Multi-Objective Optimization Design of an Electrohydrostatic Actuator Based on a Particle Swarm Optimization Algorithm and an Analytic Hierarchy Process

Abstract

:1. Introduction

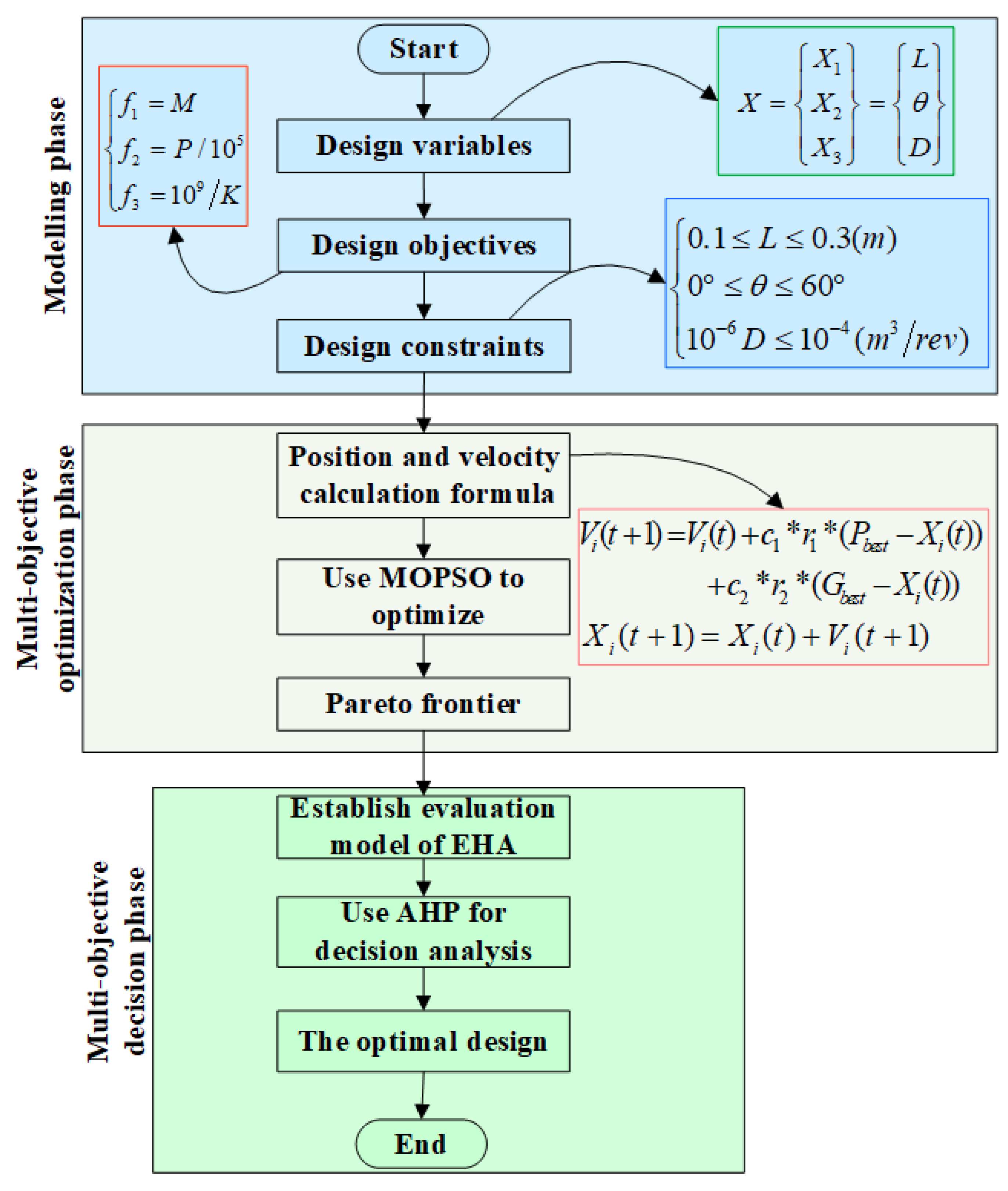

2. Multi-Objective Optimization Model

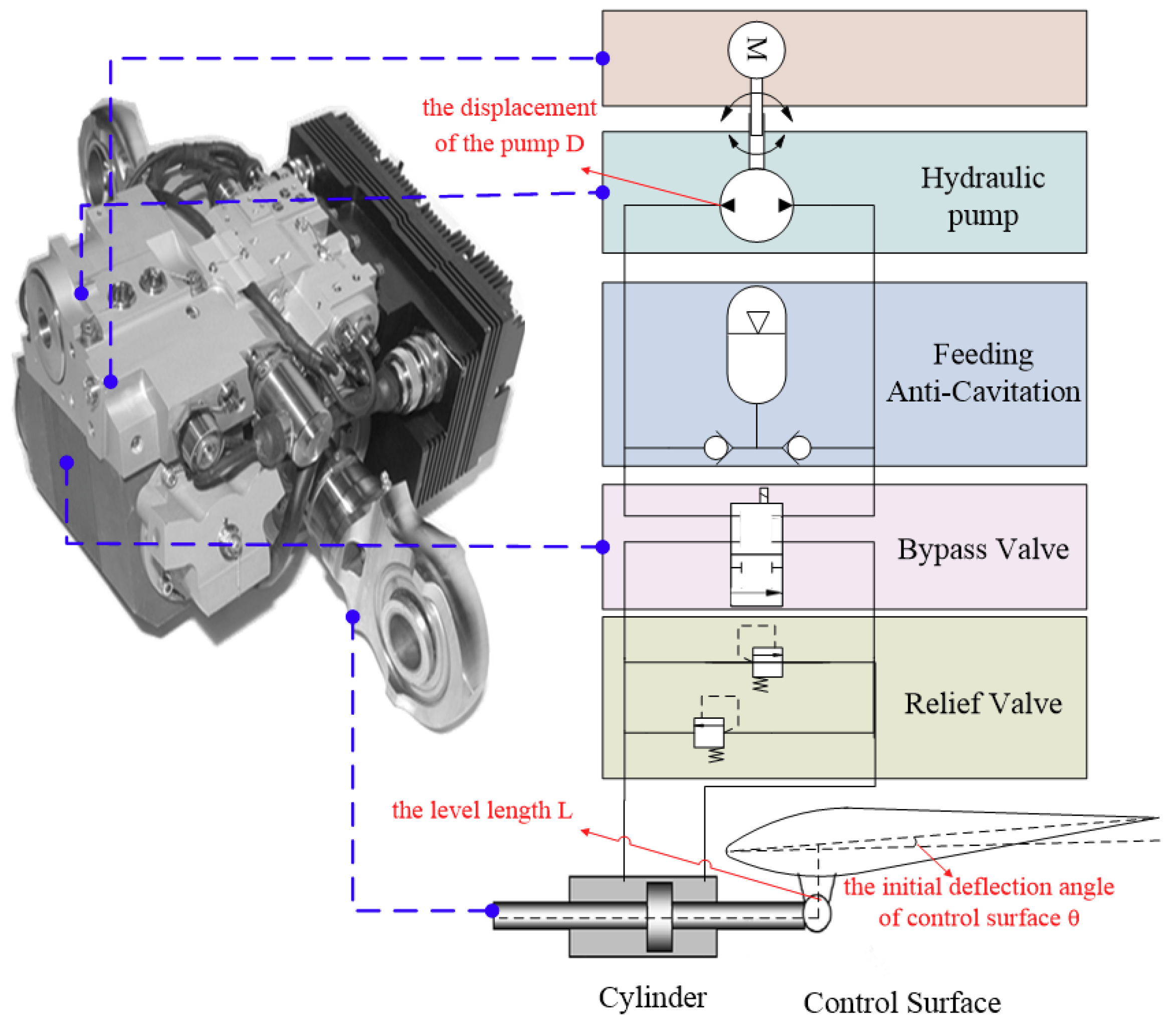

2.1. The Optimization Model of EHA

2.2. Objective Function

2.2.1. Weight

2.2.2. Power Consumption

2.2.3. Stiffness

2.3. Design Variables

- (1)

- The number of design variables should be reduced as far as possible. Generally, the number of design variables in mechanical optimization design should not exceed five.

- (2)

- Choose the parameters that have a great influence on the objective function. Indicators that affect the constraint and performance directly should be selected as design variables.

- (3)

- The selected variables should be independent.

- (4)

- The variables should be selected according to the optimization objective.

