Analysis and Design of a Permanent Magnet Bi-Stable Electro-Magnetic Clutch Unit for In-Wheel Electric Vehicle Drives

Abstract

:1. Introduction

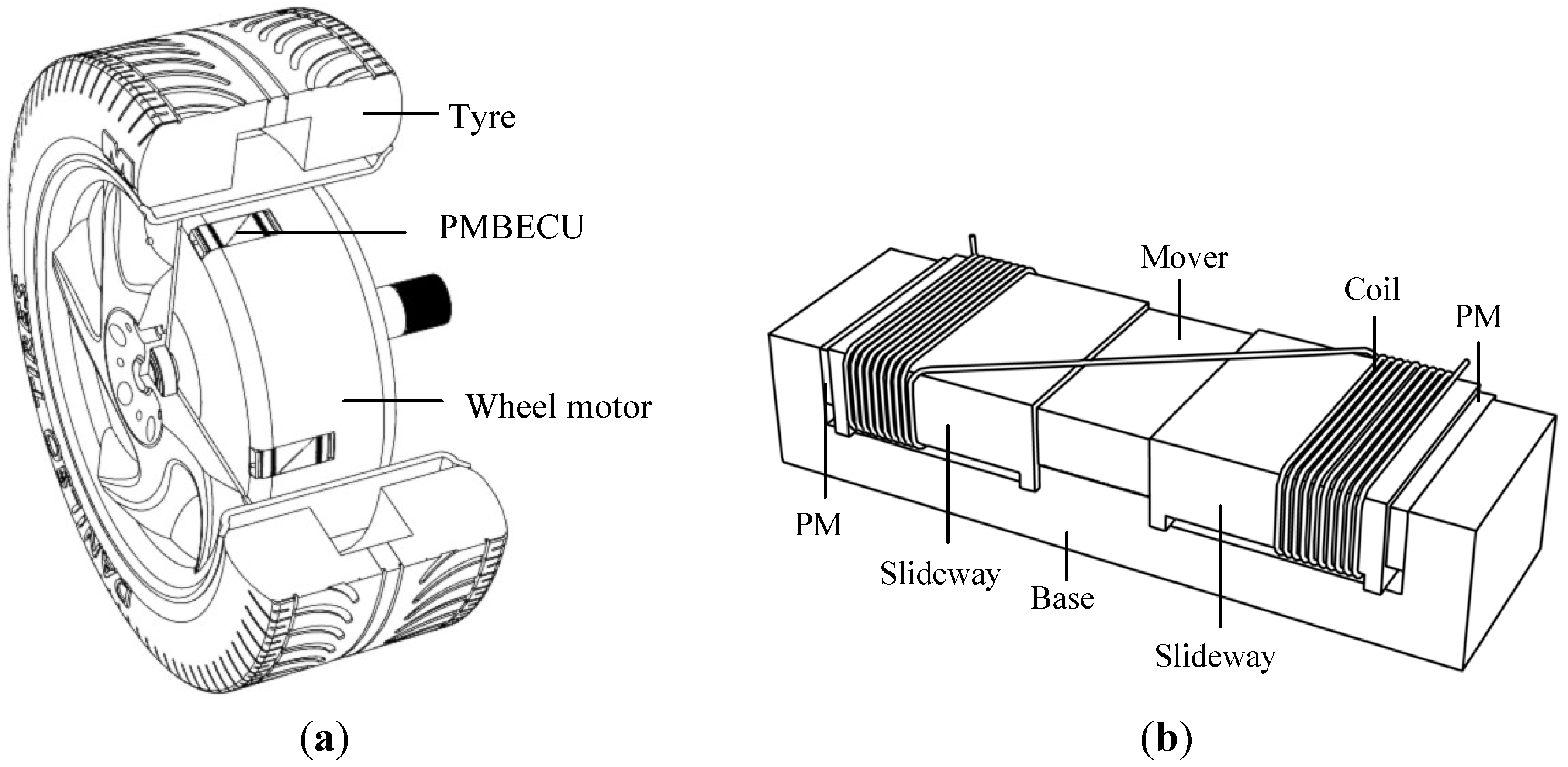

