1. Introduction

LLC series resonant converters [

1,

2] are widely adapted to consumer or industrial electronics due to their inherent advantages over contending topologies. In the past, the LLC resonant converters were largely employed as an energy-efficient power supply for consumer electronics, such as large-screen TV sets and home appliances [

1,

3]. Recently, the LLC resonant converters find ever increasing applications to more sophisticated and bigger energy conversion systems, primarily due to the high efficiency of the converter. The LLC resonant converters are used as a battery charger [

4–

6] for energy storage systems, a bidirectional converter for dc power distribution systems [

7], a line level controller for solar power systems [

8], and a DC-to-DC converter for electric vehicles [

9].

More recently, the dynamic analysis and control design of the LLC resonant converters have also received increasing research attentions [

10–

14] because modern energy conversion systems demand good dynamic performance and high reliability for DC-to-DC converters. The purpose of this paper is to develop a new control scheme that could enhance the dynamic performance and reliability of LLC series resonant converters adopted to modern energy conversion systems.

In the aforementioned energy conversion applications, LLC resonant converters often confront wide variations in operational conditions. For example, LLC resonant DC-to-DC converters employed as an off-line power supply receive the input from a power factor corrected rectifier whose output voltage could vary substantially due to sagging and swelling in the line voltage.

It is well known [

1,

2,

15] that the small-signal dynamics of LLC resonant converters drift substantially as the operational condition is altered. For this case, the control scheme should be designed in consideration of potential changes in small-signal dynamics. The control should be designed in a manner, which consistently offers the desired dynamic performance for the entire operational range, regardless of possible changes in operational conditions.

LLC series resonant DC-to-DC converters are traditionally controlled by voltage mode control in which the output voltage alone is employed as the feedback signal. The performance of the conventional voltage mode control is directly influenced by potential changes in power stage dynamics. Accordingly, it is quite possible that a specific control design optimized at one particular operating point becomes less appropriate when the operational condition is varied.

This paper proposes a new current mode control scheme for LLC series resonant converters, which offers good closed-loop performance for the entire operational region, thereby resolving the problem of the conventional voltage mode control. The proposed control scheme employs an additional current feedback from the resonant tank network on top of the output voltage feedback. The purpose of the tank current feedback is to construct a composite feedback signal which is not influenced by potential changes in power stage dynamics. Accordingly, the proposed current mode control could retain desired closed-loop performance even in the presence of substantial fluctuations in operational environment.

The prime candidates for adapting the proposed control scheme are the LLC resonant converters whose operational conditions and environment could change widely. Typical examples are the off-line power supplies for consumer electronics, bidirectional converters for DC distribution systems, wide output voltage range chargers for energy storage systems, and wide load range DC-to-DC converters for electric vehicles.

First, the small-signal dynamics of LLC converters are presented to address the problem of the conventional voltage mode control. Second, the concept and principle of the proposed current mode control are illustrated. Then, some design considerations for the proposed current mode control are discussed and design procedures are formulated. Finally, the performance of the proposed current mode control is demonstrated in comparison with that of the conventional voltage mode control.