2.4. Constraints

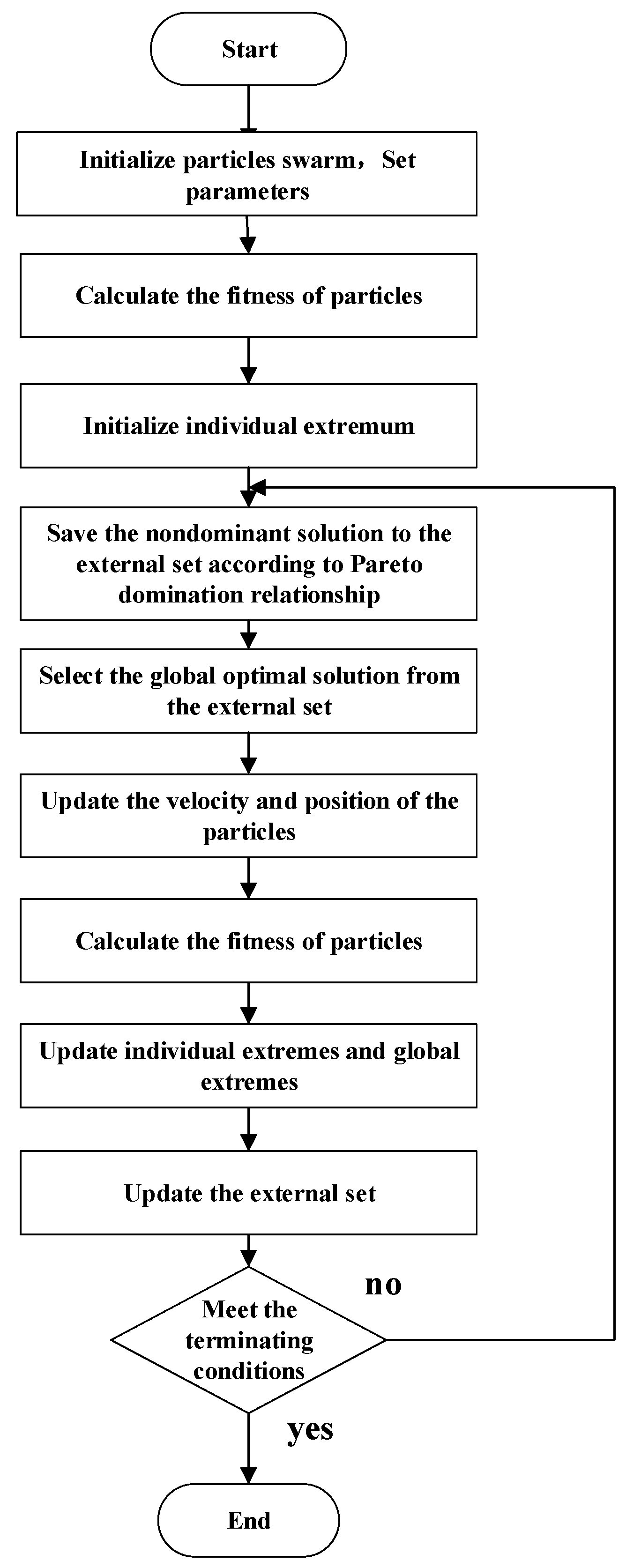

3. Multi-Objective Optimization Algorithm

- (1)

- Initialize the particle swarm, set parameters and maximum iterations, the dimensions of the particles are three (), and number of particles is 100.

- (2)

- Set the velocity and initial position of particles, and limit the value range of velocity. If the particle is out of range, give it an opposite speed to make the particle optimize in the correct range.

- (3)

- Put the velocity and position of particles into the objective function , and obtain the values of the fitness function of each particle.

- (4)

- Select the nondominated particles according to the Pareto dominance relation and put them into the nondominated set.

- (5)

- Update the velocity and position of the particles according to the modified multi-objective particle swarm optimization algorithm.

- (6)

- Put the updated velocity and position of the particles into the objective function , and obtain the updated fitness values. After comparing to the particles deposited in the nondominated set according to the Pareto dominance relation, deposit the nondominated values and delete the dominated values.

- (7)

- Put the particles in the nondominated set into the external set. If the number of particles deposited is larger than the maximum storage of the external set, the method of crowding distance should be applied and redundant inferior solutions should be deleted.

- (8)

- Put the particles in the external set in descending order.

- (9)

- Determine whether the number of iterations has been reached or not. If the maximum number of iterations is not reached, turn to step 5 and continue to iterate; if the maximum number of iterations is reached, export the particles in the external set and take them as the non-inferior solution set of the objective function.

