Dynamic Efficiency Analysis of an Off-Shore Hydrocyclone System, Subjected to a Conventional PID- and Robust-Control-Solution

Abstract

:1. Introduction

2. Materials and Methods

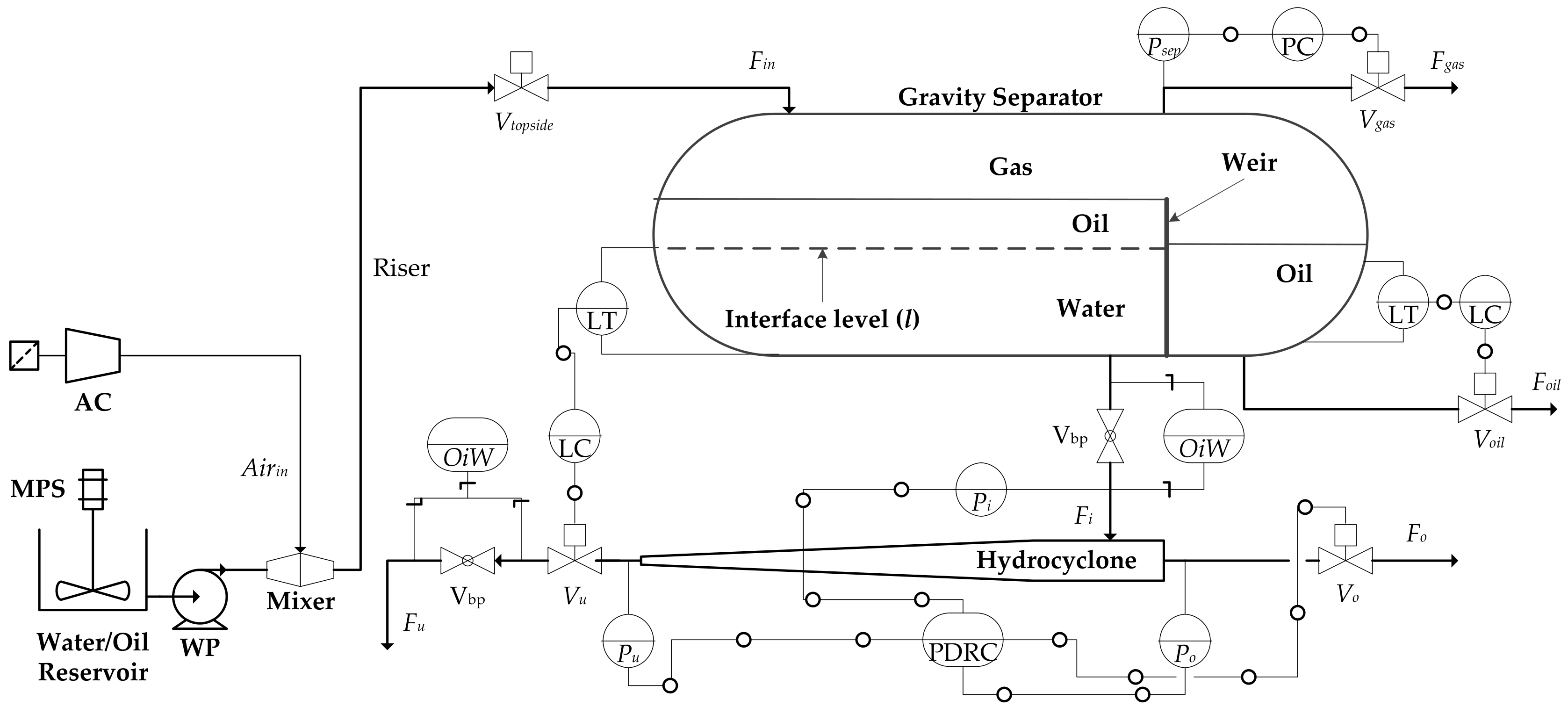

