Thermoelectric Properties of Alumina-Doped Bi0.4Sb1.6Te3 Nanocomposites Prepared through Mechanical Alloying and Vacuum Hot Pressing

Abstract

:1. Introduction

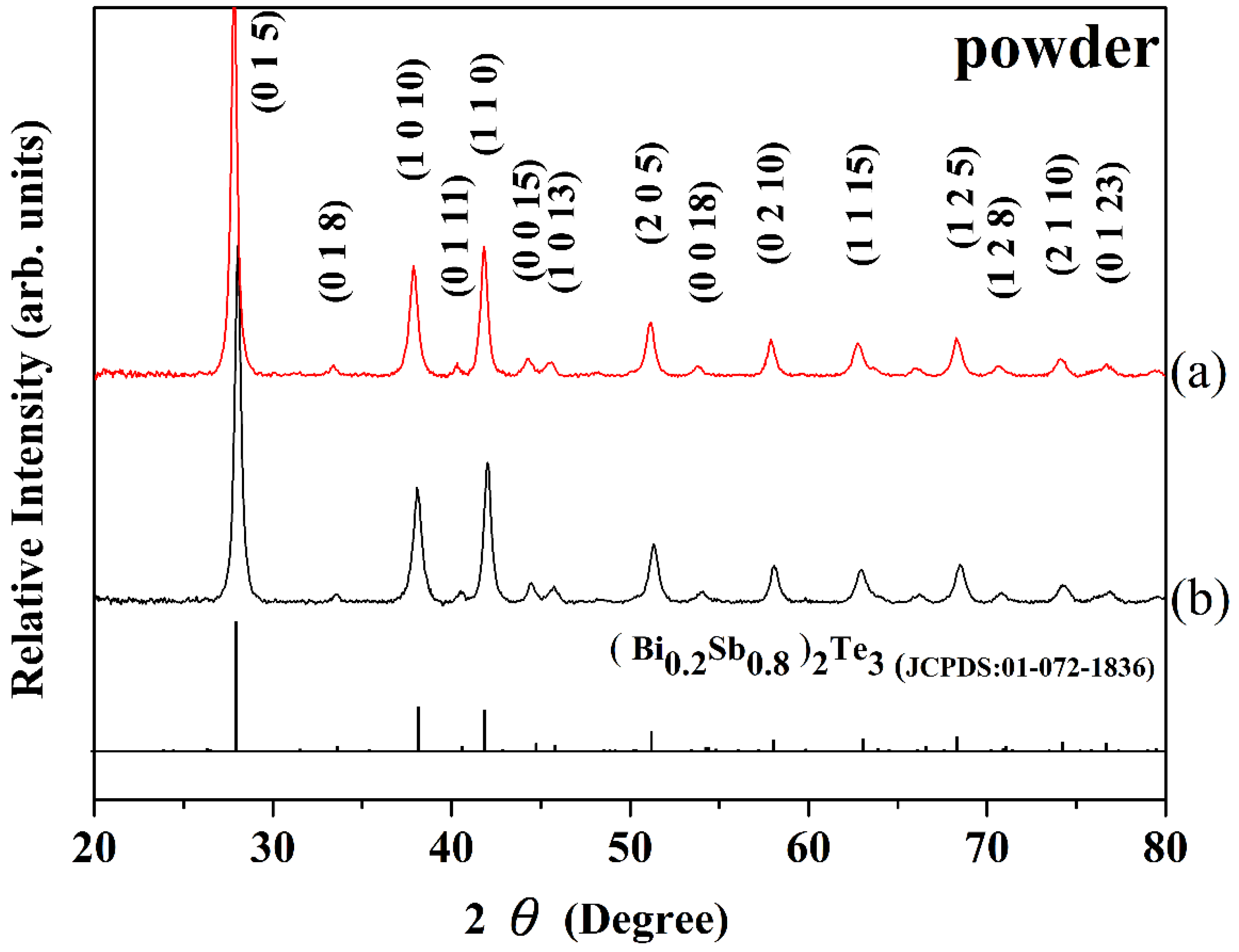

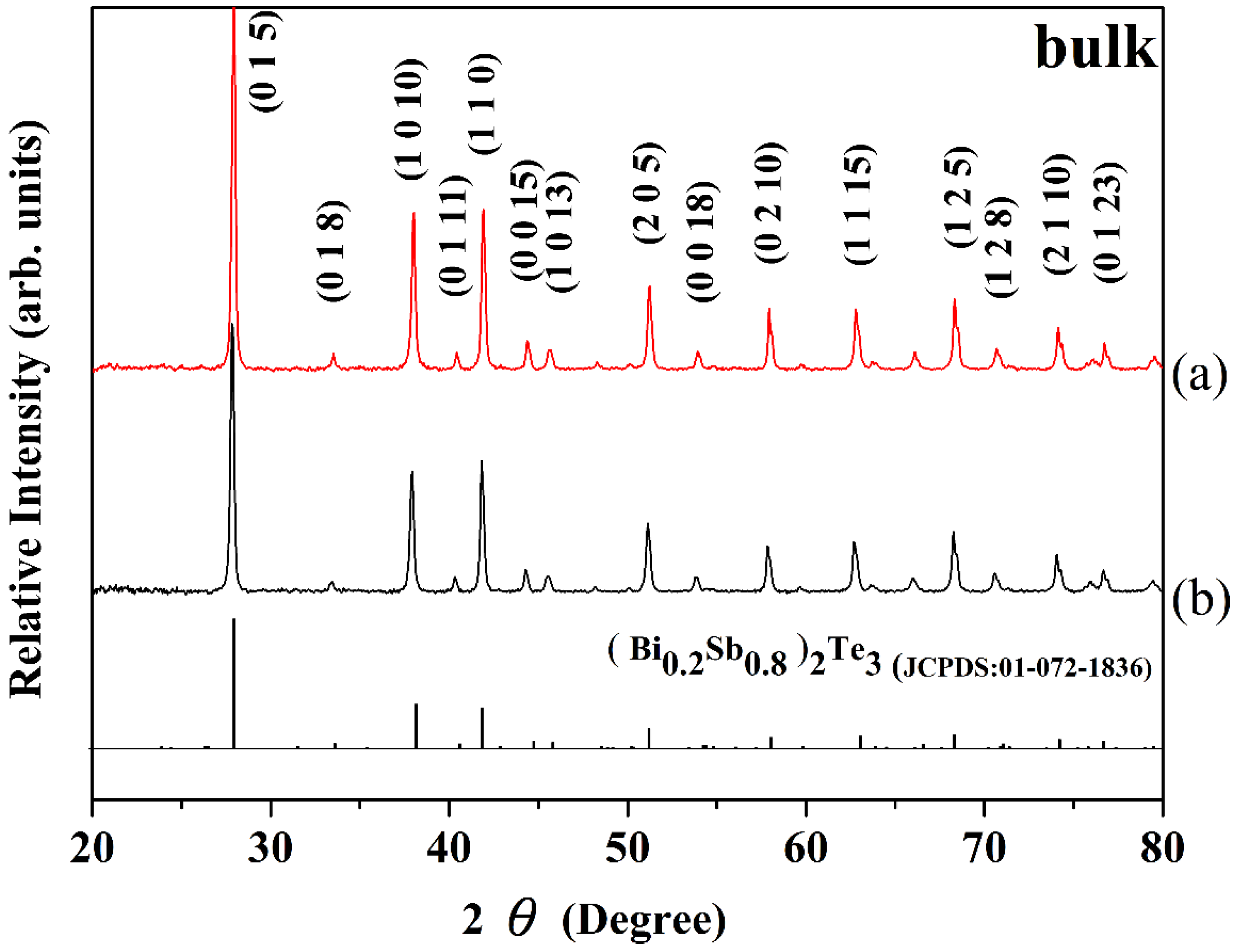

2. Experimental Procedure

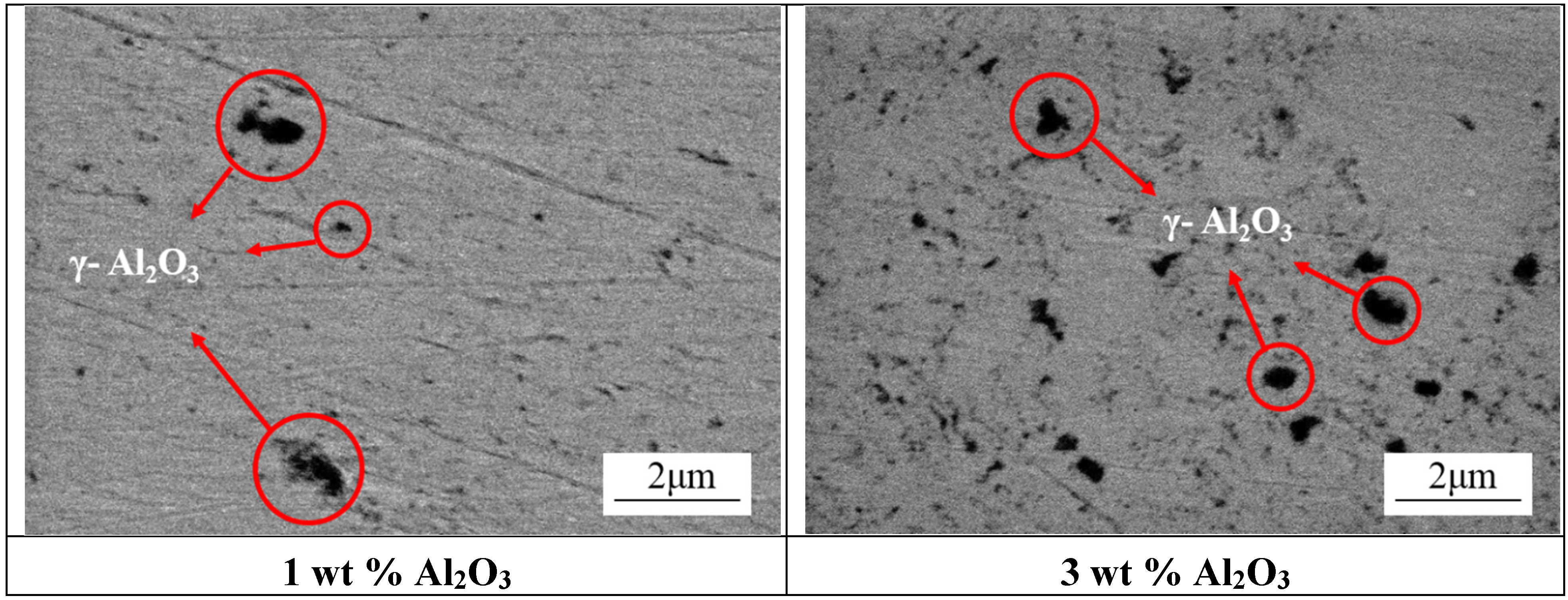