2. Operation Principle

3. Electromagnetic Design

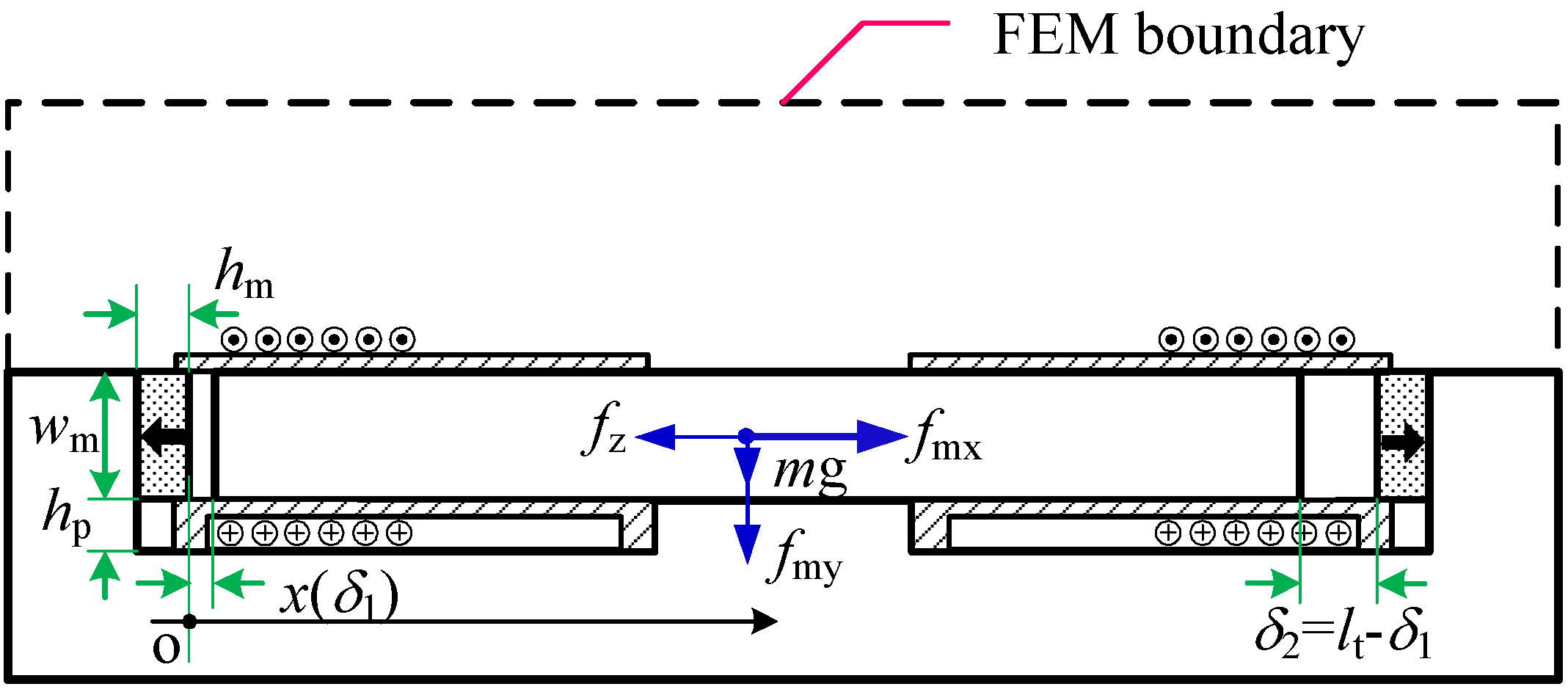

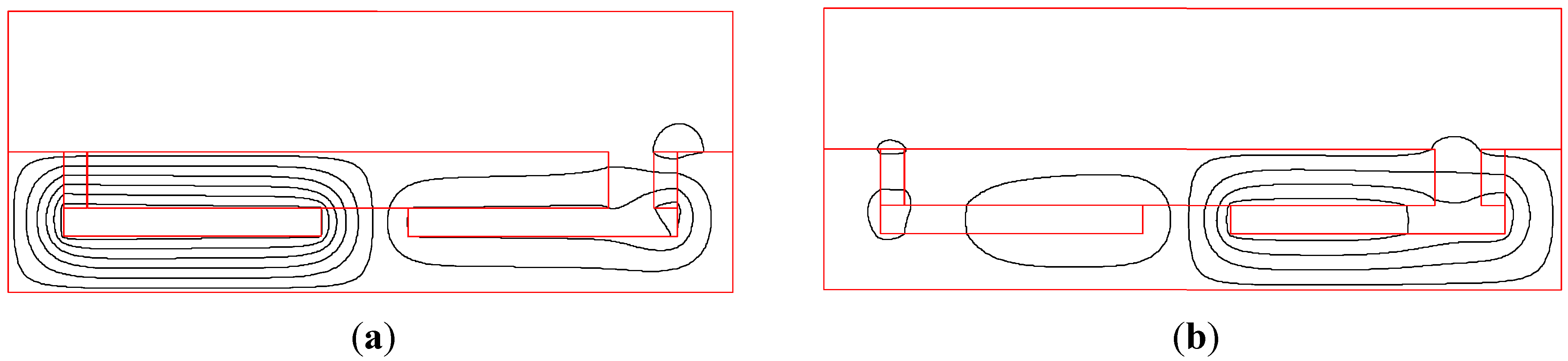

