A New Optimization Method for Centrifugal Compressors Based on 1D Calculations and Analyses

Abstract

:1. Introduction

2. Review of Loss Model

2.1. Impeller Loss Model

2.1.1. Incidence Loss

2.1.2. Blade Loading Loss

2.1.3. Skin Friction Loss

2.1.4. Disk Friction Loss

2.1.5. Recirculation Loss

2.1.6. Clearance Loss

2.1.7. Mixing Loss

2.2. Slip Factor

2.3. Vaneless Diffuser Loss Model

2.4. Vaneless Diffuser Loss Model

3. Validation of the Loss Model

| HPCC impeller | |

|---|---|

| Inlet total temperature (K) | 288.15 |

| Inlet total pressure (Pa) | 101,325 |

| Rotation speed (rpm) | 21,789 |

| Mass flow (kg/s) | 4.54 |

| Pressure ratio | 4 |

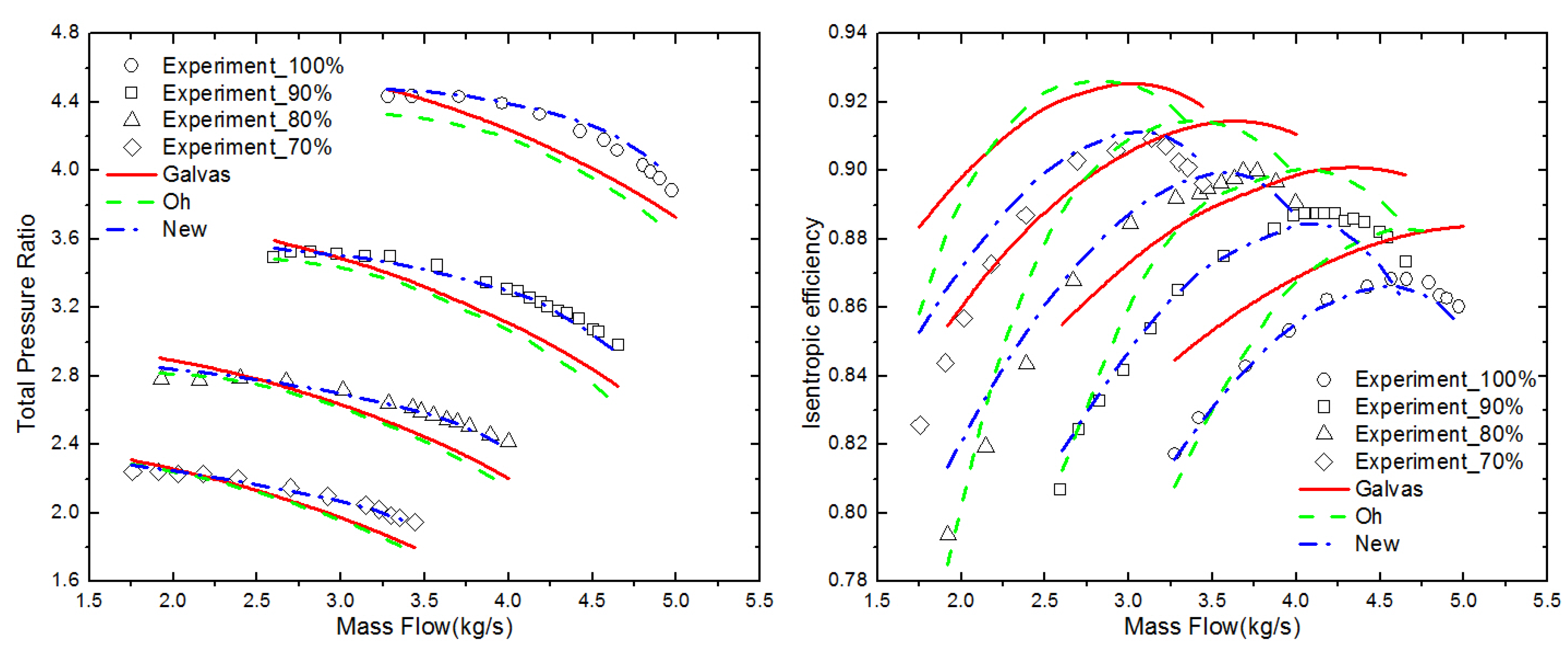

3.1. Validation of the Impeller and Vaneless Diffuser Loss Model

| Losses | Galvas | Oh | New |

|---|---|---|---|

| Incidence | Galvas [1] | Conrad [11] | Aungier [2] |

| Skin friction | Galvas [1] | Jasen [12] | Jasen [11] |

| Blade loading | Coppage [12] | Coppage [13] | Coppage [13] |

| Clearance | None | Jasen [12] | Jasen [12] |

| Mixing | None | Johnston and Dean [16] | Johnston and Dean [16] |

| Disk Friction | Galvas [12] | Daily and Nece [14] | Daily and Nece [14] |

| Recirculation | Jasen [13] | Oh [3] | Japikse [4] |

