1. Introduction

The Institute of Manufacturing Systems’ main interest in the environmental area is the engineering and design of densification machines and equipment. This technology is a suitable option in the treatment of biomass prior to energy recovery [

1]. The Institute is attempting to develop new progressive densification machines, and trying to optimize the biomass treatment process prior to densification. The development of new machines is more effective if information about the discrete densification process is available. Requirements of biofuel production demonstrate that another important factor to take into consideration is the possibility of variable changes in the material for compression. Each different type of raw material requires a separate approach. Currently, not every densification machine can produce biofuels to the required quality according to technical standards [

2]. This fact demonstrates the many problems which have to be solved. As each type of raw material has its own specific properties and chemical composition, any small change in the properties of the raw material can influence the final quality of the biofuel. Different raw material properties produce different conditions during the densification process, and this causes the final quality of the biofuel produced to be very different [

3]. For each raw material it is necessary to find the optimal parameter settings for densification. This is the reason why it is so important to undertake experimental research to determine the impact of the technological and material variables on the final quality of the biofuel during densification. Briquette quality, as a final output of the densification process, is evaluated mainly by its density, and is influenced by many different variables [

2]. Experience suggests that these can be divided into the following three groups [

4]:

- -

raw material parameters (variables);

- -

technological parameters (variables);

- -

structural parameters (variables).

The general purpose of this paper is to determine the relationship between the technological and material variables, and the final quality of solid biofuels, specifically briquettes, made from beech sawdust. Initially, to evaluate if the briquettes fulfill the requirements established in the European standards, a physical characterization of each densified briquette was undertaken. Subsequently, to determine the impact of the material and technological variables, all related parameters were measured, and the densification according to the design experimental plan was carried out. Finally, in order to better understand the impact of the material and technological variables, the data was processed, and the mutual interactions between the variables investigated are described.

2. Investigated Variables

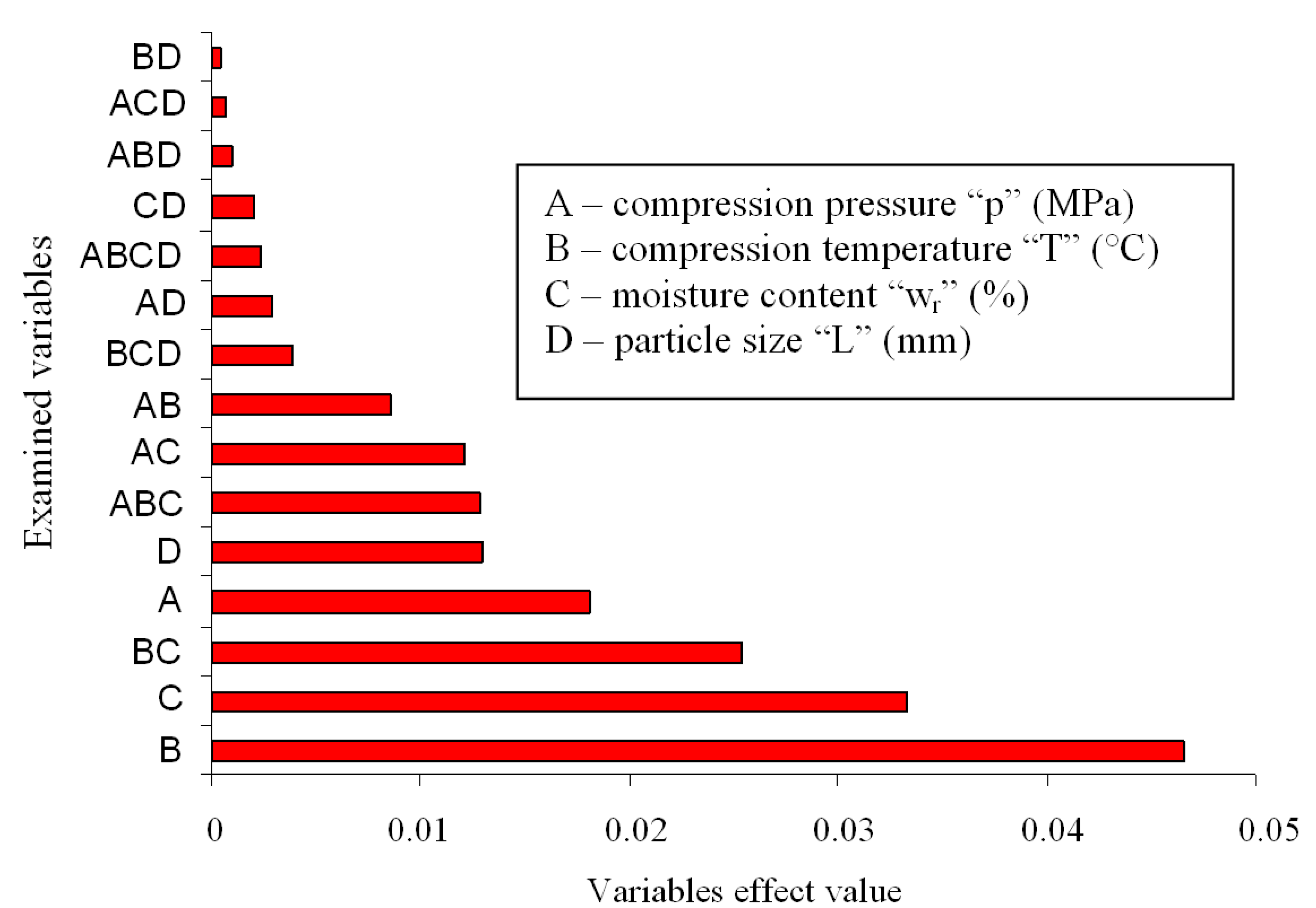

As mentioned above, several different variables which influence the process of densification can be detected. The first group of variables relates to the type of material to be compressed; the second group relates to the densification technology; and the third group includes all the structural parameters of the machinery. Theoretical analysis of their impact significance was undertaken, and variables for the experimental research were chosen. The accuracy of these results and the appropriateness of the choice of parameters were confirmed by experimental results which were obtained from densification of pine and oak sawdust. In

Figure 1 the effect of each variable during densification of pine sawdust can be seen. These variables are compression pressure “

p”, compression temperature “

T”, raw material particle size “

L”, and raw material moisture content “

wr”. The goal of this research work is to determine the impact of the aforementioned variables on the quality of the final briquette.

Figure 1.

Paret’s effect diagram for pine sawdust densification [

5].

Figure 1.

Paret’s effect diagram for pine sawdust densification [

5].

The compression pressure is one of the most important variables affecting the resulting briquette strength [

6]. With increased pressure, the briquette tends to become stronger until the yield strength of the material is reached. This also reduces the tendency of the briquette to absorb moisture when stored. It is important to find the optimum combination of force and force vector direction in order to obtain a highly compact briquette. Analysis of the pressure is interesting and complicated. To obtain a high quality briquette, it is necessary to ensure maximum pressure within the pressing chamber. This value represents the pressure needed for densification and the smooth feeding of the briquette through the chamber. Biomass under pressure undergoes two types of deformation: elastic and plastic. Elastic deformation returns to its original position once the pressure is released; however, plastic deformation permanently deforms the material. The compression temperature and pressure, and the moisture content of the material have a direct effect on the elastic and plastic deformation [

5,

6,

7].

The compression temperature has a significant effect on the quality and the strength of the briquette [

8]. Pressure and temperature go “hand in hand” in the densification process. If we increase the pressure, we can reduce the required temperature, and

vice versa. This latter variable influences the excretion of lignin from the cellular structures [

8]. Lignin is a very important substance in the densification process because of its adhesive effects in the compressed material. It connects fibres and acts as a reinforcing agent in the cellular molecules. The more lignin in the input material, and the more that can be extracted during the pressing process, the greater the uniformity and thus the quality achievable in the resulting briquette. Lignin strengthens the briquette primarily during compression, but lignin is excreted only at certain compression temperatures, which must be attained for the densification process to be optimized [

9].

The optimum moisture content of the material is an essential condition for the optimal densification of the biomass and also for energy recovery [

10]. The effects of moisture content on the material must be known in order to produce quality briquettes as defined by the Standards [

2]. It is known from specific research results discussed in the literature that density and strength depend on the moisture content of the compressed material, for example, in the case of compressing wood sawdust [

6,

7]. We can therefore say that the briquette quality depends on the moisture in the compressed material, and that a large difference is not expected in the optimal level of moisture between different materials. The optimal value, however, is not known. If the moisture content of the compressed material is very low, or very high for that matter, the particles become inconsistently arranged, and the resulting briquette becomes unstable [

9,

11]. Research and experiments have shown that moisture has an effect on the plasticization of lignin. The mutual interaction between the material moisture, compression pressure, and compression temperature is particularly important. If we set the process to the optimal temperature and pressure, but allow moisture content to exceed the optimal range, the resultant briquette will be unstable. The correct temperature ensures that the lignin plasticizes in the compressed material, and the optimal pressure provides densification of this material [

4,

8]. However, if the compressed material has a high moisture content, escaping water in the form of steam will crack the briquette. If the moisture content is very low, on the other hand, the briquette must be pressed at a higher temperature and pressure in order to obtain a high-quality product, and this becomes economically unprofitable. With reduced moisture content, the heating value must be increased. Certain moisture levels cause a higher temperature in the densification process and thus a higher briquette quality [

12]. Optimal moisture level improves the compaction of the material by causing a degree of sintering which improves homogeneity of the briquette particles.

