M.; Wu, C.F.; Snyder, G.J.; Li, J.F. Thermoelectric properties of Sn-doped p-type Cu3SbSe4: A compound with large effective mass and small band gap. J. Mater. Chem. A 2014, 2, 13527–13533. [Google Scholar] [CrossRef]

- Zhang, Y.; Ozolin, V.; Morelli, D.; Wolverton, C. Prediction of new stable compounds and promising thermoelectrics in the Cu-Sb-Se System. Chem. Mater. 2014, 26, 3427–3435. [Google Scholar] [CrossRef]

- Lu, X.; Morelli, D.T.; Xia, Y.; Zhou, F.; Ozolins, V.; Chi, H.; Zhou, X.; Uher, C. High performance thermoelectricity in earth-Abundant compounds based on natural mineral tetrahedrites. Adv. Energy Mater. 2013, 3, 342–348. [Google Scholar] [CrossRef]

- Zhang, Y.; Skoug, E.; Cain, J.; Ozolin, V.; Morelli, D.T.; Wolverton, C. First-principles description of anomalously low lattice thermal conductivity in thermoelectric Cu-Sb-Se ternary semiconductors. Phys. Rev. B 2012, 85. [Google Scholar] [CrossRef]

- Skoug, E.J.; Morelli, D.T. Role of lone-pair electrons in producing minimum thermal conductivity in nitrogen-group chalcogenide compounds. Phys. Rev. Lett. 2011, 107. [Google Scholar] [CrossRef] [PubMed]

- Kirkham, M.; Majsztrik, P.; Skoug, E.; Morelli, D.; Wang, H.; Porter, W.D.; Payzant, E.A.; Lara-Curzio, E. High-temperature order/disorder transition in the thermoelectric Cu3SbSe3. J. Mater. Res. 2011, 26, 2001–2005. [Google Scholar] [CrossRef]

- Tyagi, K.; Gahtori, B.; Bathula, S.; Toutam, V.; Sharma, S.; Singh, N.K.; Dhar, A. Thermoelectric and mechanical properties of spark plasma sintered Cu3SbSe3 and Cu3SbSe4: Promising thermoelectric materials. Appl. Phys. Lett. 2014, 105. [Google Scholar] [CrossRef]

- Majsztrik, P.W.; Kirkham, M.; Garcia-Negron, V.; Lara-Curzio, E.; Skoug, E.T.; Morelli, D.T. Effect of thermal processing on the microstructure and composition of Cu-Sb-Se compounds. J. Mater. Sci. 2013, 48, 2188–2198. [Google Scholar] [CrossRef]

- Wei, T.R.; Wu, C.F.; Sun, W.; Pan, Y.; Li, J.F. Is Cu3SbSe3 a promising thermoelectric material? RSC Adv. 2015, 5, 42848–42854. [Google Scholar] [CrossRef]

- Su, X.; Fu, F.; Yan, Y.; Zheng, G.; Liang, T.; Zhang, Q.; Cheng, X.; Yang, D.; Chi, H.; Tang, X. Self-propagating high-temperature synthesis for compound thermoelectrics and new criterion for combustion processing. Nat. Commun. 2014, 5. [Google Scholar] [CrossRef] [PubMed]

- Rouessac, F.; Ayral, R.M. Combustion synthesis: A new approach for preparation of thermoelectric zinc antimonide compounds. J. Alloys Compd. 2012, 530, 56–62. [Google Scholar] [CrossRef]

- Selig, J.; Lin, S.; Lin, H.T.; Johnson, D. Combustion synthesis of doped thermoelectric oxides. J. Aust. Ceram. Soc. 2012, 48, 194–197. [Google Scholar]

- Yi, H.; Moore, J. Self-propagating high-temperature (combustion) synthesis (SHS) of powder-compacted materials. J. Mater. Sci. 1990, 25, 1159–1168. [Google Scholar] [CrossRef]

- Munir, Z.A.; Munir, J.B. Combustion and Plasma Synthesis of High-Temperature Materials; Wiley-VCH: Hoboken, NJ, USA, 1990. [Google Scholar]

- Samanta, K.; Gupta, N.; Kaur, H.; Sharma, H.; Pandey, S.D.; Singh, J.; Senguttuvan, D.T.; Sharma, N.D.; Bandyopadhyay, A.K. Order–disorder transition and Fano-interference in thermoelectric Cu3SbSe3 nanoparticles. Mater. Chem. Phys. 2015, 151, 99–104. [Google Scholar] [CrossRef]

- Pfitzner, A. Disorder of Cu+ in Cu3SbS3: Structural investigation of the high- and low-temperature modification. Cryst. Mater. 1998, 213, 228–236. [Google Scholar] [CrossRef]

- Makovicky, E. Polymorphism in Cu3SbS3 and Cu3BiS3—The ordering schemes for copper atoms and electron-microscope observations. Neues Jahrbuch für Mineralogie - Abhandlungen 1994, 168, 185–212. [Google Scholar]

- Qiu, W.; Wu, L.; Ke, X.; Yang, J.; Zhang, W. Diverse lattice dynamics in ternary Cu-Sb-Se compounds. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Ren, G.; Tan, X.; Lin, Y.; Nan, C. Enhanced Thermoelectric Properties of Cu3SbSe3-Based Composites with Inclusion Phases. Energies 2016, 9, 816. https://doi.org/10.3390/en9100816

Liu R, Ren G, Tan X, Lin Y, Nan C. Enhanced Thermoelectric Properties of Cu3SbSe3-Based Composites with Inclusion Phases. Energies. 2016; 9(10):816. https://doi.org/10.3390/en9100816

Chicago/Turabian StyleLiu, Rui, Guangkun Ren, Xing Tan, Yuanhua Lin, and Cewen Nan. 2016. "Enhanced Thermoelectric Properties of Cu3SbSe3-Based Composites with Inclusion Phases" Energies 9, no. 10: 816. https://doi.org/10.3390/en9100816