Fast Charging Battery Buses for the Electrification of Urban Public Transport—A Feasibility Study Focusing on Charging Infrastructure and Energy Storage Requirements

Abstract

:1. Introduction

2. Material and Boundary Conditions

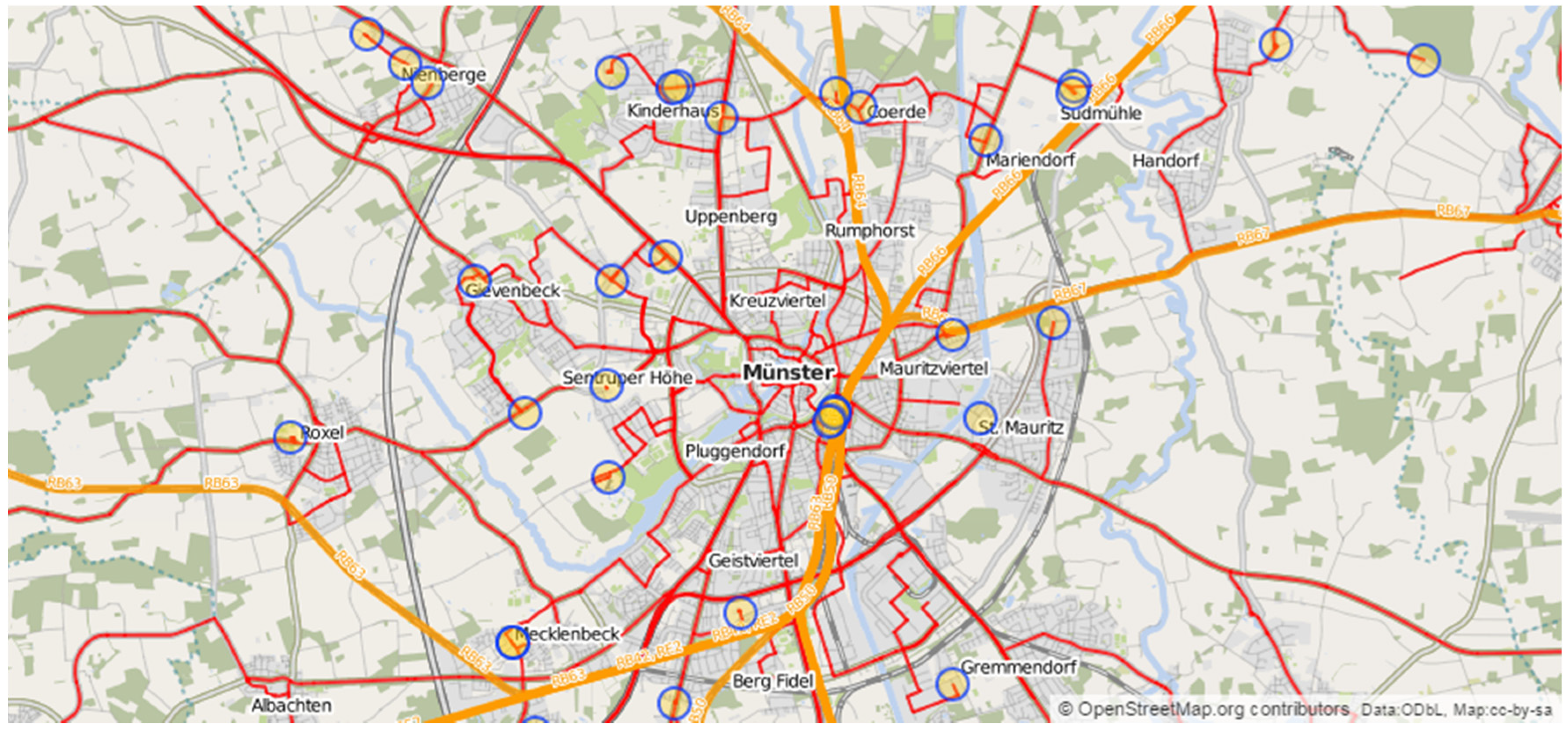

2.1. Bus Network

| Route | No. of service trip types | No. of service trips per day | Daily driving distance [km] | Route | No. of service trip types | No. of service trips per day | Daily driving distance [km] |

