Prevention of Potential Hazards Associated with Marine Gas Hydrate Exploitation: A Review

Abstract

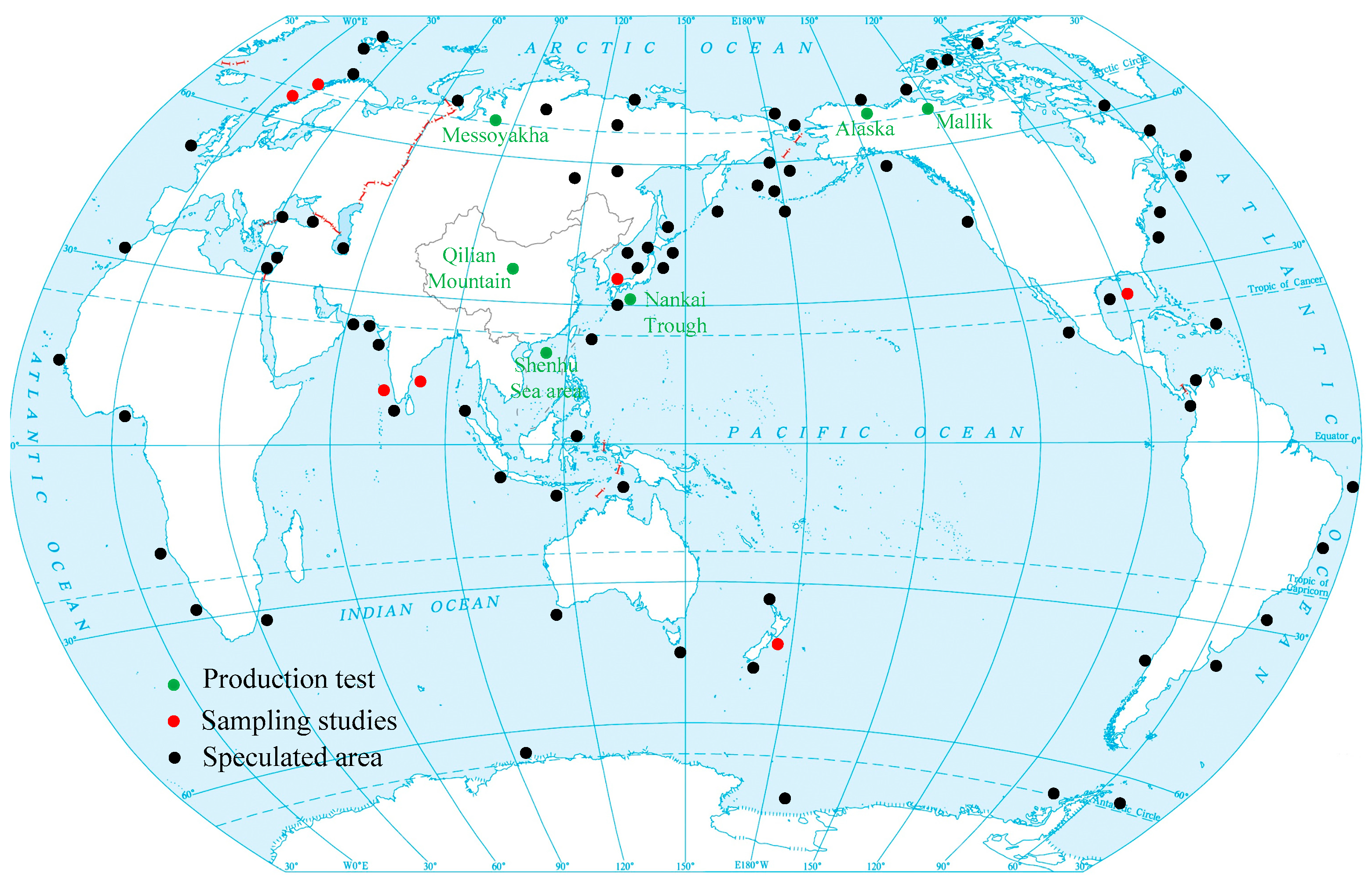

:1. Introduction

2. Classification and Causes of Potential Hazards from MGHs

2.1. Marine Geohazards

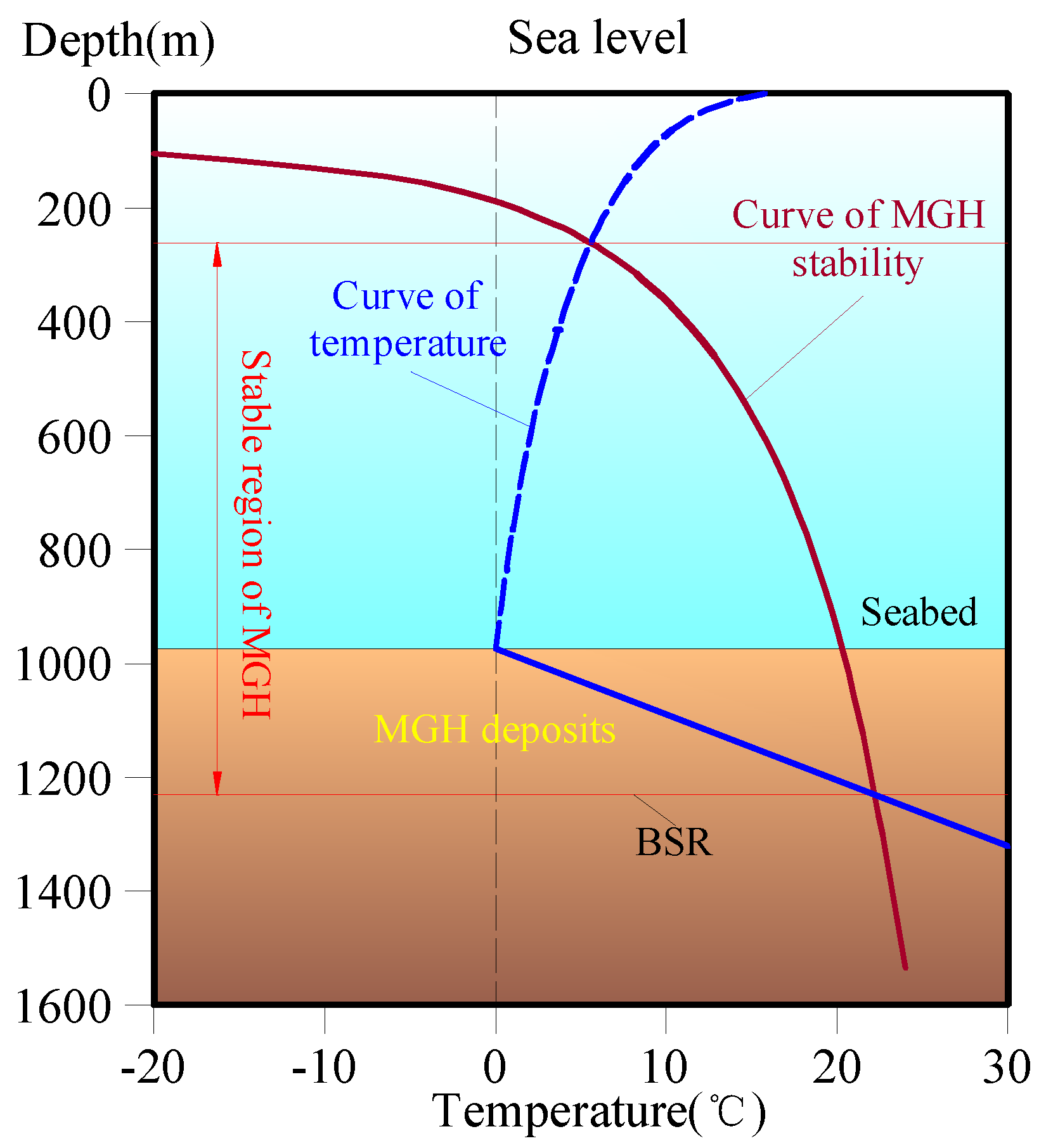

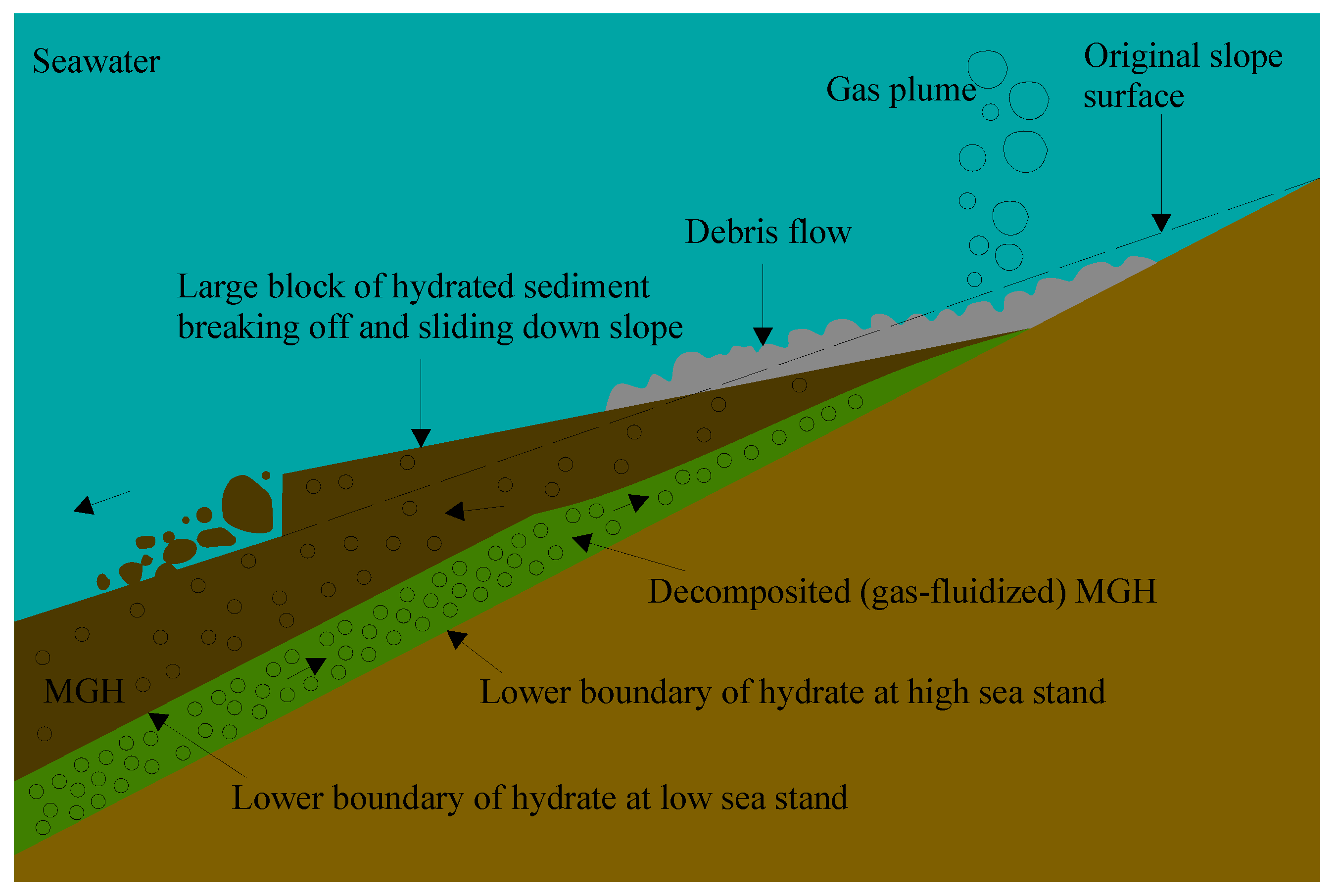