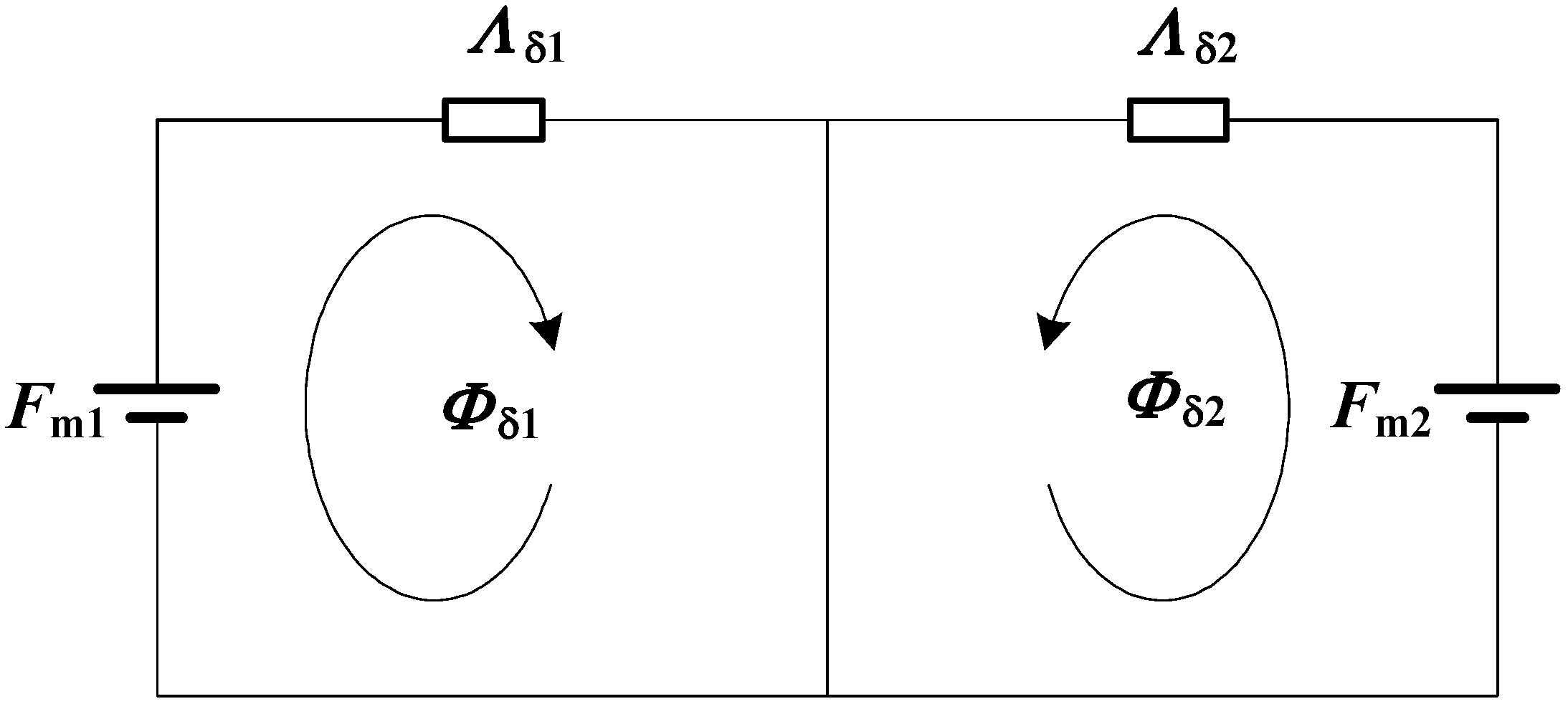

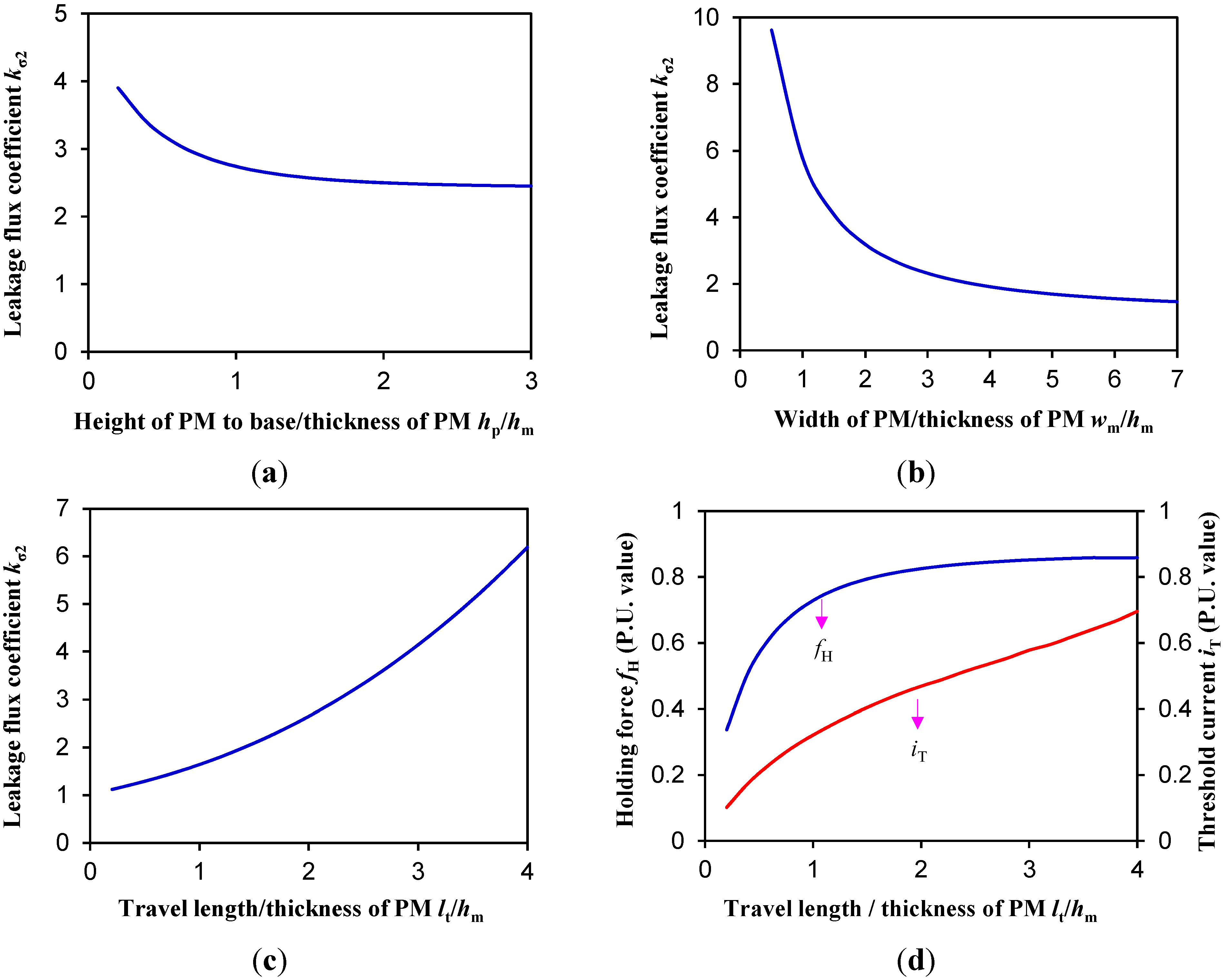

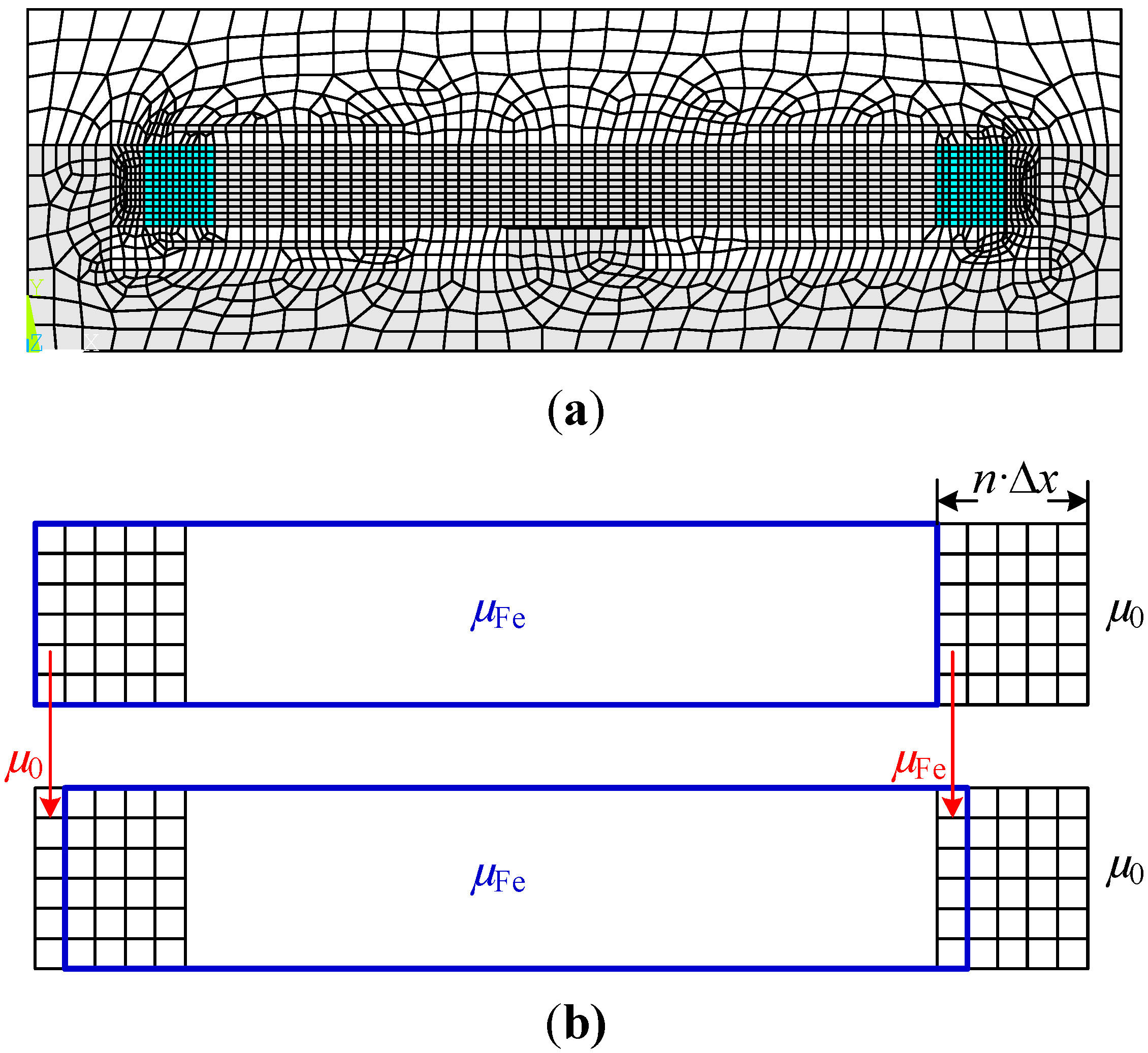

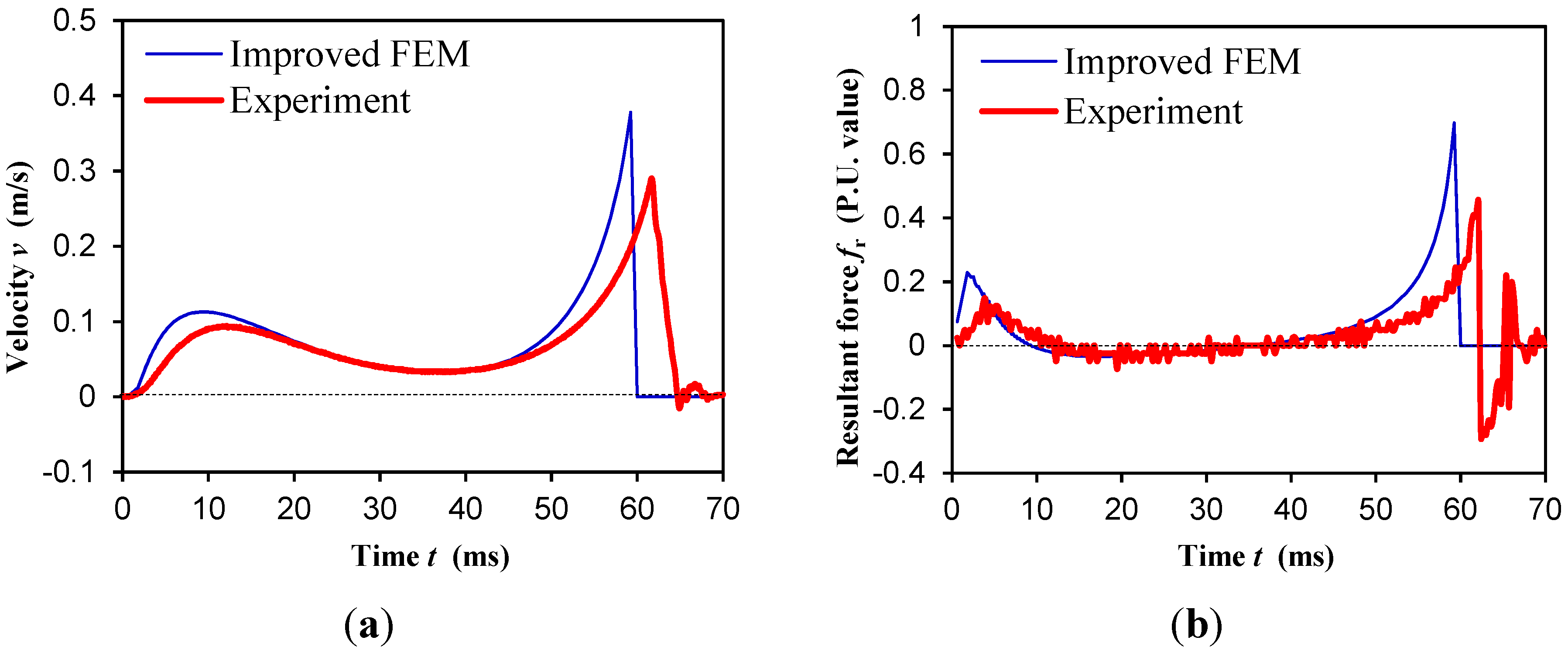

3.1. Magnetic Circuit Model

