Thermoeconomic Analysis of Hybrid Power Plant Concepts for Geothermal Combined Heat and Power Generation

Abstract

:1. Introduction

2. Methodology

2.1. Process Simulations

, outlet temperature of cooling water TCW,out, mass flow of cooling water ṁCW or outlet temperature of the exhaust gases TEG,out are shown in Table 2.

, outlet temperature of cooling water TCW,out, mass flow of cooling water ṁCW or outlet temperature of the exhaust gases TEG,out are shown in Table 2.

| Parameter | Unit | |

|---|---|---|

| Isentropic efficiency of the ORC-turbine ηi,T | % | 80 |

| Generator efficiency ηG | % | 95 |

| Isentropic efficiency of the ORC-pump ηi,P | % | 75 |

| ΔTPP,EVP | K | 5 |

| TCW,in | °C | 15 |

| ΔTCW | K | 5 |

| Parameter | Unit | |

|---|---|---|

| Electrical power output Pel | kW | 2717 |

Thermal power output  | kW | 1315 |

| Engine coolant outlet temperature TCW,out | °C | 87.8 |

| Engine coolant inlet temperature TCW,in | °C | 65.5 |

| Engine coolant mass flow rate ṁCW | kg/s | 19.9 |

| Exhaust gas outlet temperature TEG,out | °C | 463.9 |

| Exhaust gas mass flow rate ṁEG | kg/s | 4.35 |

2.2. Second Law Analyses

describes the molar fraction for each component and Em,i is the molar exergy of each component according to Baehr and Kabelac [15]. A gas mixture of 65% methane and 35% carbon dioxide is assumed. In the following, second law efficiency for a certain power plant concept is calculated by evaluating each load step and finally rating according to the annual contribution.

describes the molar fraction for each component and Em,i is the molar exergy of each component according to Baehr and Kabelac [15]. A gas mixture of 65% methane and 35% carbon dioxide is assumed. In the following, second law efficiency for a certain power plant concept is calculated by evaluating each load step and finally rating according to the annual contribution.2.3. Economic Analyses

