The Influence of Non-Uniform High Heat Flux on Thermal Stress of Thermoelectric Power Generator

Abstract

:1. Introduction

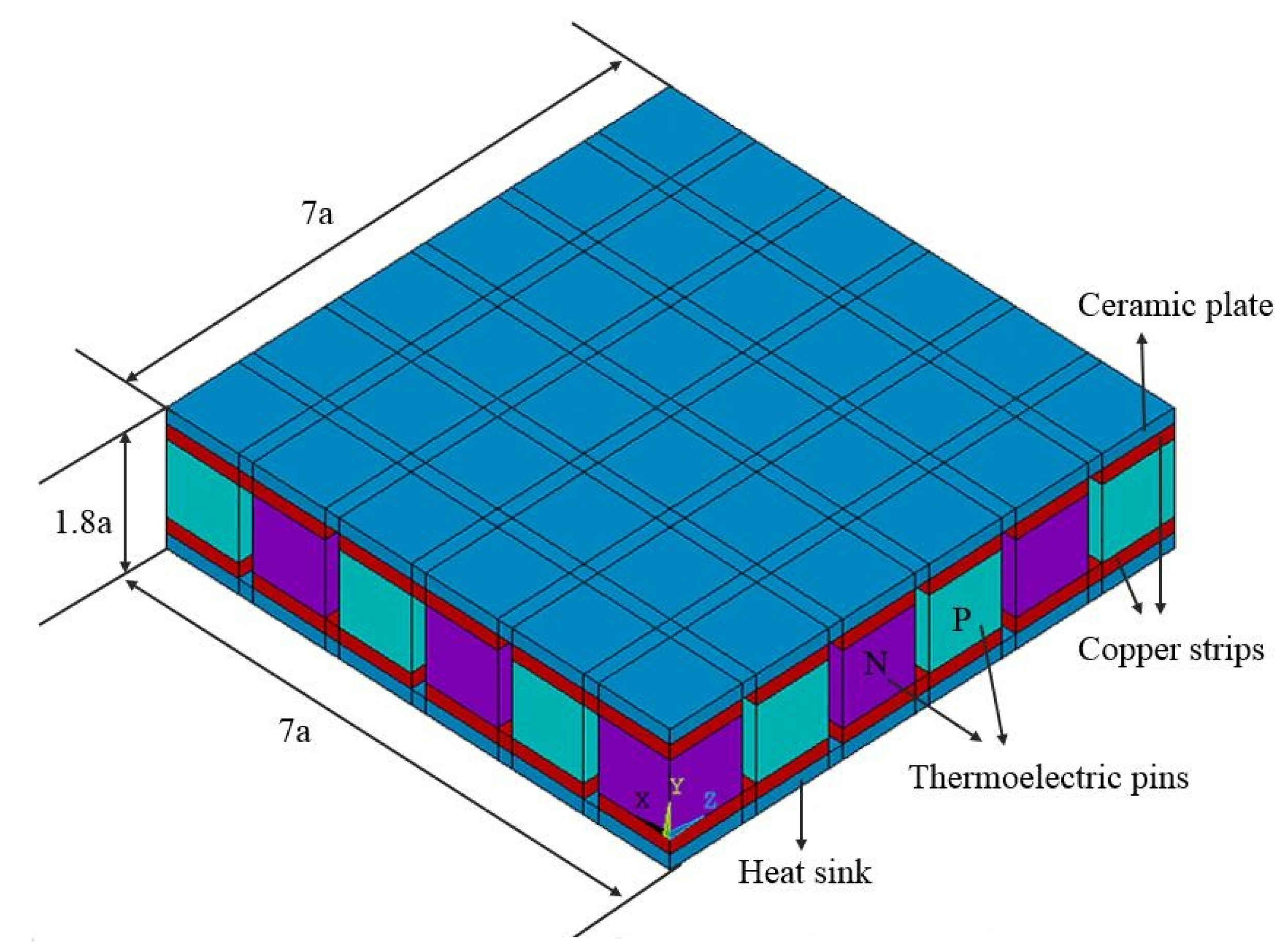

2. Model Description

2.1. Physical Model

| Temperature (°C) | Thermal expansion (10−5 m/°C) | |

|---|---|---|

| 24 | 0.8 | |

| 31 | 1.01 | |

| 92 | 1.21 | |

| 178 | 1.24 | |

| 340 | 1.32 | |

| 520 | 1.33 | |

| 591 | 1.41 | |

| Temperature (°C) | Poisson’s ratio | Young’s modulus (GPa) |

| −73 | 0.23 | 65 |

| 27 | 0.23 | 63 |

| 127 | 0.23 | 62 |

| 227 | 0.23 | 60 |

| 327 | 0.23 | 59 |

| Materials | Thermal conductivity (W/(m·°C)) | Thermal expansion (10−5m/°C) | Poisson’s ratio | Young’s modulus (GPa) | Electrical resistivity (Ω·m) |

|---|---|---|---|---|---|

| Cu | 400 | 1.7 | 0.31 | 110 | 2.5 × 10−8 |

| Al2O3 | 25 | 0.75 | 0.22 | 300 | 1.14 × 10−7 |

2.2. Mathematical Model and Boundary Conditions

2.2.1. Heat Transfer Analysis

- (a)

- All surfaces of the model except the hot end and cold end are considered to be heat insulation.