3.2. Main Structure Parameters Design

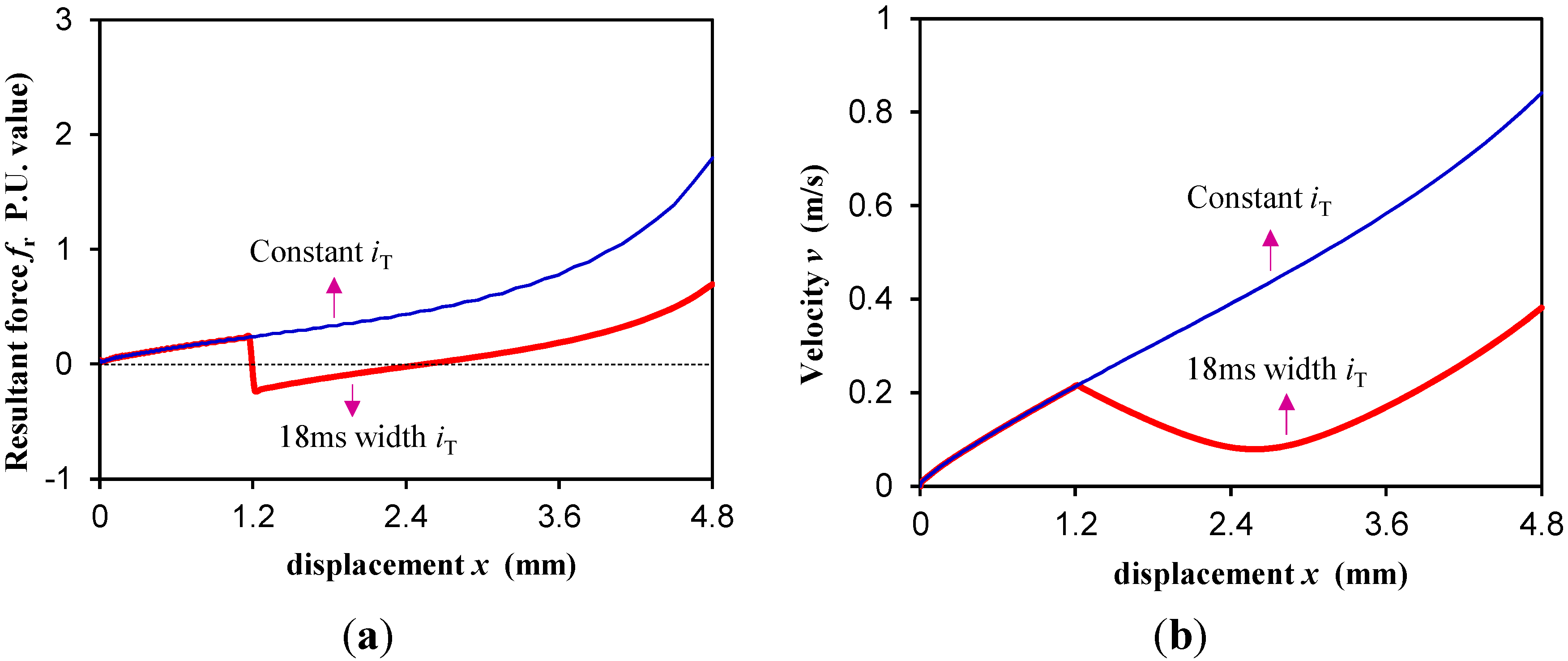

4. Dynamics Analysis

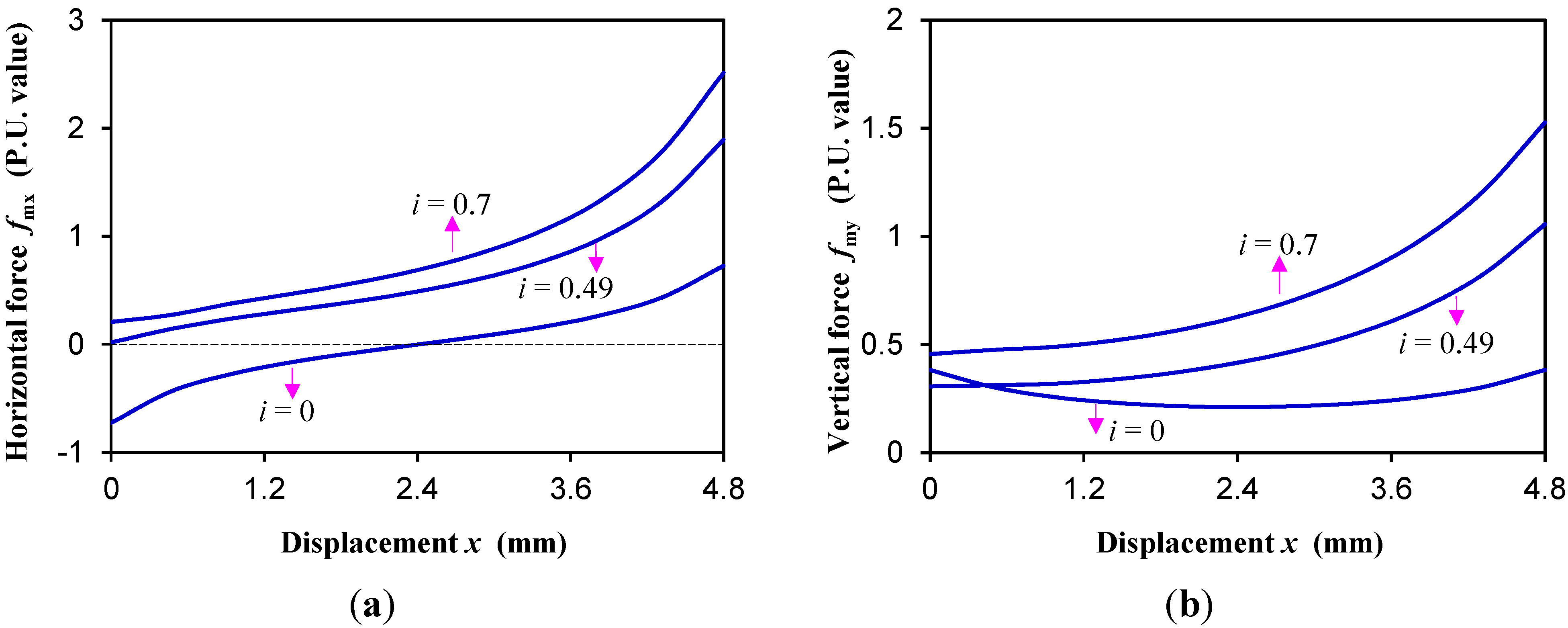

