1. Introduction

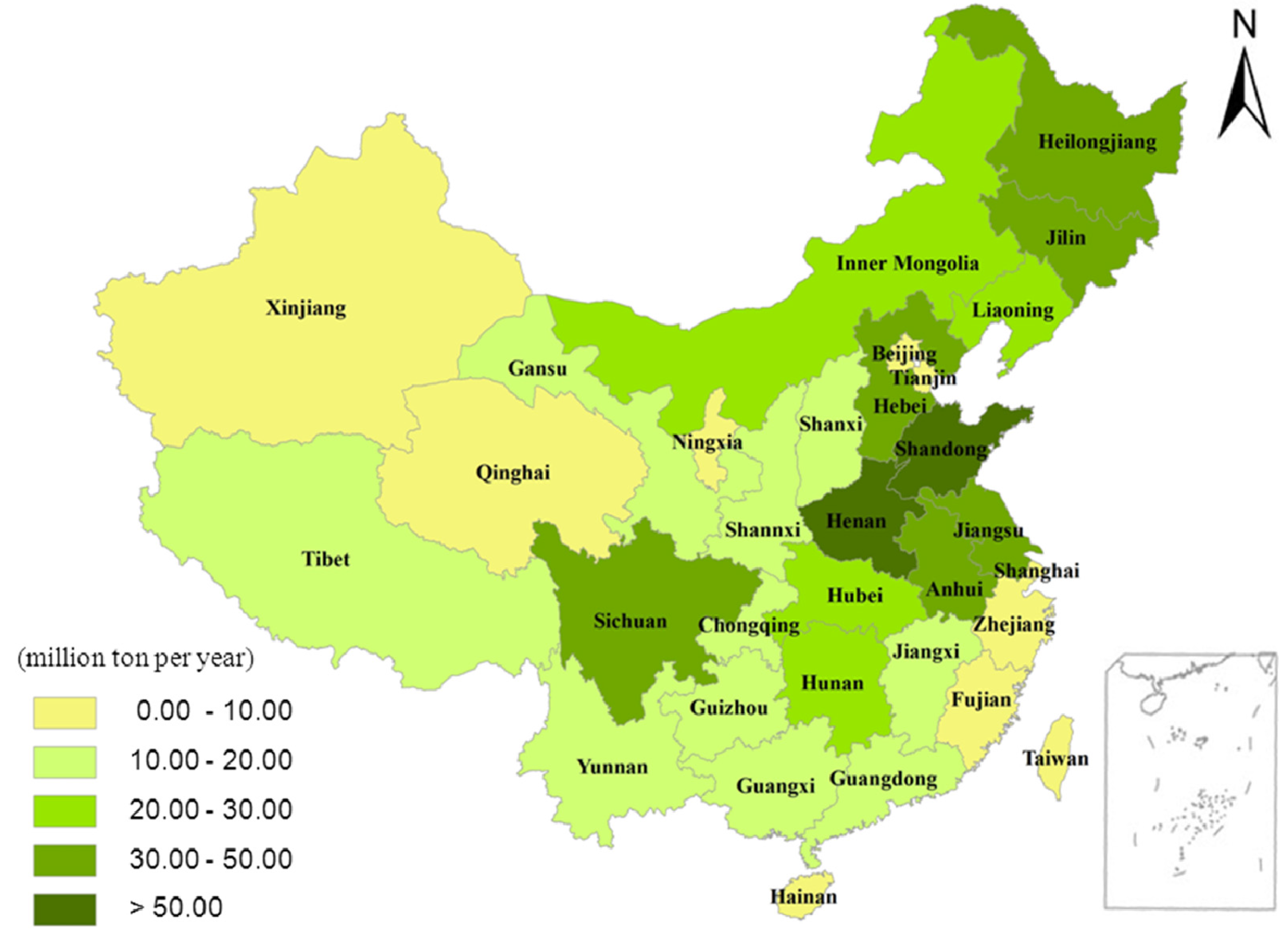

Due to the rapid development of economies and society in recent years, the demand for energy increases significantly in the global world, while the limited fossil energy and high emission of pollutants makes government begin to emphasize and encourage the use of biomass energy [

1]. The World Energy Council (WEC) predicted that the proportion of biomass in the total global renewable energy will be increased to 60% by 2020 [

1,

2].

Generally speaking, the final products of biomass include three forms,

i.e., gaseous, liquid and solid ones [

2], among which Densified Biomass Solid Fuel (DBSF) is a typical representative of the solid form of biomass. After being processed and treated under a certain temperature and pressure, many loose raw materials such as straw, twigs, sawdust,

etc. can be squeezed into special shapes and changed into DBSF with high density and low ash contents, which makes it convenient for transportation and combustion, and cost-effective to be utilized [

3]. DBSF can be widely used for steam, in hot water boilers as fuel, and for power generation by direct combustion or CHP (combined heat and power).

Table 1 shows the main differences between DBSF and traditional fossil fuels. Among them, Datong Coal as one kind of high quality coal in China, was selected as a typical fossil fuel representative with low ash content.

Table 1.

The property difference between the Densified Biomass Solid Fuel (DBSF) and Datong Coal.

Table 1.