2. Operational Region, Small-Signal Dynamics and Limitation of Voltage Mode Control

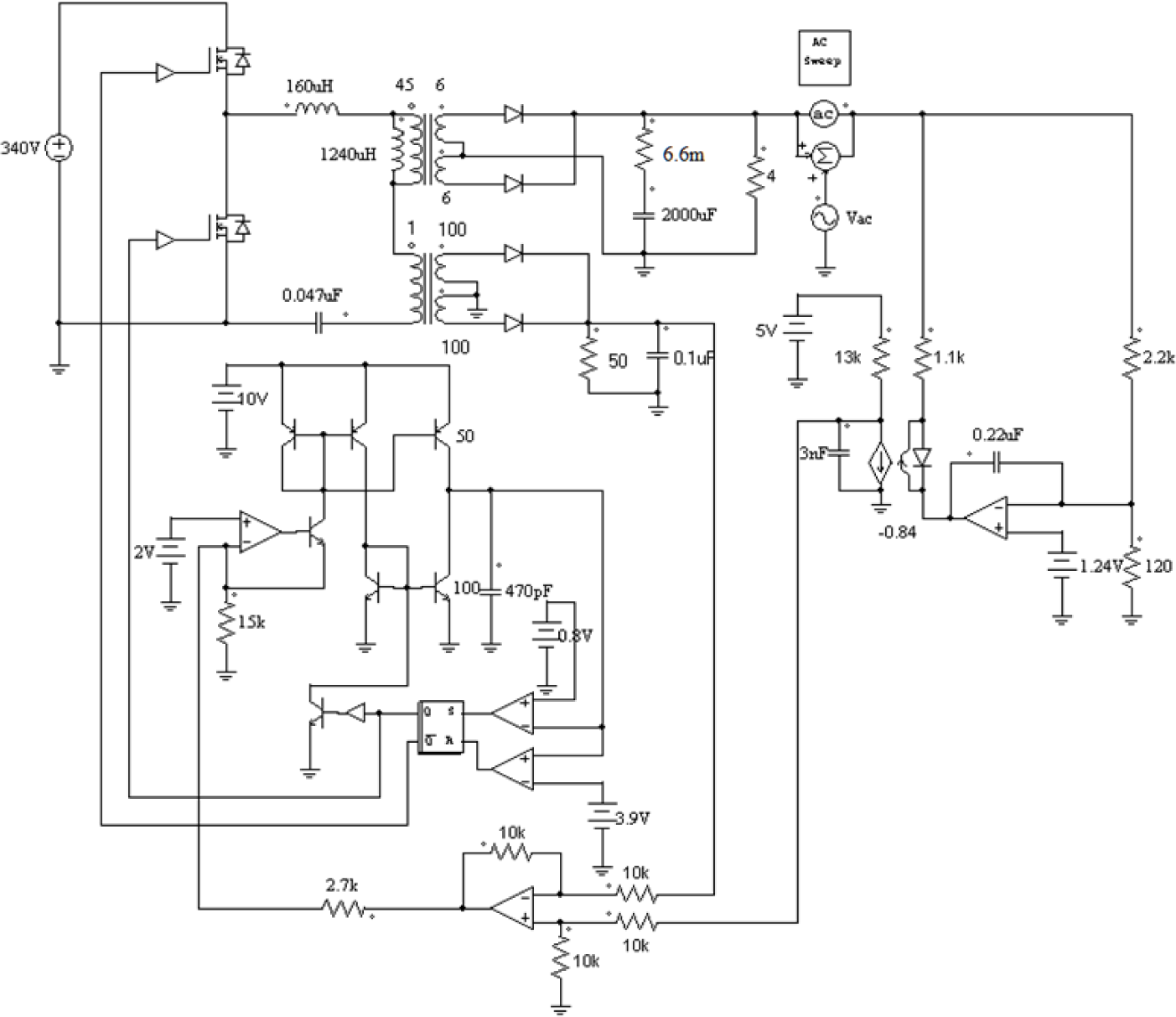

Figure 1 shows the circuit diagram of the experimental LLC converter employing the proposed current mode control. As a typical off-line power supply, the input voltage of the converter is varied between 340 V

< VS < 390 V, while the load current is changed between 1 A

< IO < 6 A. In addition to an optocoupler-isolated voltage feedback circuit, a current feedback circuit is configured using a center-tapped current transformer and rectifier circuit, in order to exploit the tank current as an integral part of the feedback signal. The functional block in

Figure 1 represents the voltage controlled oscillator (VCO).

