Research on and Design of a Self-Propelled Nozzle for the Tree-Type Drilling Technique in Underground Coal Mines

Abstract

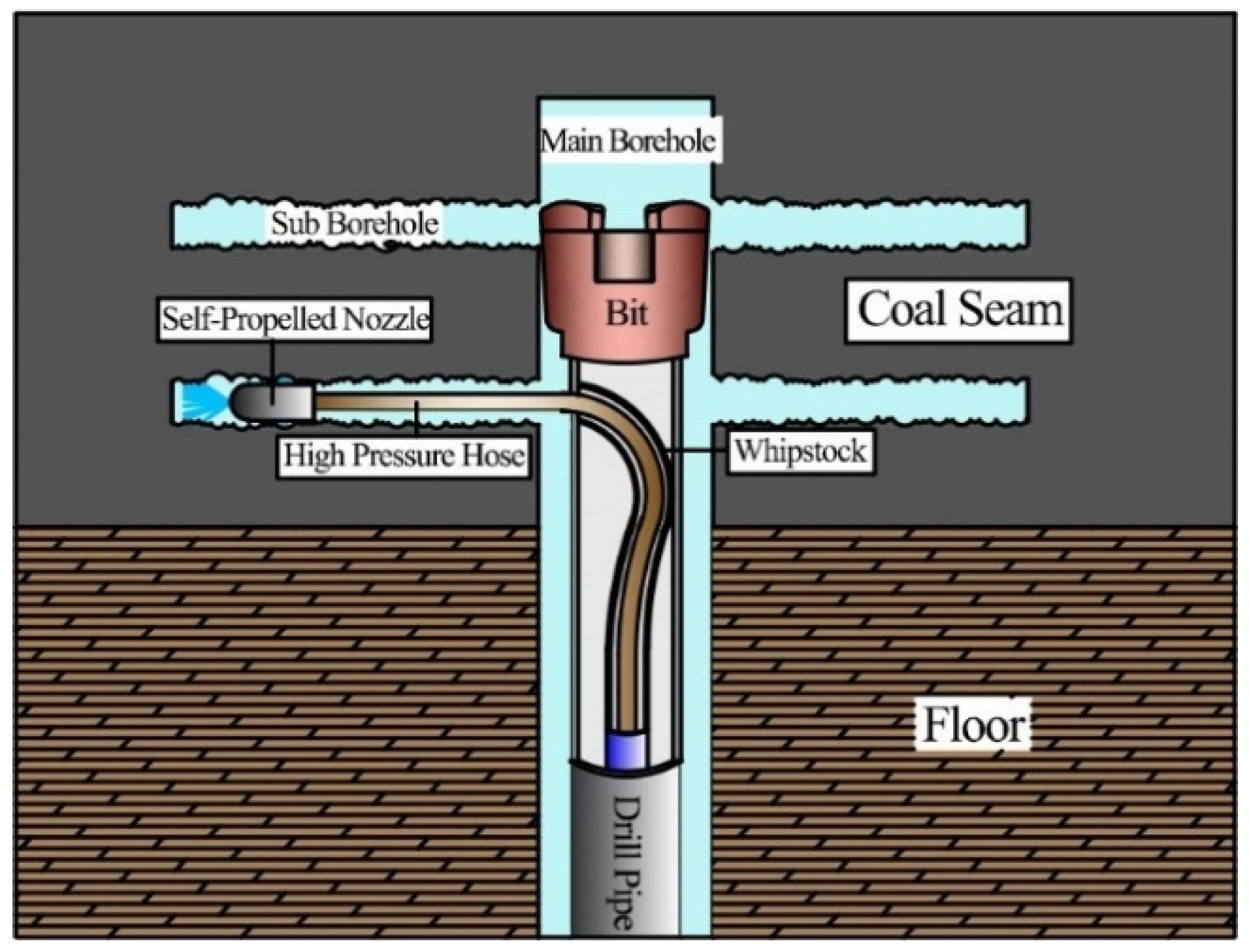

:1. Introduction

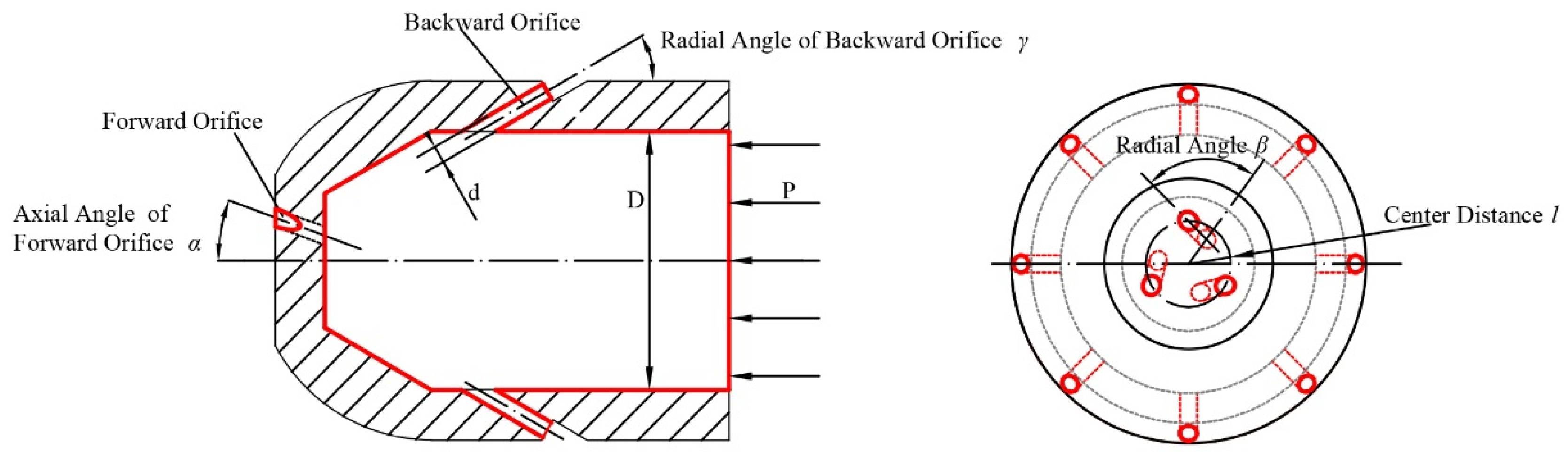

2. Preliminary Design

3. Drilling Speed Tests