| Slip factor | Wiesner [18] | Wiesner [18] | Qiu [19] |

| Vaneless diffuser loss | Stanitz [24] | Stanitz [24] | Stanitz [24] |

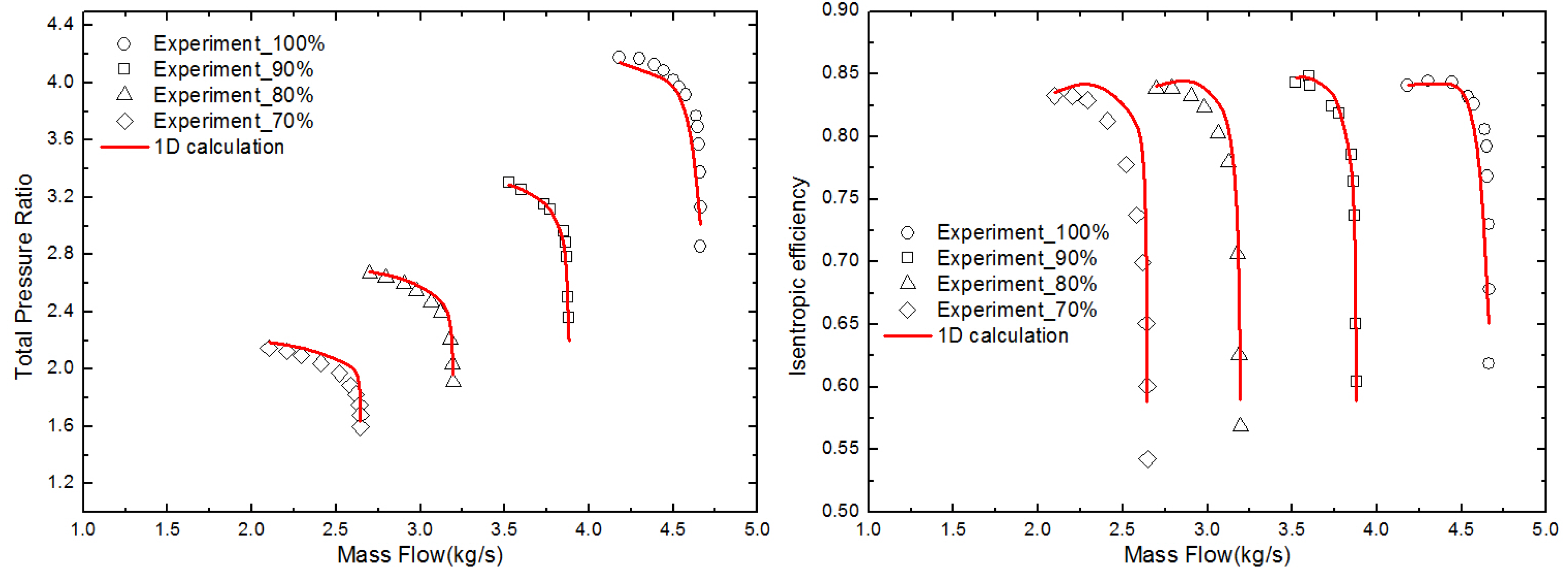

3.2. Validation of the Vaned Diffuser Loss Model

4. Optimization Results

4.1. Results of the 1D Optimization Calculations

4.2. Redesign of the Vaned Diffuser

| Parameter | Original Design | Optimization Design |

|---|---|---|

| (m) | 0.082 | 0.075 |

| (m) | 0.202 | 0.190 |

| (m) | 0.326 | 0.326 |

| Lz (m) | 0.08 | 0.075 |

| (m) | 0.0151 | 0.0158 |

| (m) | 0.44 | 0.3586 |

| (m) | 0.601 | 0.601 |

| D3/D2 | 1.34 | 1.10 |

| 94.87% | 95.15% | |

| 86.29% | 92.63% | |

| 81.09% | 83.38 |

| Original design | Optimization design 1 | Optimization design 2 | |

|---|---|---|---|

| 1..161 | 0.922 | 1.043 |

5. Conclusions

- (1)

- A new set of loss model combinations is presented by reviewing the existing 1D loss models, which contains loss models of the impeller, vaneless diffuser and vaned diffuser. At design speeds, the 1D calculation results agree well with the experiment data; at off-design speeds, especially at low speeds, there is large difference betweent the 1D calculation results and the experiment data.

- (2)