- (b)

- Neglect heat convection on all the surfaces.

- (c)

- There is no difference in properties as a function of position.

- (d)

- Electrical contact resistance and thermal contact resistance are not taken into consideration.

2.2.2. Thermal Stress Analysis

2.3. Computational Procedure and Verification

3. The Discussion of Simulation Results

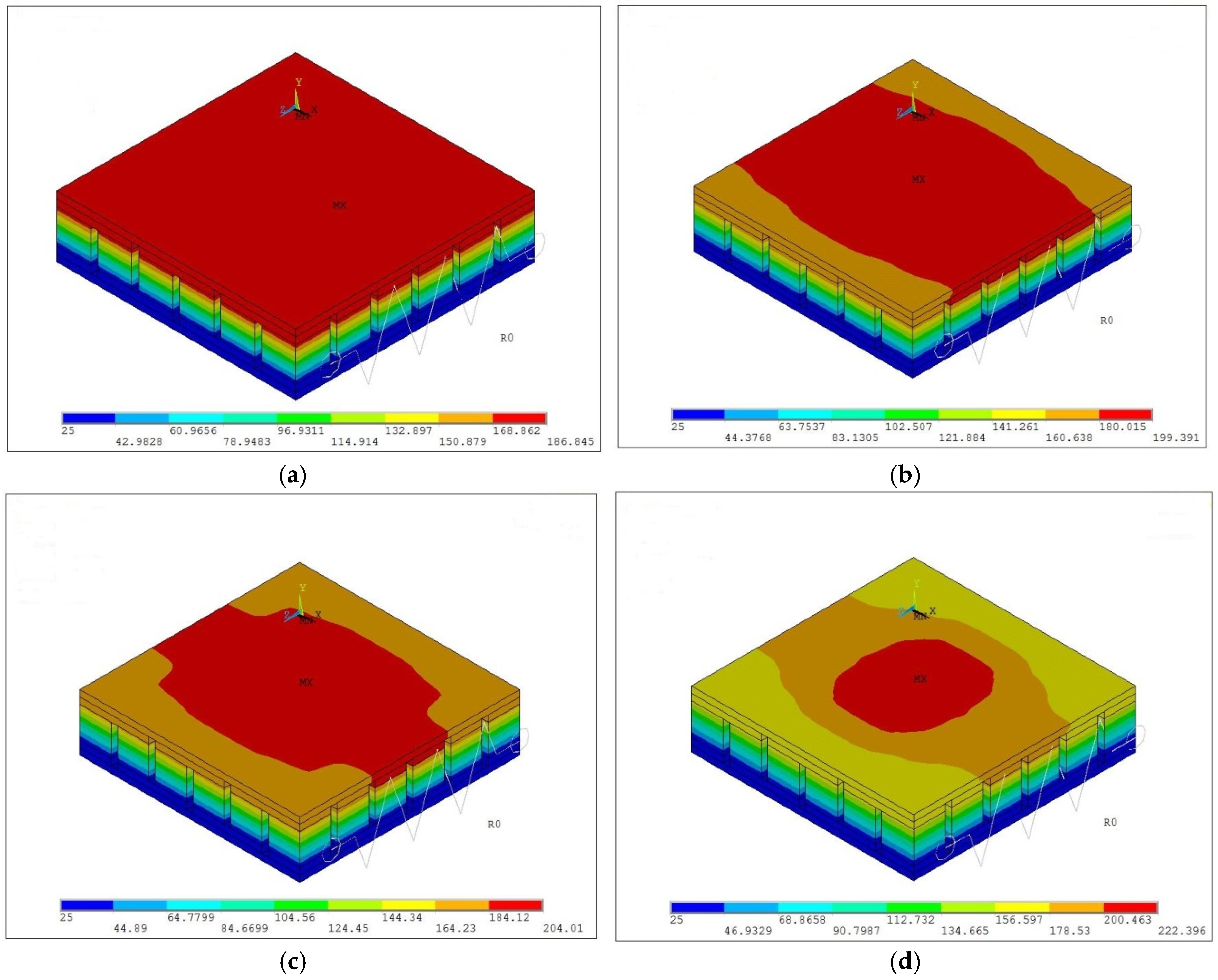

3.1. Temperature Distribution of the TEG Model

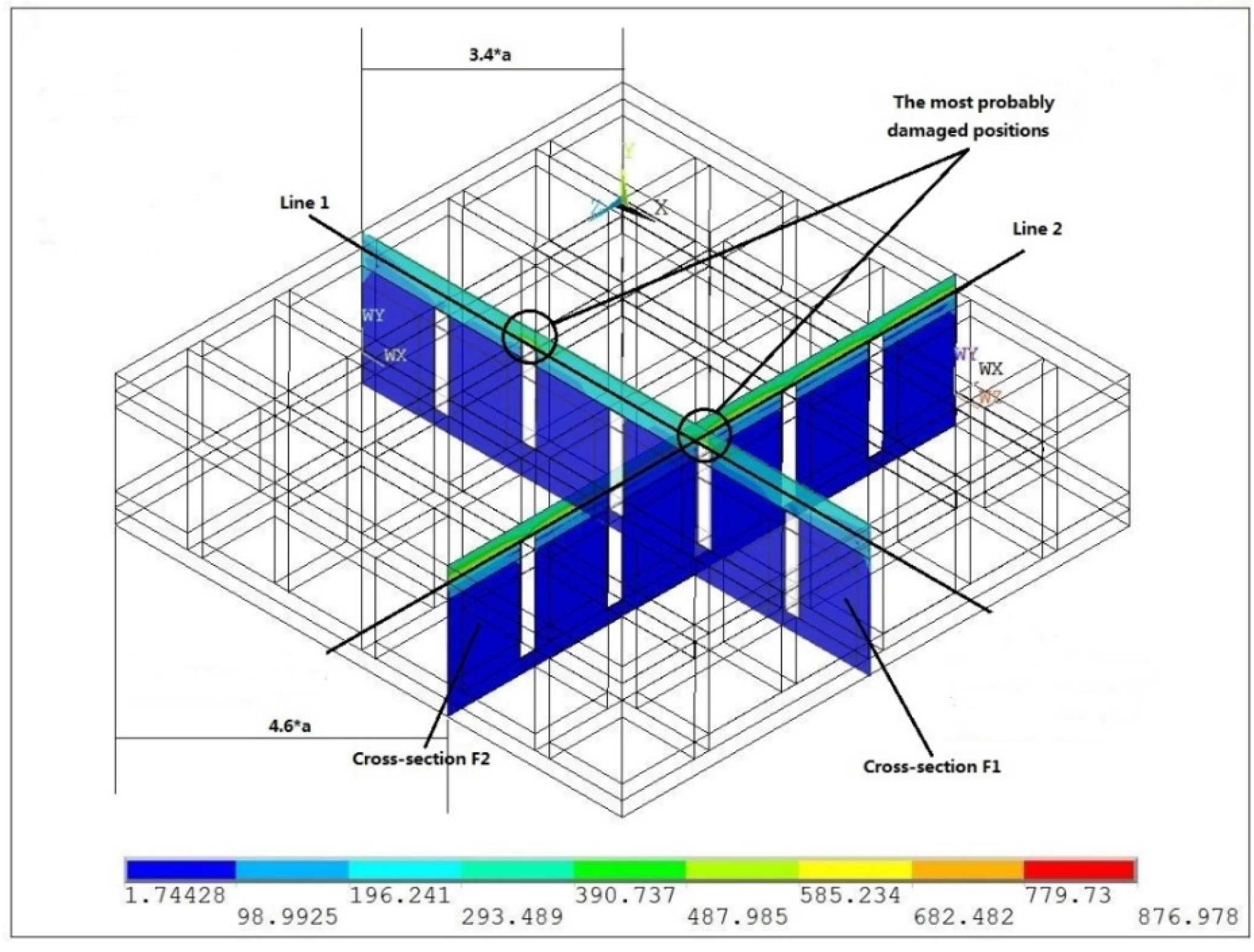

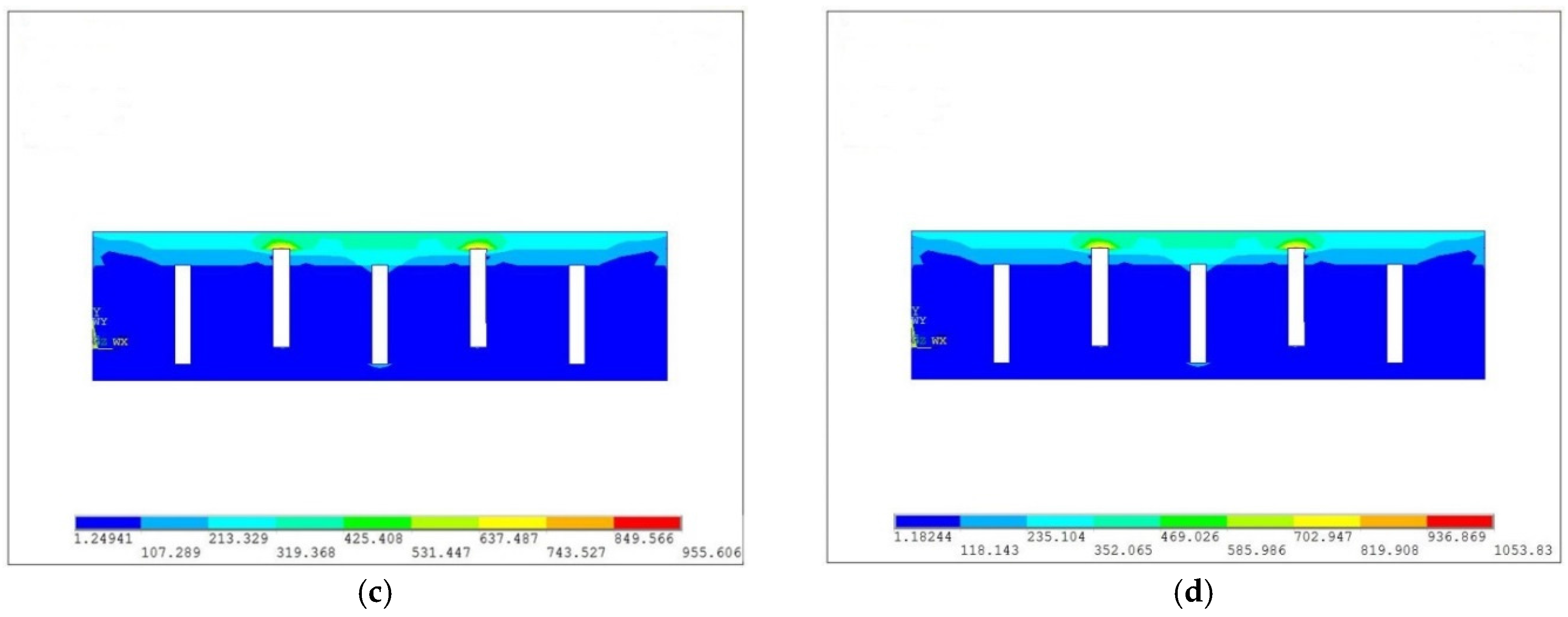

3.2. Thermal Stress Distribution of the TEG Model

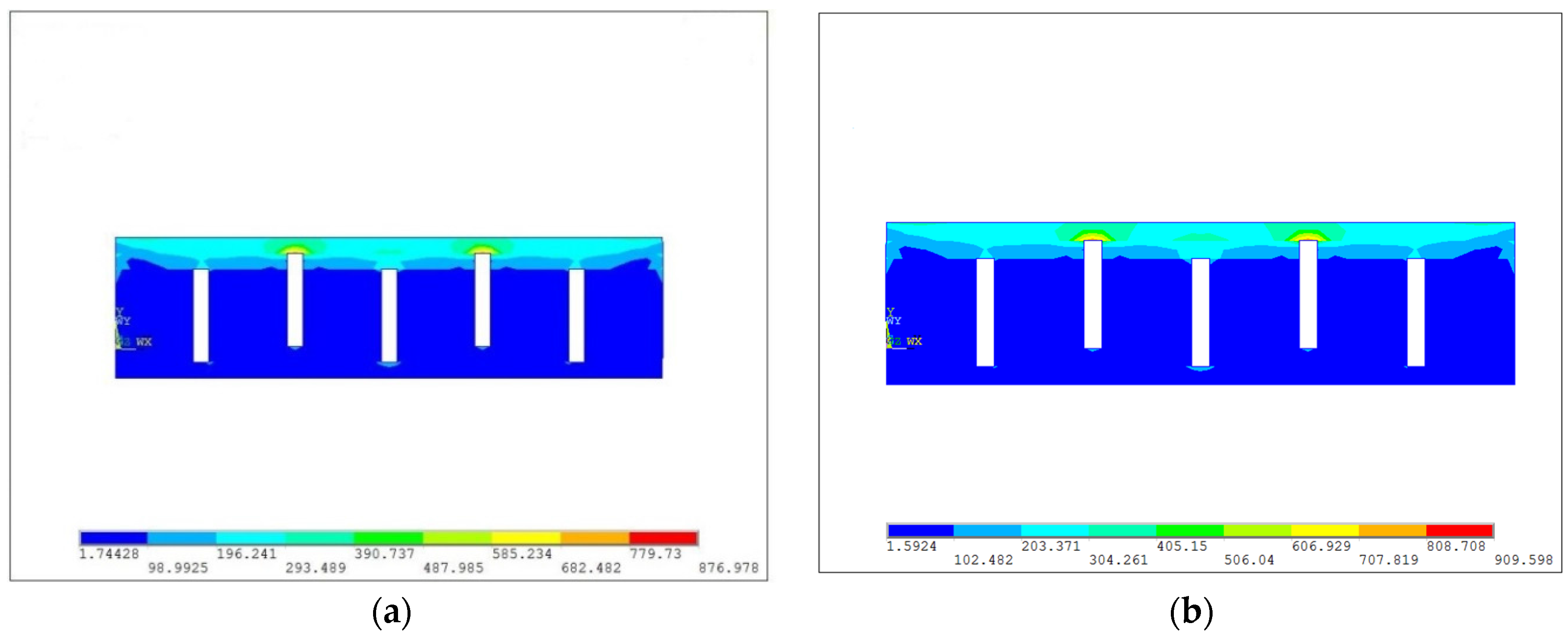

3.3. Thermal Stress Distribution on the Horizontal and Longitudinal Cross-Section

