1. Introduction

In face of the serious energy and environmental pollution crisis, lots of researchers have looked to renewable sources to find solutions. Wind power generation, as an indispensable part of the energy mix, has already shown its competitiveness and reliability to governments, electricity producers and customers all around the world. The rapid growth of the wind generation is surprising: 17.6 GW of wind capacity was installed in the first half of 2014, and the cumulative worldwide wind power capacity is expected to reach 360 GW by end of 2014. The prospects for wind power investment remain positive [

1]. Wind generation systems (WGS) containing power electronics devices are often adopted to guarantee high quality electric power supply. Various power electronics converters applied for wind generation have been reviewed and compared in [

2]. Most of them are applied for medium and large power levels and few focus their attention on low power level wind power generation, although small-scale wind power generation systems (e.g., under 1 kW) are commonly used on domestic roofs in power-hungry areas, including mountainous or insular regions. Thus, more research on distributed, small-scale wind application should be conducted. A considerable number of the existing small-scale WGS still simply copy the structures, designs and control methods for medium- and large-scale WGS, and are unable to meet the practical requirements of the smaller scale scenarios.

Compared to large-scale power level wind generation, small-scale WGS possesses advantages of higher flexibility for distributed applications, lower cost and reduced impact on the power grid, thus further research on this topic and its promotion are of great value.

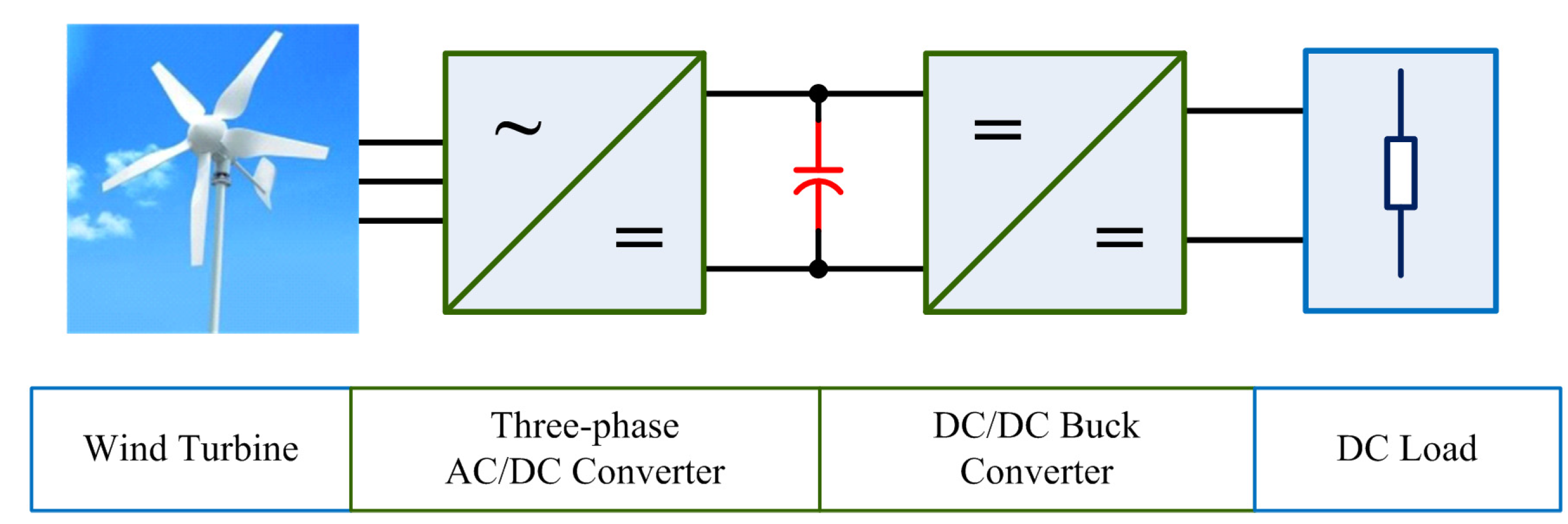

Usually, small-scaled WGS can be classified into two application forms: off-grid and grid-tied. Off-grid wind generation systems [

3,

4,

5,

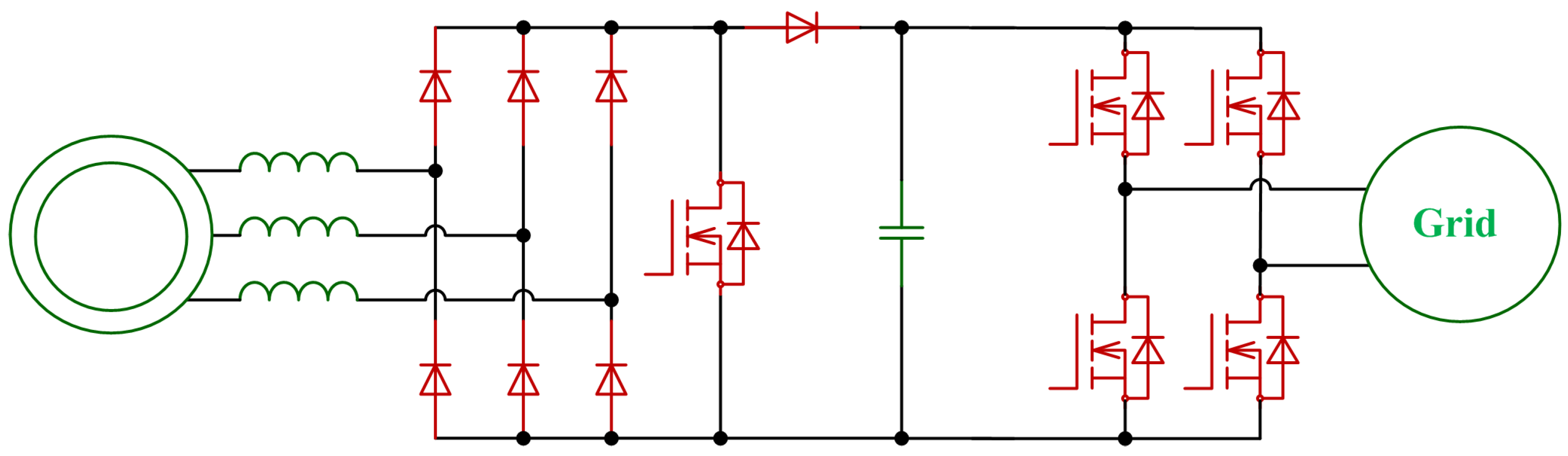

6] are one available form for small-scale wind applications. An off-grid system usually includes a wind generator, a three-phase AC/DC rectifier, a DC/DC Buck converter and the load, as shown in

Figure 1.

Figure 1.

Block diagram of the off-grid wind generation system.

Figure 1.

Block diagram of the off-grid wind generation system.