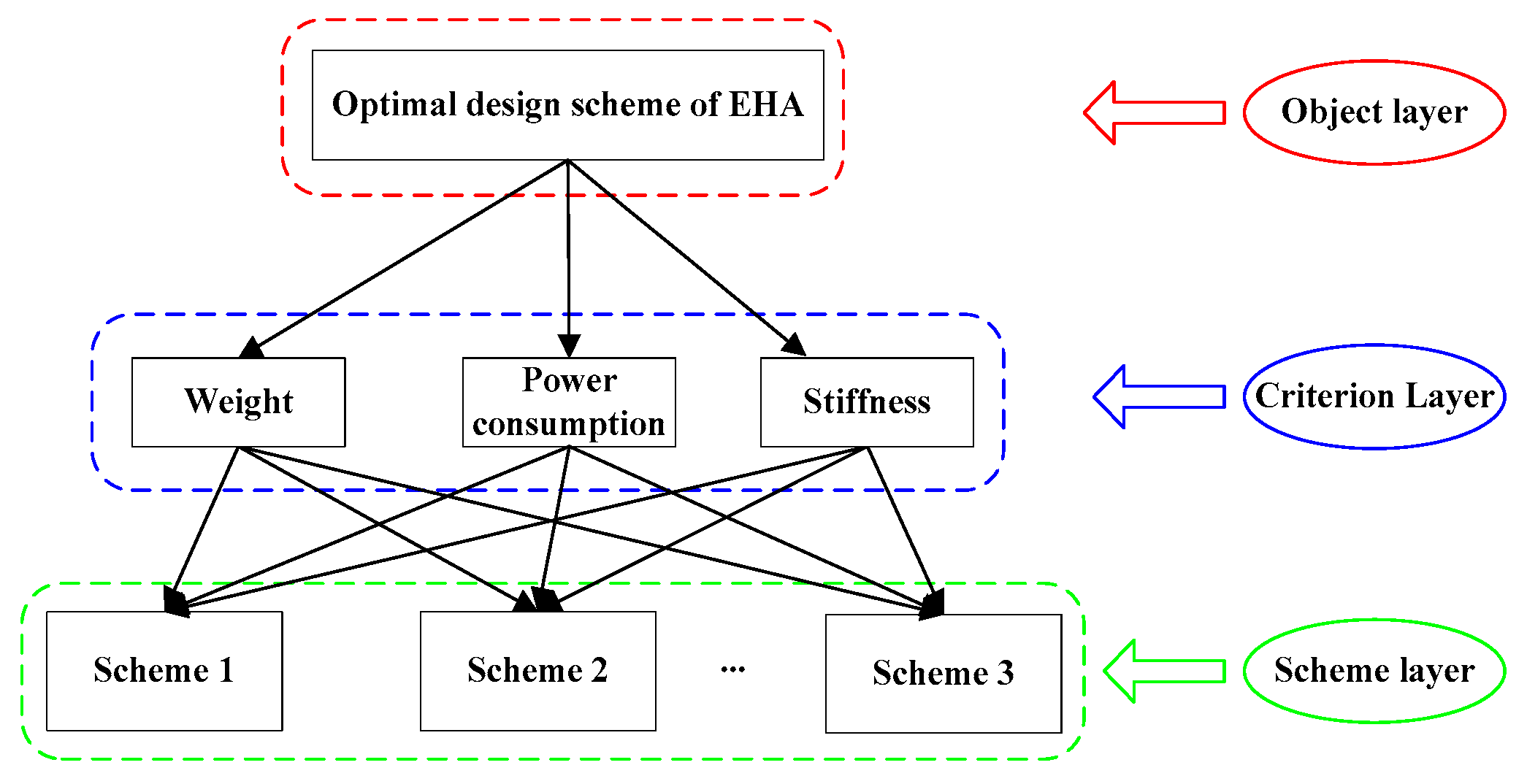

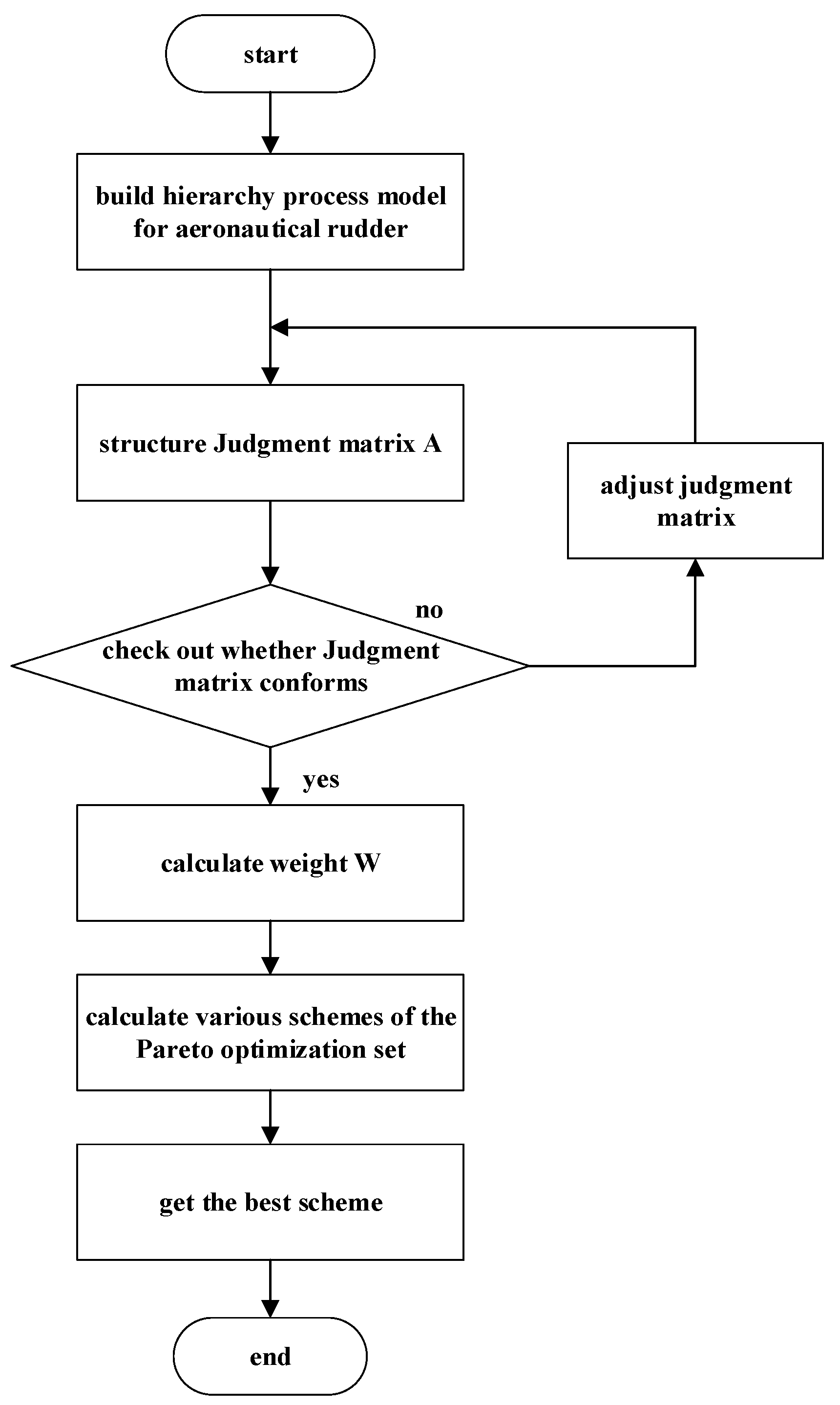

4. Multi-Criterion Decision Making Technique

- (1)

- Establish the decision model for AHP as shown in Figure 4.

- (2)

- Structure the judgment matrix . Judgment matrix is constructed according to the relationships between the objectives in the criteria layer.