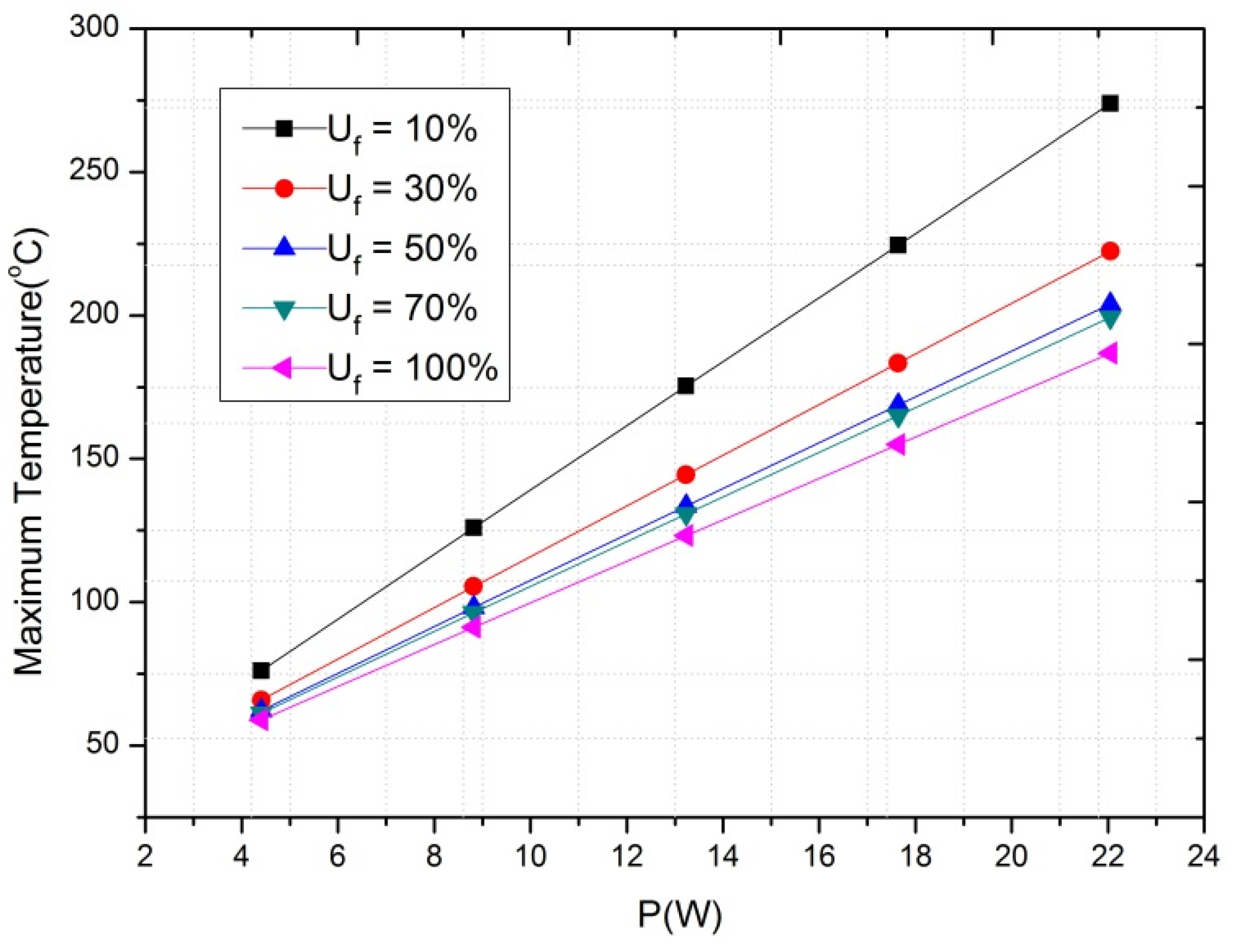

3.4. The Effect of Heating Power on Temperature and Thermal Stress

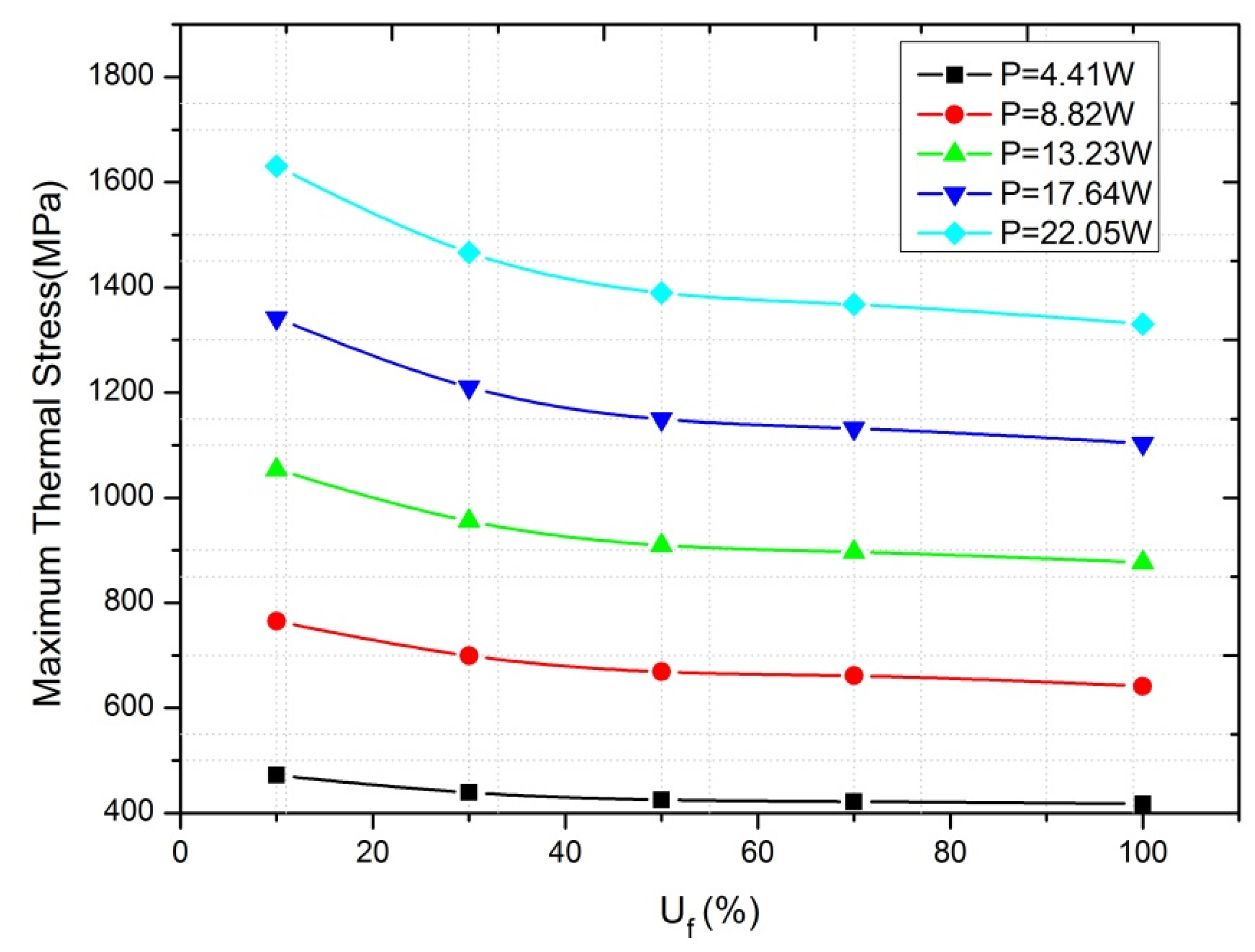

3.5. The Effect of Heating Uniformity on Temperature and Thermal Stress

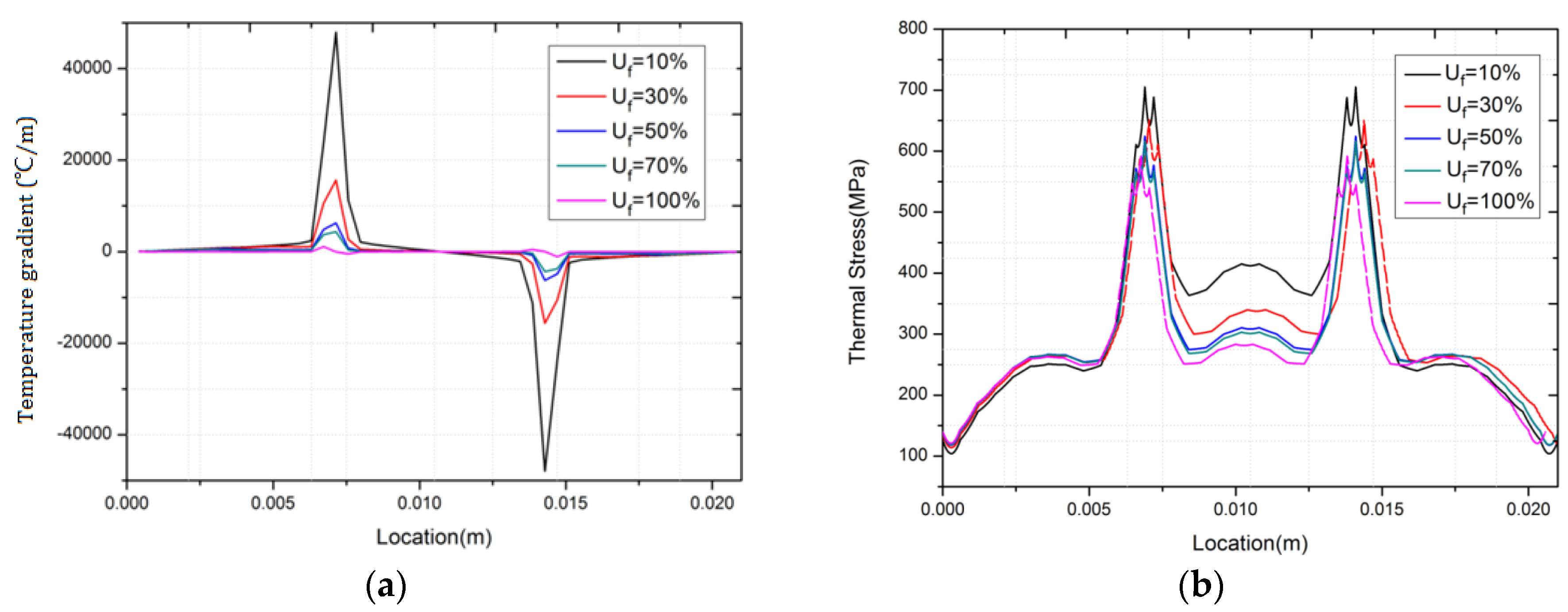

3.6. Temperature Gradient and Thermal Stress Distribution on Line 1 and Line 2

4. Conclusions

- (1)

- The un-uniformity of heat flux imposed upon the hot end has a significant effect on the thermal stress of TEG and life expectancy of the device. When the heating uniformity exceed 70%, however, un-uniformity of heat flux have little influence on the maximum thermal stress in the model. Uniform heat flux is favorable for solar energy concentration device design, but it is not a strict requirement.

- (2)

- The maximum temperature and thermal stress of the TEG model will increase with the total heat flow. Higher efficiency of the model is at the cost of the life expectancy of the device.