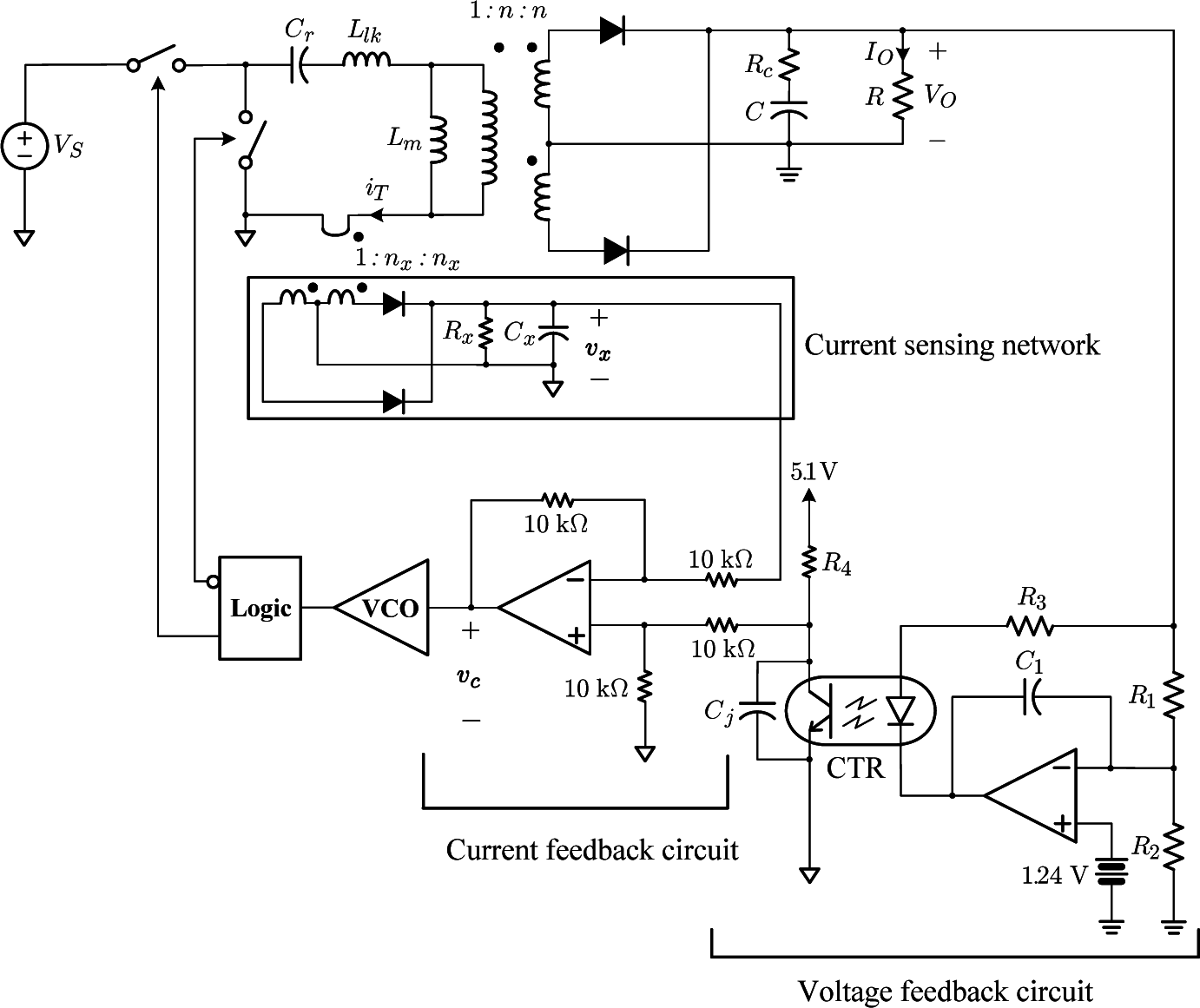

Figure 2 shows a functional block diagram of the current-mode controlled LLC converter.

Table 1 shows the expressions and parameters of the gain blocks defined in

Figure 2.

2.1. Operational Region

Figure 3a shows a family of the input-to-output curves of the experimental LLC converter, each with a different load condition. The frequency

denotes the short-circuit resonant frequency of the LLC tank [

1]. On the other hand, the frequency

is the open-circuit resonant frequency of the LLC tank. For the given input and load specifications, the operational region of the converter can be defined on the voltage gain curves, as highlighted in blue in

Figure 3a.

Figure 3b shows the expanded view of the operational region in which all the operating points of the LLC converter could locate for the given input and load conditions. On the operational region, the four extreme operating points, Points A, B, C, and D, are shown; Point A: 340 V/6 A, Point B: 390 V/6 A, Point C: 340 V/1 A, and Point D: 390 V/1 A.

For the given LLC converter, the operating point normally lies on the curve between Point A and Point B: VS = 340 − 390 V with IO = 6 A. Accordingly, the dynamic analysis and control design will be mainly focused on Point A and Point B. Nonetheless, the converter performance will be evaluated for the entire operational region.

2.2. Power Stage Dynamics

The earlier studies [

1,

2,

15] proved that small-signal dynamics of LLC converters vary substantially as operational conditions are altered. The major result of these analyses is shown in

