1. Introduction

There are great efforts all over the world for moving energy generation to wind energy instead of the conventional fossil fuels as it provides clean, safe, and environmentally-friendly power. For this purpose, many large-scale wind power farms (WPFs) are already in the operation phase, and others are currently under construction or in the design phase. This progress in the wind power industry has enabled a new generation of wind turbines with more mature technology to have longer blades that capture more energy, taller towers, higher efficiency, and lower maintenance costs. Nevertheless, wind turbines are still blind machines because the control center manages and controls individual wind turbines. With the smart grid revolution, future electric power systems will be more reliable, efficient, and secure [

1]. There are three major components to the smart grid: generation, distribution, and consumption. With respect to future communication and networking technologies for smart grids, most prior research has focused on communication network architectures for power consumption (home, building, factory,

etc.) and on how to balance between power demand of the consumers and electric power generation. Little research has focused on communication network architectures for energy generation from renewable sources (wind power, solar energy,

etc.).

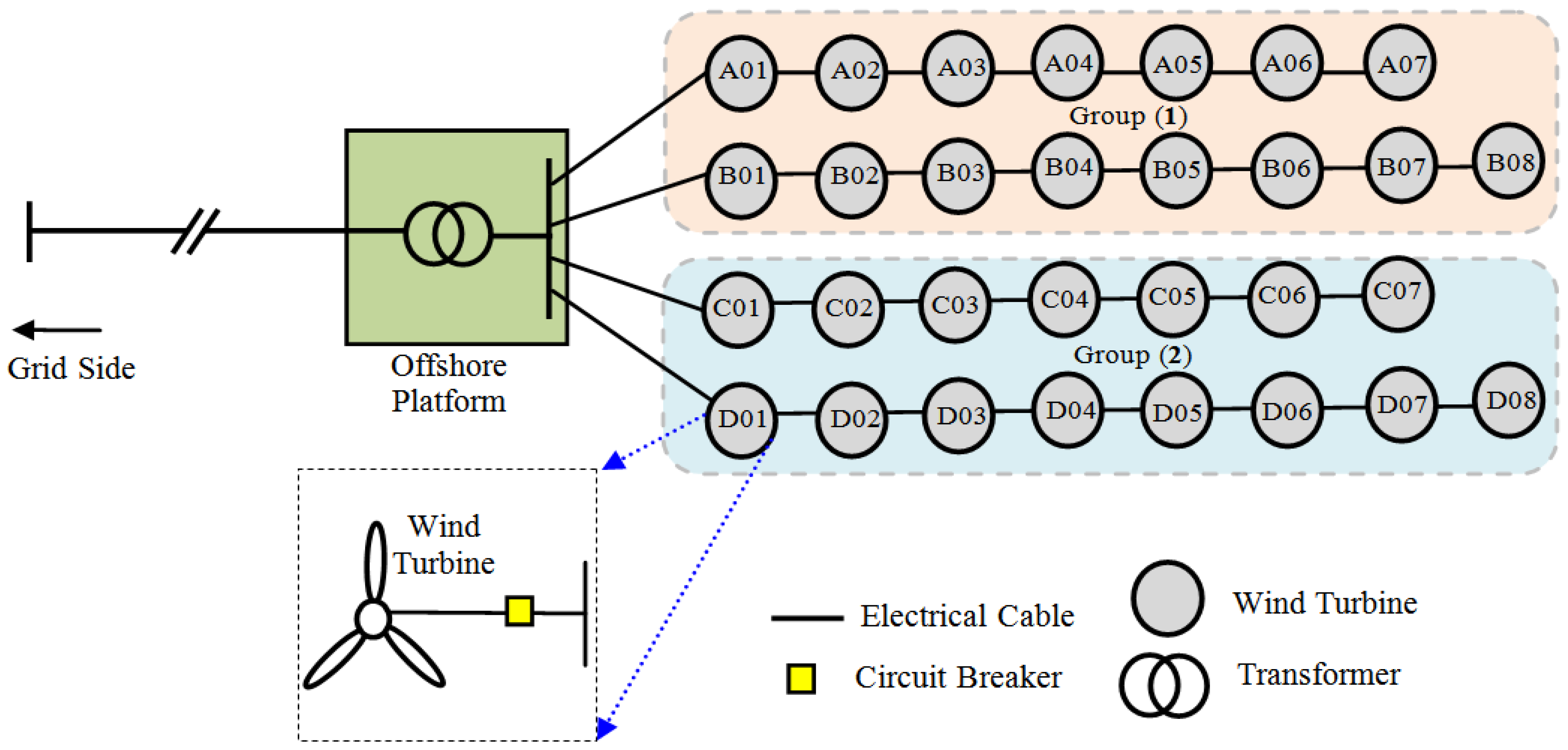

The International Electrotechnical Commission (IEC) 61400-25 standard has been developed to provide uniform information exchange for monitoring and control in wind power plants. In the context of communication networks, the focus of the IEC 61400-25 standard is on onshore wind farms. The standard only provides data structures without considering new developments in wind energy. Therefore, Nguyen

et al. [

2] developed an information model for offshore wind farms in the smart grid. Machine-to-machine (M2M) communication is a communication technology without any form of human intervention. It is mainly driven by the maturity of wireless communication systems and sensors. Zhang

