An Experimental Investigation on the Combustion and Heat Release Characteristics of an Opposed-Piston Folded-Cranktrain Diesel Engine

Abstract

:1. Introduction

2. Experimental Set-up and Methods

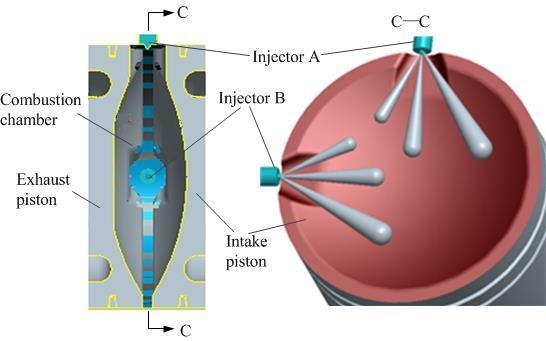

2.1. OPFC Diesel Engine Concept

| Specification Item | Value |

|---|---|

| Number of the culinder(-) | 2 |

| Bore (mm) | 100 |

| Stroke (intake/exhaust) (mm) | 110/110 |

| Nominal compression ratio (-) | 22 |

| Trapping compression ratio (-) | 15.8 |

| Displacement (L) | 3.4 |

| Opposed-piston motion phase difference (°CA) | 17 |

| Exhaust valve open (AIDC) (°CA) | 100 |