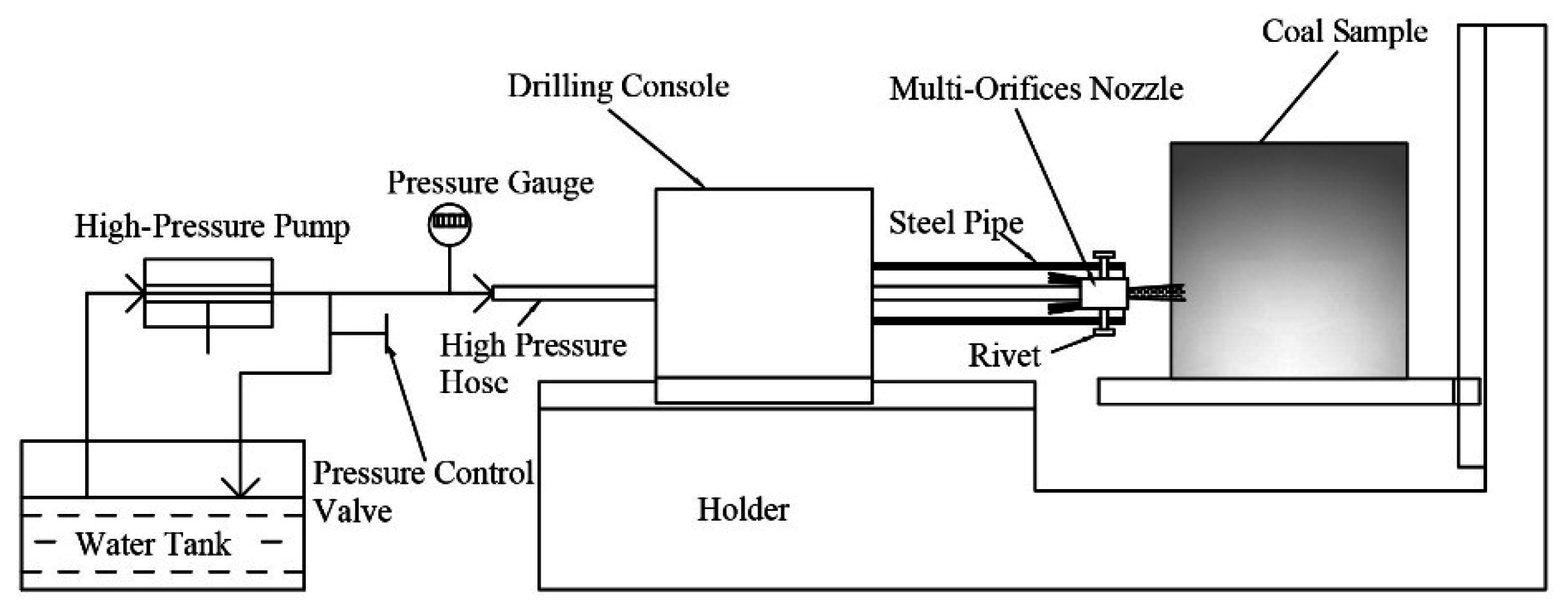

3.1. Test Apparatus and Method

- The high-pressure pump; rated pressure 32.5 MPa, rated flow rate 200 L/min.

- The jet generator; main components include the hose connector, the pressure gauge, high-pressure hose, and the nozzle connector.