- (3)

- Verify the consistency of the judgment matrix. Coincidence indicator is calculated as follows:where is the coincidence indicator of the judgment matrix, is the average random consistence indicator of the judgment matrix (specific values are in Table 1), is the random consistence ratio of the judgment matrix, is the maximum value of the matrix eigenvalue, and is the order of the judgment matrix.By calculation, if , and , then , which means the weight matrix is consistent. If the consistency check is not satisfied, return to step 2 where the judgment matrix should be reconstructed.

- (4)

- Calculate the weight coefficient between the compared elements with the corresponding criteria. Calculate the continued product of every row element in , the product of each row element and its n-th root .Normalize as , is the weight coefficient of each factor.

- (5)

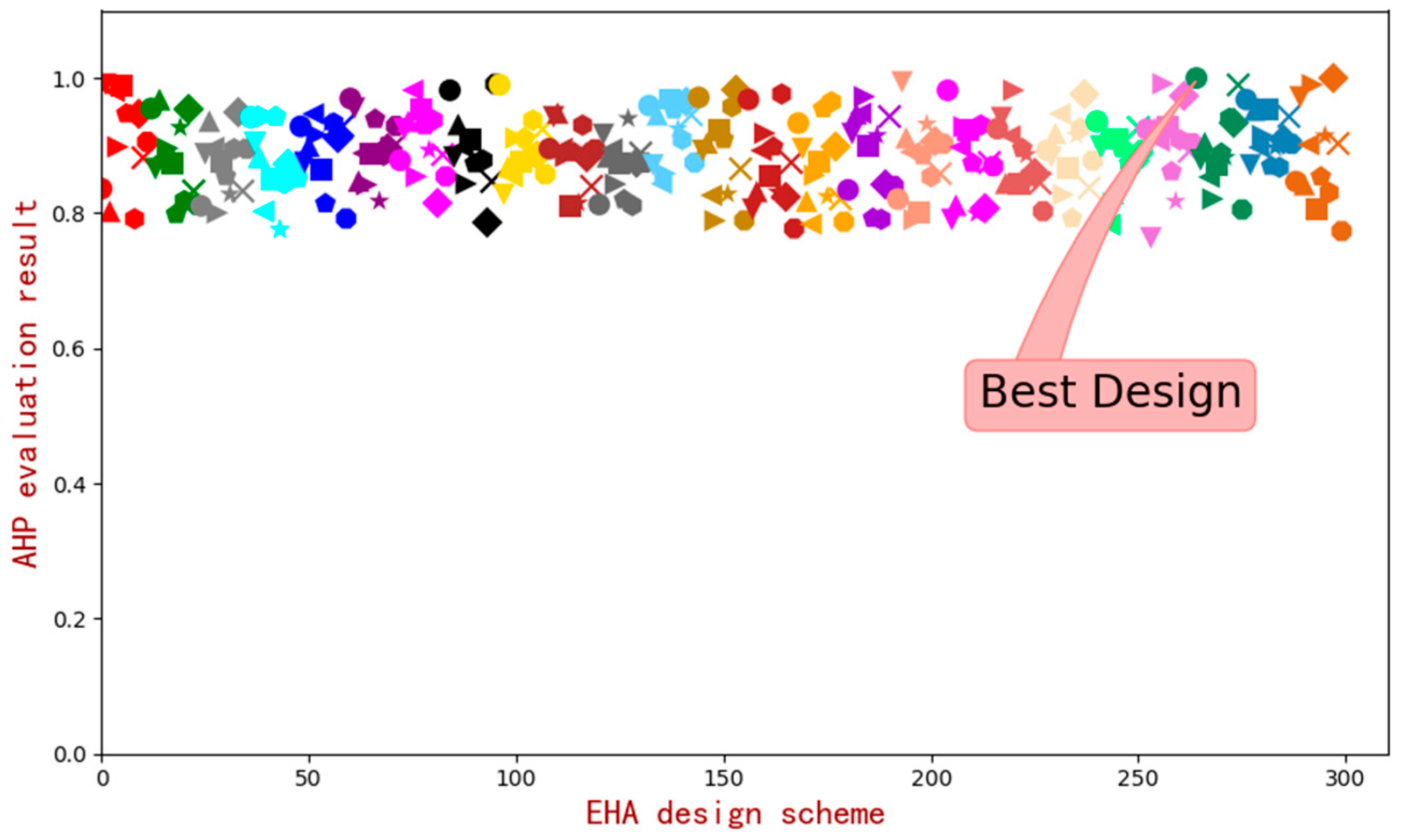

- Estimate the designs in the Pareto frontier according to the weight coefficients of each criterion, and then get the optimal design of the EHA.