|---|---|---|---|---|---|---|---|

| 1 | 4 | 98 | 2,297 | 13 | 2 | 90 | 583 |

| 2 | 5 | 88 | 1,558 | 14 | 2 | 91 | 1,063 |

| 3 | 1 | 45 | 550 | 15 | 2 | 94 | 1,977 |

| 4 | 1 | 45 | 562 | 16 | 4 | 91 | 1,768 |

| 5 | 3 | 95 | 2,201 | 17 | 7 | 90 | 1,184 |

| 6 | 4 | 116 | 1,847 | 80 | 2 | 16 | 224 |

| 7 | 7 | 93 | 2,019 | 81 | 2 | 16 | 453 |

| 8 | 4 | 92 | 1,700 | 82 | 7 | 17 | 312 |

| 9 | 3 | 91 | 1,678 | 83 | 2 | 16 | 323 |

| 10 | 6 | 90 | 1,962 | 84 | 2 | 16 | 279 |

| 11 | 2 | 92 | 1,392 | 85 | 2 | 16 | 419 |

| 12 | 2 | 90 | 653 | ∑ | 76 | 1,588 | 27,003 |

2.2. Fast Charging Systems

| Supplier | System | Technology | Charging power |

|---|---|---|---|

| Proterra | FastFill | conductive | 500 kW |

| Bombardier | Primove | inductive | 200 kW |

| ABB | TOSA | conductive | 200 kW; 400 kW (15 s) |

| Conductix Wampfler | IPT charger | inductive | 60–180 kW |

2.3. Positioning of Fast Charging Infrastructure

3. Calculation Method

3.1. Energy Consumption

| Parameter | Value | Relevant for | Parameter | Value | Relevant for |

|---|---|---|---|---|---|

| Width | 2.55 m | Cross section area for air drag calculation | Efficiency of the traction system | 90% | Loss calculation |

| Height | 3.44 m | Cross section area for air drag calculation | Efficiency of the battery system | 95% | Loss calculation for charging and discharging |

| Maximum gross vehicle weight | 28 t | Rolling resistance, climbing resistance | Max auxiliary power | 9 kW | Energy consumption of the auxiliaries |