- (3)

- The interfaces between the copper strips, ceramic plates, and the thermo-pins are the place that is most likely to be damaged. When designing the TEG modules, in order to prolong the life cycle of device, we should strengthen these positions.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| E | Voltage potential (V) |

| T | temperature (K) |

| Z (z) | thermoelectric figure-of-merit of materials (K−1) |

| q | thermal heat flux density (W/m2 ) |

| I | load current (A) |

| J | current density (A/m2) |

| k | thermal conductivity (W/(m.K)) |

| ρ | electric resistivity (Ω·m) |

| α | Seebeck coefficient (v/K) |

| A | heating area of hot end (m2) |

| S | total area of the hot end (m2) |

| Uf | heating uniformity (-) |

| P | total heat flow (W) |

| HF | heat flux (W/m2) |

displacement | |

| εx, εy, εz | strain |

| σij | stress |

| τ | shear stress |

| σx, σy, σz | normal stress |

References

- Li, Y.; Shi, X.; Ren, D.; Chen, J.; Chen, L. Investigation of the Anisotropic Thermoelectric Properties of Oriented Polycrystalline SnSe. Energies 2015, 8, 6275–6285. [Google Scholar] [CrossRef]

- Scott, C.A.; Sugg, Z.P. Global Energy Development and Climate-Induced Water Scarcity—Physical Limits, Sectoral Constraints, and Policy Imperatives. Energies 2015, 8, 8211–8225. [Google Scholar] [CrossRef]

- Goldsmid, H.J.; Sharp, J. Extrapolation of Transport Properties and Figure of Merit of a Thermoelectric Material. Energies 2015, 8, 6451–6467. [Google Scholar] [CrossRef]

- Kim, J.; Shim, K.; Jeon, J. Thermoelectric Power Generation in a Vacuum Cell of Decomposing Liquid Potassium-Ammonia Solutions. Energies 2013, 6, 5960–5972. [Google Scholar] [CrossRef]

- Zhao, M.Z.; Zhang, H.C.; Hu, Z.Y.; Zhang, Z.F.; Zhang, J.J. Performance characteristics of a direct carbon fuel cell/thermoelectric generator hybrid system. Energy Convers. Manag. 2015, 89, 683–689. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, W.B.; Kan, J.M. Behavior of a thermoelectric power generation device based on solar irradiation and the earth’s surface-air temperature difference. Energy Convers. Manag. 2015, 97, 178–187. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Huang, C.K.; Wang, J.Y.; Lin, G.X.; Chen, J.C. Optimum energy conversion strategies of a nano-scaled three-terminal quantum dot thermoelectric device. Energy 2015, 85, 200–207. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Ali, H. Thermoelectric generator performance analysis: Influence of pin tapering on the first and second law efficiencies. Energy Convers. Manag. 2015, 100, 138–146. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Wu, S.Y.; Xiao, L. Performance analysis of photovoltaic-thermoelectric hybrid system with and without glass cover. Energy Convers. Manag. 2015, 93, 151–159. [Google Scholar] [CrossRef]

- Wijesekara, W.; Rezania, A.; Rosendahl, L. Simple engineering design for complex thermoelectric generators based on reduced current approach. Energy 2015, 86, 455–466. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, X.J.; Cai, Y.X.; Zhang, C.; Bao, W.W. Experimental study on the thermal management of high-power LED headlight cooling device integrated with thermoelectric cooler package. Energy Convers. Manag. 2015, 101, 532–540. [Google Scholar] [CrossRef]

- Tian, H.; Sun, X.X.; Jia, Q.; Liang, X.Y.; Shu, G.Q.; Wang, X. Comparison and parameter optimization of a segmented thermoelectric generator by using the high temperature exhaust of a diesel engine. Energy 2015, 84, 121–130. [Google Scholar] [CrossRef]

- Sahin, A.Z.; Yilbas, B.S. The thermoelement as thermoelectric power generator: Effect of leg geometry on the efficiency and power generation. Energy Convers. Manag. 2013, 65, 26–32. [Google Scholar] [CrossRef]

- Khattab, N.M.; EI Shenawy, E.T. Optimal operation of thermoelectric cooler driven by solar thermoelectric generator. Energy Convers. Manag. 2006, 47, 407–426. [Google Scholar] [CrossRef]

- Rodriguez, A.; Vian, J.G.; Astrain, D.; Martinez, A. Study of thermoelectric systems applied to electric power generation. Energy Convers. Manag. 2009, 50, 1236–1243. [Google Scholar] [CrossRef]

- O'Brien, R.C.; Ambrosi, R.M.; Bannister, N.P.; Howe, S.D.; Atkinson, H.V. Safe radioisotope thermoelectric generators and heat sources for space applications. J. Nucl. Mater. 2008, 377, 506–521. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Sahin, A.Z. Thermoelectric device and optimum external load parameter and slenderness ratio. Energy 2010, 35, 5380–5384. [Google Scholar] [CrossRef]

- Omer, S.A.; Infield, D.G. Design and thermal analysis of a two stage solar concentrator for combined heat and thermoelectric power generation. Energy Convers. Manag. 2000, 41, 737–756. [Google Scholar] [CrossRef]