The size of the input particle also has an important effect on the densification process because larger input particles increase the energy needed for densification. Briquettes formed from large input particles also have less homogeneity and strength [

7]. On the other hand, a large number of fine particles provide better material densification. The resulting briquette is uniform, of high quality, and displays higher volumetric density [

11]. With increasing particle size, the bond strength between particles decreases, causing them to crumble [

9]. As a result, the quality of the briquette decreases and the compression pressure necessary to counteract this drop in quality increases. During compression, especially without additives, the surfaces of the particles must have contact over the greatest possible area [

7]. The size of this contact area increases as the particle size becomes finer and higher compression pressures need to be applied. In the material, particles exist which deform and load mainly the contact regions, due to external forces. In terms of densification, it is very important that bonding forces are created between the particles. The strength of the resultant bonds increases with decreasing particle size. However, the optimum particle size changes in relation to the densification technology employed, and the raw material used. Therefore, it is important to investigate the effects of particle size on the resulting density of the briquette. Thus particle size was one of the variables that this research attempted to identify and verify in the experiments.

3. Experimental Research Conditions

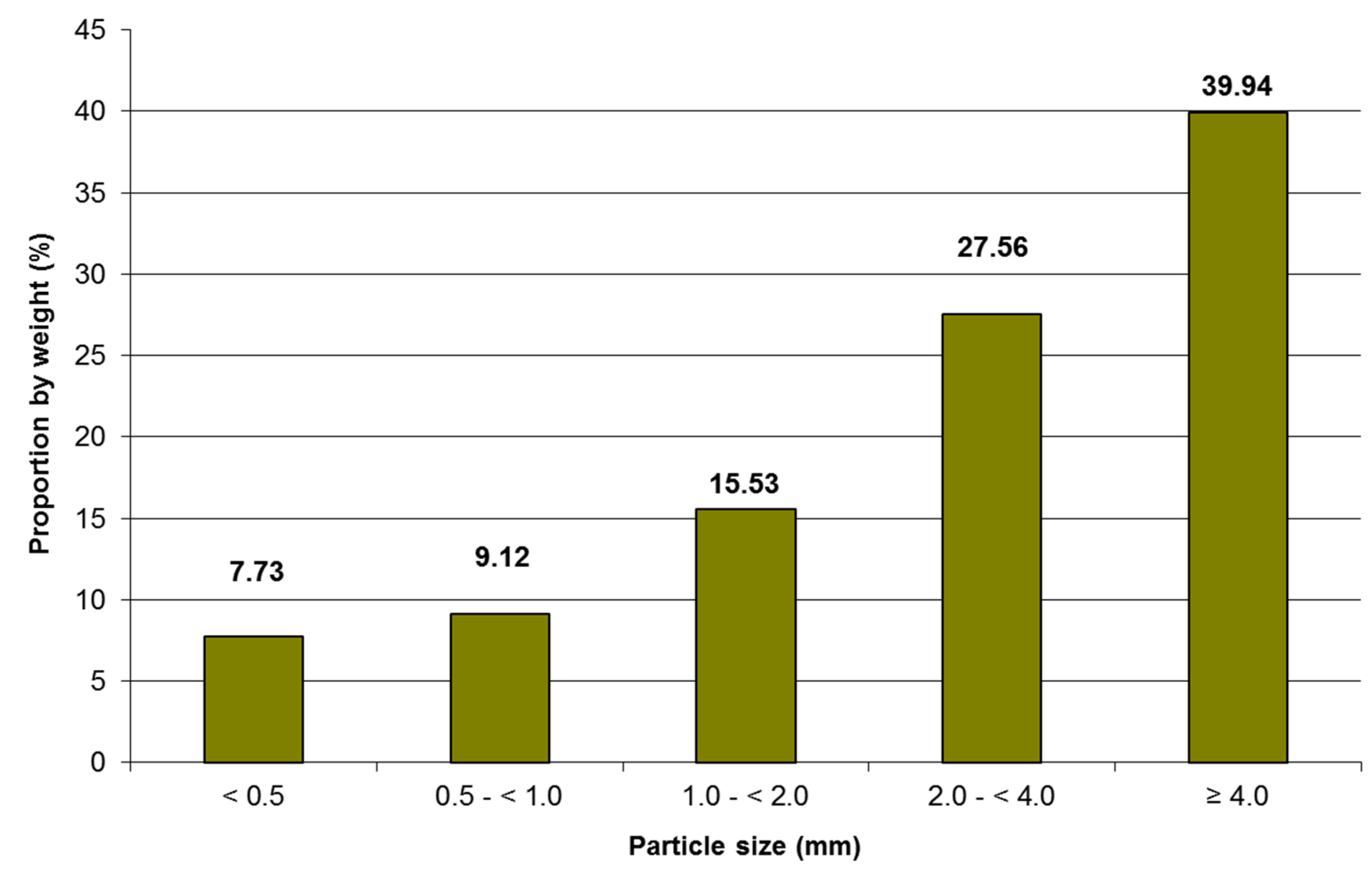

European beech (

Fagus sylvatica) sawdust with a moisture content of 8%, without bark, and originating from Western Slovakia was obtained from a wood processing company. Initially, the particle size distribution was analyzed using an AS 200 Vibrating Sieve Shaker (Retsch, Haan, Germany). The raw material particle size distribution was calculated by weight, see

Figure 2. For the experimental research particle sizes 0.5, 1.0, 2.0, 4.0 mm and an unsorted mix were chosen, (see

Figure 3).

Figure 2.

Raw material particle size distribution.

Figure 2.

Raw material particle size distribution.

Figure 3.

Beech sawdust particle sizes.

Figure 3.

Beech sawdust particle sizes.

The moisture content of the beech sawdust was measured prior to undertaking the experimental research using a MRS 120-3 balance (Kern, Balingen, Germany). This measurement was based on heating the material (gravimetric method of moisture content measuring) at 105 ± 2 °C until a constant weight was achieved [

13]. Due to the complicated moisture content change process and time limitations, only one moisture content level was used in this phase of the experiments (

wr = 8%), so the impact of moisture content on briquette quality was not investigated or calculated in our experiments.

Briquettes were produced using a vertical hydraulic press which was modified with the use of an experimental pressing stand (see

Figure 4). The experimental pressing stand consists of a base frame, a cylindrical pressing chamber with a 20 mm diameter die, a heating device with a temperature sensor for temperature control, and the backpressure plug. When the temperature in the chamber was reached, the raw material was fed into the chamber and compression with a hydraulic piston commenced. The hydraulic press made it possible to set the compression pressure in the range 31 MPa to 318 MPa. Adhering to the experimental plan for each experiment setting, five briquettes were produced. This number was chosen to satisfy standard mathematical and statistical methods for experiment evaluation [

4]. The described hydraulic press with stand allowed experimental settings over a wide range of compression pressures and temperatures. Densification of the beech sawdust was increased gradually in order to achieve the optimum results.

Figure 4.

Experimental pressing stand.

Figure 4.

Experimental pressing stand.

Briquette density was calculated using the ratio between briquette weight and its volume. The weight, length and diameter of each briquette were measured with a digital caliper and an electronic balance. The volume of the briquettes was calculated as the volume of a cylinder with dimensions (length and diameter), according to EN 16127 [

14]. Average density was calculated for each sample briquette. All the results in this phase, showing the interrelation between the different variables, were depicted graphically, as seen in the figures below. The results of this experimental research are applicable to the choice of dimensions of densification machines, and gave a comprehensive overview of the behavior of different variables during the densification process.