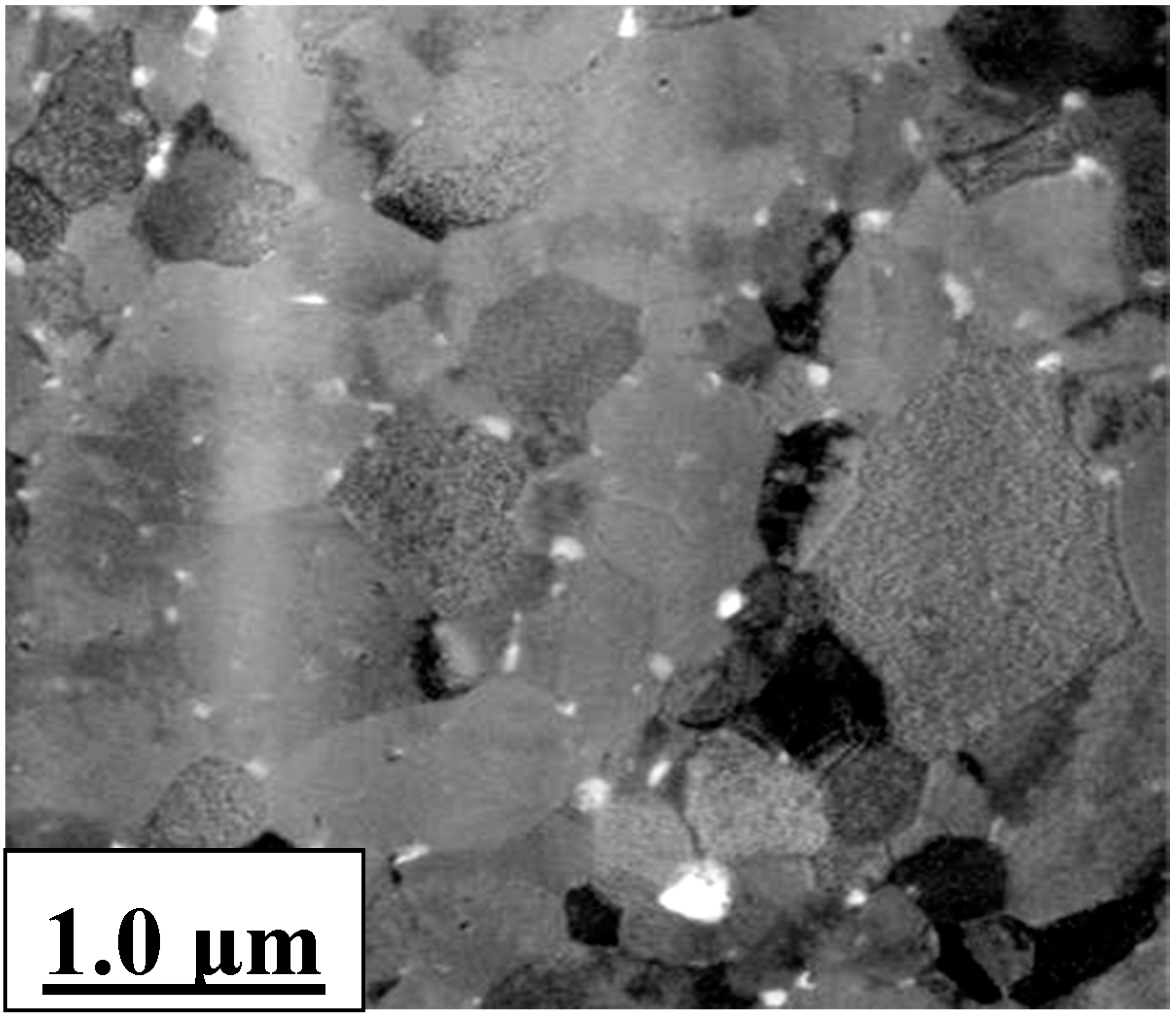

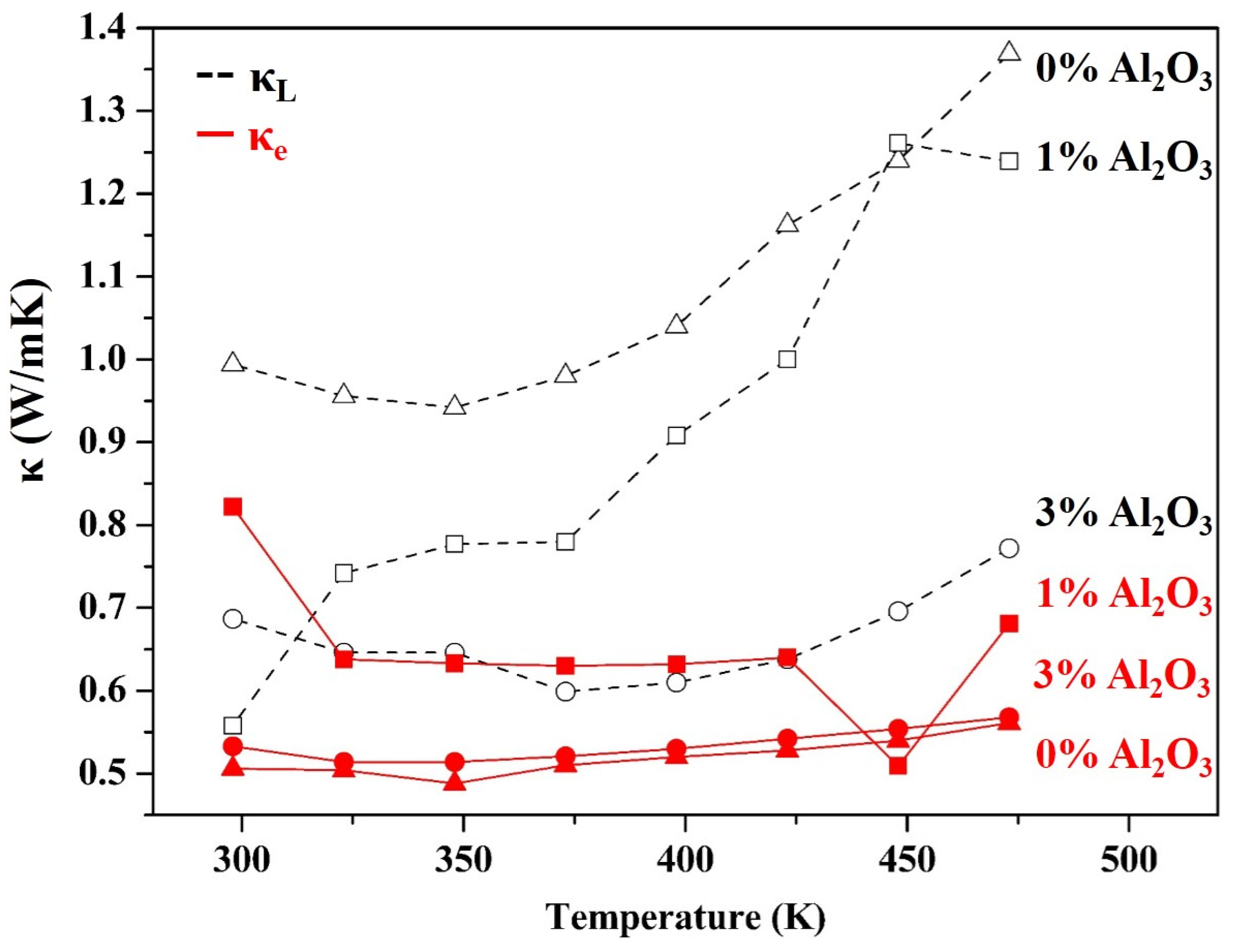

3. Results and Discussion

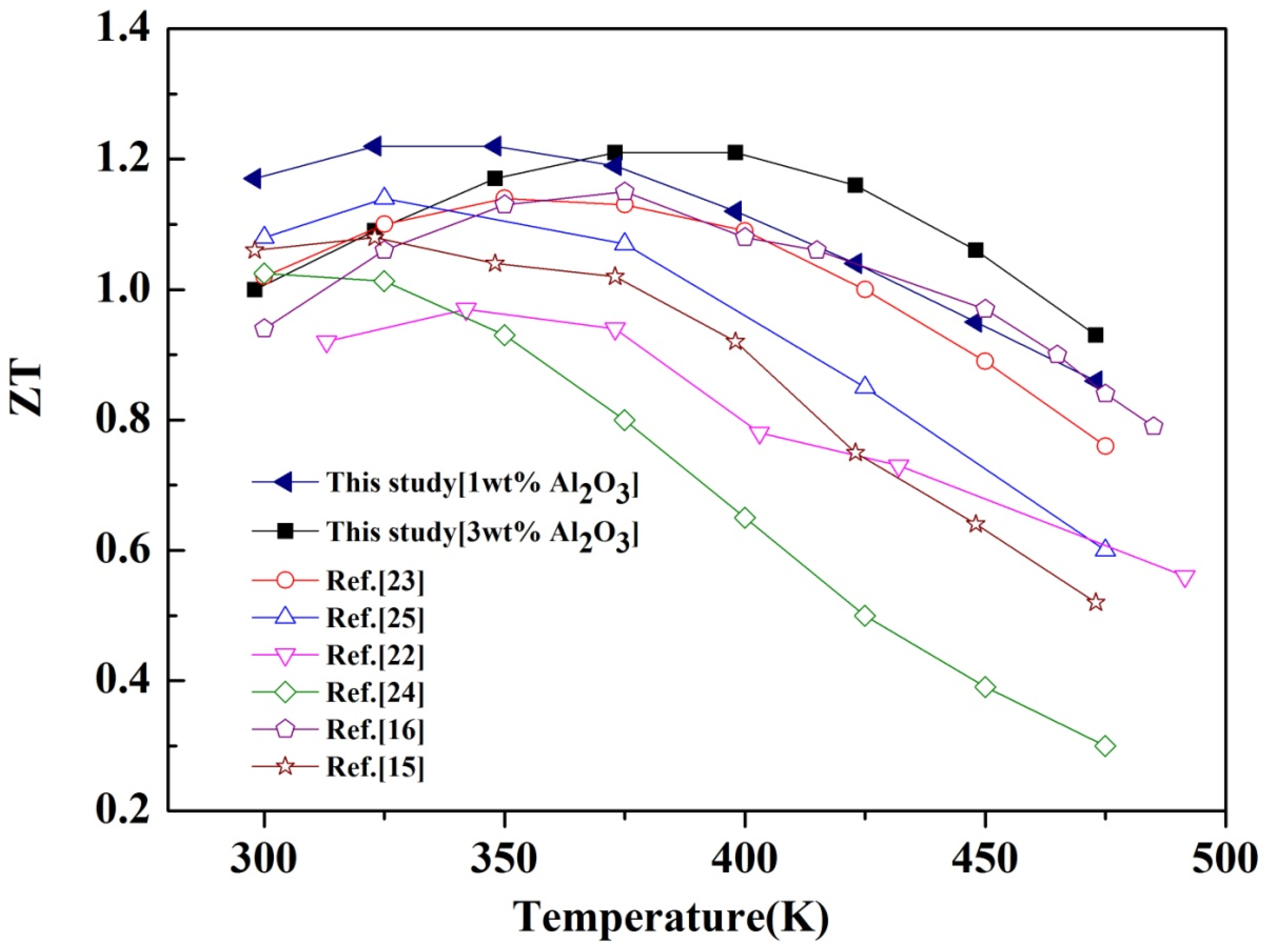

| Nanocomposite | Highest ZT | ZT(>400 K) | Methoda,b | Ref. |

|---|---|---|---|---|

| Bi0.4Sb1.6Te3 | 1.15 at 350 K | 0.2~0.4 | BM + HP (200 MPa/430 C/2 h) | [24] |

