Regulatory Promotion of Waste Wood Reused as an Energy Source and the Environmental Concerns about Ash Residue in the Industrial Sector of Taiwan

Abstract

:1. Introduction

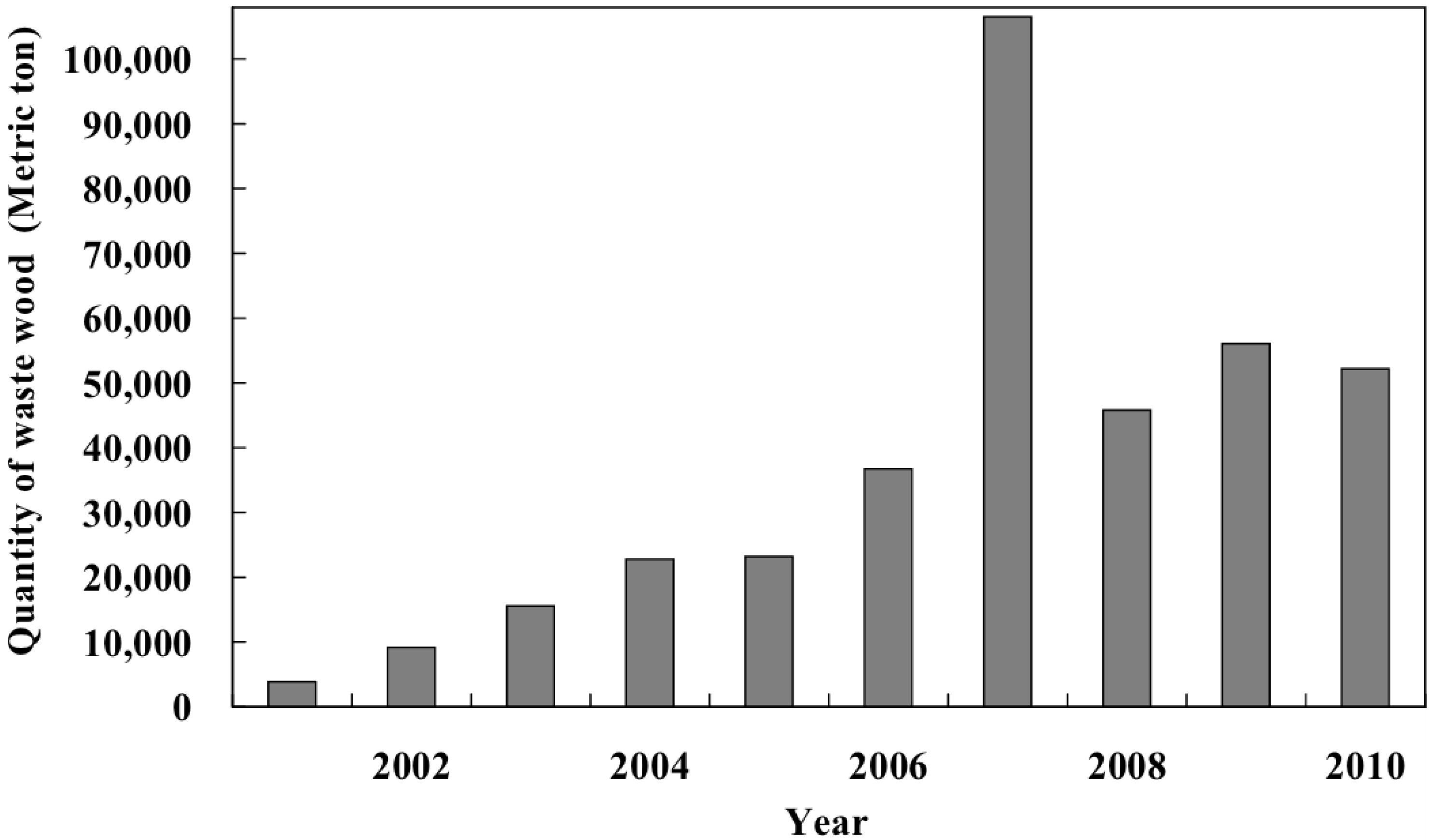

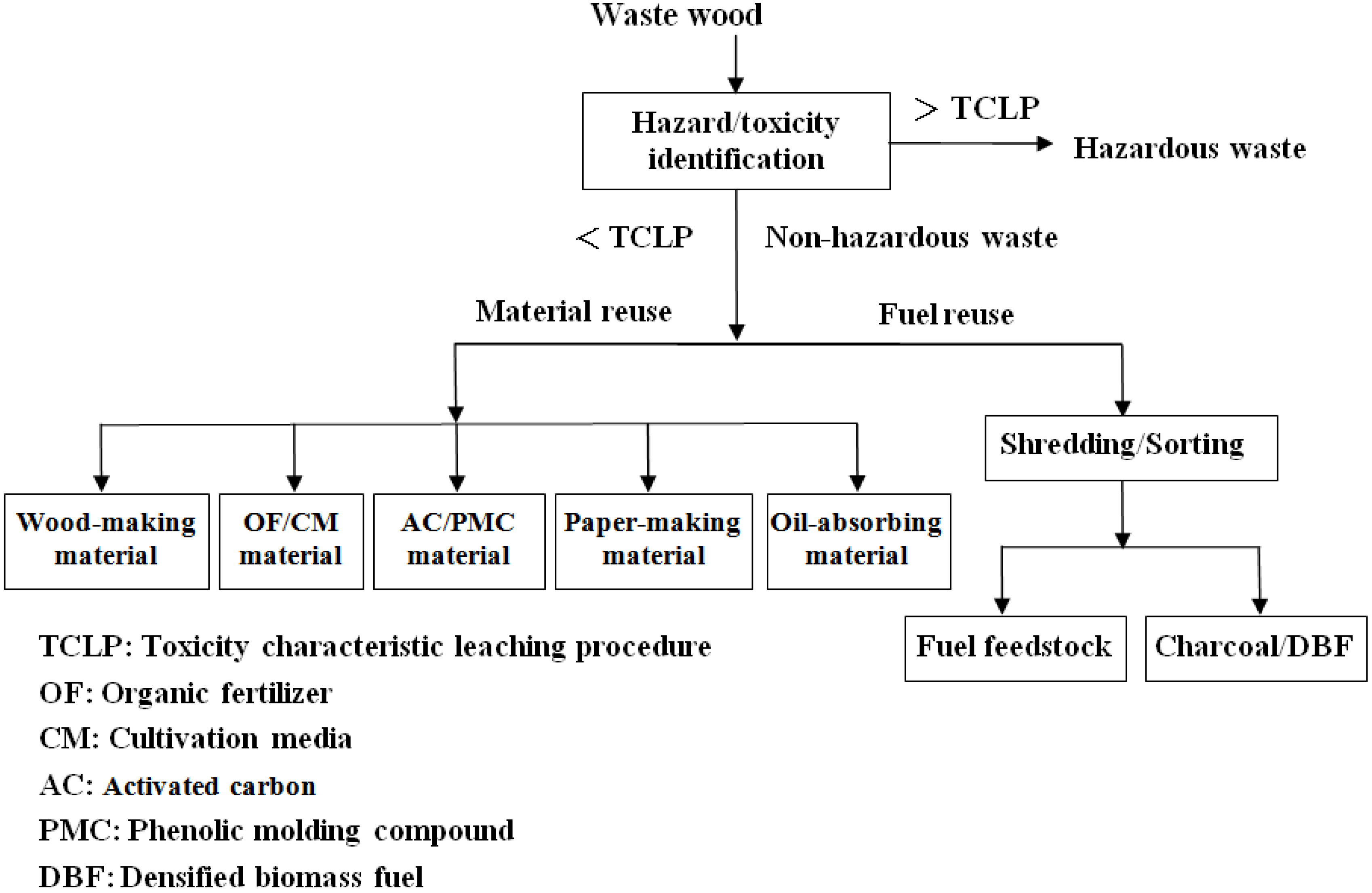

2. Generation and Management of Waste Wood in the Industrial Sector of Taiwan

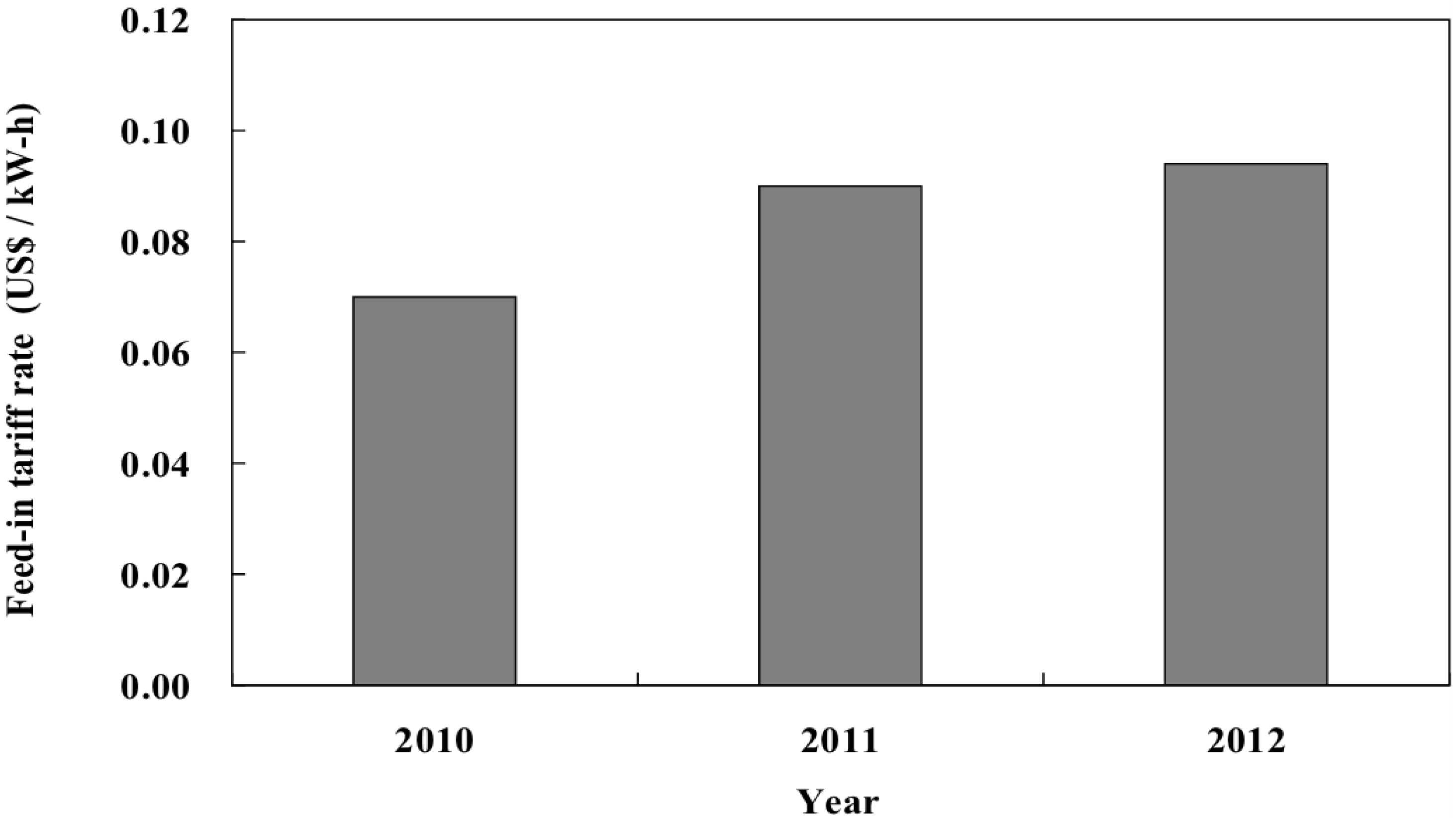

3. Governmental Policies and Regulatory Promotion for Reusing Waste Wood as Energy Source

- Biomass energy shall mean the domestic energy produced by directly utilizing or processing the agricultural & forest plants, biogas, general wastes, and general industrial wastes;

- The goal of the Act is to increase Taiwan’s renewable energy generation capacity by 6.5 million kilowatts to 10 million kilowatts under subsidy assistance within 20 years. The central competent authority should set the promotion goals for various renewable energy sources and their respective rates biennially;

- Electricity generated from renewable energy sources should be connected to and purchased by the local operator of the electricity grid (i.e., Taipower Co., Taipei, Taiwan). The feed-in tariff (FIT) paid for electricity generated from renewable energy sources shall be not lower than the average cost of electricity generated by the sector using fossil fuels.