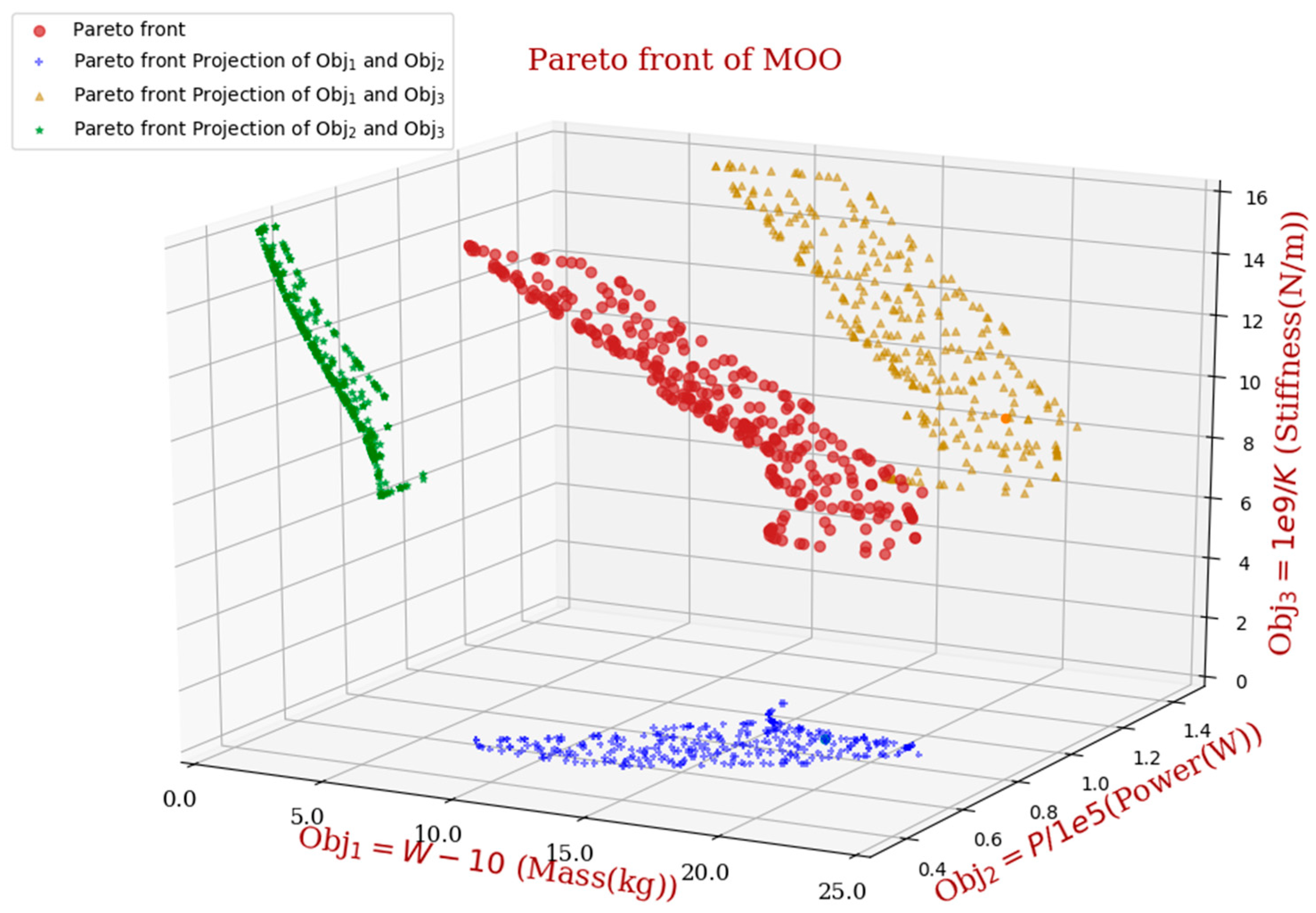

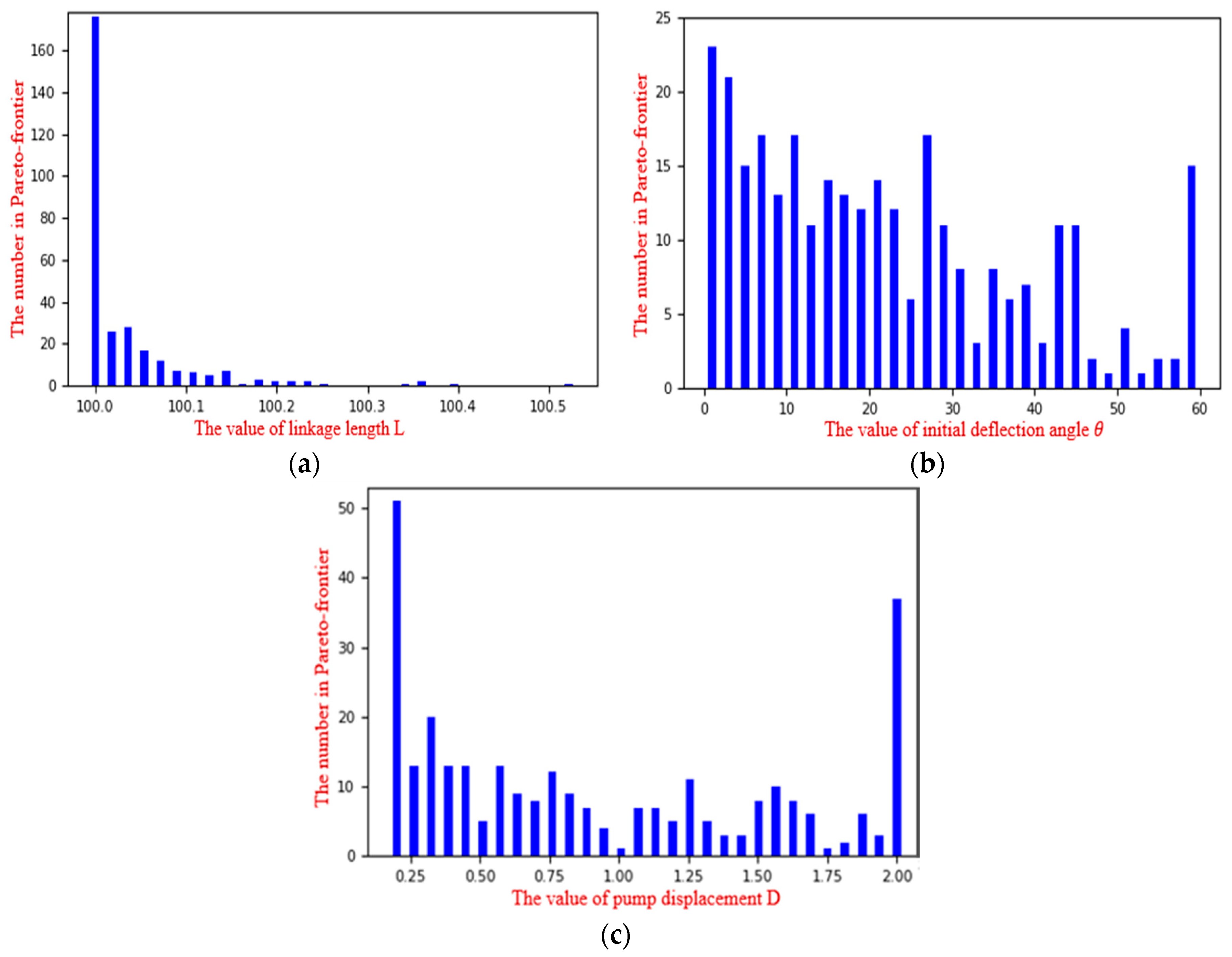

5. Optimization Results and Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kargov, A.; Werner, T.; Pylatiuk, C.; Schulz, S. Development of a miniaturised hydraulic actuation system for artificial hands. Sens. Actuators A Phys. 2008, 141, 548–557. [Google Scholar] [CrossRef]

- Samer, A.; Fethi, B.O.; Faycal, N.; Gordon, G. High performance Integrated Electro-Hydraulic Actuator for robotics—Part I: Principle, prototype design and first experiments. Sens. Actuators A Phys. 2011, 169, 115–123. [Google Scholar]

- Samer, A.; Fethi, B.O.; Faycal, N.; Gordon, G. High performance Integrated Electro-Hydraulic Actuator for robotics. Part II: Theoretical modelling, simulation, control & comparison with real measurements. Sens. Actuators A Phys. 2011, 169, 124–132. [Google Scholar]

- Shi, C.; Wang, X.; Wang, S.; Wang, J.; Tomovic, M.M. Adaptive decoupling synchronous control of dissimilar redundant actuation system for large civil aircraft. Aerosp. Sci. Technol. 2015, 47, 114–124. [Google Scholar] [CrossRef]

- Ahn, K.K.; Nam, D.N.C.; Jin, M. Adaptive backstepping control of an electrohydraulic actuator. IEEE/ASME Trans. Mechatron. 2014, 19, 987–995. [Google Scholar] [CrossRef]

- Mahamat, M.; Balira, O.K.; Souleymane, K.; Blaise, S. Alienor Method for Nonlinear Multi-Objective Optimization. Appl. Math. 2011, 2, 217–224. [Google Scholar]