3.2. Vehicle Scheduling and Grid Load Profiles

3.3. Battery Capacity

4. Results and Discussion

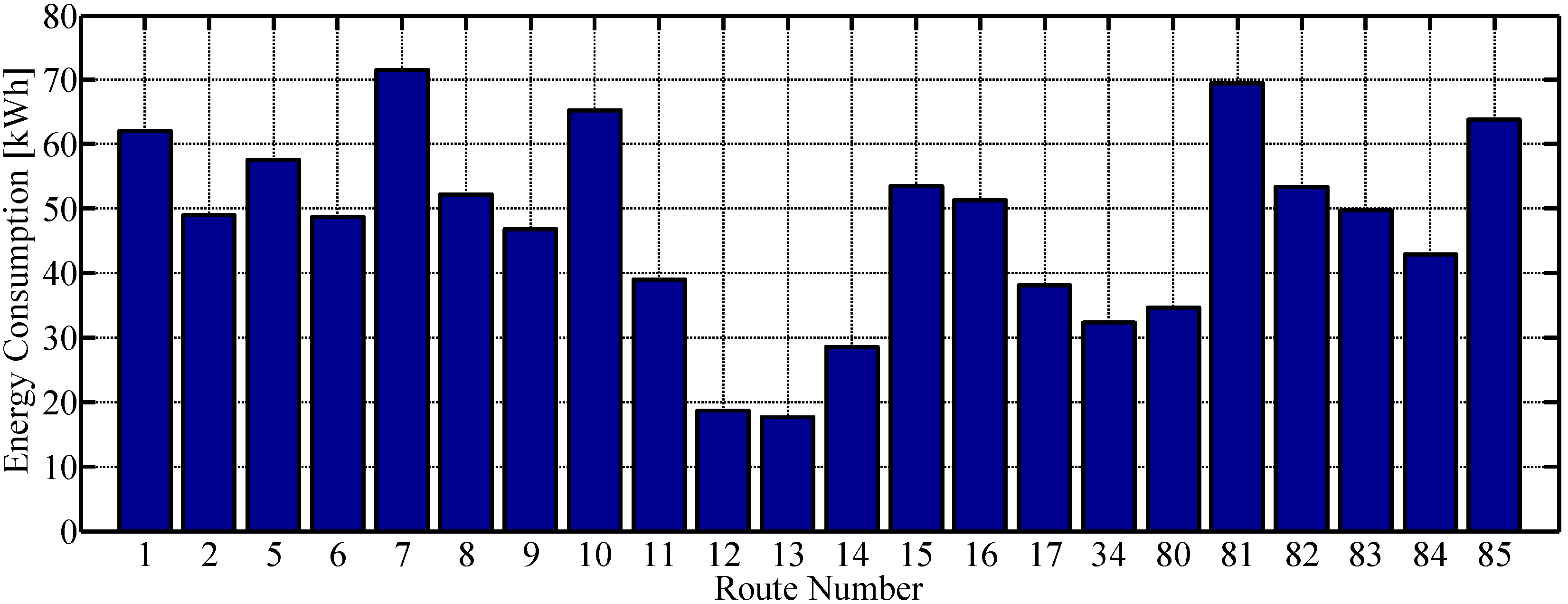

4.1. Energy Consumption

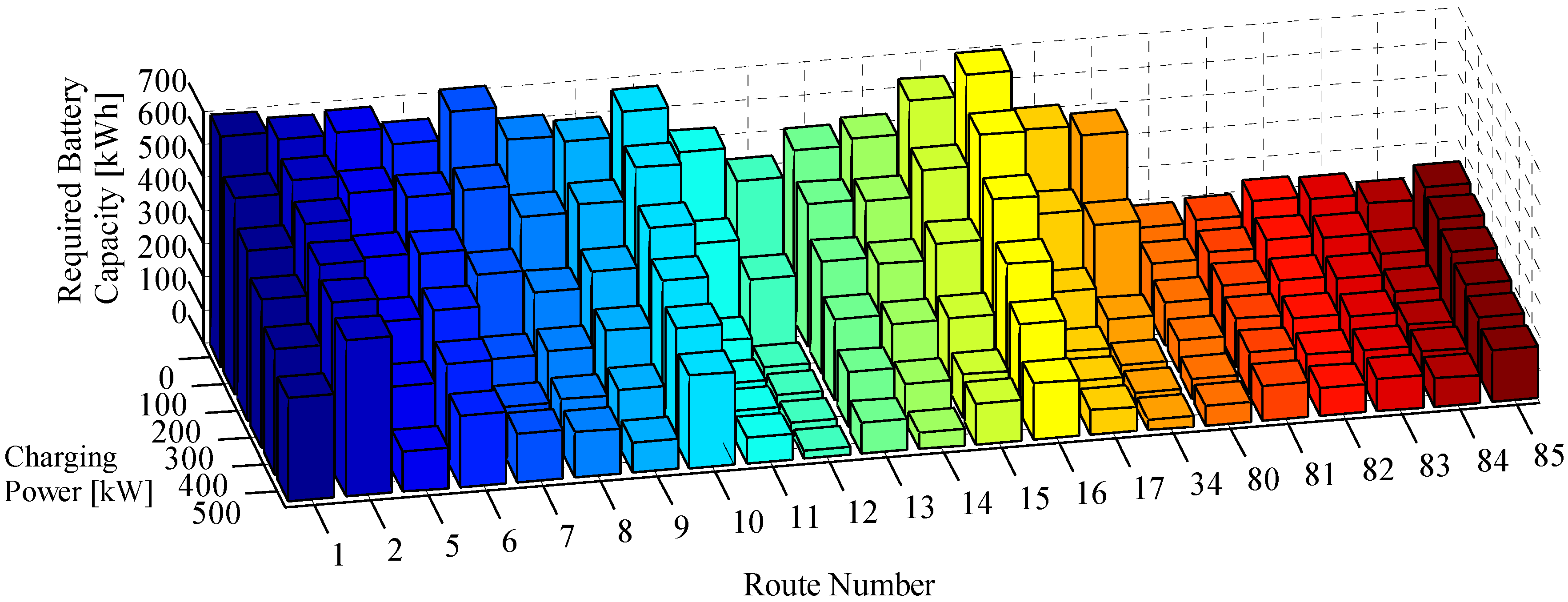

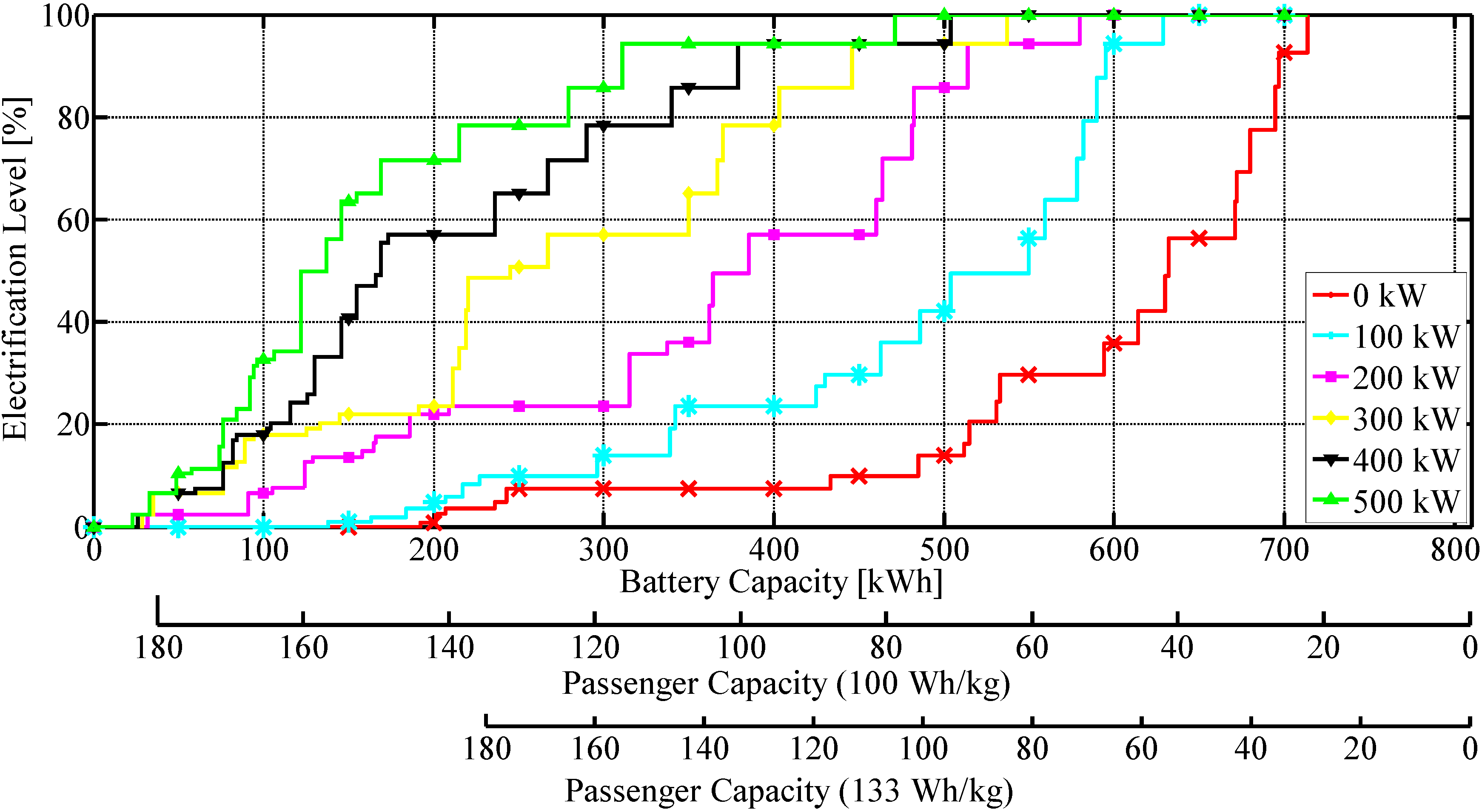

4.2. Impact of the Charging Power on the Required Battery Capacity

| Route | Charging Power [kW] | Route | Charging Power [kW] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 100 | 200 | 300 | 400 | 500 | 0 | 100 | 200 | 300 | 400 | 500 | ||

| 1 | 695 | 590 | 514 | 446 | 379 | 311 | 14 | 531 | 425 | 315 | 215 | 116 | 49 |

| 2 | 672 | 629 | 580 | 537 | 504 | 471 | 15 | 632 | 504 | 362 | 219 | 130 | 122 |