After rectification by the AC/DC circuit, the collected wind energy is further regulated by the Buck converter and delivered directly to the DC load. In [

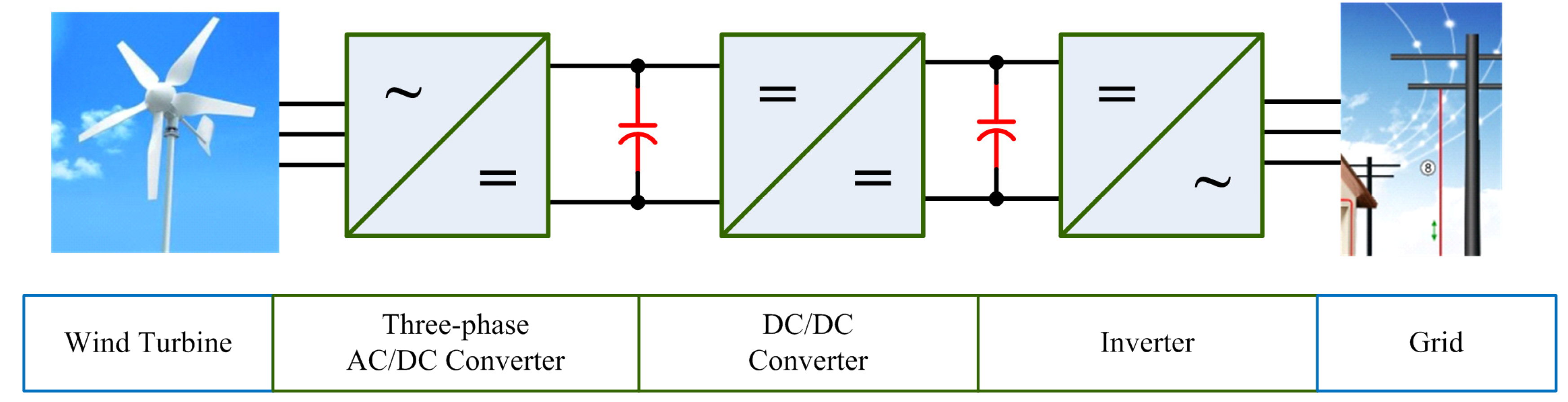

3], a converter for off-grid usage is proposed. By the combination of a three-phase diode bridge rectifier and an interleaved Buck converter, wind energy is converted to the load as power supply. The converter also realizes soft switching for the power switches, which can bring about higher conversion efficiency. Besides, for the general case, the load voltage level always remains low in off-grid WGS, therefore no particular requirements for the DC-link voltage level are needed. Instead, only a simple match for the voltage levels of wind generator, DC-link and the load is required. Thus, the off-grid WGS is relatively easy to realize. However, its applications are limited, because generally, off-grid systems are only suitable for special loads with a narrow voltage/power range. Conversely, as a more extensive application form, grid-tied WGS are often made up of a wind generator, a three-phase AC/DC rectifier, a DC/DC converter, an inverter and the grid, as shown in

Figure 2.

Figure 2.

Traditional structure of small-scaled grid-tie wind generation system.

Figure 2.

Traditional structure of small-scaled grid-tie wind generation system.

Due to the changeable amplitude and frequency, the alternating electric power generated by the generally adopted permanent magnet synchronous machine (PMSM) must be converted into DC power form first, where the low-cost solution of the three-phase diode bridge rectifier is often used. Then, the DC power is further inverted to AC power again and delivered into the grid. The DC-link voltage should be designed to be higher than the grid voltage to fulfill grid-tie generation [

2]. Unfortunately, in small-scale wind fields, the low average and large fluctuation of wind speed will result in rapid fluctuations and low output voltage of the wind generator. The output voltage provided by existing AC/DC converters using the maximum power point tracking (MPPT) control strategy is also very low and cannot match up with the required DC-link voltage level for the post-stage grid-tie inverter. Besides, the disability of the power converters to obtain adequate voltage gain at low input voltage, the disability of collecting weak wind energy, and the rigid requirements of the inverters for grid-tie generation also hinder its normal operation. Accordingly, for most existing small-scale WGS it is hard to realize a well-performed grid-tie wind power generation. Several topologies for small-scale WGS have been already researched and compared, as presented in [

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23]. A classical small-scale grid-tie WGS topology, consisting of diode bridge rectifier, DC/DC boost converter and grid-tie inverter is analyzed in [

7,

8,

9] and shown in

Figure 3. This topology possesses advantages like a simple structure, low cost and easy control. In [

7], a converter consisting of wind turbine, PMSM generator, three-phase diode rectifier, boost DC/DC circuit, inverter and an LCL filter is analyzed, and can basically realize the wind power delivery. However, the promotion of this converter is limited. On the one hand, although the DC/DC boost circuit can provide a high voltage gain, it has drawbacks like high power losses and reduction in reliability. On the other hand, the three-phase diode bridge rectifier is a cost-efficient alternative for small-scaled wind generation, due to its low cost and simple configuration, but it still suffers from high power losses, caused by larger input current, and low power factor, which will introduce rich harmonics and may give rise to vibration, large noise and power resonance [

10,

11,

12].

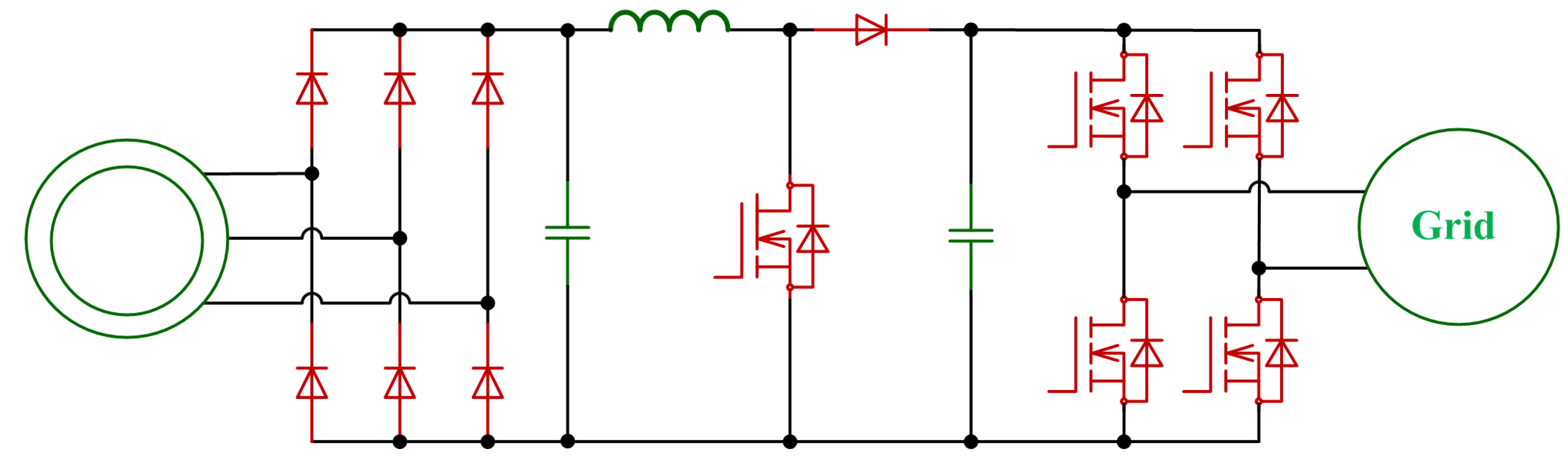

To overcome these problems, the back-to-back three-phase pulse width modulation (PWM) converter, as the most frequently used three-phase power converter topology so far in wind turbine systems, was developed [

2]. In [

13,

14], the back-to-back PWM power conversion configuration is chosen and analyzed, as presented in

Figure 4. The PWM converter substitutes the diode devices by full controlled switches in both generator side and grid side, and decouples the two sides by a bulky DC-link capacitor. It achieves bidirectional power delivery and has a wide power range of applications, from kW to MW by adopting different levels of power devices. The PWM converter can also obtain outstanding performances of high efficiency, unity power factor and high reliability, but in view of the complicated control strategy and higher cost, which is an important factor of the design purpose, the PWM converter is not the optimal alternative for small-scale WGS [

15,

16].