4. Results and Discussion

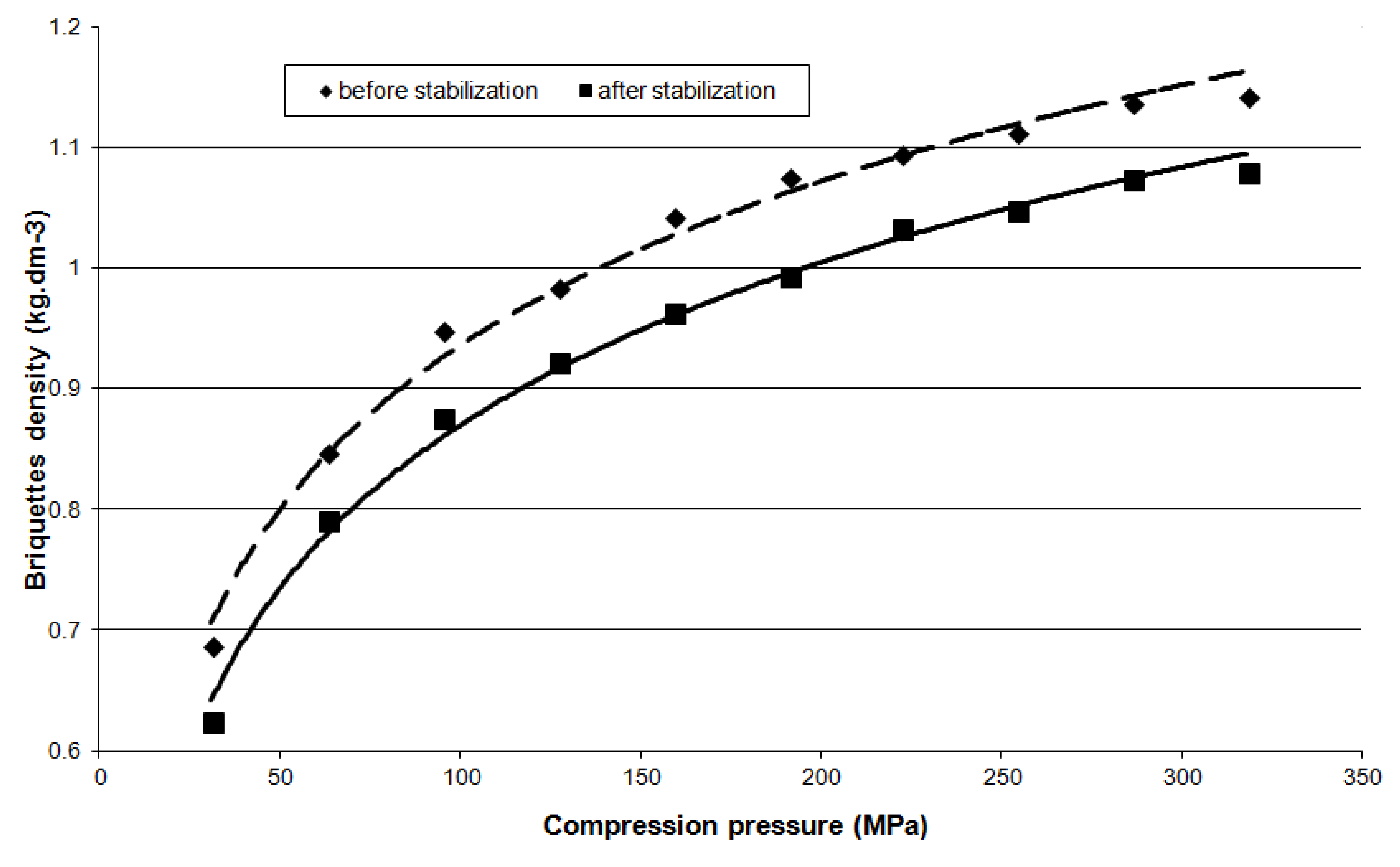

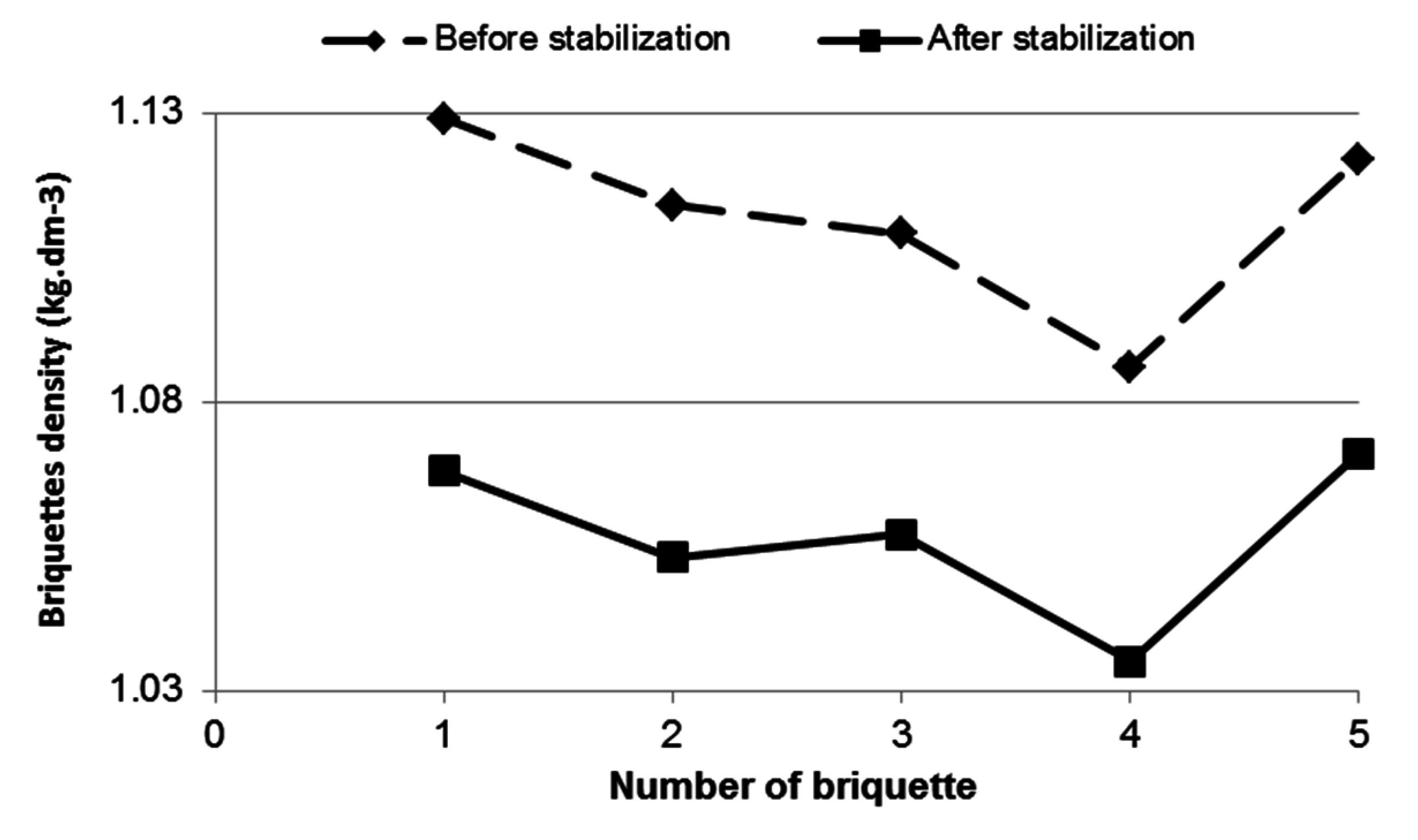

The impact of compression pressure on final briquette density can be seen in

Figure 5. As the compression pressure increases so too does the briquette density. This interdependence also highlights the importance of briquette stabilization time.

Briquette stabilization time is the time interval during which dilatation occurs; it is also the time interval during which the briquette stabilizes. Briquette stabilization time takes approximately 24 h depending on the type of compressed material and the densification technology used, but it can also take longer. The DIN 52182 Standard [

2] describes the conditions and process for detecting briquette density after stabilization time. After compression, the briquettes had to be placed under stable climatic conditions.

Figure 5.

Briquette density of beech sawdust, related to compression pressure at 25 °C (

wr = 8%;

L = 2 mm) [

4].

Figure 5.

Briquette density of beech sawdust, related to compression pressure at 25 °C (

wr = 8%;

L = 2 mm) [

4].

During this stabilization time the briquette dimensions (length and diameter) were frequently measured and its weight and density were evaluated. If the briquette weight had changed by no more than a maximum of 0.1% during the last 24 h, the briquette was considered stable [

2]. Briquette dilatation is a process during which the briquette’s dimensions (diameter, length) and weight undergo a change. These changes result from the internal variables of the briquette material, and also from the external variables of the densification technology. Dilatation has a direct influence on the briquette density because the density was calculated from the aforementioned briquette dimensions. The dilatation effect is produced when the compression pressure is removed, and, as a result of the relationship of the interactions between the compression temperature, material moisture, and input particle size.