- The drilling console mounted on tracks. There is a removable steel bar for fixing the nozzle to the steel pipe connected to the drilling console. When measuring the self-drilling speed, the bar is removed freeing the nozzle to move forward. When conducting the rock breaking tests and studying the pattern of broken holes, the bar is replaced to fix the nozzle to the drilling console so that the two will move together. The rate at which the drilling console can move is controlled by an electric motor and ranges from 0.01 to 100 mm/s.

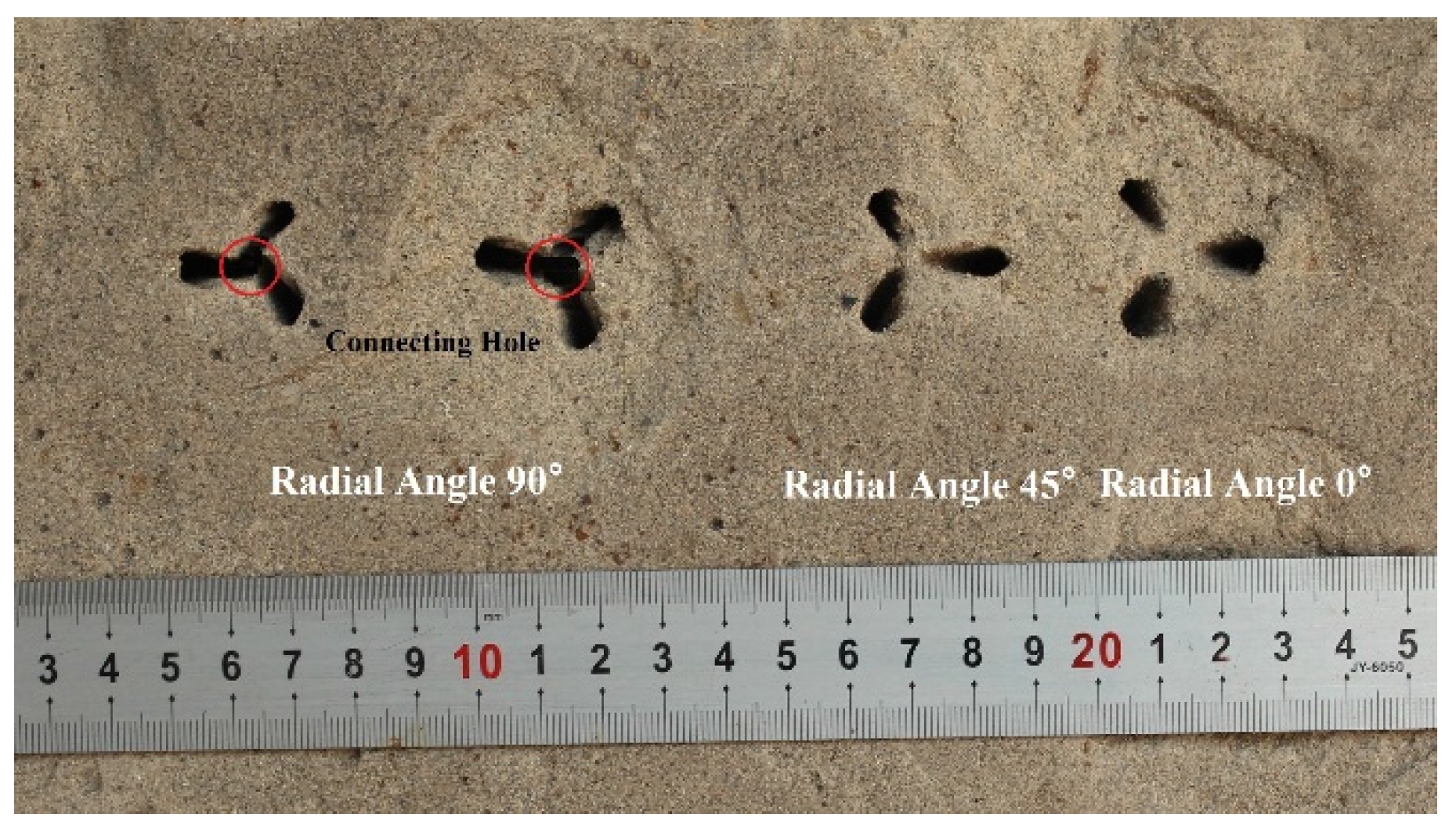

- The nozzle. Using the control variable method to design experiments, the influence law of each forward orifice configuration on rock breaking efficiency of the nozzle was studied. Thirteen different self-propelled nozzles were designed and machined for testing. The nozzles, shown in Figure 5, all have the same backward orifices axial angle (25°). The specifications for the forward orifices are shown in Table 1. According to previous research, the optimal axial angle for a nozzle orifice is about 20° for rock breaking [20]. Therefore, the values of axial angle in the nozzles used for this study are around 20° and 5° as a research level considering machining limits. The values of radial angle cover the whole range from 0° to 90°. The values of center distance are limited by the diameter of the nozzle, so the maximum is 1.8 mm (±0.1 mm as a level also due to machining limits).