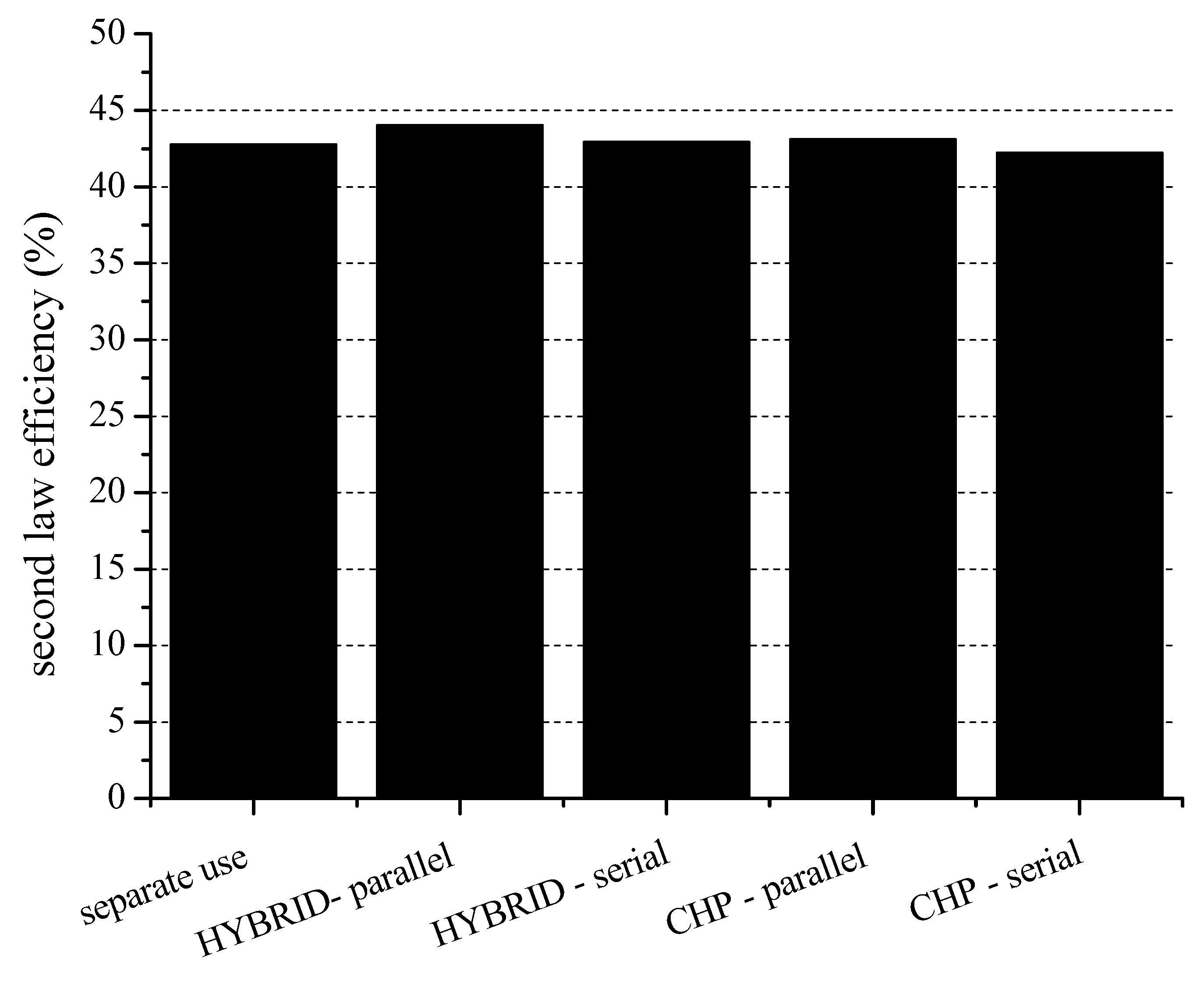

3. Results and Discussion

3.1. Thermodynamic Results

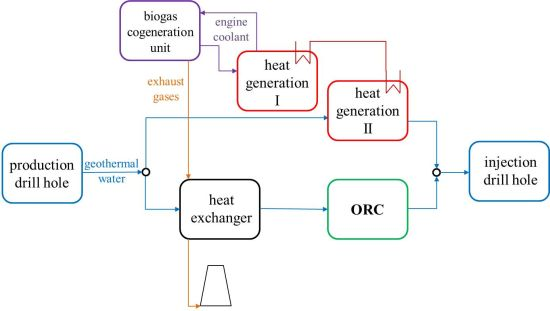

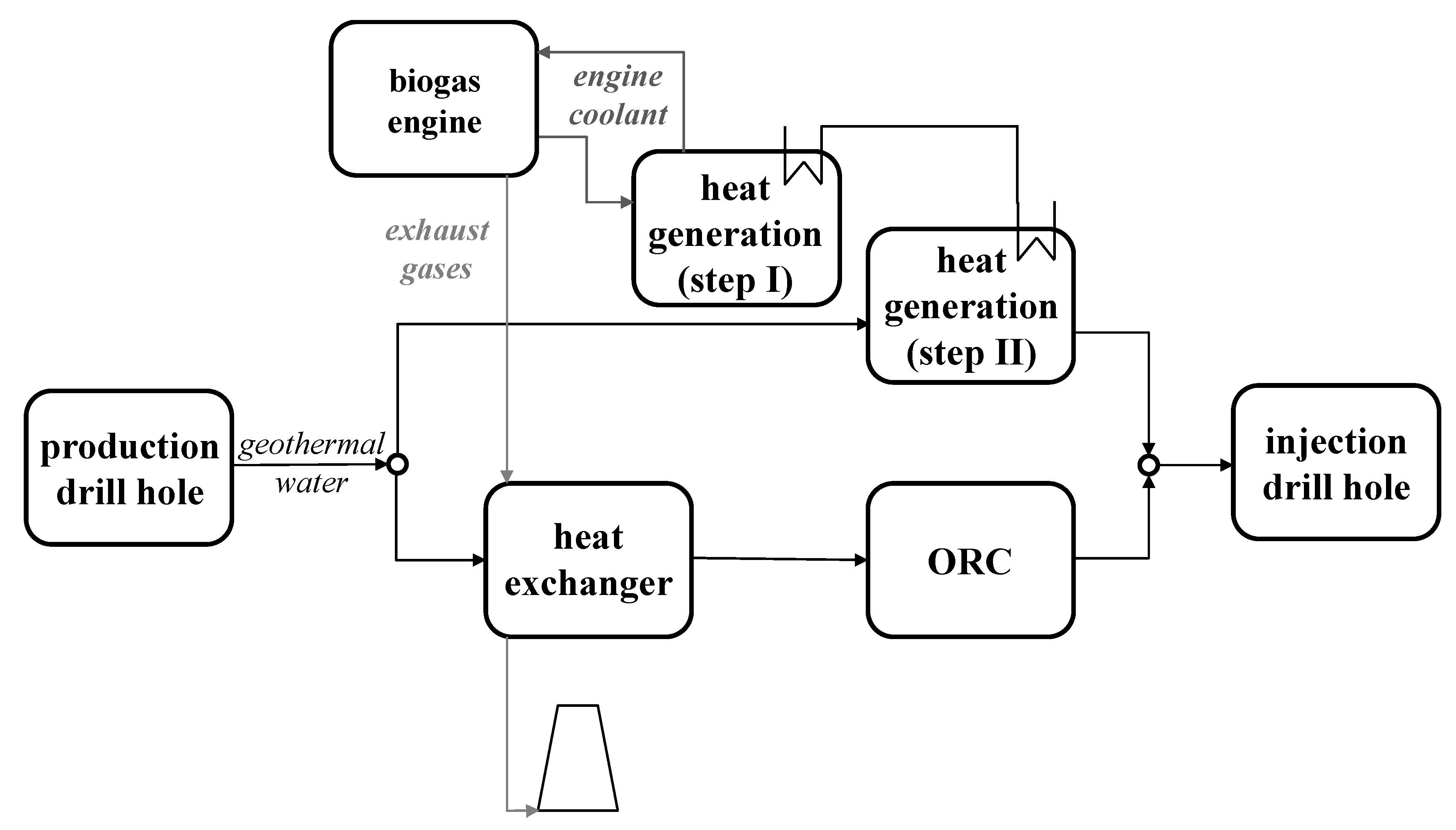

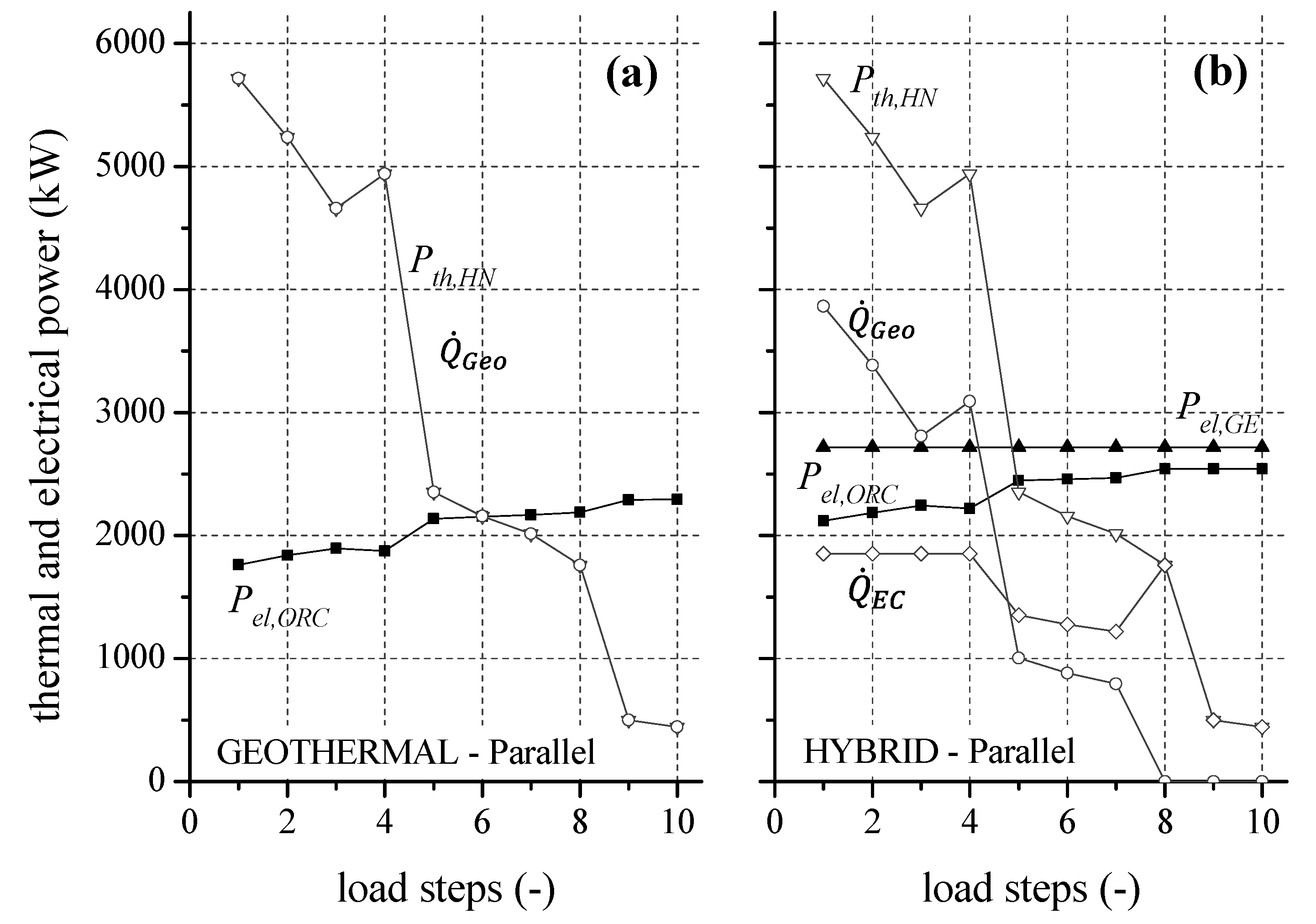

