Synergetic Effect between Lighting Efficiency Enhancement and Building Energy Reduction Using Alternative Thermal Operating System of Indoor LED Lighting

Abstract

:1. Introduction

2. Methodology

2.1. Theoretical Background of Indoor Heat Gain from Lighting

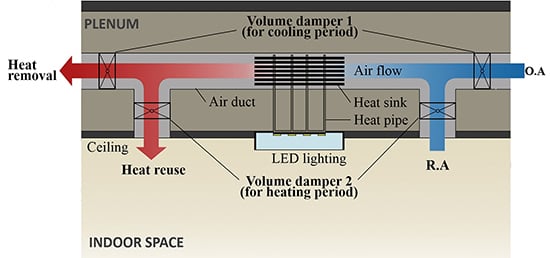

2.2. Alternative Thermal Operating System of Indoor LED lighting

2.3. Experimental Setup

| Measurement Items | Summer | Winter |

|---|---|---|

| Outdoor air temperature | 15.2 °C to 27.4 °C | −5.5 °C to 3.0 °C |

| Mean relative humidity | 63.8% | 69.8% |

| Mean air velocity | 1.3 m/s | 0.9 m/s |

3. Results and Discussion

3.1. Illuminance and Temperature Variation under Active Cooling Control

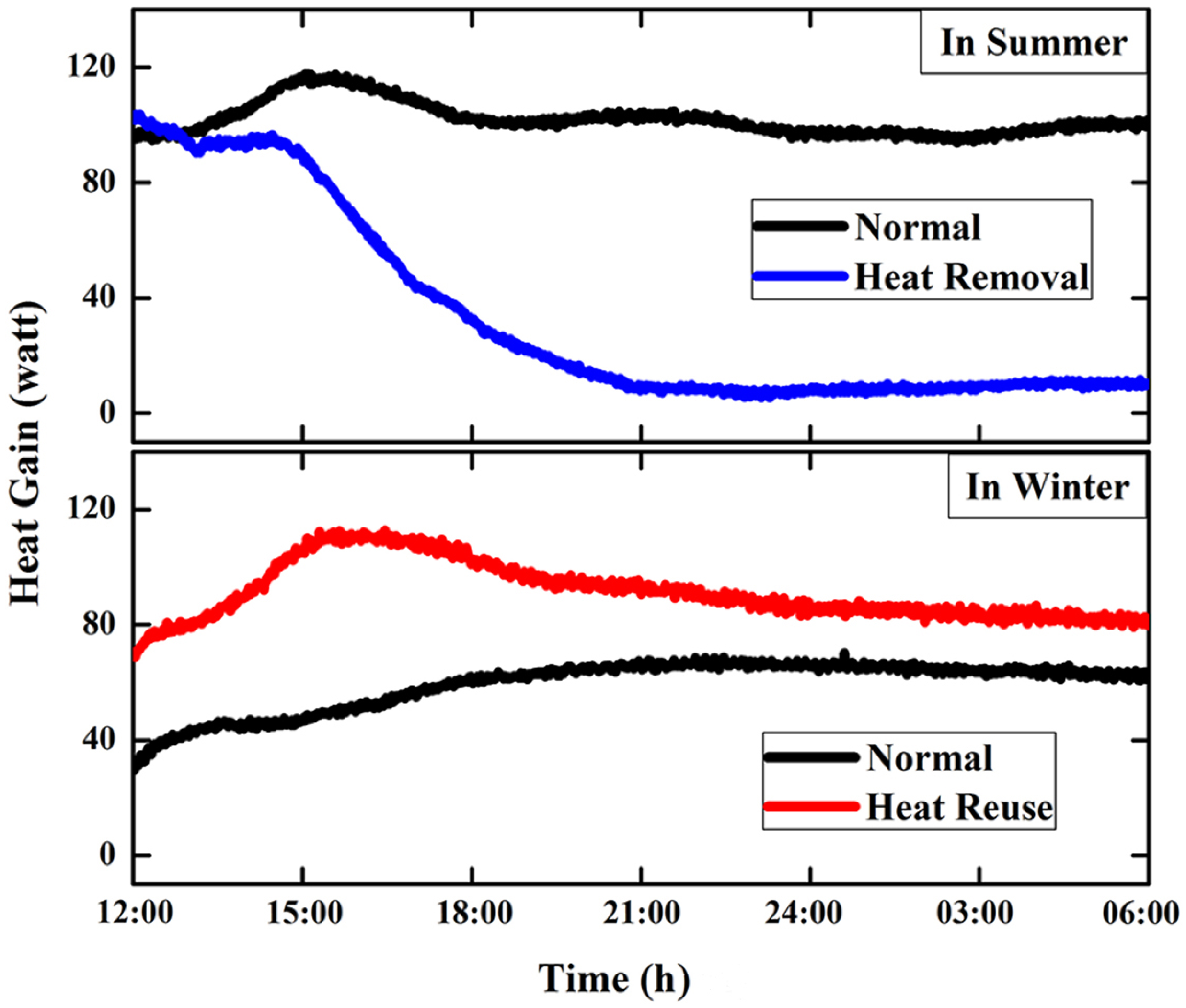

3.2. Indoor Heat Gain from LED Lighting and Temperature Distribution

| Zone | Indoor space | Plenum area | Outdoor | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Height (m) | 0.05 | 1.05 | 2.05 | Avg. | 0.05 | 0.25 | 0.50 | Avg. | ||