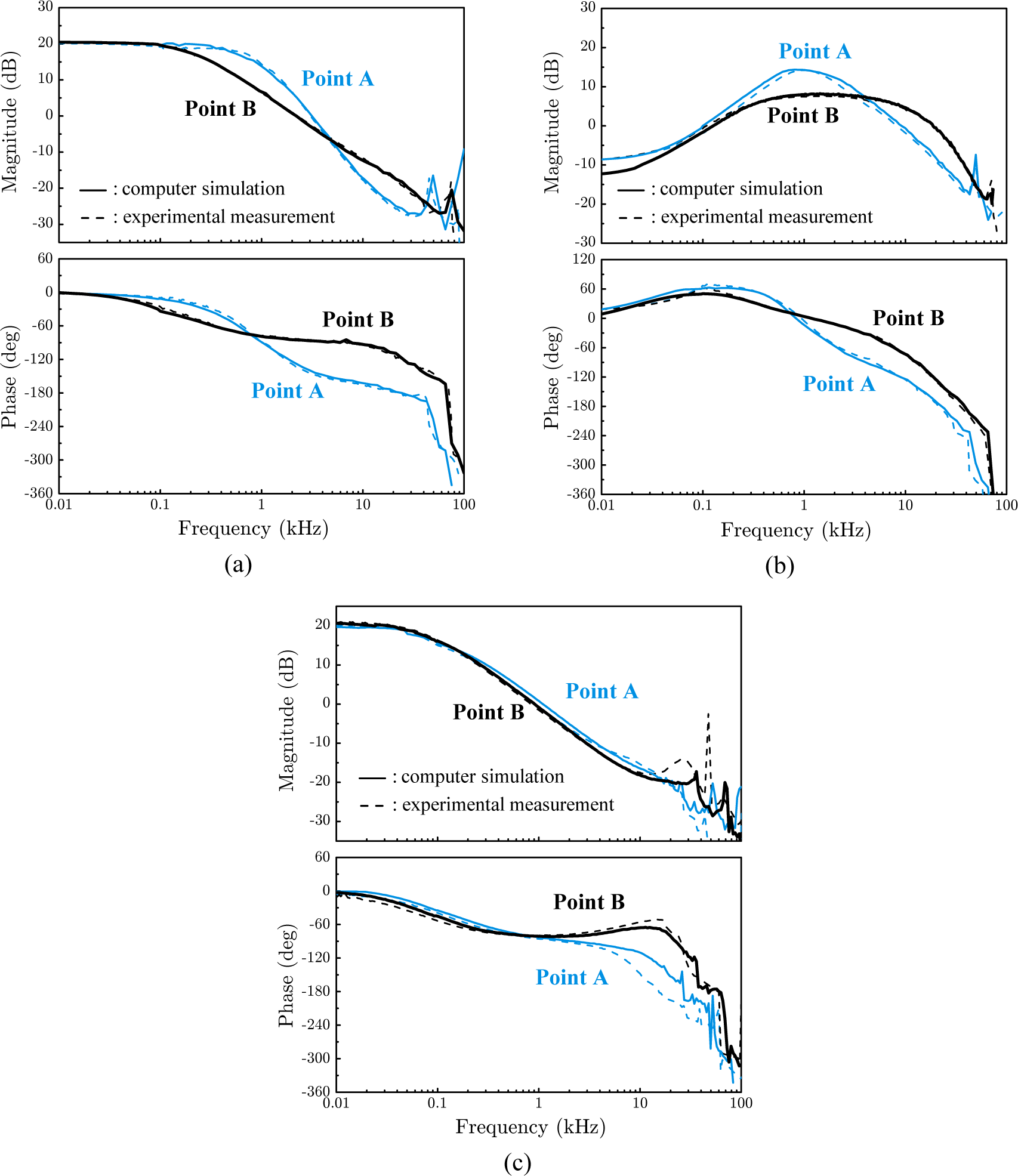

Figure 4 in conjunction with the small-signal dynamics of the experimental LLC converter.

Figure 4a depicts the pole/zero trajectory of the frequency-to-output transfer function with respect to the input voltage variation. The trajectory portraits the locations of the poles and zero as the input voltage decreases from

VS = 390 V, represented by Point B in

Figure 4, to

VS = 340 V, denoted as Point A, while delivering the load current of

IO = 6 A. Detailed analyses for the locations of poles and zero at Point A and Point B were given in [

1,

2,

15].

The sensitivity of the power stage dynamics can readily be illustrated using the control-to-output transfer function. For this purpose,

Figure 4b shows the control-to-output transfer function of the experimental LLC converter, evaluated not employing the proposed resonant tank current feedback. The transfer function is expressed as

where

Fvco is the VCO gain and

is the frequency-to-output voltage transfer function. The control-to-output transfer functions

Gvco(

s), along with all the forthcoming power stage and closed-loop transfer functions, are evaluated at Point A and Point B. In the transfer function analysis, the time-domain simulation method [

1,

2,

15,

16] is used for theoretical predictions. Theoretical predictions are then presented in parallel with experimental measurements. The PSIM [

17] model used for the time-domain simulation method is given in

Appendix.