| Intake valve open (AIDC) (°CA) | 116 |

| Exhaust valve close (BIDC) (°CA) | 113 |

| Intake valve close (BIDC) (°CA) | 110 |

| Maximum engine power (kW) | 80 @ 2400 rpm |

| Maximum engine moment (N.m) | 420 @ 1600 rpm |

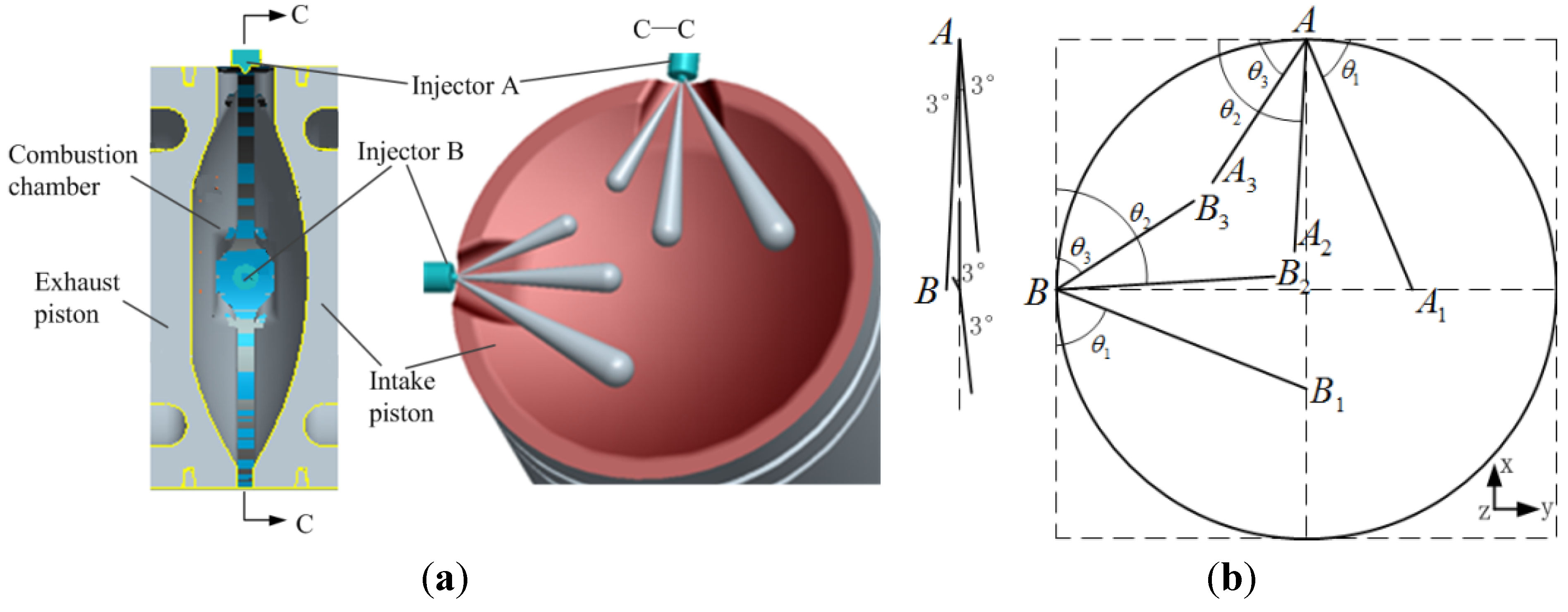

2.2. Experimental Set-up

2.3. Calculation of Heat Release (HR)