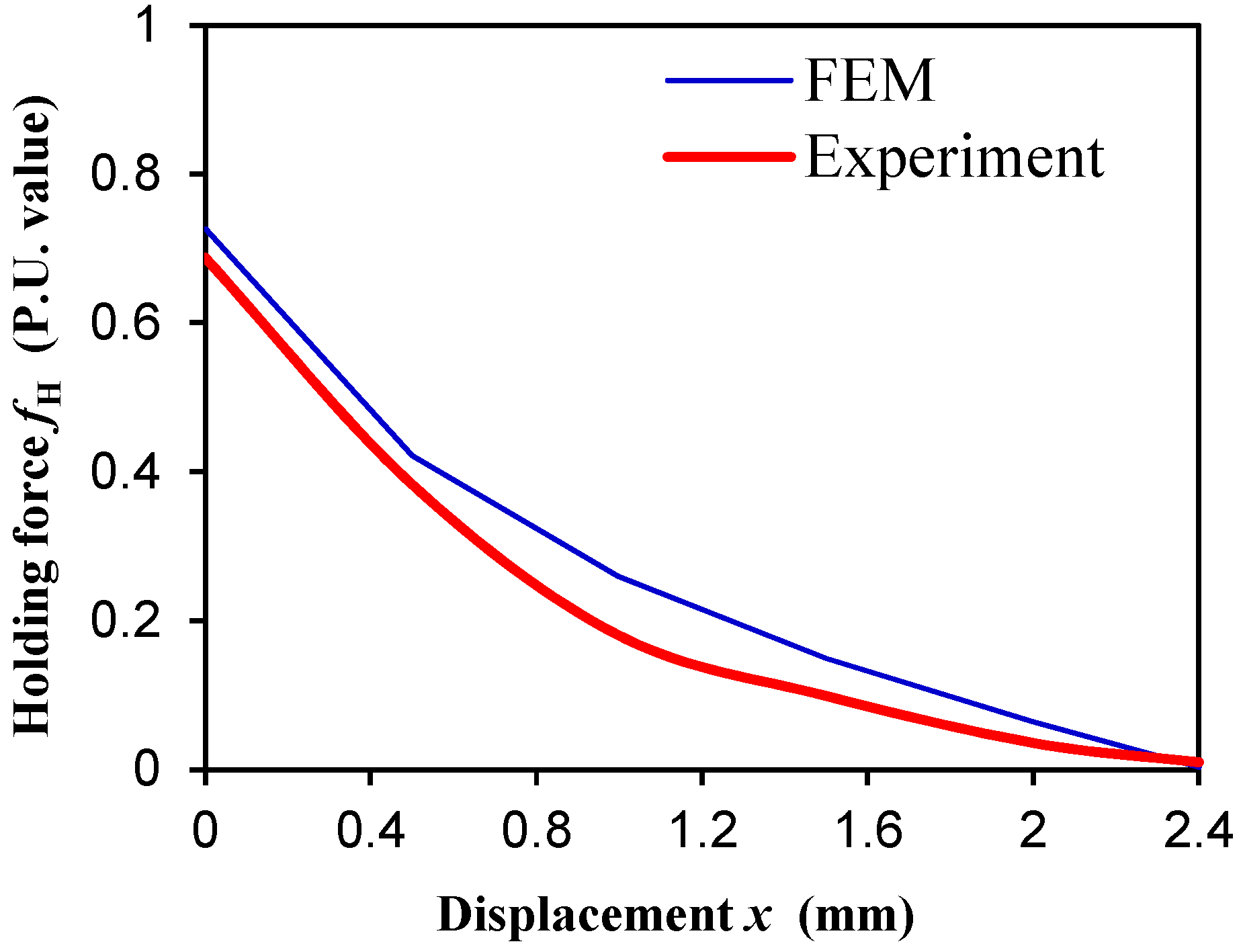

4.1. Electromagnetic Characteristics

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Thickness of PM hm | 2.5 mm | Width of base wb | 80 mm |