| Air temperatures in summer (°C) | Without heat removal | 24.4 | 25.0 | 26.3 | 25.2 | 27.7 | 27.9 | 27.8 | 27.8 | 18.4 |

| With heat removal | 20.9 | 21.3 | 21.7 | 21.3 | 22.6 | 22.6 | 22.8 | 22.6 | 16.4 | |

| Air temperatures in winter (°C) | Without heat removal | 0.0 | 0.9 | 2.6 | 1.0 | 2.5 | 2.8 | 4.6 | 3.3 | −4.7 |

| With heat removal | 1.1 | 2.1 | 2.8 | 2.1 | 2.8 | 3.0 | 3.4 | 3.0 | −4.4 | |

| Operation type | Summer | Winter | ||

|---|---|---|---|---|

| Normal | Heat removal | Normal | Heat reuse | |

| Indoor heat gain (Qin) | 97.78 W | 9.31 W | 64.29 W | 83.73 W |

| Contribution rate (Qin/PLED a) | 81.5% | 7.8% | 53.6% | 69.8% |

3.3. Predicted Building Energy Savings

| Input parameter | |

|---|---|

| Internal heat gains Equipment | - 10.76 W/m2 8.60 W/m2 120 W/person |

| Lighting Occupancy | |

| U-value of Envelopes Exterior wall Roof Floor Window | - 0.86 W/(m2K) 0.19 W/(m2K) 1.86 W/(m2K) 3.24 W/(m2K) |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Majid, M.Z.A. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Napp, T.A.; Gambhir, A.; Hills, T.P.; Florin, N.; Fennell, P.S. A review of the technologies, economics and policy instruments for decarbonising energy-intensive manufacturing industries. Renew. Sustain. Energy Rev. 2014, 30, 616–640. [Google Scholar] [CrossRef]

- Deng, S.; Wang, R.Z.; Dai, Y.J. How to evaluate performance of net zero energy building—A literature research. Energy 2014, 71, 1–16. [Google Scholar] [CrossRef]

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- Yoo, S.; Jeong, H.; Ahn, B.-L.; Han, H.; Seo, D.; Lee, J.; Jang, C.-Y. Thermal transmittance of window systems and effects on building heating energy use and energy efficiency ratings in South Korea. Energy Build. 2013, 67, 236–244. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Coronel, J.F.; Maestre, I.R. A review of HVAC systems requirements in building energy regulations. Energy Build. 2011, 43, 255–268. [Google Scholar] [CrossRef]

- Li, D.H.W.; Yang, L.; Lam, J.C. Zero energy buildings and sustainable development implications—A review. Energy 2013, 54, 1–10. [Google Scholar] [CrossRef]

- Dubois, M.-C.; Blomsterberg, A. Energy saving potential and strategies for electric lighting in future north European, low energy office buildings: a literature review. Energy Build. 2011, 43, 2572–2582. [Google Scholar] [CrossRef]

- Tsuei, C.-H.; Sun, W.-S.; Kuo, C.-C. Hybrid sunlight/LED illumination and renewable solar energy saving concepts for indoor lighting. Opt. Express 2010, 18, A640–A653. [Google Scholar] [CrossRef] [PubMed]

- Adriaenssens, S.; Rhode-Barbarigos, L.; Kilian, A.; Baverel, O.; Charpentier, V.; Horner, M.; Buzatu, D. Dialectic form finding of passive and adaptive shading enclosures. Energies 2014, 7, 5201–5220. [Google Scholar] [CrossRef]

- Yoon, Y.B.; Manandhar, R.; Lee, K.H. Comparative study of two daylighting analysis methods with regard to window orientation and interior wall reflectance. Energies 2014, 7, 5825–5846. [Google Scholar] [CrossRef]

- Djavid, M.; Liu, X.; Mi, Z. Improvement of the light extraction efficiency of GaN-based LEDs using rolled-up nanotube arrays. Opt. Express 2014, 22, A1680–A1686. [Google Scholar] [CrossRef] [PubMed]