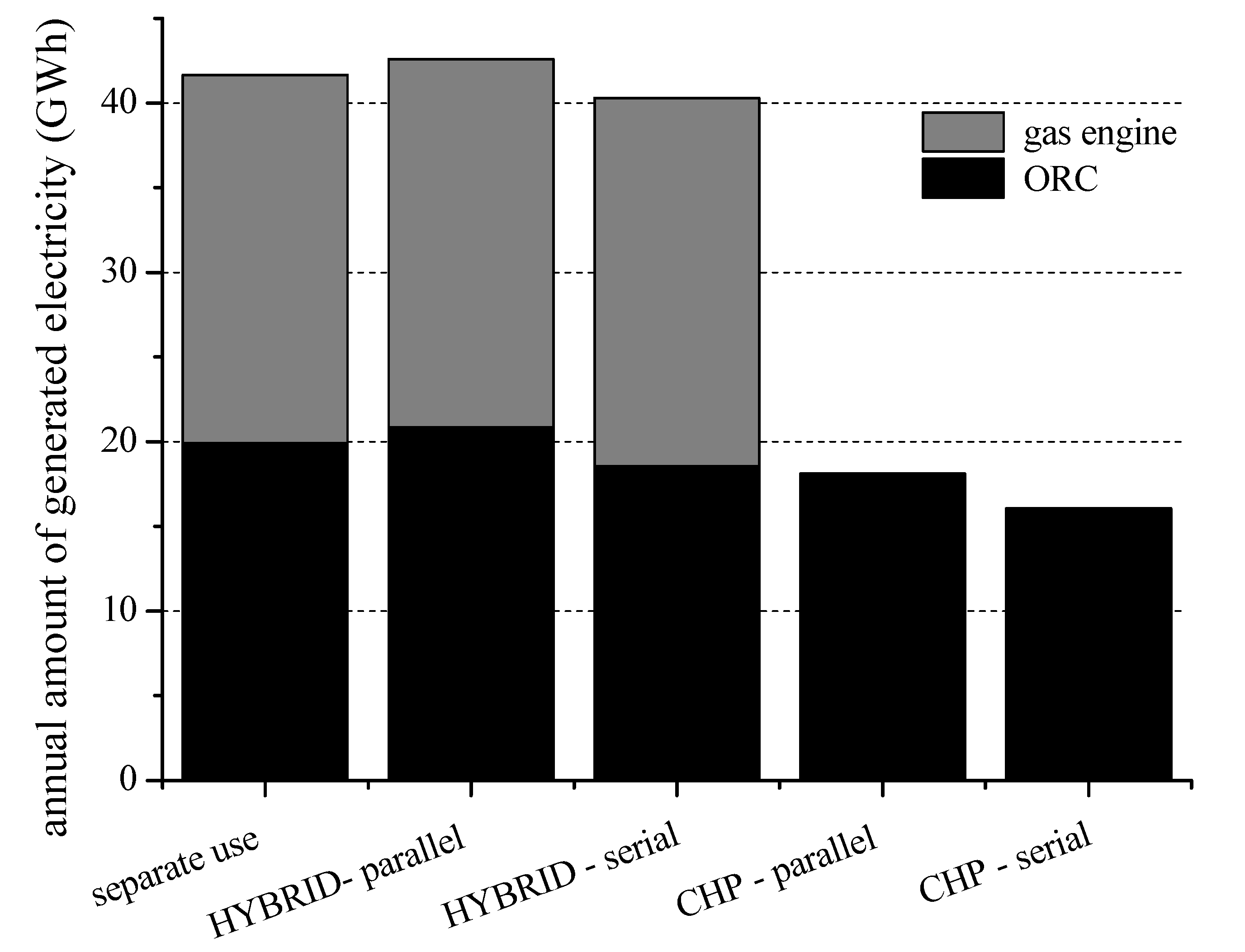

pointed out. For geothermal CHP the heat demand is supplied completely by the geothermal fluid. Therefore in Figure 5a the values for Pth,HN and