Figure 3.

Diode bridge + boost converter wind generation system.

Figure 3.

Diode bridge + boost converter wind generation system.

Figure 4.

The PWM converter wind generation system.

Figure 4.

The PWM converter wind generation system.

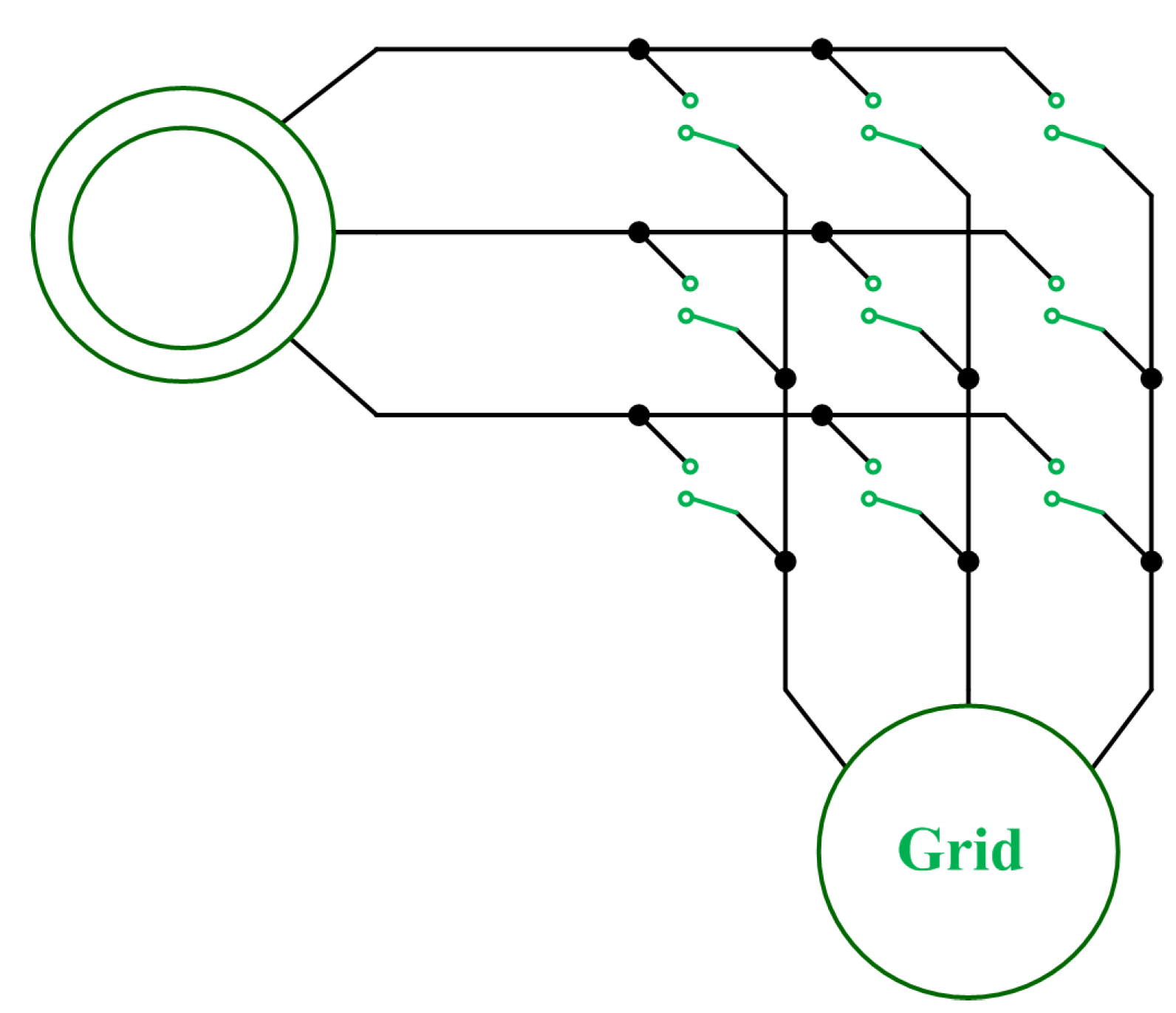

In [

17,

18], matrix converters are proposed and analyzed for small-scale WGS as shown in

Figure 5. It is made up of full controlled switches with no passive components, and can adjust its current and voltage waveforms by controlling the switching signals [

14]. The matrix converter system can realize bidirectional power delivery, controllable current/voltage/power factor and is free of electrolytic capacitor. However, its high cost, intricate control strategy and lack of decoupling between the input and output make it less competitive when applied in small-scale WGS.

Figure 5.

The matrix converter wind generation system.

Figure 5.

The matrix converter wind generation system.

To take the performance and the cost into consideration comprehensively, a WGS described in [

19,

20] adopts the three-phase single-switch boost converter and an inverter as shown in

Figure 6. In [

20], with only one power switch, the proposed converter possesses the advantages of all three aforementioned converters, including straightforward topology, simple control method, relatively high power factor and efficiency. Thus, it is suitable for small-scale WGS applications [

19,

20,

21,

22].

Figure 6.

The three-phase single-switch boost converter wind generation system.

Figure 6.

The three-phase single-switch boost converter wind generation system.

Nevertheless, few of these converters can provide a high enough voltage gain and perform a well-functioned grid-tie wind power generation, because of the low average wind speed in small-scale wind fields.

Trying to deal with the DC-link voltage level issue, a boost grid-tie inverter is simulated and tested in [

23], where the voltage gain is shared between both the rectifier and the proposed inverter. Grid-tie generation can be realized even when the DC-link voltage is lower than the grid voltage. However, in this topology, high power losses and high current stresses may occur, because of the large ripples in the input inductor currents and the bulky output filter.

Owing to all these problems that exist in the boost inverter, many researches on high step-up DC/DC converters have been developed. Currently, efficient technologies including coupled inductor [

24,

25,

26,

27,

28] and switched capacitor [

25,

26,

29,

30,

31,

32,

33] are often adopted to improve the voltage conversion ratio.

In [

24,

25,

26,

27], the proposed flyback converter is able to build an additional energy transmission circuit by means of coupled inductors, and can superimpose the output voltage of the additional circuit on that of the main circuit as shown in

Figure 7.

Figure 7.

The circuit topology of flyback DC/DC converter.

Figure 7.

The circuit topology of flyback DC/DC converter.

Thus, a relatively high voltage gain can be achieved. This proposed converter is very suitable for high frequency, low power and high step-up voltage gain applications, but it is usually applied in DC/DC cases and needs a cascaded front-stage rectifier to convert the input AC voltage into DC, which may lead to larger losses, lower efficiency and higher cost.

Switched capacitors are also employed frequently in the proposed converters in [

29,

30,

31,

32,

33]. In

Figure 8, as energy snubbers, switched capacitors are able to store and deliver energy from the input source to the output load during one switching cycle, and therefore fulfill high step-up voltage conversion. This technology is widely adopted in many cases, for its light weight and high power density, but its utilization is also generally restrained in DC/DC areas.

Figure 8.

The circuit topology of switched-capacitor DC/DC converter.