| 5 | 680 | 578 | 464 | 350 | 236 | 122 | 16 | 697 | 595 | 481 | 367 | 267 | 169 |

| 6 | 630 | 550 | 460 | 370 | 290 | 215 | 17 | 515 | 342 | 186 | 89 | 82 | 74 |

| 7 | 715 | 559 | 385 | 211 | 146 | 146 | 34 | 485 | 296 | 91 | 35 | 33 | 33 |

| 8 | 614 | 463 | 315 | 220 | 155 | 137 | 80 | 192 | 163 | 129 | 94 | 60 | 58 |

| 9 | 594 | 486 | 364 | 267 | 169 | 92 | 81 | 201 | 184 | 165 | 145 | 126 | 106 |

| 10 | 671 | 582 | 482 | 403 | 340 | 279 | 82 | 243 | 207 | 166 | 133 | 104 | 84 |

| 11 | 533 | 339 | 124 | 76 | 76 | 76 | 83 | 236 | 200 | 158 | 125 | 102 | 96 |

| 12 | 433 | 217 | 32 | 29 | 26 | 23 | 84 | 207 | 138 | 105 | 84 | 84 | 84 |

| 13 | 512 | 430 | 337 | 245 | 166 | 94 | 85 | 243 | 227 | 209 | 191 | 173 | 155 |