The property difference between the Densified Biomass Solid Fuel (DBSF) and Datong Coal.

| Fuel Type | ρ (g/cm3) | Sad (%) | Aad (%) | FCad (%) | FT (°C) |

|---|

| DBSF | 1.0–1.4 | 0.05–0.2 | 1.0–13 | 13–20 | 1000–1200 |

| Coal (Datong) | 1.25–1.5 | 1.78 | 12.04 | 47.82 | 1500 |

ρ means density, and DBSF’s density has less difference with that of coal. Sad is Sulphur content (Air dried basis). Sad in per unit of DBSF is much less than that of Datong Coal. Generally, Sad in DBSF from straw is not more than 0.2%, and that from woody material is only about 0.05%. Aad refers to ash content (Air dried basis). The ash content of corn straw DBSF accounts for about 8%, and that of woody DBSF is roughly 5%. Only the ash content of DBSF made from Rice straw and rice husk reach 13%. FCad means fixed carbon (Air dried basis). FCad in DBSF amounts to roughly one third of that of Datong Coal. FT means ash fusion temperature.

Hong Hao

et al. [

2] utilized 2 × 1400 kW hot-water boilers and 2 × 1400 kW steam boilers as pilot targets, and the results showed that the actual measured data of hot conversion efficiency accounted for about 84% using DBSF as fuel, and the emission indicators of actual data was much lower than that of National Boiler Ambient air quality standards. Particulate pollutant emission concentration of DBSF boilers is about 30 mg/m

3, much less than that of coal boiler emission standard as 80 mg/m

3, and equal to that of natural gas combustion. The SO

2 emission concentration was about 41.3 mg/m

3, much less than that of coal boiler emission, which has a standard of 400 mg/m

3.

Meanwhile, Zong Yi

et al. pointed out that the combustion of DBSF in the stove had the high thermal conversion efficiency of 60%–80% due to more full combustion, compared to that of 5%–8% using traditional firewood combustion [

4]. DBSF combustion produces less black smoke with less concentration of C particle caused by incomplete combustion compared to the traditional direct combustion of biomass material [

4]. In general, the emission concentration of SO

2, NO

x all decrease using DBSF as fuel, and DBSF is considered as a kind of clean fuel in China [

2]. Therefore, DBSF promotion and application in China can play a major role in environmental improvement.

Recently, some regions of China have experienced severe threats by fog and haze, among these,

in situ concentrated combustion of agricultural residues was considered to partly contribute to haze formation in harvest season [

4]. Studies have shown that agricultural residue seasonal burning can contribute to around 30% of particle generation as concentrated combustion in one or two days in large cropland area [

4]. DBSF utilization is considered to be an ideal solution for the disposal of agricultural and forestry residues, associated with reduction of land occupy and air pollutant generation. Meanwhile, DBSF as alternative to fossil energy, the emission of SO

2 and ash can reduce by 80% compared to coal under the same heat value.

In the past decade, DBSF utilization has been broadly expanded in many countries across the world including China. According to “the national renewable energy medium and long-term development plan in China”, the annual consumption of DBSF in China would have reached 50 million tons by 2020 [

5]. In order to achieve the goal of DBSF utilization, industrial development should inextricably link with the incentives and preferential policies with relevant departments of the central and local governments. Therefore, it is meaningful for China to analyze the industrial policies to support the development of DBSF utilization. However, there are a number of issues associated with DBSF exploitation and utilization, such as its supply chain, availability and distribution.

Focusing on the particular stages of the supply chain may enable policy advocates or policy makers to identify particular interventions to target bottlenecks to utilization, interaction effects of policies, or to assess the degree to which current policy practices are conducive to objectives. Such a framework may contribute to increase understanding of the factors critical to DBSF development in China. Although the main focus of the paper is on China, it would be relevant to other developing countries, which would be looking to further develop their DBSF industry [

6]. Therefore, this review paper focuses on DBSF policies and strategies in China based on the supply chain classification, in particular by addressing the following issues with a holistic approach: (1) what is the potential of DBSF in China; (2) what are the DBSF industrial strategies and policies in China, and how were the strategies articulated and executed for attaining policy objectives in each supply chain stage, and (3) what is the deficiency of current DBSF industry policies in China, and how can it be improved?