Figure 8.

The circuit topology of switched-capacitor DC/DC converter.

Consequently, in order to solve the problems existing in small-scale WGS, in this paper, a novel three-phase high step-up single stage flyback AC/DC converter with switched capacitors is presented and analyzed. The proposed converter is suitable for urban-roof or power-hungry usage scenarios, and can obtain high voltage gain at low input voltage and high power factor, high efficiency in rated situations. Since it has both rectification and voltage gain improvement functions, no additional DC/DC converter is needed any longer. The input current is designed to be operated in discontinuous current mode (DCM), and inherent power factor correction (PFC) is also achieved at full load. In addition, no electrolytic capacitor is employed, thus the proposed converter can also collect weak power and has a reduced volume.

2. Circuit Configuration

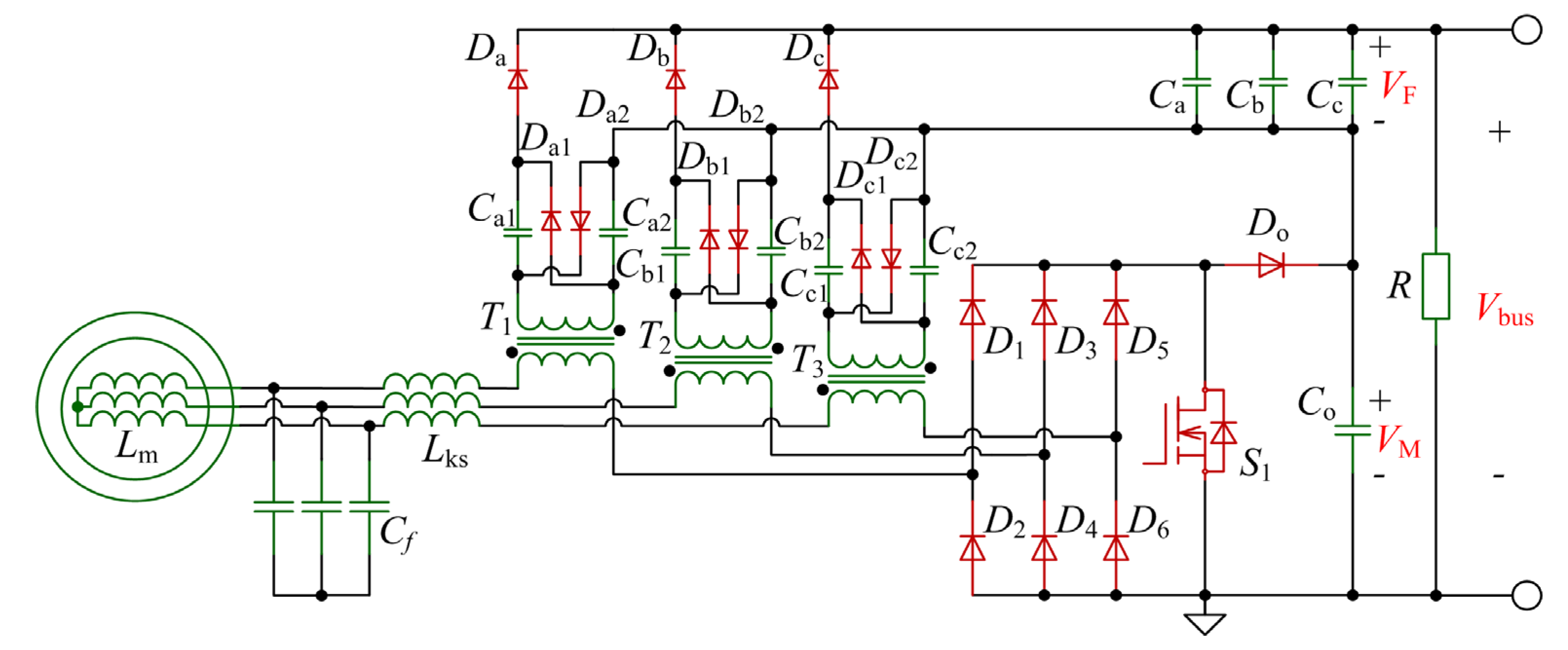

The topology of the proposed converter is presented in

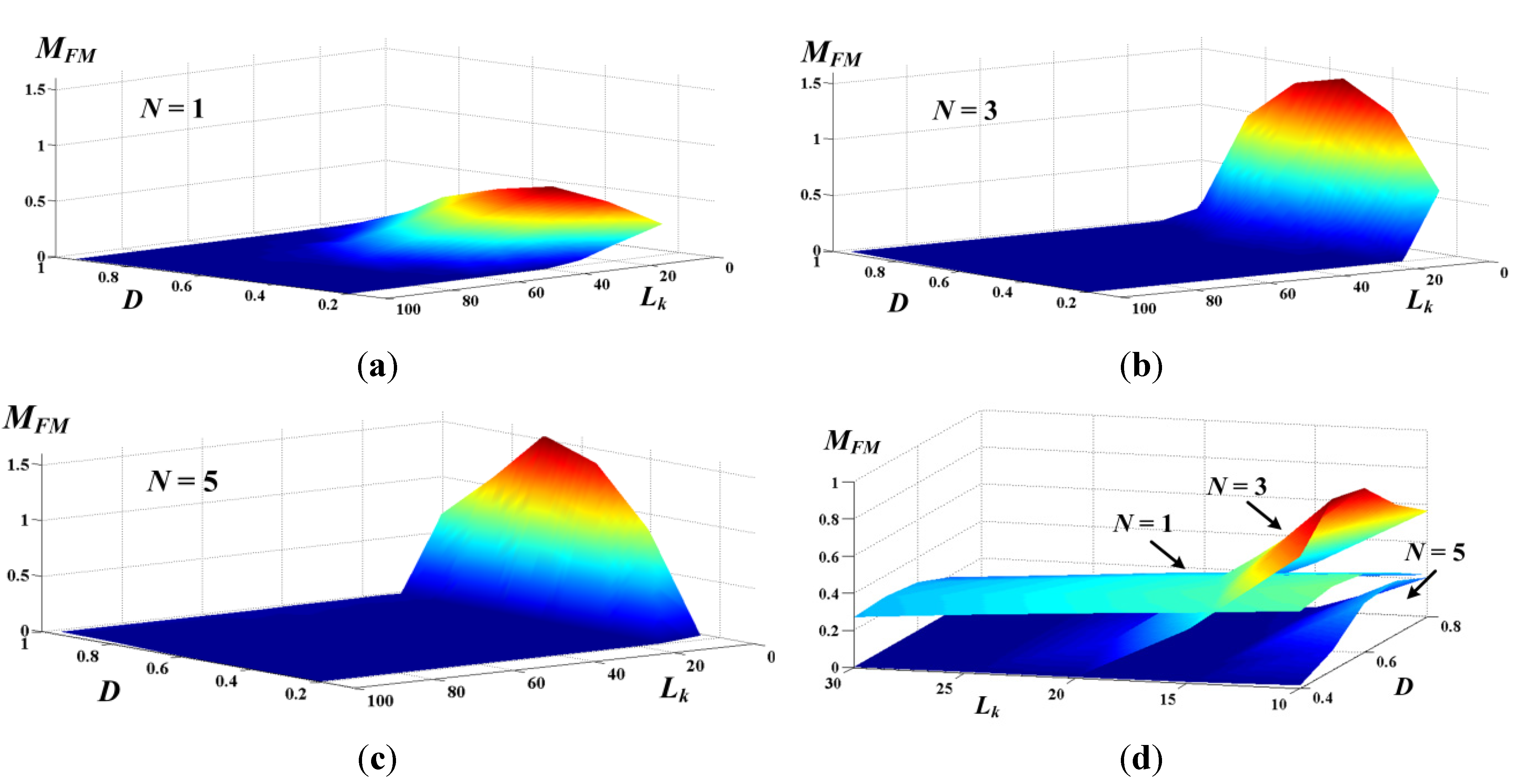

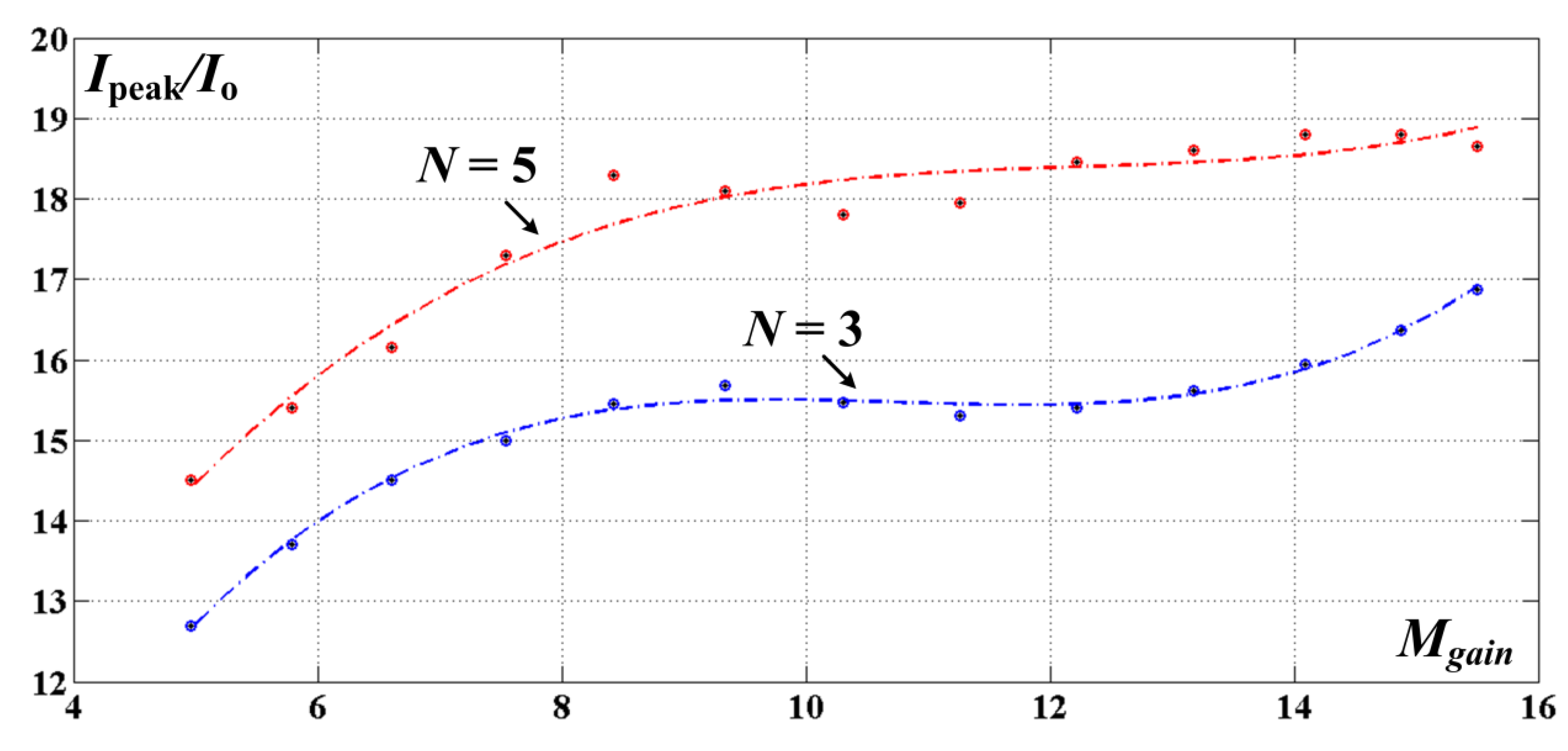

Figure 9. By integrating the three-phase single-switch boost circuit and flyback circuits with switched capacitors, the converter can obtain a high voltage gain at low input voltage. The converter is totally divided into four main parts including high frequency filter capacitors

Cf, uncontrolled diode bridge rectifier

D1 ~ D6, flyback cells and a boost cell (

Lks,

S1,

Do and

Co). Moreover, for the purpose of tracking the maximum wind power, a variable step size algorithm is adopted [

34,

35]. The control strategy will be analyzed in detail in further work, and this paper mainly focuses on the topology of the proposed converter.

The diode bridge will rectify the input AC current to DC at first, and then the boost cell is able to boost the rectified voltage as the output voltage of boost cell VM. In flyback cells, since each unit is completely symmetrical, we take phase A for example to explain the configuration of the cells. In phase A, the flyback cell is composed of transformer T1, diode Da, output capacitor Ca and a switched capacitor cell consisting of capacitor Ca1, Ca2 and diode Da1, Da2. Switched capacitors can store the energy