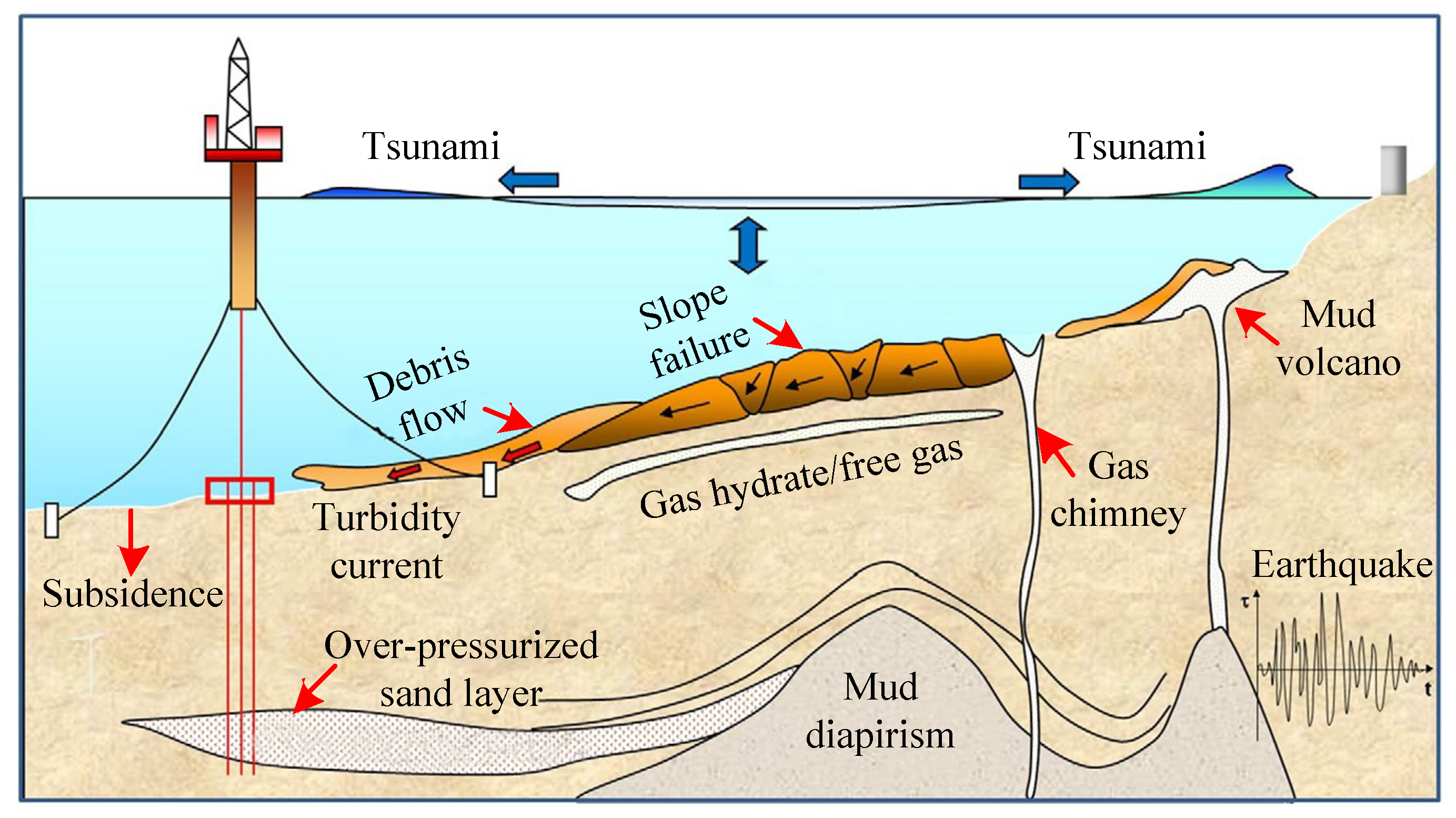

2.1.1. Submarine Landslide

2.1.2. Earthquakes and Other Geohazards

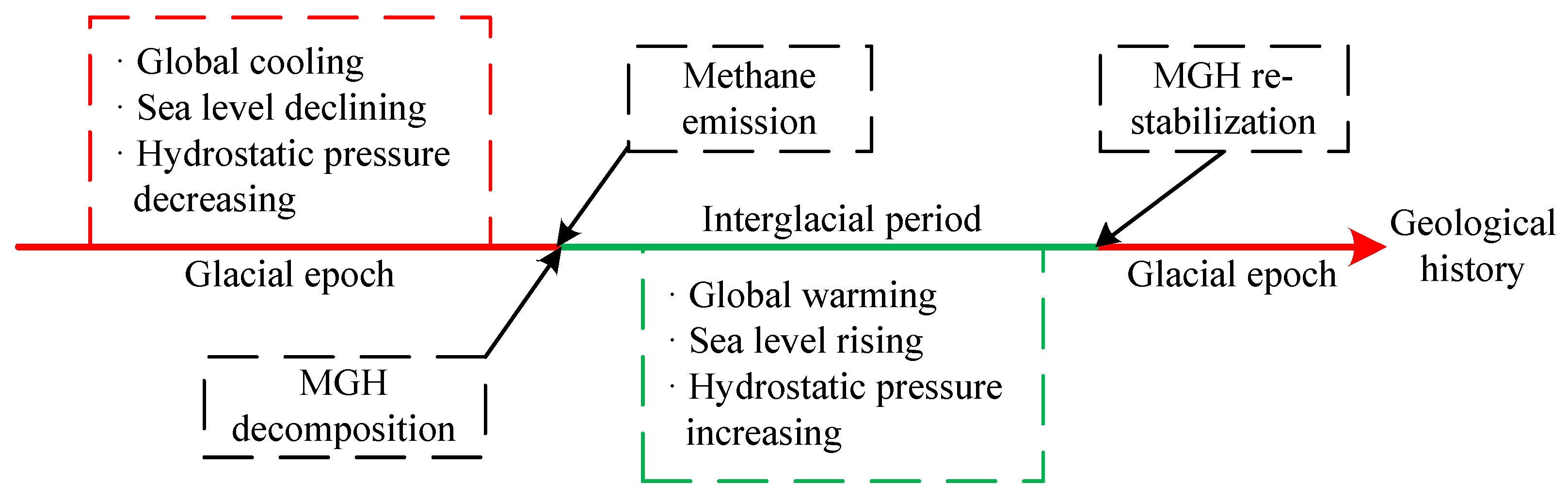

2.2. Greenhouse Gas Emissions

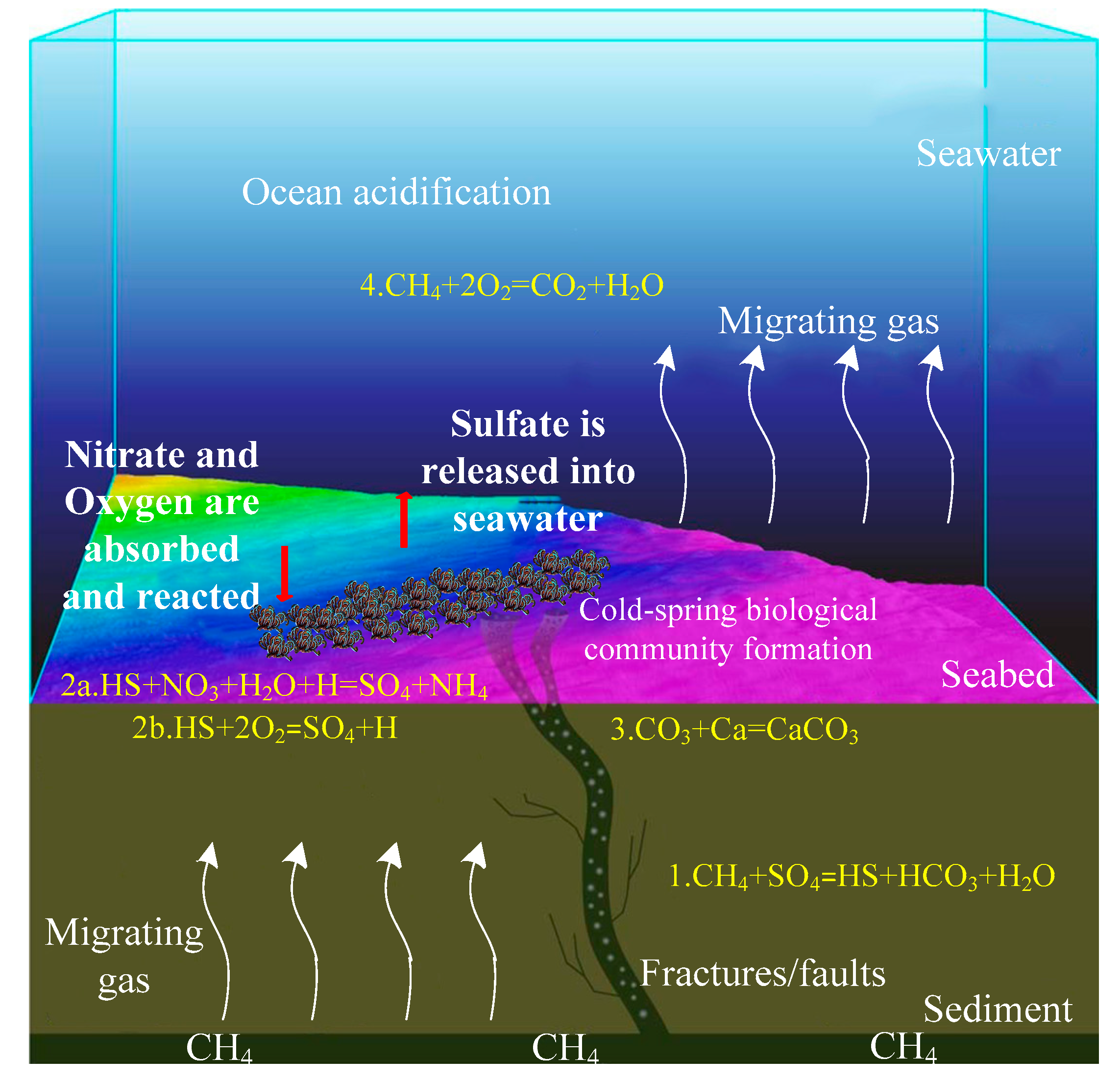

2.3. Marine Ecological Hazards

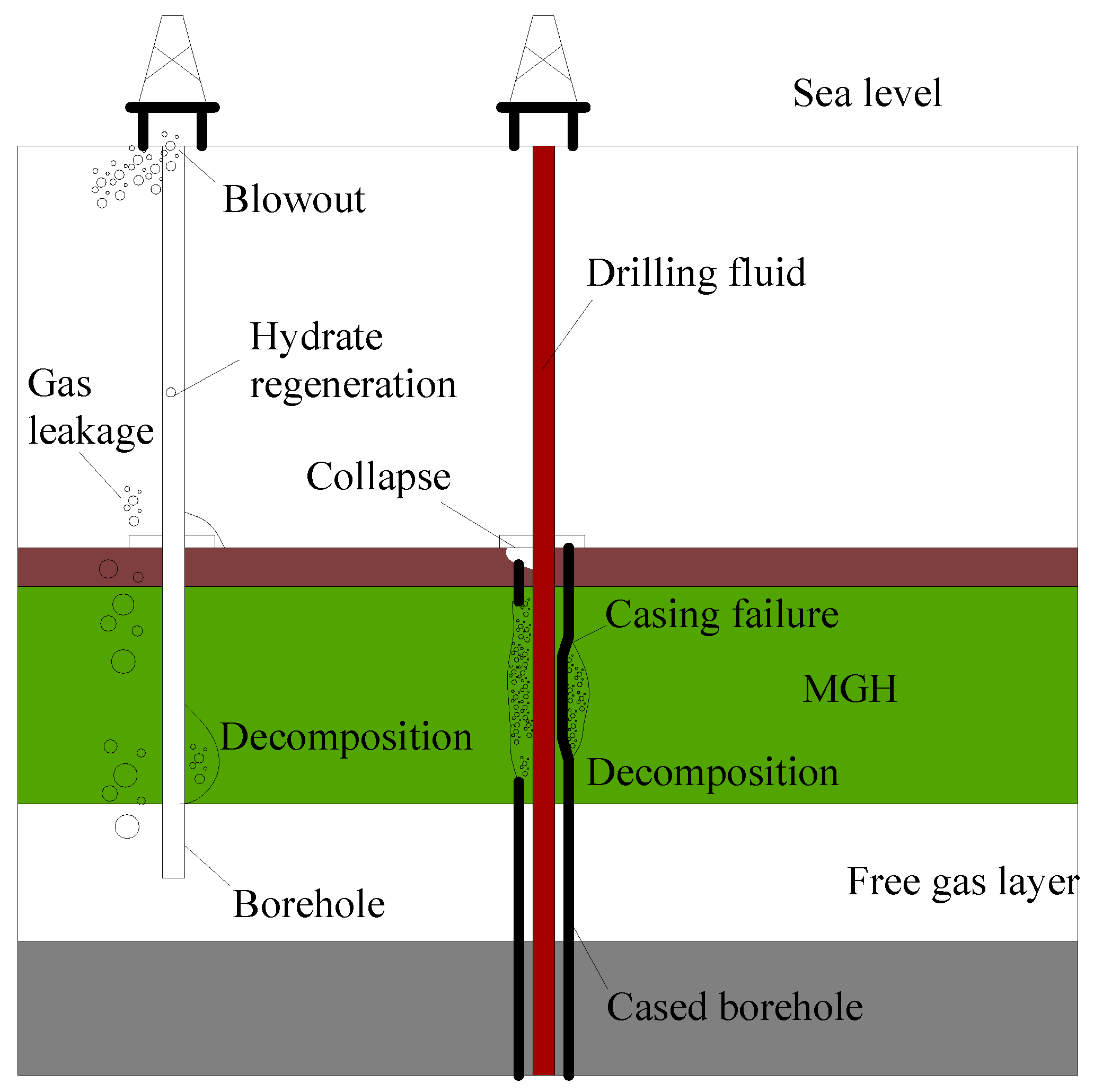

2.4. Marine Engineering Hazards

2.3.1. MGH Stability Hazards