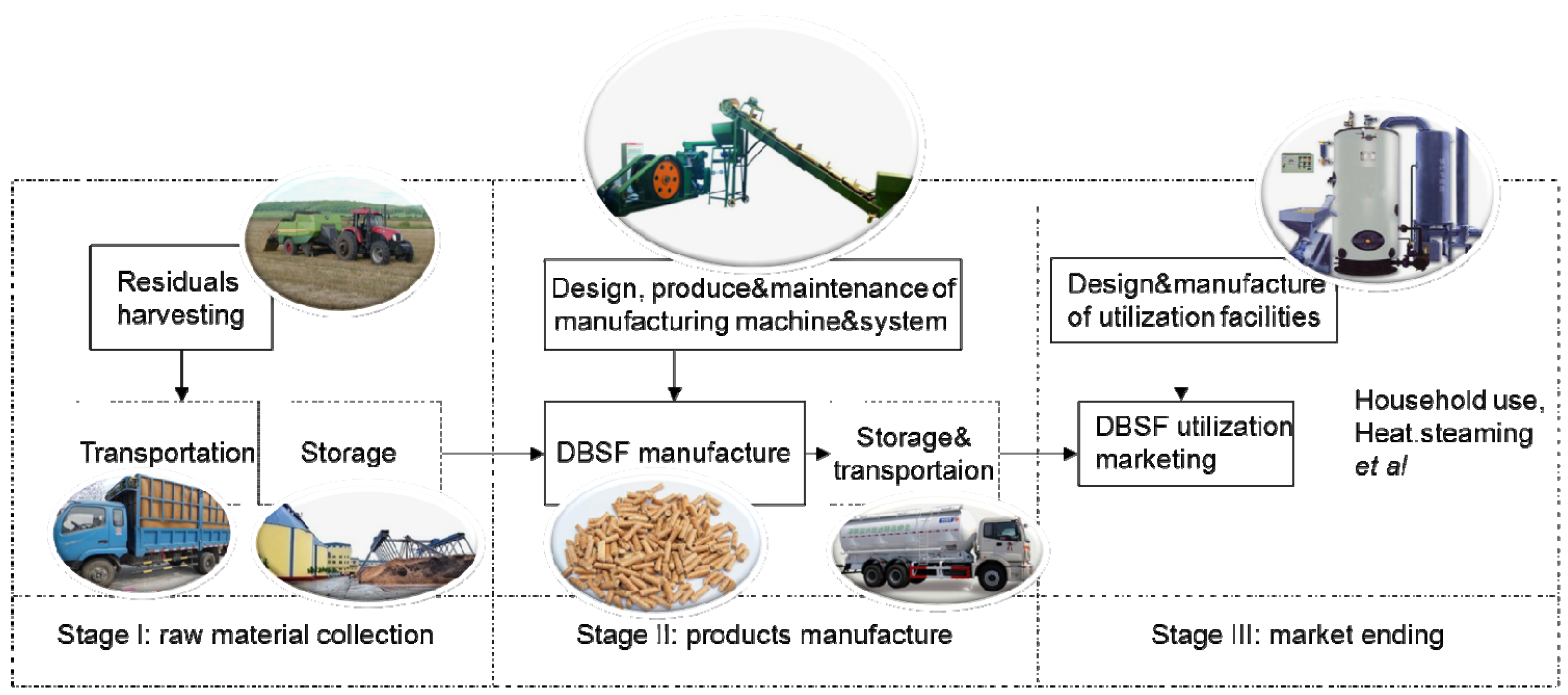

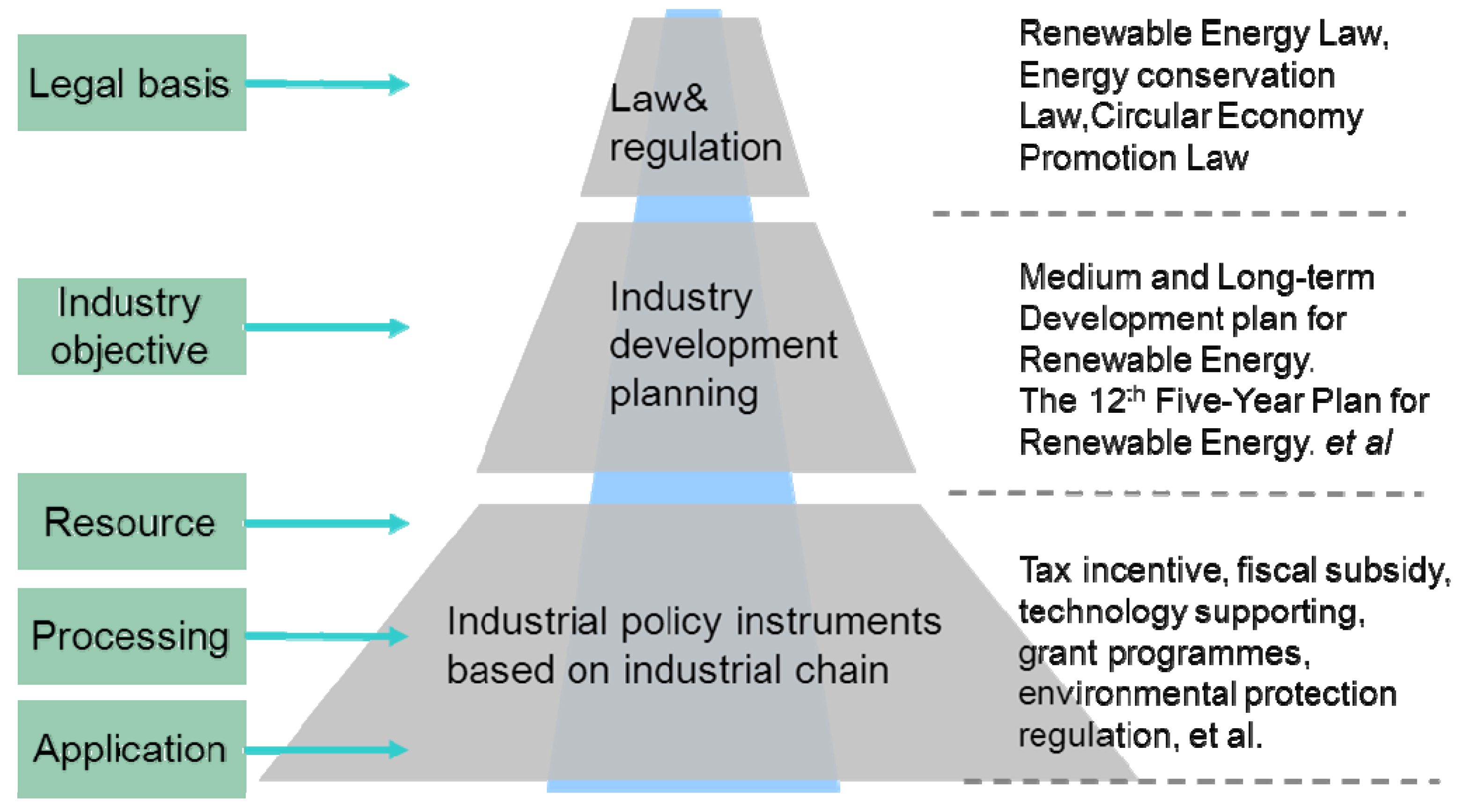

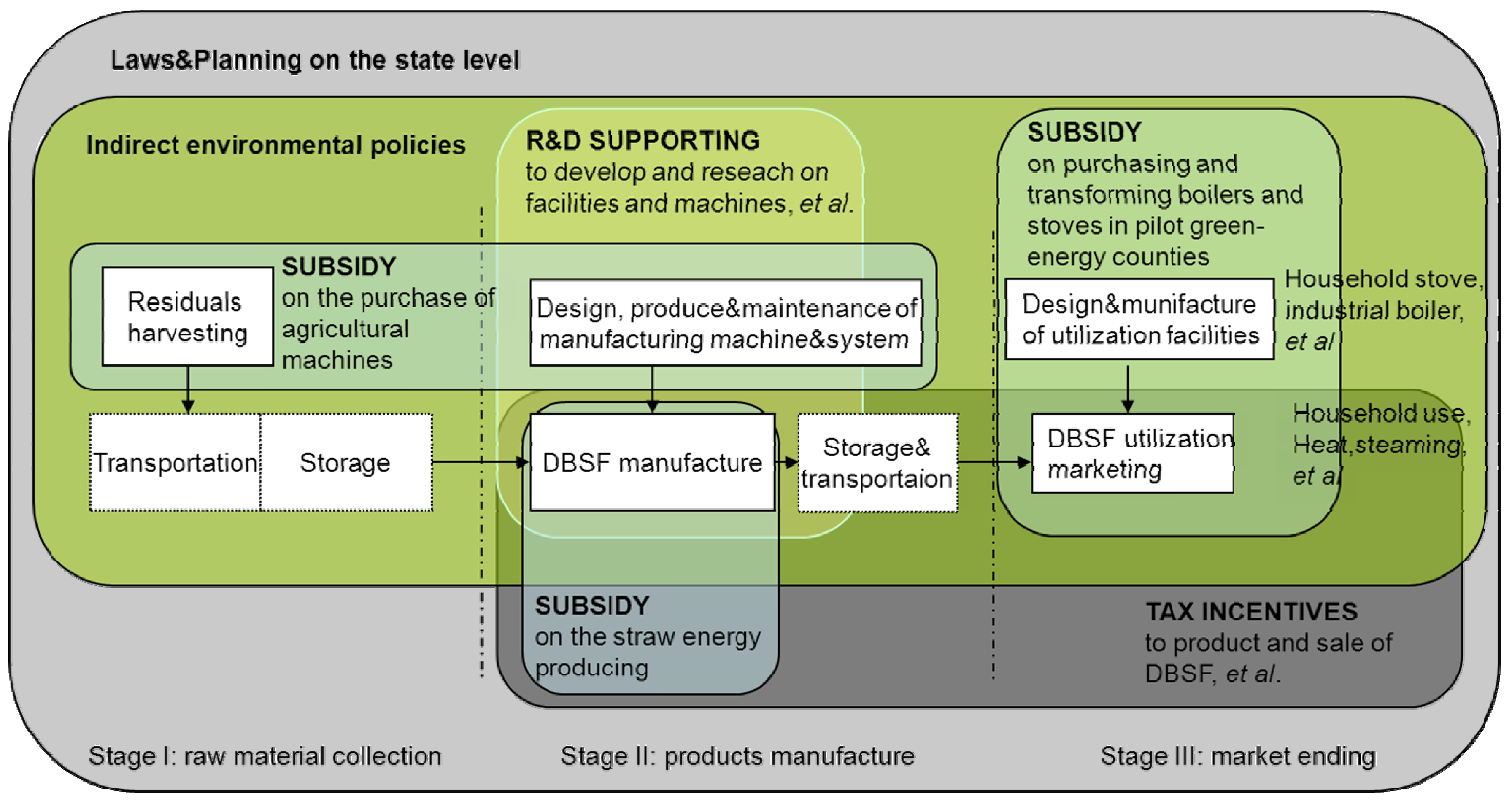

4. Policy Instrument Analysis Based on DBSF Supply Chain

Central and local governments have developed and implemented a series of policy instruments to support and motivate the development of DBSF industry, e.g., financial subsidies of straw energy utilization, preferential income tax and Value Added Tax (VAT) policies, science and technology projects supporting policies, the coal-fired limits policies,

etc. These policies have played a decisive role in promoting the production and use of DBSF. The policy instruments based on the supply chain are illustrated in

Figure 6.

Figure 6.

The policy instruments based on DBSF industry chain.

Figure 6.

The policy instruments based on DBSF industry chain.

