A Comparative Study of Novel Topologies of Magnetic Gears

Abstract

:1. Introduction

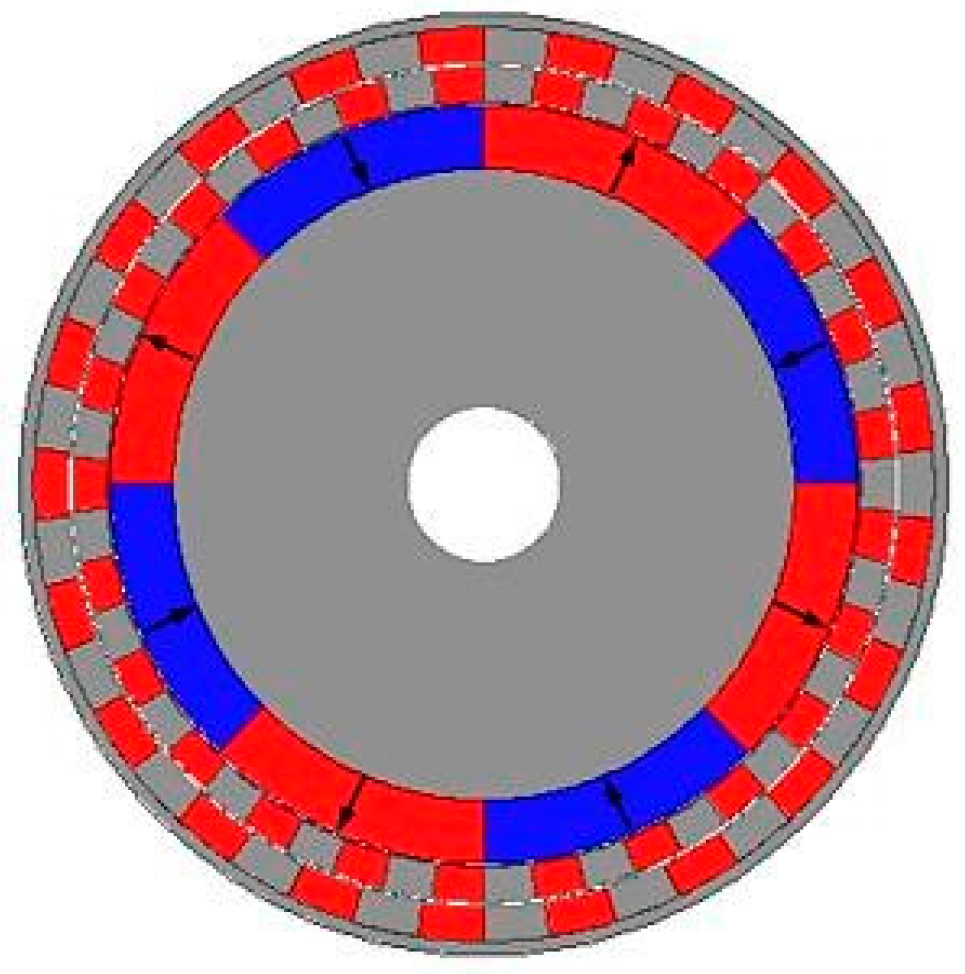

2. Working Principle and Structure