et al. [

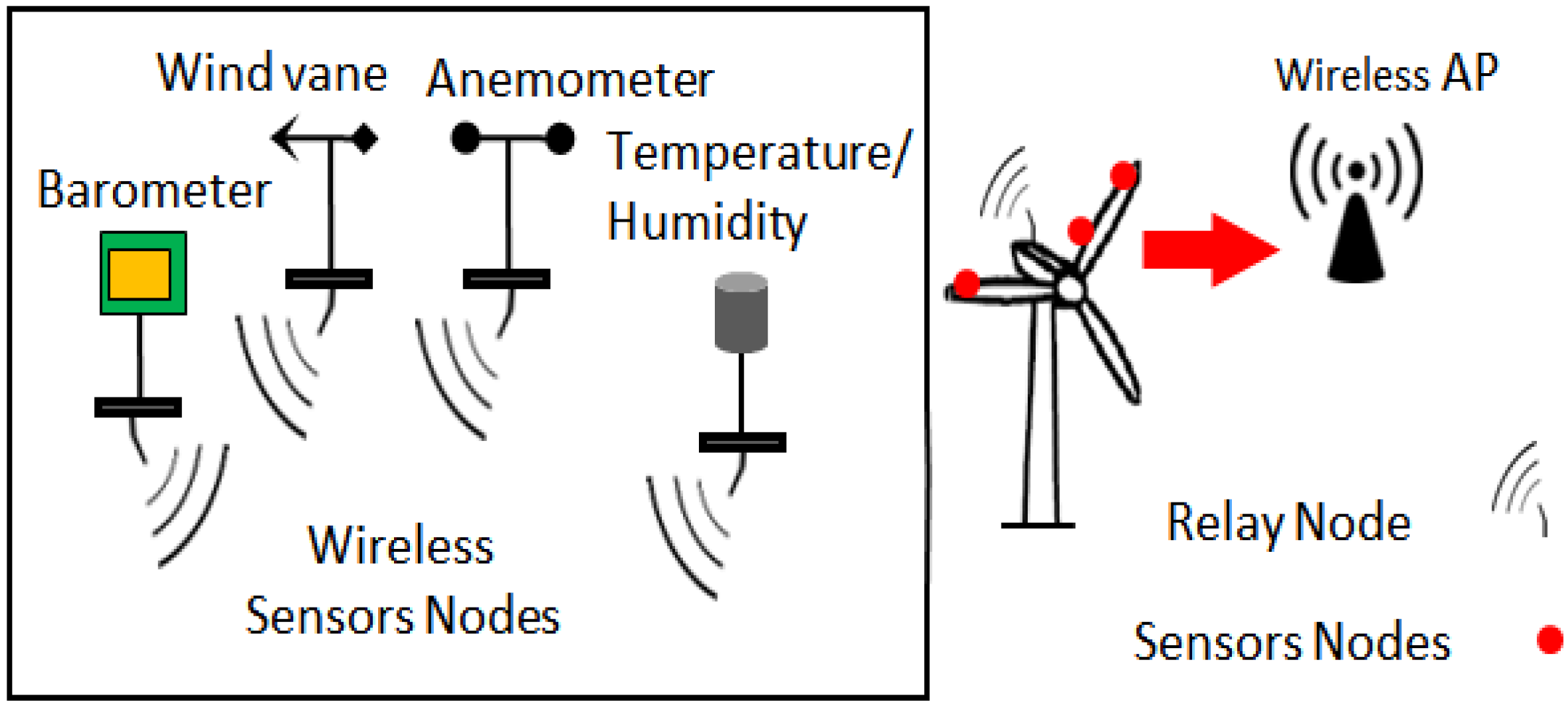

3] proposed cognitive radio M2M communication for the smart grid. The authors outlined the network architecture for renewable energy field area networks (wind power and solar energy). They also described the communication networks for grid protector field area networks, neighbored area networks, and home area networks.

One of the most important demands for WPFs is to design a reliable communication network for wind farm monitoring. The control center is responsible for autonomously monitoring, managing and controlling the operation of the WPF, and human intervention is only needed in the case of configuration, maintenance, or failure repairs [

4]. There are different solutions for communication networks associated with industrial applications. For example, fieldbus systems represent the first generation of industrial networks, and due to their bandwidth and throughput limitations, these systems are no longer attractive solutions in industrial applications. Currently, the second-generation industrial network is known as the real-time Ethernet, which can assure lower costs, improved performance, and higher data transfer rates [

5]. Passive optical networks (PON) based on real-time Ethernet are considered to be the next generation communication networks for different industrial applications [

6].

Most supervisory control and data acquisition (SCADA) systems operate with proprietary protocols with limited bandwidth and low capabilities that cannot support future communication needs. A reliable communication infrastructure is needed, as it plays the main part of enabling effective monitoring, operation, and protection both for WPF generators and power systems. There is a need for smart communication networks without human intervention between the wind turbines and the control center. To the best of our knowledge, no previous work has provided insight into smart-wind power farms (Smart-WPFs). No detailed model has been given for communication network architectures, network topologies, communication technologies, or types of shared data among wind turbines. Since wind turbines will be intelligent machines in Smart-WPFs, turbines will be able to communicate and share sensing data. Our recent work considered the recent progress of PON infrastructure for next generation large-scale WPFs [

7].