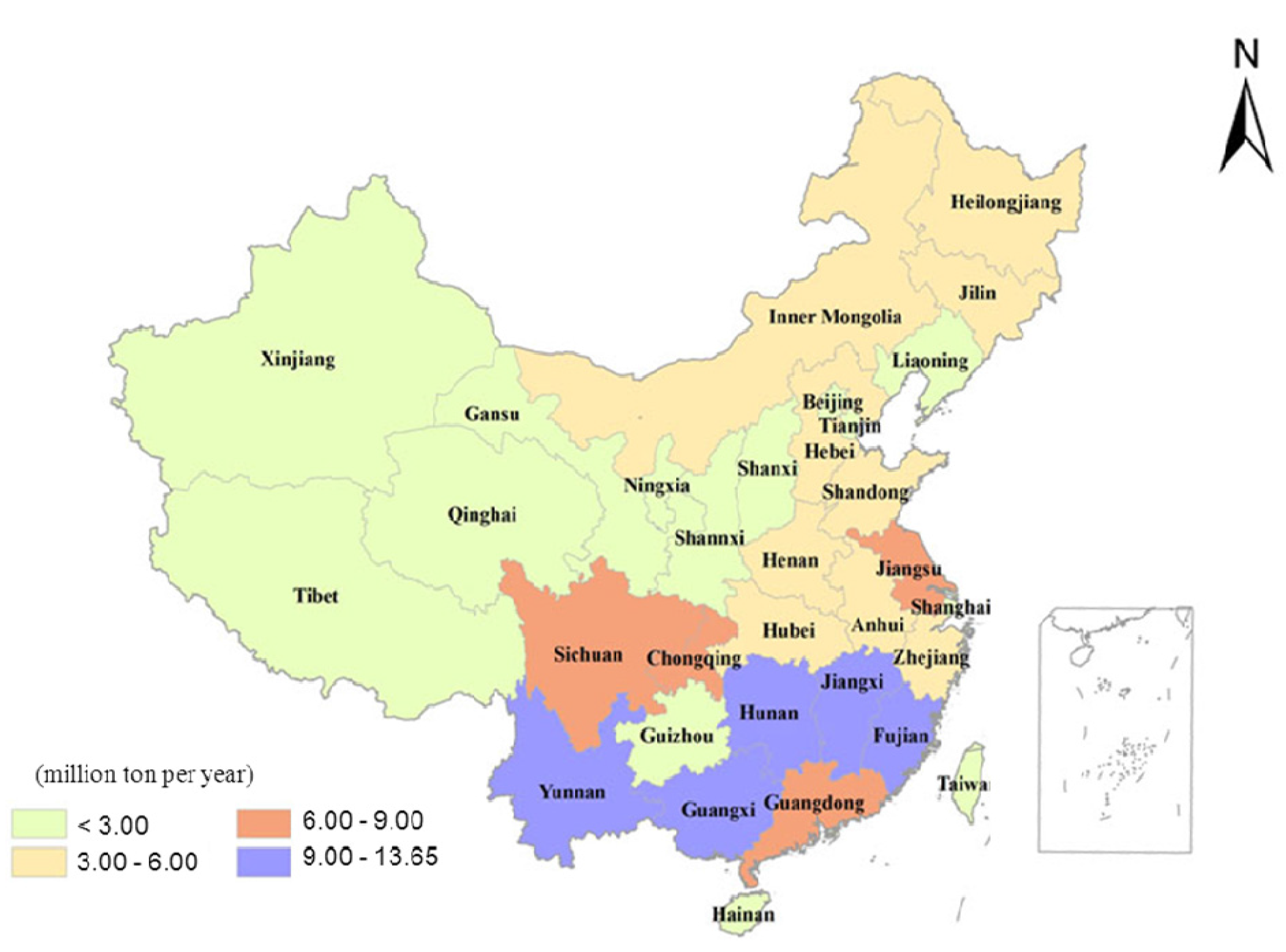

4.1. Policy Related to Resource Collection

The first phase of DBSF supply chain is defined as the collection and storage of agricultural and forestry residues. Among them, the existing policies mainly focus on the harvesting of agricultural residues. Forestry residue, as another available DBSF resource, is so far absent in the consideration of policy makers.

4.1.1. Subsidy on the Purchase of Agricultural Machines

For enterprises engaged in the harvest of agricultural residues, especially small businesses, the cost of agricultural machinery and equipment is a huge burden. In order to accelerate the pace of agricultural mechanization in China, an agricultural machinery purchase subsidy policy has been implemented in recent years. The list of equipment types in agricultural purchase subsidy policy, includes corn harvester, cotton harvester, tall crops swather, peanut harvester, rapeseed harvester, binder machine, baling machine, pick-up baler, straw chopper, peanut shelling machine, feed crusher, dryer,

etc. [

12]. A great many of these mechanical functions are coincident with those of DBSF’s collection and pretreatment features. Financial subsidies on the purchase of these machines can help reduce the DBSF resource collection cost.

4.1.2. Prohibition of Burning Straw

Recent studies have shown that centralized straw burning in farmland can cause serious air pollution event. National Satellite Meteorological Center (NSMC) of China Meteorological Administration would regularly publish the information on Satellite-Remote-Sensing-Based Monitoring of Straw Burning in harvest season. It is shown that the air pollution problem is very serious caused by burning straw in Anhui, Henan, Jiangsu and other provinces in harvest season [

13].

Therefore, some local governments have developed a set of corresponding local prohibiting policies of burning straw to reduce the air pollution especially in harvest season. The amount of straw returning to the field and other losses only accounts for about 20% of the total straw generation [

2]. DBSF is accepted as an efficient solution for agricultural residues. In fact, the prohibition of burning straw in rural areas contributes to the local straw harvest and pretreatment, and is considered to be the driving force for the comprehensive utilization of straw and the production of DBSF.