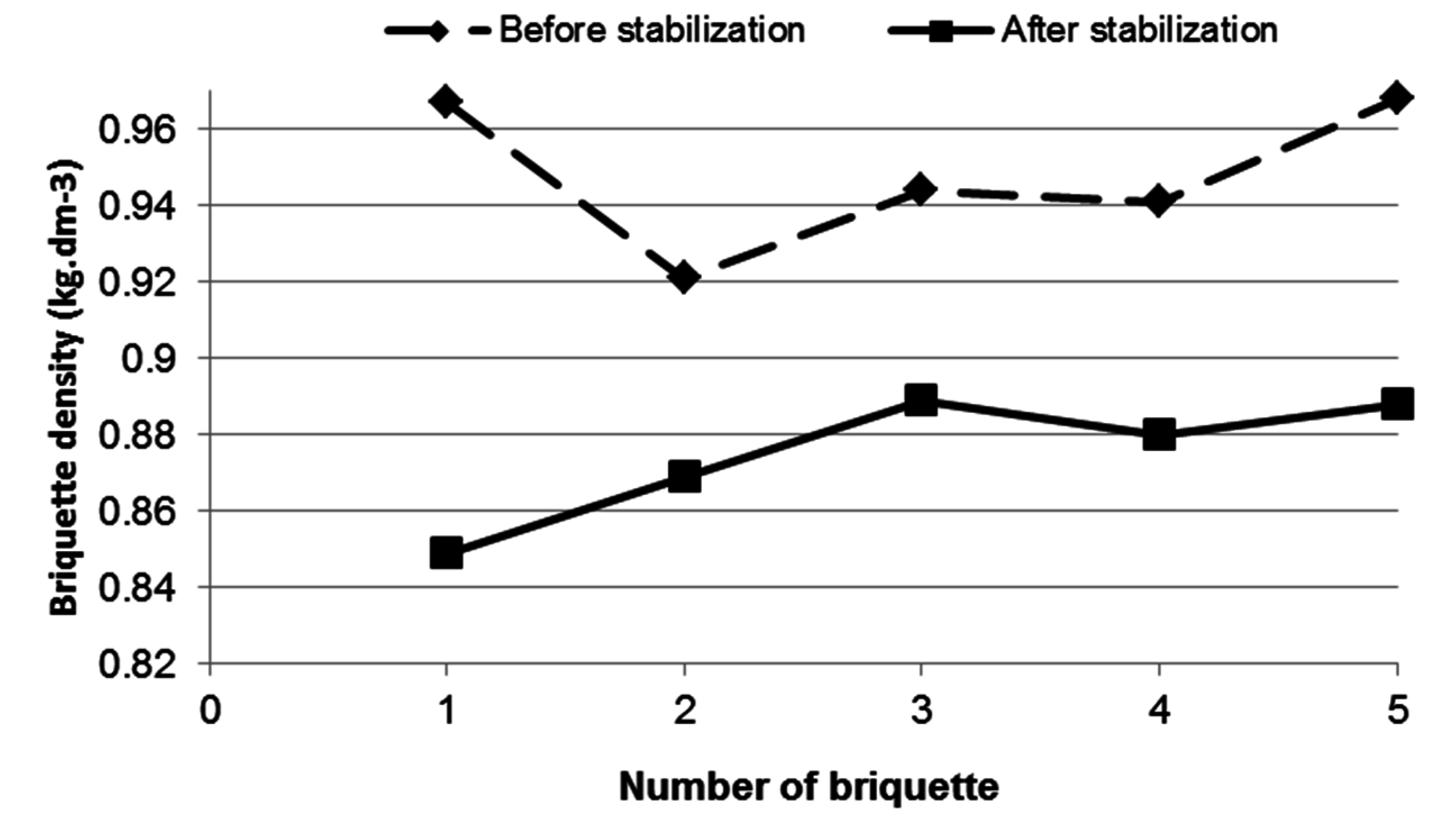

Two of these interdependencies can be seen in

Figure 5, one for densities evaluated immediately after releasing the briquettes from the compression chamber,

i.e., before stabilization, and the second for densities evaluated after the stabilization time. The briquette density changed significantly, and dilatation negatively influenced the briquette density in this case.

This effect can significantly distort the results of the experiment. Briquette density is important from the point of view of material particle cohesion. During densification, lignin, which acts as a natural glue, is released from the biomass. If the briquette is not created under optimally adjusted conditions, dilatation of the briquette can also significantly influence the absorption of moisture from its surroundings. In practice, the stabilization time can be reduced by cooling. In

Figure 6,

Figure 7 and

Figure 8, it can be seen that each briquette produced from the same settings, and also those from other settings were subject to dilatation during the stabilization time. The size of dilatation depends on the variables investigated here. Increasing the compression pressure positively affects the degree of dilatation;

i.e., dilatation is reduced. We can see that the differences between individual briquette density values before and after stabilization are reduced when the compression pressure is increased.

Figure 6.

Briquette density values at 95 MPa compression pressure (wr = 8%; L = 2 mm).

Figure 6.

Briquette density values at 95 MPa compression pressure (wr = 8%; L = 2 mm).

Figure 7.

Briquette density values at 159 MPa compression pressure (wr = 8%; L = 2 mm).

Figure 7.

Briquette density values at 159 MPa compression pressure (wr = 8%; L = 2 mm).

Figure 8.

Briquette density values at 254 MPa compression pressure (wr = 8%; L = 2 mm).

Figure 8.

Briquette density values at 254 MPa compression pressure (wr = 8%; L = 2 mm).

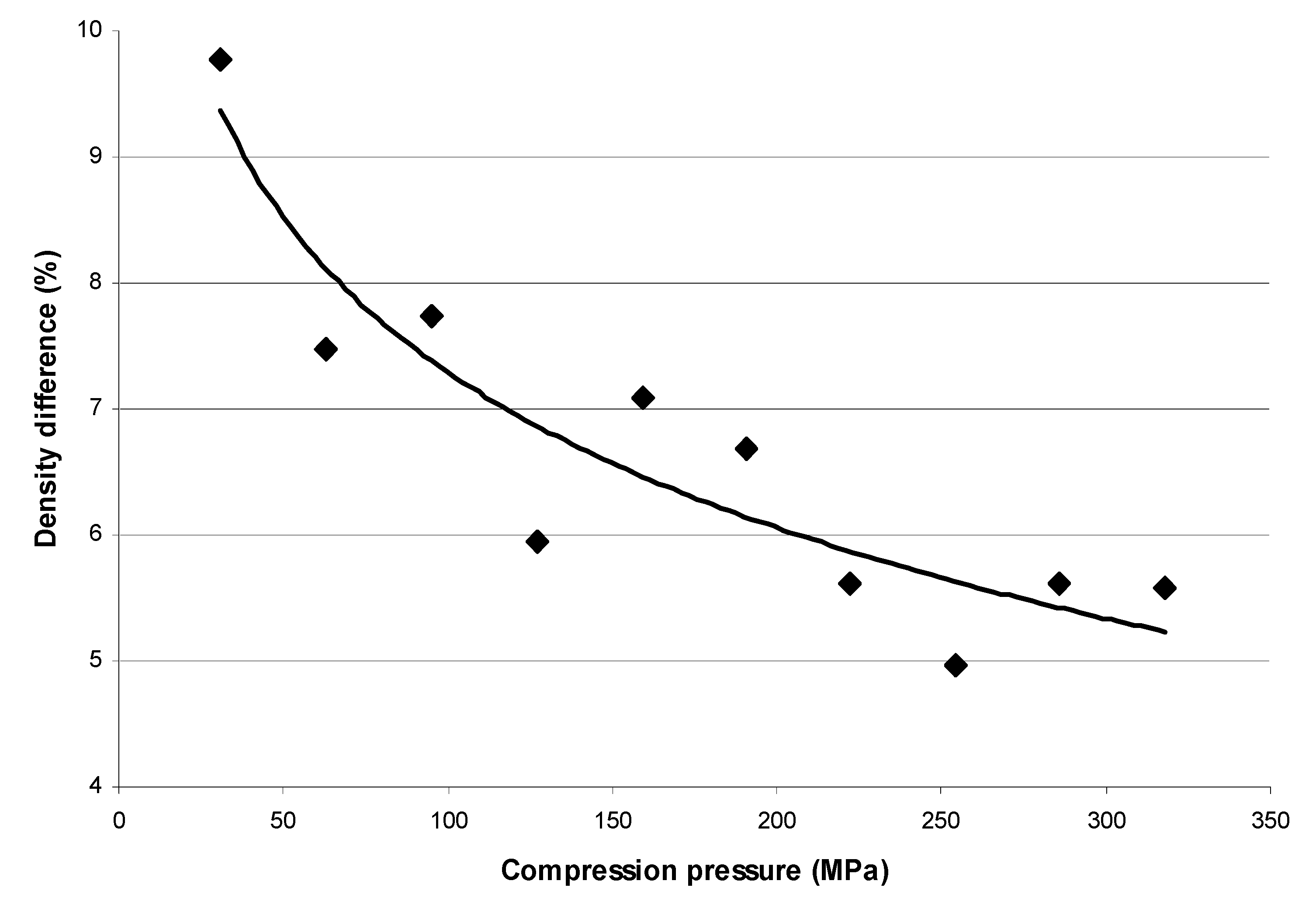

In

Figure 9, the interdependence between differing densities, both before and after stabilization, and compression pressure, can be observed graphically. This dependence clearly evidences the impact of compression pressure on briquette dilatation and means that with increasing compresson pressure, briquette dilatation is reduced.

Figure 9.

Density difference, dependent on pressing pressure (wr = 8%; L = 2 mm).

Figure 9.

Density difference, dependent on pressing pressure (wr = 8%; L = 2 mm).