4. Environmental Concerns about Ash Residue from the Combustion of Waste Wood

| Toxic metal a | Regulatory level (mg/L) |

|---|---|

| Mercury | 0.2 |

| Selenium | 1.0 |

| Cadmium | 1.0 |

| Chromium (VI) | 2.5 |

| Lead | 5.0 |

| Chromium b | 5.0 |

| Arsenic | 5.0 |

| Silver | 5.0 |

| Copper c | 15.0 |

| Barium | 100.0 |

5. Conclusions and Recommendations

- Put high priority on fresh wood types such as driftwood, fruit trimmings, tree trimmings (from parks and streets), and sawdust;

- Encourage the utilization of waste wood in municipal solid waste (MSW) incinerators to enhance the production of electricity from the combined heat and power (CHP) systems;

- Boost the application of biomass-to-electricity by a certified system for validating amount of waste wood co-fired in the power plant, and a profitable feed-in tariff (FIT) system for a period of several years (e.g., 20 years);

- Establish a definite legislation for the resource utilization (e.g., fertilizer) of wood ash from the thermal recovery of chemically untreated woody biomass, exclusive of filter fly-ash.

Acknowledgments

References

- Stehlik, P. Contribution to advances in waste-to-energy technologies. J. Clean. Product. 2009, 17, 919–931. [Google Scholar] [CrossRef]

- Psomopoulos, C.S.; Bourka, A.; Themelis, N.J. Waste-to-energy: A review of the status and benefits in USA. Waste Manag. 2009, 29, 1718–1724. [Google Scholar] [CrossRef] [PubMed]

- Antizar-Ladislao, B.; Turrion-Gomez, J.L. Decentralized energy from waste system. Energies 2010, 3, 194–205. [Google Scholar] [CrossRef]

- Tsai, W.T.; Chou, Y.H. An overview of renewable energy utilization from municipal solid waste (MSW) incineration in Taiwan. Renew. Sustain. Energy Rev. 2006, 10, 491–502. [Google Scholar]

- Van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-firing; Earthscan: London, UK, 2008. [Google Scholar]

- Tame, N.W.; Dlugogorski, B.Z.; Kennedy, E.M. Formation of dioxins and furans during combustion of treated wood. Prog. Energy Combust. Sci. 2007, 33, 384–408. [Google Scholar] [CrossRef]

- Tsai, W.T. Analysis of the sustainability of reusing industrial wastes as energy source in the industrial sector of Taiwan. J. Clean. Product. 2010, 18, 1440–1445. [Google Scholar]

- Environmental Protection Administration (Taiwan). Industrial Waste Report and Management System. Available online: http://waste.epa.gov.tw/prog/IndexFrame.asp?Func=eng (accessed on 15 August 2012).

- Tsai, W.T.; Wu, P.H. Environmental concerns about carcinogenic air toxics produced from waste woods as alternative energy sources. Energy Sourc. A 2011, in press. [Google Scholar]

- Krook, J.; Martensson, A.; Eklund, M. Metal contamination in recovered waste wood used as energy source in Sweden. Resour. Conserv. Recycl. 2004, 41, 1–14. [Google Scholar] [CrossRef]

- Krook, J.; Martensson, A.; Eklund, M. Evaluating waste management strategies—A case of metal-contaminated waste wood. Resour. Conserv. Recycl. 2007, 52, 103–118. [Google Scholar] [CrossRef]

- Reijnders, L. Disposal, uses and treatments of combustion ashes: A review. Resour. Conserv. Recycl. 2005, 42, 313–336. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of wood ash in concrete manufacturing. Resour. Conserv. Recycl. 2012, 67, 27–33. [Google Scholar] [CrossRef]

- Tame, N.W.; Dlugogorski, B.Z.; Kennedy, E.M. Increased PCDD/F formation in the bottom ash from fires of CCA-treated wood. Chemosphere 2003, 50, 1261–1263. [Google Scholar] [CrossRef] [PubMed]

- Lavric, E.D.; Konnov, A.A.; Ruyck, J.D. Dioxin levels in wood combustion—A review. Biomass Bioenergy 2004, 26, 115–145. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Tsai, W.-T. Regulatory Promotion of Waste Wood Reused as an Energy Source and the Environmental Concerns about Ash Residue in the Industrial Sector of Taiwan. Energies 2012, 5, 4390-4398. https://doi.org/10.3390/en5114390

Tsai W-T. Regulatory Promotion of Waste Wood Reused as an Energy Source and the Environmental Concerns about Ash Residue in the Industrial Sector of Taiwan. Energies. 2012; 5(11):4390-4398. https://doi.org/10.3390/en5114390

Chicago/Turabian StyleTsai, Wen-Tien. 2012. "Regulatory Promotion of Waste Wood Reused as an Energy Source and the Environmental Concerns about Ash Residue in the Industrial Sector of Taiwan" Energies 5, no. 11: 4390-4398. https://doi.org/10.3390/en5114390