3. Optimization Approach

3.1. Improve the Move Criteria

3.2. Set a Normalized Step Vector

3.3. Set a Constraint of Permanent Magnetic (PM) Volume

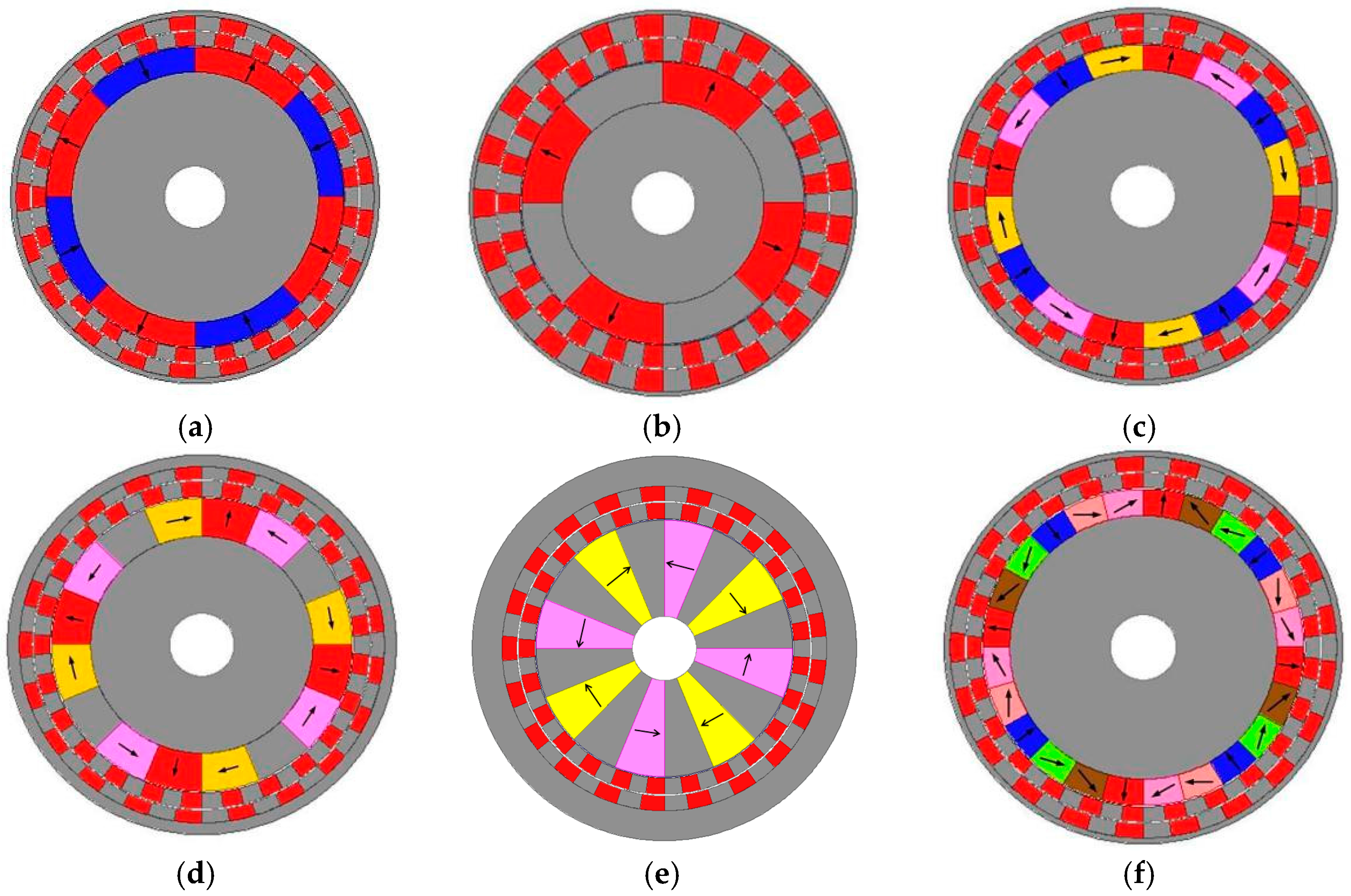

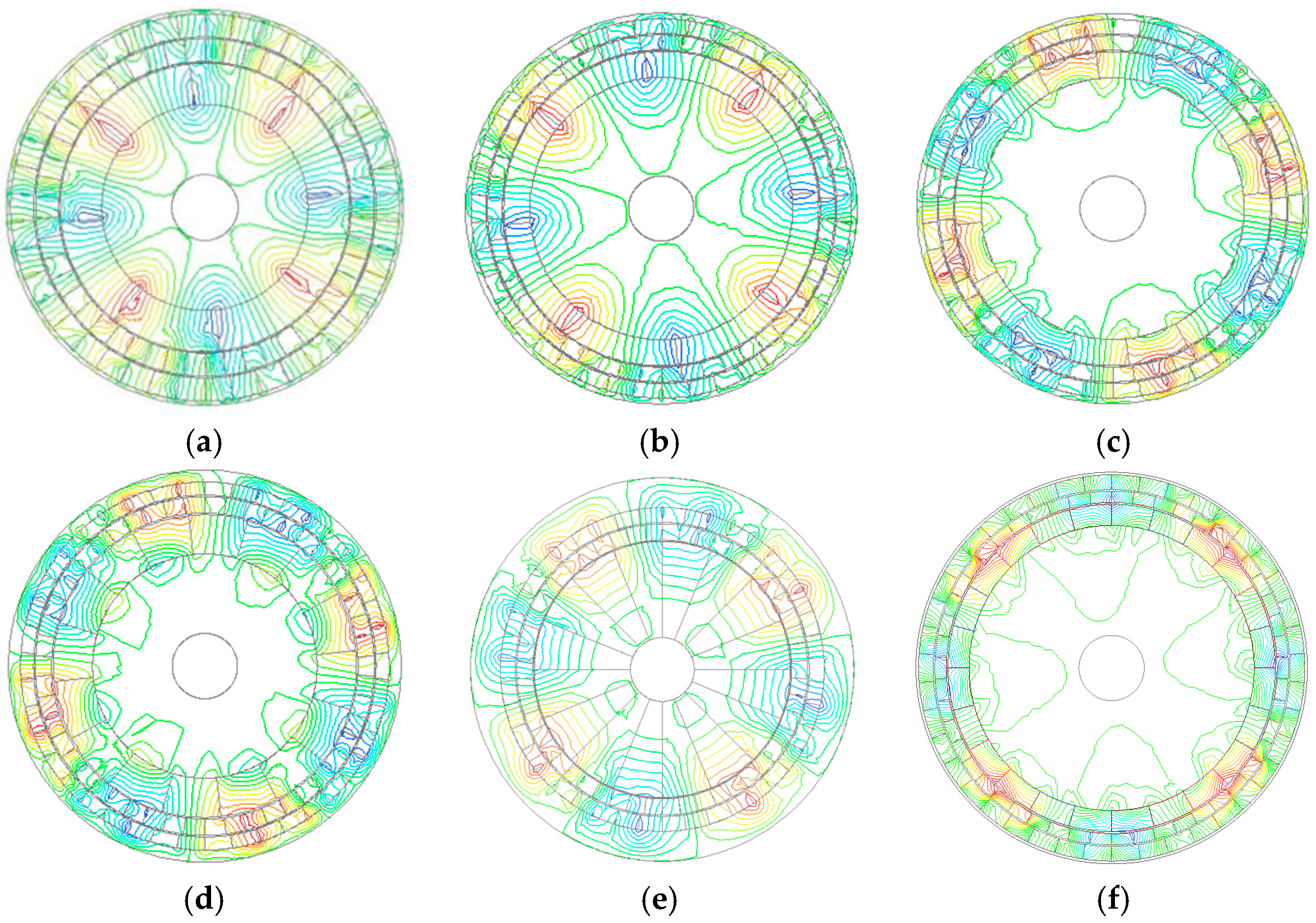

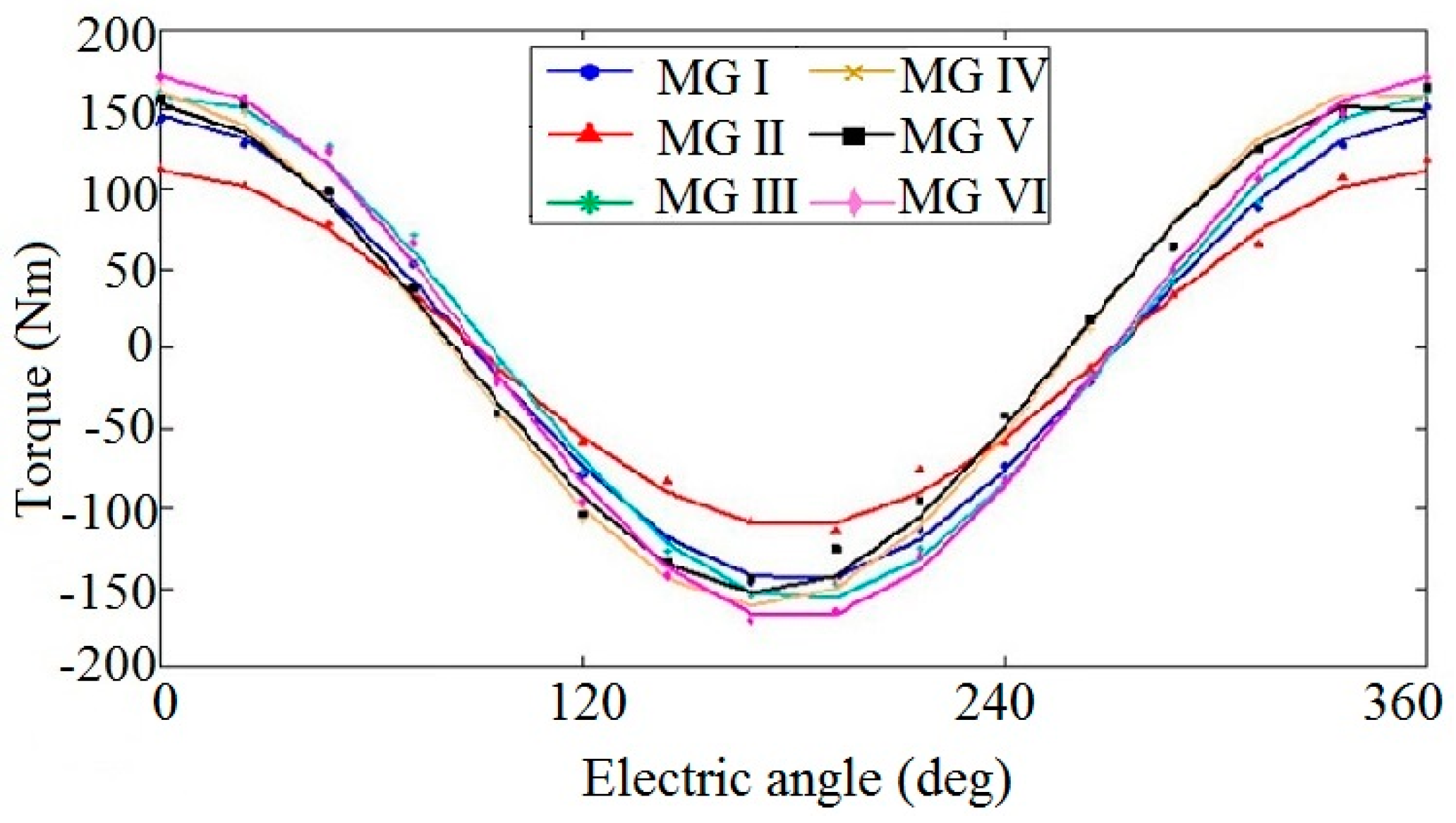

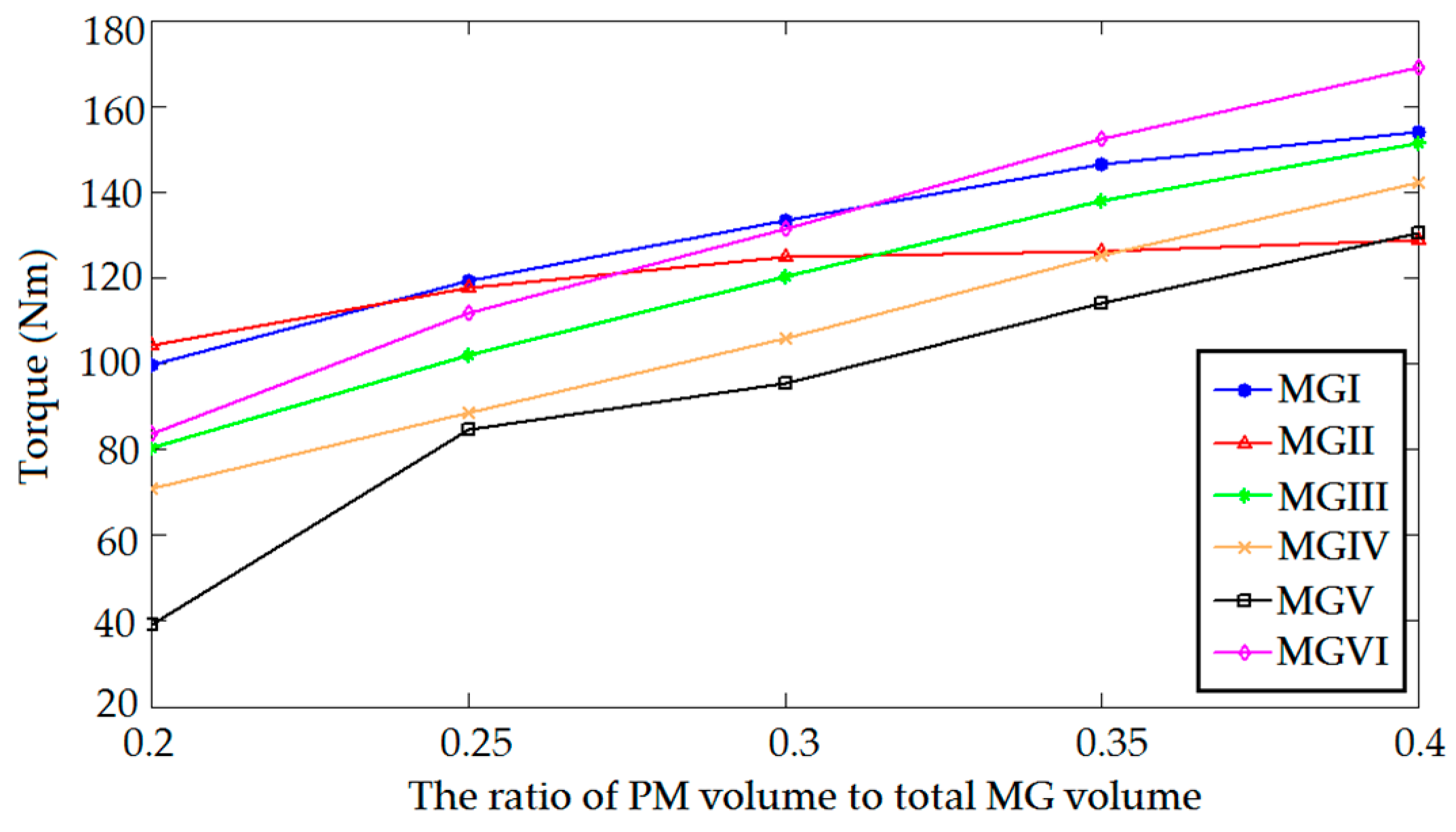