2.3.2. Risks Associated with Drilling or Installing Structures in MGH Areas

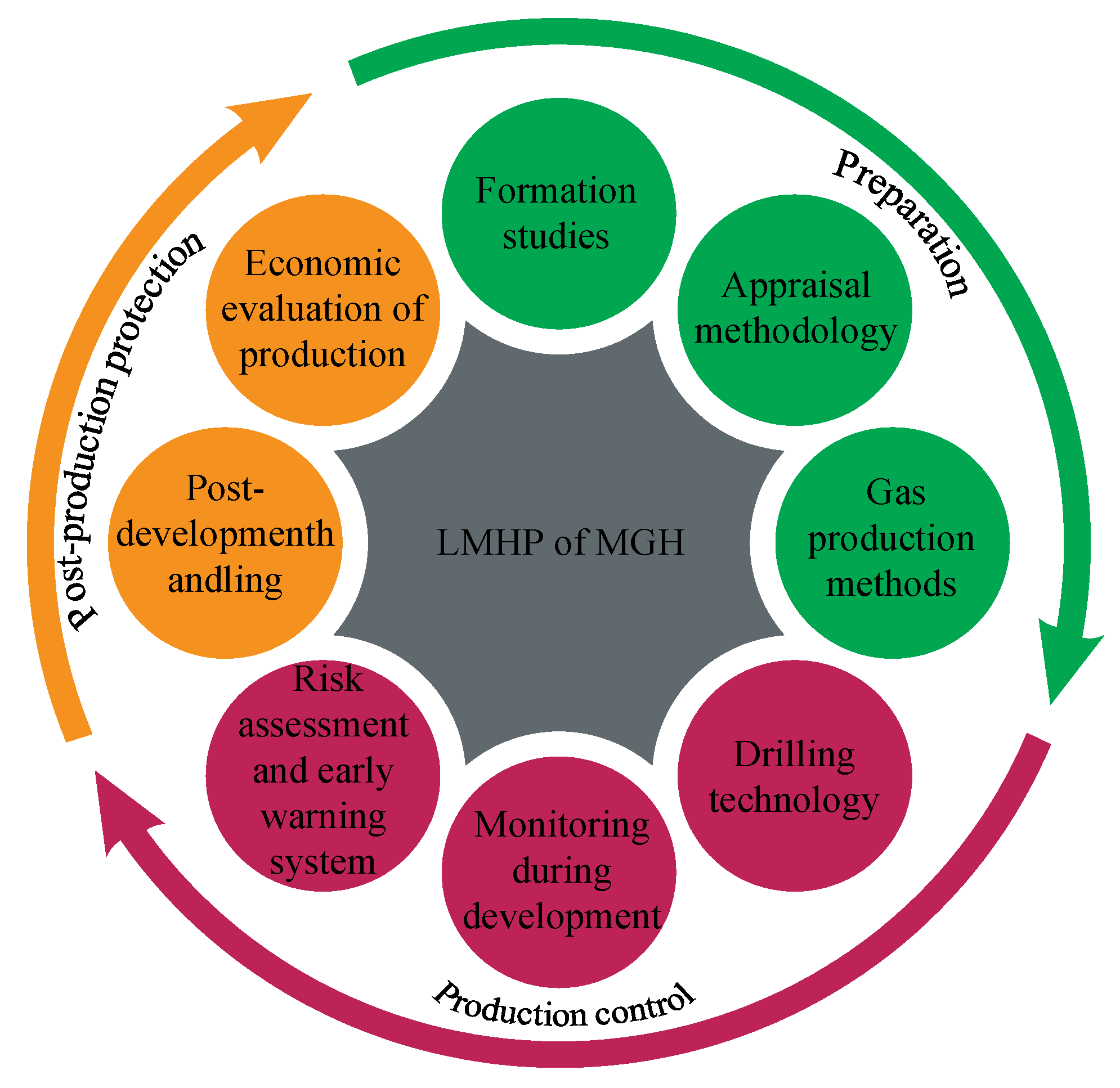

3. Control and Prevention of Potential Hazards in MGH Development

3.1. Preparation

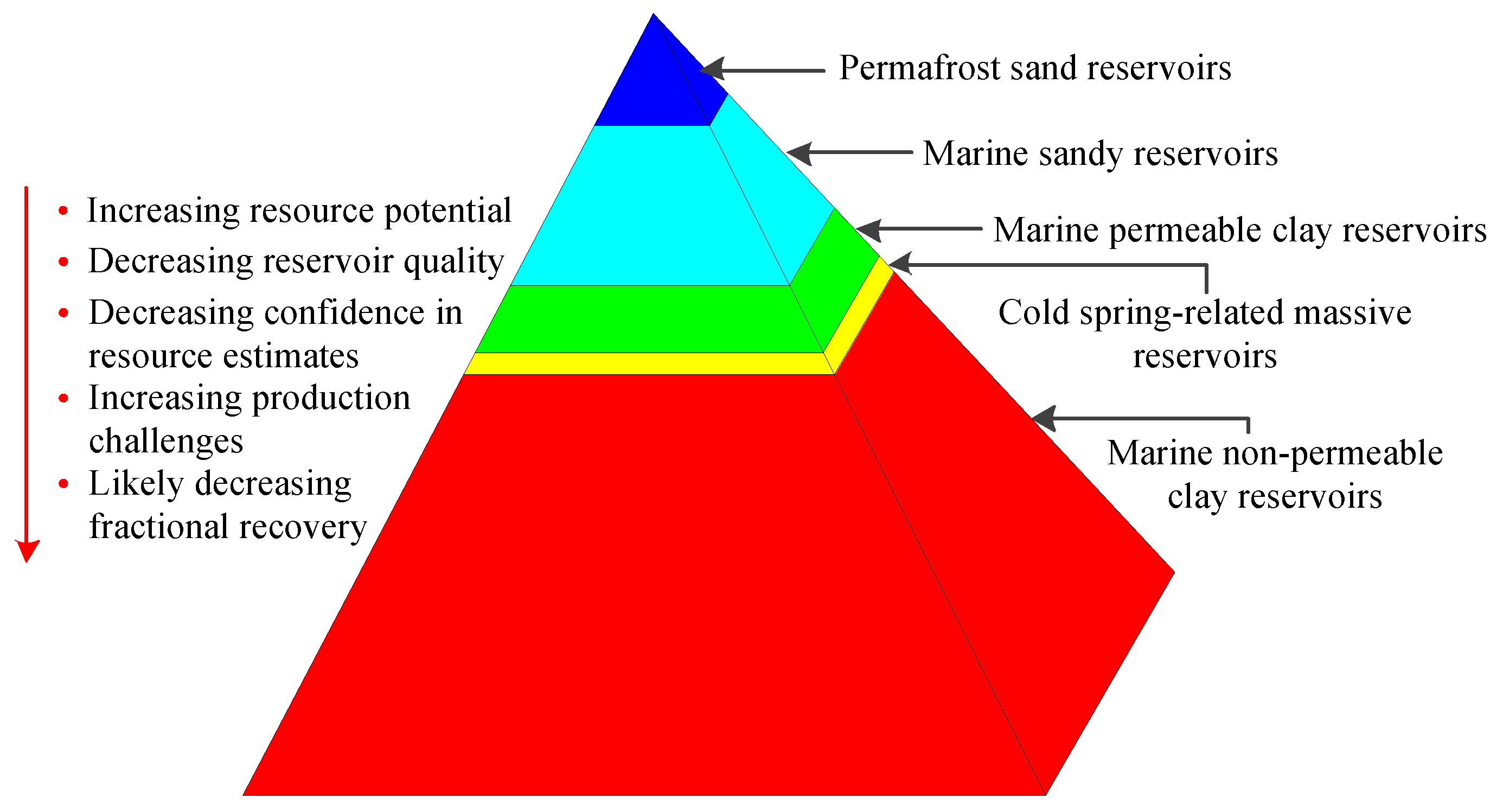

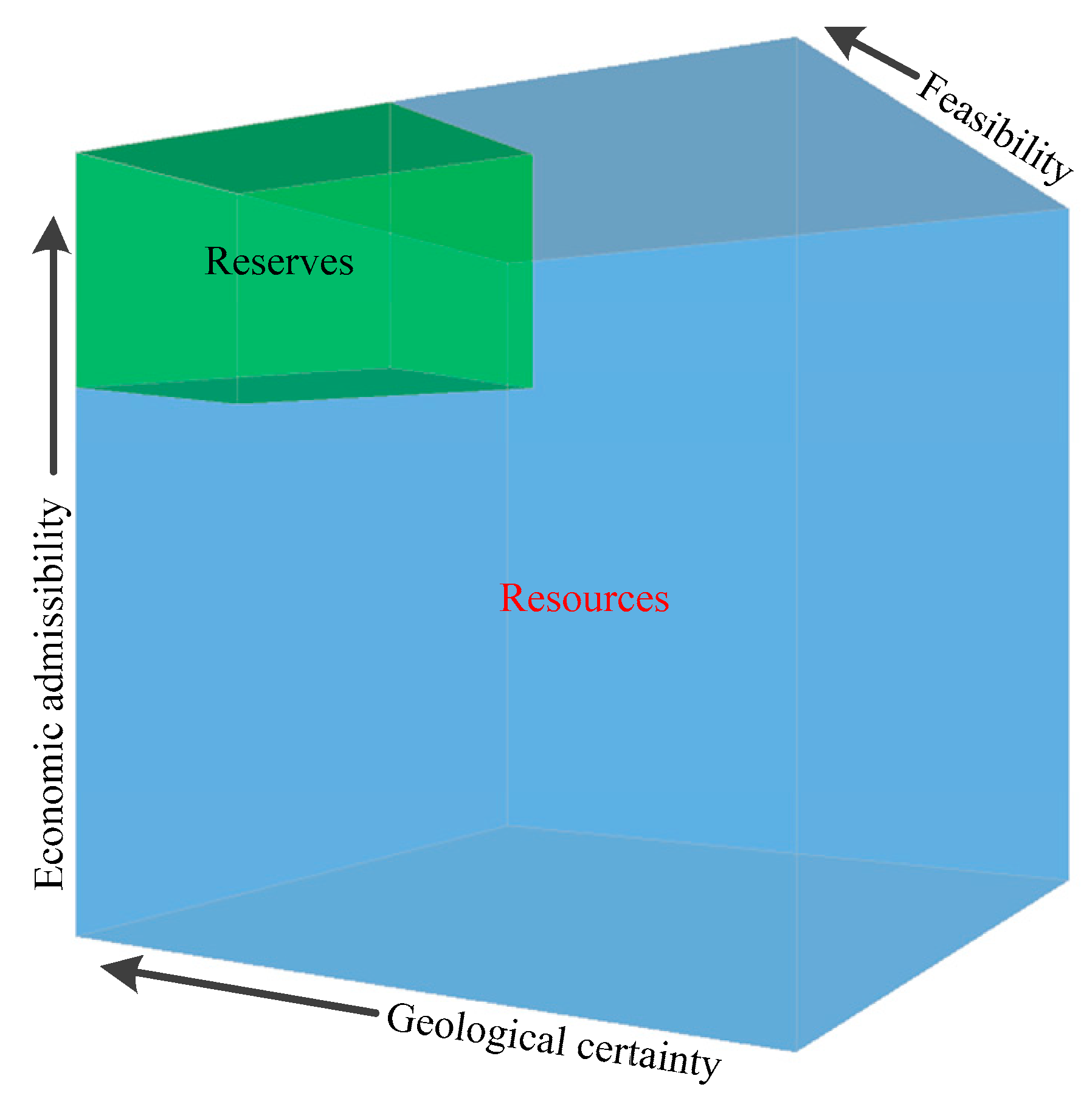

3.1.1. MGH Formation Studies

3.1.2. Appraisal Methodology

3.1.3. Gas Production Methods

- (1)

- Chemical agent injection, used in permafrost NGH developments, is expensive and toxic and application in MGH development will damage marine ecological environments.

- (2)

- Depressurization operations of MGHs do not require continuous operation so have lower costs, and are appropriate for large-scale production.