- Experimental coal sample. Coals from different mines in different regions can have very different physical properties. In order to test drilling in different kinds of coal and determine if the technique is broadly applicable, large blocks of coal were collected from three coal mines for drilling tests. The mines were the Songzao mine in southwest China, the Pingdingshan mine in central China, and the Tashan mine in northwest China. The coal ranks are from high volatile bituminous to anthracite and their hardnesses range from low to high. The experimental coal block sample from the Pingdingshan mine is shown in Figure 6.

| Number | Forward Orifice Structure Parameters | ||

|---|---|---|---|

| Axial Angle α/° | Radial Angle β/° | Center Distance l/mm | |

| 1# | 15 | 0 | 1.5 |

| 2# | 20 | 0 | 1.5 |

| 3# | 25 | 0 | 1.5 |

| 4# | 30 | 0 | 1.5 |

| 5# | 35 | 0 | 1.5 |

| 6# | 25 | 25 | 1.5 |

| 7# | 25 | 45 | 1.5 |

| 8# | 25 | 65 | 1.5 |

| 9# | 25 | 90 | 1.5 |

| 10# | 25 | 90 | 1.4 |

| 11# | 25 | 90 | 1.6 |

| 12# | 25 | 90 | 1.7 |

| 13# | 25 | 90 | 1.8 |

3.2. Experimental Results and Discussion

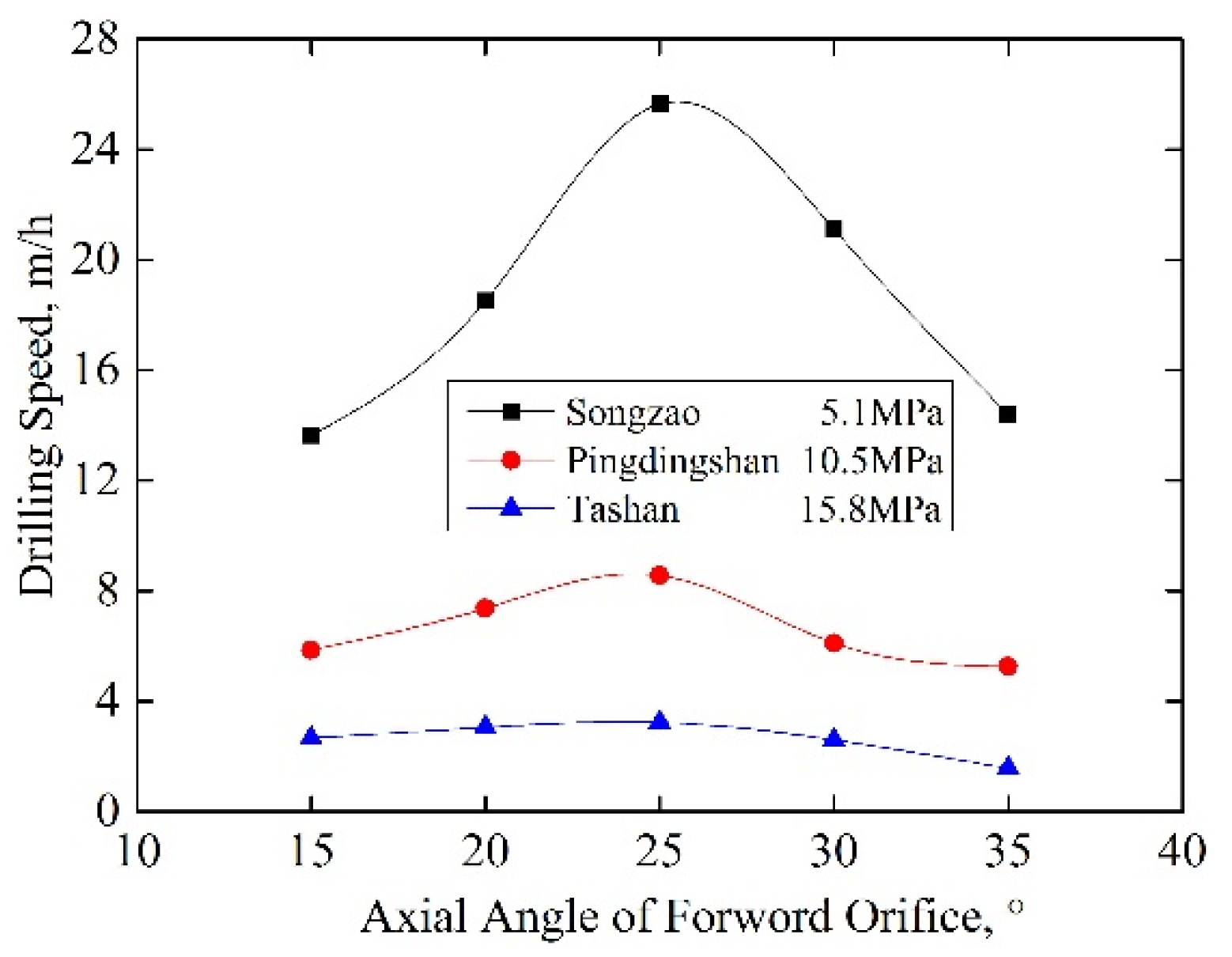

3.2.1. The Effect of the Forward Orifice Axial Angle on Self-Drilling Speeds