4.2. Policy Related to DBSF Producing

The subsequent phase of the DBSF supply chain is mainly about DBSF production and processing, as well as the manufacture of DBSF production equipment. The subsidy and incentive policies are mainly inclined to this section.

4.2.1. Subsidy Funds for Straw Energy Utilization

The Ministry of Finance established funds to support the straw industrial development, and formulated “Interim Measures on financial subsidies for straw energy utilization” [

14] (referred to as the “Interim Measures”) in October 2008. “Interim Measures” explained that this fiscal subsidy only supports enterprises engaged in straw energy production, such as DBSF producers; enterprises applying for grant funds shall have more than 10,000 tons of annual straw usage capacity. In 2011, a total of 50 enterprises in straw energy production received the principal subsidy funds, in which 46 enterprises engaged in the production of DBSF.

4.2.2. Subsidy Policy on the Purchase of Agricultural Machines

As mentioned in

Section 4.1, agricultural machinery can receive subsidy. The equipment of DBSF briquette and pellet production in the second stage of DBSF supply chain is also included in the agricultural machinery to enjoy farm machinery purchase subsidy.

4.2.3. The policy on VAT of Resource Comprehensive Utilization Products

On 21 November 2011, the Ministry of Finance and the State Administration of Taxation issued “A notice on the adjustment and improvement VAT policy on the resources comprehensive utilization and services” [

15]. Enterprises such as DBSF producers can enjoy the support of immediately returning VAT, if the production uses rice husks, peanut shells, corncobs, camellia shells, cottonseed hulls, forestry residues, and small fuel wood as raw materials. In order to encourage the enterprises comprehensive utilization of agricultural and forestry residues, this policy has clarified VAT would be refundable for those DBSF production enterprises as soon as it is imposed.

4.2.4. Science and Research Project Support

Currently, the support of science and technology projects, mainly concentrated for DBSF production equipment and molding technology research and development in stage II of supply chain [

16,

17]. The main R&D programme on DBSF production is listed in

Table 4.

Table 4.

R&D programme on DBSF production in China.

Table 4.

R&D programme on DBSF production in China.

| Starting Year | Supporting Organization or Project | Name of Programme | Main Contents or Outputs |

|---|

| 2006 | National Key Technology R&D Program in the 11th Five year Plan | “DBSF products and equipment development” programme | R&D of the movable DBSF equipment with integrated function of the raw material pretreatment, grinding, molding process on a large scale with low energy consumption. |

| 2011 | Chinese government, the World Bank (WB) and the Global Environment Facility (GEF) | China Renewable Energy Scale-up Programme CRESP) | (1) Develop the PM485-II biomass pellet molding machine with high-efficiency and low-cost;

(2) Optimization of biomass pellet fuel molding technology and equipment with low-cost;

(3) R&D of biomass briquetting technology and equipment at room temperature with low power consumption, which can solve the problem of high moisture of straw materials;

(4) R&D of Biomass compact molding equipment, which should complete the split ring molded briquetting machine design; |

| 2013 | National Key Technology R&D Program in the 12th Five year Plan | “Low-cost DBSF equipment research and application” programme | Within this programme, “Large-scale DBSF technology integration and industrialization demonstration” projects should form 100,000 tons of annual DBSF production capacity and 300 sets of DBSF molding equipment. |

5. Effects of Policies on DBSD Development

5.1. The Effect on Technical and Technological Development

Researchers considered that the foremost technical bottleneck in DBSF supply chain is DBSF production [

7,

9], namely biomass solidification technology. In order to promote the development of biomass solidification technology, Chinese government has extended the supporting on production technology through policy incentives and R&D projects [

21]. Currently, the gap between the technologies used in China and developed countries has been gradually reduced, and the direction of DBSF production technologies can be highly automatic with high thermal efficiency, less pollution, and more reasonable process.

Many studies suggest that the main technical barriers of DBSF development in China focus on the manufacturing technologies in stage II. However, the main technical issues also exist in the collection phase and application market. One of the major challenges in DBSF supply chains is to ensure that raw material is exploited in a resource efficient manner [

22]. There exist evidences that resource consumption for energy production is often implemented without setting a proper plan of replacement planting [

23,

24]. Considering the seasonality and instability of biomass resources, these inefficiencies could trigger future scarcities of biomass feedstocks, baffling the resilience of biomass supply chains. The research proved that the current feedstock management systems find it extremely difficult to meet the requirements of large scale bioenergy developments, because they are only designed for small-to-medium scale handling and logistics requirements. Therefore, resource and supply chain efficiencies and process productivity consist of the main technical or technological factors of biomass supply chains, and current studies should consider the whole DBSF supply chain.

5.2. The Effect on DBSF Production Enterprises

Through data collection of the companies who gained grant fund of straw energy utilization, and trade information statistics from the Industry Bureau registration website, this paper has compiled a DBSF enterprise distribution map in China, as shown in

Figure 7. Enterprises with an annual DBSF production capacity of less than 10 thousand tons are not involved in the statistical data.

Figure 7.

The distribution of DBSF production enterprise in China.

Figure 7.

The distribution of DBSF production enterprise in China.