3. Results and Discussion

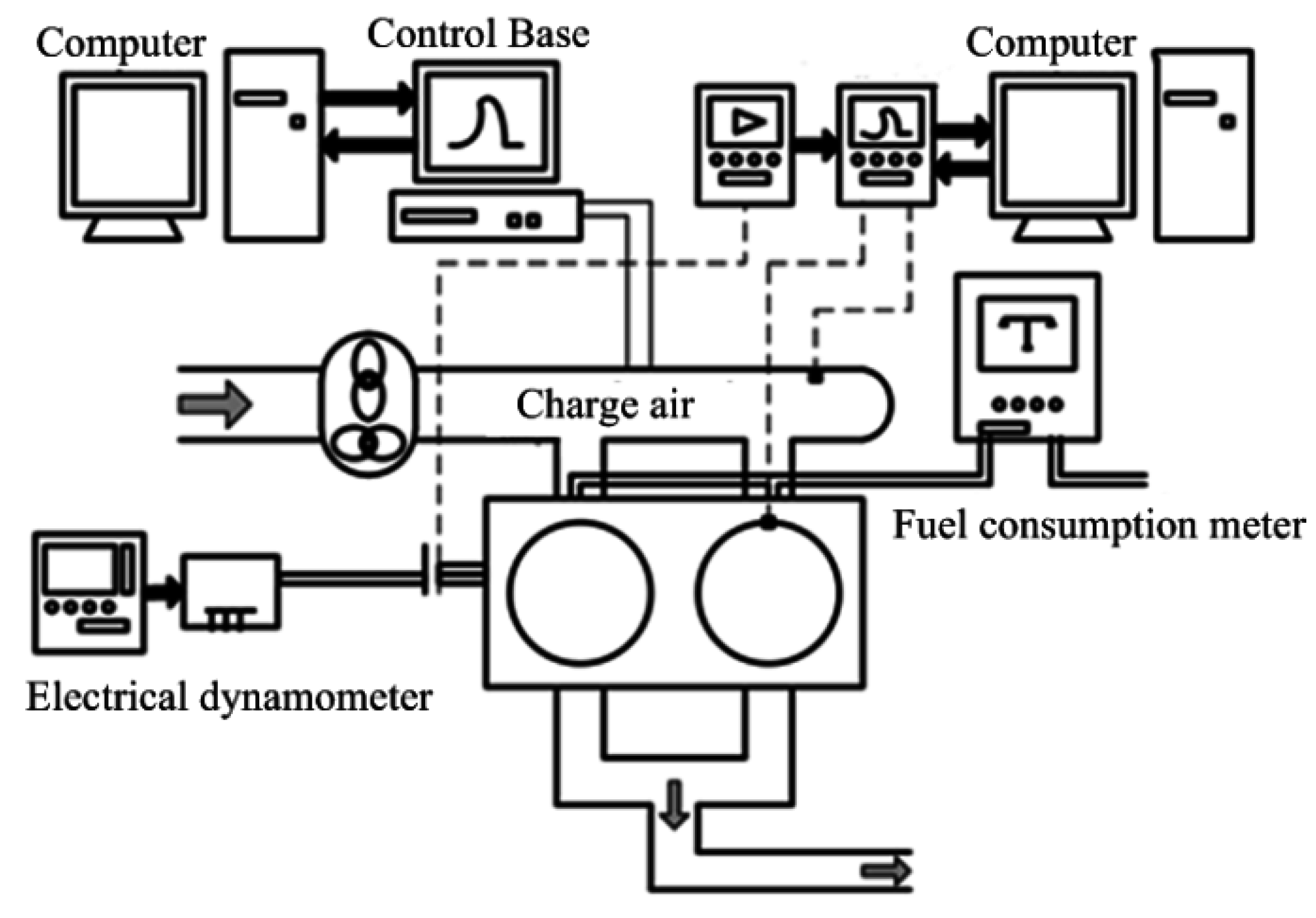

3.1. Combustion Characteristics

3.1.1. Cylinder Gas Pressure (CGP)

3.1.2. Rate of Pressure Rise (ROPR)

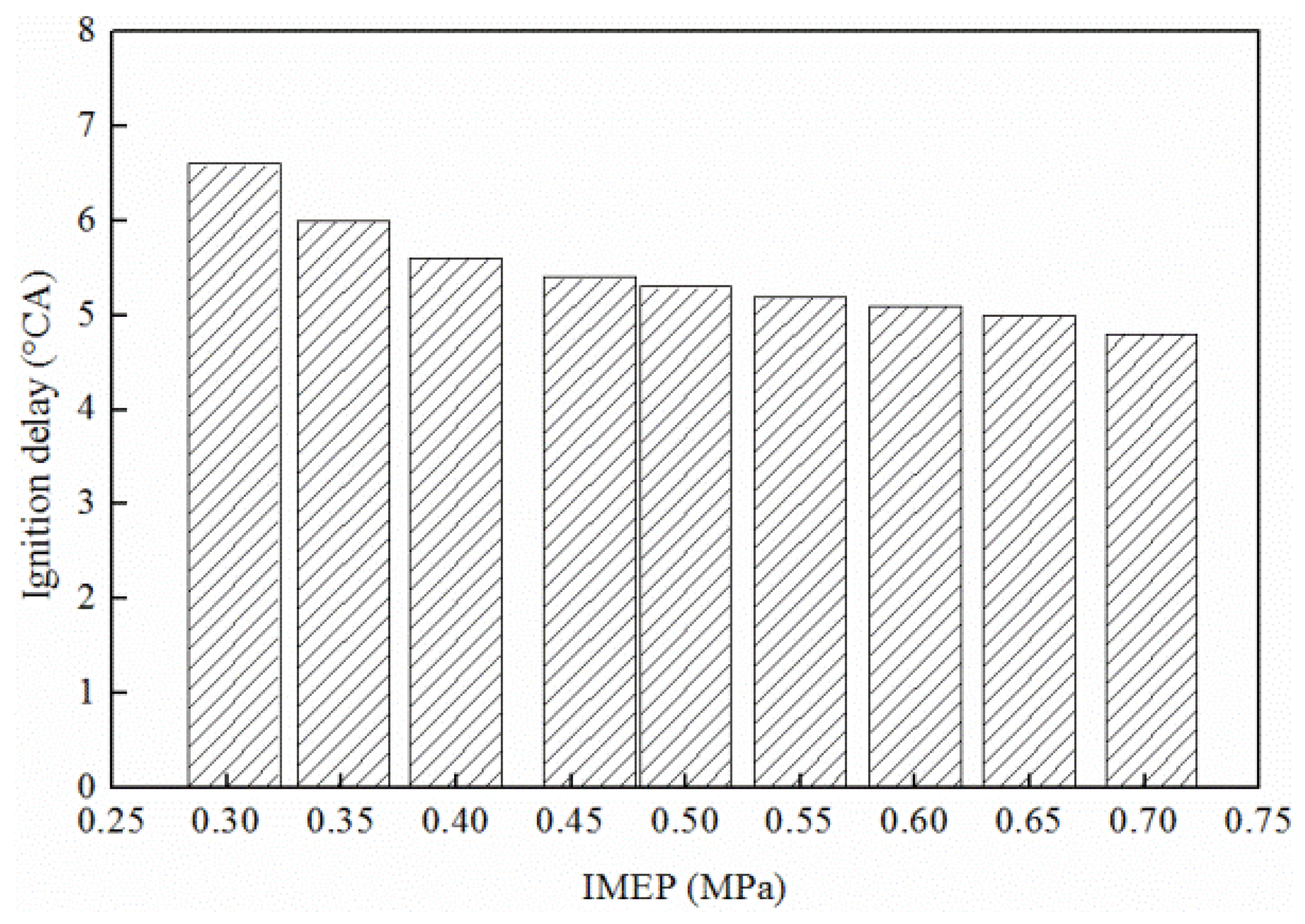

3.1.3. Ignition Delay (ID)

3.2. Analysis of Heat Release

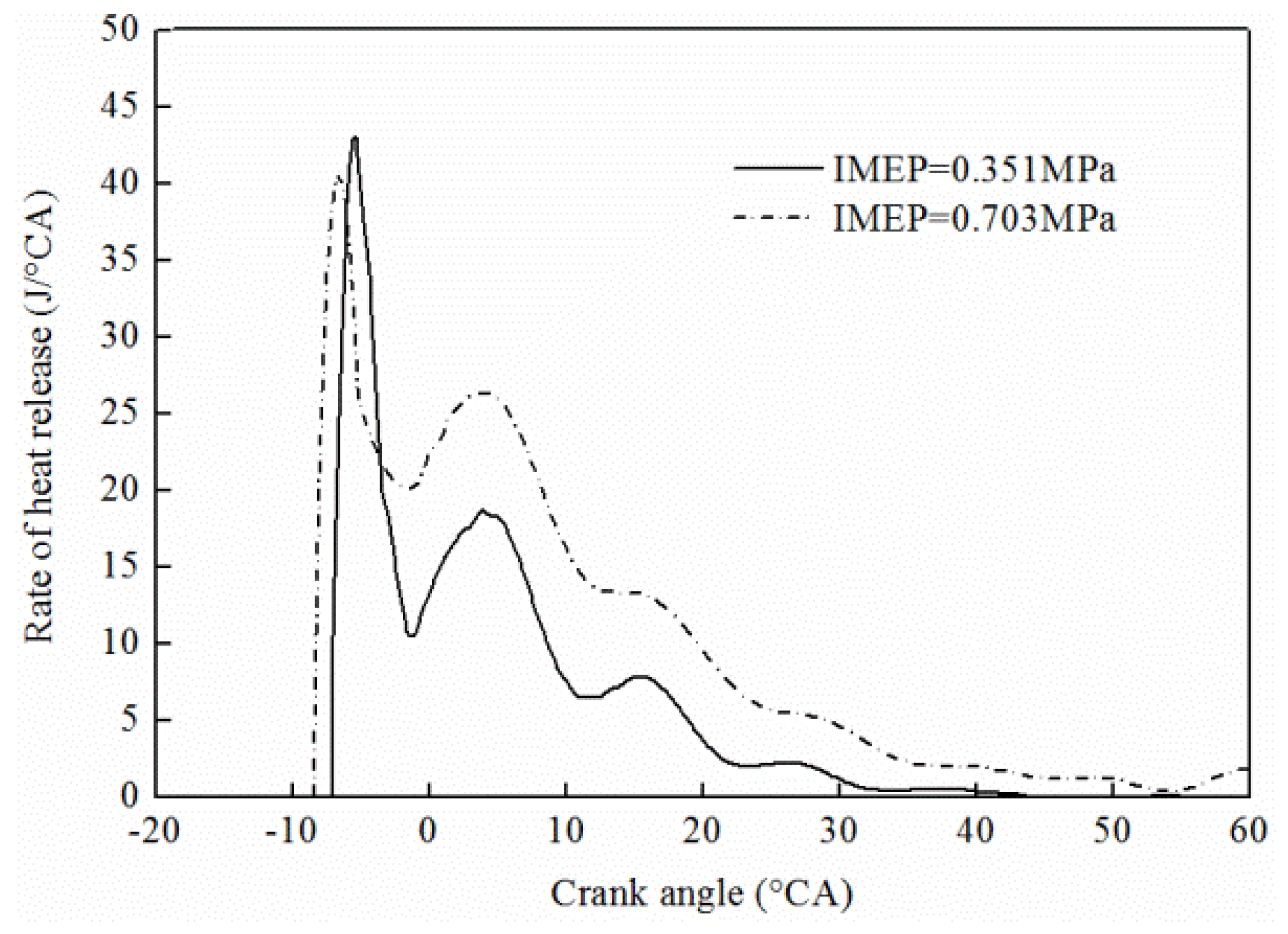