3.2.2. The Effect of the Forward Orifice Radial Angle on Self-Drilling Speeds

3.2.3. The Effect of Forward Orifice Center Distance on Self-Drilling Speeds

4. Self-Propelling Force Measurement

4.1. Test Apparatus and Method

- The high-pressure pump and jet generator. The performance parameters are the same as those described in Section 3.1.

- A through-hole load cell. A load cell, model number LC8200-625-50 (from Omega Engineering Company, Stamford, CT, USA) was used to measure the forces. The load cell has a ~5 cm (2-inch) outer diameter and ~16 mm (0.625-inch) inner diameter and can measure forces in the 0–222 N range accurately.

- A glass pipe. The glass pipe was used to simulate a gas drainage borehole in a coal seam. The pipe’s inner diameter was 50 mm.

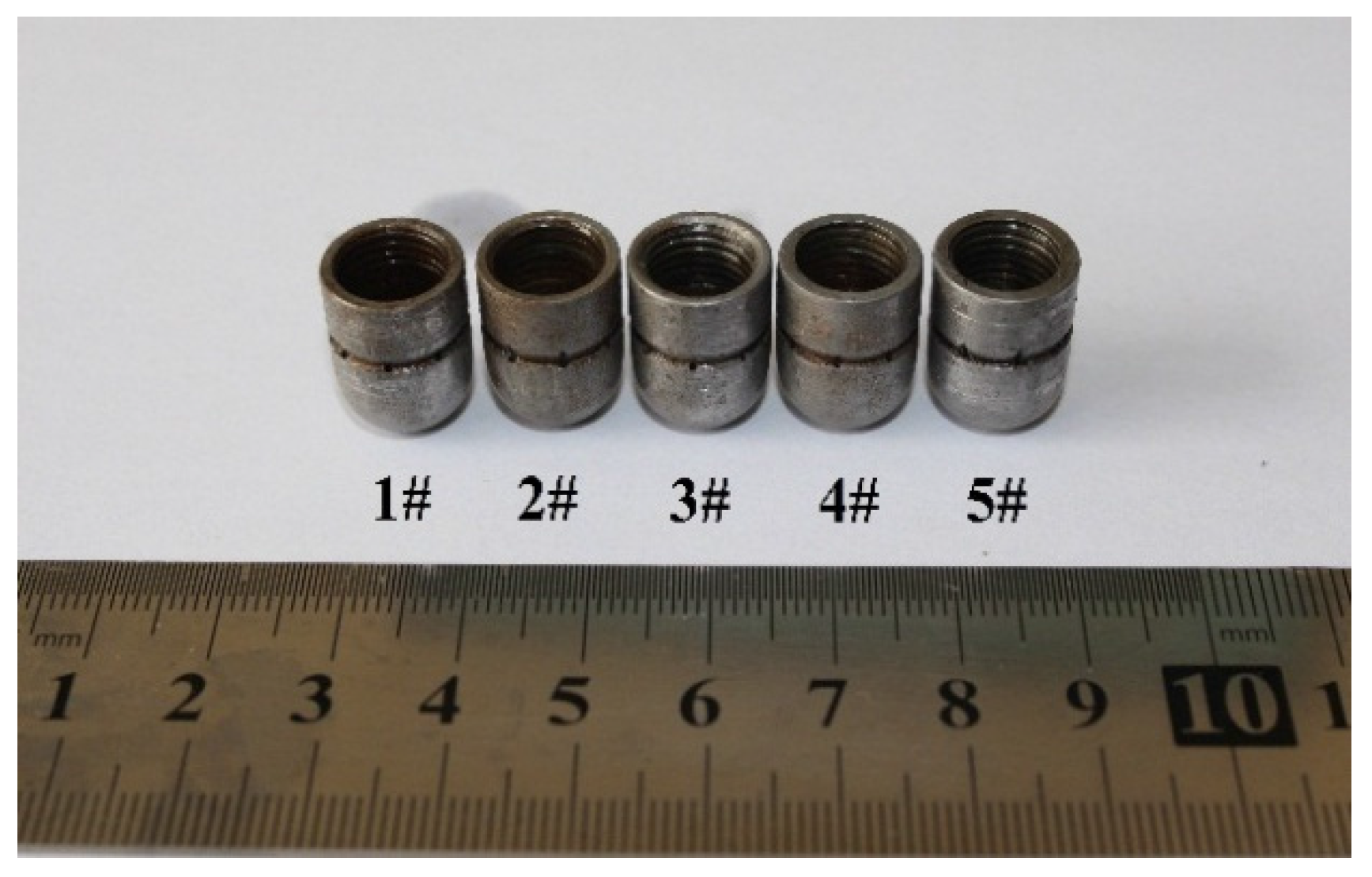

- Self-propelled nozzles. To analyze the total self-propelling force of the nozzle, five self-propelled nozzles with different backward orifice structures were machined. The nozzles are shown in Figure 12. These five nozzles all have the same forward orifice configuration (axial angle 25°; radial angle 90°; center distance 1.5 mm). The specifications for the backward orifices on the nozzles are shown in Table 2.