| Width of PM wm | 6 mm | Remanence of PM Br | 0.4 T |

| Length of PM lm | 20 mm | Coercivity of PM Hc | 318 kA/m |

| Height of PM to base hp | 3 mm | Turns of coil N | 60 |

| Travel length lt | 4.8 mm | Mass of mover m | 56 g |

4.2. Dynamics Equations and Analysis Method

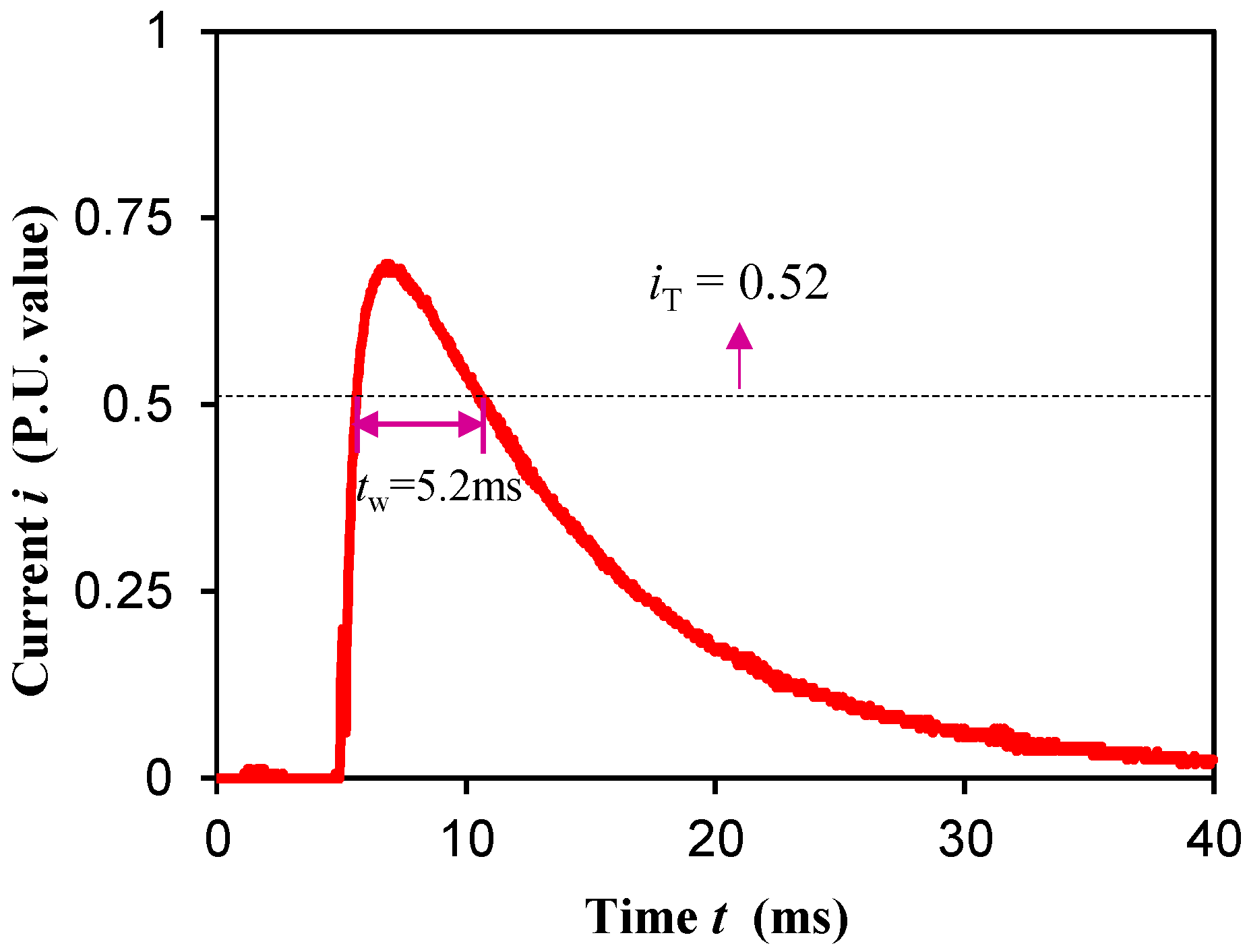

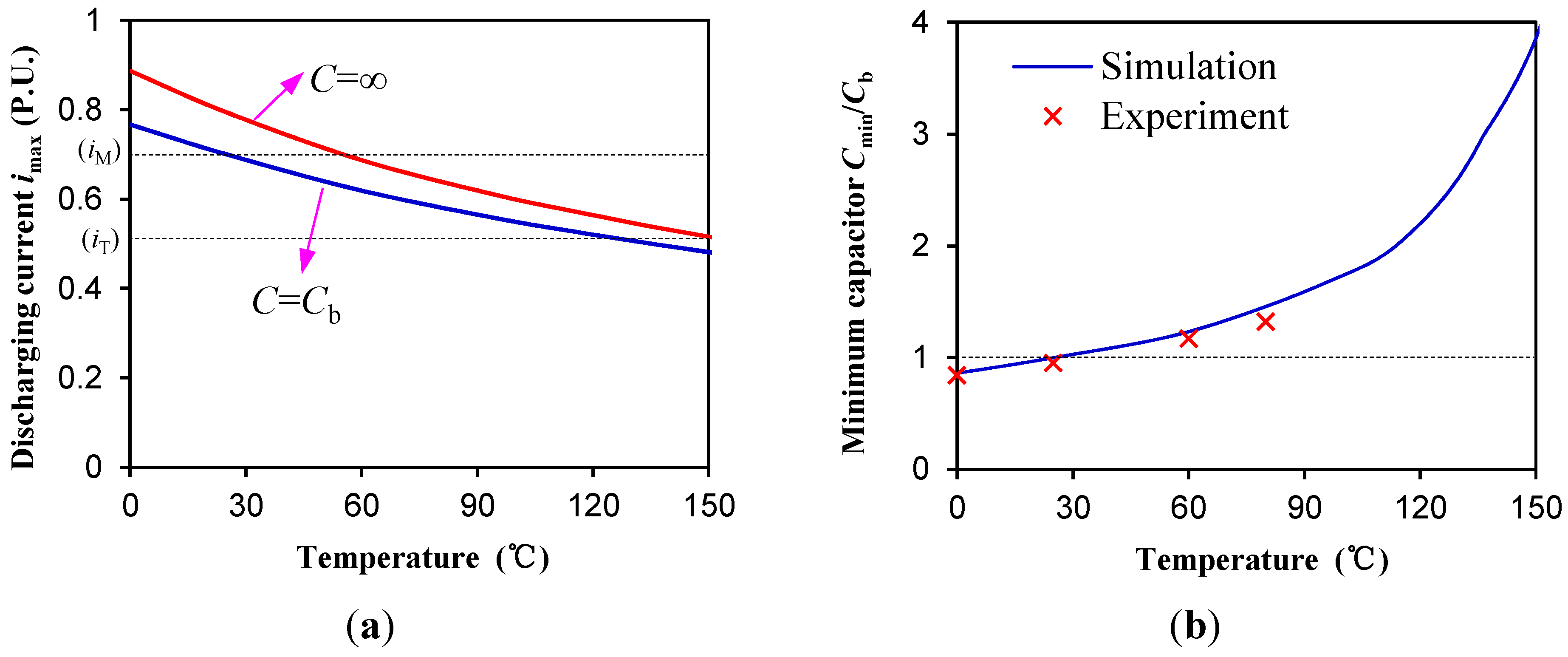