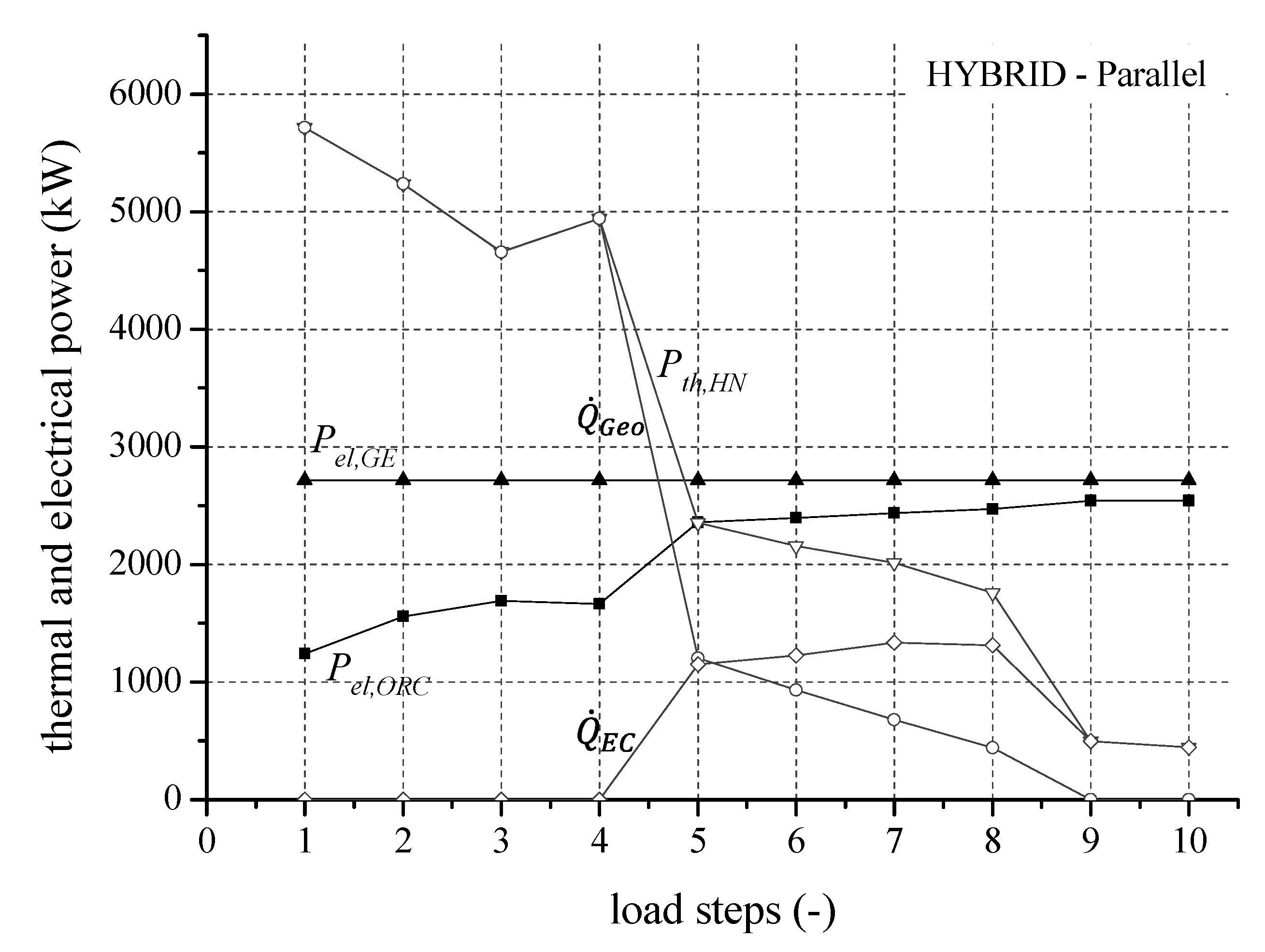

pointed out. For geothermal CHP the heat demand is supplied completely by the geothermal fluid. Therefore in Figure 5a the values for Pth,HN and  are equal. For higher load steps the thermal power of the heating network decreases and a higher amount of thermal energy is coupled to the ORC. As a result the power output of the ORC increases. In Figure 5b these parameters are shown for a hybrid power plant in parallel circuit, extended by electric power of the gas engine Pel,GE and part of thermal power supplied by engine coolant