| Bi0.4Sb1.6Te3 | 1.14 at 323 K | 0.2~0.74 | BM (300 rpm/10 h) + SPS (50 MPa/420 C/10 min) | [25] |

| Bi0.4Sb1.6Te3 | 1.15 at 350 K | 0.63~0.9 | BM (1200 rpm/5 h) + SPS (60 MPa/420 C/5 min) | [23] |

| Bi0.4Sb1.6Te3 | 1.0 at 300 K | - | BM (400 rpm/2 h) + SPS (50 MPa/450 C/5 min) | [26] |

| Bi0.4Sb1.6Te3 + 4 wt % Te | 0.98 at 343 K | 0.55~0.68 | BM (400 rpm/12 h) + HP (60 MPa/290 C/1 h) + ECAE (753 K) | [22] |

| Bi0.4Sb1.6Te3 + 1 wt % CNT | 1.08 at 323 K | 0.52~0.92 | ZM + BM + HP (27.6 MPa/440 C/10 min) | [15] |

| Bi0.4Sb1.6Te3 + 1.5 wt % C60 | 1.15 at 375 K | 0.79~1.08 | BM (500~2220 rpm/30 min) + sinter (5 kbar/400 C) +annealing (300 C/2 h) | [16] |

| Bi0.4Sb1.6Te3 + 7 wt % BN | 0.54 at 300 K | - | BM (1200 rpm/5 h) + HP (425 MPa/550 C/30 min) | [17] |

| Bi0.4Sb1.6Te3 + 7 wt % WO3 | 0.75 at 300 K | - | BM (1200 rpm/5 h) + HP (425 MPa/550 C/30 min) | [17] |

