Design and Optimization of Multiple Circumferential Casing Grooves Distribution Considering Sweep and Lean Variations on the Blade Tip

Abstract

:1. Introduction

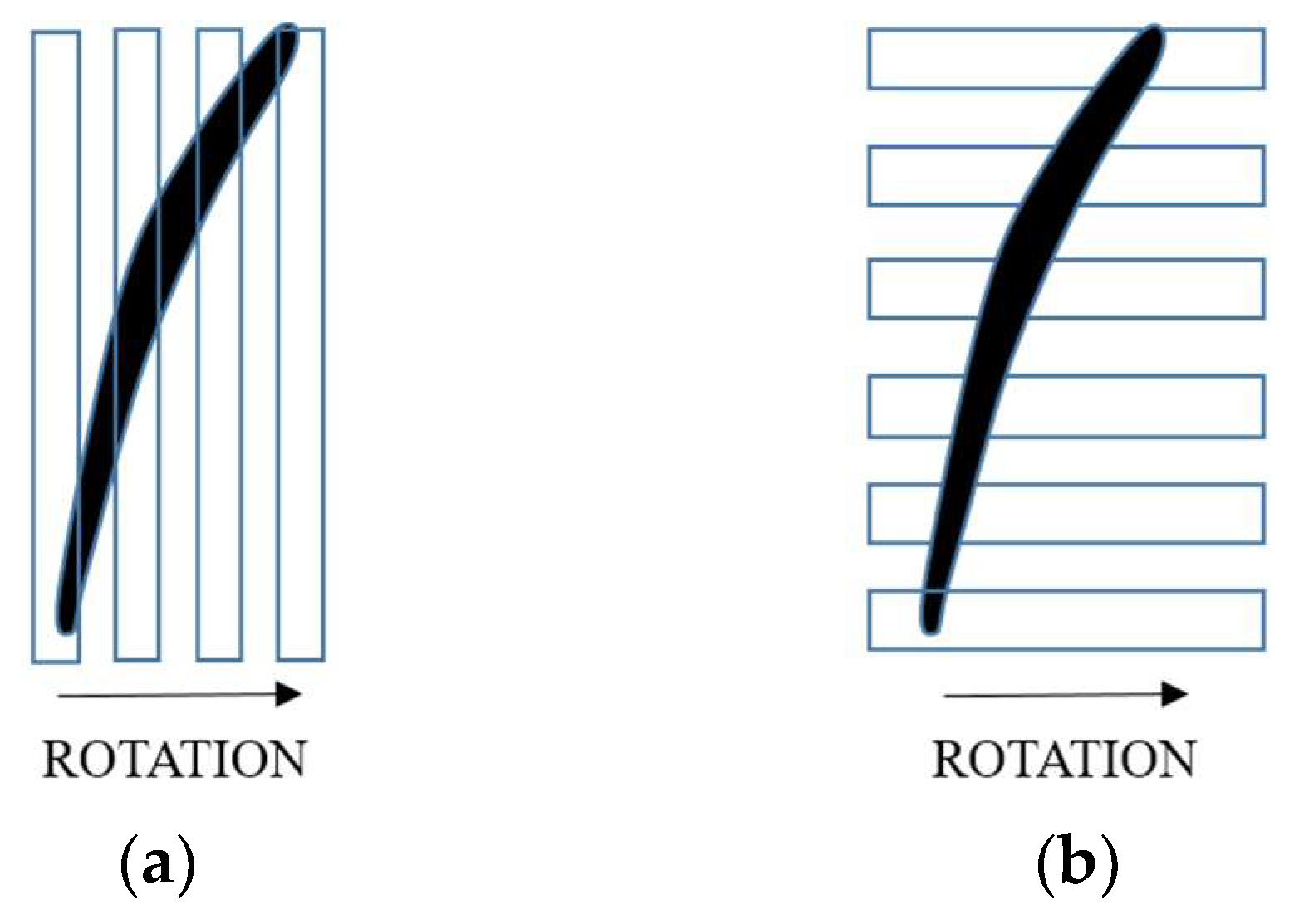

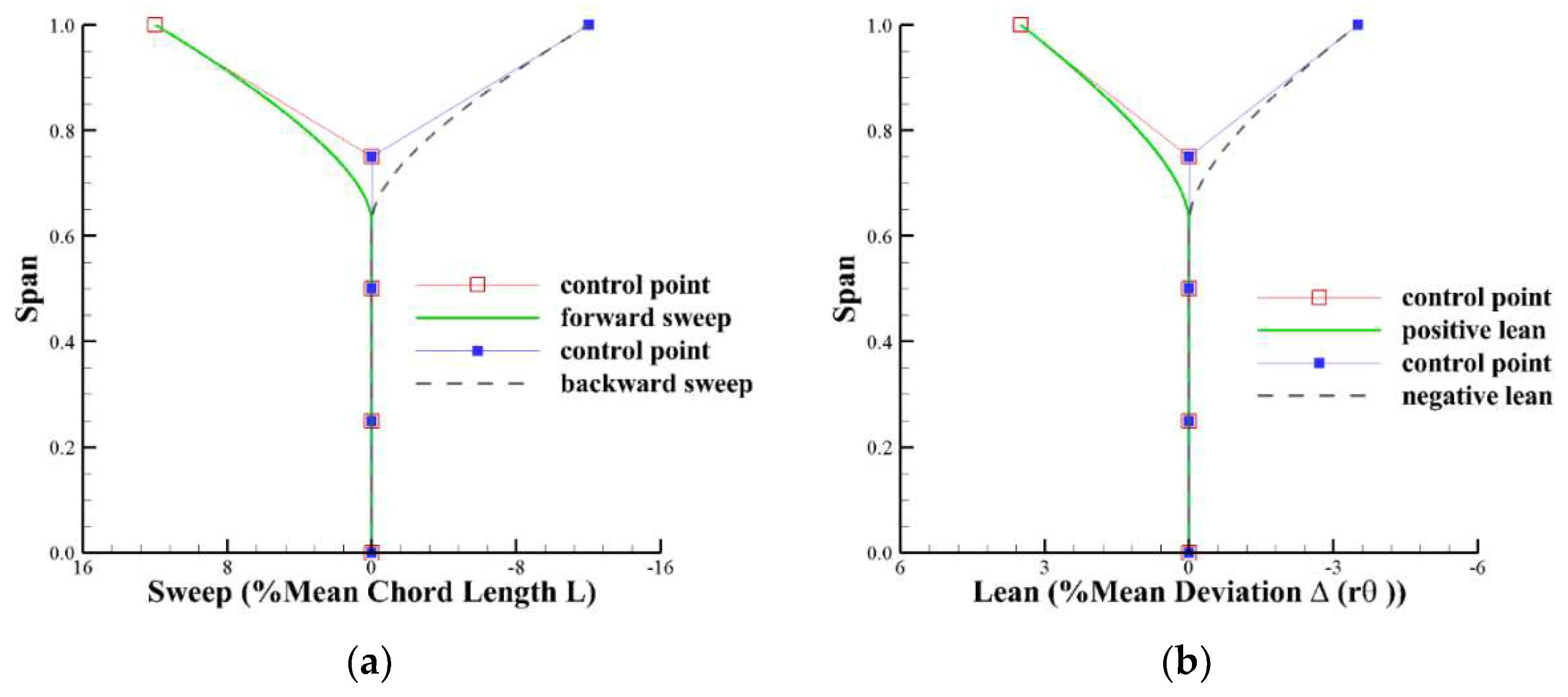

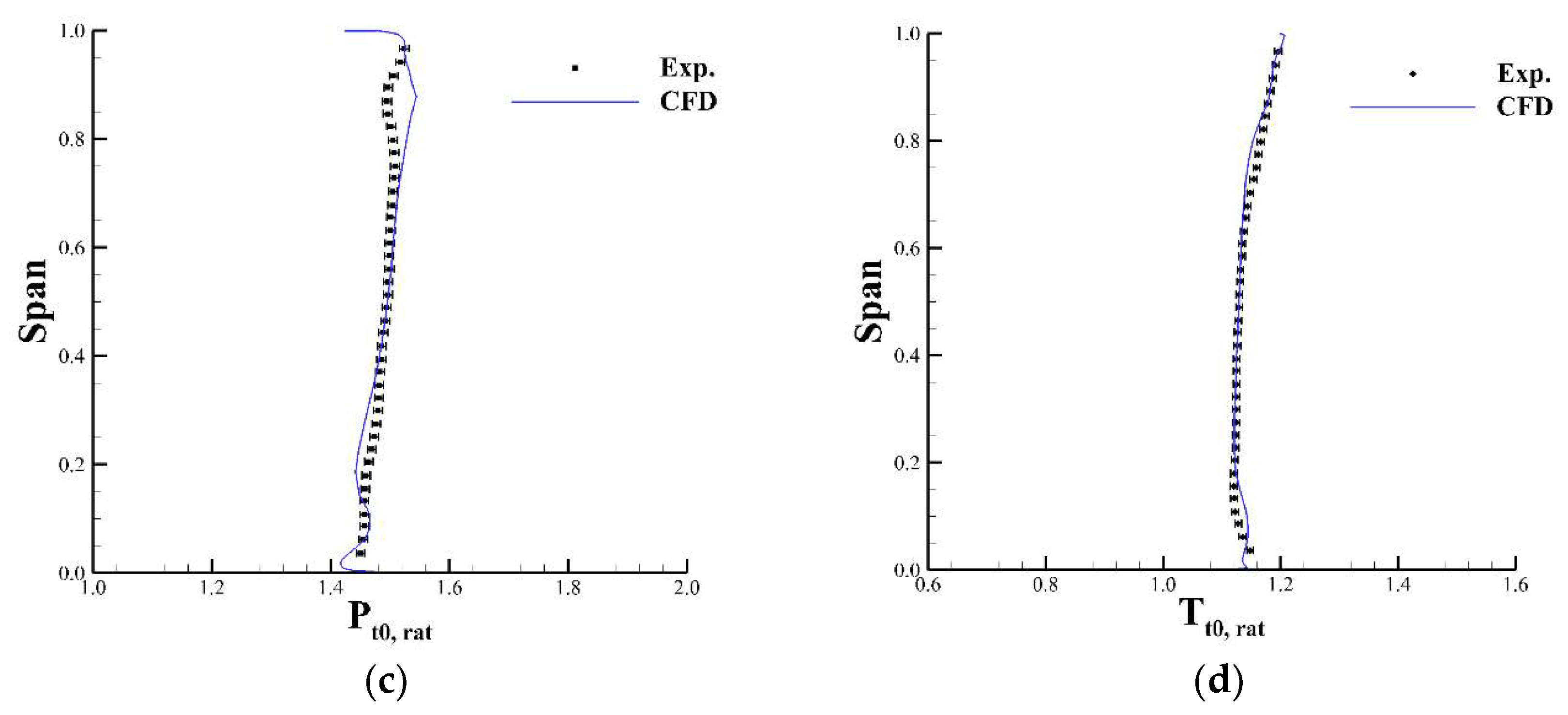

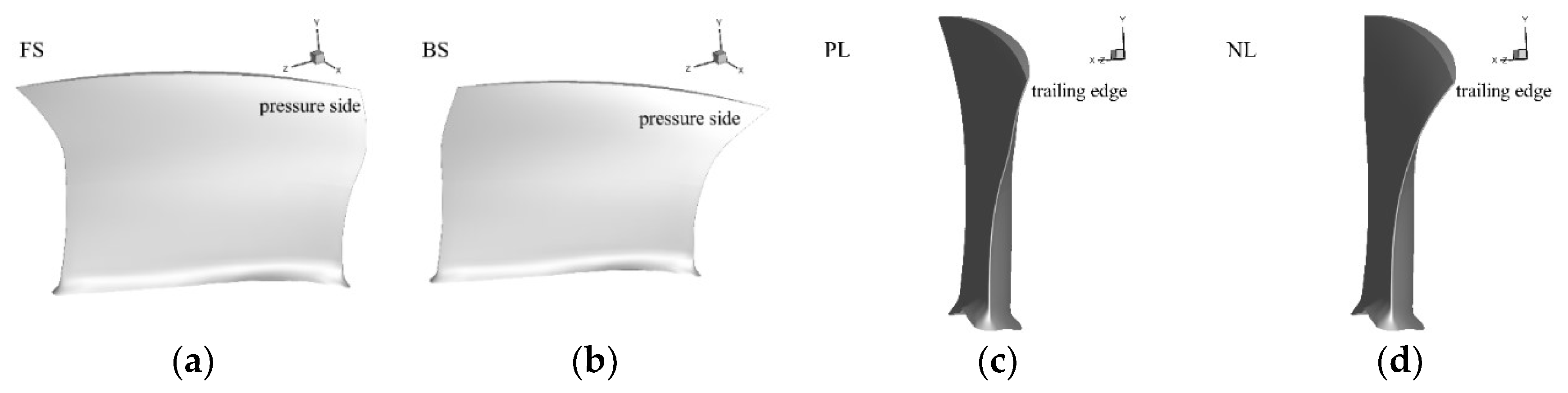

2. Parameterization of the Blade and CGCT