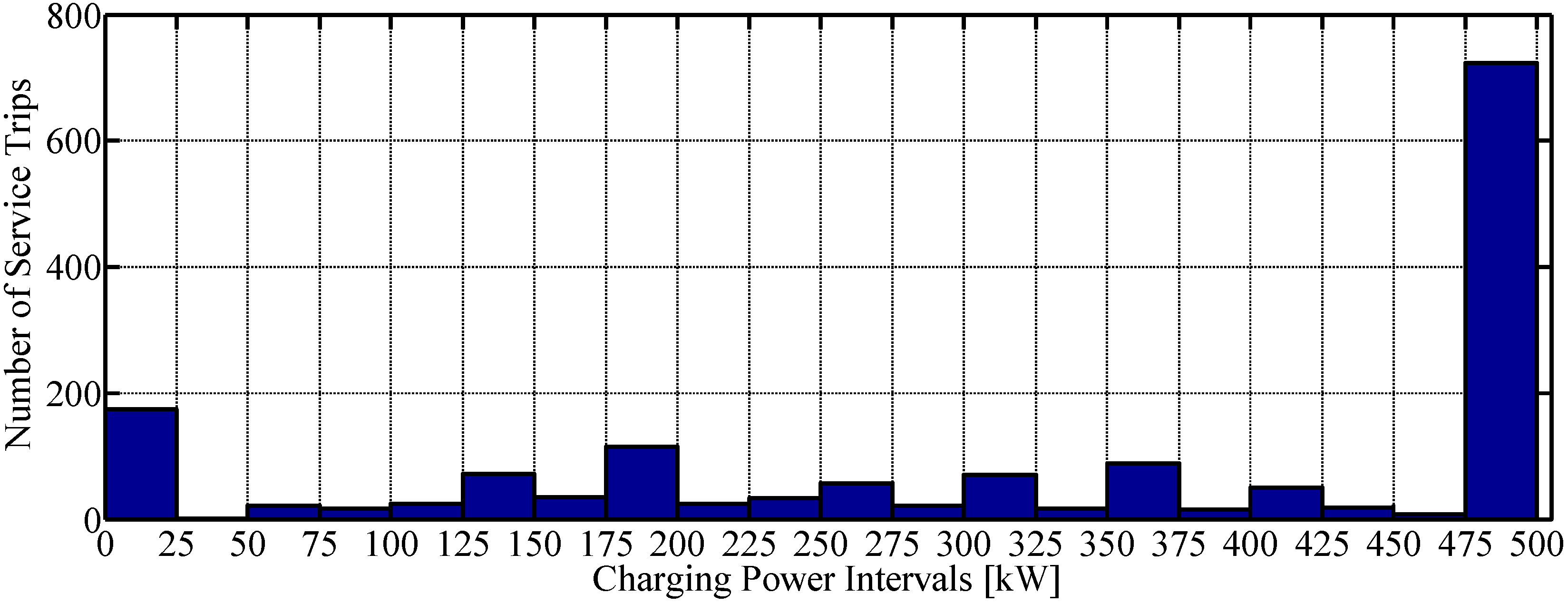

4.3. Electrification Level of the Bus Network

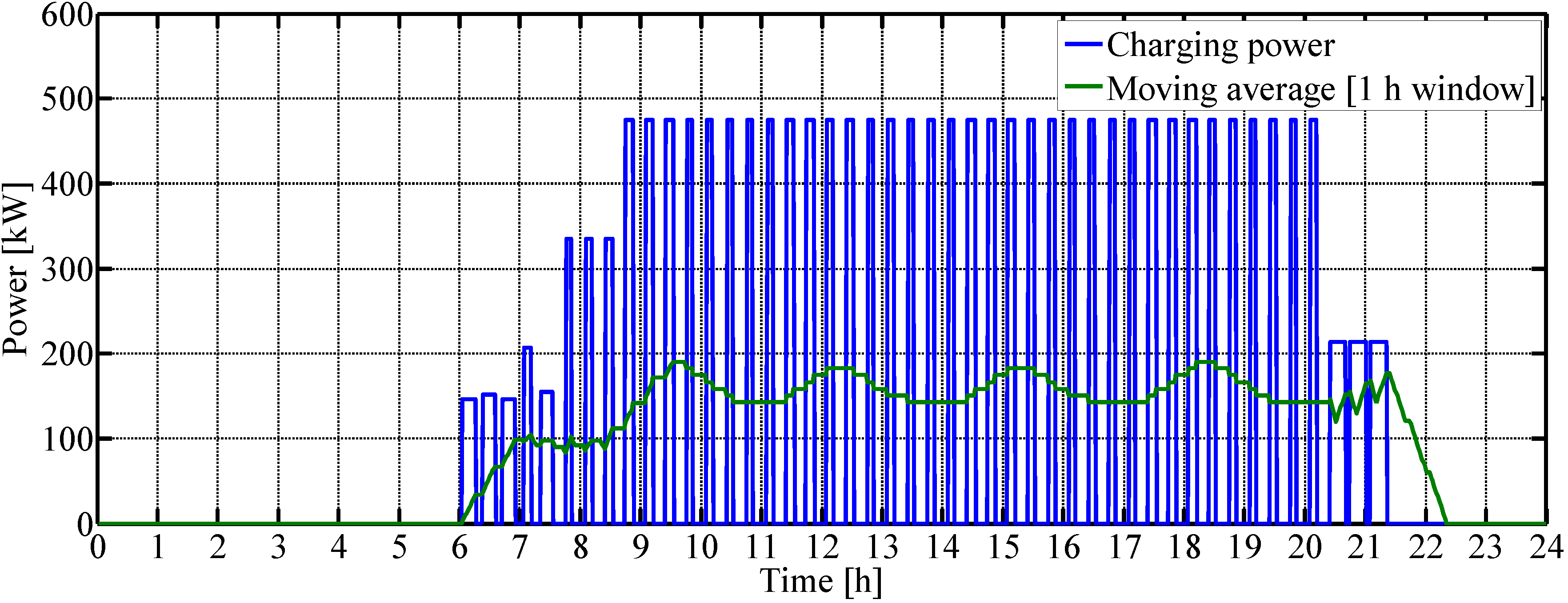

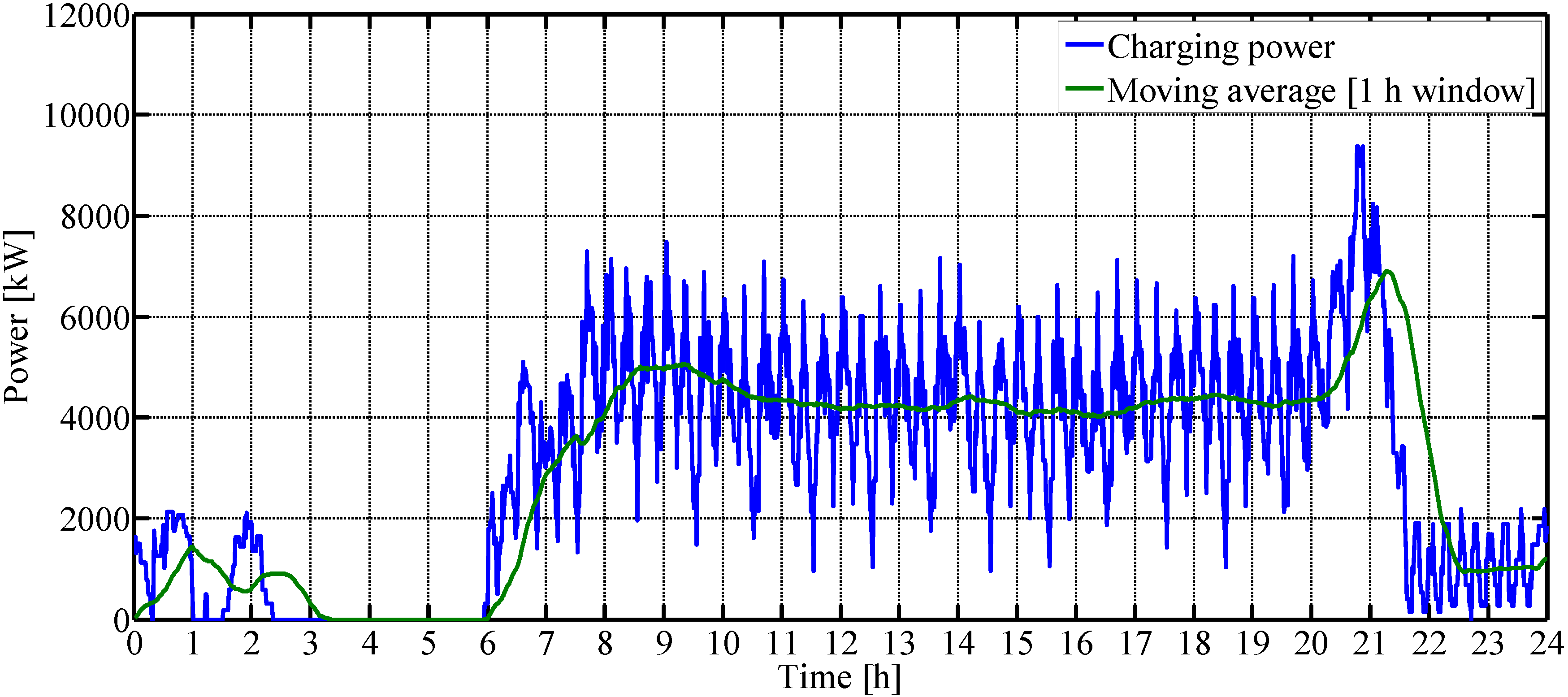

4.4. Grid Load Profile

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Brunton, L.J. Why not the trolleybus? In Proceedings of the IEEE Seminar on Electric, Hybrid and Fuel Cell Vehicles, Durham, UK, 11 April 2000; p. 5.

- Wu, W.; Bucknall, R.W.G. Conceptual evaluation of a fuel-cell-hybrid powered bus. In Proceedings of the 48th Universitiesʼ Power Engineering Conference (UPEC), Dublin, Ireland, 2–5 September 2013; pp. 1–5.

- Kellaway, M.J. Hybrid buses—What their batteries really need to do. J. Power Sources 2007, 168, 95–98. [Google Scholar] [CrossRef]

- Sasaki, M.; Araki, S.; Miyata, T.; Kawaji, T. Development of capacitor hybrid system for urban buses. JSAE Rev. 2002, 23, 451–457. [Google Scholar] [CrossRef]

- Xiong, W.; Zhang, Y.; Yin, C. Optimal energy management for a series–parallel hybrid electric bus. Energ. Convers. Manag. 2009, 50, 1730–1738. [Google Scholar] [CrossRef]

- Klingner, M.; Potthoff, U. The AutoTram: A system integration platform of multiple energy storage and transfer concepts. In Proceedings of the VDE Kongress 2010, Leipzig, Germany, 8–9 November 2010.

- Wang, X.; He, H.; Sun, F.; Sun, X.; Tang, H. Comparative study on different energy management strategies for plug-in hybrid electric vehicles. Energies 2013, 6, 5656–5675. [Google Scholar] [CrossRef]

- Kühne, R. Electric buses—An energy efficient urban transportation means. Energy 2010, 35, 4510–4513. [Google Scholar] [CrossRef]

- Campanari, S.; Manzolini, G.; Garcia de la Iglesia, F. Energy analysis of electric vehicles using batteries or fuel cells through well-to-wheel driving cycle simulations. J. Power Sources 2009, 186, 464–477. [Google Scholar] [CrossRef]

- Sauer, D.U.; Rohlfs, W.; Sinhuber, P.; Rogge, M. Energy consumption, battery size, battery type and charging infrastructure—Optimal eÖPNV mobility through integral analysis. In Proceedings of the 4th VDV Conference Electric Buses—Market of the Future, Berlin, Germany, 18–19 February 2013.