The transfer function exhibits notable changes, in the exact same manner as predicted from the pole/zero trajectory in

Figure 4a. It is observed that Point B has a single pole ω

pl at low frequencies and shows the first-order system behavior from low- to mid-frequencies. In contrast, Point A reveals the second-order behavior with rapid-declining phase characteristics due to the two neighboring poles,

and ω

sp1. Detailed discussions about the small-signal dynamics are given in [

1,

2,

15].

2.3. Limitation of Conventional Voltage Mode Control

In conventional voltage mode control, the output voltage alone is employed as the feedback signal. Accordingly,

Gvco(

s) shown in

Figure 4b is used as the basis for the voltage feedback design. For this case, the loop gain and other closed-loop transfer functions will be directly affected by the changes in

Gvco(

s).

One practical design strategy at the presence of wide variations in

Gvco(

s) is to design the voltage compensation for the worst-case operational condition. Point A exhibits the second-order behavior with unfavorable phase characteristics and thus can be considered as the worst-case condition. As demonstrated in [

1], a three-pole two-zero compensation can be employed to achieve stable operation with good dynamic performance at Point A. However, the resulting design becomes overly conservative and offers only limited performance at other operating points than Point A.

3. Principle of Current Mode Control

The basic concept of current mode control is to employ an additional feedback from the tank circuit variable to construct the composite feedback signal that would not be affected by potential changes in power stage dynamics. This aim can be accomplished by adapting the two-loop control scheme [

16]. When one tank circuit variable is applied as the inner feedback signal and subsequently mixed with the outer voltage feedback signal, the composite feedback signal will be generated, which will largely remain unaffected by potential drifts in power stage dynamics. The theoretical validation of this statement will be given later in this section.

Among the tank circuit variables, the current waveforms are easier to sense and process than the voltage waveforms. Thus, one of the current waveforms is commonly employed as the second feedback signal in the two-loop control scheme [

16]. Any current waveform in the tank circuit can be exploited, as far as it carries the tank circuit dynamics. The possible candidates will be the switch current, diode current, and tank current. In the proposed current mode control, the tank current feedback signal is added to the optocoupler-isolated voltage feedback signal to generate the composite feedback signal. The reasons for this selection are as follows.

The switch current is a half sinusoid and should be low-pass filtered to yield a continuous current feedback signal. The half sinusoid requires a low pass filter whose corner frequency is located at lower frequencies. The resulting filter would incur an undesirable low-frequency phase delay to the current feedback signal.

The diode current is only available at the secondary side of the transformer. The diode current feedback signal, extracted from the secondary side, should be transmitted to the primary side with isolation. This would complicate the feedback circuit implementation.

The tank current is a full sinusoid, which is easier to rectify and filter. Also, the tank current is sensed at the primary side of the transformer and directly mixed with the voltage feedback signal.

The control-to-output transfer function, evaluated with the resonant tank current feedback, is determined from

Figure 2where

Hi(

s) is the transfer function of the current feedback circuit and

is the frequency-to-tank current transfer function.