- (3)

- Thermal activation methods can be used in situations of complex geology; however, these methods require high levels of energy consumption as well as having low heat exchange efficiency.

- (4)

- CO2 replacement methods are environmentally friendly, but are technically difficult and require a steady supply of CO2.

- (5)

- Solid fluidization is only applicable to deep-sea reservoirs at shallow depths, with limited-diagenesis and poor cementation. It has only been applied in the Liwan area of the northern South China Sea [35].

3.2. Production Control

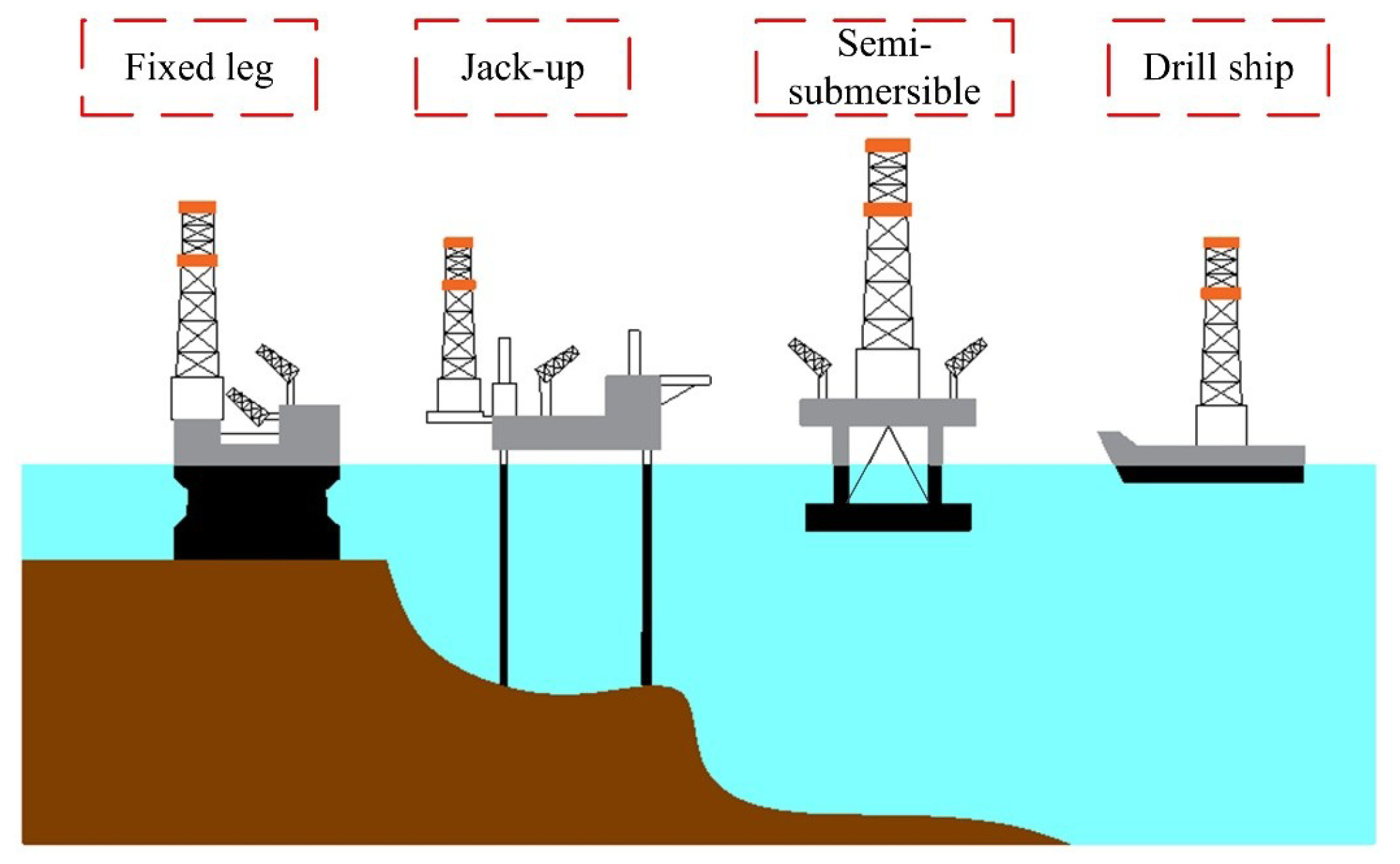

3.2.1. Drilling Technology Management

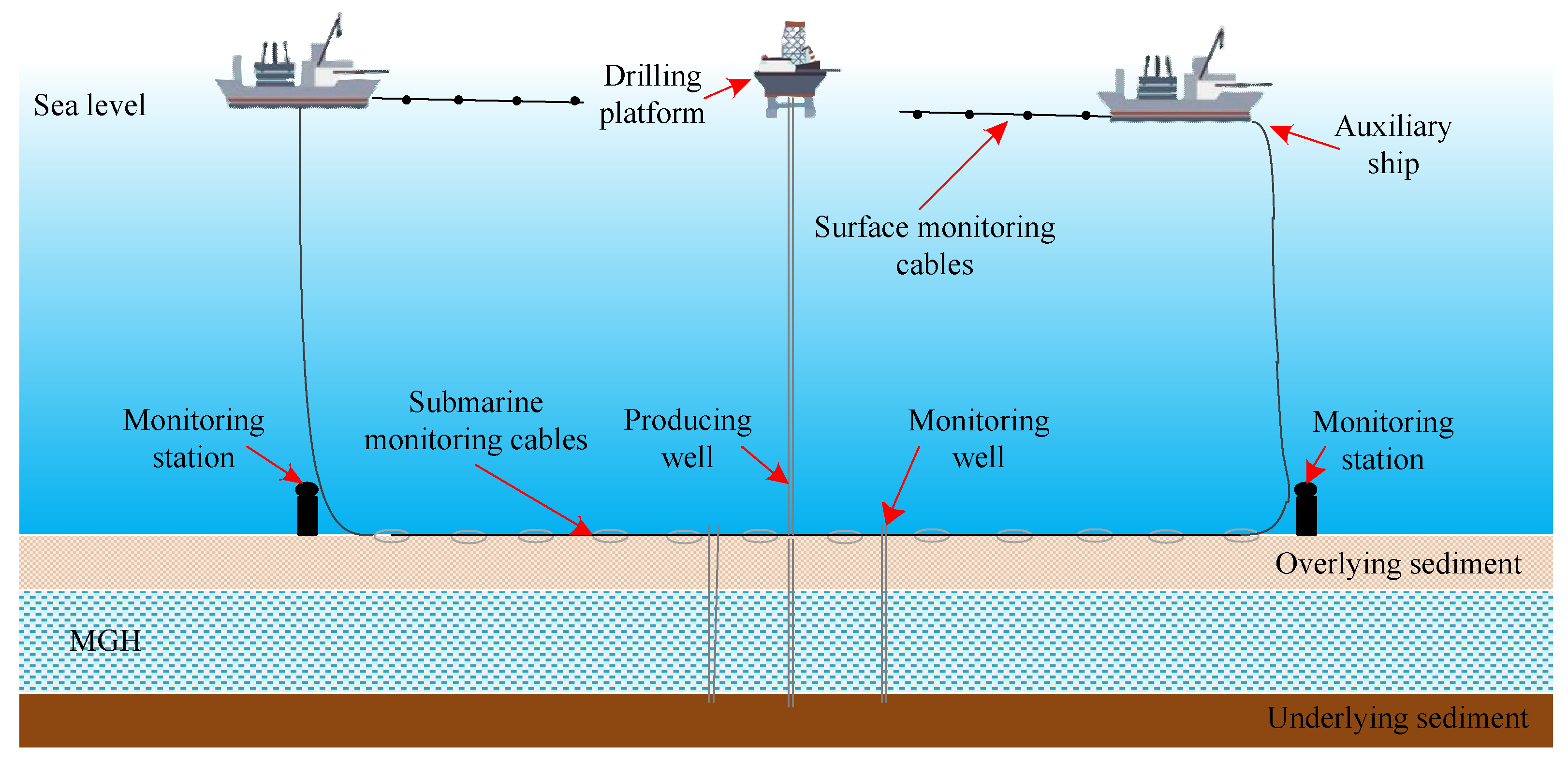

3.2.2. Monitoring during Development

3.2.3. Risk Assessment and Early Warning System

3.3. Post-Production Protection

3.3.1. Post-Development Handling

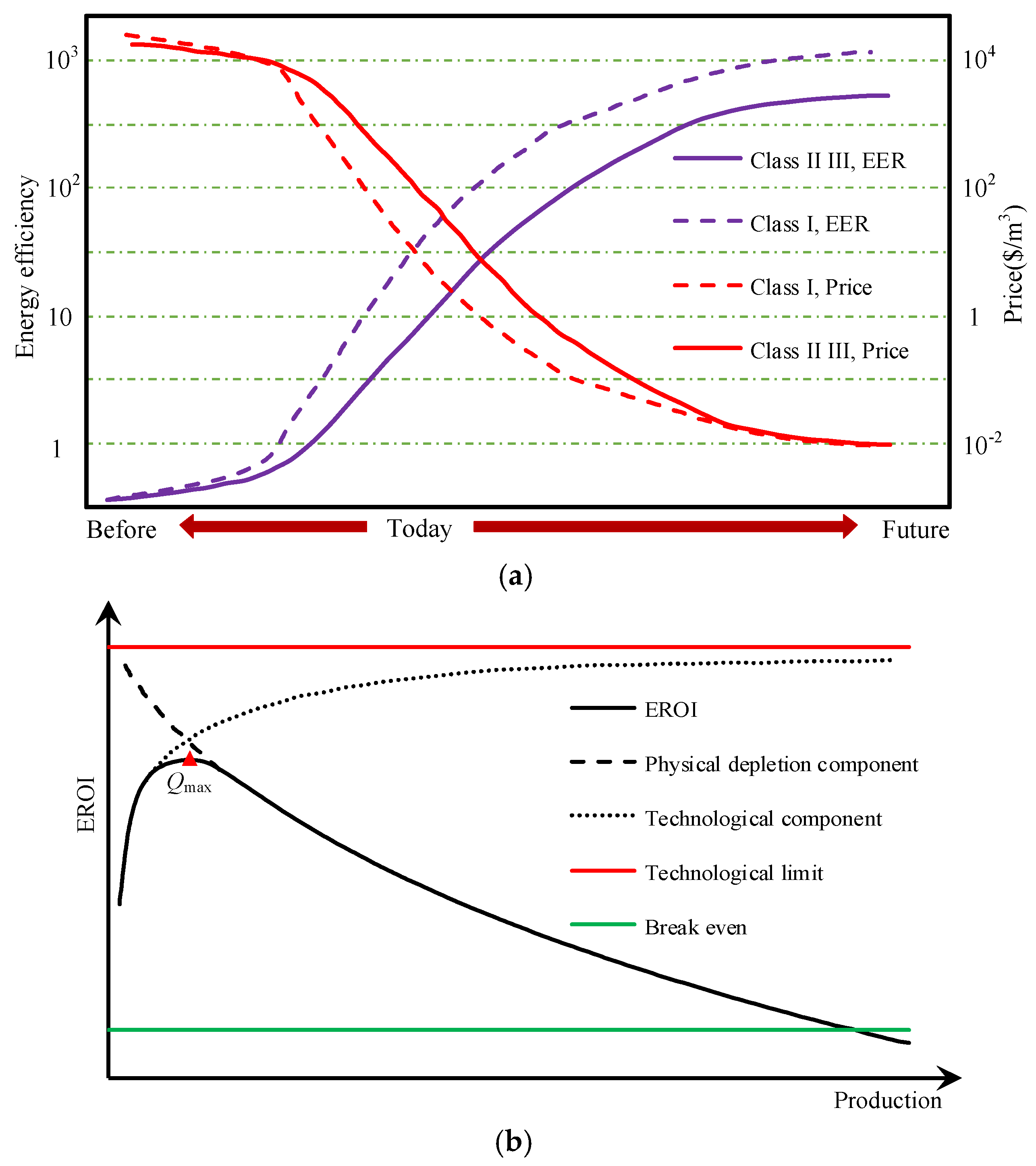

3.3.2. Economic Evaluation of Production

4. Key Challenges and Prospects

4.1. Key Challenges

4.2. Prospects

5. Conclusions

- (1)

- Four inter-related hazards which may occur during MGH exploitation were identified as follows: marine geohazards, greenhouse gas emissions, marine ecological hazards, and marine engineering hazards.

- (2)

- Lifecycle management of potential hazards prevention in the exploitation of MGHs (LMHP) was proposed firstly. It has three stages: preparation, which involves investigating the accumulation mechanism, appraisal methodology and gas production methods; production control, which includes drilling techniques, monitoring during production risk assessment and early warning system; and post-production protection, including post-production remediation and economic evaluation of production. All these factors are inter-related and need to be systematically evaluated.

- (3)

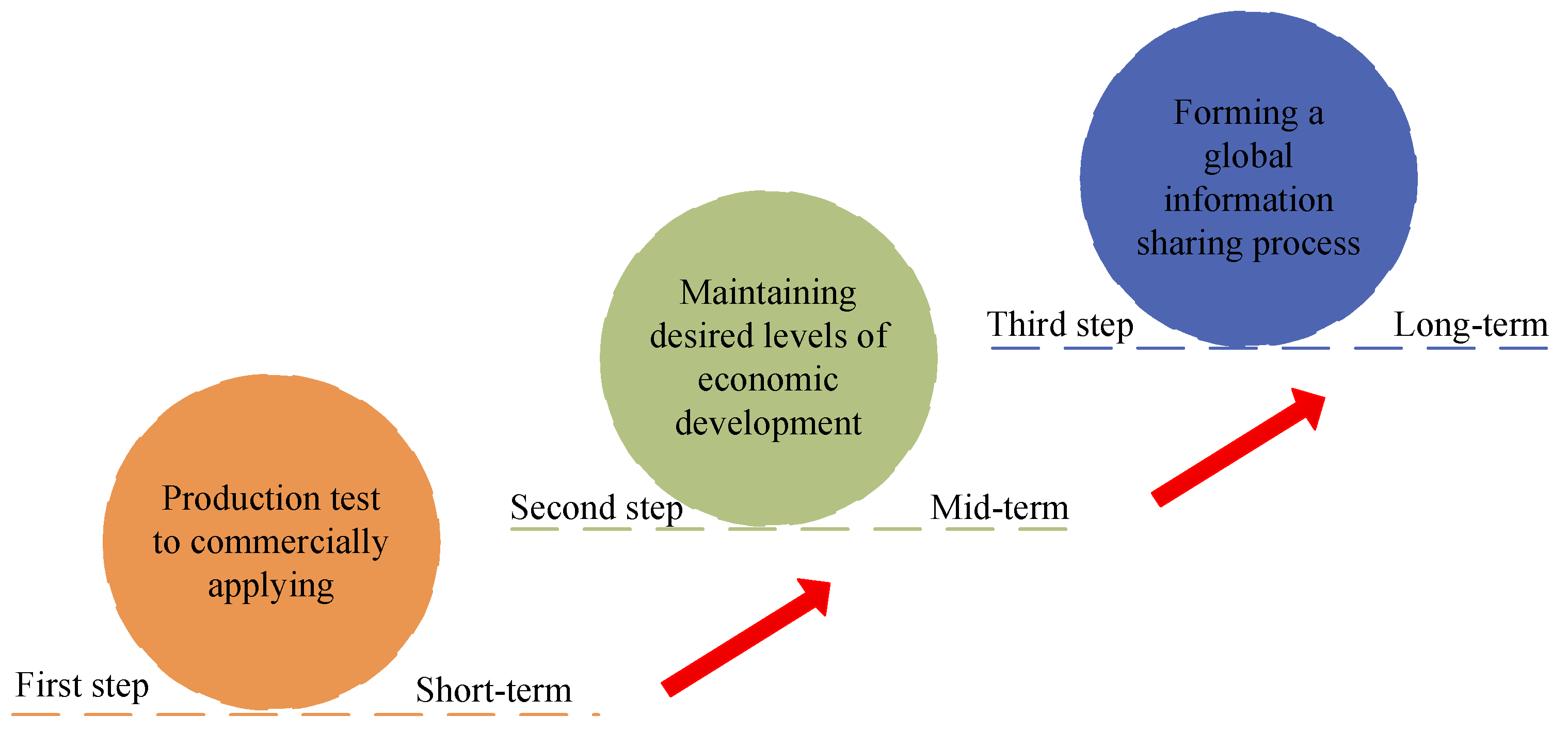

- A “three-step” strategy for the development of LMHP is proposed, which consists of commercially applying the results of MGH research in the short-term, maintaining desired levels of economic development in the mid-term and forming a global information sharing process associated with hydrate in the long-term. Understanding this “three step” strategy will allow the successful development of MGH resources.