- Horng, R.-H.; Wu, B.-R.; Tien, C.-H.; Ou, S.-L.; Yang, M.-H.; Kuo, H.-C.; Wuu, D.-S. Performance of GaN-based light-emitting diodes fabricated using GaN epilayers grown on silicon substrates. Opt. Express 2014, 22, A179–A187. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.H.; Huang, D.-S.; Lin, M.-T. Heat dissipation design and analysis of high power LED array using the finite element method. Microelectron. Reliab. 2012, 52, 905–911. [Google Scholar] [CrossRef]

- Jang, D.; Yook, S.-J.; Lee, K.S. Optimum design of a radial heat sink with a fin-height profile for high-power LED lighting applications. Appl. Energy 2014, 116, 260–268. [Google Scholar] [CrossRef]

- Tamura, T.; Setomoto, T.; Taguchi, T. Illumination characteristics of lighting array using 10 candela-class white LEDs under AC 100 V operation. J. Lumin. 2000, 87–89, 1180–1182. [Google Scholar] [CrossRef]

- Yang, K.-S.; Chung, C.-H.; Lee, M.-T.; Chiang, S.-B.; Wong, C.-C.; Wang, C.-C. An experimental study on the heat dissipation of LED lighting module using metal/carbon foam. Int. Commun. Heat Mass Transf. 2013, 48, 73–79. [Google Scholar] [CrossRef]

- Schubert, E.F.; Kim, J.K. Solid-state light sources getting smart. Science 2005, 308, 1274–1278. [Google Scholar] [CrossRef] [PubMed]

- Christensen, A.; Graham, S. Thermal effects in packaging high power light emitting diode arrays. Appl. Therm. Eng. 2009, 29, 364–371. [Google Scholar] [CrossRef]

- Ramos-Alvarado, B.; Feng, B.; Peterson, G.P. Comparison and optimization of single-phase liquid cooling devices for the heat dissipation of high-power LED arrays. Appl. Therm. Eng. 2013, 59, 648–659. [Google Scholar] [CrossRef]

- Lam, J.C.; Tsang, C.L.; Yang, L. Impacts of lighting density on heating and cooling loads in different climates in China. Energy Convers. Manag. 2006, 47, 1942–1953. [Google Scholar] [CrossRef]

- Sezgen, O.; Koomey, J.G. Interactions between lighting and space conditioning energy use in US commercial buildings. Energy 2000, 25, 793–805. [Google Scholar] [CrossRef]

- Ahn, B.-L.; Jang, C.-Y.; Leigh, S.-B.; Yoo, S.; Jeong, H. Effect of LED lighting on the cooling heating loads in office buildings. Appl. Energy 2014, 113, 1484–1489. [Google Scholar] [CrossRef]

- U.S. Department of Energy, Energy Efficiency and Renewable Energy. Thermal Management of White LEDs; U.S. Department of Energy, Energy Efficiency and Renewable Energy: Washington, DC, USA, 2007.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), Inc. 2013 ASHRAE Handbook––Fundamentals, Ventilation and Infiltration, American Society of Heating; ASHRAE Inc.: Atlanta, GA, USA, 2013.

- U.S. Department of Energy. Standard Measurement and Verification Plan for Lighting Retrofit Projects for Buildings and Building Sites; Pacific Northwest National Laboratory: Richland, WA, USA, 2012.

- Lawrence Berkeley National Laboratory. WINDOW 6.3 Glass Library, 2012. Available online: https://windows.lbl.gov/software/window/window.html (accessed on 29 June 2015).

- U.S. Department of Energy. Commercial Reference Building Models of the National Building Stock; National Renewable Energy Laboratory: Golden, CO, USA, 2011.

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), Inc. 2001 ASHRAE Standard 62, Ventilation for Acceptable Indoor Air Quality; ASHRAE Inc.: Atlanta, GA, USA, 2001.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, B.-L.; Park, J.-W.; Yoo, S.; Kim, J.; Jeong, H.; Leigh, S.-B.; Jang, C.-Y. Synergetic Effect between Lighting Efficiency Enhancement and Building Energy Reduction Using Alternative Thermal Operating System of Indoor LED Lighting. Energies 2015, 8, 8736-8748. https://doi.org/10.3390/en8088736

Ahn B-L, Park J-W, Yoo S, Kim J, Jeong H, Leigh S-B, Jang C-Y. Synergetic Effect between Lighting Efficiency Enhancement and Building Energy Reduction Using Alternative Thermal Operating System of Indoor LED Lighting. Energies. 2015; 8(8):8736-8748. https://doi.org/10.3390/en8088736

Chicago/Turabian StyleAhn, Byung-Lip, Ji-Woo Park, Seunghwan Yoo, Jonghun Kim, Hakgeun Jeong, Seung-Bok Leigh, and Cheol-Yong Jang. 2015. "Synergetic Effect between Lighting Efficiency Enhancement and Building Energy Reduction Using Alternative Thermal Operating System of Indoor LED Lighting" Energies 8, no. 8: 8736-8748. https://doi.org/10.3390/en8088736