4.3. Minimum Driving Pulse Width

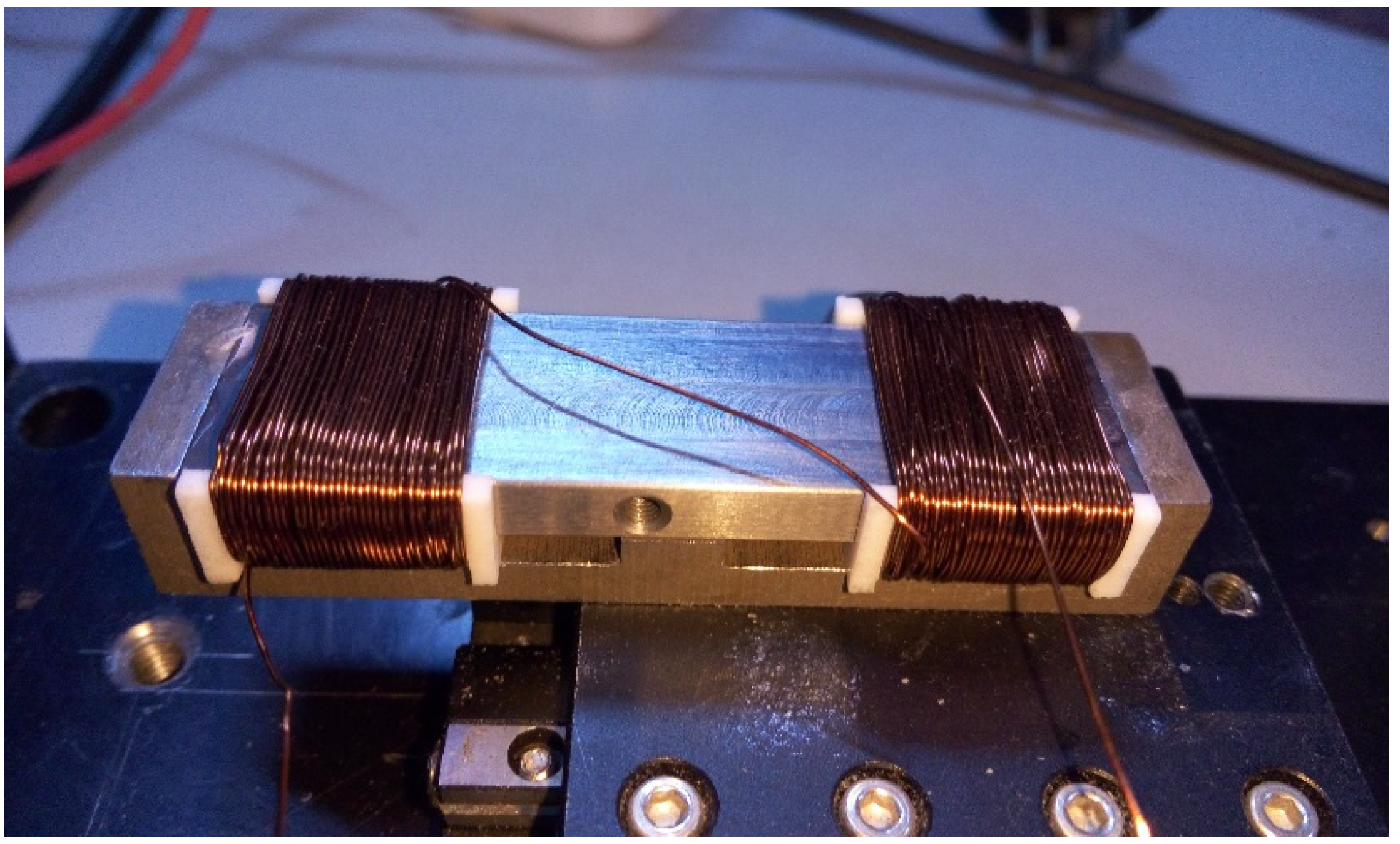

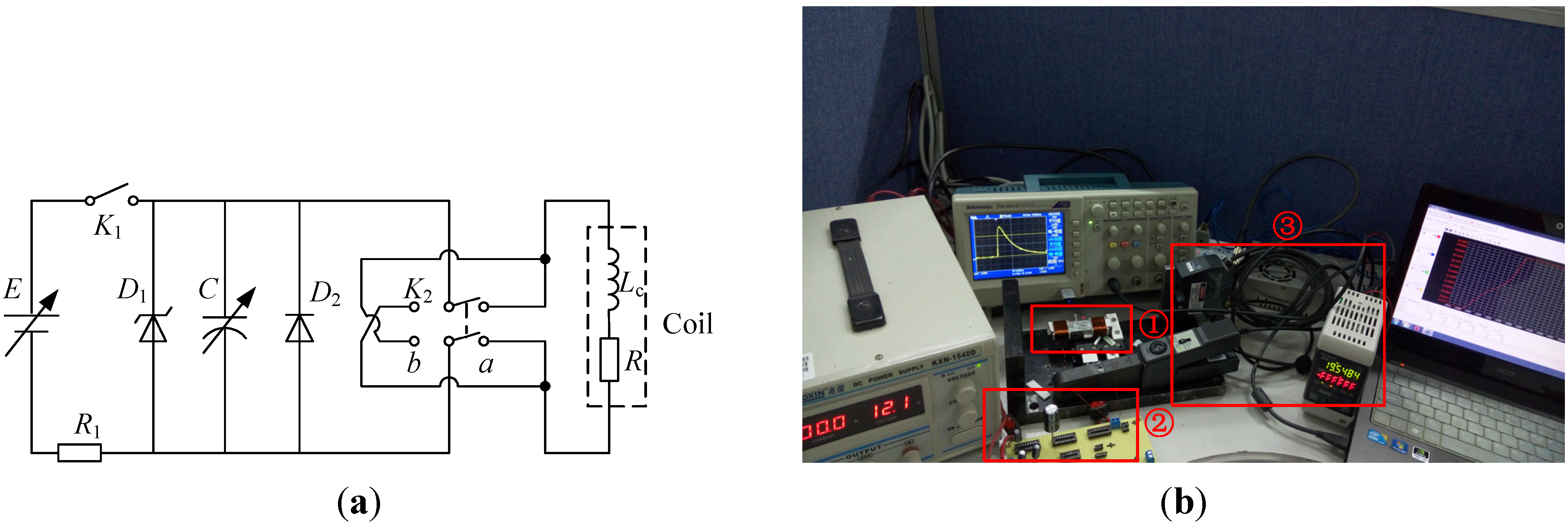

5. Experimental Validation

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chan, C.C.; Bouscayrol, A.; Chen, K.Y. Electric, hybrid, and fuel-cell vehicles: Architectures and modeling. IEEE Trans. Veh. Technol. 2010, 59, 589–598. [Google Scholar] [CrossRef]