3.2.1. Rate of Heat Release (ROHR)

3.2.2. Cumulative Heat Release (CHR)

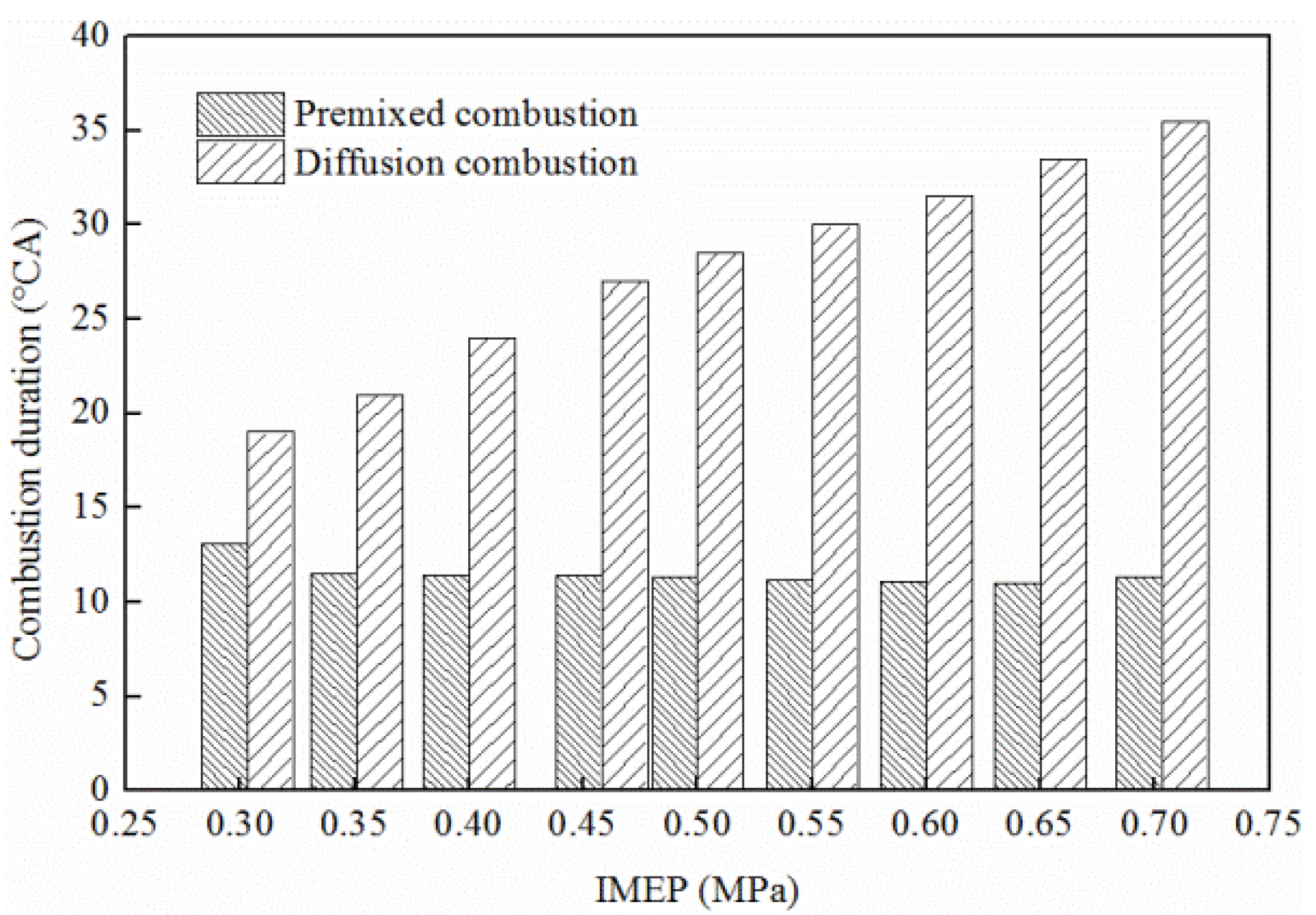

3.2.3. Combustion Duration (CD)

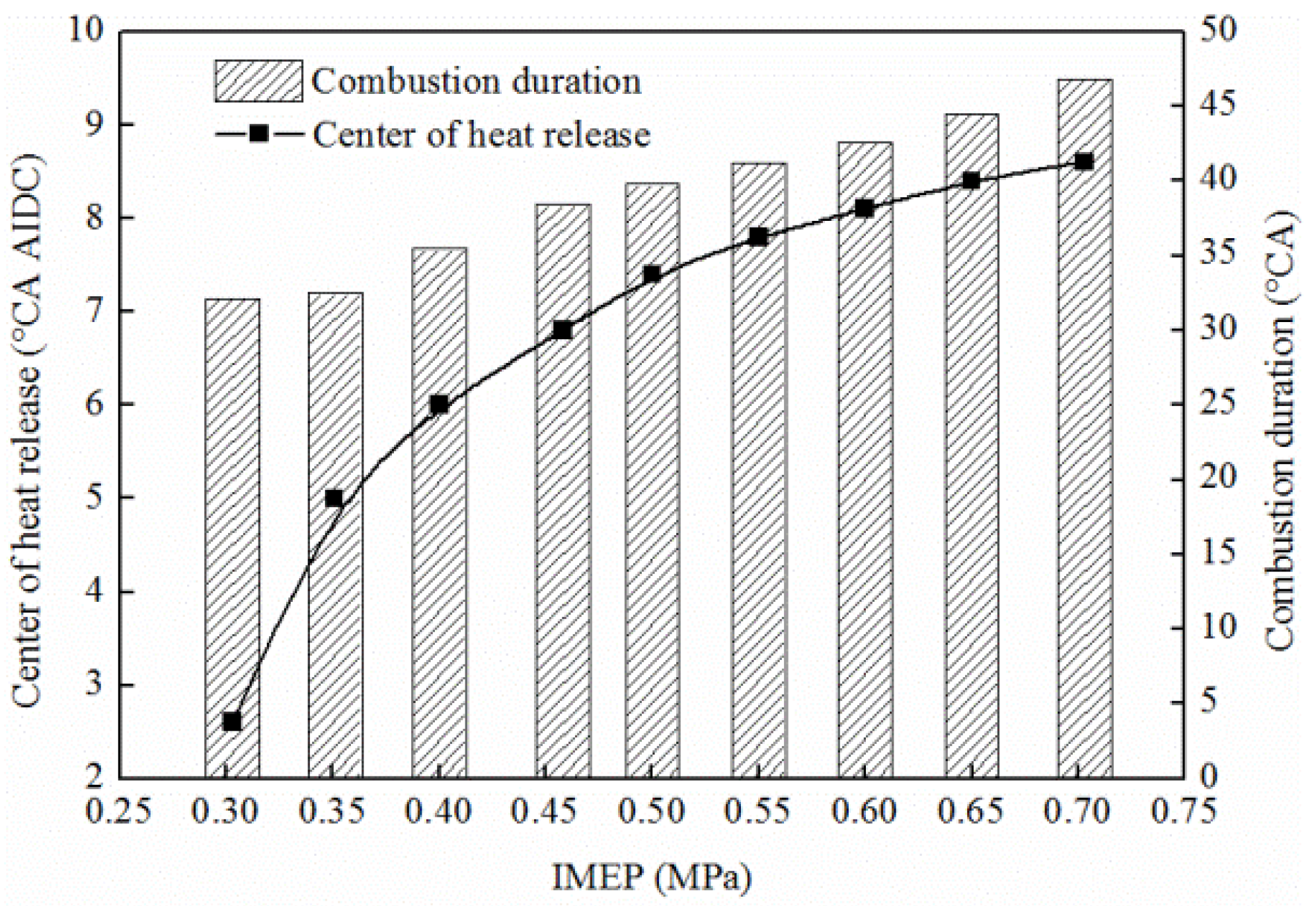

3.2.4. Center of Heat Release (COHR)

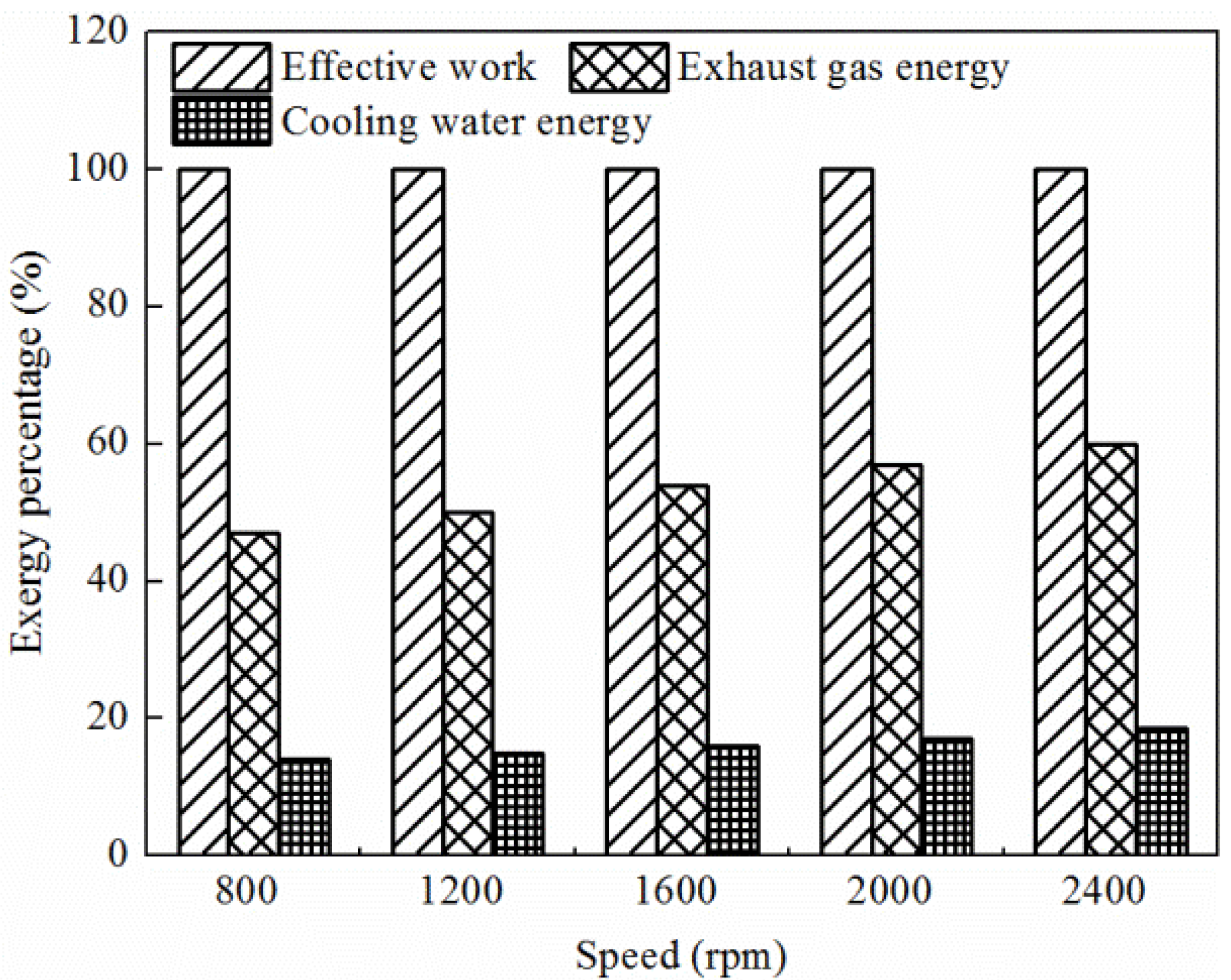

3.3. Analysis of Waste Heat Energy

4. Conclusions

- (1)

- The heat release process of OPFC diesel engines can be divided into four phases: ignition delay, premixed combustion, diffusion combustion and after combustion, which have more significant isochoric and isobaric combustion because of a smaller relative velocity of opposed-pistons and heat transfer loss around IDC.