- (4)

- The production test in the Shenhu area of the South China Sea showed that the development of MGHs is a complex and constantly changing problem with difficult challenges. Safe and efficient development and production of MGHs can be achieved by innovation and breakthroughs in the use of technology as well as through extensive international cooperation and exchange of information around the world.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- US Energy Information Administration (EIA). Annual Energy Outlook 2013; US Energy Information Administration: Washington, DC, USA, 2013; pp. 60–62.

- Chong, Z.R.; Yang, S.H.B.; Babu, P.; Linga, P.; Li, X.S. Review of natural gas hydrates as an energy resource: Prospects and challenges. Appl. Energy 2016, 162, 1633–1652. [Google Scholar] [CrossRef]

- Makogon, Y.F.; Trebin, F.A.; Trofimuk, A.A.; Tsarev, V.P.; Cherskiy, N.V. Detection of a pool of natural gas in a solid (hydrate gas) state. Dokl. Akad. Nauk. SSSR 1972, 196, 197–200. [Google Scholar]

- Trofimuk, A.A.; Chersky, N.V.; Tsaryov, V.P. The role of continental glaciation and hydrate formation on petroleum occurrence. In The Future Supply of Nature-Made Petroleum and Gas Technical Reports; Pergamon Press: Oxford, UK, 1977; pp. 919–926. [Google Scholar]

- Sloan, E.D. Gas Hydrates: Review of Physical/Chemical Properties. Energy Fuels 1998, 12, 191–196. [Google Scholar] [CrossRef]

- Xu, C.G.; Li, X.S. Research progress on methane production from natural gas hydrates. RSC Adv. 2015, 5, 54672–54699. [Google Scholar] [CrossRef]

- Beaudoin, Y.C.; Waite, W.; Boswell, R.; Dallimore, S.R. Frozen Heat: A UNEP Global Outlook on Methane Gas Hydrates; United Nations Environment Programme, GRID-Arendal: Arendal, Norway, 2014; p. 1. [Google Scholar]

- Makogon, Y.F. Natural gas hydrates—A promising source of energy. J. Nat. Gas Sci. Eng. 2010, 2, 49–59. [Google Scholar] [CrossRef]