It is illustrated that the production enterprises are mainly situated in Hebei, Shandong, Henan, Heilongjiang, Jiangsu, and Guangdong provinces. The district setting of production Enterprises in China mainly follows the proximity-based principle, to reduce transportation and storage costs of raw materials. Henan, Hebei, and Shandong are China’s major crop production regions, and Heilongjiang Province is among the main national grain bases, that all could provide abundant agricultural biomass resources. Meanwhile, the environmental protection policy and the incentive subsidy could be the main driving forces behind DBSF production in these three provinces. The local prohibition of straw burning guides the peasants to find a reasonable disposal method of agricultural residues. Subsidy on the manufacturing machines and tax incentives like VAT actually has positive effect on enterprises establishment and development.

Otherwise, the impetus of the regions in Jiangsu, Guangdong and other provinces for the most part relies on the vigorous demand for energy, as they are all located in coastal areas and classified as developed areas with higher industrial production output values. These regions need the multiple schemes of fossil energy alternatives, and DBSF is selected as energy supplement. In the same way, medium-density agricultural crops and forest resources in Jiangsu and Guangdong province reflect sufficient raw materials could meet the DBSF production demands. The subsidy and tax incentive cannot be considered as the core elements of positive effects but the energy demands, that a little different from above regions.

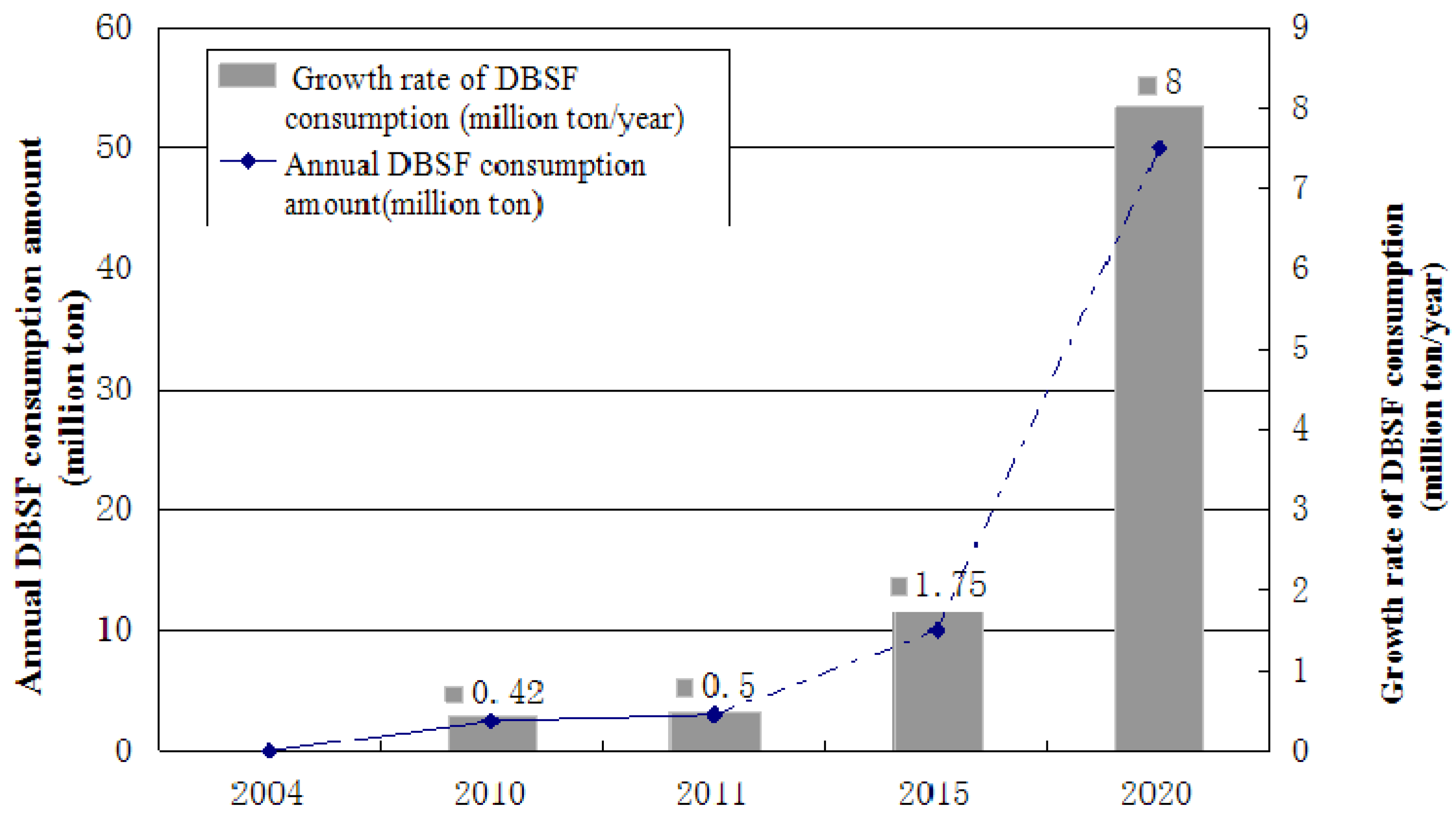

5.3. The Effect on DBSF Market Utilization

The market is the major benchmark of industrial development; therefore, only the products can meet the market demand and gain market recognition and acceptance, which will ultimately drive the rational industry development. The annual DBSF consumption amount in China has been concluded and illustrated in

Figure 8. DBSF industry is among the latecomers to the Chinese market, and the initial stage could be identified from 2004 to 2010. Until 2010, the annual consumption amount of DBSF was only 2.5 million tons [

9]. Resent policy instruments seem not to play a powerful role in pushing the DBSF utilization in stage III of supply chain.