- Sinhuber, P.; Rohlfs, W.; Sauer, D.U. Study on power and energy demand for sizing the energy storage systems for electrified local public transport buses. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Seoul, Korea, 9–12 October 2012; pp. 315–320.

- Paul, T.; Yamada, H. Operation and charging scheduling of electric buses in a city bus route network. In Proceedings of the 17th IEEE International Conference on Intelligent Transportation Systems (ITSC), Qingdao, China, 8–11 October 2014; pp. 2780–2786.

- Wang, H.; Shen, J. Heuristic approaches for solving transit vehicle scheduling problem with route and fueling time constraints. Appl. Math. Comput. 2007, 190, 1237–1249. [Google Scholar] [CrossRef]

- Zhu, C.; Chen, X. Optimizing battery electric bus transit vehicle scheduling with battery exchanging: Model and case study. Procedia Soc. Behav. Sci. 2013, 96, 2725–2736. [Google Scholar] [CrossRef]

- Mapelli, F.L.; Tarsitano, D.; Annese, D.; Sala, M.; Bosia, G. A study of urban electric bus with a fast charging energy storage system based on lithium battery and supercapacitors. In Proceedings of the 2013 Eighth International Conference and Exhibition on Ecological Vehicles and Renewable Energies (EVER 2013), Monte Carlo, Monaco, 27–30 March 2013; pp. 1–9.

- Stadtwerke Muenster. Timetable of Muenster and the Region. Available online: https://www.stadtwerke-muenster.de/privatkunden/busverkehr/fahrplaninfos/fahrplaene-netzplaene/fahrplantabellen.html (accessed on 10 February 2014).

- Goldman, J. The proterra fast charge battery bus and charging station. In Proceedings of the International Workshop on Environment and Energy, San Diego, CA, USA, 2–4 November 2010.

- Koebel, C. Update primove technology and projects. In Proceedings of the 5th VDV Conference Electric Buses—Market of the Future, Berlin, Germany, 17–18 February 2014.

- Wechlin, M. Charging electric buses quickly and efficiently. Bus stops fitted with modular components make “Charge & Go” simple to implement. Wireless Charging of Electric Vehicles, 13 May 2013. [Google Scholar]

- Prenaj, B. TOSA flash electric bus system: Experiences and perspectives after nine months of operation. In Proceedings of the 5th VDV Conference Electric Buses—Market of the Future, Berlin, Germany, 17–18 February 2014.

- Cruz-Zambrano, M.; Corchero, C.; Igualada-Gonzalez, L.; Bernardo, V. Optimal location of fast charging stations in Barcelona: A flow-capturing approach. In Proceedings of the 10th International Conference on the European Energy Market (EEM 2013), Stockholm, Sweden, 27–31 May 2013; pp. 1–6.

- Dong, J.; Liu, C.; Lin, Z. Charging infrastructure planning for promoting battery electric vehicles: An activity-based approach using multiday travel data. Transport. Res. Part C Emerg. Technol. 2014, 38, 44–55. [Google Scholar] [CrossRef]

- Wang, Y.-W. An optimal location choice model for recreation-oriented scooter recharge stations. Transport. Res. Part D Transp. Environ. 2007, 12, 231–237. [Google Scholar] [CrossRef]

- Wiesinger, P. Battery buses for Vienna. In Proceedings of the 4th VDV Conference Electric Buses—Market of the Future, Berlin, Germany, 18–19 February 2013.

- Lajunen, A. Energy consumption and cost-benefit analysis of hybrid and electric city buses. Transport. Res. Part C Emerg. Technol. 2014, 38, 1–15. [Google Scholar] [CrossRef]

- López-López, Á.J.; Pecharromán, R.R.; Fernández-Cardador, A.; Cucala, A.P. Assessment of energy-saving techniques in direct-current-electrified mass transit systems. Transport. Res. Part C: Emerg. Technol. 2014, 38, 85–100. [Google Scholar] [CrossRef]

- Basile, R. Challenges for HVAC solutions in the electric bus—Status Quo. In Proceedings of the 4th VDV Conference Electric Buses—Market of the Future, Berlin, Germany, 18–19 February 2013.

- Cho, C.-W.; Lee, H.-S.; Won, J.-P.; Lee, M.-Y. Measurement and evaluation of heating performance of heat pump systems using wasted heat from electric devices for an electric bus. Energies 2012, 5, 658–669. [Google Scholar] [CrossRef]

- Schmidt, M.; Classen, A. Life-Cycle-Cost-optimierte Klimatisierung von Linienbussen. Teilklimatisierung Fahrgastraum - Vollklimatisierung Fahrerarbeitsplatz; VDV Schrift 236-1; Verband Dt. Verkehrsunternehmen (VDV): Cologne, Germany, 2009. [Google Scholar]

- Kaup, D.; Bouwman, R.; Schaedlich, G.; Sauer, D.U.; Lohner, A. H2 Bus NRW The Hybrid Electric Fuel-Cell Bus. In Proceedings of the 18th World Hydrogen Energy Conference - WHEC 2010, 16–21 May 2010.