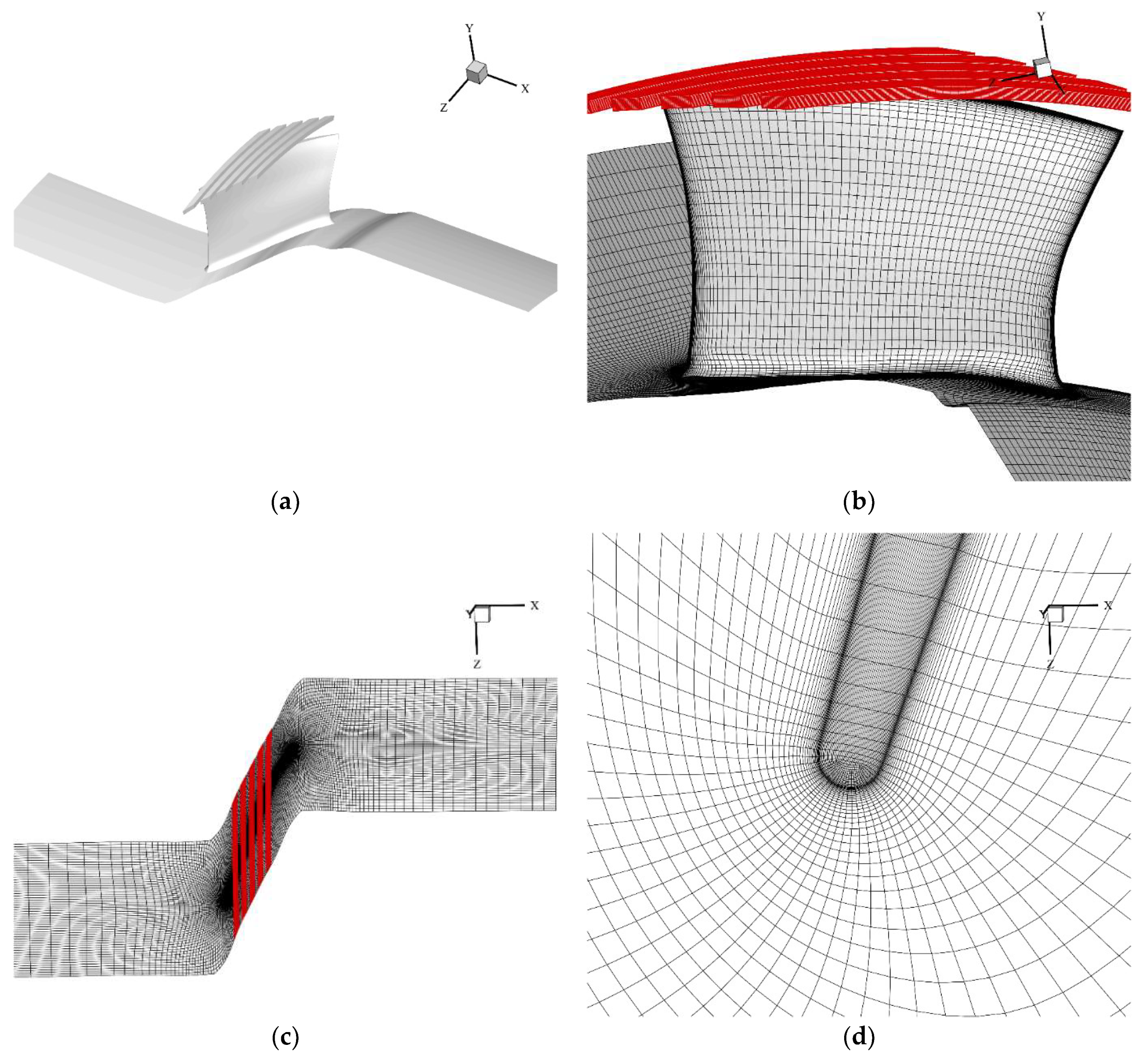

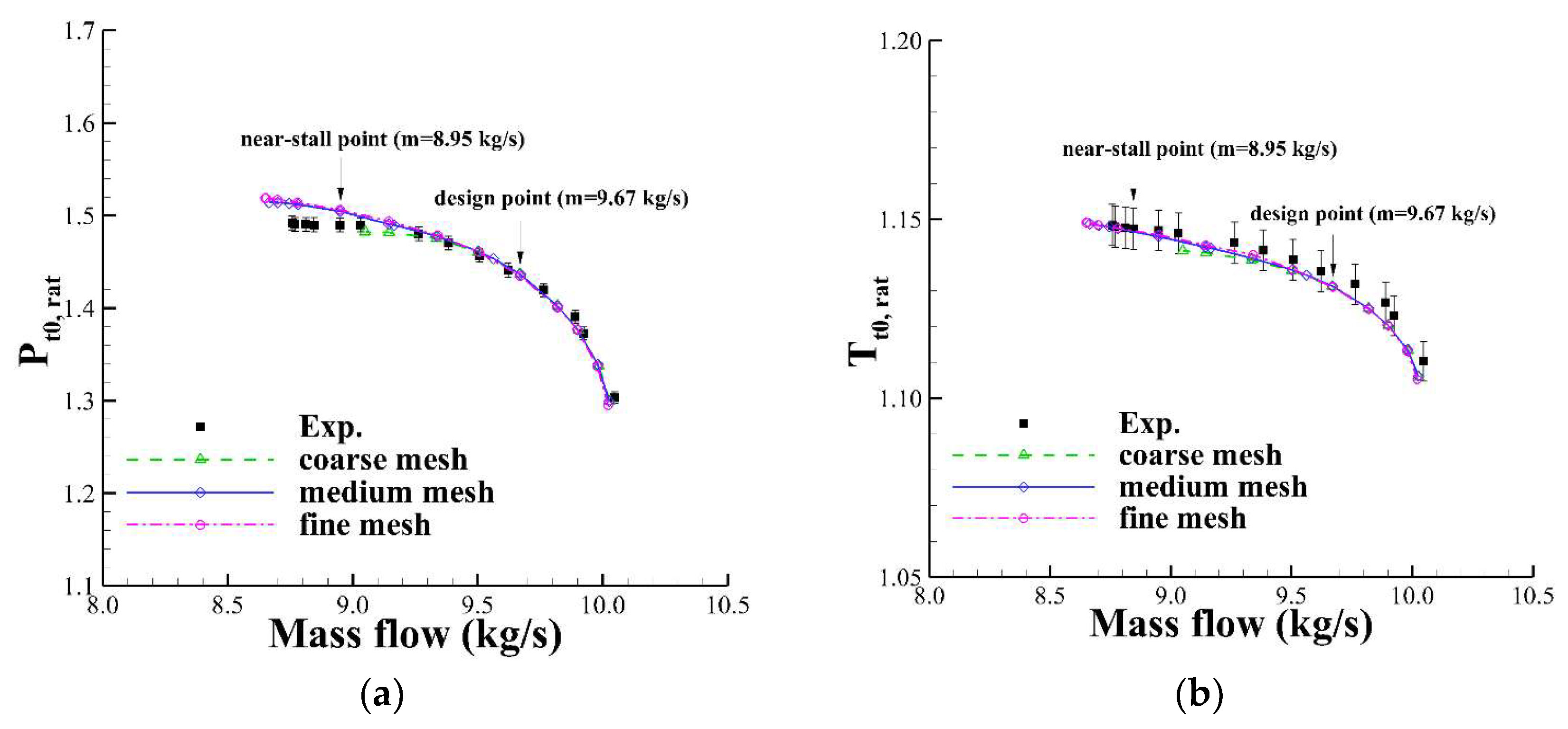

3. Numerical Methods

4. CGCT Application Tests

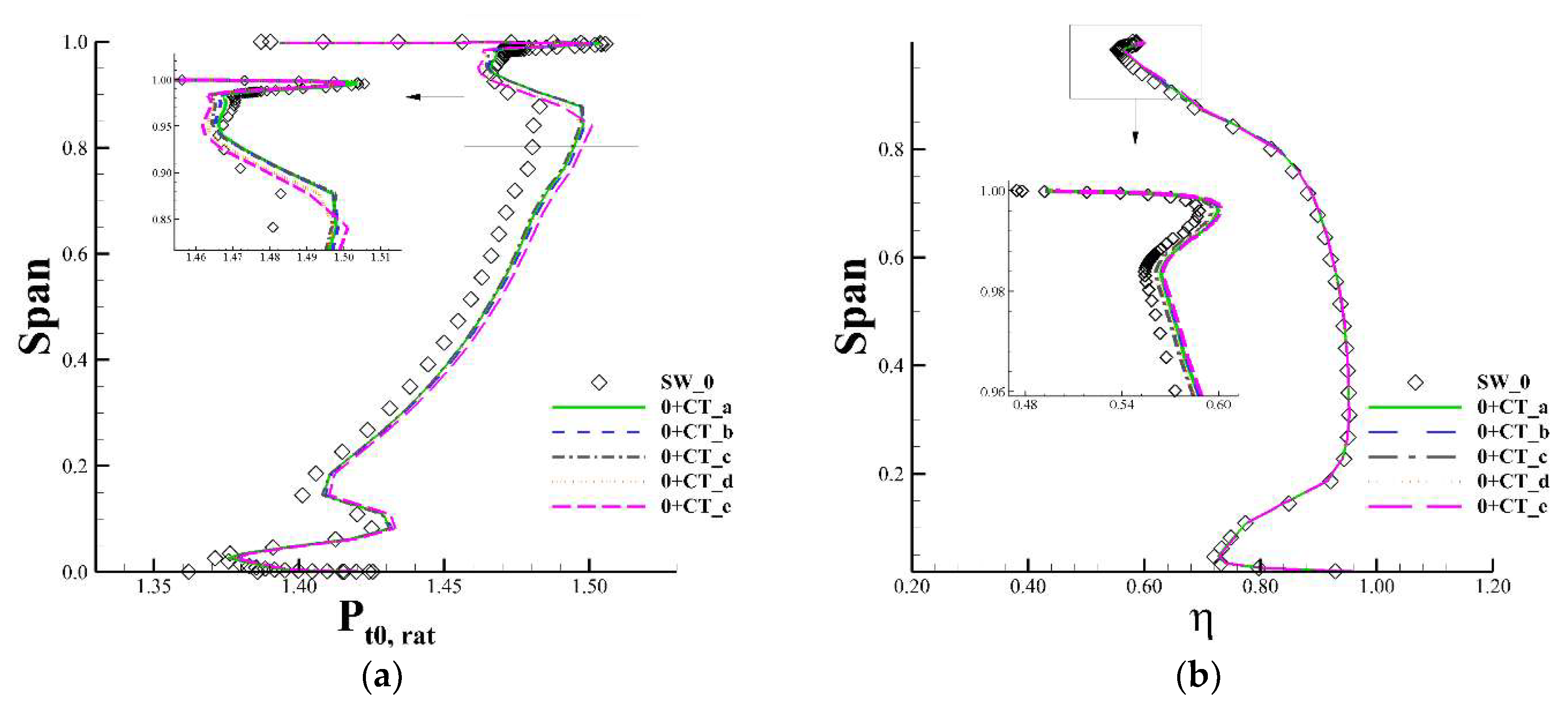

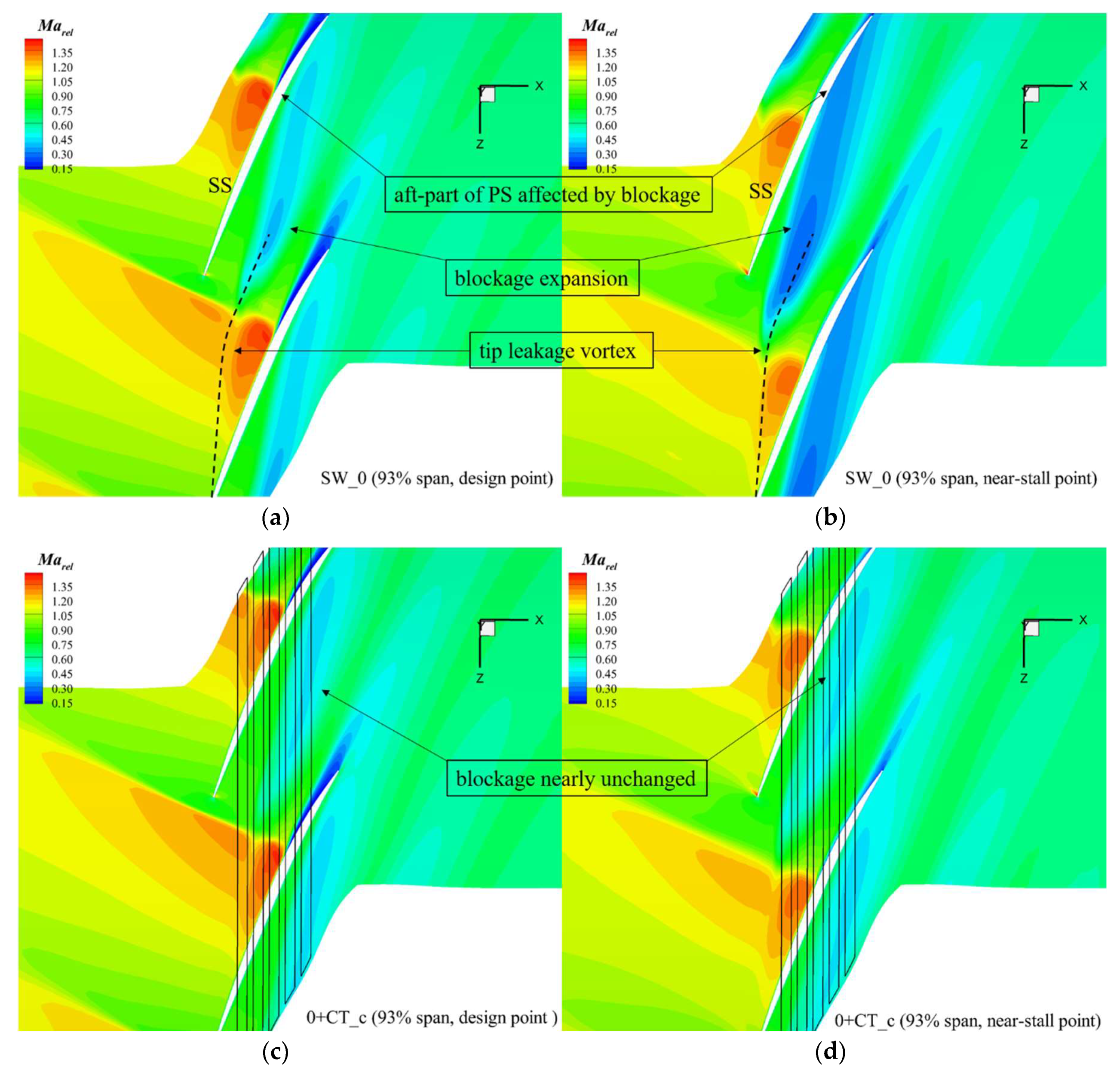

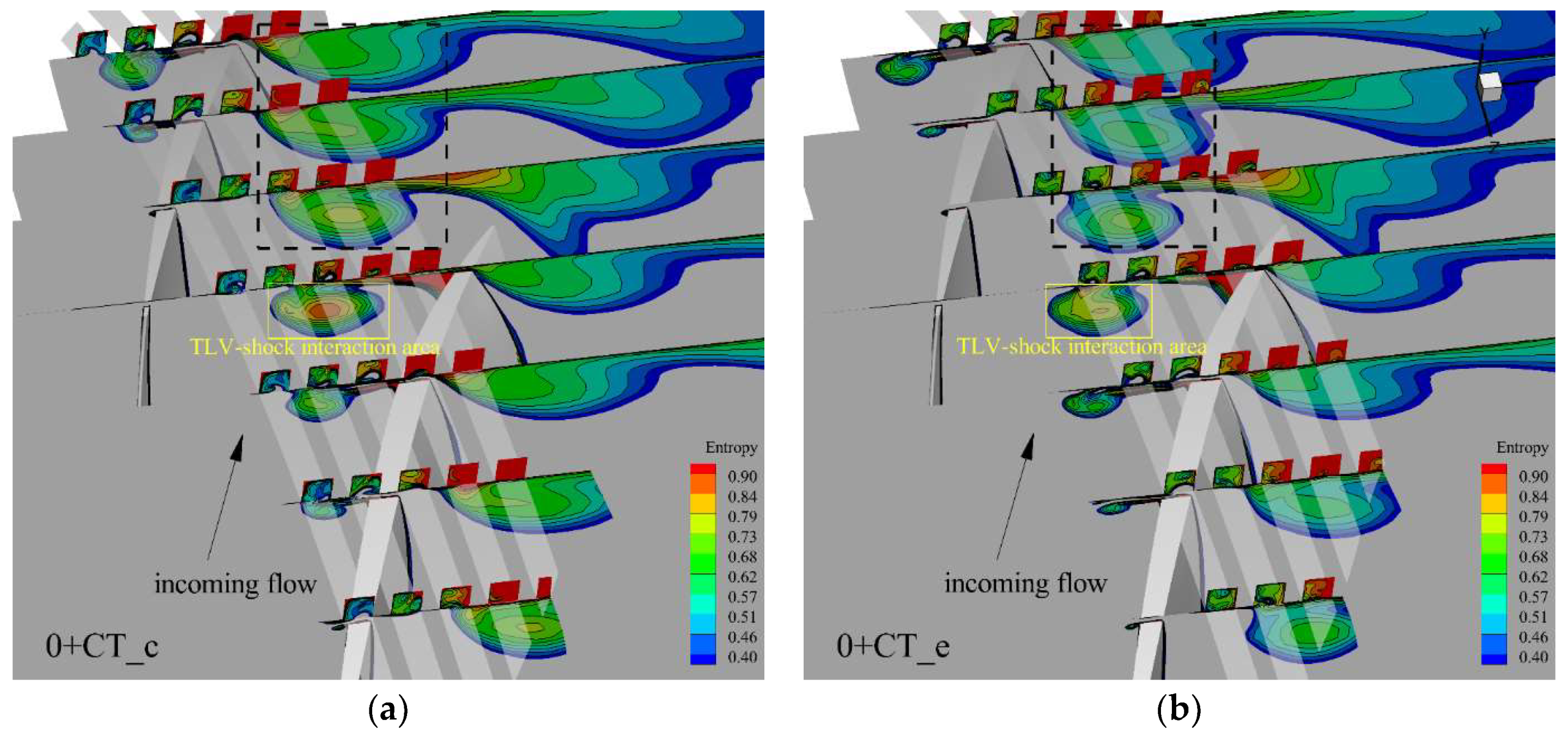

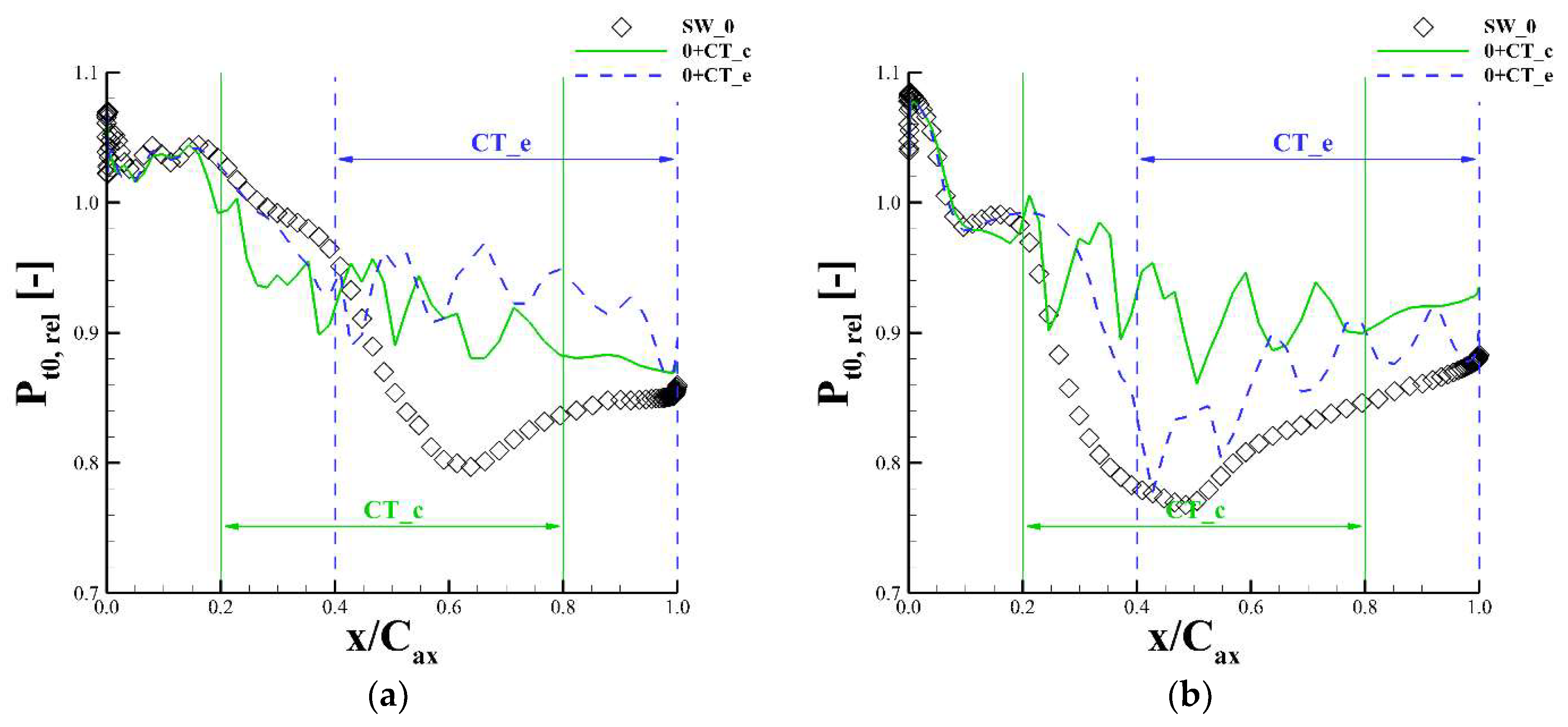

4.1. Effects of the CGCT on the Performance of the Baseline Blade