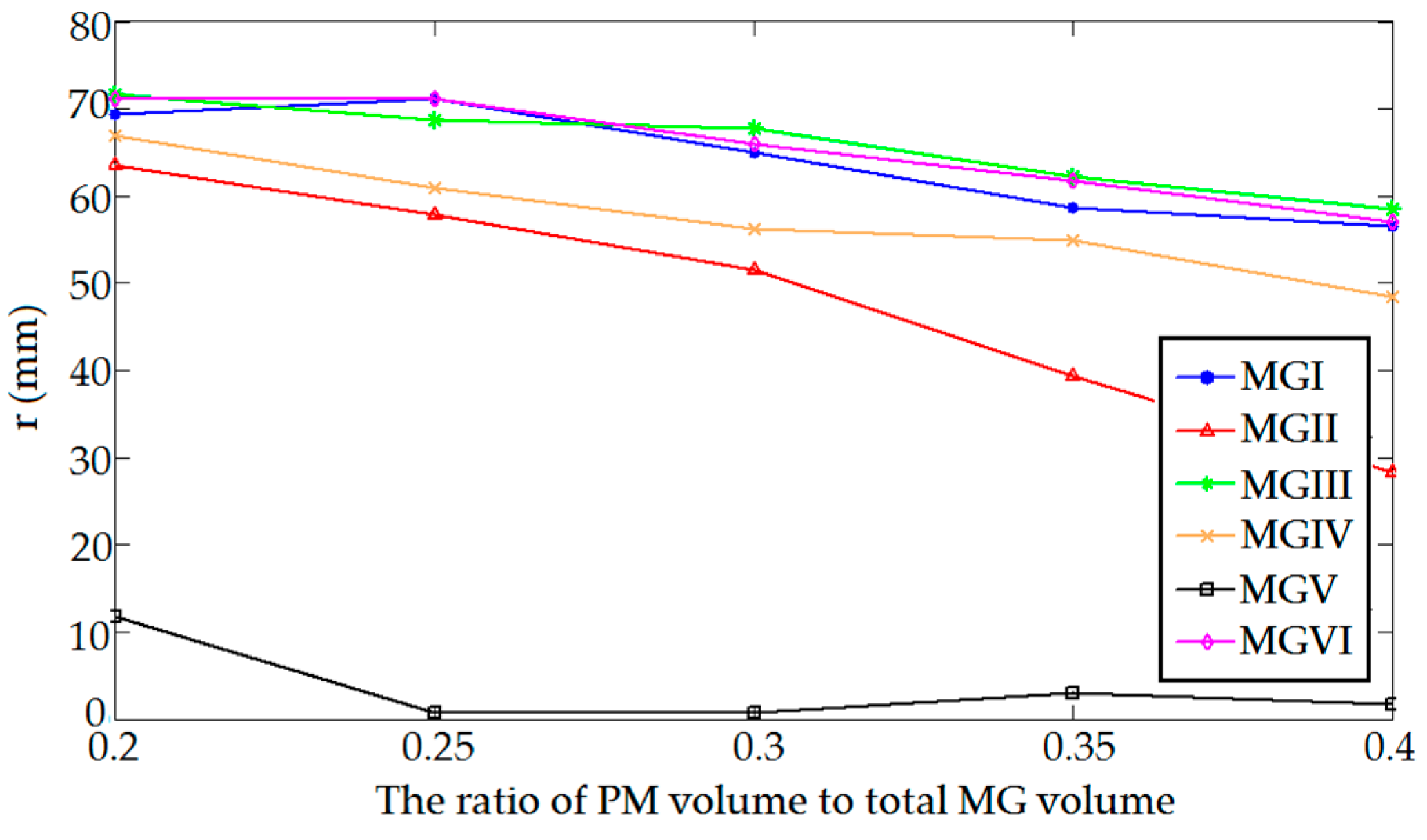

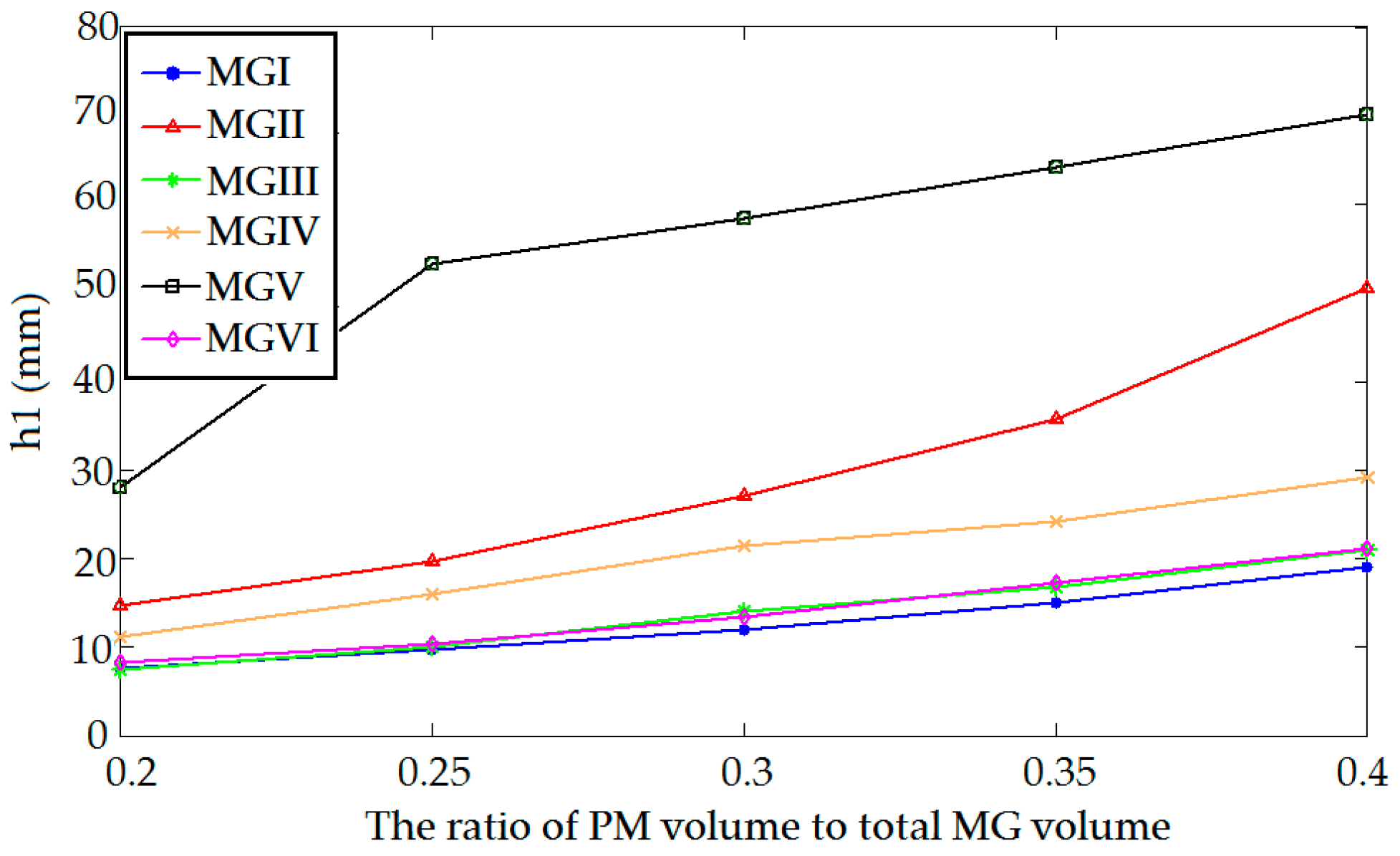

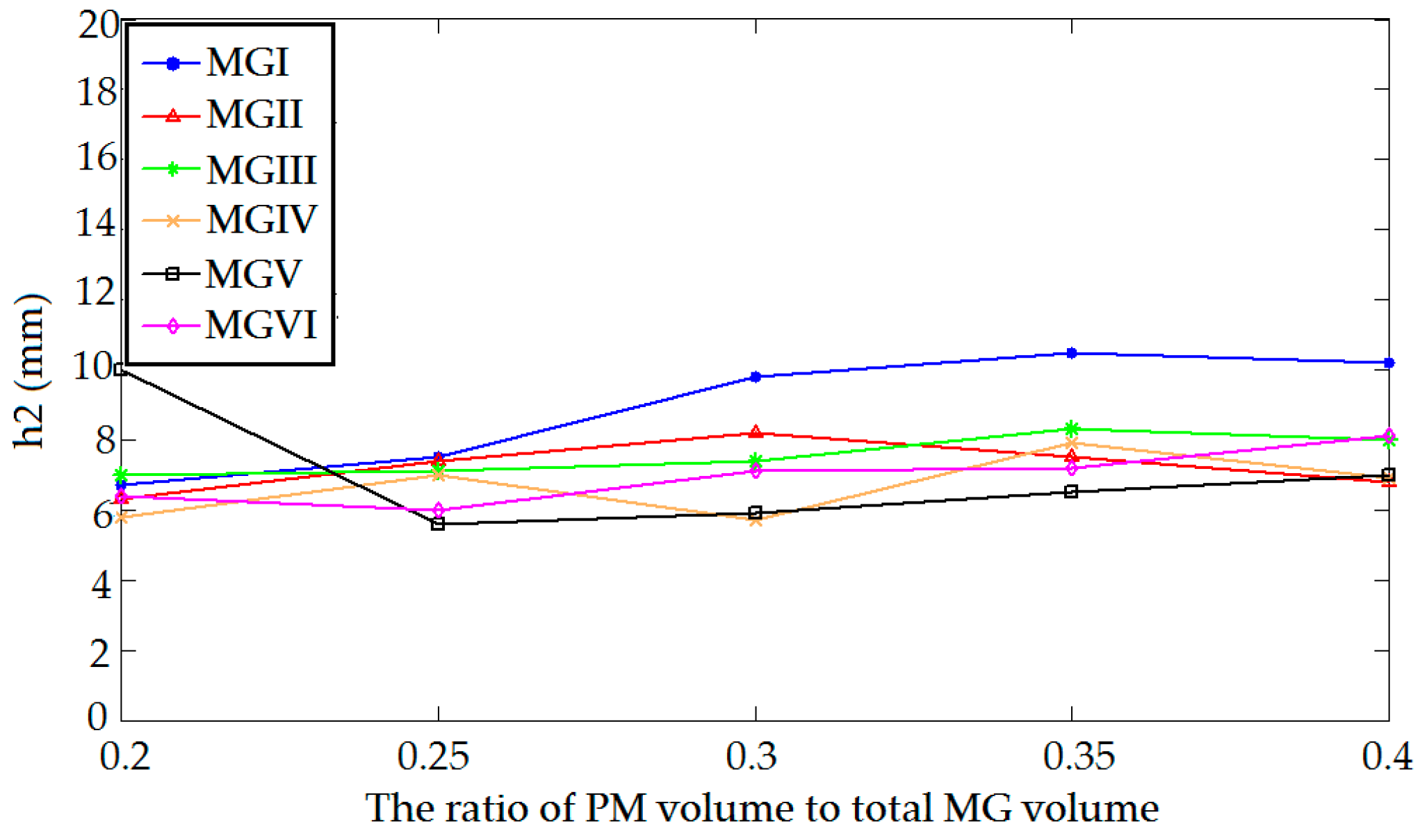

4. Comparative Study of Magnetic Gears (MGs)

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| MG | magnetic gear |

| PM | permanent magnet |

| FEM | finite element method |

References

- Atallah, K.; Howe, D. A novel high-performance magnetic gear. IEEE Trans. Magn. 2001, 37, 2844–2846. [Google Scholar] [CrossRef]