2.1. Pilot Plant

2.2. The Measurement of OiW

2.3. Oil-in-Water Mixture

3. Experiment Design

3.1. Dynamic-Tracking Capability

3.2. Controller Evaluation 1

3.3. Controller Evaluation 2

4. Results and Discussion

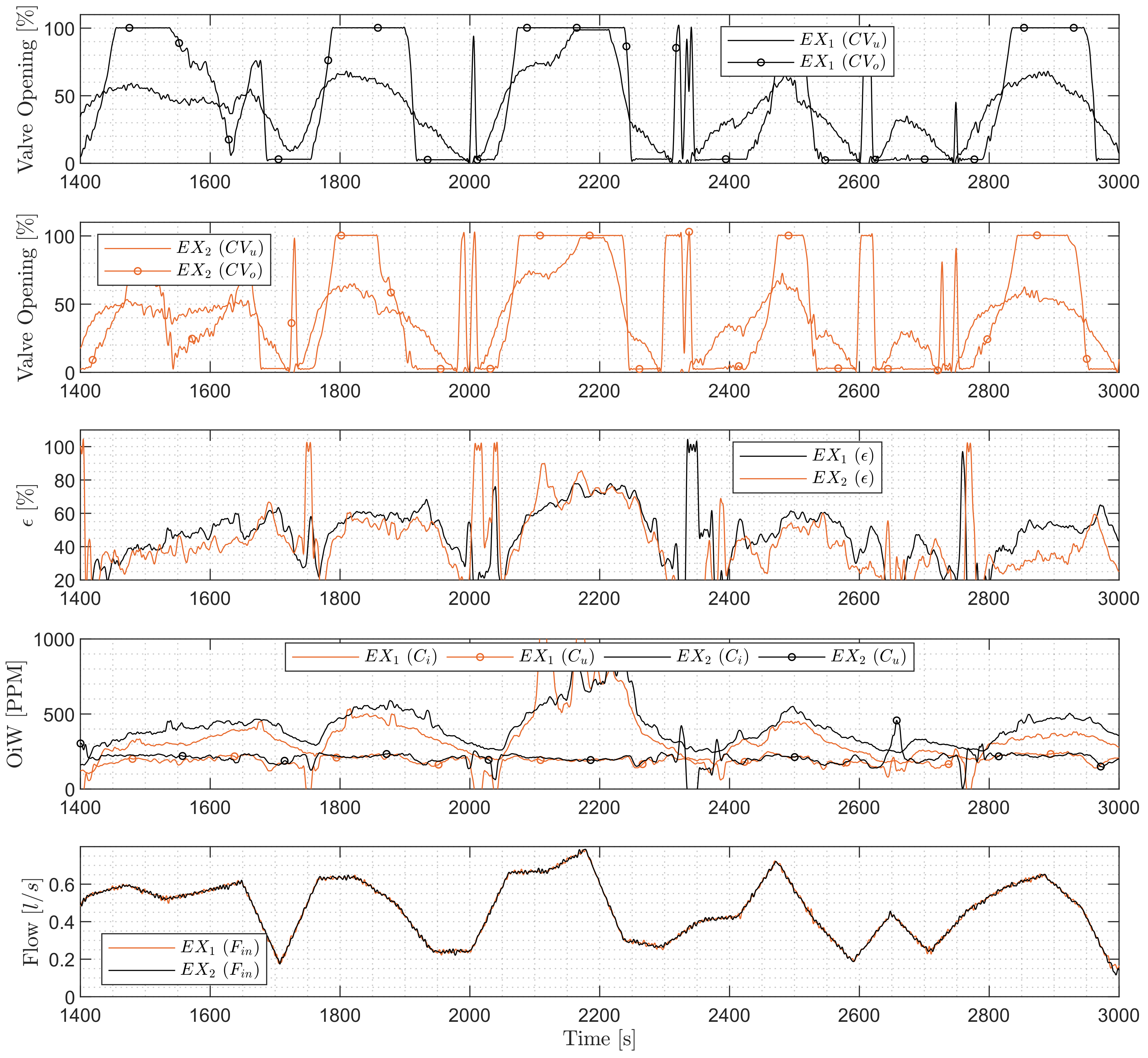

4.1. Experiment Discussion: Dynamic-Tracking Capability

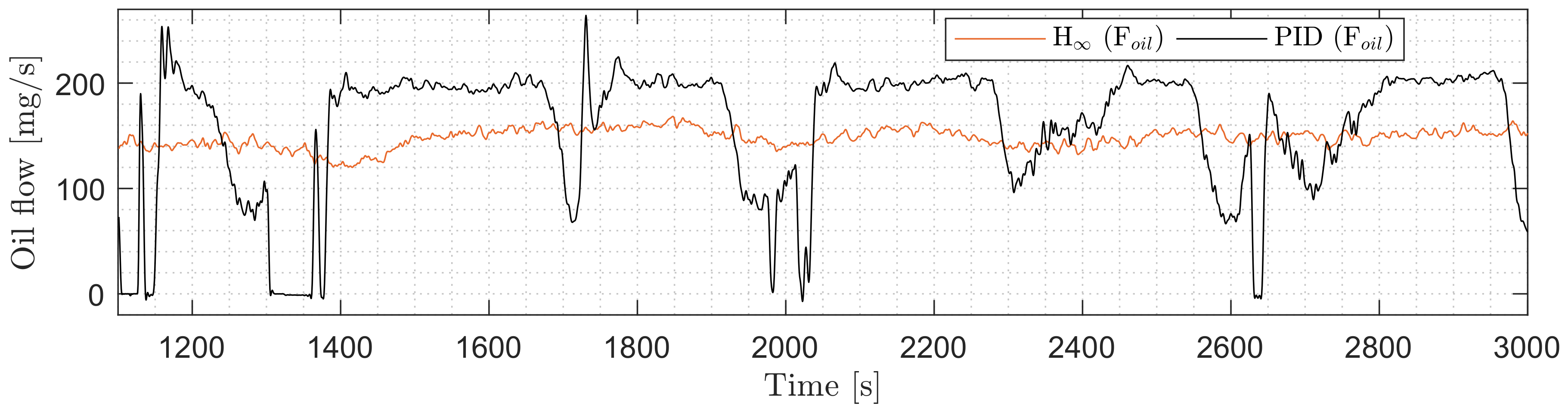

4.2. Experiment Discussion: Controller Evaluation With a Fluctuating Flow Rate