- (2)

- With an increasing IMEP, premixed CD increases slightly while diffusion CD increases significantly, resulting in a slight increase of CGP in premixed CD while it increases substantially in diffusion CD. When IMEP increases from 0.351 MPa to 0.703 MPa, peak ROPR is shortened by 7%.

- (3)

- The relative movement rule of opposed-pistons is a main impact factor for the combustion process of OPFC diesel engines. A smaller relative velocity of the opposed-pistons around IDC results in more obvious isochoric combustion so the ROPR is higher than in a conventional diesel engine. With the increase of IMEP, isobaric combustion is obvious because the heat transfer loss is less in the opposed-piston combustion chamber components.

- (4)

- An OPFC diesel engine features high exhaust pressure and temperature due to its two-stroke and uniflow scavenging characteristics, through which relatively high-quality exhaust gas heat energy is produced. The available energy efficiency is about 50% of exhaust gas energy and 25% of the total fuel energy can be recovered under full load.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| AIDC | after inner dead center | ID | ignition delay |

| BIDC | before inner dead center | IDC | inner dead center |

| CA | crank angle | IMEP | indicated mean effective pressure |

| CD | combustion duration | OPOC | opposed-piston and opposed-cylinder |

| CGP | cylinder gas pressure | OPFC | opposed-piston folded-cranktrain |

| CHR | cumulative heat release | OP2S | opposed-piston two-stroke |

| CI | compression ignition | rpm | revolution per minute |

| COHR | center of heat release | ROPR | rate of pressure rise |

| HCCI | homogeneous charge compression ignition | ROHR | rate of heat release |

| HR | heat release | TDC | top dead center |

References

- Callahan, B.J.; Wahl, M.H.; Froelund, K. Oil consumption measurements for a modern opposed-piston two-stroke diesel engine. In Proceedings of the ASME 2011 Internal Combustion Engine Division Fall Technical Conference, Morgantown, WV, USA, 2–5 October 2011; pp. 1019–1028.

- Kalebjian, C.; Redon, F.; Wahl, M. Low Emissions and Rapid Catalyst Light-off Capability for Upcoming Emissions Regulations with an Opposed-Piston, Two-Stroke Diesel Engine; Global Automotive Management Council and Emissions: Troy, MI, USA, 2012. [Google Scholar]

- Hofbauer, P. Opposed Piston Opposed Cylinder (OPOC) Engine for Military Ground Vehicles; SAE Technical Paper 2005-01-1548; SAE: Warrendale, PA, USA, 2005. [Google Scholar]

- Hirsch, N.R.; Schwarz, E.E.; McGough, M.G. Advanced Opposed-Piston Two-Stroke Diesel Demonstrator; SAE Technical Paper 2006-01-0926; SAE: Warrendale, PA, USA, 2006. [Google Scholar]

- Herold, R.E.; Wahl, M.H.; Regner, G.; Lemke, J.U.; Foster, D.E. Thermodynamic Benefits of Opposed-Piston Two-Stroke Engines; SAE Technical Paper 2011-01-2216; SAE: Warrendale, PA, USA, 2011. [Google Scholar]

- Pirault, J.P.; Flint, M. Opposed-Piston Engines: Evolution, Use, and Future Applications; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Naik, S.; Johnson, D.; Koszewnik, J.; Fromm, L.; Redon, F. Practical Applications of Opposed-Piston Engine Technology to Reduce Fuel Consumption and Emissions; SAE Technical Paper 2013-01-2754; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Regner, G.; Herold, R.E.; Wahl, M.H.; Dion, E. The Achates Power Opposed-Piston Two-Stroke Engine: Performance and Emissions Results in a Medium-Duty Application; SAE Technical Paper 2011-01-2221; SAE: Warrendale, PA, USA, 2011. [Google Scholar]

- Redon, F.; Kalebjian, C.; Kessler, J.; Rakovec, N.; Headley, J. Meeting Stringent 2025 Emissions and Fuel Efficiency Regulations with an Opposed-Piston, Light-Duty Diesel Engine; SAE Technical Paper 2014-01-1187; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Francisco, B.; Santos, A.; Gregorio, J. Computational analysis of the scavenging of a two-stroke opposed piston diesel engine. In Proceedings of the 2010 International Conference of Mechanical Engineering, London, UK, 30 June–2 July 2010; Volume 30.