| Number | Backward Orifice Axial Angle/° |

|---|---|

| 1# | 10 |

| 2# | 15 |

| 3# | 20 |

| 4# | 25 |

| 5# | 30 |

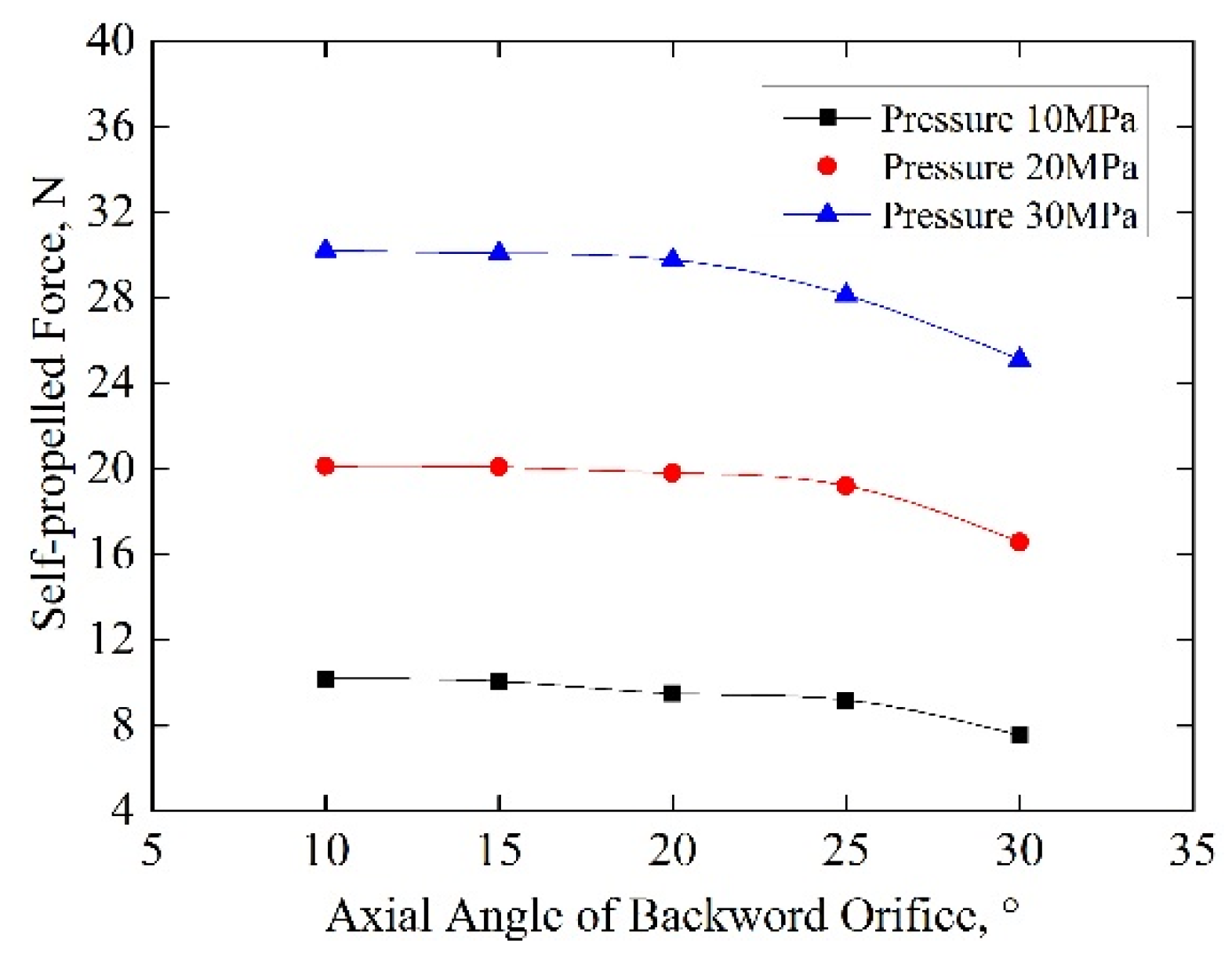

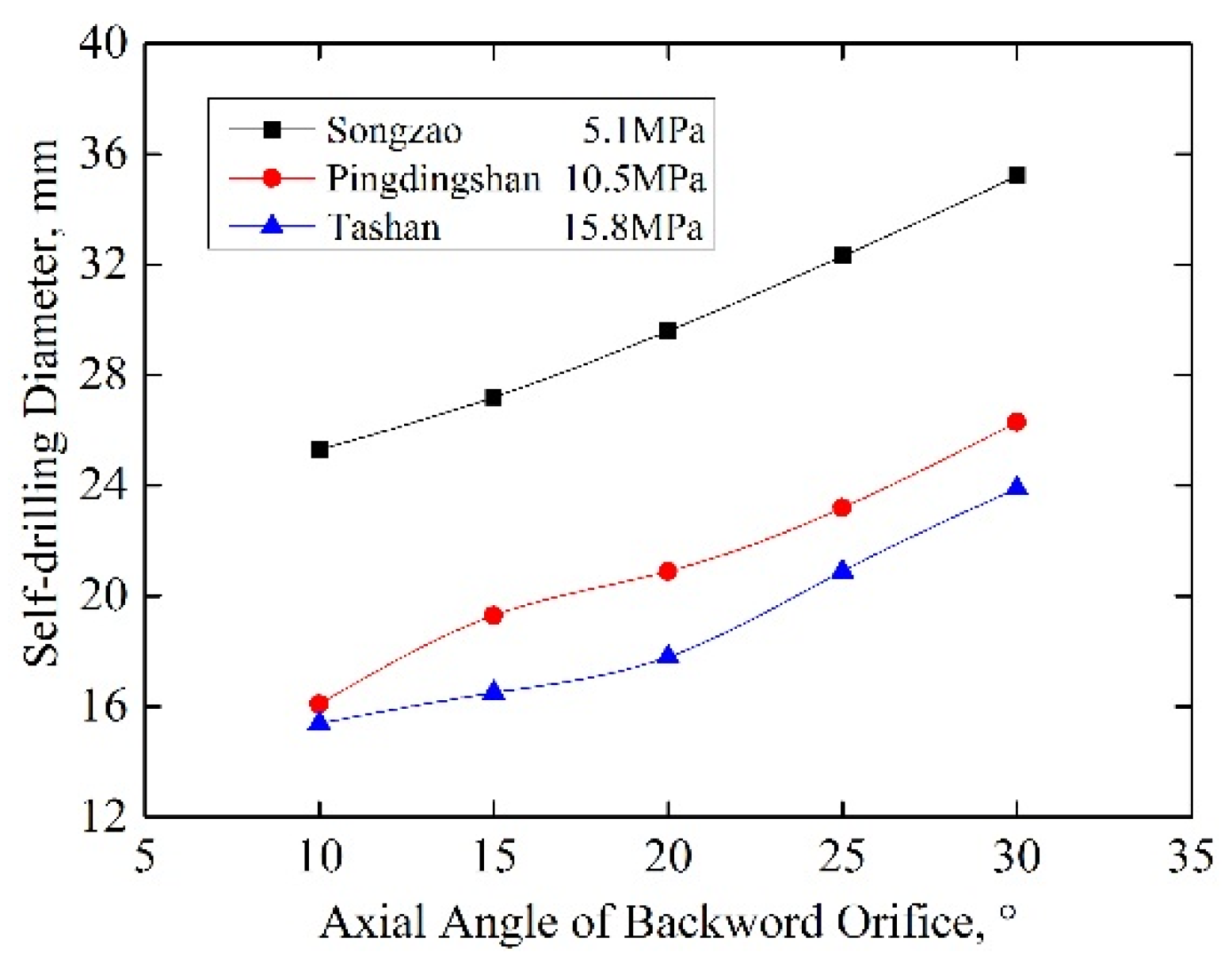

4.2. Experimental Results and Discussion

4.2.1. The Effect of Backward Orifice Axial Angle on Total Self-Propelling Force

4.2.2. The Effect of the Backward Orifice Axial Angle on the Diameter of the Self-Drilled Borehole

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dai, J.X.; Ni, Y.Y.; Wu, X.Q. Tight gas in China and its significance in exploration and exploitation. Pet. Explor. Dev. 2012, 39, 277–284. [Google Scholar] [CrossRef]

- Shen, C.M.; Lin, B.Q.; Sun, C.; Zhang, Q.Z.; Li, Q.Z. Analysis of the stress–permeability coupling property in water jet slotting coal and its impact on methane drainage. J. Pet. Sci. Eng. 2015, 126, 231–241. [Google Scholar] [CrossRef]

- Hu, G.Z.; Xu, J.L.; Zhang, F.X.; Zhao, C.C.; Qin, W.; Zhu, Y.R. Coal and coalbed methane co-extraction technology based on the ground movement in the Yangquan coalfield, China. Energies 2015, 8, 6881–6897. [Google Scholar] [CrossRef]

- Sachsenhofer, R.F.; Privalov, V.A.; Panova, E.A. Basin evolution and coal geology of the Donets Basin (Ukraine, Russia): An overview. Int. J. Coal Geol. 2012, 89, 26–40. [Google Scholar] [CrossRef]