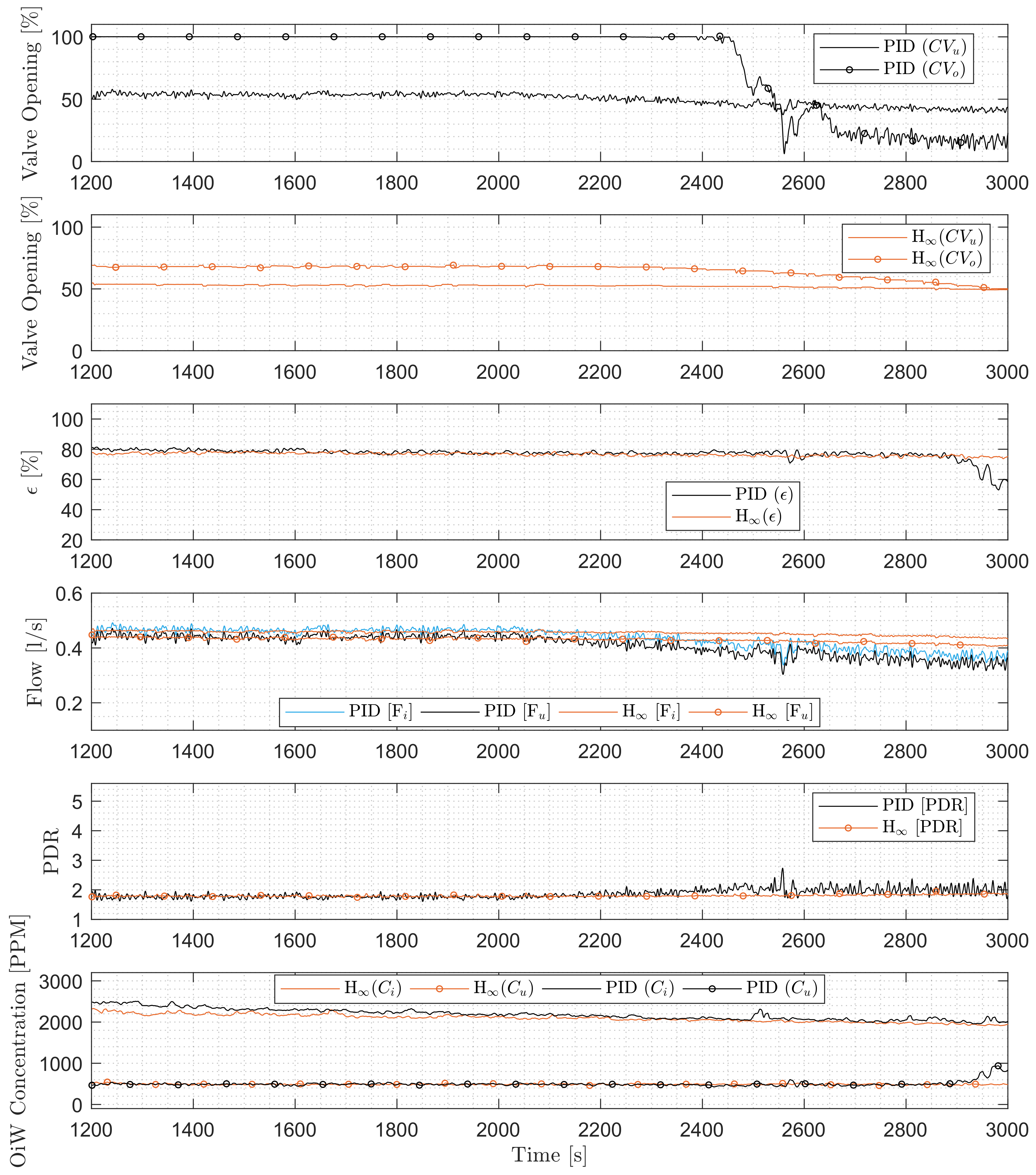

4.3. Experiment Discussion: Controller Evaluation With Constant Flow Rate Followed by a Linearly Decreasing Flow Rate

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| Name | Description | Unit |