- Atallah, K.; Calverley, S.D.; Howe, D. High-performance magnetic gears. J. Magn. Magn. Mater. 2004, 272, 1727–1729. [Google Scholar] [CrossRef]

- Li, W.; Chau, K.T.; Jiang, J.Z. Application of linear magnetic gears for pseudo-direct-drive oceanic wave energy harvesting. IEEE Trans. Magn. 2001, 47, 2624–2627. [Google Scholar] [CrossRef] [Green Version]

- Niu, S.; Ho, S.L.; Fu, W.N. Performance analysis of a novel magnetic-geared tubular linear permanent magnet machine. IEEE Trans. Magn. 2011, 47, 3598–3601. [Google Scholar] [CrossRef]

- Ho, S.L.; Niu, S.; Fu, W.N. Transient analysis of a magnetic gear integrated brushless permanent magnet machine using circuit-field-motion coupled time-stepping finite element method. IEEE Trans. Magn. 2010, 46, 2074–2077. [Google Scholar] [CrossRef]

- Atallah, K.; Rens, J.; Mezani, S.; Howe, D. A novel “Pseudo” direct-drive brushless permanent magnet machine. IEEE Trans. Magn. 2008, 44, 4349–4352. [Google Scholar] [CrossRef]

- Jian, L.; Chau, K.T. A coaxial magnetic gear with halbach permanent-magnet arrays. IEEE Trans. Energy Convers. 2010, 25, 319–328. [Google Scholar] [CrossRef] [Green Version]

- Peng, S.; Fu, W.N.; Ho, S.L. A novel high torque-density triple-permanent-magnet-excited magnetic gear. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Niu, S.; Chen, N.; Ho, S.L.; Fu, W.N. Design optimization of magnetic gears using mesh adjustable finite-element algorithm for improved torque. IEEE Trans. Magn. 2012, 48, 4156–4159. [Google Scholar] [CrossRef]

- Glover, F. Tabu search-Part 1. ORSA J. Comput. 1989, 1, 190–206. [Google Scholar] [CrossRef]

- Glover, F. Tabu search-Part 2. ORSA J. Comput. 1990, 2, 4–32. [Google Scholar] [CrossRef]