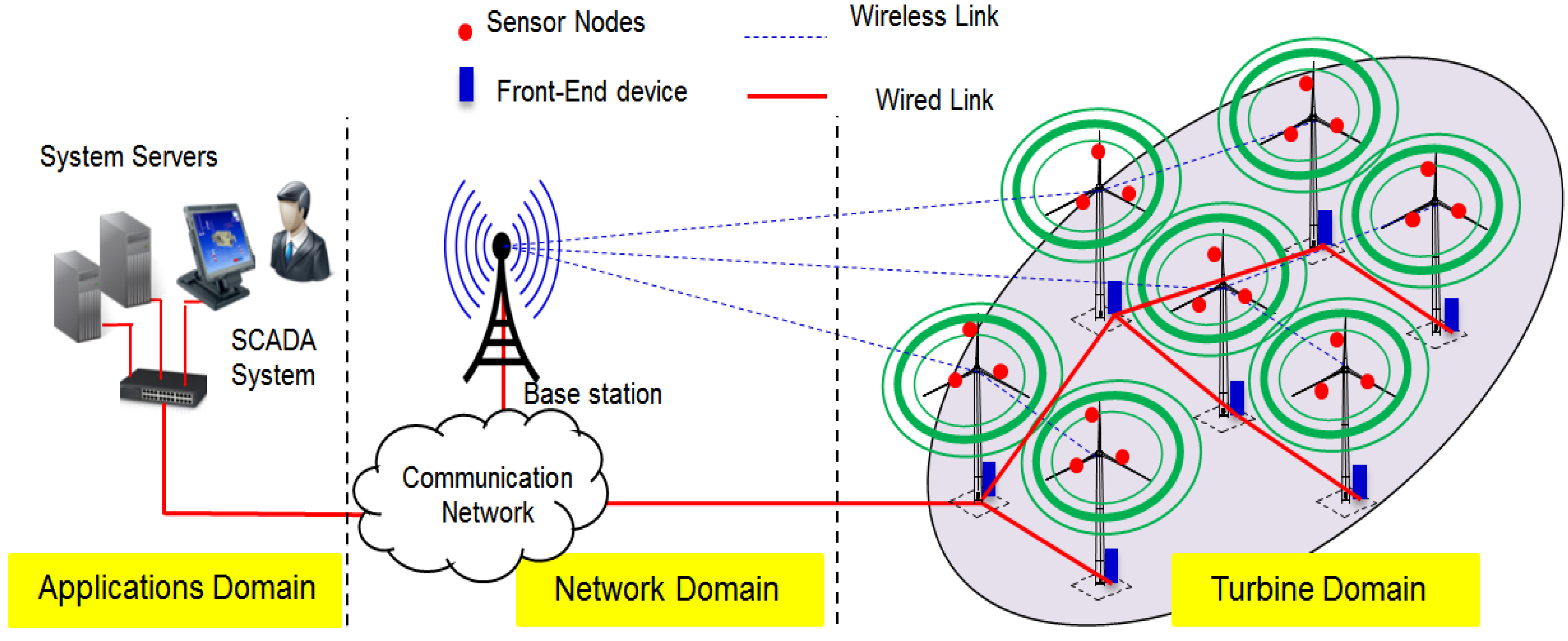

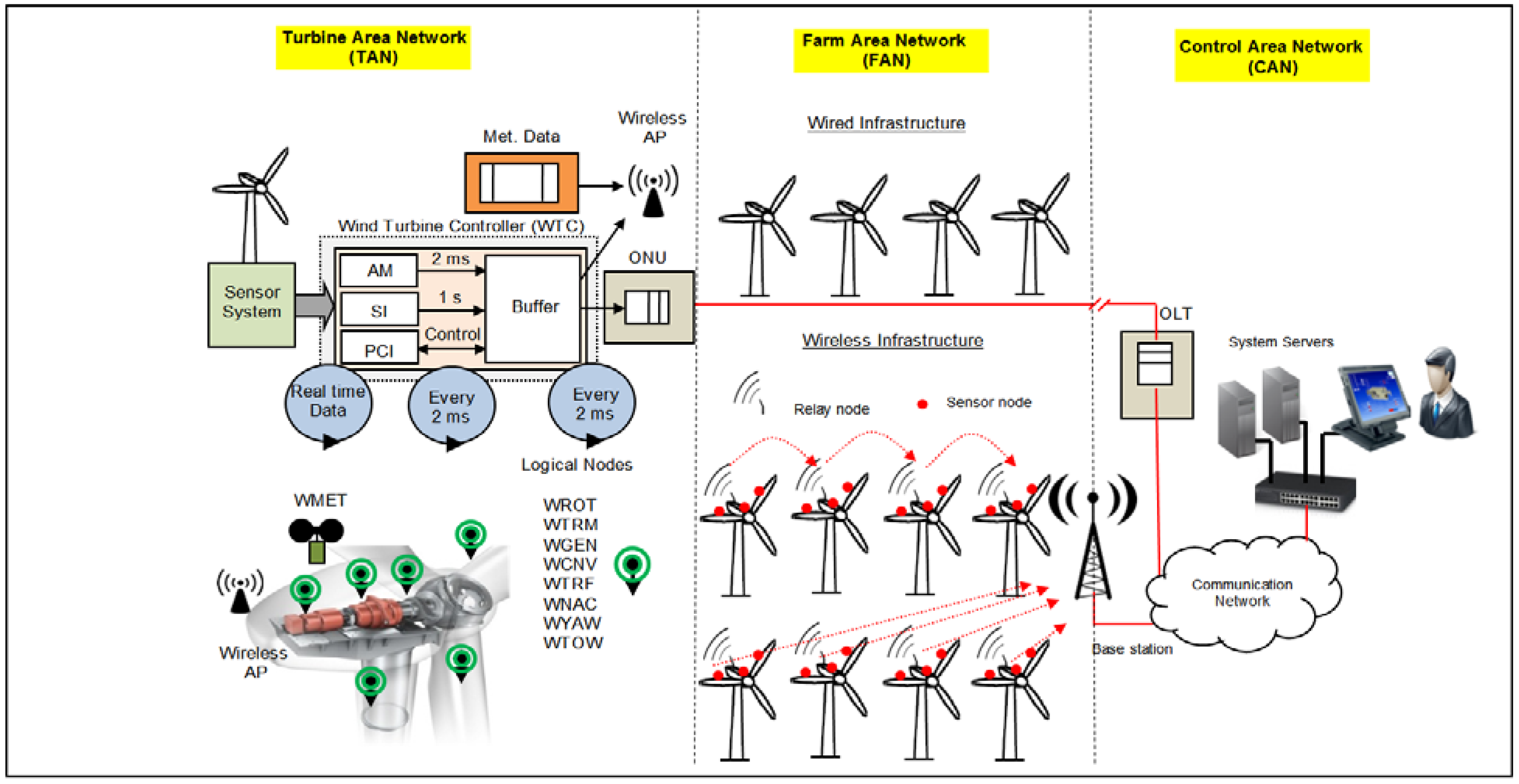

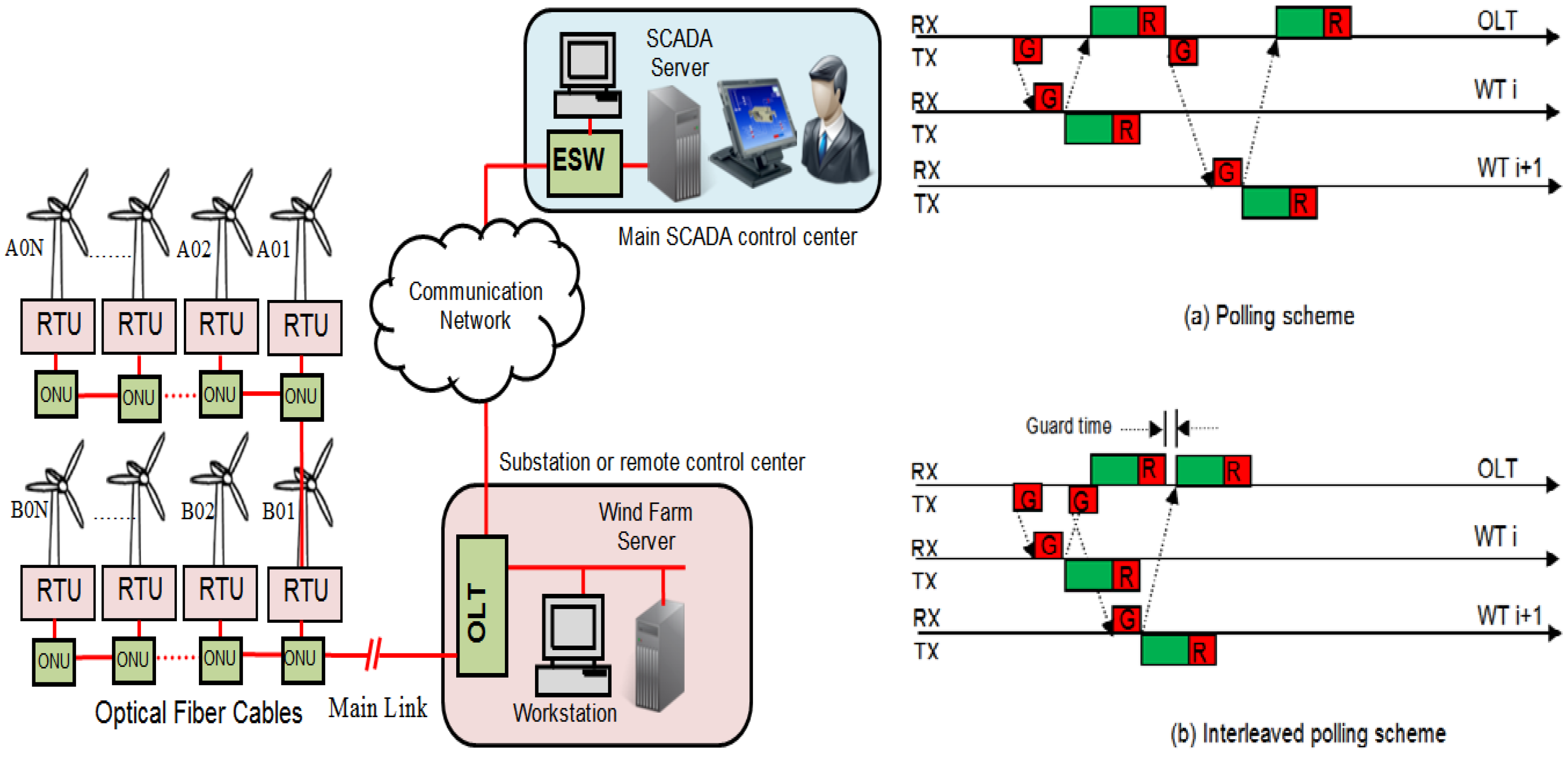

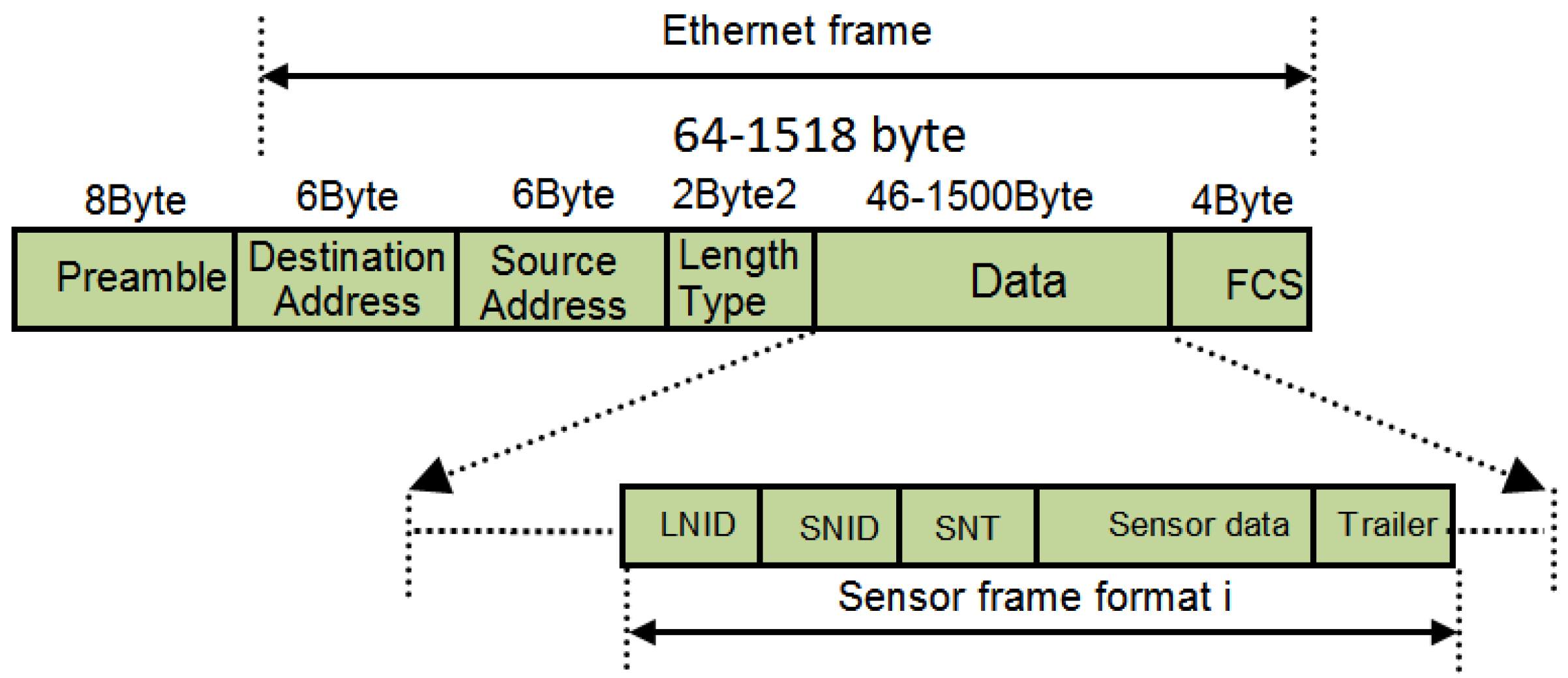

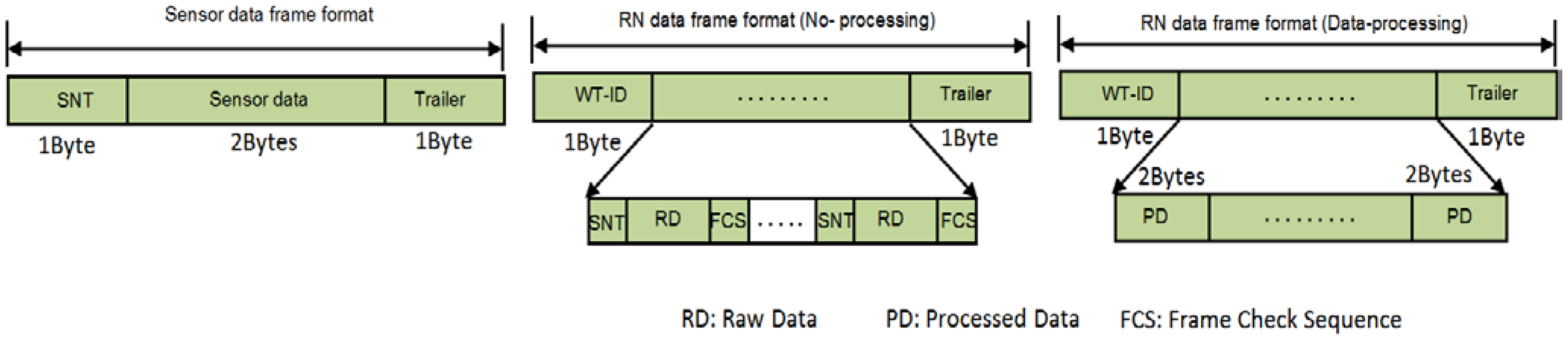

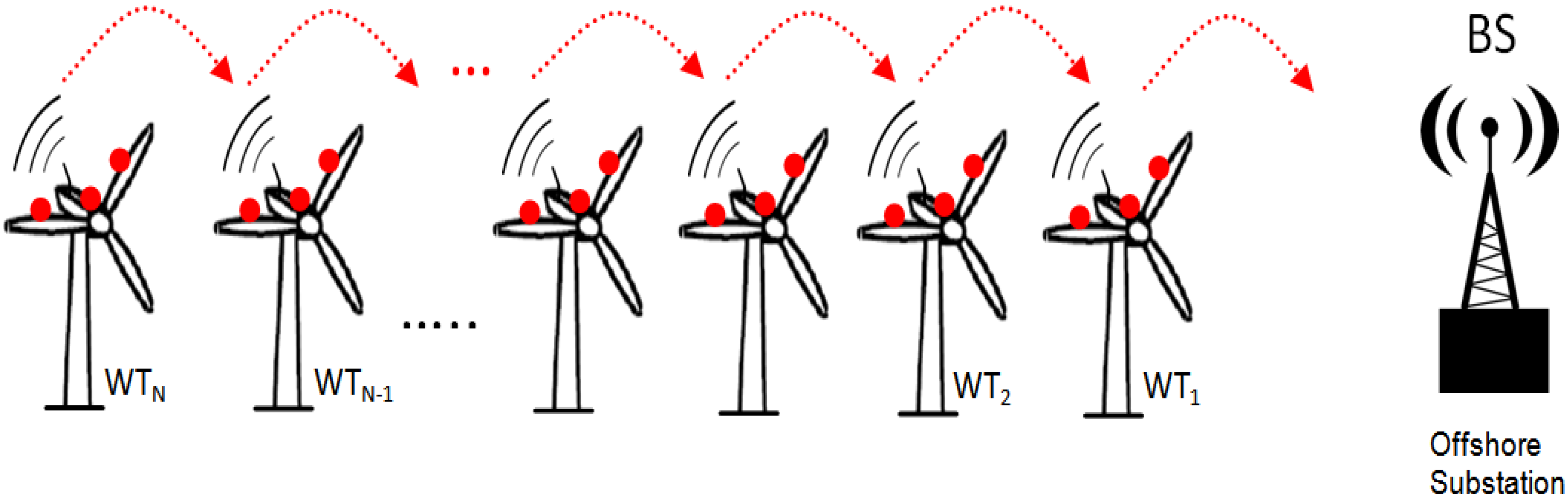

In this paper, we develop the communication network architecture for Smart-WPFs. The proposed network model converge the advances in wireless communication with Ethernet passive optical network (EPON) architecture in order to implement future Smart-WPFs. We define different wind turbine applications based on IEC 61400-25 standard. We design a sensor data frame structure to carry the sensing data from different wind turbine parts and characterize the senor types and sensor data size for EPON based architecture. Fixed bandwidth allocation (FBA) is considered in order to transmit the sensing data efficiently. For wireless-based solution, we define the data type and data packet format for transmitting meteorological data among wind turbines. We evaluate the proposed network architectures in light of analytical and simulation models.

The remainder of the paper is organized as follows: in

Section 2, we introduce the WPF communication network and data flow within the wind turbine and its design requirements;

Section 3 explains the proposed communication network architectures for the Smart-WPFs, including the EPON-based network solution, data frame structure, and shared data among wind turbines;

Section 4 provides a performance evaluation of the proposed network architectures; finally,

Section 5 concludes the paper and gives directions for future work.