| Inlet flow rate | L/s | |

| Separator gas outlet flow rate | m/s | |

| Hydrocyclone inlet flow rate | L/s | |

| Hydrocyclone underflow flow rate | L/s | |

| Hydrocyclone overflow flow rate | L/s | |

| Separator oil outlet flow rate | L/s | |

| Concentration of oil in the inlet | mg/L | |

| Concentration of oil in the underflow | mg/L | |

| Concentration of oil in the overflow | mg/L | |

| Concentration of water in the underflow | mg/L | |

| Concentration of water in the overflow | mg/L | |

| Separator pressure | bar | |

| Hydrocyclone inlet pressure | bar | |

| Hydrocyclone underflow pressure | bar | |

| Hydrocyclone overflow pressure | bar | |

| PDR | Hydrocyclone pressure drop ratio | - |

| Topside choke valve | % | |

| Separator gas outlet valve | % | |

| Separator oil outlet valve | % | |

| Hydrocyclone underflow valve | % | |

| Hydrocyclone overflow valve | % | |

| OIW instrument bypass valve | % | |

| OiWT | Oil-in-water transmitter | mg/L |

| OiW | Oil-in-water | - |

| Hydrocyclones de-oiling efficiency | % | |

| E | Hydrocyclones de-watering efficiency | % |

Appendix A. Analysis of the OiW Mixture’s Droplet Size Distribution

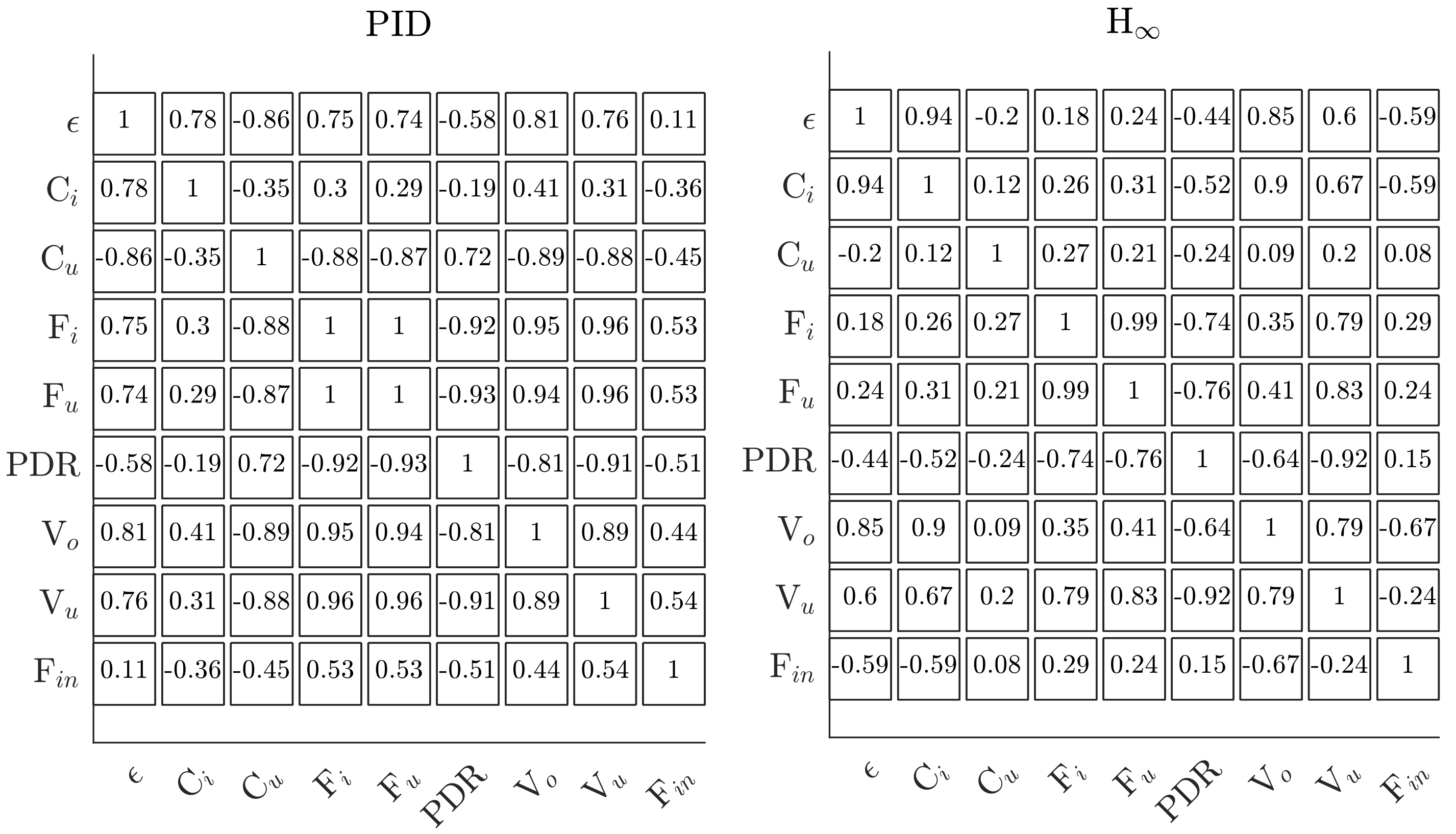

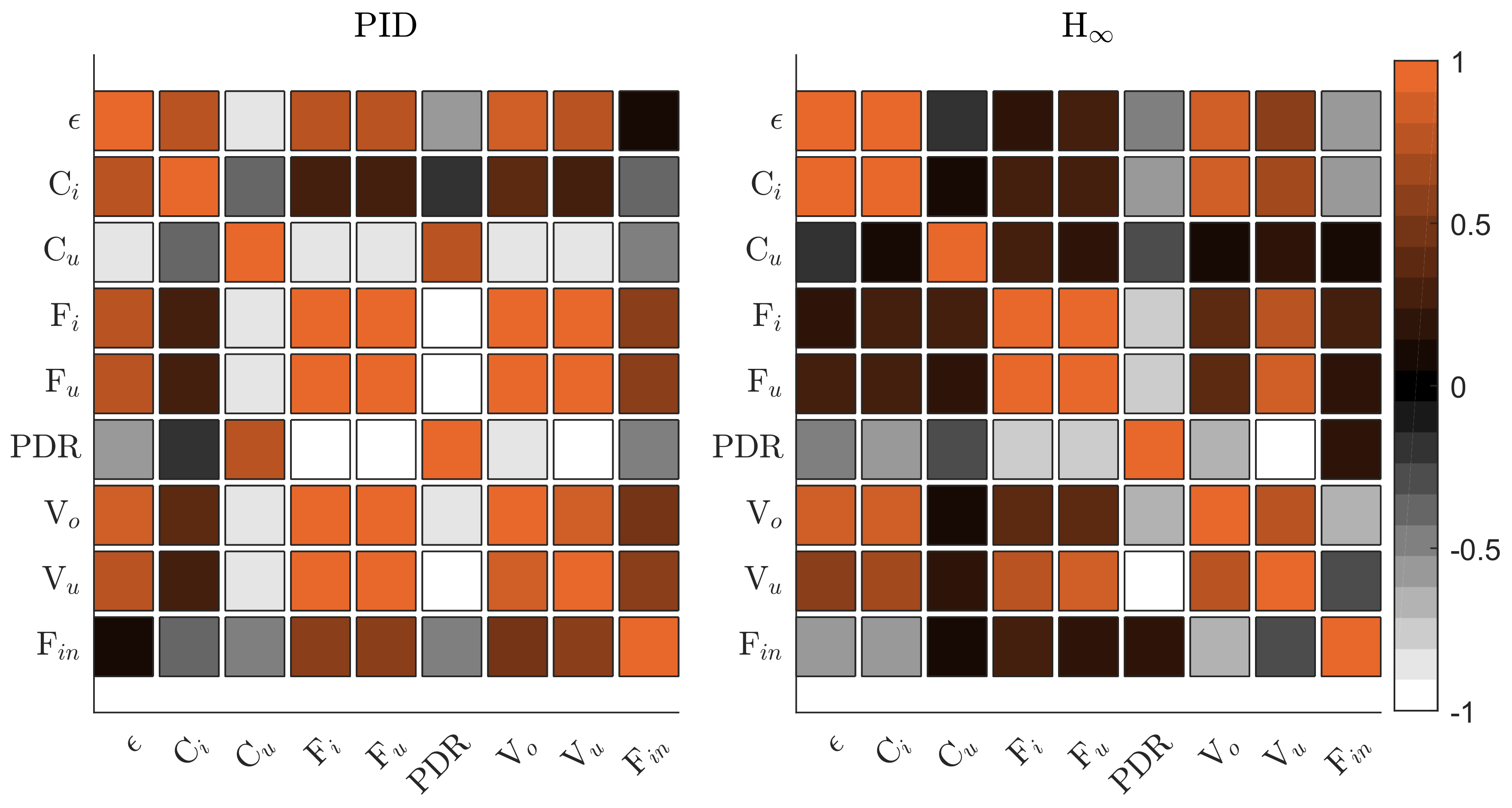

Appendix B. Correlation Analysis

References

- Stephenson, M. A survey of produced water studies. In Produced Water; Springer: Boston, MA, USA, 1992. [Google Scholar]