- Pandian, V.; Utku, K.; Junzo, W. Metaheuristic Techniques in Enhancing the Efficiency and Performance of Thermo-Electric Cooling Devices. Energies 2017, 10, 1703. [Google Scholar] [Green Version]

- Sanghamitra, B.; Sriparna, S.; Ujjwal, M. A Simulated Annealing-Based Multiobjective Optimization Algorithm: AMOSA. IEEE Trans. Evolut. Comput. 2008, 12, 269–283. [Google Scholar] [Green Version]

- Ehsan, G.; Man-Hoe, K. Multi-Objective Optimization of a Solar Chimney Power Plant with Inclined Collector Roof Using Genetic Algorithm. Energies 2016, 9, 971. [Google Scholar] [Green Version]

- Myeong, J.K.; Yong, S.K.; Min, H.C.; Hung Chan, J. Multi-Objective Optimization Design for a Hybrid Energy System Using the Genetic Algorithm. Energies 2015, 8, 2924–2949. [Google Scholar] [Green Version]

- Alexandru, C.Z.; Gerd, B.; Edwin, L.; Sdwin, S.; Wolfgang, A.; Erich, P.K. Hybridization of multi-objective evolutionary algorithms and artificial neural networks for optimizing the performance of electrical drives. Eng. Appl. Artif. Intell. 2013, 26, 1781–1794. [Google Scholar]

- Yizhe, L.; Zhiyong, F. Enterprise Femtocell Network Optimization based on Neural Network Modeling. In Proceedings of the 8th Annual IEEE Consumer Communications and Networking Conference, Las Vegas, NV, USA, 9–12 January 2011; pp. 1130–1131. [Google Scholar]

- Sara, G.S.; Anders, M.; Viktoria, M. Design Optimization of a Small-Scale Polygeneration Energy System in Different Climate Zones in Iran. Energies 2018, 11, 1115. [Google Scholar] [Green Version]