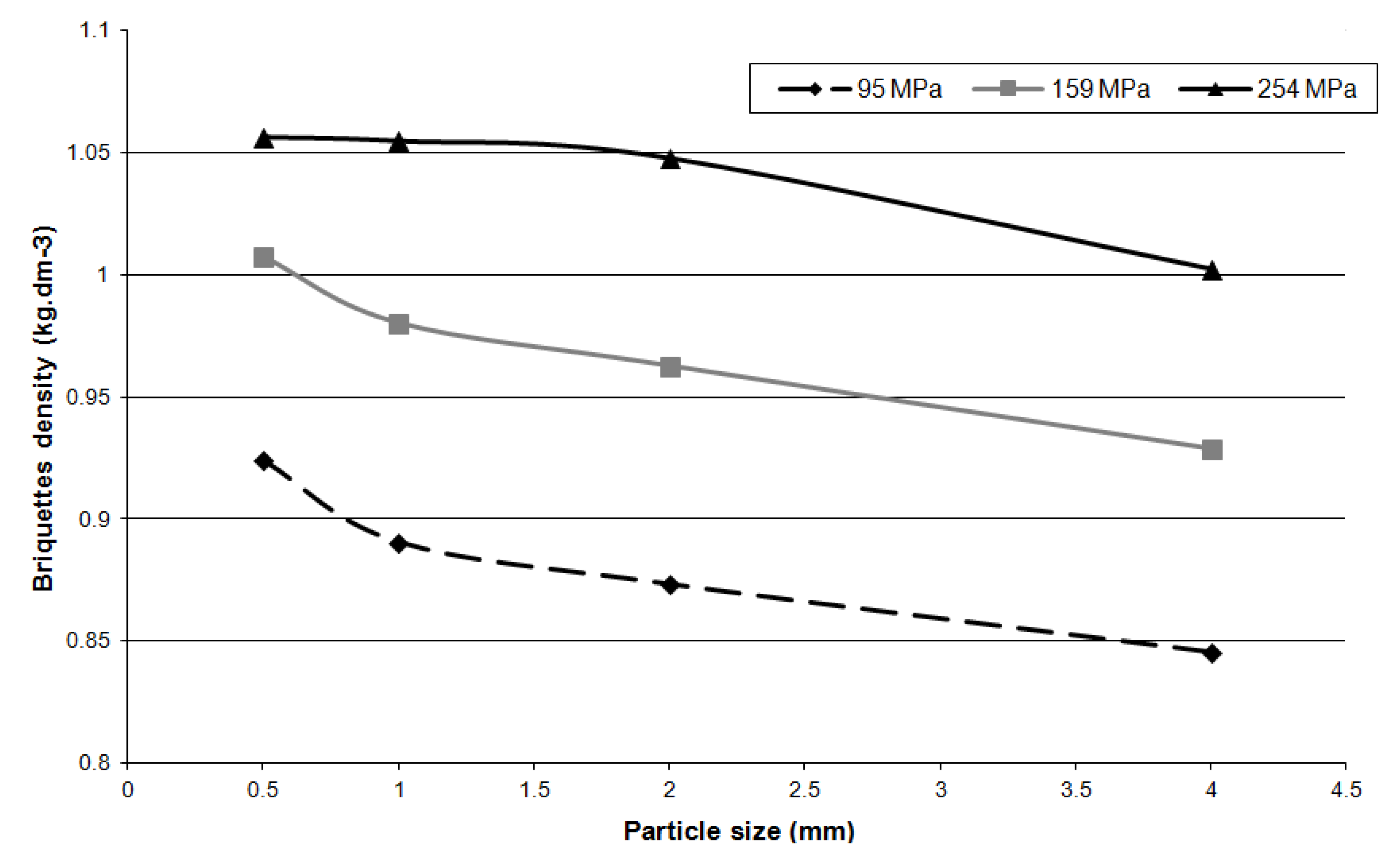

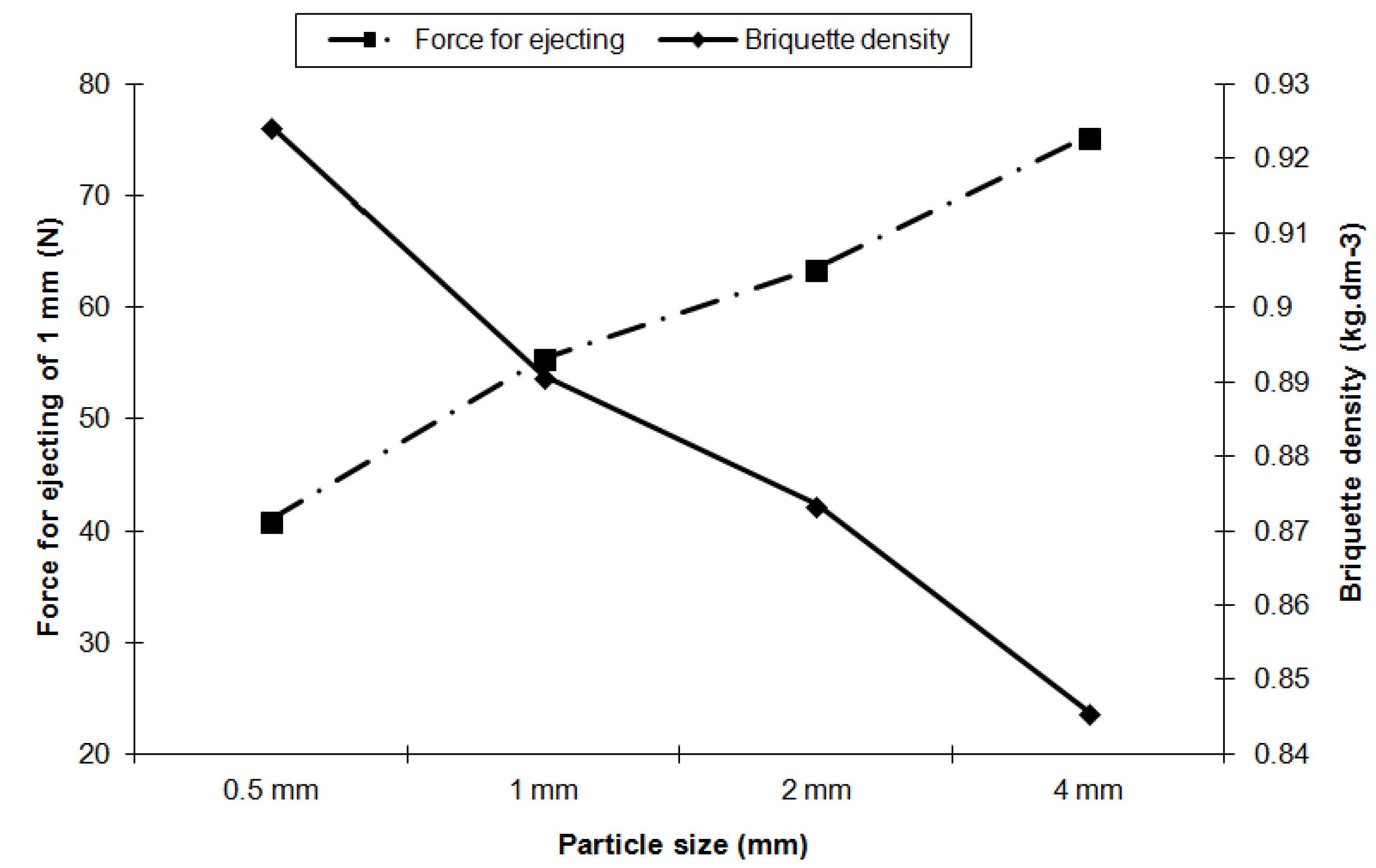

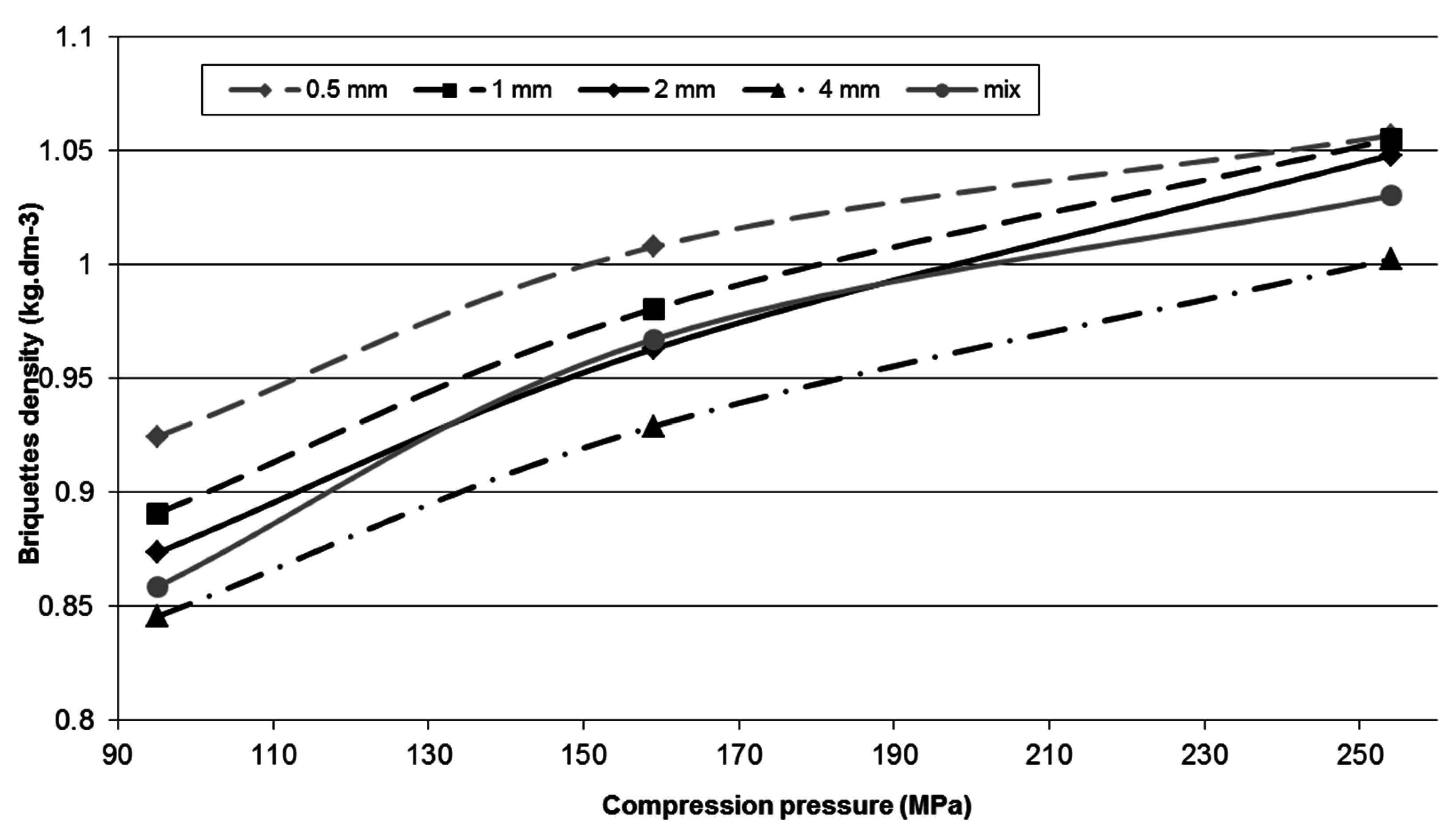

A significant part of the experimental research was also studying the effect of raw material particle size on briquette density. The influence of particle size on briquette density (see

Figure 10) has shown that reducing the particle size positively influences the increase in briquette density.