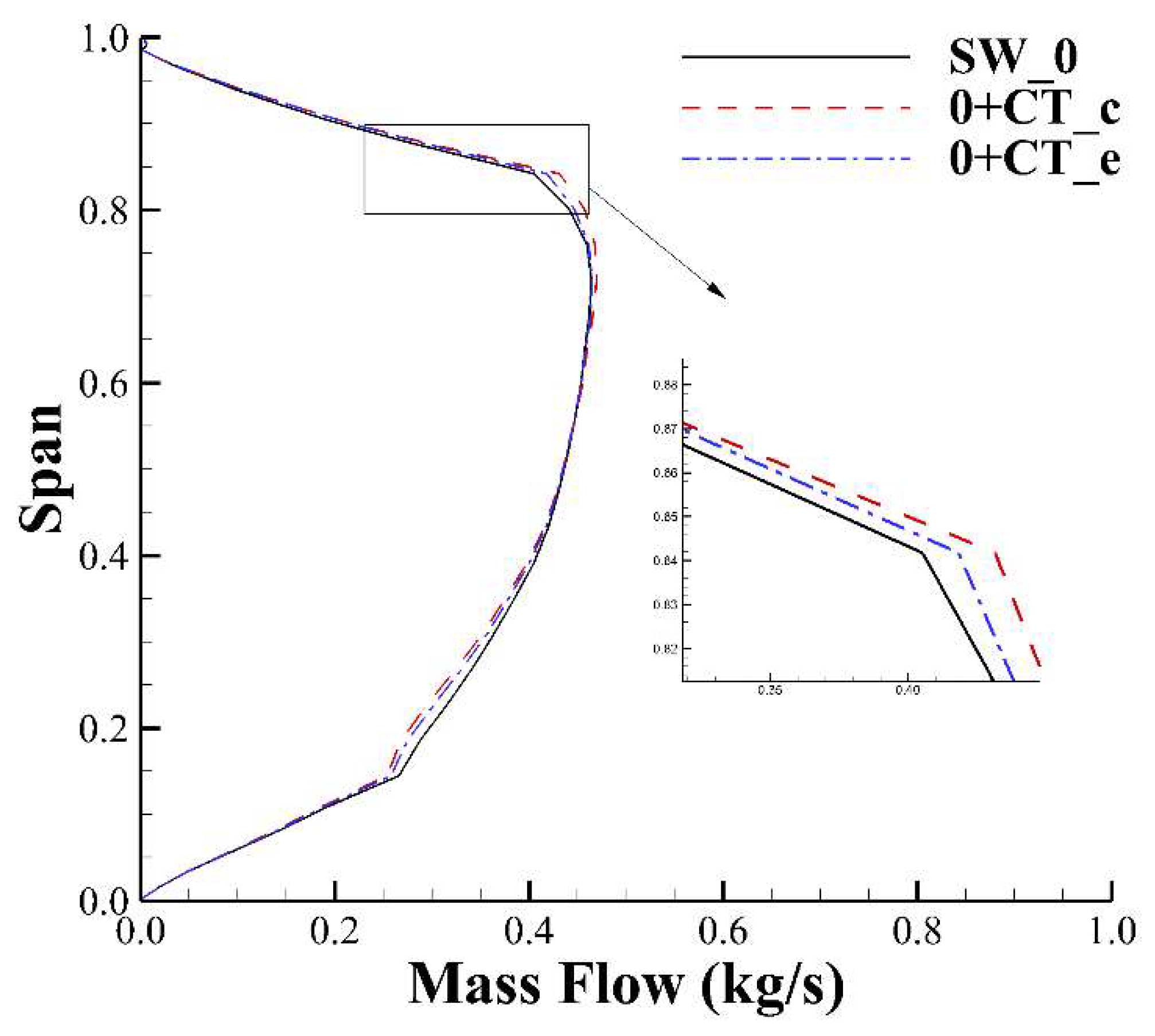

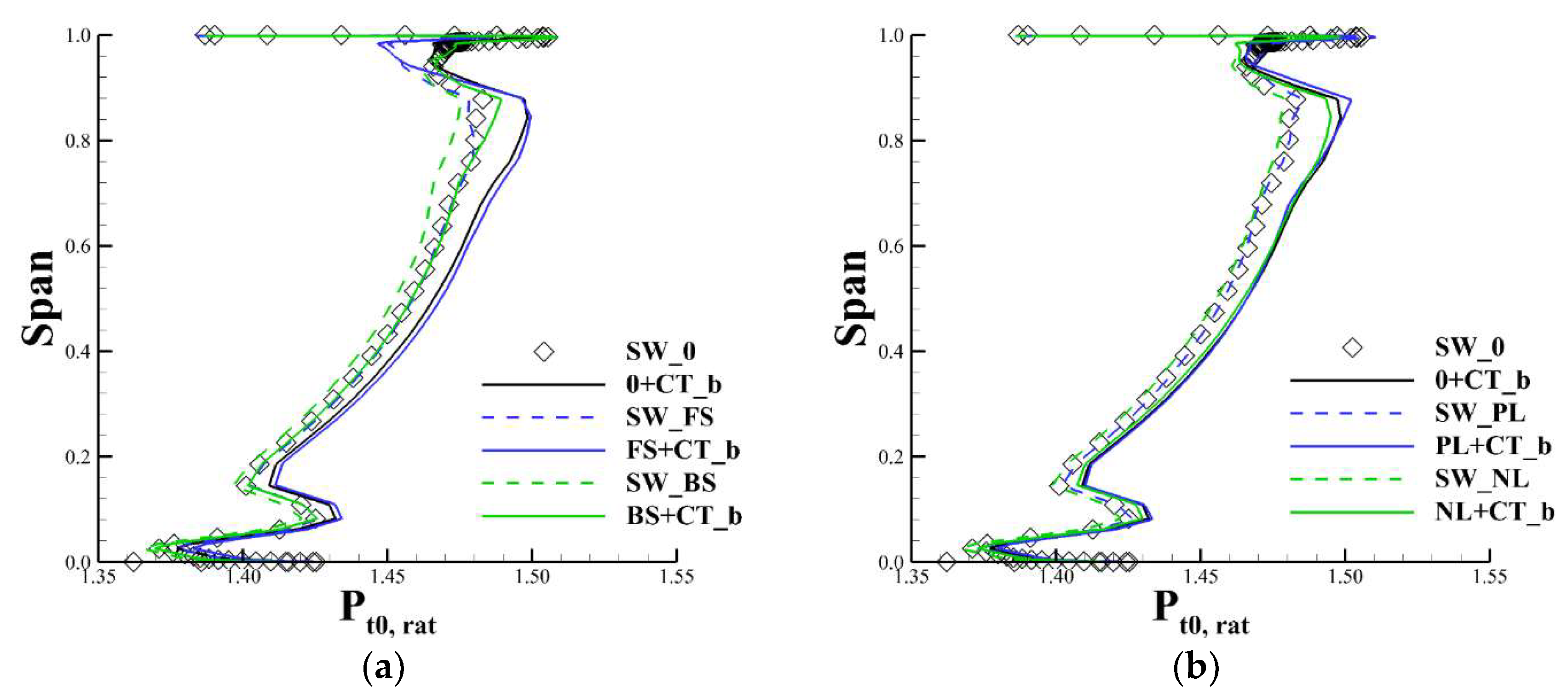

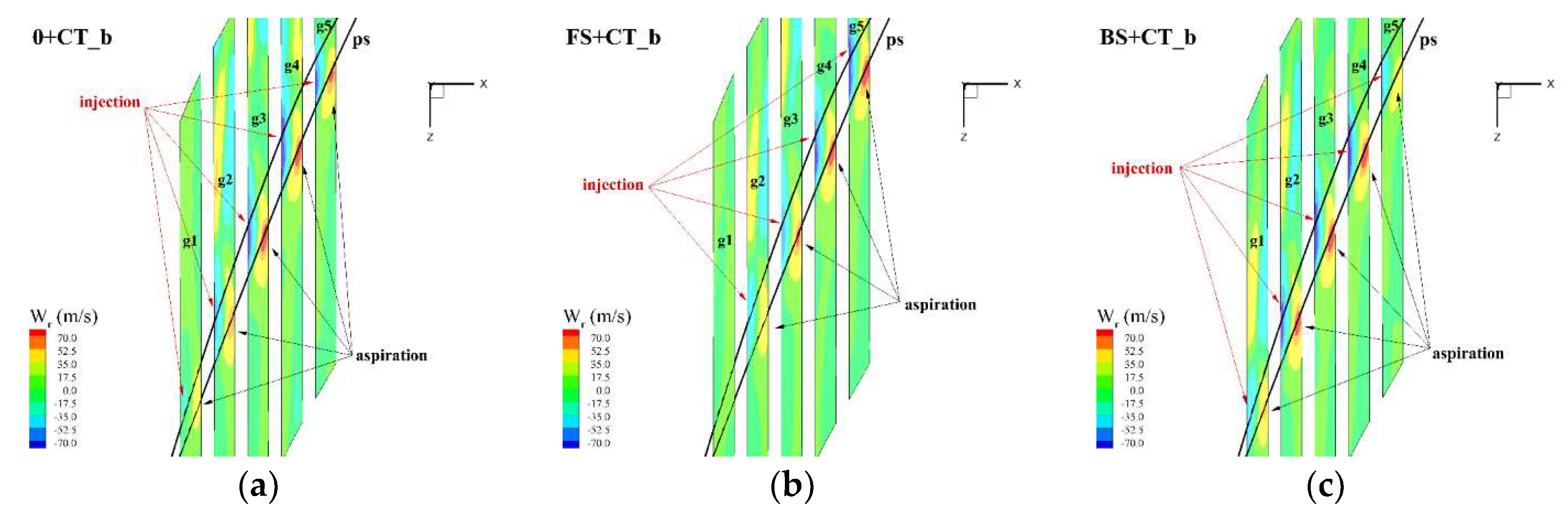

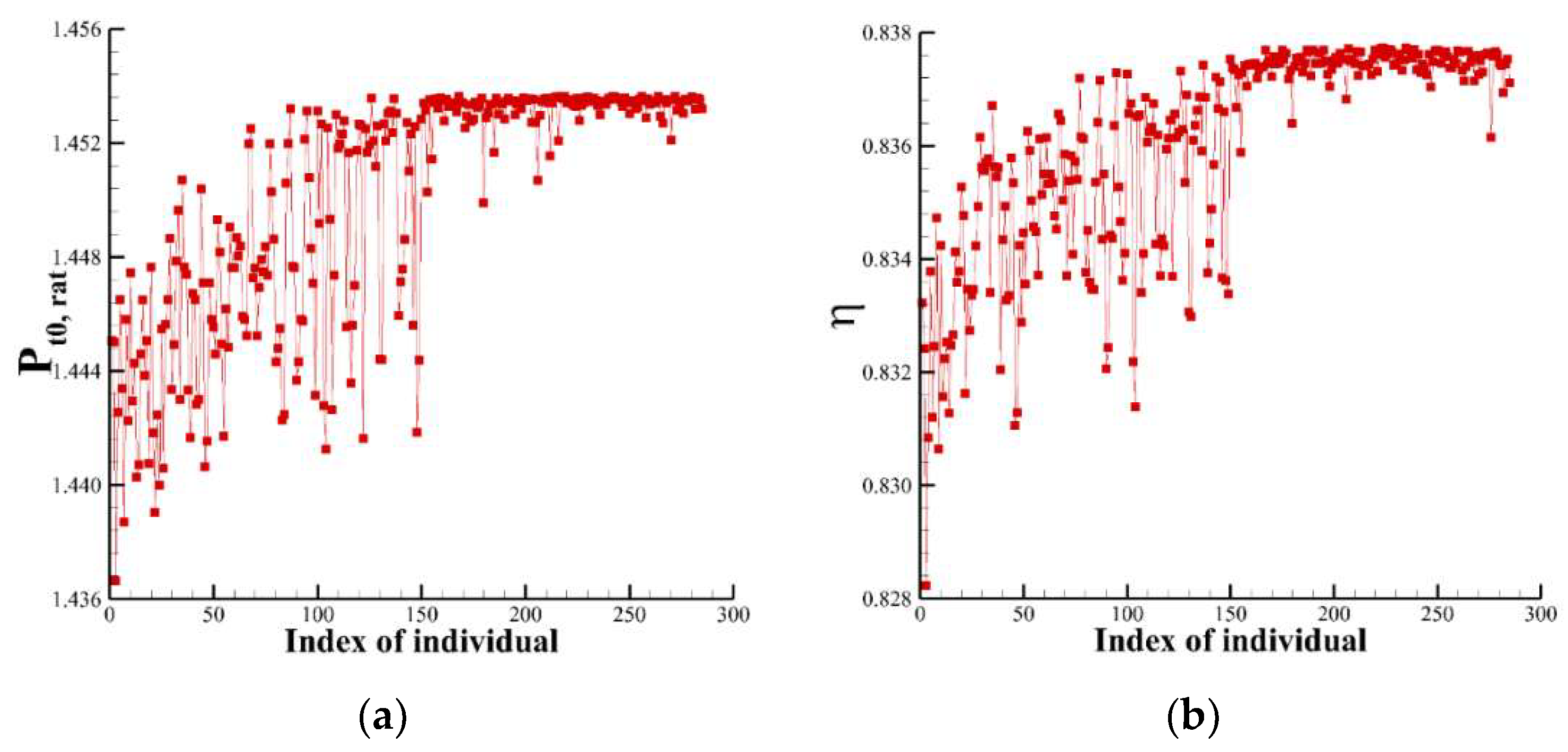

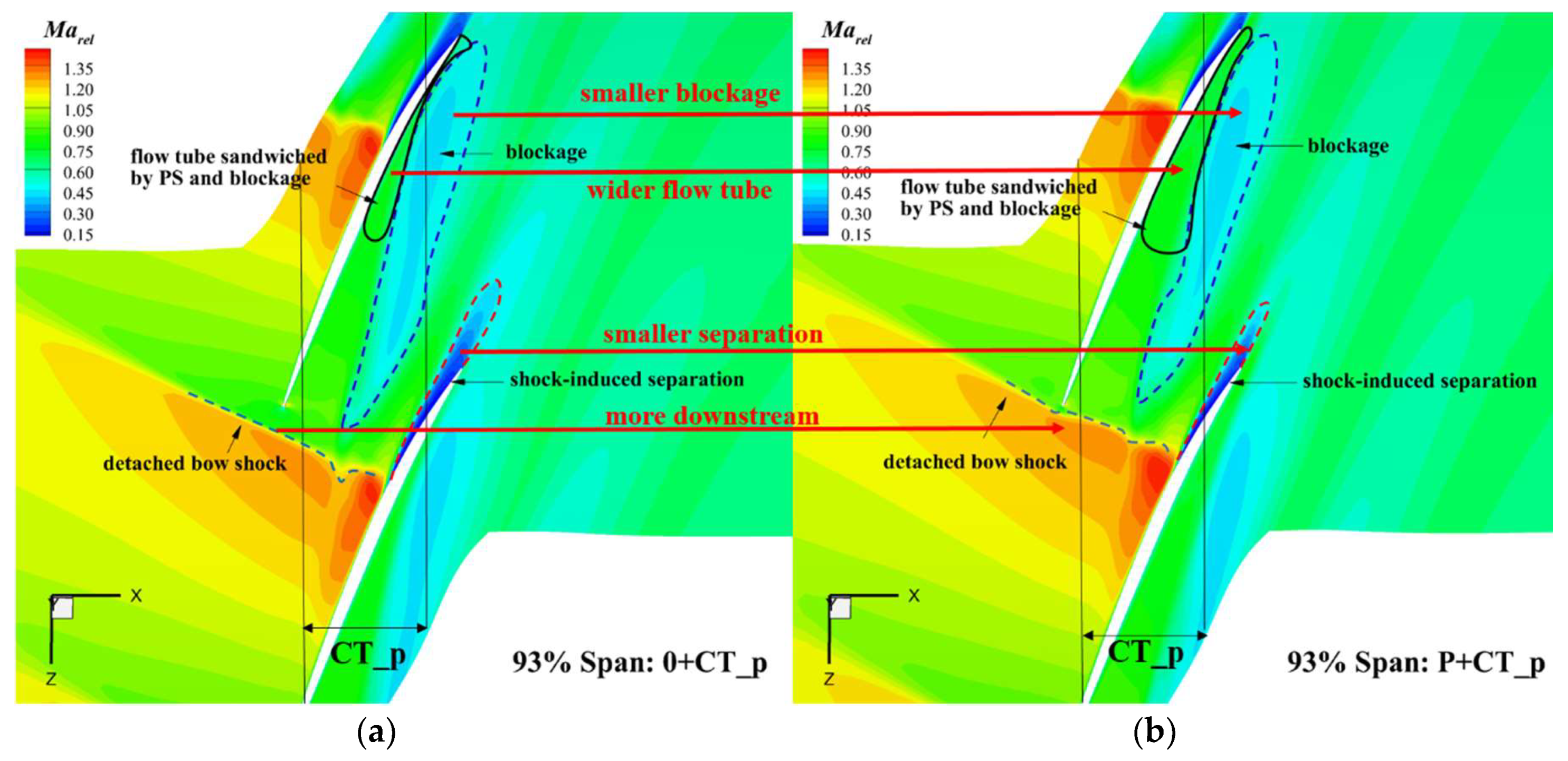

4.2. Effects of the Sweep and Lean on the Effectiveness of the CGCT

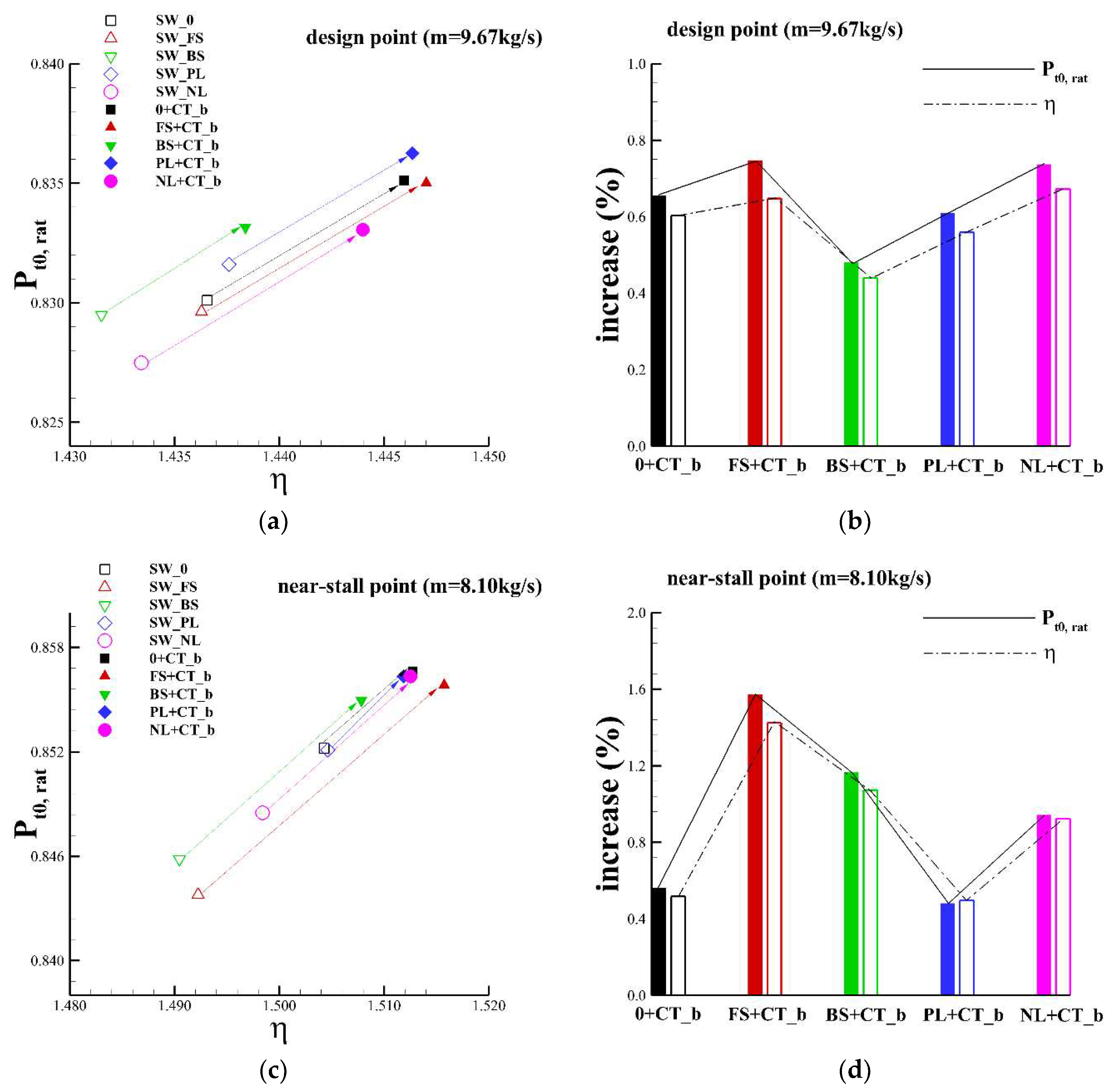

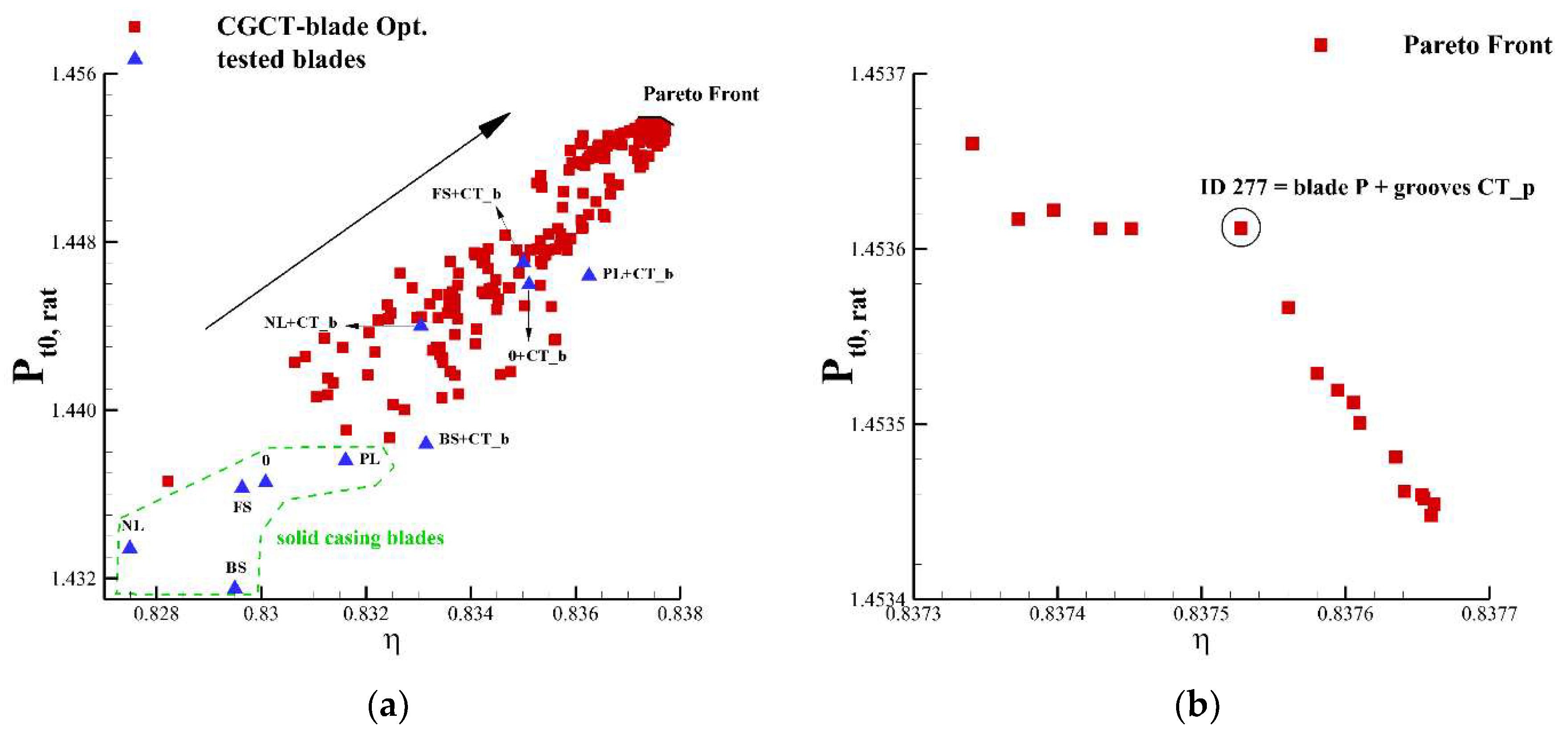