- Bailey, B.; Crabtree, M.; Tyrie, J.; Elphick, J.; Kuchuk, F.; Romano, C.; Roodhart, L. Water control. Oilfield Rev. 2000, 12, 30–51. [Google Scholar]

- Veil, J.A.; Puder, M.G.; Elcock, D.; Redweik, R.J., Jr. A white paper describing produced water from production of crude oil, natural gas, and coal bed methane. Argonne Nat. Lab. Tech. Rep. 2004, 63. [Google Scholar] [CrossRef]

- Peel, J.; Howarth, C.; Ramshaw, C. Process intensification: Higee seawater deaeration. Chem. Eng. Res. Des. 1998, 76, 585–593. [Google Scholar] [CrossRef]

- Emmerson. Reducing Size in Offshore Topsides Valve Automation. 2018. Available online: http://www2.emersonprocess.com/en-US/brands/bettis/featuredSolutions/Pages/bettisSY.aspx (accessed on 19 February 2018).

- Meldrum, N. Hydrocyclones: A Solution to Produced-Water Treatment. SPE Prod. Eng. 1988, 3, 669–676. [Google Scholar] [CrossRef]

- Svarovsky, L. Solid-liquid Separation; Elsevier: Oxford, UK, 2000. [Google Scholar]

- Svarovsky, L. Hydrocyclones. In Solid-Liquid Separation; Elsevier: Oxford, UK, 2001; pp. 191–245. [Google Scholar]

- Svarovsky, L.; Thew, M. Hydrocyclones: Analysis and Applications; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Thew, M. Hydrocyclone redesign for liquid-liquid separation. Chem. Eng. 1986, 427, 17–23. [Google Scholar]

- Thew, M.; Silk, S.; Colman, D. Determination and use of residence time distributions for two hydrocyclones. In Proceedings of the International Conference on Hydrocyclones, Churchill College, Cambridge, UK, 1–3 October 1980. [Google Scholar]

- Young, G.; Wakley, W.; Taggart, D.; Andrews, S.; Worrell, J. Oil-water separation using hydrocyclones: An experimental search for optimum dimensions. J. Pet. Sci. Eng. 1994, 11, 37–50. [Google Scholar] [CrossRef]

- Husveg, T.; Rambeau, O.; Drengstig, T.; Bilstad, T. Performance of a deoiling hydrocyclone during variable flow rates. Min. Eng. 2007, 20, 368–379. [Google Scholar] [CrossRef]

- Husveg, T. Operational Control of Deoiling Hydrocyclones and Cyclones for Petroleum Flow Control. Ph.D. Thesis, University of Stavanger, Stavanger, Norway, 2007. [Google Scholar]

- Durdevic, P.; Pedersen, S.; Yang, Z. Challenges in Modelling and Control of Offshore De-oiling Hydrocyclone Systems. J. Phys. Conf. Ser. 2017, 783. [Google Scholar] [CrossRef]

- Wolbert, D.; Ma, B.F.; Aurelle, Y.; Seureau, J. Efficiency estimation of liquid-liquid Hydrocyclones using trajectory analysis. AIChE J. 1995, 41, 1395–1402. [Google Scholar] [CrossRef]

- Durdevic, P. Real-Time Monitoring and Robust Control of Offshore De-oiling Processes. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2017. [Google Scholar]

- Durdevic, P.; Yang, Z. Application of H∞ Robust Control on a Scaled Offshore Oil and Gas De-Oiling Facility. Energies 2018, 11, 287. [Google Scholar] [CrossRef]

- Husveg, T.; Johansen, O.; Bilstad, T. Operational Control of Hydrocyclones During Variable Produced Water Flow Rates—Frøy Case Study. SPE Prod. Oper. 2007, 22, 294–300. [Google Scholar]