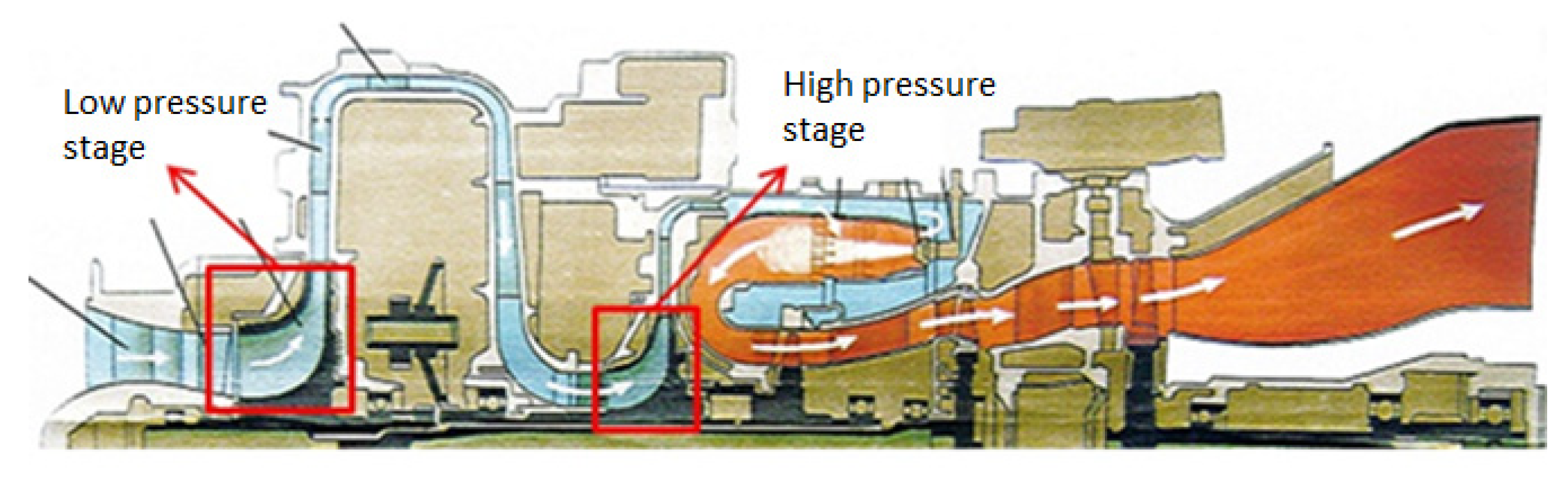

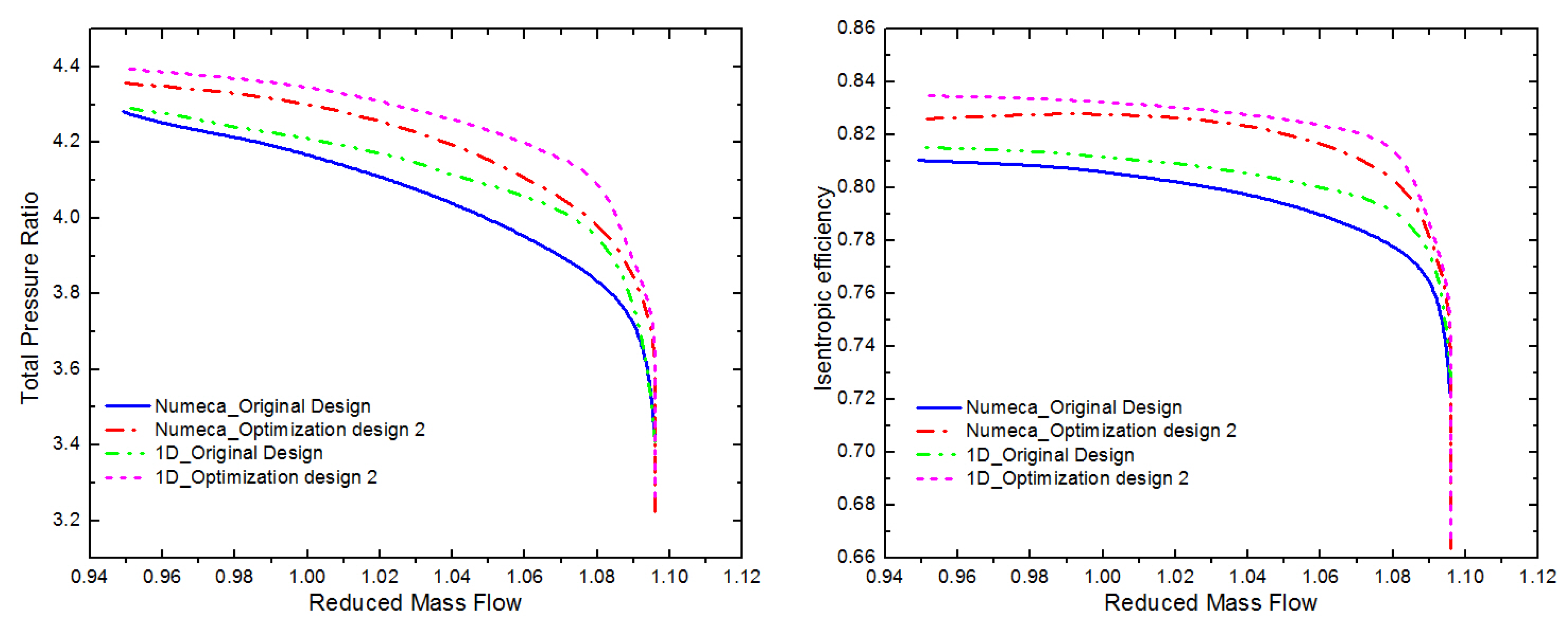

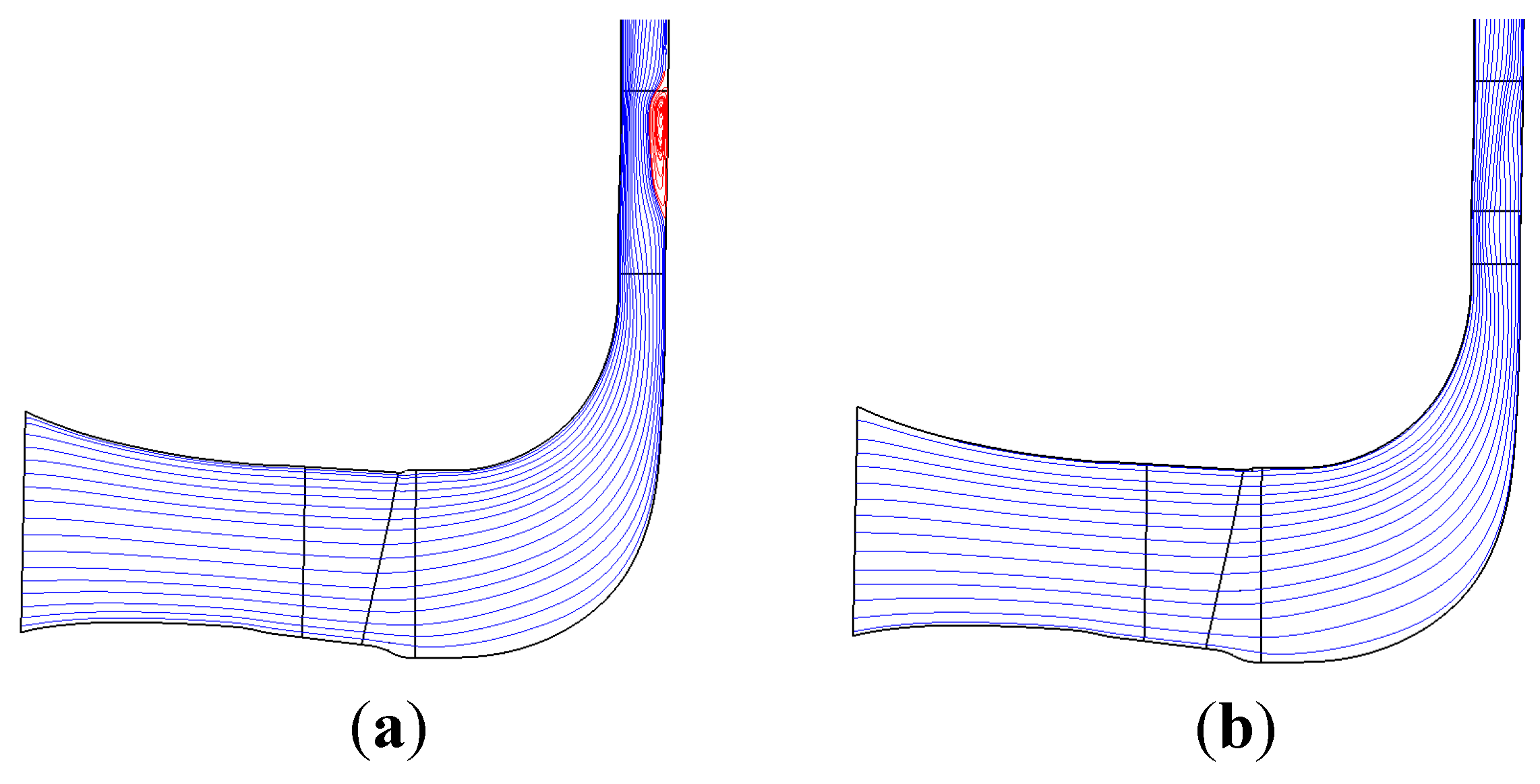

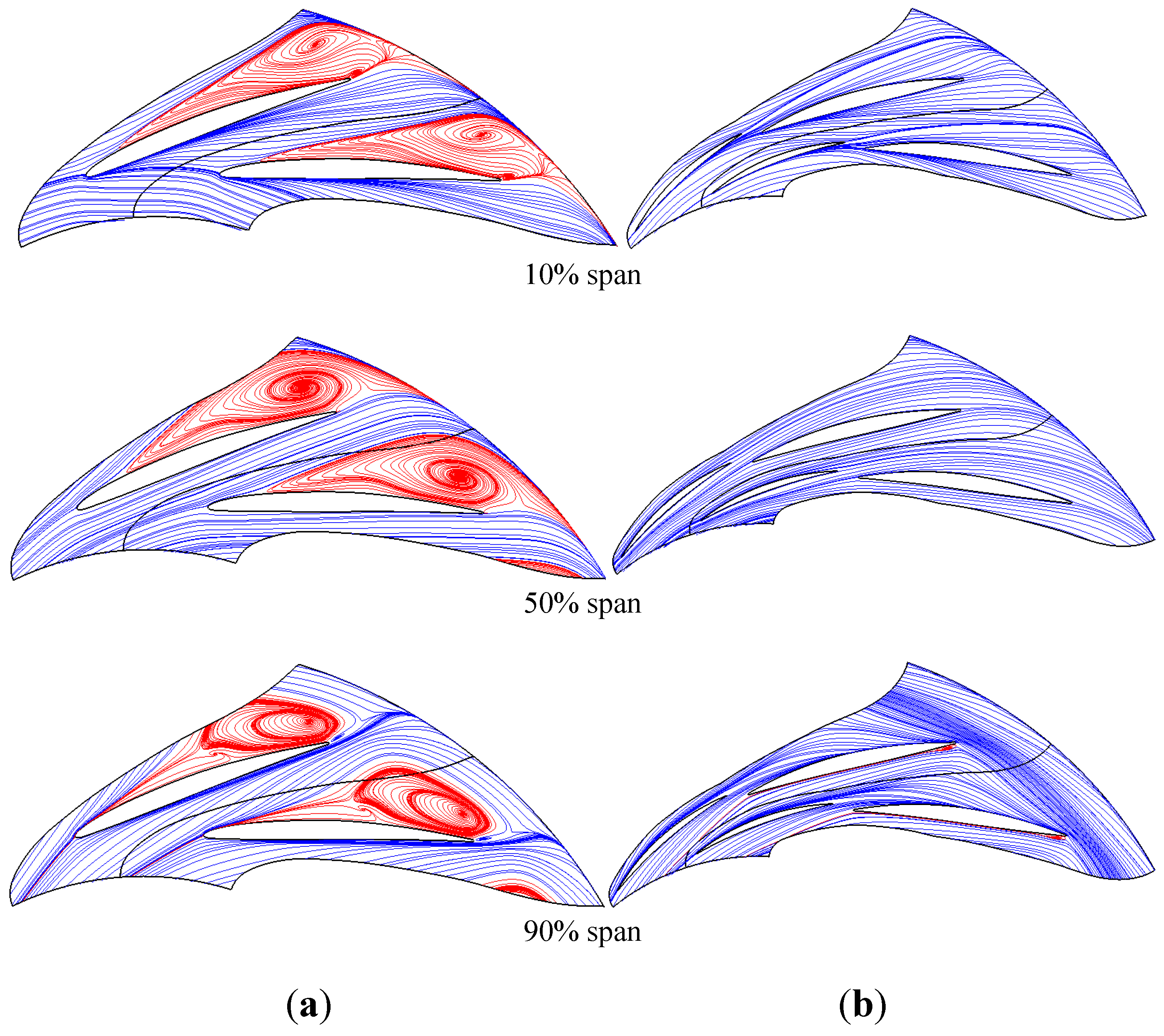

- A low pressure stage centrifugal compressor in a MW level gas turbine is optimized by the 1D optimization method based on the iSIGHT software. The optimization results show that too large diameter ratio D3/D2 is the main cause of low efficiency. The Numeca results also show that there is a large vortex in the vaneless diffuser, which also validates the reliability of the 1D calculation results.

- (3)

- The vaned diffuser is redesigned according to the 1D optimization results and the matching of vaneless and vaned diffusers. The Numeca results show that the vortex in the vaneless diffuser disappears in optimization design. After optimization, the entire stage pressure ratio is increased by approximately 4%, and the efficiency is increased by approximately 2%.