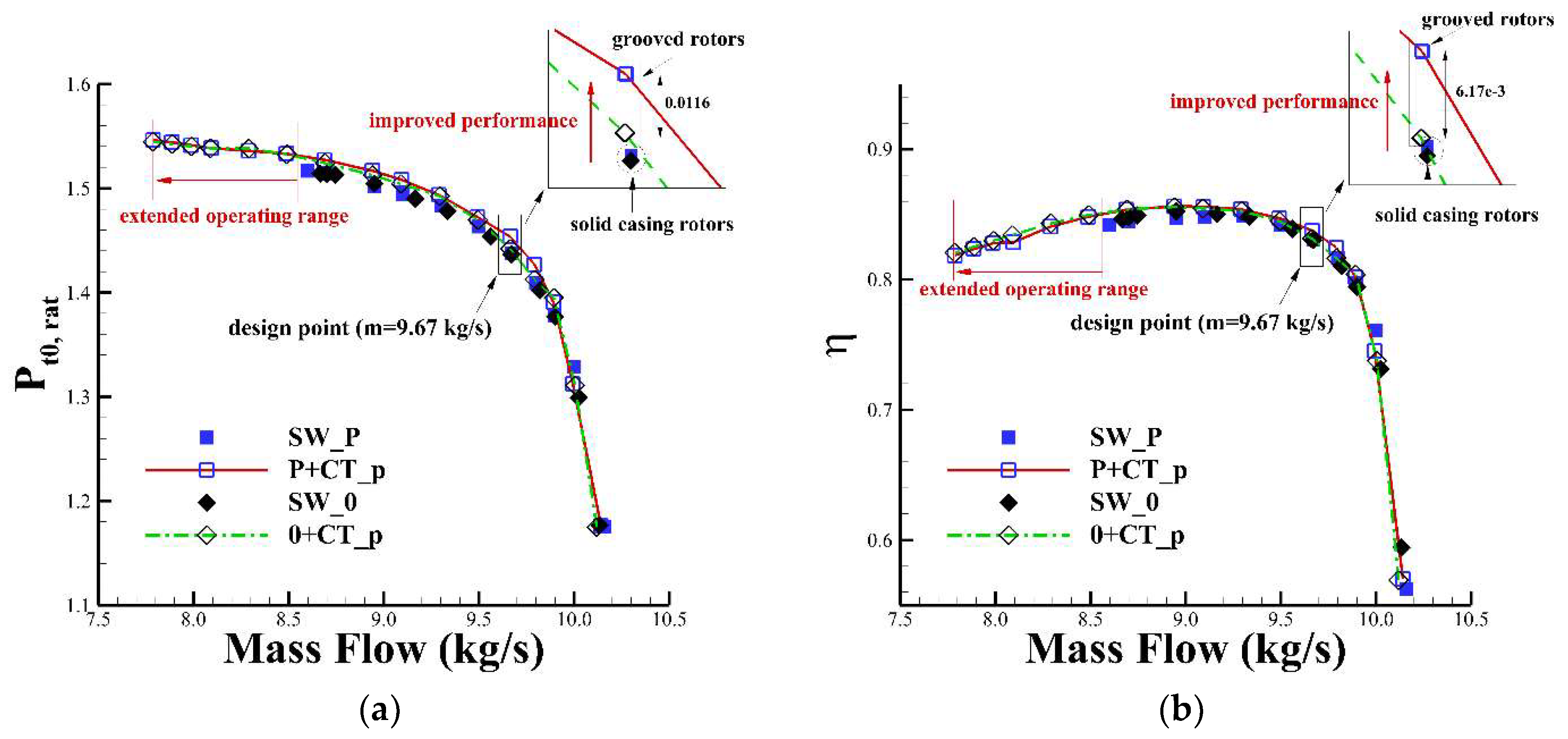

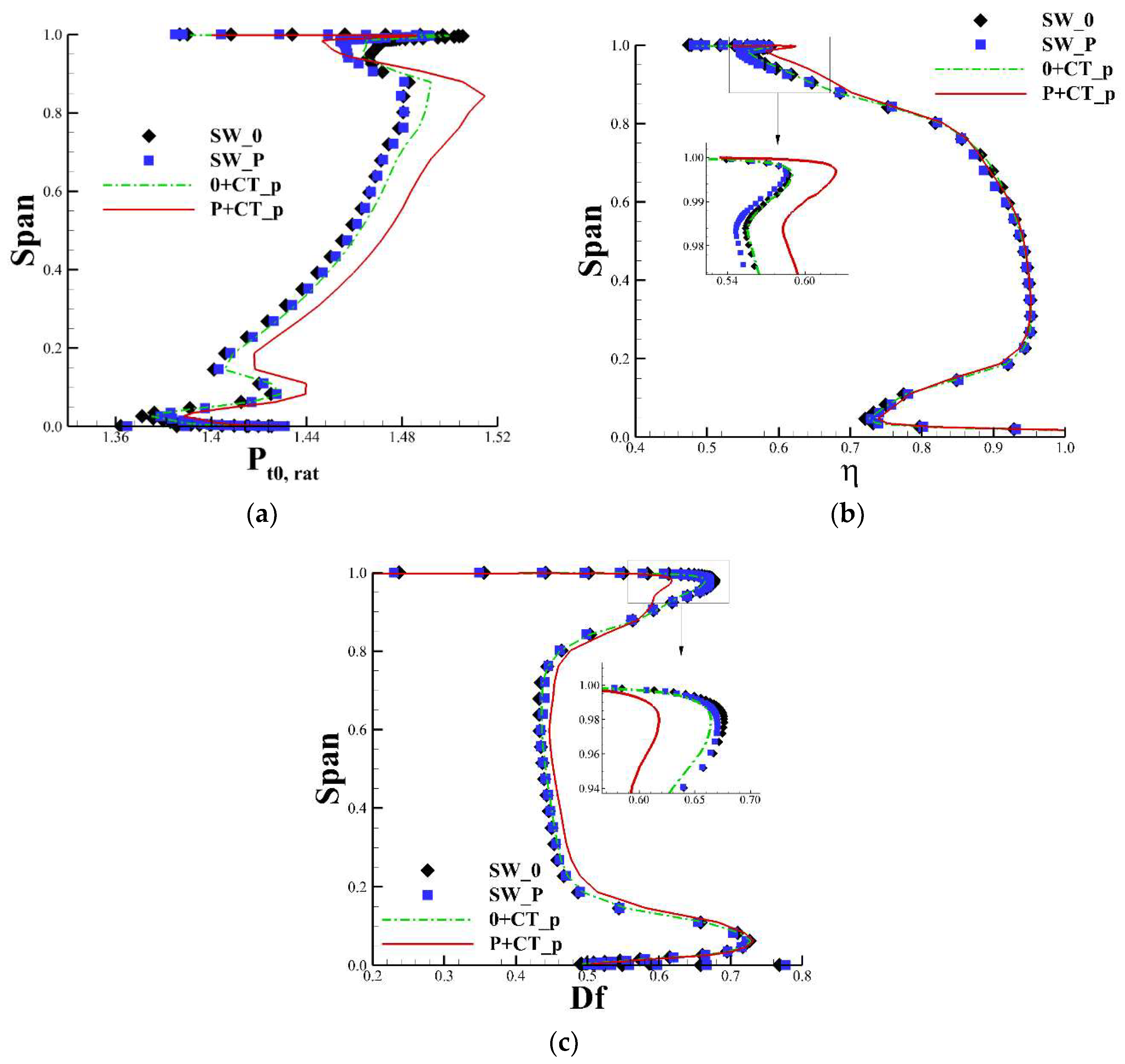

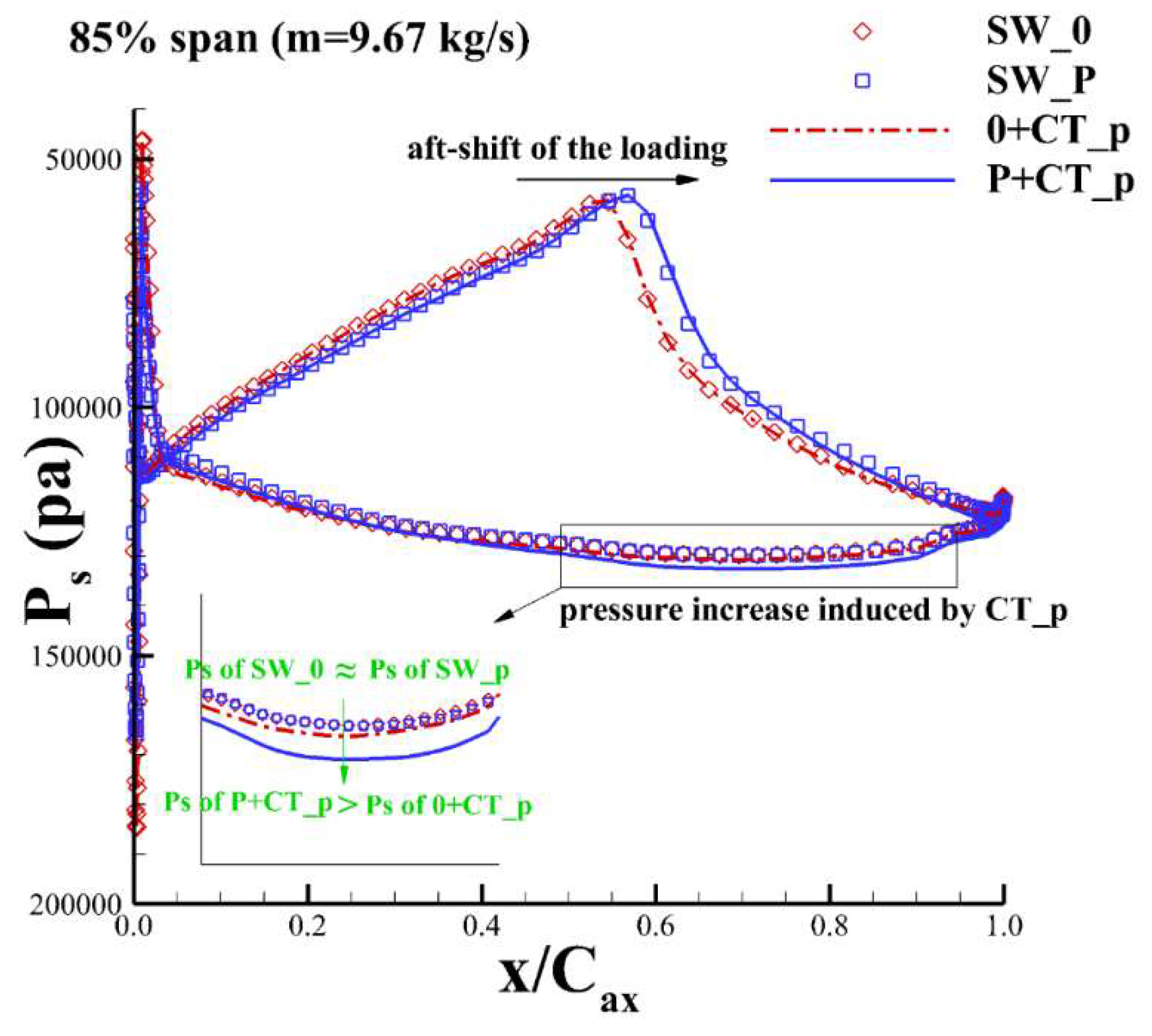

5. CGCT-Blade Integrated Optimization

5.1. Optimization Setup

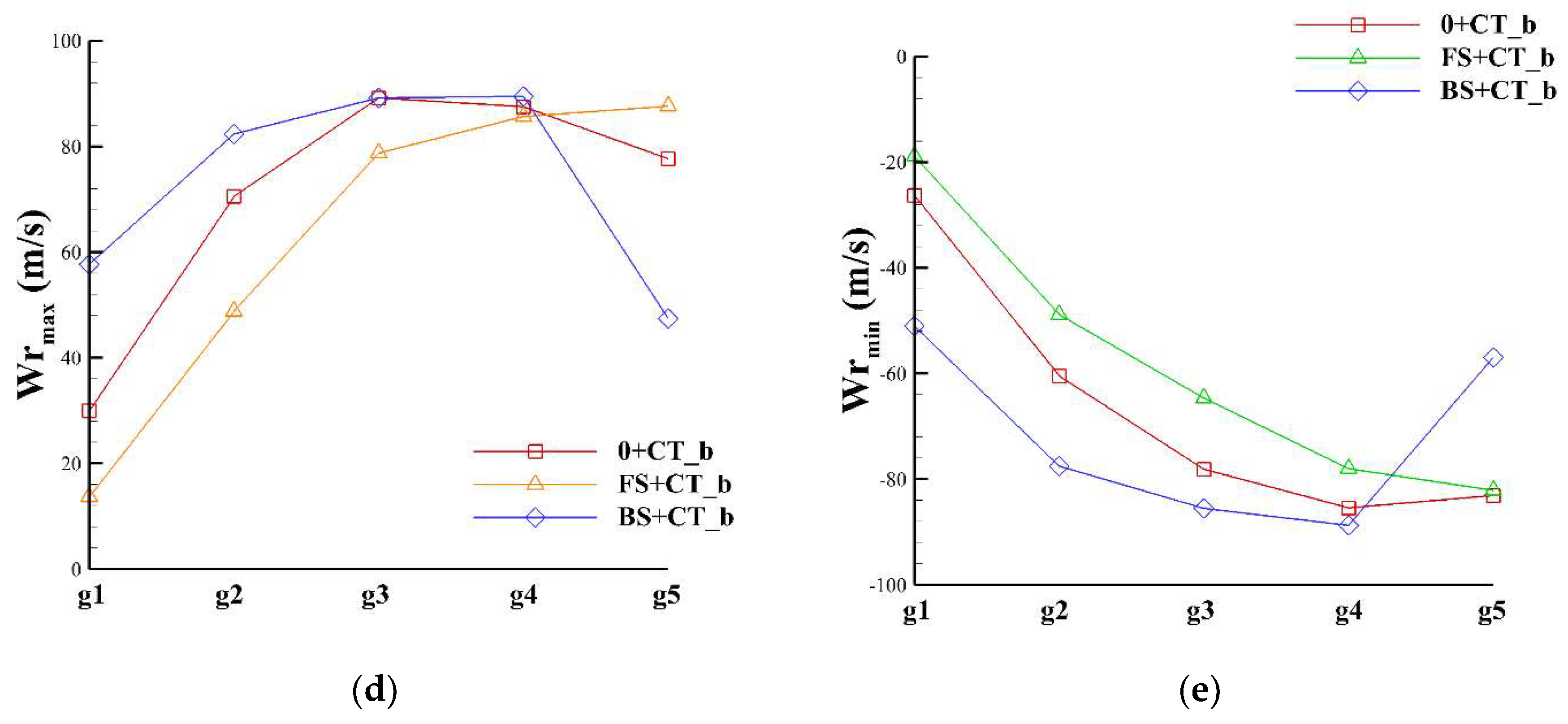

5.2. Results and Analysis

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Rotational speed (rpm) | |

| Blade tip velocity (m/s) | |