The figure shows that with increasing particle size, briquette density changes. Also it is important to note that for these results, the measurements were taken while compacting without any increase in temperature during the process, and at three levels of compression pressure.

In the case of particle size, the beech sawdust compressibility factor is an important variable. The compressibility factor characterizes one of the basic properties of sawdust—compression. Sawdust compression is defined as the tendency of bulk sawdust to change volume under the effect of an external force. This means that the magnitude of this compressibility or compression factor is affected by the pressure acting upon it. The results of the experiments show that increasing the compression pressure for beech sawdust of equal particle size increases the briquette density (see

Figure 17 below). Also it was proven that by increasing the particle size the briquette density decreases. These results imply that important variables affecting the compression factor are the pressure applied and the particle size.

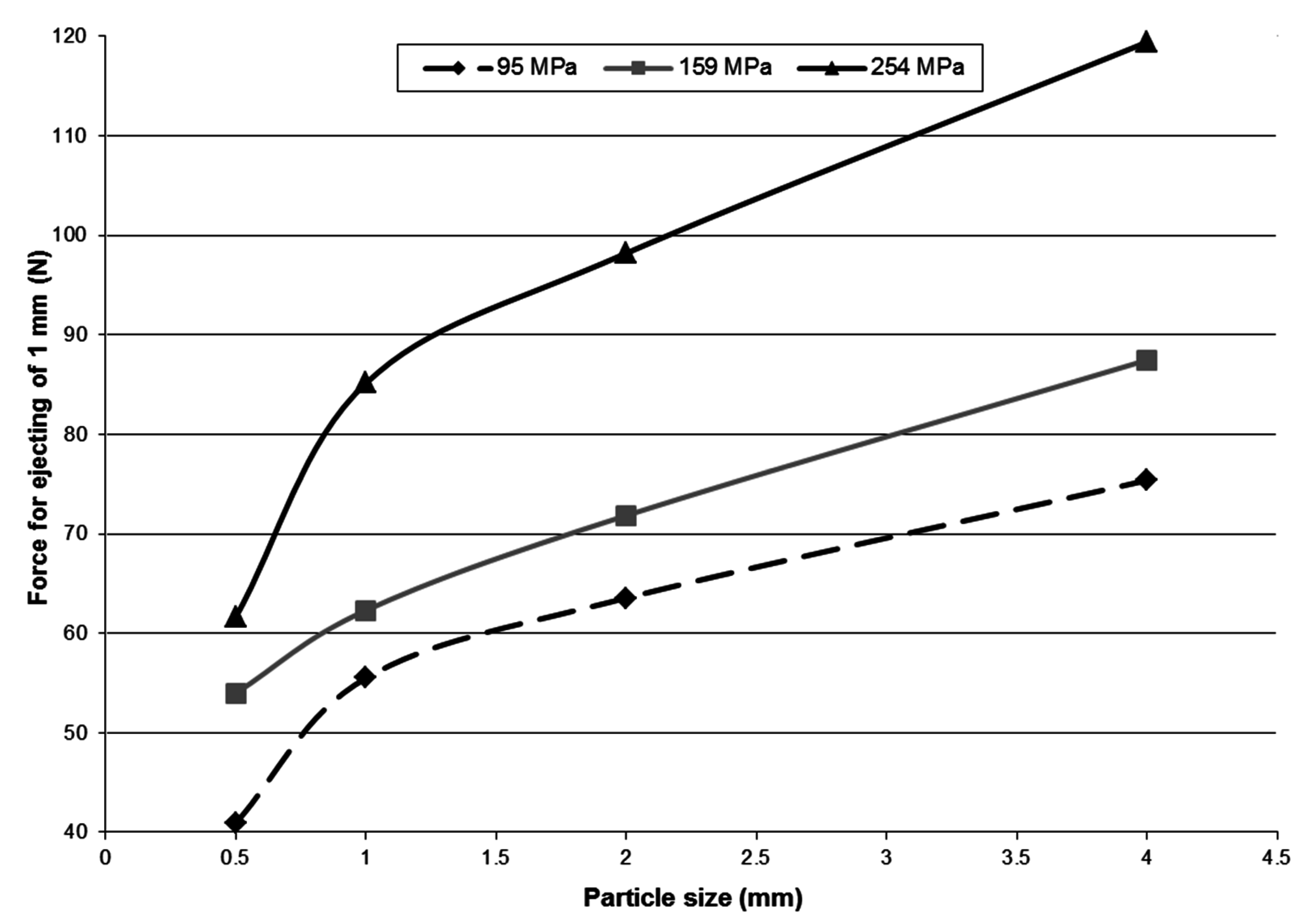

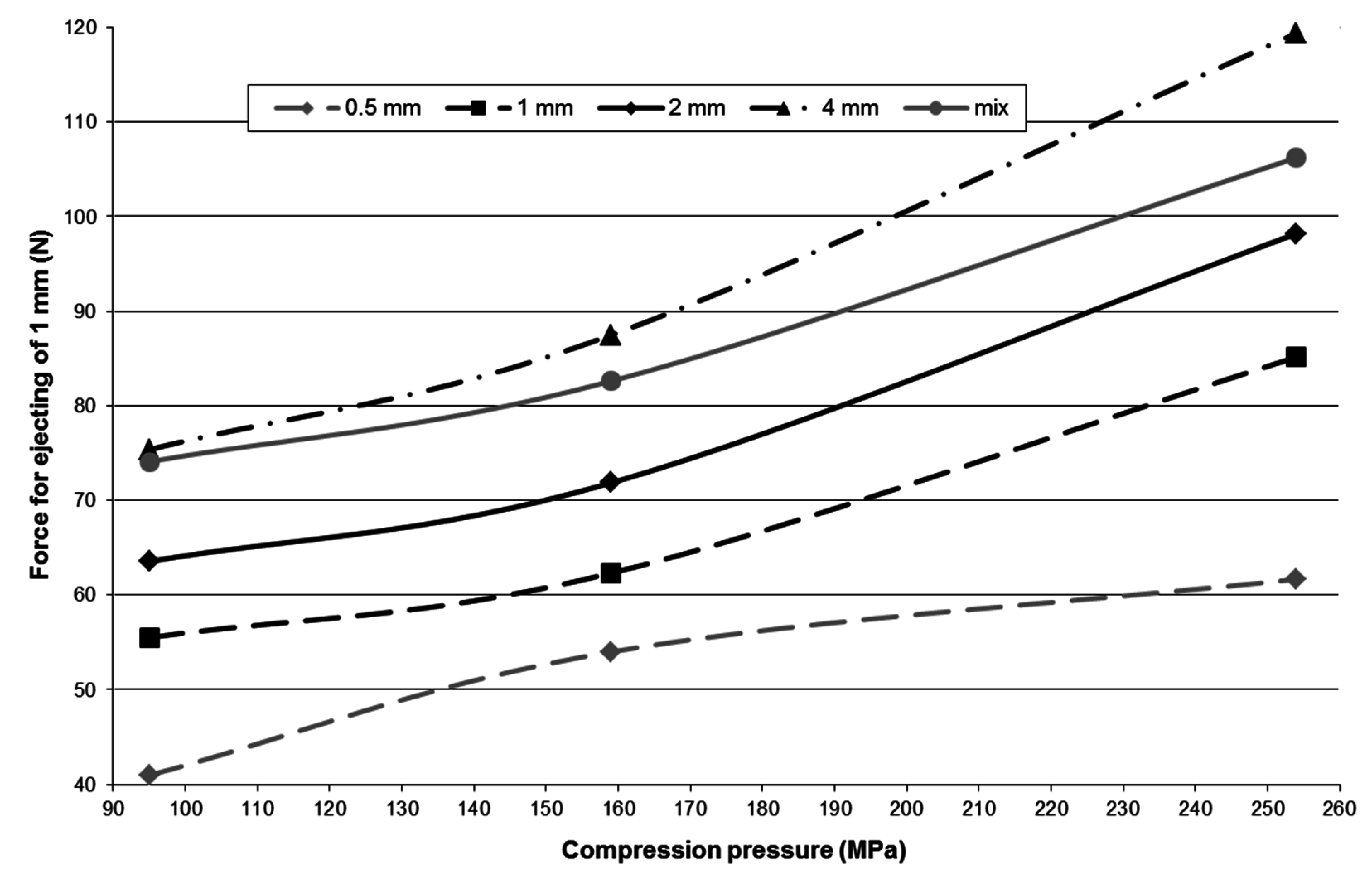

These two variables also influence the friction conditions in the pressing chamber and thus also the force needed to eject the briquette from the pressing chamber. The process of densification of biomass is caused by the piston moving from one end of the chamber, and by the frictional resistance of the briquettes through the chamber. The increased friction, depending on the length of the chamber, causes a higher compression pressure on the raw material. The determination of the force needed to eject the briquette from the chamber depending on the material and technological variables chosen was a secondary objective of this research.