- Boswell, R.; Collett, T.S. Current perspectives on gas hydrate resources. Energy Environ. Sci. 2011, 4, 1206–1215. [Google Scholar] [CrossRef]

- Wu, S.G.; Wang, J.L. On the China’s successful gas production test from marine gas hydrate reservoirs. Chin. Sci. Bull. 2018, 63, 2–8. [Google Scholar]

- Zhu, C.Q.; Zhang, M.S.; Liu, X.L.; Wang, Z.H.; Shen, Z.C.; Zhang, B.W.; Zhang, X.T.; Jia, Y.G. Gas hydrates: Production, geohazards and monitoring. J. Catastrophol. 2017, 32, 51–56. [Google Scholar]

- Li, X.S.; Xu, C.G.; Zhang, Y.; Ruan, X.K.; Li, G.; Wang, Y. Investigation into gas production from natural gas hydrate: A review. Appl. Energy 2016, 172, 286–322. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.W.; Chen, W.; Li, Q.P. The green solid fluidization development principle of natural gas hydrate stored in shallow layers of deep water. China Offshore Oil Gas 2014, 26, 1–7. [Google Scholar]

- Wu, N.Y.; Huang, L.; Hu, G.W.; Li, Y.L.; Chen, Q.; Liu, C.L. Geological controlling factors and scientific challenges for offshore gas hydrate exploitation. Mar. Geol. Quat. Geol. 2017, 37, 1–11. [Google Scholar]

- Fujii, T.; Suzuki, K.; Takayamaet, T.; Tamaki, M.; Komatsua, Y.; Konnoc, Y.; Yonedac, J.; Yamamotoa, K.; Nagaoc, J. Geological setting and characterization of a methane hydrate reservoir distributed at the first offshore production test site on the Daini-Atsumi Knoll in the eastern Nankai Trough, Japan. Mar. Pet. Geol. 2015, 66, 310–322. [Google Scholar] [CrossRef]

- Yamamoto, K.; Terao, Y.; Fujii, T.; Ikawa, T.; Seki, M.; Matsuzawa, M.; Kanno, T. Operational overview of the first offshore production test of methane hydrates in the Eastern Nankai Trough. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014. [Google Scholar]

- Collett, T.S.; Johnson, A.H.; Knapp, C.C.; Boswell, R. Natural gas hydrates: A review. Browse Collections 2009, 146–219. [Google Scholar] [CrossRef]

- Collett, T.S.; Lewis, R.E.; Winters, W.J.; Lee, M.W.; Rose, K.K.; Boswell, R.M. Downhole well log and core montages from the Mount Elbert gas hydrate stratigraphic test well, Alaska North Slope. Mar. Pet. Geol. 2011, 28, 561–577. [Google Scholar] [CrossRef]

- Wang, L.F.; Fu, S.Y.; Liang, J.Q.; Shang, J.J.; Wang, J.L. A review on gas hydrate developments propped by worldwide national projects. Geol. China 2017, 44, 439–448. [Google Scholar]

- Haeckel, M.; Bialas, J.; Klaucke, I.; Wallmann, K.; Bohrmann, G.; Schwalenberg, K. Gas hydrate occurrences in the Black Sea—New observations from the German SUGAR project. Fire Ice Methane Hydr. Newslett. 2015, 15, 6–9. [Google Scholar]

- Beeskow-Strauch, B.; Schicks, J.; Zimmer, M. Evaluation of CH4 Gas Permeation Rates through Silicone Membranes and Its Possible Use as CH4-Extractor in Gas Hydrate Deposits. Energies 2015, 8, 5090–5106. [Google Scholar] [CrossRef]

- Vanneste, M.; Sultan, N.; Garziglia, S.; Forsberg, C.F.; L’Heureux, J.S. Seafloor instabilities and sediment deformation processes: The need for integrated, multi-disciplinary investigations. Mar. Geol. 2014, 352, 183–214. [Google Scholar] [CrossRef]

- Maslin, M.; Owen, M.; Betts, R.; Day, S.; Jones, T.D.; Ridgwell, A. Gas hydrates: Past and future geohazard? Philos. Trans. R. Soc. Lond. A Math. Phys. Eng. Sci. 2010, 368, 2369–2393. [Google Scholar] [CrossRef] [PubMed]

- Kvalstad, T.J.; Andresen, L.; Forsberg, C.F.; Berg, K.; Bryn, P.; Wangen, M. The Storegga slide: Evaluation of triggering sources and slide mechanics. Mar. Pet. Geol. 2005, 12, 245–256. [Google Scholar] [CrossRef]

- Hornbach, M.J.; Lavier, L.L.; Ruppel, C.D. Triggering mechanism and tsunamogenic potential of the Cape Fear Slide complex, US Atlantic margin. Geochem. Geophys. Geosyst. 2007, 8, Q12008. [Google Scholar] [CrossRef]

- Qin, Z.L.; Wu, S.G.; Wang, Z.J.; Li, Q.P. Geohazards and risk of deepwater engineering induced by gas hydrate—A case study from oil leakage of deep water drilling well in GOM. Prog. Geophys. 2011, 26, 1279–1287. [Google Scholar]

- Cai, J.C.; Wei, W.; Hu, X.Y.; Liu, R.C.; Wang, J.J. Fractal characterization of dynamic fracture network extension in porous media. Fractals-Complex Geom. Patterns Scaling Nat. Soc. 2017, 25, 1750023. [Google Scholar] [CrossRef]

- Paull, C.K.; Iii, W.U.; Dallimore, S.R.; Blasco, S.M.; Lorenson, T.D.; Melling, H.; Medioli, B.E.; Nixon, F.M.; McLaughlin, F.A. Origin of pingo-like features on the Beaufort Sea shelf and their possible relationship to decomposing methane gas hydrates. Geophys. Res. Lett. 2007, 34, 223–234. [Google Scholar] [CrossRef]

- Jia, Y.G.; Zhu, C.Q.; Liu, L.P.; Wang, D. Marine geohazards: Review and future perspective. Acta Geol. Sin. 2016, 90, 1455–1470. [Google Scholar]

- He, J.; Liang, Q.Y.; Ma, Y.; Shi, Y.H.; Xiao, Z. Geohazards types and their distribution characteristics in the natural gas hydrate area on on the northern slope of the South China Sea. Geol. China 2018, 45, 15–28. [Google Scholar]

- Intergovernmental Panel on Climate Change. The Fourth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- Global Anthropogenic Non-CO2 Greenhouse Emissions: 1990–2020; Office of Atmospheric Programs Climate Change Division US Environmental Protection Agency: Washington, DC, USA, 2006.

- Sloan, E.D.; Koh, C. Clathrate Hydrates of Natural Gases; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Steffensen, J.P.; Andersen, K.K.; Bigler, M.; Clausenet, H.B.; Jensen, D.D. High-resolution Greenland ice core data show abrupt climate change happens in few years. Science 2008, 321, 680–684. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.; Zhang, J.H.; Yu, R.Z.; Lin, B.B.; Chen, L.Q.; Peng, Y.; Xiao, H.P. Review on natural gas hydrate in 2017. Sci. Technol. Rev. 2018, 36, 83–90. [Google Scholar]

- Zhang, J.X.; Ren, J.Y. Several important problems in the research of gas hydrates. Geol. Sci. Technol. Inf. 2001, 20, 44–48. [Google Scholar]

- Mestdagh, T.; Poort, J.; De Batist, M. The sensitivity of gas hydrate reservoirs to climate change: Perspectives from a new combined model for permafrost-related and marine settings. Earth-Sci. Rev. 2017, 169, 104–131. [Google Scholar] [CrossRef] [Green Version]

- Suess, E. Marine cold seeps and their manifestations: Geological control, biogeochemical criteria and environmental conditions. Int. J. Earth Sci. 2014, 103, 1889–1916. [Google Scholar] [CrossRef]

- James, R.H.; Bousquet, P.; Bussmann, I.; Haeckel, M.; Kipfer, R.; Leifer, I.; Niemann, H.; Ostrovsky, I.; Piskozub, J.; Rehder, G.; et al. Effects of climate change on methane emissions from seafloor sediments in the Arctic Ocean: A review. Limnol. Oceanogr. 2016, 61, S283–S299. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.L.; Sun, Z.L.; Wang, L.B.; Zhang, X.R.; Cao, H.; Huang, W.; Bai, F.L.; He, Y.J.; Zhang, X.L.; Zhai, B. Perspective of the environmental effect of natural gas hydrate system. Mar. Geol. Quat. Geol. 2016, 36, 1–13. [Google Scholar]

- Wang, S.H.; Song, H.B.; Yan, W. Environmental Effects of Natural Gas Hydrate. Bull. Miner. Pet. Geochem. 2004, 23, 160–165. [Google Scholar]

- Farrimond, P. Massive dissociation of gas hydrate during a Jurassic oceanic anoxic event. Nature 2000, 406, 392–395. [Google Scholar] [Green Version]

- Dickens, G.R.; O’Neil, J.R.; Rea, D.K.; Rea, D.K.; Owen, R.M. Dissociation of oceanic methane hydrate as a cause of the carbon isotope excursion at the end of the Paleocene. Paleoceanography 1995, 10, 965–971. [Google Scholar] [CrossRef]

- He, Y.; Tang, C.P.; Liang, D.Q. The potential risks of drilling in marine gas hydrate bearing sediments and the corresponding strategies. Adv. New Renew. Energy 2016, 4, 42–47. [Google Scholar]

- Ning, F.L.; Liu, L.; Li, S.; Zhang, K.; Jiang, G.S.; Wu, N.Y.; Sun, C.Y.; Chen, G.J. Well logging assessment of natural gas hydrate reservoirs and relevant influential factors. Acta Pet. Sin. 2013, 34, 591–606. [Google Scholar]

- Koh, C.A.; Sum, A.K.; Sloan, E.D. State of the art: Natural gas hydrates as a natural resource. J. Nat. Gas Sci. Eng. 2012, 8, 132–138. [Google Scholar] [CrossRef]

- Shipp, R.C. Gas Hydrates as a Geohazard: What Really Are the Issues? Shell International Exploration and Production Inc.: Houston, TX, USA, 2014. Available online: https://www.energy.gov/sites/prod/files/2014/04/f14/GH-as-Geohazards_MHAC-Galveston_27-mar-2014_final_0.pdf (accessed on 27 March 2014).