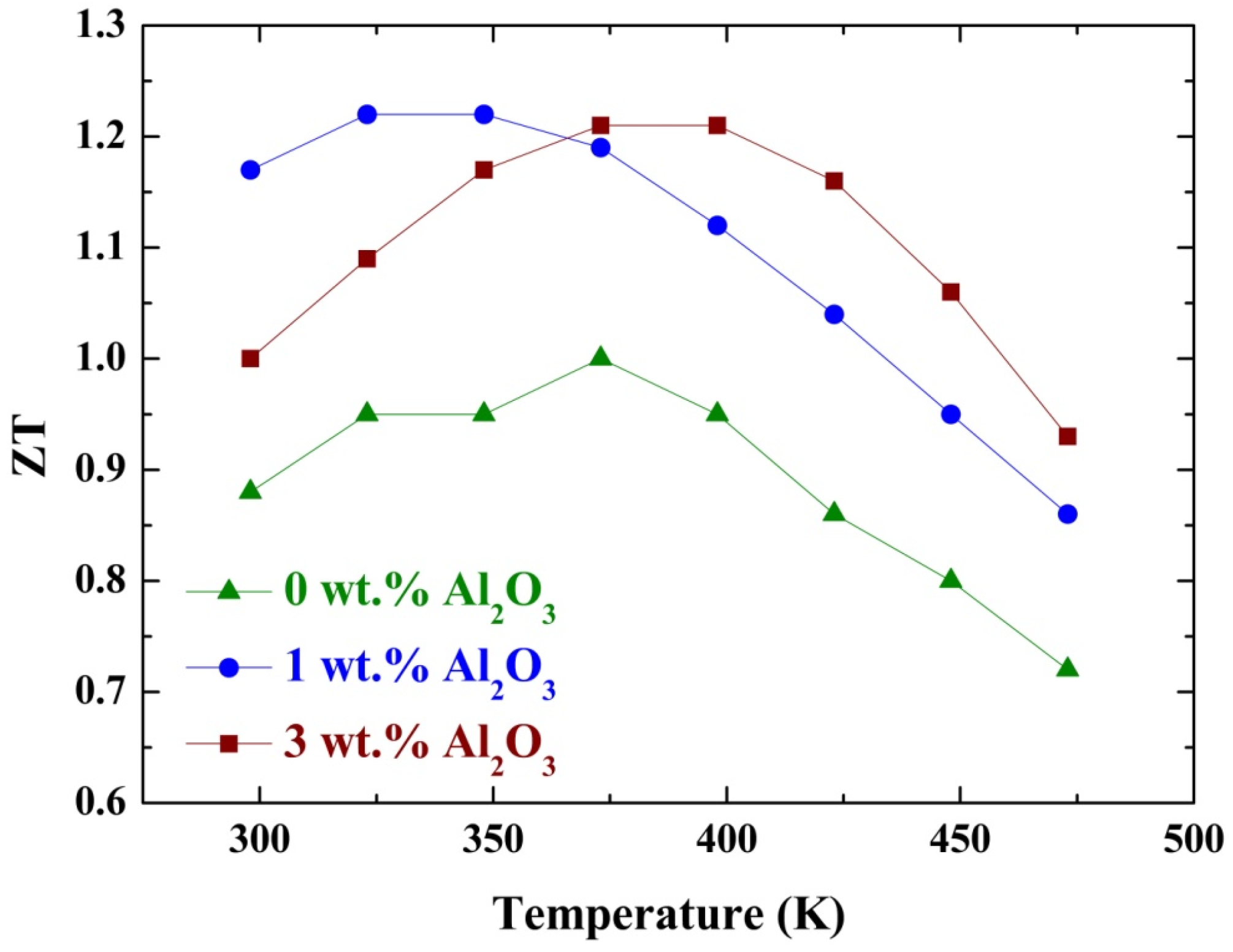

| Bi0.4Sb1.6Te3 + 1 wt % Al2O3 | 1.22 at 340 K | 0.86~1.12 | BM + HP (700 MPa/300 C/1 h) | This work |

| Bi0.4Sb1.6Te3 + 3 wt % Al2O3 | 1.21 at 398 K | 0.93~1.21 | BM + HP (700 MPa/300 C/1 h) | This work |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tritt, T.M.; Subramanian, M.A. Thermoelectric Materials, Phenomena, and Applications: A bird’s eye view. MRS Bull. 2006, 31, 188–198. [Google Scholar] [CrossRef]

- Tang, X.; Xie, W.; Li, H.; Du, B.; Zhang, Q.; Tritt, T.M.; Uher, C. High-performance nanostructured thermoelectric materials prepared by melt spinning and spark plasma sintering. In Thermoelectrics and Its Energy Harvesting: Materials Preparation, and Characterization in Thermoelectrics; Rowe, D.M., Ed.; CRC Taylor and Francis: Boca Raton, FL, USA, 2012; pp. 16.1–16.33. [Google Scholar]