delivered from primary side of T1 when the power switch S1 turns on, and releases it to charge flyback output capacitor Ca through Da when S1 turns off. As a consequence, T1 is able to transform power from primary side to secondary side during the entire switching period. Lkt, which is defined as the leakage inductor of T1, connects the boost inductor Lks serially, and their sum (Lkt + Lks) can be regarded as the equivalent leakage inductor Lk.

Figure 9.

The circuit topology of the proposed converter.

Figure 9.

The circuit topology of the proposed converter.

In order to further improve the performance at low input voltage, all of the flyback output capacitors Ca, Cb, Cc and the boost output capacitor Co employ film capacitors with small capacitance and small volume instead of electrolytic capacitors. On one hand, by doing so, the converter can prevent the large current leakage and large losses introduced by electrolytic capacitors, and thus can achieve weak energy collection. On the other hand, the adoption of film capacitors can also lead to larger voltage ripples, since the capacitance is small. To restrain the voltage ripples, Ca, Cb, Cc are designed to connect in parallel, for the reason that the ripple of each phase is identical in amplitude and 120° behind sequentially in phase and will weaken each other. CF, which consists of Ca, Cb, Cc, is defined as the equivalent flyback output capacitor and connects Co serially. As a result, the voltage gain is further improved, because the flyback output voltage VF is superimposed to the boost output voltage VM.

The comparison among the proposed AC/DC converter and other three-phase AC/DC converters are made as manifested in

Table 1. According to the table, although the proposed converter has the maximum quantity of power switches and diodes, the unit-price of the chosen auxiliary diodes in flyback cells is exceedingly low (ES3G, less than $0.05/pieces). Moreover, some traditional converters even need low-frequency transformers to achieve high voltage gain, which will further increase the converter cost. With a relatively low cost and good performance, the proposed AC/DC converter is competitive in small-scale WGS applications.

Table 1.

Cost Comparison.

Table 1.