- Chau, K.T.; Chan, C.C.; Liu, C.H. Overview of permanent-magnet brushless drives for electric and hybrid electric vehicles. IEEE Trans. Ind. Electron. 2008, 55, 2246–2257. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.; Liu, C.H.; Chau, K.T. A magnetless axial-flux machine for range-extended electric vehicles. Energies 2014, 7, 1483–1499. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.D.; Sul, S.K.; Cho, H.S.; Lee, J.M. Advanced gear-shifting and clutching strategy for a parallel-hybrid vehicle. IEEE Ind. Appl. Mag. 2000, 6, 26–32. [Google Scholar]

- Rahman, K.M.; Patel, N.R.; Ward, T.G.; Nagashima, J.M.; Caricchi, F.; Crescimbini, F. Application of direct-drive wheel motor for fuel cell electric and hybrid electric vehicle propulsion system. IEEE Trans. Ind. Appl. 2006, 42, 1185–1192. [Google Scholar] [CrossRef]

- Sakai, S.; Sado, H.; Hori, Y. Motion control in an electric vehicle with four independently driven in-wheel motors. IEEE Trans. Mech. 1999, 41, 9–16. [Google Scholar] [CrossRef]

- Ifedi, C.J.; Mecrow, B.C.; Brockway, S.T.M.; Boast, G.S.; Atkinson, G.J.; Perovic, D.K. Fault-Tolerant in-wheel motor topologies for high-performance electric vehicles. IEEE Trans. Ind. Appl. 2013, 49, 1269–1278. [Google Scholar] [CrossRef]

- Yang, Y.P.; Liu, J.J.; Wang, T.J.; Kuo, K.C.; Hsu, P.E. An electric gearshift with ultracapacitors for the power train of an electric vehicle with a directly driven wheel motor. IEEE Trans. Veh. Technol. 2007, 56, 2421–2431. [Google Scholar] [CrossRef]

- Usami, Y. Controller for Electric Vehicle. U.S. Patent 5896283, 20 April 1999. [Google Scholar]

- Kasten, R.E.; Newendorp, B.C.; Lemmen, N.F. Variable Current Limit Control for Vehicle Electric Drive System. U.S. Patent 6492785, 10 December 2002. [Google Scholar]

- Gu, C.L. Comprehensive review of electric vehicle PM wheel motors. MICROMOTORS (China) 2008, 41, 56–59. [Google Scholar]

- Xiong, P.; Gu, C.L. Optimal idling speed control of direct-drive electric vehicle launch in consideration of drive comfort. In Proceedings of the 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 21–24 October 2014; pp. 225–228.

- Wu, D. Special Electromagnetic Clutch for a Novel Type of Transverse Flux Permanent Magnet Motor Direct Drive. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, May 2011. [Google Scholar]

- Chen, L.; Xi, G.; Sun, J. Torque coordination control during mode transition for a series–parallel hybrid electric vehicle. IEEE Trans. Veh. Technol. 2012, 61, 2936–2949. [Google Scholar] [CrossRef]

- Camilleri, R.; Armstrong, P.; Ewin, N.; Richardson, R.; Howey, D.A.; McCulloch, M.D. The value of a clutch mechanism in electric vehicles. In Proceedings of the Conference of EVS27, Barcelona, Spain, 17–20 November 2013; pp. 1–11.

- Balau, A.E.; Caruntu, C.F.; Lazar, C. Simulation and control of an electro-hydraulic actuated clutch. Mech. Syst. Signal Process. 2011, 25, 1911–1922. [Google Scholar] [CrossRef]

- Gauthier, J.P.; Micheau, P.; Rioux, R. Vehicle Clutch Control Method. U.S. Patent 8,744,709, 3 June 2014. [Google Scholar]

- Ando, J.; Tsuda, T.; Ando, H.; Niikawa, Y.; Suzuki, K. Development of third-generation electronically controlled AWD coupling with new high-performance electromagnetic clutch. SAE Int. 2014, 7, 882–887. [Google Scholar] [CrossRef]

- Boules, N.M. Design analysis of electromagnetic particle clutch. In Proceedings of the Conference Record of the 1994 IEEE Industry Applications Society Annual Meeting, Denver, CO, USA, 2–6 October 1994; pp. 357–360.

- Duan, G.H. Clutch Structure Atlas; National Defence Industry Press: Beijing, China, 1985. [Google Scholar]

- Ohdachi, Y.; Kawase, Y.; Murakami, Y.; Inaguma, Y. Optimum design of dynamic response in automotive solenoid valve. IEEE Trans. Magn. 1991, 27, 5226–5228. [Google Scholar] [CrossRef]

- Kim, J.; Chang, J. A new electromagnetic linear actuator for quick latching. IEEE Trans. Magn. 2007, 43, 1849–1852. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Chen, X. Analysis of an E-core interior permanent magnet linear oscillating actuator. IEEE Trans. Magn. 2009, 45, 4384–4387. [Google Scholar] [CrossRef]

- Srairi, K.; Feliachi, M. Electromagnetic actuator behavior analysis using finite element and parametrization methods. IEEE Trans. Magn. 1995, 31, 3497–3499. [Google Scholar] [CrossRef]

- Kawase, Y.; Tatsuoka, S.; Yamaguchi, T.I. 3-D finite element analysis of operating characteristics of ac electromagnetic contactors. IEEE Trans. Magn. 1994, 30, 3244–3247. [Google Scholar] [CrossRef]

- Fang, S.H.; Lin, H.Y.; Ho, S.L. Transient co-Simulation of low voltage circuit breaker with permanent magnet actuator. IEEE Trans. Magn. 2009, 45, 1242–1245. [Google Scholar] [CrossRef]

- Woo, K.I.; Kwon, B.I. Characteristic analysis and modification of PM-type magnetic circuit breaker. IEEE Trans. Magn. 2004, 40, 691–694. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, W.; Gu, C.; Hu, X. Analysis and Design of a Permanent Magnet Bi-Stable Electro-Magnetic Clutch Unit for In-Wheel Electric Vehicle Drives. Energies 2015, 8, 5598-5612. https://doi.org/10.3390/en8065598

Cai W, Gu C, Hu X. Analysis and Design of a Permanent Magnet Bi-Stable Electro-Magnetic Clutch Unit for In-Wheel Electric Vehicle Drives. Energies. 2015; 8(6):5598-5612. https://doi.org/10.3390/en8065598

Chicago/Turabian StyleCai, Wanli, Chenglin Gu, and Xiaodong Hu. 2015. "Analysis and Design of a Permanent Magnet Bi-Stable Electro-Magnetic Clutch Unit for In-Wheel Electric Vehicle Drives" Energies 8, no. 6: 5598-5612. https://doi.org/10.3390/en8065598