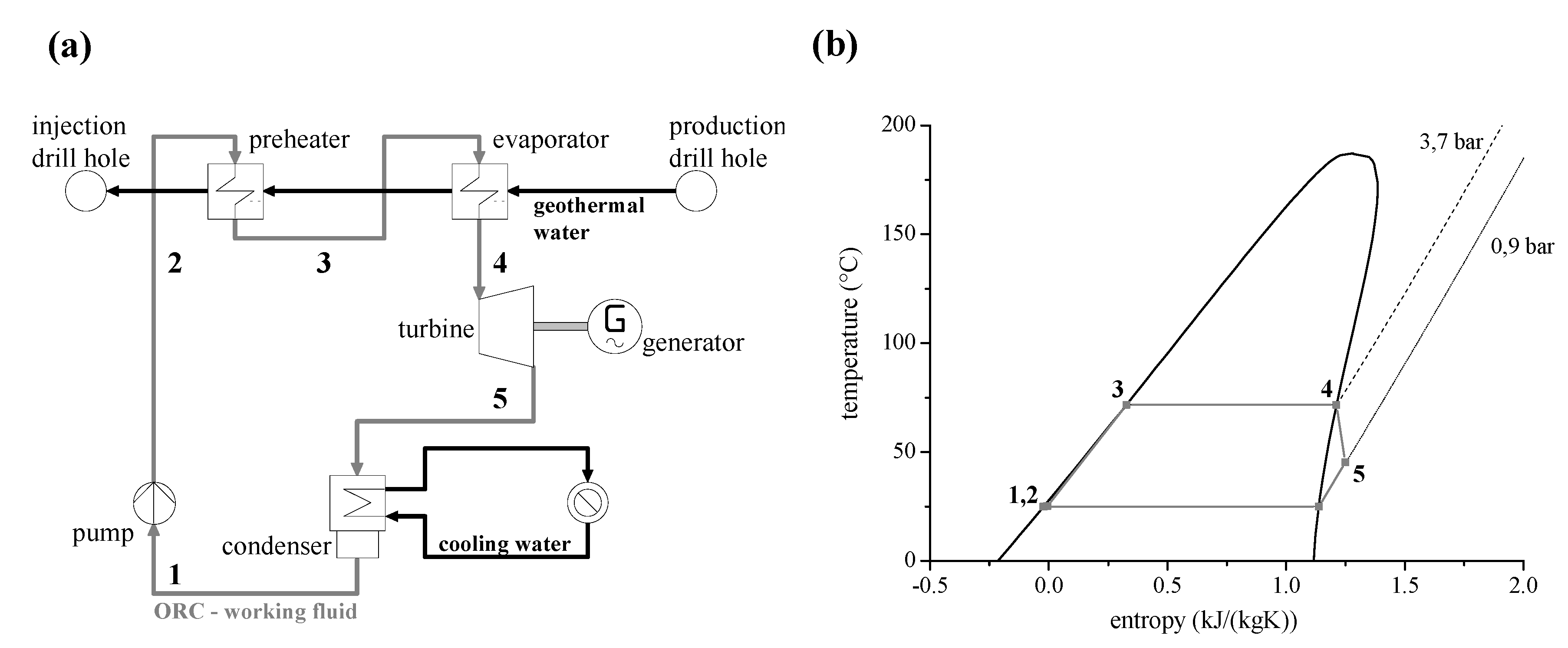

are equal. For higher load steps the thermal power of the heating network decreases and a higher amount of thermal energy is coupled to the ORC. As a result the power output of the ORC increases. In Figure 5b these parameters are shown for a hybrid power plant in parallel circuit, extended by electric power of the gas engine Pel,GE and part of thermal power supplied by engine coolant  . In case of the hybrid power plant, the biogas engine operates 8000 h/a with a maximum electrical power of 2717 kW. The electrical power of the ORC-unit increases for higher load steps which correspond to higher ambient temperatures and less heat demand. The engine coolant supplies the heating network partly for all load steps. Finally, for load steps 8 to 10, corresponding to 2952 h/a, the heating network is fully supplied by engine coolant. In this period, the geothermal water is not required for heat generation. Therefore, the complete geothermal mass flow rate can be coupled to the ORC-unit for power generation. In addition, in case of a hybrid power plant, geothermal water temperature is increased. As a result, higher process pressures of the ORC can be reached and the efficiency of the ORC-unit is about 3% higher. In this context, the ORC pressure at condensation and evaporation for the geothermal CHP and the hybrid power plant are listed in Table 4.

. In case of the hybrid power plant, the biogas engine operates 8000 h/a with a maximum electrical power of 2717 kW. The electrical power of the ORC-unit increases for higher load steps which correspond to higher ambient temperatures and less heat demand. The engine coolant supplies the heating network partly for all load steps. Finally, for load steps 8 to 10, corresponding to 2952 h/a, the heating network is fully supplied by engine coolant. In this period, the geothermal water is not required for heat generation. Therefore, the complete geothermal mass flow rate can be coupled to the ORC-unit for power generation. In addition, in case of a hybrid power plant, geothermal water temperature is increased. As a result, higher process pressures of the ORC can be reached and the efficiency of the ORC-unit is about 3% higher. In this context, the ORC pressure at condensation and evaporation for the geothermal CHP and the hybrid power plant are listed in Table 4.

| Parameter | R245fa-GeoCHP | R245fa-Hybrid | Isopentane-GeoCHP | Isopentane-Hybrid |