- Maneewan, S.; Chindaruksa, S. Thermoelectric Power Generation System Using Waste Heat from Biomass Drying. J. Electron. Mater. 2009, 38, 974–980. [Google Scholar] [CrossRef]

- Maneewan, S.; Hirunlabh, J.; Khedari, J.; Zeghmati, B.; Teekasap, S. Heat gain reduction by means of thermoelectric roof solar collector. Sol. Energy 2005, 78, 495–503. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Sammakia, B.G.; White, B.; Borgesen, P. Multiscale modeling of thermoelectric generators for the optimized conversion performance. Int. J. Heat Mass. Transf. 2013, 62, 435–444. [Google Scholar] [CrossRef]

- Xiao, J.S.; Yang, T.Q.; Li, P.; Zhai, P.C.; Zhang, Q.J. Thermal design and management for performance optimization of solar thermoelectric generator. Appl. Energy 2012, 93, 33–38. [Google Scholar] [CrossRef]

- Nguyen, N.Q.; Pochiraju, K.V. Behavior of thermoelectric generators exposed to transient heat sources. Appl. Therm. Eng. 2013, 51, 1–9. [Google Scholar] [CrossRef]

- Rezania, A.; Yazawa, K.; Rosendahl, L.A.; Shakouri, A. Co-optimized design of microchannel heat exchangers and thermoelectric generators. Int. J. Therm. Sci. 2013, 72, 73–81. [Google Scholar] [CrossRef]

- Zhang, Q.; Agbossou, A.; Feng, Z.H.; Cosnier, M. Solar micro-energy harvesting based on thermoelectric and latent heat effects. Part II: Experimental analysis. Sens. Actuat. A-Phys. 2010, 163, 284–290. [Google Scholar] [CrossRef]

- Chen, W.H.; Liao, C.Y.; Wang, C.C.; Hung, C.I. Evaluation of power generation from thermoelectric cooler at normal and low-temperature cooling conditions. Energy Sustain. Dev. 2015, 25, 8–16. [Google Scholar] [CrossRef]

- Chen, W.H.; Wang, C.C.; Hung, C.I.; Yang, C.C.; Juang, R.C. Modeling and simulation for the design of thermal-concentrated solar thermoelectric generator. Energy 2014, 64, 287–297. [Google Scholar] [CrossRef]

- Chen, W.H.; Wang, C.C.; Hung, C.I. Geometric effect on cooling power and performance of an integrated thermoelectric generation-cooling system. Energy Convers. Manag. 2014, 87, 566–575. [Google Scholar] [CrossRef]

- Chen, W.H.; Liao, C.Y.; Hung, C.I. A numerical study on the performance of miniature thermoelectric cooler affected by Thomson effect. Appl. Energy 2012, 89, 464–473. [Google Scholar] [CrossRef]

- Chen, W.H.; Liao, C.Y.; Hung, C.I.; Huang, W.L. Experimental study on thermoelectric modules for power generation at various operating conditions. Energy 2012, 45, 874–881. [Google Scholar] [CrossRef]

- Wang, C.C.; Hung, C.I.; Chen, W.H. Design of heat sink for improving the performance of thermoelectric generator using two-stage optimization. Energy 2012, 39, 236–245. [Google Scholar] [CrossRef]

- Al-Merbati, A.S.; Yilbas, B.S.; Sahin, A.Z. Thermodynamics and thermal stress analysis of thermoelectric power generator: Influence of pin geometry on device performance. Appl. Therm. Eng. 2013, 50, 683–692. [Google Scholar] [CrossRef]

- Ziabari, A.; Suhir, E.; Shakouri, A. Minimizing thermally induced interfacial shearing stress in a thermoelectric module with low fractional area coverage. Microelectron. J. 2014, 45, 547–553. [Google Scholar] [CrossRef]

- Wu, Y.J.; Ming, T.Z.; Li, X.H.; Pan, T.; Peng, K.Y.; Luo, X.B. Numerical simulations on the temperature gradient and thermal stress of a thermoelectric power generator. Energy Convers. Manag. 2014, 88, 915–927. [Google Scholar] [CrossRef]

- Ming, T.; Wu, Y.; Peng, C.; Tao, Y. Thermal analysis on a segmented thermoelectric generator. Energy 2015, 80, 388–399. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ming, T.; Wang, Q.; Peng, K.; Cai, Z.; Yang, W.; Wu, Y.; Gong, T. The Influence of Non-Uniform High Heat Flux on Thermal Stress of Thermoelectric Power Generator. Energies 2015, 8, 12584-12602. https://doi.org/10.3390/en81112332

Ming T, Wang Q, Peng K, Cai Z, Yang W, Wu Y, Gong T. The Influence of Non-Uniform High Heat Flux on Thermal Stress of Thermoelectric Power Generator. Energies. 2015; 8(11):12584-12602. https://doi.org/10.3390/en81112332

Chicago/Turabian StyleMing, Tingzhen, Qiankun Wang, Keyuan Peng, Zhe Cai, Wei Yang, Yongjia Wu, and Tingrui Gong. 2015. "The Influence of Non-Uniform High Heat Flux on Thermal Stress of Thermoelectric Power Generator" Energies 8, no. 11: 12584-12602. https://doi.org/10.3390/en81112332