Figure 10.

Dependence of briquette density on particle size (wr = 8%; T = 25 °C).

Figure 10.

Dependence of briquette density on particle size (wr = 8%; T = 25 °C).

The interdependence of force required for ejection and particle size can be seen on

Figure 11. During the experiments, briquettes of differing lengths were produced. Therefore the force required to eject the briquette was recalculated to provide a “per 1 mm length of briquette” figure. Increasing particle size while increasing compression pressure also increases the force needed for briquette eject.

Figure 11.

Interdependence of force needed to eject the briquette and particle size (wr = 8%; T = 25 °C).

Figure 11.

Interdependence of force needed to eject the briquette and particle size (wr = 8%; T = 25 °C).

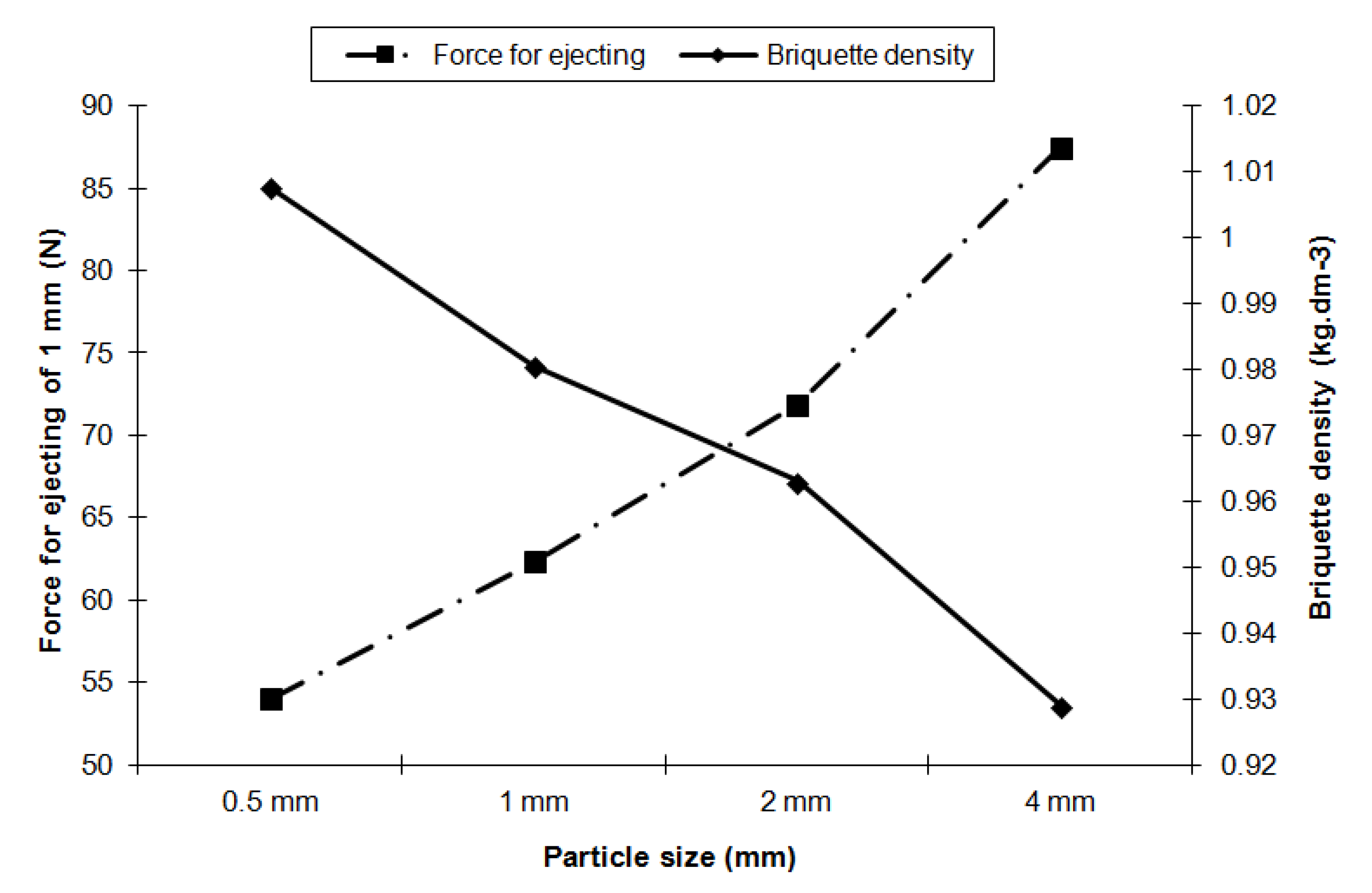

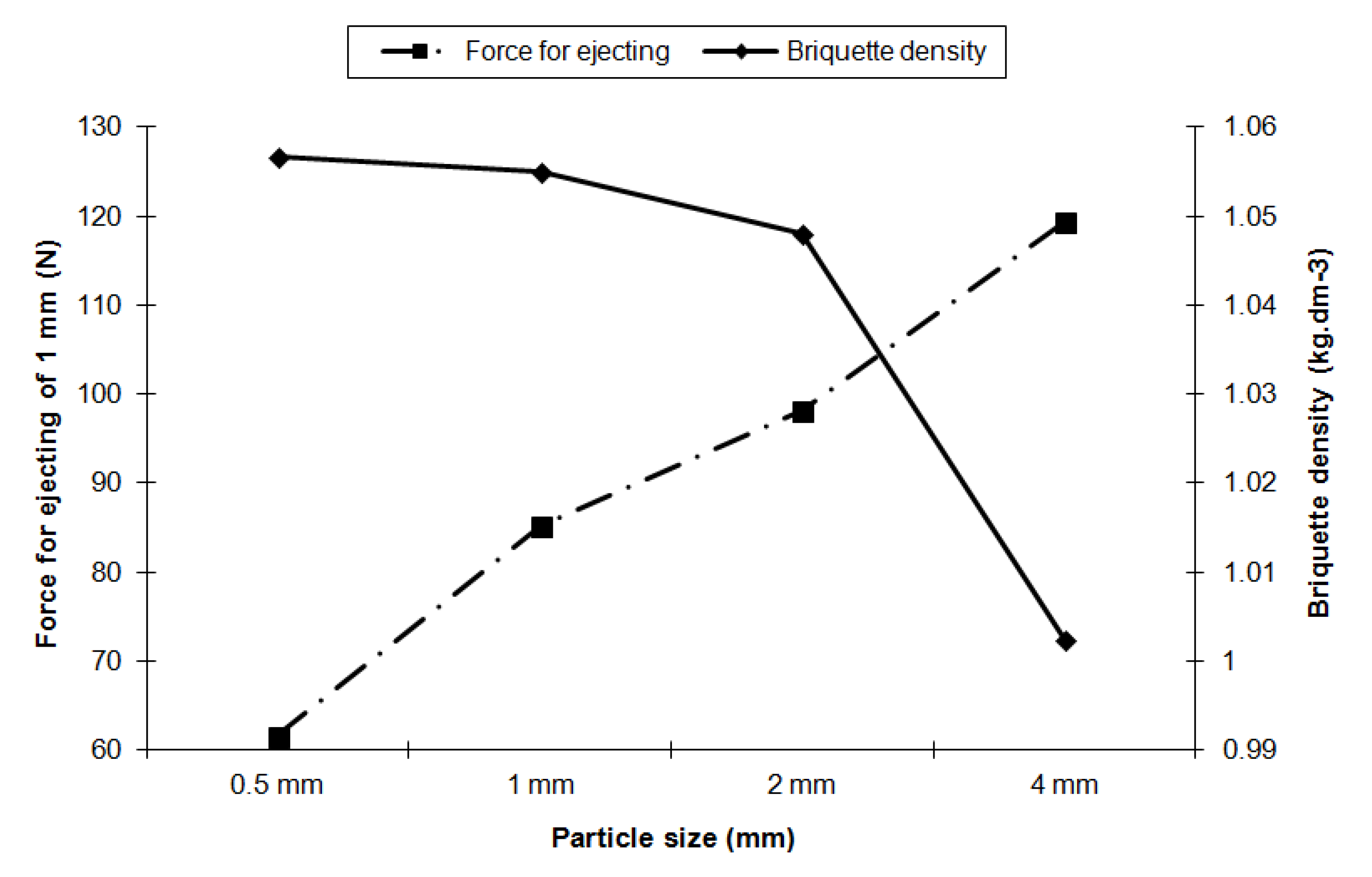

These findings should be combined with the impact on briquette density. The results are presented in

Figure 12,

Figure 13 and

Figure 14. Here the cumulative interdependencies can be seen in graphic form. These show that the degree of force needed for ejecting and briquette density depend on particle size. For economic efficiency, it is very important to know how much the raw material needs to be pulverized in order to obtain the optimal particle size.

Figure 12.

Cumulative interdependence—force required for ejecting, briquette density, and particle size (wr = 8%; T = 25 °C) at 95 MPa.

Figure 12.

Cumulative interdependence—force required for ejecting, briquette density, and particle size (wr = 8%; T = 25 °C) at 95 MPa.

Figure 13.

Cumulative interdependence—force required for ejecting, briquette density, and particle size (wr = 8%; T = 25 °C) at 159 MPa.

Figure 13.

Cumulative interdependence—force required for ejecting, briquette density, and particle size (wr = 8%; T = 25 °C) at 159 MPa.

Figure 14.