5. Conclusions

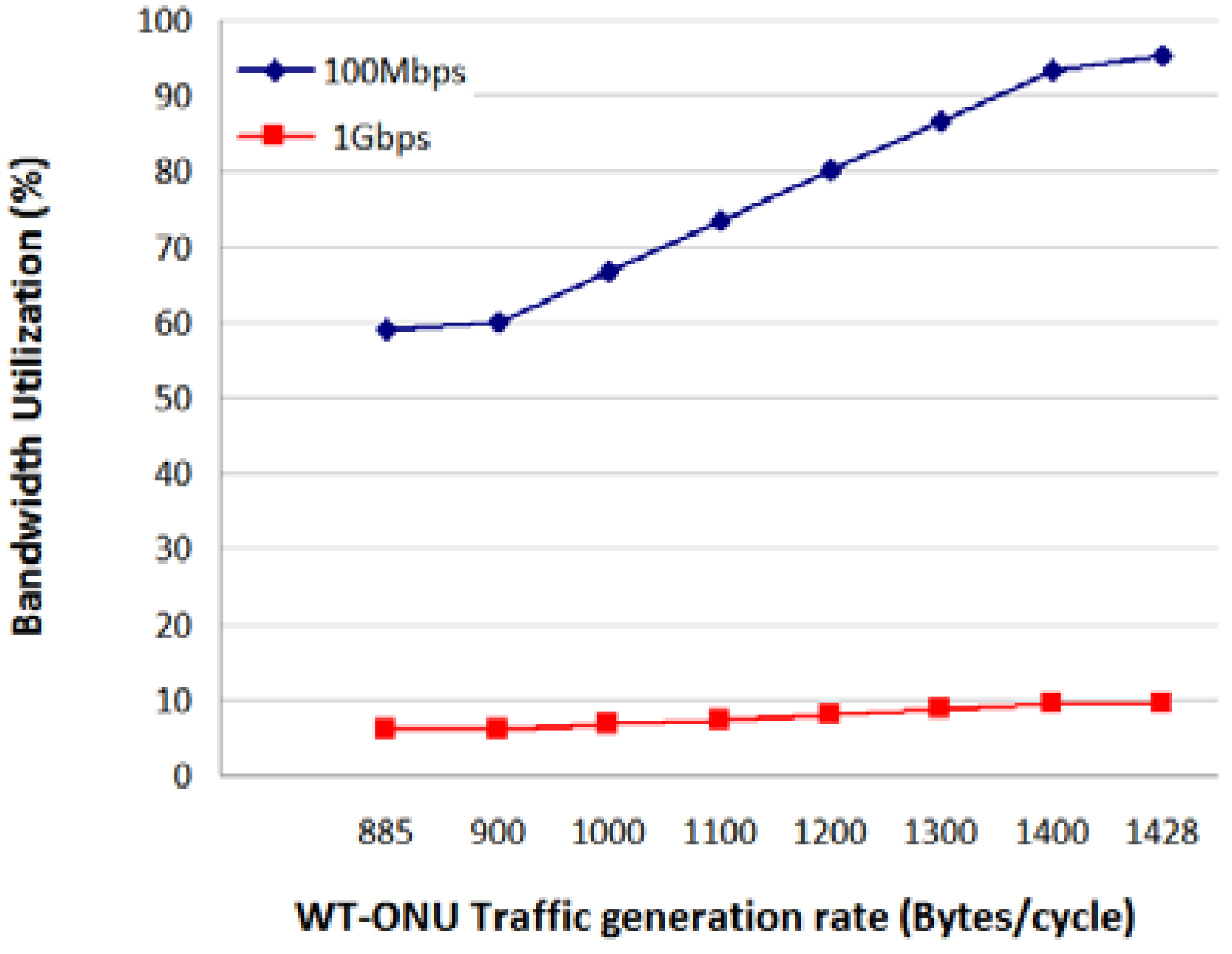

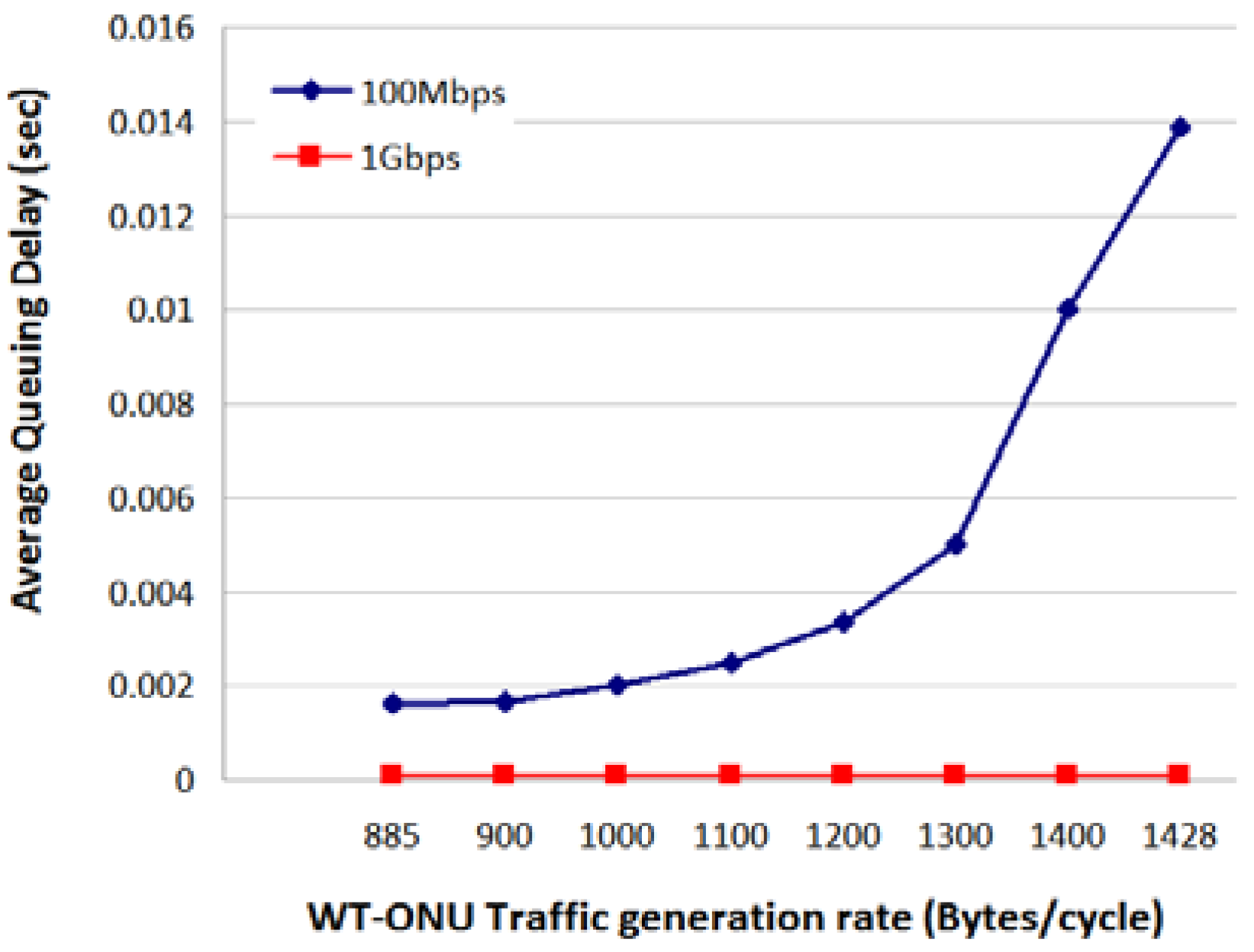

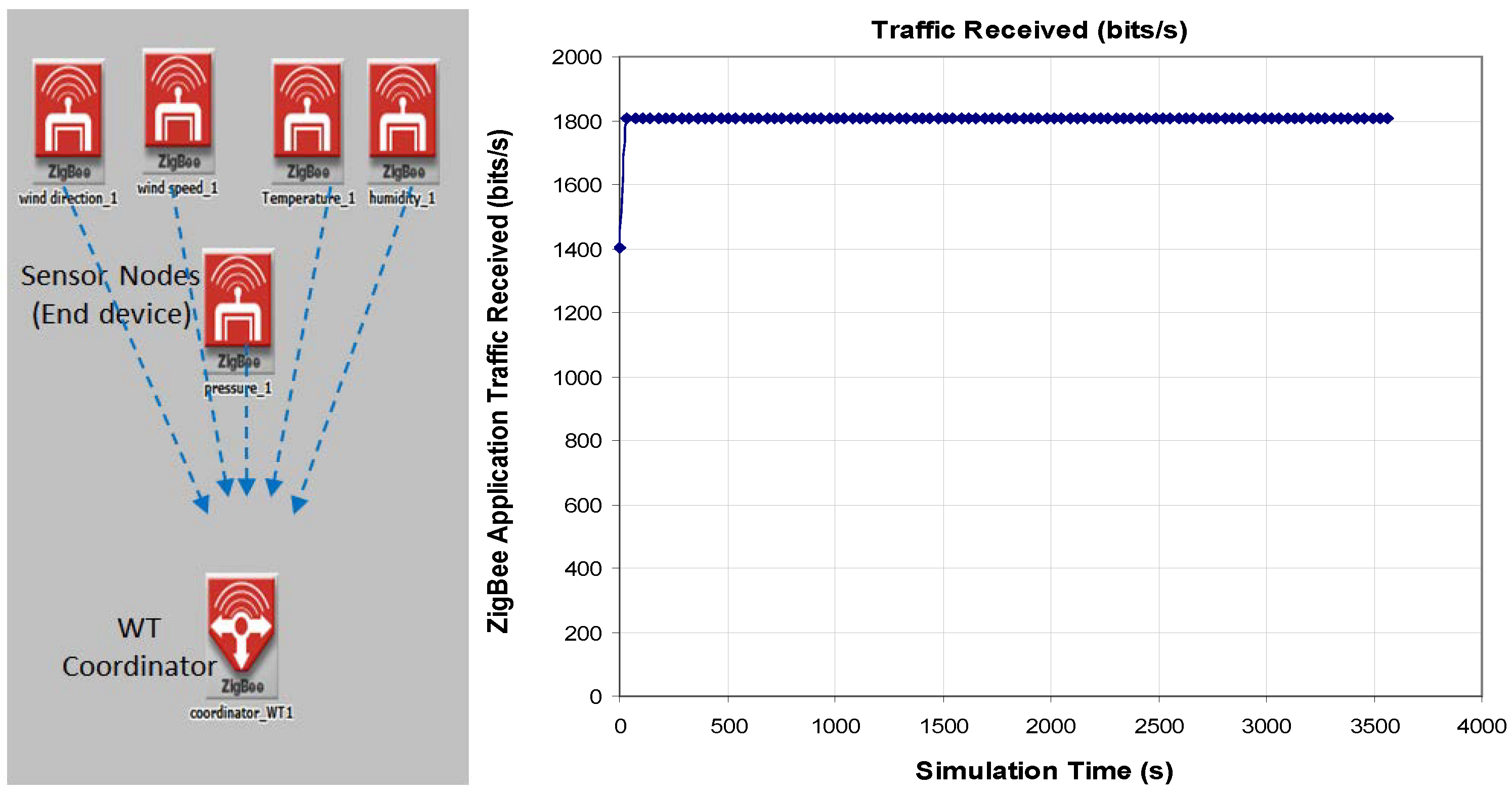

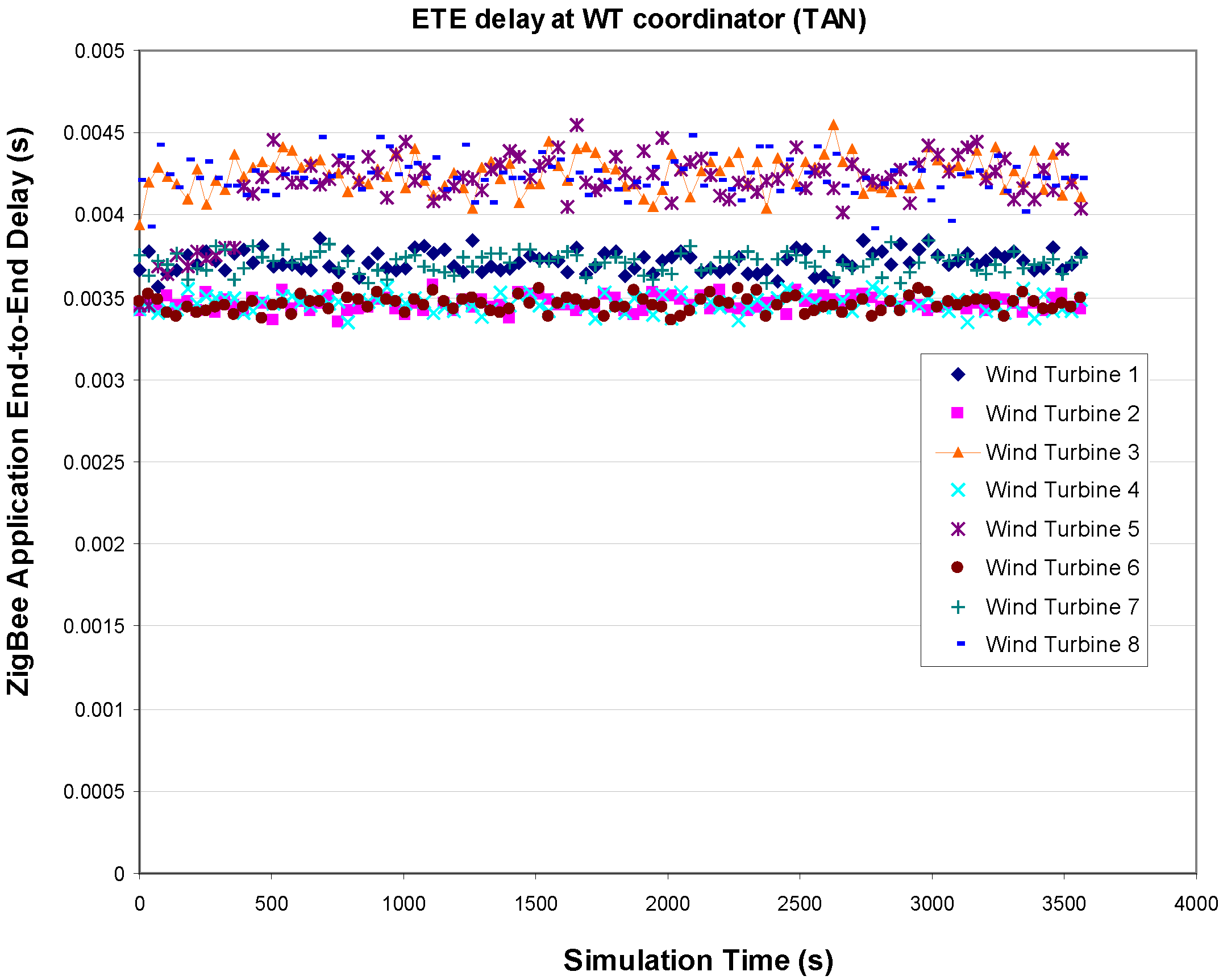

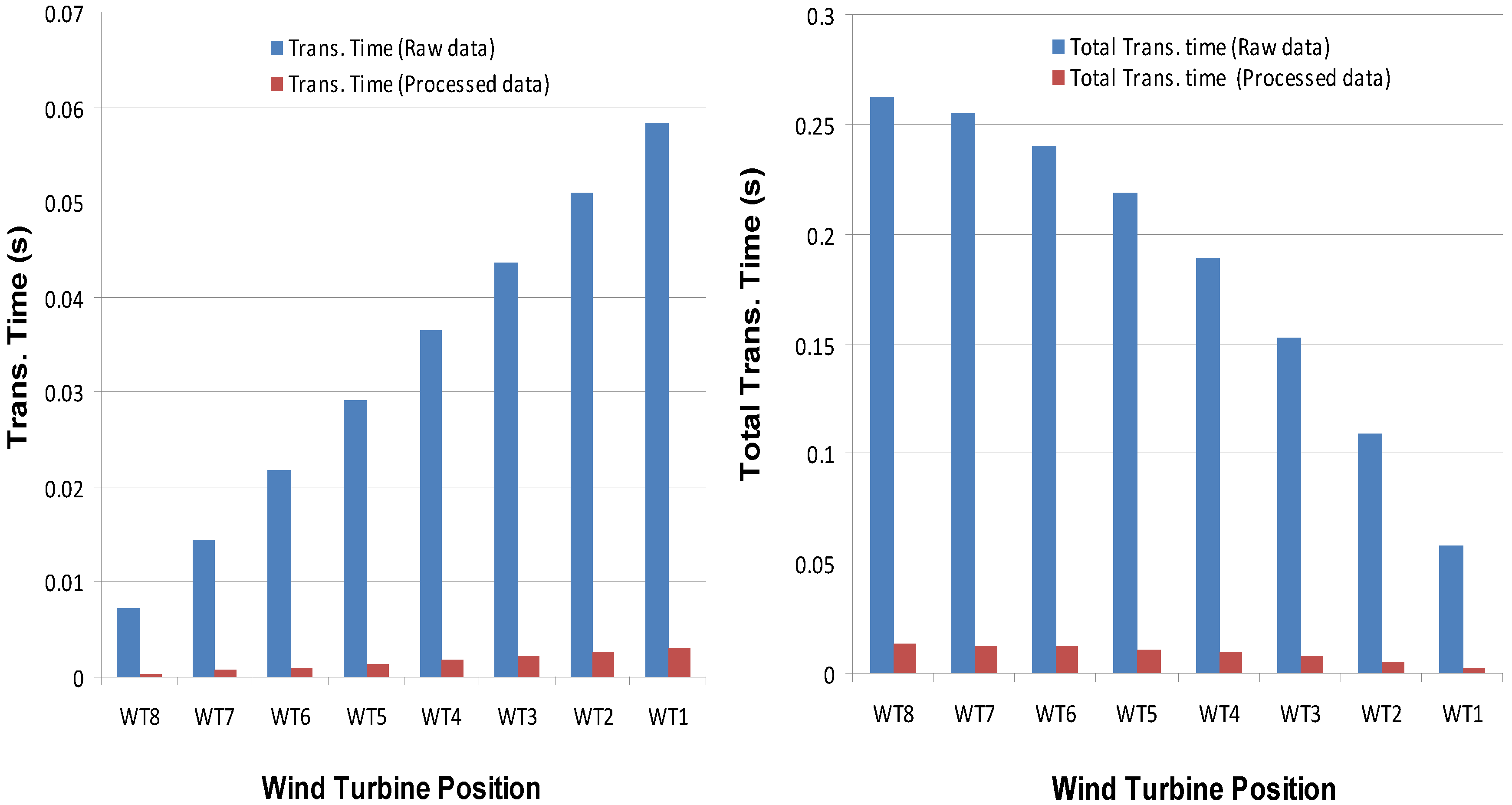

In this paper, we have proposed communication network architectures for S-WPFs. To do it, we have explored network architectures, topologies, and technologies for establishing communications within and among wind turbines in a WPF. The proposed communication architecture consists of three networks: the TAN, the FAN, and the CAN. With respect to a wired solution, we studied the upstream traffic for the proposed EPON-based architecture for a standalone wind turbine. Based on the IEC 61400-25 standard, we classified the generated amount of traffic into three different categories: AM, SI, and protection information. A sensor data frame structure is designed to carry the sensing data from different wind turbine parts, and FBA is considered in order to transmit the sensing data efficiently. An analytical model using queueing theory is used to evaluate network performance in view of bandwidth utilization and average queuing delay. Using a 1 Gbps link, the average queuing delay showed stable performance compared to the 100 Mbps link. Under heavy traffic loads, the average queuing delay was about 13.88 ms for the 100 Mbps link while it was about 0.073 ms for the 1 Gbps link. With respect to a wireless solution, there are two types of nodes, SN and RN, in the TAN. The meteorological data in each turbine are selected to be shared and forwarded directly to the control center. The proposed TAN was modeled and simulated in terms of the amount of received data and end to end delay using an OPNET modeler. The FAN transmitted the meteorological data from the wind turbines to the control center within 0.0138 s. The simulation results showed that the maximum ETE delay of sensing data at the RN was of about 4.5 ms. Our ongoing work is to develop a simulation model to evaluate the network performance for a hybrid network architecture (EPON/WiMAX).