Cost Comparison.

| AC/DC Converter | High Frequency Transformer/Inductor | Power Switch Quantity | Power Diode Quantity | Auxiliary Diode Quantity | Cost |

|---|

| Diode Bridge + Boost Converter | 1 | 1 | 7 | 0 | Lowest |

| PWM Converter | 3 | 6 | 0 | 0 | High |

| Matrix Converter | 3 | 9 | 0 | 0 | Highest |

| Three-phase Single-switched Converter | 3 | 1 | 7 | 0 | Low |

| Proposed Converter | 3 | 1 | 7 | 9 | Low |

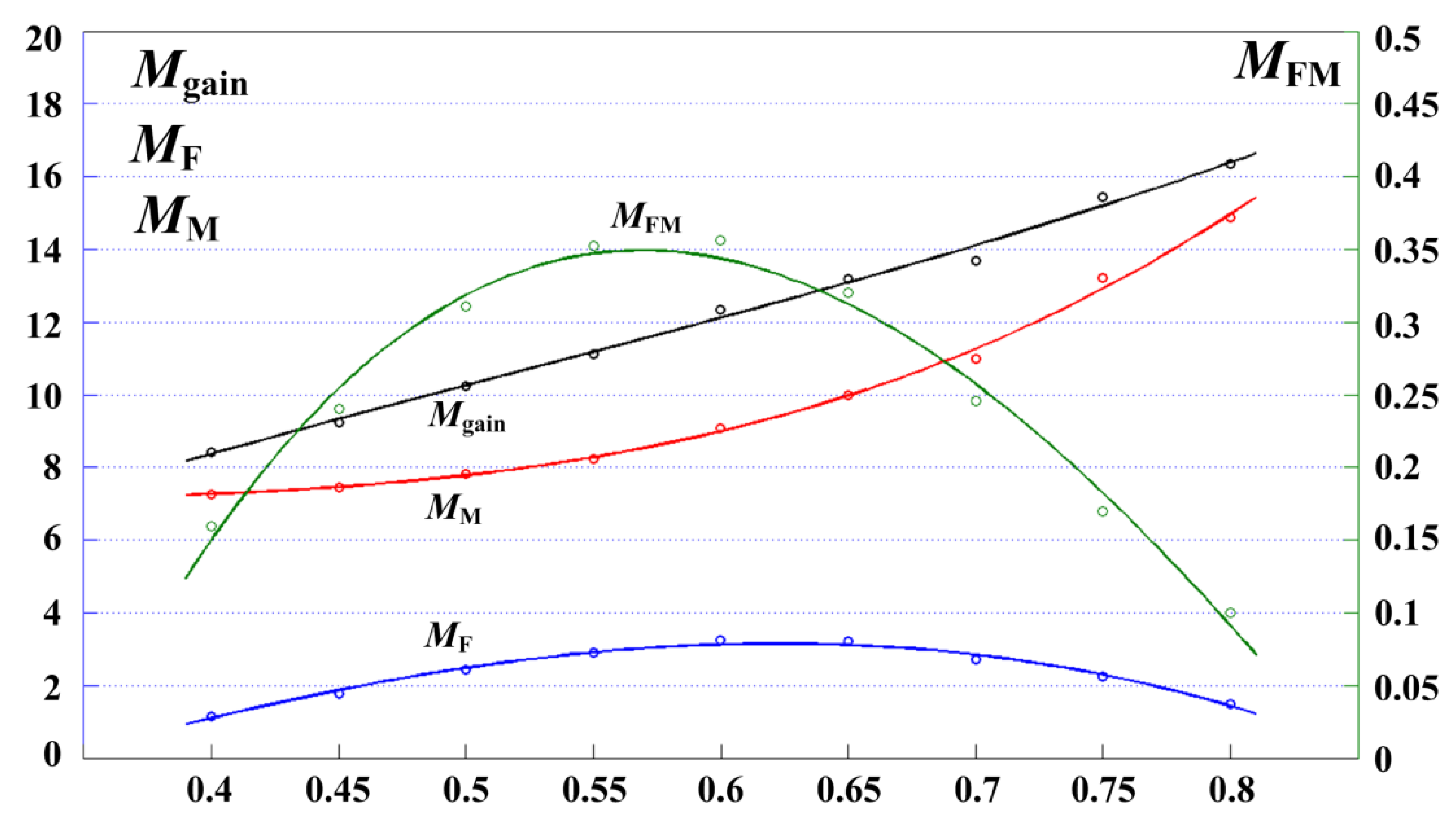

4. Experimental Results

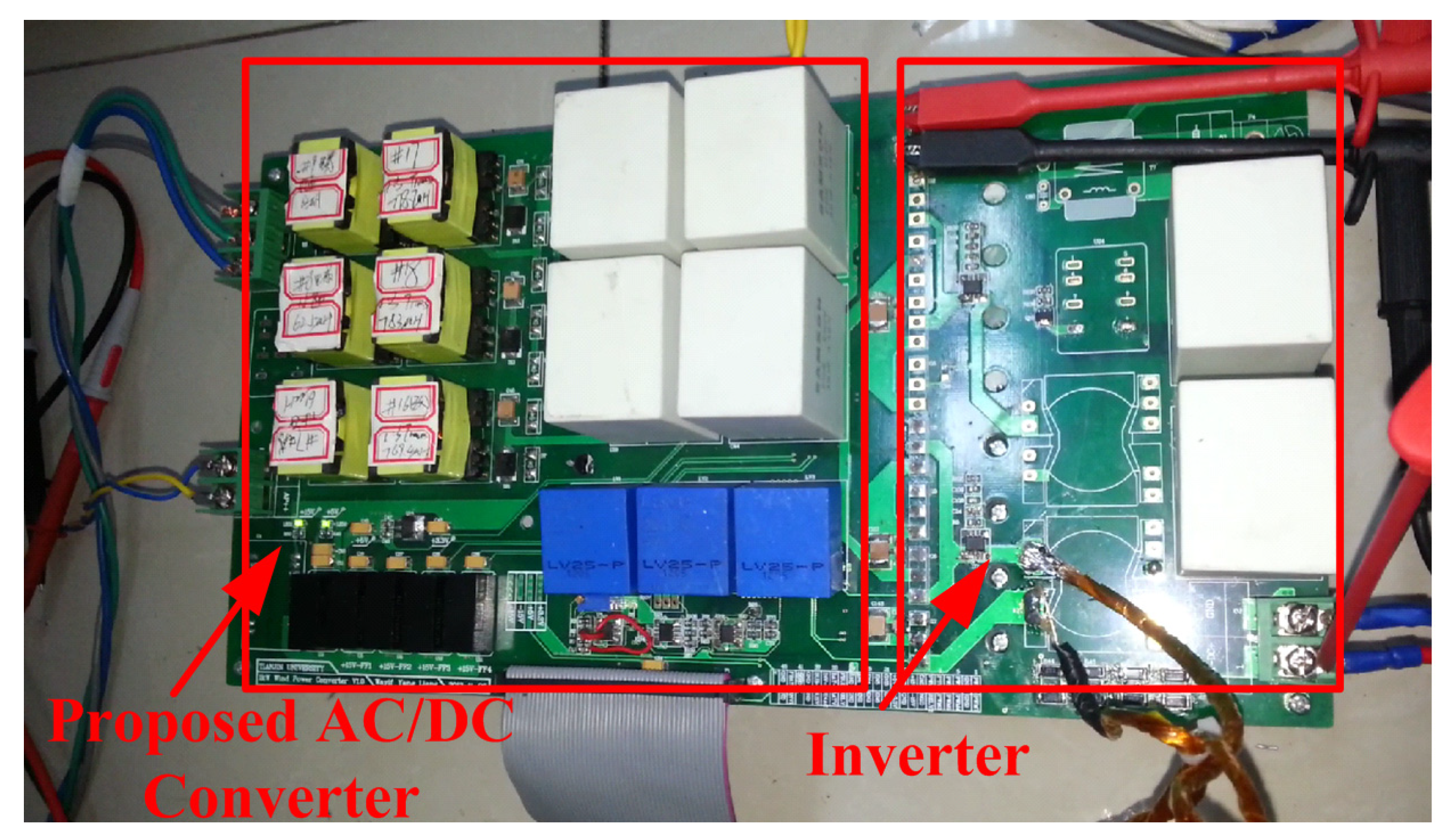

In order to verify the feasibility of the proposed converter, a 400 W prototype was made and shown in