- DiSalvo, F.J. Thermoelectric cooling and power generation. Science 1999, 285, 703–706. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Zide, J.; Gossard, A.; Klenov, D.; Stemmer, S.; Shakouri, A.; Majumdar, A. Thermal conductivity reduction and thermoelectric figure of merit increase by embedding nanoparticles in crystalline semiconductors. Phys. Rev. Lett. 2006, 96, 045901-1–045901-4. [Google Scholar] [CrossRef] [PubMed]

- Dmitriev, A.V.; Zvyagin, I.P. Current trends in the physics of thermoelectric materials. Phys. Usp. 2010, 53, 789–803. [Google Scholar] [CrossRef]

- Minnich, A.J.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Bulk nanostructured thermoelectric materials: Current research and future prospects. Energy Environ. Sci. 2009, 2, 466–479. [Google Scholar] [CrossRef]

- Ballikaya, S.; Uzar, N.; Yildirim, H.; Chi, H.; Su, X.; Tan, G.; Tang, X.; Uher, C. Lower thermal conductivity and higher thermoelectric performance of Fe-substituted and Ce, Yb double-filled p-type skutterudites. J. Electron. Mater. 2013, 42, 1622–1627. [Google Scholar] [CrossRef]

- Kadhim, A.; Hmood, A.; Hassan, H.A. Preparation of Bi0.4Sb1.6Se3xTe3(1-x) hexagonal rods and effect of Se on structure and electrical property. Solid State Sci. 2013, 21, 110–115. [Google Scholar] [CrossRef]

- Buga, S.G.; Serebryanaya, N.R.; Dubitskiy, G.A.; Semenova, E.E.; Aksenenkov, V.V.; Blank, V.D. Structure and electrical properties of Sb2Te3 and Bi0.4Sb1.6Te3 metastable phases obtained by HPHT treatment. High Press. Res. Int. J. 2011, 31, 86–90. [Google Scholar] [CrossRef]

- Zhang, Q.; Znang, Q.; Chen, S.; Liu, W.; Lukas, K.; Yan, X.; Wang, H.; Wang, D.; Opeil, C.; Chen, G.; et al. Suppression of grain growth by additive in nanostructured p-type bismuth antimony tellurides. Nano Energy 2012, 1, 183–189. [Google Scholar] [CrossRef]

- Xie, W.; Wang, S.; Zhu, S.; Ho, J.; Tang, X.; Zhang, Q.; Tritt, T.M. High performance Bi2Te3 nanocomposites prepared by single-element-melt-spinning spark-plasma sintering. J. Mater. Sci. 2013, 48, 2745–2760. [Google Scholar] [CrossRef]

- Pichanusakorn, P.; Bandaru, P. Nanostructured thermoelectrics. Mater. Sci. Eng. R. 2010, 67, 19–63. [Google Scholar] [CrossRef]

- Medlin, D.L.; Snyder, G.J. Interfaces in bulk thermoelectric materials: A review for Current Opinion in Colloid and Interface Science. Curr. Opin. Colloid In. 2009, 14, 226–235. [Google Scholar] [CrossRef]

- Chen, L.D.; Huang, X.Y.; Zhou, M.; Shi, X.; Zhang, W.B. The high temperature thermoelectric performances of Zr0.5Hf0.5Ni0.8Pd0.2Sn0.99Sb0.01 alloy with nanophase inclusions. J. Appl. Phys. 2006, 99, 064305-1–064305-6. [Google Scholar] [CrossRef]

- Ren, F.; Wang, H.; Mechhofer, P.A.; Kiggans, J.O. Thermoelectric and mechanical properties of muti-walled carbon nanotube doped Bi0.4Sb1.6Te3 thermoelectric material. Appl. Phys. Lett. 2013, 103, 221907-1–221907-5. [Google Scholar] [CrossRef]

- Popov, M.; Buga, S.; Vysikaylo, P.; Stepanov, P.; Skok, V.; Medvedev, V.; Tatyanin, F.; Denisov, V.; Kirichenko, A.; Aksenenkov, V.; et al. C60-doping of nanostructured Bi-Sb-Te thermoelectrics. Phys. Status Solidi A 2011, 208, 2783–2789. [Google Scholar] [CrossRef]

- Lee, J.S.; Oh, T.S.; Hyun, D.B. Thermoelectric properties of the hot-press (Bi0.2Sb0.8)2Te3 alloy with addition of BN and WO3 powders. J. Mater. Sci. 2000, 35, 881–887. [Google Scholar] [CrossRef]

- Ganguly, S.; Zhou, C.; Morelli, D.; Sakamoto, J.; Uher, C.; Brock, L.S. Synthesis and evaluation of lead telluride/bismuth antimony telluride nanocomposites for thermoelectric applications. J. Solid State Chem. 2011, 184, 3195–3201. [Google Scholar] [CrossRef]