| Items | MG (I, III, VI) | MG (V) | MG (II) | MG (IV) |

|---|---|---|---|---|

| Pole pair No. in inner rotor | 4 | 4 | 4 | 4 |

| PM segment No. in modulation rings | 25 | 25 | 25 | 25 |

| Pole pair No. in outer rotor | 21 | 21 | 21 | 21 |

| Air-gap length (mm) | 1 | 1 | 1 | 1 |

| Outside radius (mm) | 120 | 120 | 120 | 120 |

| Shaft radius (mm) | 20 | 20 | 20 | 20 |

| Inner radius of inner PM layer (r) (mm) | 65 | 20 | 62.5 | 68.6 |

| Height of inner PM layer (h1) (mm) | 20 | 25 | 25 | 24 |

| Height of stationary ring (h2) (mm) | 15 | 14 | 14 | 10 |

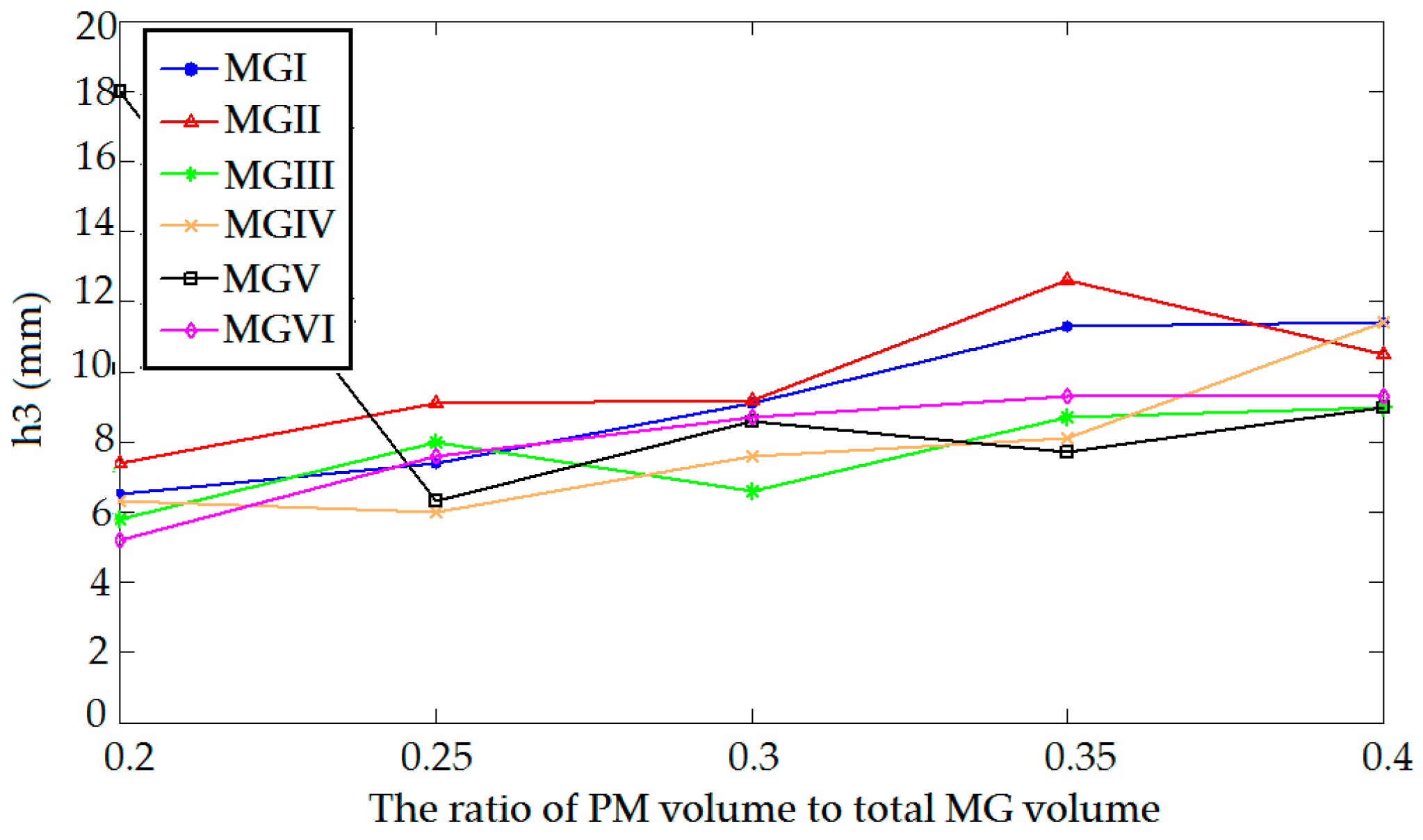

| Height of outer PM layer (h3) (mm) | 15 | 14 | 14 | 8 |

| Shaft depth (mm) | 100 | 100 | 100 | 100 |

| Remanence of NdFeB (T) | 1.1 | 1.1 | 1.1 | 1.1 |

| Parameters | MG (I) | MG (II) | MG (III) | MG (IV) | MG (V) | MG (VI) |

|---|---|---|---|---|---|---|

| r | 58.7 | 39.3 | 62.3 | 55.0 | 3.0 | 61.7 |

| h1 (mm) | 15.0 | 35.7 | 16.8 | 24.2 | 64.2 | 17.2 |

| h2 (mm) | 10.5 | 7.5 | 8.3 | 7.9 | 6.5 | 7.2 |

| h3 (mm) | 11.3 | 12.6 | 8.7 | 8.1 | 7.7 | 9.3 |

| Torque (Nm) | 146.5 | 126.3 | 138.0 | 125.3 | 114.0 | 152.3 |

| PM Ratio | MG (I) | MG (II) | MG (III) | MG (IV) | MG (V) | MG (VI) |

|---|---|---|---|---|---|---|

| 0.2 | 70.7 | 74.0 | 57.0 | 50.6 | 28.0 | 59.8 |

| 0.25 | 85.2 | 84.0 | 72.7 | 63.3 | 60.3 | 79.8 |

| 0.3 | 95.1 | 89.1 | 85.9 | 75.7 | 68.1 | 93.9 |

| 0.35 | 104.5 | 90.2 | 98.5 | 89.5 | 81.4 | 108.8 |

| 0.4 | 109.9 | 91.9 | 108.1 | 101.5 | 93.0 | 120.7 |

| PM Ratio | MG (I) | MG (II) | MG (III) | MG (IV) | MG (V) | MG (VI) |

|---|---|---|---|---|---|---|

| 0.2 | 353.5 | 370.0 | 285.0 | 253.0 | 140.0 | 299.0 |

| 0.25 | 340.8 | 336.0 | 290.8 | 253.2 | 241.2 | 319.2 |

| 0.3 | 317.0 | 297.0 | 286.3 | 252.3 | 227.0 | 313.0 |

| 0.35 | 298.6 | 257.7 | 281.4 | 255.7 | 232.6 | 310.9 |

| 0.4 | 274.8 | 229.8 | 270.3 | 253.8 | 232.5 | 301.8 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, S.; Mao, Y. A Comparative Study of Novel Topologies of Magnetic Gears. Energies 2016, 9, 773. https://doi.org/10.3390/en9100773

Niu S, Mao Y. A Comparative Study of Novel Topologies of Magnetic Gears. Energies. 2016; 9(10):773. https://doi.org/10.3390/en9100773

Chicago/Turabian StyleNiu, Shuangxia, and Yuan Mao. 2016. "A Comparative Study of Novel Topologies of Magnetic Gears" Energies 9, no. 10: 773. https://doi.org/10.3390/en9100773