- McGough, M.G.; Fanick, E.R. Experimental Investigation of the Scavenging Performance of a Two-Stroke Opposed-Piston Diesel Tank Engine; SAE Technical Paper 2001-01-1591; SAE: Warrendale, PA, USA, 2004. [Google Scholar]

- Xu, H.J.; Song, J.O.; Yao, C.D. Simulation on in-cylinder flow on mixture formation and combustion in OPOC engine. Trans. CSICE 2009, 27, 395–400. [Google Scholar]

- Xu, S.; Wang, Y.; Zhu, T. Numerical analysis of two-stroke free piston engine operating on HCCI combustion. Appl. Energy 2011, 88, 3712–3725. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engines Fundamentals; McGraw Hill International: New York, NY, USA, 1988. [Google Scholar]

- Rakopoulos, C.D.; Giakoumis, E.G. Second-law analyses applied to internal combustion engines operation. Prog. Energy Combust. Sci. 2006, 32, 2–47. [Google Scholar] [CrossRef]

- Franke, M.; Huang, H.; Liu, J.P. Opposed Piston Opposed Cylinder (opoc™) 450 hp Engine: Performance Development by CAE Simulations and Testing; SAE Technical Paper 2006-01-0277; SAE: Warrendale, PA, USA, 2006. [Google Scholar]

- Zhao, Z.F.; Wu, D.; Zhang, F.J. Design and Performance Simulation of Opposed-Piston Folded-Cranktrain Engines; SAE Technical Paper 2014-01-1638; SAE: Warrendale, PA, USA, 2014. [Google Scholar]

- Xie, Z.Y.; Zhao, Z.F.; Zhang, Z.Y. Numerical Simulation of an Opposed-Piston Two-Stroke Diesel Engine; SAE Technical Paper 2015-01-0404; SAE: Warrendale, PA, USA, 2015. [Google Scholar]

- Ma, F.K.; Zhao, C.L.; Zhang, S.L. Scheme Design and Performance Simulation of Opposed-Piston Two-Stroke Gasoline Direct Injection Engine; SAE Technical Paper 2015-01-1276; SAE: Warrendale, PA, USA, 2015. [Google Scholar]

- Krieger, R.B.; Borman, G.L. The Computation of Applied Heat Release for Internal Combustion Engines; ASME Paper 66-WA/DGP-4; SAE: Warrendale, PA, USA, 1966. [Google Scholar]

- Brunt, M.F.J.; Rai, H.; Emtage, A.L. The Calculation of Heat Release Energy from Engine Cylinder Pressure Data; SAE Technical Paper 981052; SAE: Warrendale, PA, USA, 1998. [Google Scholar]

- Selim, M.Y.E.; Radwan, M.S.; Elfeky, S.M.S. Combustion of jojoba methyl ester in an indirect injection diesel engine. Renew Energy 2003, 28, 1401–1420. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M.; Turkcan, A.; Sayin, C. Performance and combustion characteristics of a DI diesel engine fueled with waste palm oil and canola oil methyl esters. Fuel 2009, 88, 629–636. [Google Scholar] [CrossRef]

- Azoumah, Y.; Blin, J.; Daho, T. Exergy efficiency applied for the performance optimization of a direct injection compression ignition (CI) engine using biofuels. Renew Energy 2009, 34, 1494–1500. [Google Scholar] [CrossRef]

- Abusoglu, A.; Kanoglu, M. Exergetic and thermoeconomic analyses of diesel engine powered cogeneration. Part 1–Formulations. Appl. Therm. Eng. 2009, 29, 234–241. [Google Scholar] [CrossRef]

- Gungor, A.; Erbay, Z.; Hepbasli, A. Exergoeconomic analyses of a gas engine driven heat pump drier and food drying process. Appl. Energy 2011, 88, 2677–2684. [Google Scholar] [CrossRef]

- Fu, J.Q.; Liu, J.P.; Feng, R.H. Energy and exergy analysis on gasoline engine based on mapping characteristics experiment. Appl. Energy 2013, 102, 622–630. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, F.; Zhao, C.; Zhang, F.; Zhao, Z.; Zhang, Z.; Xie, Z.; Wang, H. An Experimental Investigation on the Combustion and Heat Release Characteristics of an Opposed-Piston Folded-Cranktrain Diesel Engine. Energies 2015, 8, 6365-6381. https://doi.org/10.3390/en8076365

Ma F, Zhao C, Zhang F, Zhao Z, Zhang Z, Xie Z, Wang H. An Experimental Investigation on the Combustion and Heat Release Characteristics of an Opposed-Piston Folded-Cranktrain Diesel Engine. Energies. 2015; 8(7):6365-6381. https://doi.org/10.3390/en8076365

Chicago/Turabian StyleMa, Fukang, Changlu Zhao, Fujun Zhang, Zhenfeng Zhao, Zhenyu Zhang, Zhaoyi Xie, and Hao Wang. 2015. "An Experimental Investigation on the Combustion and Heat Release Characteristics of an Opposed-Piston Folded-Cranktrain Diesel Engine" Energies 8, no. 7: 6365-6381. https://doi.org/10.3390/en8076365