Nomenclature

| b | hub to shroud passage width |

ratio of vaneless diffuser inlet width to impeller exit width | |

| B | aerodynamic blockage |

skin friction coefficient | |

| C | absolute velocity |

specific heat at constant pressure | |

absolute meridional velocity | |

absolute tangential velocity | |

| d | diameter |

hydraulic diameter | |

diffusion factor | |

euler work | |

impeller flow length | |

axial length of impeller | |

mass flow rate | |

| U | Impeller periphery velocity |

| W | relative velocity |

| Z | number of blade |

absolute flow angle | |

relative angle | |

flow coefficient | |

meridional inclination angle | |

Efficiency | |

wake fraction of blade-to-blade space | |

slip factor, | |

density | |

slip factor, |

Subscripts

| 1 | impeller inlet condition |

| 2 | impeller outlet condition |

| 3 | vaneless diffuser outlet condition |

| 4 | vaned diffuser outlet condition |

| m | meriditional direction |

tangential direction | |

| h | hub |

| s | shroud |

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Galvas, M.R. Fortran Program for Predicting Off-Design Performance of Centrifugal Compressors; TN D-7487; Technical Report for National Aeronautics and Space Administration (NASA): Cleveland, OH, USA, 1973. [Google Scholar]

- Aungier, R.H. Mean streamline aerodynamic performance analysis of centrifugal compressors. J. Turbomach. 1995, 117, 360–366. [Google Scholar] [CrossRef]

- Oh, H.W.; Yoon, E.S.; Chung, M.K. An optimum set of loss models for performance prediction of centrifugal compressors. Proc. Inst. Mech. Eng. Part A J. Power Energy 1997, 211, 331–338. [Google Scholar] [CrossRef]

- Japikse, D. Centrifugal Compressor Design and Performance, 3rd ed.; Concepts ETI Inc.: Wilder, TN, USA, 1996; pp. 2.26–2.81. [Google Scholar]

- Mengistu, T.; Ghaly, W.; Mansour, T. Aerodynamic shape optimization of turbine blades using a designparameter-based shape representation. Proc. ASME Turbo Expo 2007 Power Land Sea Air 2007, 6, 1395–1404. [Google Scholar]

- Rossetti, G.; Ardizzon, G.; Pavesi, G. An optimum design procedure for an aerodynamic radial diffuser with incompressible flow at different reynolds numbers. J. Power Energy 2014, 224, 69–84. [Google Scholar] [CrossRef]

- Klassen, H.A.; Wood, J.R. Experimental Performance of a 16.1 Centimetre Tip Diameter Centrifugal Compressor Designed for a 6:1 Pressure Ratio; National Aeronautics and Space Administration (NASA): Cleveland, OH, USA, 1979. [Google Scholar]

- Tamaki, H.; Nakao, H.; Saito, M. The experimental study of matching between centrifugal compressor impeller and diffuser. J. Turbomach. 1999, 121, 113–118. [Google Scholar] [CrossRef]

- Caser, M. The matching of a vaned diffuser with a radial compressor impeller and its effect on the stage performance. J. Turbomach. 2014, 136. [Google Scholar] [CrossRef]

- Cumpsty, N.A. Compressor Aerodynamics; Longman Group Ltd.: Harlow, Essex, UK, 1989. [Google Scholar]

- Conrad, O.; Raif, K.; Wessels, M. The calculation of performance maps for centrifugal compressors with vane-island diffusers. In Proceedings of the ASME Twenty-fifth Annual International Gas Turbine Conference and Twenty Second Annual Fluids Engineering Conference on Performance Prediction of Centrifugal Pumps and Compressors, New Orleans, LA, USA, 9–13 March 1980; pp. 135–147.