| Blade number | |

| Radius of casing (mm) | |

| Radius of hub (mm) | |

| Tip gap size (mm) | |

| Mass flow (kg/s) | |

| Stall mass flow (kg/s) | |

| Total pressure ratio | |

| Total temperature ratio | |

| Adiabatic efficiency | |

| Relative Mach number | |

| Non-dimensional relative total pressure | |

| Df | Diffusion factor |

| Relative radial velocity (m/s) | |

| Axial chord length (mm) | |

| Static pressure (Pa) | |

| PS | Pressure side |

| SS | Suction side |

References

- Broichhausen, K.D.; Ziegler, K.U. Supersonic and Transonic Compressors: Past, Status and Technology Trends. In Proceedings of the ASME Turbo Expo 2005: Power for Land, Sea, and Air, Reno, NV, USA, 6–9 June 2005; pp. 63–74. [Google Scholar] [CrossRef]

- Fujita, H.; Takata, H. A Study on Configurations of Casing Treatment for Axial Flow Compressors. Bull. JSME 1984, 27, 1675–1681. [Google Scholar] [CrossRef] [Green Version]

- Hathaway, M.D. Passive Endwall Treatments for Enhancing Stability; NASA Rep. No. TM-2007-214409; NASA Glenn Research Center: Cleveland, OH, USA, 2007.