- König, D.; Oellers, F.-W.; Roes, J.; Schulte, R.; Wittenberg, H.-U. 2. Nahverkehrsplan Stadt Münster. Available online: http://www.muenster.de/stadt/stadtplanung/pdf/Nahverkehrsplan-Schlussfassung.pdf (accessed on 10 September 2014).

- Schmalstieg, J.; Kabitz, S.; Ecker, M.; Sauer, D.U. From accelerated aging tests to a lifetime prediction model: Analyzing lithium-ion batteries. In Proceedings of the World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013; pp. 1–12.

- Zhu, C.; Lu, R.; Tian, L.; Wang, Q. The development of an electric bus with super-capacitors as unique energy storage. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Windsor, UK, 6–8 September 2006; pp. 1–5.

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.-C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Rogge, M.; Rohlfs, W.; Sauer, D.U. Fast charging of battery buses and its impact on the aging of various lithium-ion cell types. In Proceedings of the 10th Symposium of Hybrid and Electric Vehicles, Braunschweig, Germany, 13–14 February 2013.

- Ecker, M.; Nieto, N.; Käbitz, S.; Schmalstieg, J.; Blanke, H.; Warnecke, A.; Sauer, D.U. Calendar and cycle life study of Li(NiMnCo)O2-based 18650 lithium-ion batteries. J. Power Sources 2014, 248, 839–851. [Google Scholar] [CrossRef]

- MAN Truck & Bus AG. Lionsʼs City datasheet. Available online: http://www.bus.man.eu/man/media/en/content_medien/doc/business_website_bus_master_1/Lions_City.pdf (accessed on 28 November 2014).

- Mercedes-Benz. Citaro G technical information. Available online: http://www.mercedes-benz.de/content/media_library/hq/hq_mpc_reference_site/bus_ng/services_accessories/brochures/2013/citaro_g_tech/2081_0114Tech_Info_Citaro_G_EuroVI_EN_pdf.object-Single-MEDIA.tmp/2081_0114 Tech_Info_Citaro_G_EuroVI_EN.pdf (accessed on 28 November 2014).

- Akasol GmbH. Akasystem 45m Datasheet. Available online: http://www.akasol.com/fileadmin/Kundendaten/pdf/datenblatt/update_AKASYSTEM_09_2013_E/AKASOL_Datenblatt_AKASYSTEM_45M_E_09_2013.pdf (accessed on 27 November 2014).

- Riegel, B. High-Voltage-Battery-Concepts for public transport application. In Proceedings of the 5th VDV Conference Electric Buses—Market of the Future, Berlin, Germany, 17–18 February 2014.

- Schoewel, F. The High-Voltage Batteries of the BMW i3 and BMW i8. In Proceedings of the Advanced Automotive Battery Conference (AABC), Atlanta, GA, USA, 4–5 February 2014.

- Jiang, G.; Zeng, X.; Xiao, S.; Chen, M.; Pu, S.; Zhou, N. Research on control strategy of energy storage buffer system for electric vehicle smart charging station. In Proceedings of the China International Conference on Electricity Distribution (CICED), Shanghai, China, 10–14 September 2012; pp. 1–5.

- Mahmoodi, M.; McDonough, M.; Shamsi, P.; Fahimi, B. Peak shaving and minimum cost operation of an electric vehicle charging station based on Multi-port Power Electronic Interface. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012; pp. 1–5.

- Pacher, A.; Stifter, M.; Übermasser, S.; Bletterie, B. Power supply analysis of a parking garage with a controlled charging of electric vehicles. In Proceedings of the 13th Symposium Energy Innovation, Graz, Austria, 12–14 February 2014.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogge, M.; Wollny, S.; Sauer, D.U. Fast Charging Battery Buses for the Electrification of Urban Public Transport—A Feasibility Study Focusing on Charging Infrastructure and Energy Storage Requirements. Energies 2015, 8, 4587-4606. https://doi.org/10.3390/en8054587

Rogge M, Wollny S, Sauer DU. Fast Charging Battery Buses for the Electrification of Urban Public Transport—A Feasibility Study Focusing on Charging Infrastructure and Energy Storage Requirements. Energies. 2015; 8(5):4587-4606. https://doi.org/10.3390/en8054587

Chicago/Turabian StyleRogge, Matthias, Sebastian Wollny, and Dirk Uwe Sauer. 2015. "Fast Charging Battery Buses for the Electrification of Urban Public Transport—A Feasibility Study Focusing on Charging Infrastructure and Energy Storage Requirements" Energies 8, no. 5: 4587-4606. https://doi.org/10.3390/en8054587