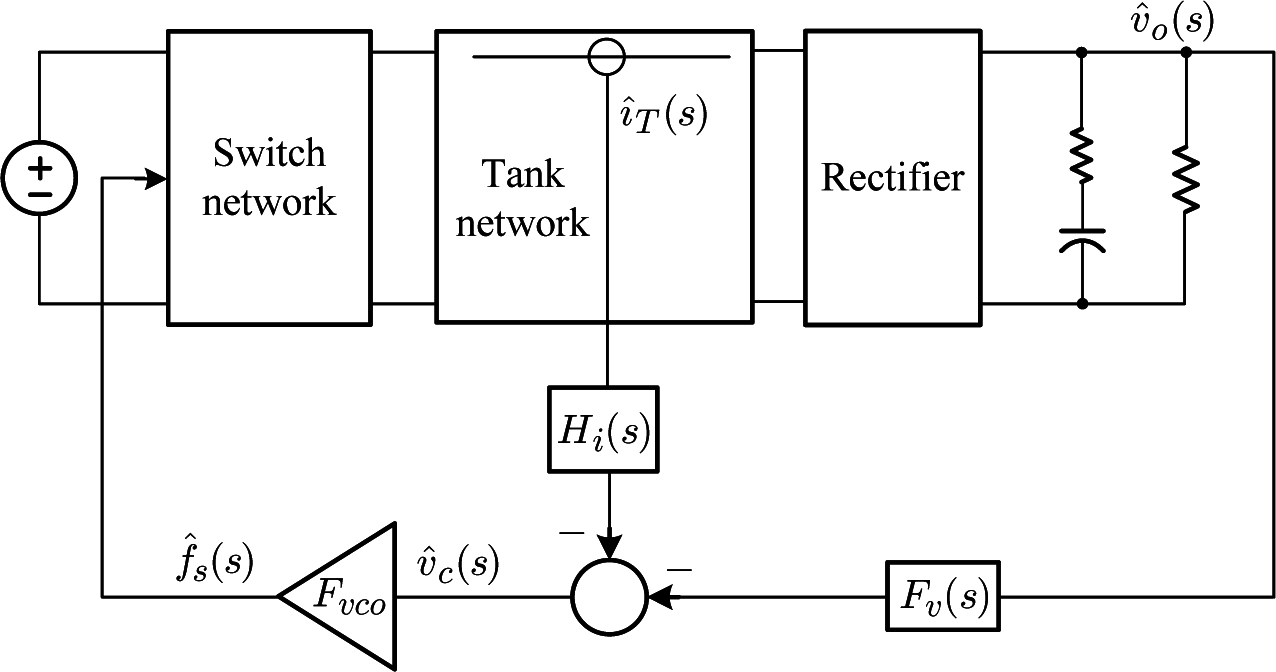

Equation (2) is approximated to

assuming the condition

, which is true over most frequency range of practical importance.

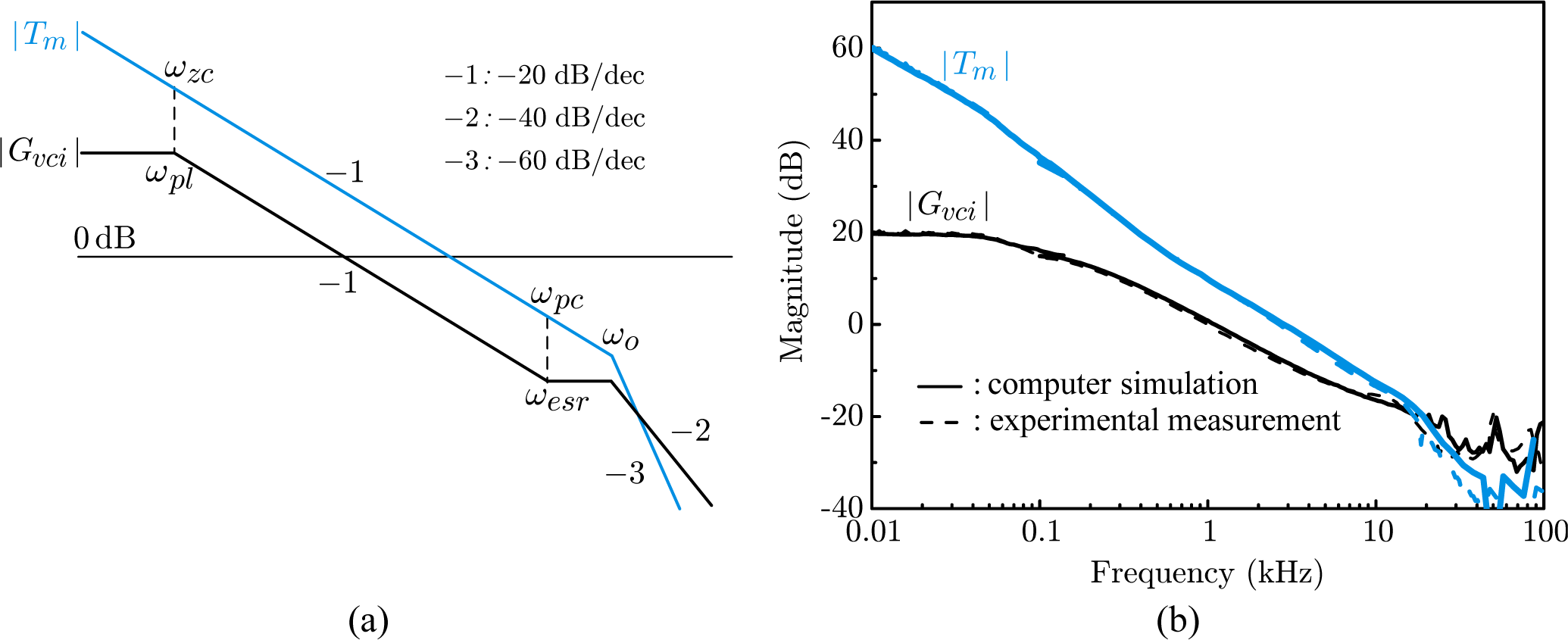

Figure 5 shows the Bode plots of the transfer functions involved with

Equation (3).