- Jansen, W. A Method for Calculating the Flow in a Centrifugal Impeller When Entropy Gradients Are Present; Royal Society Conference on Internal Aerodynamics (Turbomachinery): London, UK, 1967; pp. 133–146. [Google Scholar]

- Coppage, J.E.; Dallenbach, F.; Eichenberger, H.P. Study of Super-Sonic Radial Compressors for Refrigeration and Pressurization Systems; Technical Report for Wright Air Development Center (WADC): Los Angeles, CA, USA, 1956. [Google Scholar]

- Daily, J.W.; Nece, R.E. Chamber dimension effects on induced flow and frictional resistance of enclosed rotating disks. Trans. ASME J. Basic. Eng. Power 1966, 88, 49–62. [Google Scholar] [CrossRef]

- Rodgers, C. Influence of Impeller and Diffuser Characteristics and Matching on Radial Compressor Performance; Technical Paper for Society of Automotive Engineers: Warrendale, PA, USA, 1 January 1961. [Google Scholar]

- Johnston, J.P.; Dean, R.C. Losses in vaneless diffusers of centrifugal compressors and pumps: Analysis, experiment, and design. J. Eng. Gas Turbines Power. 1966, 88, 49–62. [Google Scholar] [CrossRef]

- Stodola, A. Steam and Gas Turbines; McGraw-Hill: New York, NY, USA, 1945. [Google Scholar]

- Wiesner, F.J. A review of slip factors for centrifugal impellers. J. Eng. Power. 1967, 89, 558–572. [Google Scholar]

- Qiu, X.W.; Japikse, D.; Zhao, J.; Anderson, M.R. Analysis and validation of a unified slip factor model for impellers at design and off-design conditions. J. Turbomach. 2011, 133, 041018:1–041018:9. [Google Scholar] [CrossRef]

- Stanitz, J.D. One-Dimensional Compressible Flow in Vaneless Diffusers of Radial and Mixed-Flow Centrifugal Compressors, Including Effects of Friction, Heat Transfer and Area Change; Technical Report for Lewis Flight Propulsion Laboratory: Cleveland, OH, USA, January 1952. [Google Scholar]

- Aungier, R.H. Aerodynamic performance analysis of vaned diffusers. Fluid Mach. Compon. 1990, 110, 37–44. [Google Scholar]

- Doostmohammadi, A.A.; Hajilouy-Benisi, A.; Mojaddam, M. Experimental and numerical investigation of losses in centrifugal compressor components. In Proceeding of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013.

- Skoch, G.J.; Prahst, P.S.; Wernet, M.P. Laser Anemometer Measurements of the Flow Field in a 4:1 Pressure Ratio Centrifugal Impeller; Technical Report for National Aeronautics and Space Administration: Orlando, FL, USA, 1997. [Google Scholar]

- Kazuyuki, S. Aerodynamic Shape optimization and knowledge mining of centrifugal fans using simulated annealing coupled with a neural network. In Proceedings of the 32nd Design Automation Conference, Philadelphia, PA, USA, 10–13 September 2006; pp. 291–300.

- Sarhadi, A.; Tahani, M.; Kolahan, F.; Sarhadi, M. Multi-Objective optimal design of sandwich composite laminates using simulated annealing and FEM. In Proceeding of the ASME 2008 Pressure Vessels and Piping Conference, Chicago, IL, USA, 27–31 July 2008; pp. 597–606.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.-Y.; Gu, C.-W.; Song, Y. A New Optimization Method for Centrifugal Compressors Based on 1D Calculations and Analyses. Energies 2015, 8, 4317-4334. https://doi.org/10.3390/en8054317

Li P-Y, Gu C-W, Song Y. A New Optimization Method for Centrifugal Compressors Based on 1D Calculations and Analyses. Energies. 2015; 8(5):4317-4334. https://doi.org/10.3390/en8054317

Chicago/Turabian StyleLi, Pei-Yuan, Chu-Wei Gu, and Yin Song. 2015. "A New Optimization Method for Centrifugal Compressors Based on 1D Calculations and Analyses" Energies 8, no. 5: 4317-4334. https://doi.org/10.3390/en8054317