|---|---|---|---|---|

| p1 (bar) | 1.47 | 1.47 | 0.90 | 0.90 |

| p2 (bar) | 6.53 | 6.94 | 3.67 | 3.85 |

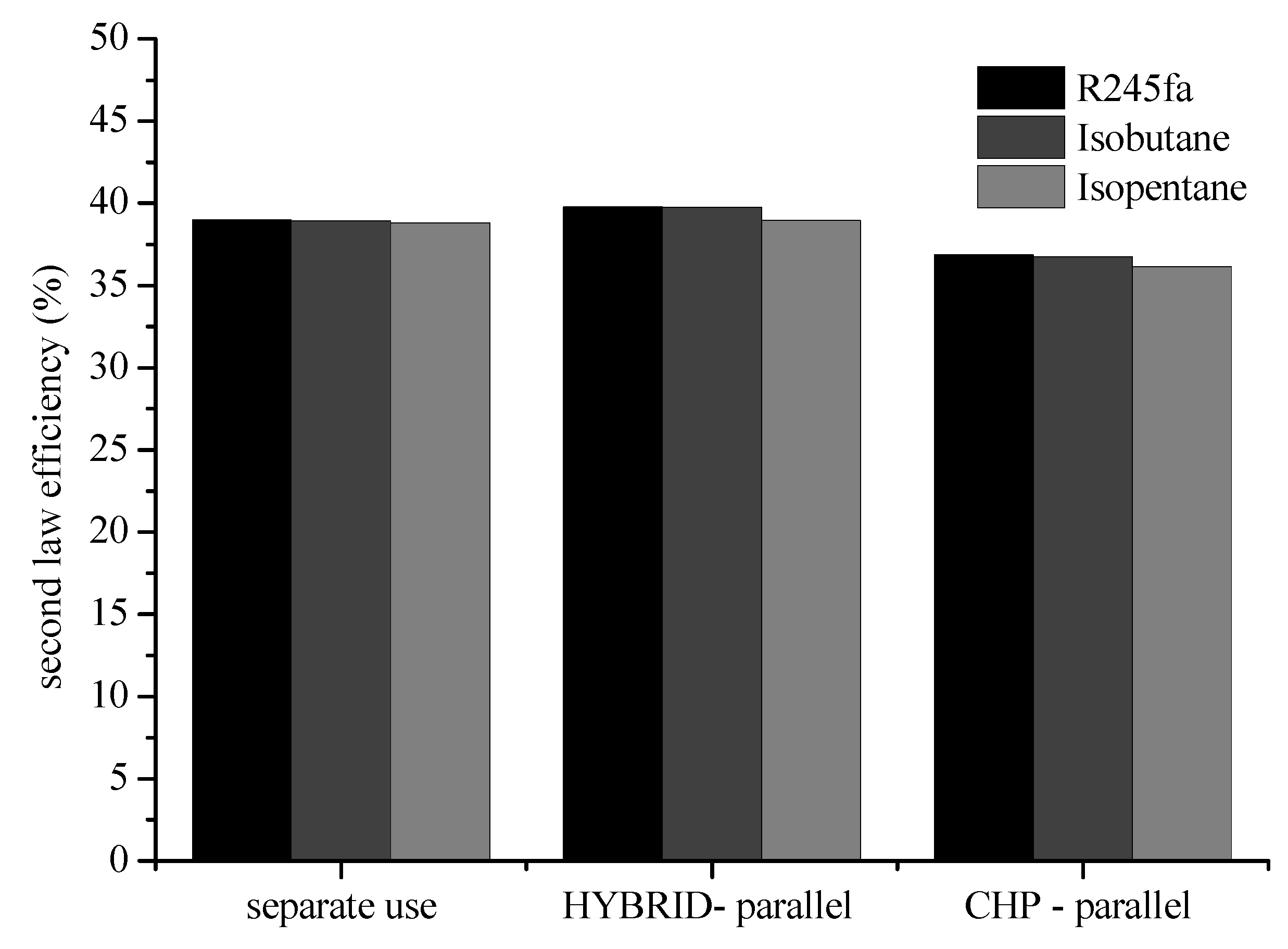

3.1.1. ORC Working Fluid

3.1.2. Geothermal Conditions

3.1.3. Supply Temperature of the Heating Network

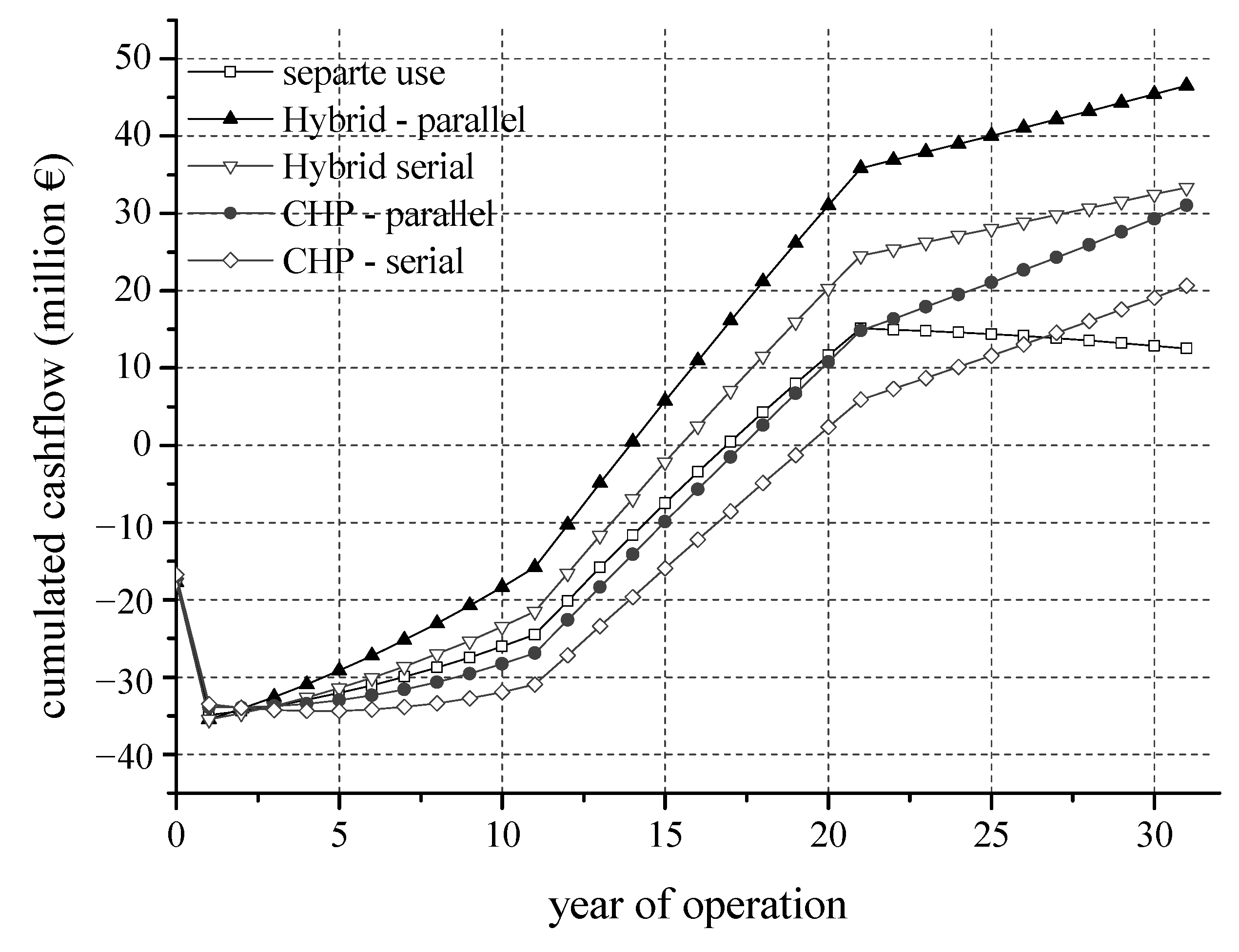

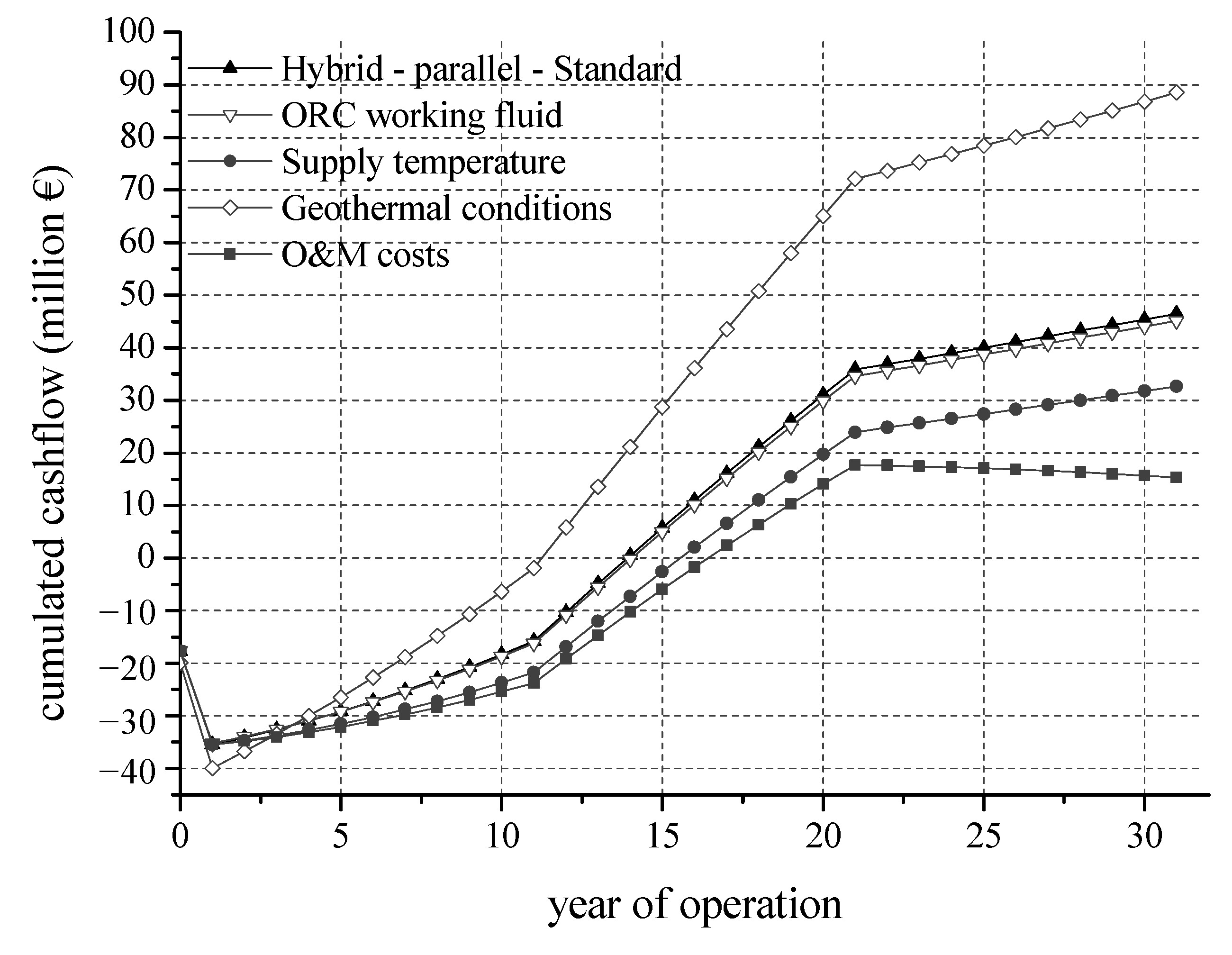

3.2. Economic Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tchanche, B.F.; Lambrinos, G.; Frangoudakis, A.; Papadakis, G. Low-grade heat conversion into power using Organic Rankine Cycles—A review of various applications. Renew. Sustain. Energy Rev. 2011, 15, 3963–3979. [Google Scholar] [CrossRef]

- Vélez, F.; Segovia, J.J.; Martín, M.C.; Antolín, G.; Chejne, F.; Quijano, A. A technical, economical and market review of Organic Rankine Cycles for the conversion of low-grade heat for power generation. Renew. Sustain. Energy Rev. 2012, 16, 4175–4189. [Google Scholar] [CrossRef]

- Heberle, F.; Brüggemann, D. Exergy based fluid selection for a geothermal Organic Rankine Cycle for combined heat and power generation. Appl. Therm. Eng. 2010, 30, 1326–1332. [Google Scholar] [CrossRef]

- Heberle, F.; Preißinger, M.; Brüggemann, D. Thermoeconomic evaluation of combined heat and power generation for geothermal applications. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; pp. 1305–1313.

- Heberle, F.; Brüggemann, D. Thermoeconomic comparison of designs for geothermal combined heat and power generation. In Proceedings of the European Geothermal Congress, Pisa, Italy, 3–7 June 2013.