Figure 5a shows the numerator of

Equation (3), which corresponds to the control-to-output transfer function,

, in case of the conventional voltage mode control.

Figure 5b shows the denominator of

Equation (3), which corresponds to the gain of the inner current loop created by the tank current feedback. While

Figure 5b shows wide variations at the two different operating points, it can be observed that the transition pattern of

Figure 5b closely resembles the transition pattern of

Figure 5a. This is because any drift in power stage dynamics will commonly propagate into both

and

and therefore will exert the same influence on the numerator and denominator of

Equation (3). Accordingly, the consequential effects of any changes in power stage dynamics will be canceled each other in

Equation (3) and the control-to-output transfer function will remain mostly invariant.

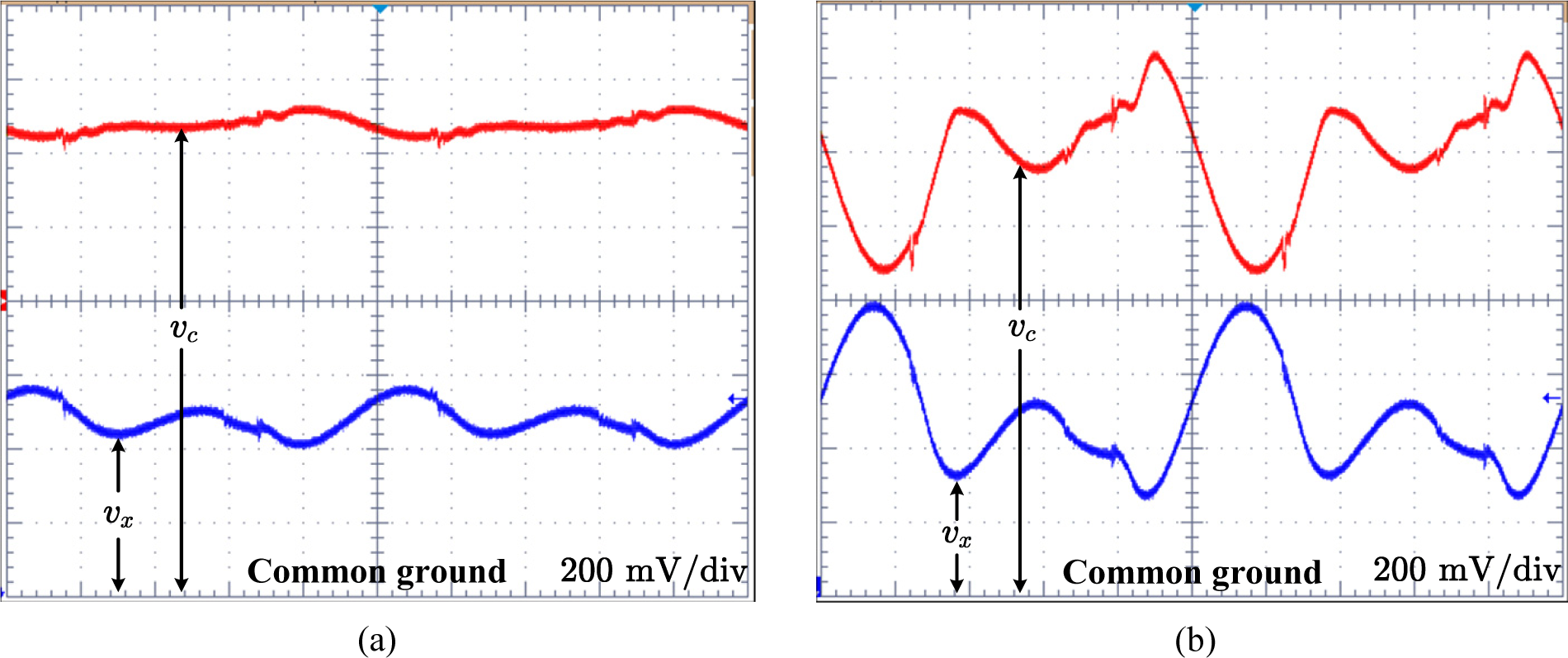

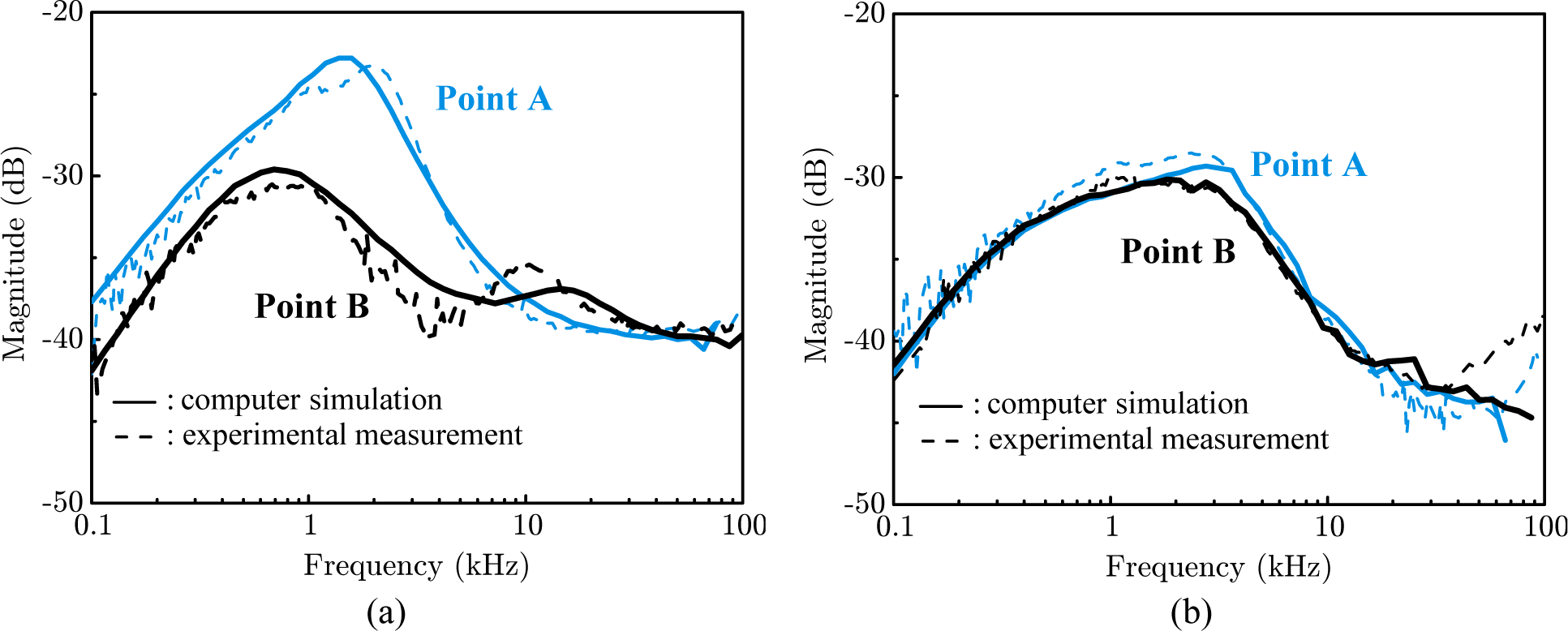

Figure 5c shows the control-to-output transfer function at the two different operating points. The experimental magnitude plot at Point B shows a peaking at the frequency near 75 kHz. This frequency corresponds to the switching frequency of the prototype converter at Point B, as demonstrated in

Figure 3b. The switching noise produced the peaking in the magnitude measurement. The transfer function indeed shows consistent characteristics for wide frequency range. The benefit of the tank current feedback is clearly seen when

Figure 5c is compared with

Figure 5a. The control-to-output transfer function remains mostly unchanged for wide frequency range and the voltage feedback compensation thus can be designed for optimal performance for the entire operational range.

6. Conclusions

This paper proposed a new current mode control scheme for LLC series resonant DC-to-DC converters. Using the additional feedback from the resonant tank current, the proposed control scheme effectively nullifies the consequential effects of possible changes in power stage dynamics, and therefore consistently provides desired closed-loop performance for the entire operational range of 340 V < VS < 390 V and 1 A < IO < 6 A.

The new current mode control outperformed the conventional voltage mode control and offered nearly the same loop gain characteristics and output impedance characteristics at the two extreme operating points. In addition, current mode control provided some improvements in the step load response. This signifies that the converter always retains the improved performance, as far as it remains in the given operational region.

This paper presented the design guidelines for the proposed current mode control scheme. The procedures for both the current feedback circuit design and voltage feedback compensation are formulated. While the LLC series resonant converter is considered in the paper, the proposed control scheme can be adapted to all types of resonant power converters as a viable substitute for the conventional voltage mode control that provides only limited performance.