- Kim, K.T.; Ha, G.H. Fabrication and ehanced thermoelectric properties of alumina nanoparticles-dispersed Bi0.5Sb1.5Te3 Matrix Composites. J. Nanomater. 2013, 2013, 1–6. [Google Scholar]

- Fei, L.; Huang, X.Y.; Sun, Z.L.; Ding, J.; Jiang, J.; Jiang, W.; Chen, L.D. Enhanced thermoelectric properties of n-type Bi2Te3-based nanocomposite fabricated by spark plasma sintering. J. Alloy. Compd. 2011, 509, 4769–4773. [Google Scholar] [CrossRef]

- Lin, C.K.; Hong, S.S.; Lee, P.Y. Formation of NiAl-Al2O3 intermetallic-matrix composite powders by mechanical alloying technique. Intermetallics 2000, 8, 1043–1048. [Google Scholar] [CrossRef]

- Fan, X.A.; Yang, J.Y.; Zhu, W.; Bao, S.Q.; Duan, X.K.; Xiao, C.J.; Li, K. Preferential orientation and thermoelectric properties of p-type Bi0.4Sb1.6Te3 system alloys by mechanical alloying and equal channel angular extrusion. J. Alloy. Compd. 2008, 461, 9–13. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, L.; Bai, S.; Yao, Q. Thermoelectric performance of p-type Bi-Sb-Te materials prepared by spark plasma sintering. J. Alloy. Compd. 2005, 390, 208–211. [Google Scholar] [CrossRef]

- Li, Y.L.; Jiang, J.; Xu, G.J.; Li, W.; Zhou, L.M.; Li, Y.; Cui, P. Synthesis of micro/nanostructured p-type Bi0.4Sb1.6Te3 and its thermoelectrical properties. J. Alloy. Compd. 2009, 480, 954–957. [Google Scholar] [CrossRef]

- Son, J.H.; Oh, M.W.; Kim, B.S.; Park, S.D.; Min, B.K.; Kim, M.H.; Lee, H.W. Effect of ball milling time on the thermoelectric properties of p-type (Bi,Sb)2Te3. J. Alloy. Compd. 2013, 566, 168–174. [Google Scholar] [CrossRef]

- Osvenskiy, V.B.; Panchenko, V.P.; Parkhomenko, Y.N.; Sorokin, A.I.; Bogomolov, D.I.; Bublik, V.T.; Tabachkova, N.Y. Nonmonotonic change in the structural grain size of the Bi0.4Sb1.6Te3 hermoelectric material synthesised by spark plasma sintering. J. Alloy. Compd. 2014, 586, S413–S418. [Google Scholar] [CrossRef]

- Harman, T.C.; Taylor, P.J.; Walsh, M.P.; LaForge, B.E. Quantum dot superlattice thermoelectric materials and devices. Science 2002, 27, 2229–2232. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Li, J.F.; Kita, T. Nanostructured AgPbmSbTem+2 system bulk materials with enhanced thermoelectric performance. J. Am. Chem. Soc. 2008, 130, 4527–4532. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Gueguen, A.; Sootsman, J.R.; Zheng, J.C.; Wu, L.; Zhu, Y.; Kanatzidis, M.G.; Dravid, V.P. Role of self-organization, nanostructuring, and lattice strain on phonon transport in NaPb18-xSnxBiTe20 thermoelectric materials. J. Am. Chem. Soc. 2009, 131, 17828–17835. [Google Scholar] [CrossRef] [PubMed]

- Goldsmith, H.J.; Douglas, R.W. The use of semiconductors in thermoelectric refrigeration. Br. J. Appl. Phys. 1954, 5, 386–390. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-K.; Chen, M.-S.; Huang, R.-T.; Cheng, Y.-C.; Lee, P.-Y. Thermoelectric Properties of Alumina-Doped Bi0.4Sb1.6Te3 Nanocomposites Prepared through Mechanical Alloying and Vacuum Hot Pressing. Energies 2015, 8, 12573-12583. https://doi.org/10.3390/en81112323

Lin C-K, Chen M-S, Huang R-T, Cheng Y-C, Lee P-Y. Thermoelectric Properties of Alumina-Doped Bi0.4Sb1.6Te3 Nanocomposites Prepared through Mechanical Alloying and Vacuum Hot Pressing. Energies. 2015; 8(11):12573-12583. https://doi.org/10.3390/en81112323

Chicago/Turabian StyleLin, Chung-Kwei, May-Show Chen, Rong-Tan Huang, Yu-Chun Cheng, and Pee-Yew Lee. 2015. "Thermoelectric Properties of Alumina-Doped Bi0.4Sb1.6Te3 Nanocomposites Prepared through Mechanical Alloying and Vacuum Hot Pressing" Energies 8, no. 11: 12573-12583. https://doi.org/10.3390/en81112323