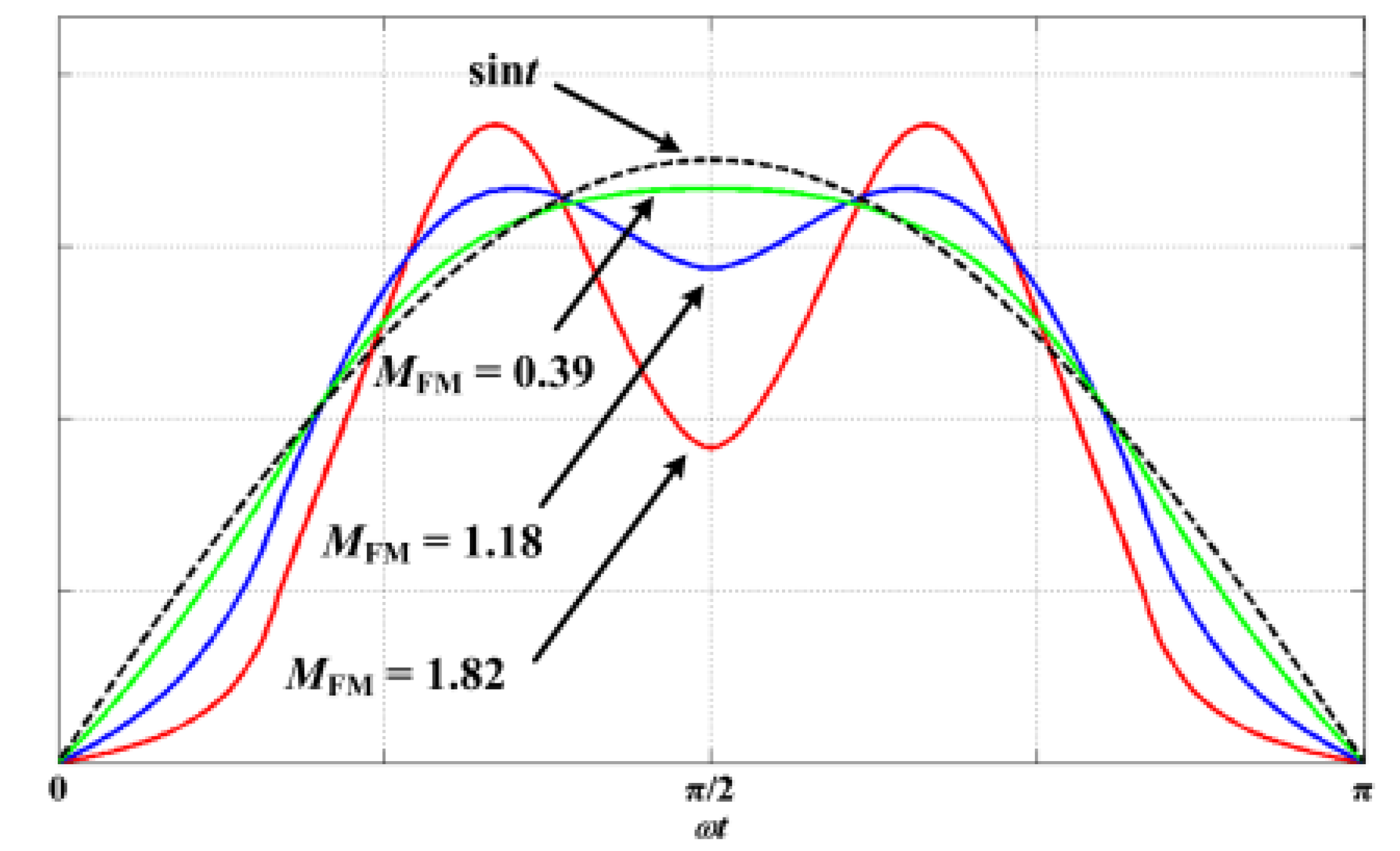

Figure 18. A front-stage PMSM is employed as the power supply. The PMSM can output a rated phase voltage of 48 V AC at its rated wind speed of 12 m/s. To match up with the voltage level of the PMSM, the proposed converter is designed to operate with rated input phase voltage of 48 V AC. Besides, the DC-link voltage is required to be maintained at around 410 ~ 430 V DC, so that the post-stage inverter is able to fulfill grid-tie generation. Consequently, a voltage gain of 9 is demanded under rated condition and the correspondent duty cycle

D is set as 0.45 according to

Figure 17.

Figure 18.

The proposed converter prototype.

Figure 18.

The proposed converter prototype.