- Kangji, L.; Lei, P.; Wenping, X.; Hui, J.; Hanping, M. Multi-Objective Optimization for Energy Performance Improvement of Residential Buildings: A Comparative Study. Energies 2017, 10, 245. [Google Scholar] [Green Version]

- Luciano, B.; Simeone, B.; Massimiliano, M. A particle swarm approach for flight path optimization in a constrained environment. Aerosp. Sci. Technol. 2013, 26, 128–137. [Google Scholar]

- Mieloszyk, J.; Goetzendorf, G.T. Introduction of full flight dynamic stability constraints in aircraft multidisciplinary optimization. Aerosp. Sci. Technol. 2017, 68, 252–260. [Google Scholar] [CrossRef]

- Liu, W.; Yang, Y. Multi-objective optimization of sheet metal forming process using Pareto-based genetic algorithm. J. Mater. Process. Technol. 2008, 208, 499–506. [Google Scholar]

- Francesco, C.; Gianmario, P.; Chris, G. Design of synchronous reluctance motors with multiobjective optimization algorithms. IEEE Trans. Ind. Appl. 2014, 50, 3617–3627. [Google Scholar]

- Perera, A.T.D.; Attalage, R.A.; Perera, K.K.C.K.; Dassanayake, V.P.C.D. A hybrid tool to combine multi-objective optimization and multi-criterion decision making in designing standalone hybrid energy systems. Appl. Energy 2013, 107, 412–425. [Google Scholar] [CrossRef]

- Shuai, W.; Bo, Y.; Zongxia, J.; Yaoxing, S. Preliminary design and multi-objective optimization of electro-hydrostatic actuator. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2016, 231, 1258–1268. [Google Scholar]

- Kasprzak, E.M.; Lewis, K.E. Pareto analysis in multiobjective optimization using the collinearity theorem and scaling method. Struct. Multidiscip. Optim. 2001, 22, 208–218. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Babaie, M.; Farmani, M.R. Implementing of the multi-objective particle swarm optimizer and fuzzy decision-maker in exergetic, exergoeconomic and environmental optimization of a benchmark cogeneration system. Energy 2011, 36, 4777–4789. [Google Scholar] [CrossRef]

- Cong, M.; Qu, L. Multiobjective Optimization of Switched Reluctance Motors Based on Design of Experiments and Particle Swarm Optimization. IEEE Trans. Energy Convers. 2015, 30, 1144–1153. [Google Scholar]

- Medineckiene, M.; Zavadskas, E.K.; Bjork, F.; Turskis, Z. Multi-criteria decision-making system for sustainable building assessment/certification. Arch. Civ. Mech. Eng. 2015, 15, 11–18. [Google Scholar] [CrossRef]

- Alfredo, A.; Pilar, G.; Manuel, S. Influence, relevance and discordance of criteria in AHP-Global Bayesian prioritization. Int. J. Inf. Technol. Decis. Mak. 2013, 12, 837–861. [Google Scholar]

- Wu, S.; Zhao, X.; Li, C.; Jiao, Z.; Qu, F. Multi-Objective Optimization of a Hollow Plunger Type Solenoid for High Speed On/Off Valve. IEEE Trans. Ind. Electron. 2018, 65, 3115–3124. [Google Scholar] [CrossRef]

- Liu, G.E.; Han, X.; Jiang, C. A novel multi-objective optimization method based on an approximation model management technique. Comput. Methods Appl. Mech. Eng. 2008, 197, 2720–2731. [Google Scholar] [CrossRef]

- Zhanlin, W. Hydraulic Servo Control; Beijing College of Aeronautic Press: Beijing, China, 1987. [Google Scholar]

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| Objectives | Weight (M) | Power Consumption (W) | Stiffness Reciprocal (1/K) |

|---|---|---|---|

| Weight (M) | 1 | 1/3 | 1/9 |

| Power consumption (W) | 3 | 1 | 1/7 |

| Stiffness reciprocal (1/K) | 9 | 7 | 1 |

| EHA Scheme | Level Length | Initial Deflection Angle | Pump Displacement | Weight | Power Consumption | Stiffness |

|---|---|---|---|---|---|---|

| Optimal design | 100 mm | 37.04° | 0.27 mL/rev | 24.03 kg | 9.6 × 105 W | 6.03 × 109 N/m |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, B.; Wu, S.; Jiao, Z.; Shang, Y. Multi-Objective Optimization Design of an Electrohydrostatic Actuator Based on a Particle Swarm Optimization Algorithm and an Analytic Hierarchy Process. Energies 2018, 11, 2426. https://doi.org/10.3390/en11092426

Yu B, Wu S, Jiao Z, Shang Y. Multi-Objective Optimization Design of an Electrohydrostatic Actuator Based on a Particle Swarm Optimization Algorithm and an Analytic Hierarchy Process. Energies. 2018; 11(9):2426. https://doi.org/10.3390/en11092426

Chicago/Turabian StyleYu, Bo, Shuai Wu, Zongxia Jiao, and Yaoxing Shang. 2018. "Multi-Objective Optimization Design of an Electrohydrostatic Actuator Based on a Particle Swarm Optimization Algorithm and an Analytic Hierarchy Process" Energies 11, no. 9: 2426. https://doi.org/10.3390/en11092426