Cumulative interdependence—force for ejecting briquette, briquette density, and particle size (wr = 8%; T = 25 °C) at 254 MPa.

Figure 14.

Cumulative interdependence—force for ejecting briquette, briquette density, and particle size (wr = 8%; T = 25 °C) at 254 MPa.

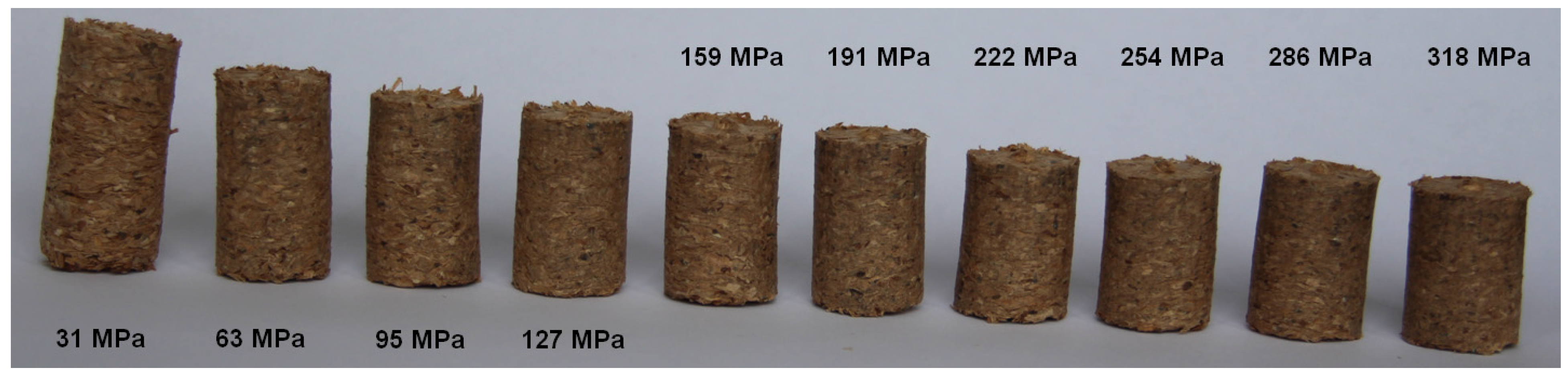

The influence of compression pressure and particle size can be very clearly seen also in

Figure 15 and

Figure 16. Briquettes with 20 mm diameter were produced and measured during the experimental research.

Table 1 presents views which were obtained during the investigation of beech briquette surfaces using a digital microscope. All views were obtained with the same zoom of 40×. Different particle deposition can be seen in the briquettes after densification, according to different particle size. A smoother briquette surface structure positively influences both the briquette density and also the frictional resistance of the briquette in the pressing chamber. When no compression temperature was applied, it can be seen that only bridges of a solid nature exist as a mechanism for internal bonding. When compression temperature is applied, this causes lignin plasticization and the creation of liquid bridges between the material particles.

Figure 15.

Comparison of beech briquettes from various particle sizes (p = 159 MPa; wr = 8%; T = 25 °C).

Figure 15.

Comparison of beech briquettes from various particle sizes (p = 159 MPa; wr = 8%; T = 25 °C).

Figure 16.

Briquettes from beech sawdust with different pressures applied (wr = 8%; T = 25 °C).

Figure 16.

Briquettes from beech sawdust with different pressures applied (wr = 8%; T = 25 °C).

Table 1.

Zoom views of the investigated briquette surfaces using a digital microscope (40×).

The interdependency of briquette density and compressive pressure during densification of different particle sizes can be seen in

Figure 17. It was proven that by reducing the particle size and increasing the compression pressure, briquette density also increases. This result demonstrating the interaction between particle size and compression pressure is extremely significant from the point of view of friction. The interactions investigated influence the binding forces produced between the material particles. How the friction changes with the particle size and the changing compression pressure can be clearly seen in

Figure 18. Reducing the particle size also reduces the force needed to eject the briquette. This force represents the friction between the pressed material and the chamber wall.

Figure 17.

Relation between briquette density and compression pressure for different particle sizes (wr = 8%; T = 25 °C).

Figure 17.

Relation between briquette density and compression pressure for different particle sizes (wr = 8%; T = 25 °C).

Figure 18.

Relation between force needed for ejection and compression pressure for different particle sizes (wr = 8%; T = 25 °C).

Figure 18.

Relation between force needed for ejection and compression pressure for different particle sizes (wr = 8%; T = 25 °C).

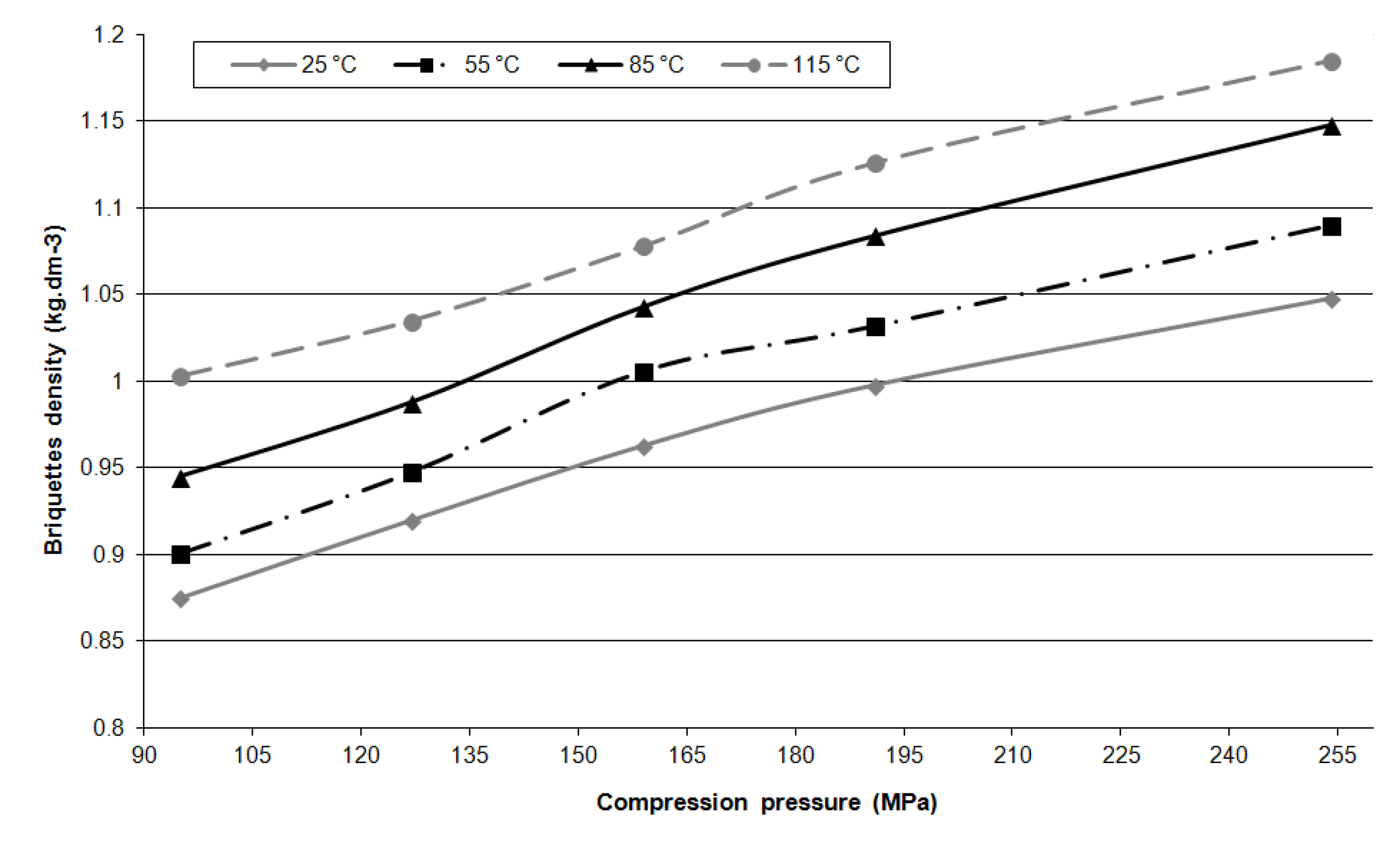

Briquette density and thus also the frictional resistance of the briquettes has a significant influence on compression temperature. The previous results were obtained at a compression temperature of 25 °C. The results presented in

Figure 19 were obtained as a result of densification at three other different pressing temperature levels (55, 85 and 115 °C).

Figure 19 shows the relationship between briquette density the compression pressure at four different levels of compression temperatures. The positive impact of compression temperature on the final briquette quality was proven. When the compression temperature and the compression pressure are increased, briquette density increases. The compression temperature has a positive impact on the lignin component of the compressed material [

9]. The compression temperature influences lignin plasticization [

8,

9]. With increased compression temperature during densification, the lignin becomes more and more liquid, plastic. Temperature significantly affects the bonding mechanism forming between the solid particles of the compressed material [

8,

9]. A more effective bonding of the cellular structure of the compressed material and the required plasticization of lignin is possible only under induced compression temperatures.

Figure 19.

Relation between briquette density and compression pressure at different compression temperatures (

wr = 8%;

L = 2 mm) [

8].

Figure 19.

Relation between briquette density and compression pressure at different compression temperatures (

wr = 8%;

L = 2 mm) [

8].