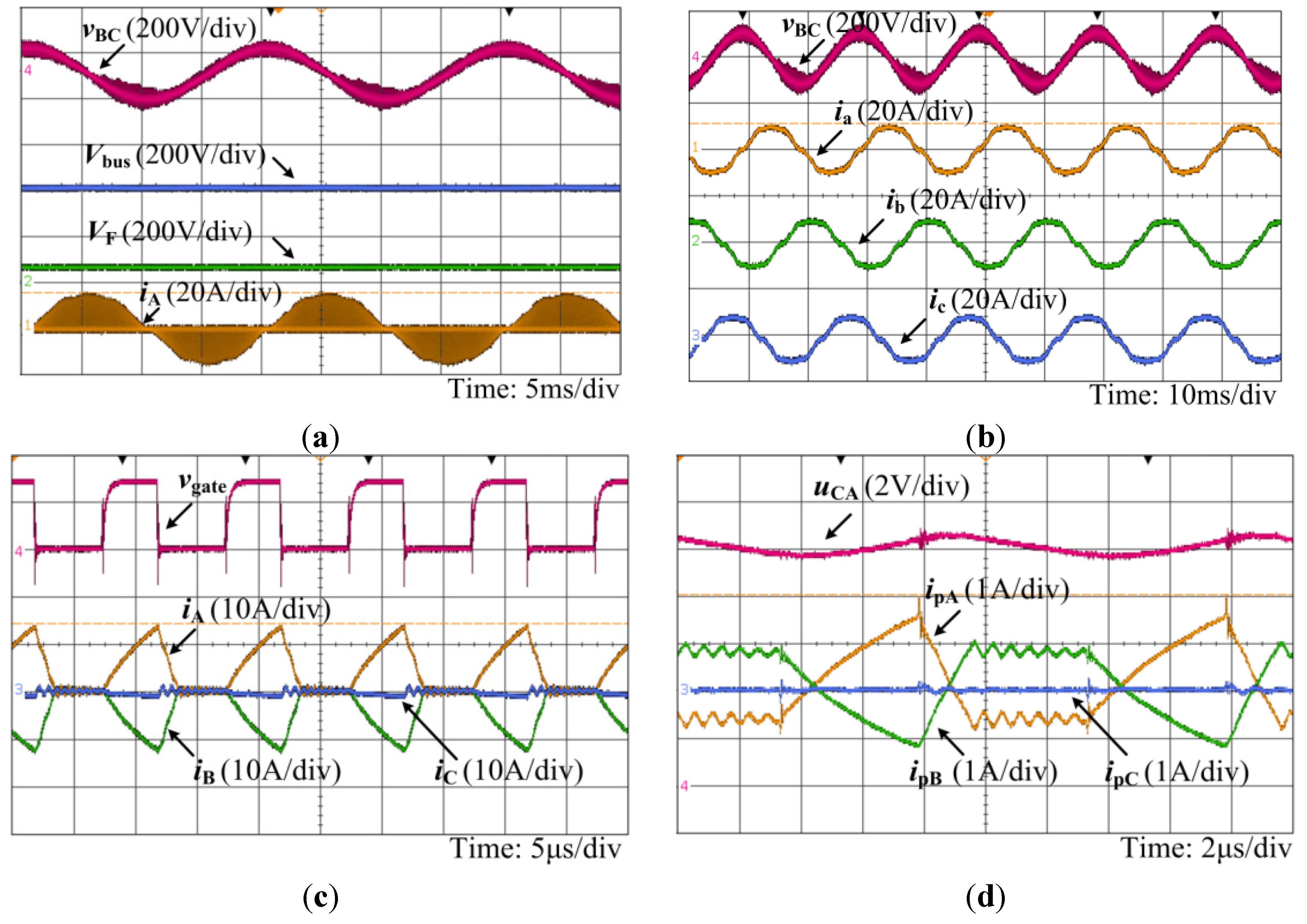

The experimental results under the rated conditions are shown in

Figure 19. In

Figure 19a, line voltage between phase B and C

vBC, total output voltage

Vbus, flyback output voltage

VF and input current

iA are presented, where

Vbus is 420 V,

VF is 80.7 V, and the input phase voltage

Vin-p is 45 V AC. The voltage gain

Mgain is calculated as 9.32, which matches well with the aforementioned demand. Moreover, the distortion

MFM is limited to 0.24, so the envelope waveform of

iA exhibits a sine-shaped waveform.

Figure 19b shows the PMSM output currents

ia,

ib and

ic, where only small distortions exist in the waveforms and the THD is 7.4%.

Figure 19c shows the control signal

vgate and the input currents

iA,

iB and

iC in several switching cycles. At this time, since

MFM is limited and the distortion introduced by flyback cells is restrained, waveforms of current

iA,

iB and

iC are regarded to vary linearly. After rising from zero and reaching their peaks simultaneously,

iC drops to zero at first and then

iA,

iB also fall to zero.

Figure 19d illustrates the secondary current of flyback cells

iPA,

iPB,

iPC and voltage across the switched capacitor

Ca1/

Ca2 uCA. Furthermore, waveforms in

Figure 19c,d match well with the theoretical waveforms presented in

Figure 11. The main experimental results of the converter are measured as follows:

D = 0.45,

Vin-P = 45 V AC,

VF = 80.7 V,

Vbus = 420 V,

Mgain = 9.32,

MFM = 0.24, THD = 7.4%, PF (power factor) = 0.99, Efficiency η = 87.6%.

Figure 19.

Experimental results under the rated conditions. (a) input line voltage, output voltage and input current; (b) input line voltage and PMSM output currents; (c) gate signal and three phase input current in detail; (d) uCA and secondary currents of flyback cells.

Figure 19.

Experimental results under the rated conditions. (a) input line voltage, output voltage and input current; (b) input line voltage and PMSM output currents; (c) gate signal and three phase input current in detail; (d) uCA and secondary currents of flyback cells.

The performance at low input voltage is also tested as shown in

Figure 20, where each of the waveform represents the same voltage/current signal as that in

Figure 19. By introducing the flyback cells and adopting high duty cycle

D = 0.7, the proposed converter can achieve high voltage gain at low input voltage. At this time,

Vbus is 163 V,

VF is 34.6 V and

Vin-p is 11.6 V AC. The voltage gain

Mgain reaches a relatively high level of 14. Besides, waveforms in

Figure 20c,d also match with the theoretical analysis. The main parameters of the converter are measured as follows:

D = 0.7,

Vin-P = 11.6 V AC,

VF = 34.6 V,

Vbus = 163 V,

Mgain = 14,

MFM = 0.27, THD = 8.2%, PF (power factor) = 0.99, Efficiency η = 81.1%.

Figure 20.

Experimental results at low input voltage. (a) input line voltage, output voltage and input current; (b) input line voltage and PMSM output currents; (c) gate signal and three phase input current in detail; (d) uCA and secondary currents of flyback cells.

Figure 20.

Experimental results at low input voltage. (a) input line voltage, output voltage and input current; (b) input line voltage and PMSM output currents; (c) gate signal and three phase input current in detail; (d) uCA and secondary currents of flyback cells.

Additionally, as analyzed before, MFM will reach its peak at around D = 0.6 if a constant Lk is set. At the same point, the input current distortion caused by flyback cells will be equal to its maximum value as well. Consequently, if the maximum value of MFM is acceptable, the optimized parameters of the proposed converter can satisfy the design requirements for conversion efficiency. The relevant experiment should be conducted.

In

Figure 21, experimental results under the condition that

MFM reaches its peak are presented, where

Vbus is 420 V,

VF is 108.5 V and

MFM is 0.35. As it can be seen from

Figure 21a,b, the waveform distortion is obviously larger than that of rated condition. The secondary currents of flyback cells

iPA,

iPB,

iPC are almost as twice as that of rated condition, which demonstrates the influence caused by flyback cells have been strengthened. The main parameters of the converter are measured as follows:

D = 0.6,

Vin-P = 34.6 V AC,

VF = 108.5 V,

Vbus = 420 V,

Mgain = 12.1,

MFM = 0.35, THD = 8.9%, PF (power factor) = 0.99, Efficiency η = 83.1%.

Figure 21.

Experimental results at maximum MFM. (a) input line voltage, output voltage and input current; (b) input line voltage and PMSM output currents; (c) gate signal and three phase input current in detail; (d) uCA and secondary currents of flyback cells.

Figure 21.

Experimental results at maximum MFM. (a) input line voltage, output voltage and input current; (b) input line voltage and PMSM output currents; (c) gate signal and three phase input current in detail; (d) uCA and secondary currents of flyback cells.

Finally, the relationships between efficiency/THD and output power are shown in

Figure 22a,b. The conversion efficiency increases from 81.9% to 87.6% when the output power grows from 100 to 400 W. The efficiency can reach 87.6% at rated condition. The maximum THD is 8.9%, and at rated condition, THD is equal to 7.4%. The power factor is 0.99 at rated. Thus, in small power level application, the proposed converter can obtain the relatively high conversion efficiency, high power factor and low THD.

Figure 22.

Relationship between efficiency/THD and output power. (a) measured efficiency; (b) measured THD.

Figure 22.

Relationship between efficiency/THD and output power. (a) measured efficiency; (b) measured THD.