- Tempesti, D.; Manfrida, G.; Fiaschi, D. Thermodynamic analysis of two micro CHP systems operating with geothermal and solar energy. Appl. Energy 2012, 97, 609–617. [Google Scholar] [CrossRef]

- Astolfi, M.; Xodo, L.; Romano, M.C.; Macchi, E. Technical and economical analysis of a solar-geothermal hybrid plant based on an Organic Rankine Cycle. Geothermics 2011, 40, 58–68. [Google Scholar] [CrossRef]

- Borsukiewicz-Gozdur, A. Dual-fluid-hybrid power plant co-powered by low-temperature geothermal water. Geothermics 2010, 39, 170–176. [Google Scholar] [CrossRef]

- Astina, I.M.; Pastalozi, M.; Sato, H. An improved hybrid and cogeneration cycle for enhanced geothermal systems. In Proceedings of the World Geothermal Congress, Bali, Indonesia, 25–29 April 2010.

- Kohl, T.; Speck, R. Electricity production by geothermal hybrid-plants in low-enthalpy areas. In Proceedings of the 29th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 26–28 January 2004.

- Karellas, S.; Terzis, K.; Manolakos, D. Investigation of an autonomous hybrid solar thermal ORC-PV RO desalination system. The Chalki Island case. Renew. Energy 2011, 36, 583–590. [Google Scholar] [CrossRef]

- Woudstra, N.; van der Stelt, T.P. Cycle-Tempo: A Program for the Thermodynamic Analysis and Optimization of Systems for the Production of Electricity, Heat and Refrigeration; Energy Technology Section, Delft University of Technology: Delft, The Netherlands, 2002. [Google Scholar]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23; Version 9.1; National Institute of Standards and Technology: Boulder, CO, USA, 2013. [Google Scholar]

- Verein Deutscher Ingenieure e.V. VDI Richtlinie 4655—Referenzlastprofile von Ein- und Mehrfamilienhäusern für den Einsatz von KWK-Anlagen; Springer-Verlag: Düsseldorf/Beuth, Germany, 2008. (In German) [Google Scholar]

- Baehr, H.D.; Kabelac, S. Thermodynamik: Grundlagen und technische Anwendungen, 15th ed.; Springer Vieweg Verlag: Auflage/Berlin, Germany, 2012. [Google Scholar]

- Quoilin, S.; Declaye, S.; Tchanche, B.F.; Lemort, V. Thermo-economic optimization of waste heat recovery Organic Rankine Cycles. Appl. Therm. Eng. 2011, 31, 2885–2893. [Google Scholar] [CrossRef]

- Preißinger, M.; Heberle, F.; Brüggemann, D. Advanced Organic Rankine Cycle for geothermal application. Int. J. Low-Carbon Technol. 2012, 8, 62–68. [Google Scholar]

- Heberle, F.; Bassermann, P.; Preissinger, M.; Brüggemann, D. Exergoeconomic optimization of an Organic Rankine Cycle for low-temperature geothermal heat sources. Int. J. Thermodyn. 2012, 15, 119–126. [Google Scholar]

- Görke, B.; Sievers, A. Gewinnbetrachtung von strom- und wärmegeführten Geothermie-Projekten unter Berücksichtigung der aktuellen EEG Novelle. In Kongressband Geothermiekongress, Karlsruhe, Germany, 11–13 November 2008; Geothermische Vereinigung—Bundesverband Geothermie e.V.: Geeste, Germany, 2008; pp. 147–156. [Google Scholar]

- Janczik, S.; Kaltschmitt, M. Kombinierte Nutzung von Geothermie und Klärschlamm. VGB PowerTech 2010, 7, 84–91. [Google Scholar]

- Fachagentur Nachwachsende Rohstoffe e.V. (FNR). Biogas—Pflanzen, Rohstoffe, Produkte. Rostock. 2011. Available online: http://www.fnr-server.de/ftp/pdf/literatur/pdf_175-biogas_broschuere_dina5_nr_175.pdf (accessed on 10 February 2014).

- Statistisches Bundesamt. Preise—Daten Zur Energiepreisentwicklung. 2014. Available online: https://www.destatis.de/DE/Publikationen/Thematisch/Preise/Energiepreise/Energiepreisentwicklung.html (accessed on 10 February 2014).

- Bundesregierung. Gesetz für den Vorrang Erneuerbarer Energien (Erneuerbare-Energien-Gesetz—EEG). 22 Dezember 2011. Available online: https://www.clearingstelle-eeg.de/eeg2012 (accessed on 12 February 2014).

- EDR Aspen Exchanger Design & Rating, version 7.3; Aspen Technology, Inc.: Burlington, MA, USA, 2011.

- Ehrig, R.; Kristöfel, C.; Pointner, C. Operating Figures and Investment Costs for District Heating Systems. 2011. Available online: http://www.afo.eu.com/default.asp?SivuID=28291 (accessed on 10 January 2014).

- Turton, R.; Bailie, R.C.; Whiting, W.B. Analysis, Synthesis and Design of Chemical Processes, 2nd ed.; Prentice Hall: Old Tappan, NJ, USA, 2003. [Google Scholar]

- Arbeitsgemeinschaft für sparsamen und umweltfreundlichen Energieverbrauch e.V. (ASUE). BHKW Kenndaten 2011—Module, Anbieter, Kosten. Frankfurt am Main. 2011. Available online: http://asue.de/themen/blockheizkraftwerke/broschueren/bhkw_kenndaten_2011.html (accessed on 4 February 2014).

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Heberle, F.; Brüggemann, D. Thermoeconomic Analysis of Hybrid Power Plant Concepts for Geothermal Combined Heat and Power Generation. Energies 2014, 7, 4482-4497. https://doi.org/10.3390/en7074482

Heberle F, Brüggemann D. Thermoeconomic Analysis of Hybrid Power Plant Concepts for Geothermal Combined Heat and Power Generation. Energies. 2014; 7(7):4482-4497. https://doi.org/10.3390/en7074482

Chicago/Turabian StyleHeberle, Florian, and Dieter Brüggemann. 2014. "Thermoeconomic Analysis of Hybrid Power Plant Concepts for Geothermal Combined Heat and Power Generation" Energies 7, no. 7: 4482-4497. https://doi.org/10.3390/en7074482