- Rabe, D.C.; Hah, C. Application of Casing Circumferential Grooves for Improved Stall Margin in a Transonic Axial Compressor. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; pp. 1141–1153. [Google Scholar] [CrossRef]

- Müller, M.W.; Schiffer, H.-P.; Hah, C. Effect of Circumferential Grooves on the Aerodynamic Performance of an Axial Single-Stage Transonic Compressor. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; pp. 115–124. [Google Scholar] [CrossRef]

- Sakuma, Y.; Watanabe, T.; Himeno, T.; Kato, D.; Murooka, T.; Shuto, Y. Numerical Analysis of Flow in a Transonic Compressor with a Single Circumferential Casing Groove: Influence of Groove Location and Depth on Flow Instability. J. Turbomach. 2013, 136, 031017. [Google Scholar] [CrossRef]

- Houghton, T.; Day, I. Stability Enhancement by Casing Grooves: The Importance of Stall Inception Mechanism and Solidity. J. Turbomach. 2012, 134, 021003. [Google Scholar] [CrossRef]

- Du, J.; Li, J.; Gao, L.; Lin, F.; Chen, J. The Impact of Casing Groove Location on Stall Margin and Tip Clearance Flow in a Low-Speed Axial Compressor. J. Turbomach. 2016, 138, 121007. [Google Scholar] [CrossRef]

- Minsuk Choi Effects of circumferential casing grooves on the performance of a transonic axial compressor. Int. J. Turbo Jet-Engines 2010, 32, 361–371. [CrossRef]

- Mao, X.; Liu, B.; Tang, T.; Zhao, H. The impact of casing groove location on the flow instability in a counter-rotating axial flow compressor. Aerosp. Sci. Technol. 2018, 76, 250–259. [Google Scholar] [CrossRef]

- Kim, J.H.; Choi, K.J.; Kim, K.Y. Aerodynamic analysis and optimization of a transonic axial compressor with casing grooves to improve operating stability. Aerosp. Sci. Technol. 2013, 29, 81–91. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhou, X.; Xiang, X. Multi-objective optimization of groove casing treatment in a transonic compressor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2014, 228, 626–637. [Google Scholar] [CrossRef]

- Houghton, T.O. Axial Compressor Stability Enhancement; University of Cambridge: Cambridge, UK, 2010. [Google Scholar]

- Denton, J.D.; Xu, L. The Effects of Lean and Sweep on Transonic Fan Performance. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; Volume 1, pp. 23–32. [Google Scholar] [CrossRef]

- Denton, J.D.; Xu, L. The exploitation of three-dimensional flow in turbomachinery design. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1998, 213, 125–137. [Google Scholar] [CrossRef]

- Wadia, A.R.; Szucs, P.N.; Crall, D.W. Inner Workings of Aerodynamic Sweep. J. Turbomach. 1998, 120, 671. [Google Scholar] [CrossRef]

- Hah, C.; Puterbaugh, S.L.; Wadia, A. Control of Shock Structure and Secondary Flow Field inside Transonic Compressor Rotors through Aerodynamic Sweep. In Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2–5 June 1998; pp. 1–15. [Google Scholar] [CrossRef]

- Gallimore, S.J.; Bolger, J.J.; Cumpsty, N.A.; Taylor, M.J.; Wright, P.I.; Place, J.M.M. The Use of Sweep and Dihedral in Multistage Axial Flow Compressor Blading—Part I: University Research andMethods Development. J. Turbomach. 2002, 124, 521–532. [Google Scholar] [CrossRef]

- Hah, C. The Inner Workings of Axial Casing Grooves in a One and a Half Stage Axial Compressor with a Large Rotor Tip Gap: Changes in Stall Margin and Efficiency. J. Turbomach. 2018, accepted. [Google Scholar]

- Goinis, G.; Nicke, E. Optimizing surge margin and efficiency of a transonic compressor. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Korea, 13–17 June 2016; pp. 1–12. [Google Scholar] [CrossRef]

- Cameron, J.D.; Cameron, J.D.; Morris, S.C.; Morris, S.C.; Corke, T.C.; Corke, T.C. A Transonic Axial Compressor Facility for Fundamental Research and Flow Control Development. Mech. Eng. 2006. [Google Scholar] [CrossRef]

- Kelly, R.; Hickman, A.R.; Shi, K.; Morris, S.C.; Jemcov, A. Very Large Eddy Simulation of a Transonic Axial Compressor Stage. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016; pp. 1–13. [Google Scholar] [CrossRef]

- Cameron, J.D.; Morris, S.C. Spatial Correlation Based Stall Inception Analysis. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; pp. 433–444. [Google Scholar] [CrossRef]

- Chen, H.; Huang, X.; Shi, K.; Fu, S.; Ross, M.; Bennington, M.A.; Cameron, J.D.; Morris, S.C.; McNulty, S.; Wadia, A. A Computational Fluid Dynamics Study of Circumferential Groove Casing Treatment in a Transonic Axial Compressor. J. Turbomach. 2013, 136, 031003. [Google Scholar] [CrossRef]

- Shi, K.; Chen, H.X.; Fu, S. Numerical investigation of the casing treatment mechanism with a single circumferential groove. Sci. China Phys. Mech. Astron. 2013, 56, 353–365. [Google Scholar] [CrossRef]

- Toro, E.F.; Spruce, M.; Speares, W. Restoration of the contact surface in the HLL-Riemann solver. Shock Waves 1994, 4, 25–34. [Google Scholar] [CrossRef]

- Van Leer, B. Towards the ultimate conservative difference scheme III. Upstream-centered finite-difference schemes for ideal compressible flow. J. Comput. Phys. 1977, 23, 263–275. [Google Scholar] [CrossRef]

- Van Albada, G.D.; Van Leer, B.; Roberts, W.W. A comparative study of computational methods in cosmic gas dynamics. Astron. Astrophys. 1982, 108, 76–84. [Google Scholar] [CrossRef]

- Menter, F.R. Improved two-equation k-omega turbulence models for aerodynamic flows. NASA Tech. Memo. 1992, 1–31. [Google Scholar] [CrossRef]

- Yoon, S.; Jameson, A. Lower-upper Symmetric-Gauss-Seidel method for the Euler and Navier-Stokes equations. AIAA J. 1988, 26, 1025–1026. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.X.; Fu, S.; Li, F.W. Navier-Stokes simulations for transport aircraft wing-body combinations with deployed high-lift systems. J. Aircr. 2003, 40, 883–890. [Google Scholar] [CrossRef]

- Huang, X.; Chen, H.; Fu, S. CFD Investigation on the Circumferential Grooves Casing Treatment of Transonic Compressor. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea and Air, Berlin, Germany, 9–13 June 2008; pp. 1–9. [Google Scholar]

- Chen, H.; Huang, X.; Fu, S. CFD Investigation on Stall Mechanisms and Casing Treatment of a Transonic Compressor. In Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Sacramento, CA, USA, 9–12 July 2006. [Google Scholar] [CrossRef]

- Siller, U.; Voß, C.; Nicke, E. Automated Multidisciplinary Optimization of a Transonic Axial Compressor. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; pp. 1–12. [Google Scholar] [CrossRef]

- Ji, L.; Chen, J.; Lin, F. Review and Understanding on Sweep in Axial Compressor Design. In Proceedings of the ASME Turbo Expo 2005: Power for Land, Sea, and Air, Reno, NV, USA, 6–9 June 2005; pp. 1–9. [Google Scholar] [CrossRef]

- Deng, K.; Chen, H. A Hybrid Aerodynamic Optimization Algorithm Based on Differential Evolution and RBF Response Surface. In Proceedings of the 17th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar] [CrossRef]

| Symbol | Value | Symbol | Value |

|---|---|---|---|

| (rpm) | 14,686 | Axial Chord (mm) | 35.56 |

| (m/s) | 352 | (mm) | 228.6 |

| Solidity | 1.21 | (mm) | 171.45 |

| 20 | (mm) | 0.762 |

| Name | Definition |

|---|---|

| SW_* | solid casing rotor, including SW_0, SW_FS, SW_BS, SW_PL and SW_NL |

| CT_* | CGCT configuration, including CT_a, CT_b, CT_c, CT_d and CT_e |

| 0 | baseline ND-TAC rotor |

| FS | re-stacked rotor with forward swept tip |

| BS | re-stacked rotor with backward swept tip |

| PL | re-stacked rotor with positive leaned tip |

| NL | re-stacked rotor with negative leaned tip |

| Name | Axial Coverage (% ) |

|---|---|

| CT_a | 0–60% |

| CT_b | 10–70% |

| CT_c | 20–80% |

| CT_d | 30–90% |

| CT_e | 40–100% |

| Name | Relative to SW_0 | Relative to SW_0 | Relative to SW_0 | |||

|---|---|---|---|---|---|---|

| SW_0 | 1.43655 | - | 0.83008 | - | 8.666 | - |

| 0 + CT_a | 1.44519 | 0.602% | 0.83355 | 0.418% | 7.882 | −9.044% |

| 0 + CT_b | 1.44596 | 0.655% | 0.83511 | 0.606% | 7.907 | −8.759% |

| 0 + CT_c | 1.44475 | 0.571% | 0.83323 | 0.379% | 7.901 | −8.820% |

| 0 + CT_d | 1.44525 | 0.606% | 0.83391 | 0.461% | 8.089 | −6.663% |

| 0 + CT_e | 1.44685 | 0.717% | 0.83474 | 0.561% | 8.403 | −3.033% |

| Working Conditions | Constraints | Objectives |

|---|---|---|

| choking point | - | |

| design point (m = 9.67 kg/s) | - | max and max |

| near-stall point (m = 8.10 kg/s) | - |

| Type | ||

|---|---|---|

| SW_0 | 1.43655 | 0.83008 |

| 0 + CT_b | 1.44596 | 0.83511 |

| tested blades with CT_b | 1.44393 | 0.83437 |

| CGCT-blade integrated opt. | 1.45354 | 0.83755 |

| Statistics | 3D Blading | CGCT Distribution | ||

|---|---|---|---|---|

| Sweep (%) | Lean (%()) | (%) | (%) | |

| average | 11.9669 | 2.9675 | 11.6883 | 7.7067 |

| variance | 0.0419 | 0.3449 | 0.0028 | 0.0673 |

| Performance and Variations | Medium Mesh (Used in the Optimization) | Fine Mesh (Used for Validation) |

|---|---|---|

| of baseline blade 0 | 1.43655 | 1.43449 |

| of grooved blade 0 + CT_b | 1.44596 | 1.44101 |

| of optimized grooved blade P + CT_p | 1.45361 | 1.45009 |

| Improvement in (P+CT_p versus 0) | 1.1876% | 1.0875% |

| Improvement in obtained by optimization (P+CT_p versus 0+CT_b) | 0.5291% | 0.6301% |

| of baseline blade 0 | 0.83008 | 0.82853 |

| of grooved blade 0 + CT_b | 0.83511 | 0.83178 |

| of optimized grooved blade P +CT_p | 0.83753 | 0.83626 |

| Improvement in (P+CT_p versus 0) | 0.8975% | 0.9330% |

| Improvement in (P+CT_p versus 0+CT_b) | 0.2898% | 0.5386% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Zhang, Y.; Chen, H. Design and Optimization of Multiple Circumferential Casing Grooves Distribution Considering Sweep and Lean Variations on the Blade Tip. Energies 2018, 11, 2401. https://doi.org/10.3390/en11092401

Song W, Zhang Y, Chen H. Design and Optimization of Multiple Circumferential Casing Grooves Distribution Considering Sweep and Lean Variations on the Blade Tip. Energies. 2018; 11(9):2401. https://doi.org/10.3390/en11092401

Chicago/Turabian StyleSong, Weimin, Yufei Zhang, and Haixin Chen. 2018. "Design and Optimization of Multiple Circumferential Casing Grooves Distribution Considering Sweep and Lean Variations on the Blade Tip" Energies 11, no. 9: 2401. https://doi.org/10.3390/en11092401