Figure 8.

The annual DBSF consumption amount and growth rate in China.

Figure 8.

The annual DBSF consumption amount and growth rate in China.

According to “Medium and Long-term Development plan for Renewable Energy in China”, the annual consumption of DBSF in China should reach 10 million tons until 2015 and 50 million tons in 2020. That indicates an annual growth rate of DBSF consumption rises up to 8 million tons per year from 2016 to 2020. In order to achieve this speed of development, China needs to enter the stage of rapid development of DBSF industry during the year of 2016 to 2020.

5.4. The Effect on Environment and Economy Improvement

DBSF production and application has solved the growing problem that tons of agricultural and forestry residues stack

in situ, and tend to eliminate chaotic and direct burning of biomass resources. Promotion policies have made DBSF a substitute for coal as energy resource with less ash and lower SO

2/NO

x [

20,

21]. DBSF utilization would decrease the atmosphere pollution caused by the combustion of coal or other fossil energy. According to the plan data in 2015, the annual consumption amount of DBSF is up to 1.75 million tons, equivalent to reducing 875 thousand tons of coal usage. To some extent, DBSF utilization in most rural families can also decrease the use of firewood to improve indoor air-quality and peasants’ living conditions.

Moreover, local peasants would increase their incomes through the harvesting and collecting of agricultural and forestry residues. Coming to the fee of 150 Yuan per ton of straw, it would increase local farmers’ income by about 150 million Yuan when the amount of straw harvesting reaches 1 million tons. During the process of DBSF harvesting and production, plenty of job opportunities would be provided that is beneficial to absorb social surplus labors. Obviously, through the promotion policies of DBSF utilization, it is proven to bring positive economic, social and ecological benefits in China.

6. Suggestions

By sorting and analyzing the policies on DBSF development, we submit some suggestions as follows.

(1) The resources of DBSF are classified as wood and agricultural residues. Among these, wood material only occupies a small portion of DBSF utilization. Unlike energy utilization of straws, which has subsidies from central government, the production cost of wood (pellet) molding fuel is relatively high. Unless the users have strict demands on the quality of molding fuel, general users cannot afford the high cost of wood particles molding fuel. As a result, developing a specialized subsidy policy for DBSF that use forestry residues as raw material is necessary. There are subsidies, awards, and tax preference and reduction policies on the production and utilization of DBSF that come from agricultural residues. Now these preferential policies should also apply to DBSF that use forestry residues as raw materials.

(2) By analyzing each preferential policy of the supply chain, we conclude that these policies tend towards intermediate link—DBSF production. Moreover, expanding production scale and improving productivity of DBSF is considered to be the vital themes for China’s DBSF development by government and research institutes. In contrast, there exists few influential policies on resource harvesting, collection and market utilization. In the field of scientific research projects, however, it is particularly imbalanced and extremely centralized. Input for scientific research is restricted in the upstream and downstream of the supply chain. From this view, state-supporting science and technology projects in DBSF should concern the technical bottlenecks from the whole supply chain, combining the strength of enterprises, universities and research institutions.

(3) In fact, the promotion driving dynamics differ from province to province and the incentives play a different role of DBSF market in different provinces. The central government has established industrial development goals, so it is necessary to distribute these goals to each province and autonomous region based on resources, markets, funds, development foundations and market demands. Provincial governments should have specific implementing regulations for each plan on the development of DBSF, such as a comprehensive utilization plan for straw, a forestry energy plan, a circular economy plan, etc. One of the conditions in the implementation of a specific plan is to enhance the management of the plan. Concretely speaking, the management should include the distribution of the plan goals and the establishment of implementing regulations.

(4) Once the supporting projects or incentives suspend, how is the sustainable development of biomass utilized, especially DBSF? This is a realistic question for most developing countries. As for the construction project of green energy demonstration counties in China, there are a few unsolved problems after the construction of the DBSF project. The first is how to make the sales of DBSF continuous in rural market and another is to ensure companies that invest on these projects have sustainable proper profits. Therefore, that makes the policy makers contemplate the idea that the present policy should be sustainable.

7. Conclusions

China has endowed with abundant biomass resources, such as forestry and agricultural residues, to promote DBSF utilization. However, due to the seasonality and instability of agricultural and forestry resources, imbalance in resources such as feedstocks could trigger future scarcities of DBSF productivity, baffling the resilience of biomass supply chains. In this research, China’s DBSF policies were reviewed and analyzed based on the views of supply chain.

The policy framework has been categorized as three levels. Policies on laws and plans have an important directing impact on the strategy and schedule of DBSF industrial development. The third level is defined as a set of policy instruments, e.g., financial subsidy, tax incentive, and R&D project support, which would ensure the realization of DBSF development milestones. Policy has a straightforward boosting or restraining influences on company operations.

Through the analysis of current policies based on the supply chain, weak links in contemporary policy systems have been described. The present DBSF market is on a small scale, lack of balance in supply chain, and short of market drive, which severely restrains the healthy development of DBSF industry. The effects of policies on R&D, production enterprises distribution, market utilization and environment and economy have been analyzed, and then proposed some suggestions. The policy makers also should be concerned with the bottlenecks from the view of whole supply chain, combining the strength of local governments, enterprises, universities and research institutions. Overall, the policy framework is important for authorities to manage and achieve the DBSF development objective in the future.