- Clarkson, C.R. Production data analysis of unconventional gas wells: Review of theory and best practices. Int. J. Coal Geol. 2013, 109–110, 101–146. [Google Scholar] [CrossRef]

- Zou, Q.L.; Lin, B.Q.; Liu, T.; Zhou, Y.; Zhang, Z. Variation of methane adsorption property of coal after the treatment of hydraulic slotting and methane pre-drainage: A case study. J. Nat. Gas. Sci. Eng. 2014, 20, 396–406. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Gong, B.; Li, J.C.; Li, H.Y. Discrete fracture modeling of 3D heterogeneous enhanced coalbed methane recovery with prismatic meshing. Energies 2015, 8, 6153–6176. [Google Scholar] [CrossRef]

- Noack, K. Control of gas emissions in underground coal mines. Int. J. Coal Geol. 1998, 35, 57–82. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Diamond, W.P.; Schatzel, S.J. Numerical analysis of the influence of in-seam horizontal methane drainage boreholes on longwall face emission rates. Int. J. Coal Geol. 2007, 72, 15–32. [Google Scholar] [CrossRef]

- Xu, T.; Tang, C.A.; Yang, T.H.; Zhu, W.C.; Liu, J. Numerical investigation of coal and gas outbursts in underground collieries. Int. J. Rock Mech. Min. 2006, 43, 905–919. [Google Scholar] [CrossRef]

- Zhu, W.C.; Wei, C.H.; Li, S.; Wei, J.; Zhang, M.S. Numerical modeling on destress blasting in coal seam for enhancing gas drainage. Int. J. Rock Mech. Min. 2013, 59, 179–190. [Google Scholar] [CrossRef]

- Lu, T.K.; Yu, H.; Zhou, T.Y.; Mao, J.S.; Guo, B.H. Improvement of methane drainage in high gassy coal seam using waterjet technique. Int. J. Coal Geol. 2009, 79, 40–48. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Liu, Y.; Li, X.H.; Kang, Y. A new method of drilling long boreholes in low permeability coal by improving its permeability. Int. J. Coal Geol. 2010, 84, 94–102. [Google Scholar] [CrossRef]

- Karacan, C.Ö. Evaluation of the relative importance of coalbed reservoir parameters for prediction of methane inflow rates during mining of longwall development entries. Comput. Geosci. 2008, 34, 1093–1114. [Google Scholar] [CrossRef]

- Lu, T.K.; Wang, Z.F.; Yang, H.M.; Yuan, P.J.; Han, Y.B. Improvement of coal seam gas drainage by under-panel cross-strata stimulation using highly pressurized gas. Int. J. Rock Mech. Min. 2015, 77, 300–312. [Google Scholar] [CrossRef]

- Labus, T.J. Fluid Jet Technology: Fundamentals and Application; Water Jet Technology Association: St. Louis, MO, USA, 1995. [Google Scholar]

- Ma, D.J.; Li, G.S.; Huang, Z.W.; Niu, J.L.; Hou, C.; Liu, M.J.; Li, J.B. A model of calculating the circulating pressure loss in coiled tubing ultra-short radius radial drilling. Pet. Explor. Dev. 2012, 39, 528–533. [Google Scholar] [CrossRef]

- Frank, M.W. Fluid Mechanics, 7th ed.; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Lu, Y.Y.; Cheng, L.; Ge, Z.L.; Xia, B.W.; Li, Q.; Chen, J.F. Analysis on the initial cracking parameters of cross-measure hydraulic fracture in underground coal mines. Energies 2015, 8, 6977–6994. [Google Scholar] [CrossRef]

- Shen, Z.H. Water Jet Theory and Technology; Petroleum University Publishing House: Dongying, Shandong, China, 1998. (In Chinese) [Google Scholar]

- Ma, D.; Miao, X.X.; Chen, Z.Q.; Mao, X.B. Experimental investigation of seepage properties of fractured rocks under different confining pressures. Rock. Mech. Rock. Eng. 2013, 46, 1135–1144. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Zhou, Z.; Ge, Z.; Zhang, X.; Li, Q. Research on and Design of a Self-Propelled Nozzle for the Tree-Type Drilling Technique in Underground Coal Mines. Energies 2015, 8, 14260-14271. https://doi.org/10.3390/en81212426

Lu Y, Zhou Z, Ge Z, Zhang X, Li Q. Research on and Design of a Self-Propelled Nozzle for the Tree-Type Drilling Technique in Underground Coal Mines. Energies. 2015; 8(12):14260-14271. https://doi.org/10.3390/en81212426

Chicago/Turabian StyleLu, Yiyu, Zhe Zhou, Zhaolong Ge, Xinwei Zhang, and Qian Li. 2015. "Research on and Design of a Self-Propelled Nozzle for the Tree-Type Drilling Technique in Underground Coal Mines" Energies 8, no. 12: 14260-14271. https://doi.org/10.3390/en81212426