- Yie, J.L.; Yin, K.; Jiang, G.S.; Tang, F.L.; Dou, B. Key technique and countermeasures for natural gas hydrate drilling. Explor. Eng. 2003, 5, 45–48. [Google Scholar]

- Lu, J.S.; Li, D.L.; He, Y.; Liang, D.Q.; Xiong, Y.M. Research status of sand production during the gas hydrate exploitation process. Adv. New Renew. Energy 2017, 5, 394–402. [Google Scholar]

- Bai, Y.H.; Li, Q.P.; Zhou, J.L.; Liu, Y.H. The Potential Risk of Gas Hydrate to Deepwater Drilling and Production and the Corresponding Strategy. Pet. Drill. Tech. 2009, 37, 17–21. [Google Scholar]

- Wu, N.Y.; Liang, J.Q.; Wang, H.B.; Su, X.; Song, H.B.; Jiang, S.Y.; Zhu, Y.H.; Lu, Z.Q. Marine gas hydrate system: State of the Art. Geoscience 2008, 22, 356–362. [Google Scholar]

- Bu, Q.T.; Hu, G.W.; Ye, Y.G.; Liu, C.L.; Li, C.F.; Wang, J.S. Research Progress in Natural Gas Hydrate Accumulation System. Adv. New Renew. Energy 2015, 3, 435–443. [Google Scholar]

- Suzuki, K.; Schultheiss, P.; Nakatsuka, Y.; Ito, T.; Egawa, K.; Holland, M.; Yamamoto, K. Physical properties and sedimentological features of hydrate-bearing samples recovered from the first gas hydrate production test site on Daini-Atsumi Knoll around eastern Nankai Trough. Mar. Pet. Geol. 2015, 66, 346–357. [Google Scholar] [CrossRef]

- Yang, S.X.; Liang, J.Q.; Liu, C.L.; Sha, Z.B. Progresses of gas hydrate resources exploration in sea area. Geol. Surv. China 2017, 4, 1–8. [Google Scholar]

- Milkov, A.V. Worldwide distribution of submarine mud volcanoes and associated gas hydrates. Mar. Geol. 2000, 167, 29–42. [Google Scholar] [CrossRef]

- Milkov, A.V.; Sassen, R. Preliminary assessment of resources and economic potential of individual gas hydrate accumulations in the Gulf of Mexico continental slope. Mar. Pet. Geol. 2003, 20, 111–128. [Google Scholar] [CrossRef]

- Sun, Y.B.; Zhao, T.H.; Cai, F. Gas hydrate resource assessment abroad and its implications. Mar. Geol. Front. 2013, 29, 27–35. [Google Scholar]

- Collett, T.S. Gas Hydrate Petroleum Systems in Marine and Arctic Permafrost Environments; Gcssepm Proceedings: Houston, TX, USA, 2009; pp. 6–30. [Google Scholar]

- Veluswamy, H.P.; Kumar, R.; Linga, P. Hydrogen storage in clathrate hydrates: Current state of the art and future directions. Appl. Energy 2014, 122, 112–132. [Google Scholar] [CrossRef]

- Zhou, S.W.; Chen, W.; Li, Q.P.; Zhou, J.L.; Shi, H.S. Research on the solid fluidization well testing and production for shallow non-diagenetic natural gas hydrate in deep water area. China Offshore Oil Gas. 2017, 29, 1–8. [Google Scholar]

- Schoderbek, D.; Martinet, K.L.; Howard, J.; Silpngarmlert, S.; Hester, K. North slope hydrate field trial: CO2/CH4 exchange. In Proceedings of the OTC Arctic Technology Conference, Houston, TX, USA, 3–5 December 2012. [Google Scholar]

- Guang, X.J.; Wang, M.S. Key production test technologies for offshore natural gas hydrate. Pet. Drill. Tech. 2016, 44, 45–51. [Google Scholar]

- Wang, Y.; Feng, J.C.; Li, X.S.; Zhang, Y.; Han, H. Experimental Investigation on Sediment Deformation during Gas Hydrate Decomposition for Different Hydrate Reservoir Types. Energy Procedia 2017, 142, 4110–4116. [Google Scholar] [CrossRef]

- Oyama, A.; Masutani, S.M. A review of the methane hydrate program in Japan. Energies 2017, 10, 1447. [Google Scholar] [CrossRef]

- Song, Y.C.; Yang, L.; Zhao, J.F.; Liu, W.G.; Yang, M.J.; Li, Y.H.; Liu, Y.; Li, Q.P. The status of natural gas hydrate research in China: A review. Renew. Sustain. Energy Rev. 2014, 31, 778–791. [Google Scholar] [CrossRef]

- Liu, C.L.; Meng, Q.G.; Li, C.F.; Sun, J.Y.; He, X.L.; Yang, S.X.; Liang, J.Q. Characterization of natural gas hydrate and its deposits recovered from the northern slope of the South China Sea. Earth Sci. Front. 2017, 24, 41–50. [Google Scholar]

- He, T.; Lu, H.L.; Lin, J.Q.; Dong, Y.F.; He, J. Geophysical techniques of reservoir monitoring for marine gas hydrate exploitation. Earth Sci. Front. 2017, 24, 368–382. [Google Scholar]

- Zhang, X.; Du, Z.F.; Luan, Z.D.; Wang, X.J.; Xi, S.C.; Wang, B.; Li, L.F.; Lian, C.; Yan, J. In situ Raman detection of gas hydrates exposed on the seafloor of the South China Sea. Geochem. Geophys. Geosyst. 2017, 18, 3700–3713. [Google Scholar] [CrossRef]

- Liu, Z.X.; Feng, F.; Wang, J.B.; Hua, H.Y.; Wang, R.X. Application of Fuzzy Synthesis Assessment Method on Classification of Rock Mass in Mine. J. Wuhan Univ. Technol. 2014, 36, 129–134. [Google Scholar]

- Chen, J.; Wang, Y.H.; Lang, X.M.; Fan, S.S. Energy-efficient methods for production methane from natural gas hydrates. J. Energy Chem. 2017, 24, 552–558. [Google Scholar] [CrossRef]

- Kurihara, M.; Ouchi, H.; Narita, H.; Masuda, Y. Gas production from methane hydrate reservoirs. In Proceedings of the 7th International Conference on Gas Hydrates (ICGH), Edinburgh, UK, 17–21 July 2011; Volume 1721. [Google Scholar]

- Liu, C.L.; Li, Y.L.; Zhang, Y.; Sun, J.Y.; Wu, N.Y. Gas hydrate production test: From experimental simulation to field practice. Mar. Geol. Quat. Geol. 2017, 37, 12–26. [Google Scholar] [CrossRef]

- Ju, X.; Liu, F.; Fu, P. Vulnerability of Seafloor at Shenhu Area, South China Sea Subjected to Hydrate Dissociation. In Proceedings of the GeoShanghai International Conference, Shanghai, China, 27–30 May 2018; pp. 54–62. [Google Scholar]

| The First Index Ui (Ai) | The Second Index Uij (Aij) | The Third Index Uijk (Aijk) |

|---|---|---|

| Climate and environmental hazards U1 (A1) | Greenhouse gas U11 (A11) | — |

| Biocoenosis hazards U12 (A12) | ||

| Marine geohazards U2 (A2) | Submarine landslide U21 (A21) | — |

| Active fault U22 (A22) | ||

| Mud diaper U23 (A23) | ||

| Sea quake U24 (A24) | ||

| Turbidity current U25 (A25) | ||

| Marine engineering hazards U3 (A3) | Drilling engineering hazards U31 (A31) | Well blowout, leakage and borehole instability U311 (A311) |

| Sand production, well plugging and hydrate secondary generation U312 (A312) | ||

| Disused well U313 (A313) | ||

| Deep-sea drilling hydrate crossing and other accidents U32 (A32) | submarine line accidents U321 (A321) | |

| Oil-gas well accidents U322 (A322) | ||

| Note: the sum of Ai is 1 | Note: the sum of Aij is 1 (i is the same) | Note: the sum of Aijk is 1 (i, j all are the same) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Zhao, B.; Li, G. Prevention of Potential Hazards Associated with Marine Gas Hydrate Exploitation: A Review. Energies 2018, 11, 2384. https://doi.org/10.3390/en11092384

Wang F, Zhao B, Li G. Prevention of Potential Hazards Associated with Marine Gas Hydrate Exploitation: A Review. Energies. 2018; 11(9):2384. https://doi.org/10.3390/en11092384

Chicago/Turabian StyleWang, Fangtian, Bin Zhao, and Gang Li. 2018. "Prevention of Potential Hazards Associated with Marine Gas Hydrate Exploitation: A Review" Energies 11, no. 9: 2384. https://doi.org/10.3390/en11092384