- Thew, M.T. Cyclones for oil/water separation. In Encyclopaedia of Separation Science, 4th ed.; Academic Press: Cambridge, MA, USA, 2000; pp. 1480–1490. [Google Scholar]

- Simms, K.; Zaidi, S.; Hashmi, K.; Thew, M.; Smyth, I. Testing of the vortoil deoiling hydrocyclone using Canadian offshore crude oil. In Hydrocyclones; Springer: Dordrecht, The Netherlands, 1992; pp. 295–308. [Google Scholar]

- Durdevic, P.; Raju, C.S.; Bram, M.V.; Hansen, D.S.; Yang, Z. Dynamic Oil-in-Water Concentration Acquisition on a Pilot-Scaled Offshore Water-Oil Separation Facility. Sensors 2017, 17, 124. [Google Scholar] [CrossRef] [PubMed]

- Miljoestyrelsen. Generel Tilladelse for Mærsk Olie og Gas A/S (Mærsk Olie) Tilanvendelse, Udledning Oganden Bortskaffelse af Stoffer og Materialer, Herunder Olie og Kemikalier i Produktions-og Injektionsvand Fraproduktionsenhederne Halfdan, Dan, Tyra og Gorm for Perioden 1. Januar 2017–31. December 2018. Available online: https://mst.dk/media/92144/20161221-ann-generel-udledningstilladelse-for-maersk-olie-og-gas-2017-18.pdf (accessed on 12 June 2018).

- Hall, O.; SchrØder, C. Mærsk Afviser Kritik: Vores Olieforurening er Minimal. 2018. Available online: https://www.dr.dk/nyheder/penge/maersk-afviser-kritik-vores-olieforurening-er-minimal (accessed on 7 September 2018).

- OSPAR Commission, about OSPAR. 2018. Available online: https://www.ospar.org/about (accessed on 10 January 2018).

- Methodology for the Sampling and Analysis of Produced Water and Other Hydrocarbon Discharges. 2016. Available online: https://www.gov.uk/guidance/oil-and-gas-offshore-environmental-legislation (accessed on 3 November 2016).

- Storkaas, E.; Skogestad, S.; Godhavn, J.M. A low-dimensional dynamic model of severe slugging for control design and analysis. In Proceedings of the 11th International Conference on Multiphase Flow (Multiphase03), San Remo, Italy, 11–13 June 2003; pp. 117–133. [Google Scholar]

- Ogazi, A.I. Multiphase Severe Slug Flow Control. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2011. [Google Scholar]

- Yang, Z.; Stigkær, J.P.; Løhndorf, B. Plant-wide control for better de-oiling of produced water in offshore oil & gas production. IFAC-papersonline 2013, 3, 45–50. [Google Scholar] [CrossRef]

- VORTOIL Deoiling Hydrocyclones. 2018. Available online: http://www.slb.com/~/media/Files/processing-separation/product-sheets/vortoil-ps.pdf (accessed on 5 July 2018).

- Rietema, K.; Maatschappij, S.I.R. Performance and design of hydrocyclones—III: Separating power of the hydrocyclone. Chem. Eng. Sci. 1961, 15, 310–319. [Google Scholar] [CrossRef]

- Bram, M.V.; Hansen, L.; Hansen, D.S.; Yang, Z. Hydrocyclone Separation Efficiency Modeled by Flow Resistances and Droplet Trajectories. IFAC-papersonline 2018, 51, 132–137. [Google Scholar] [CrossRef]

- Nezhati, K.; Roth, N.; Gaskin, R. “On-line determination of particle size and concentration (solids and oil) using ViPA Analyser-A way forward to control subsea separators ”presented at the IBC Production Separation Systems Conference. In Proceedings of the 7th Annual International Forum-Production Separation Systems, London, UK, 13–14 June 2001. [Google Scholar]

- Bradley, H.B. Petroleum Engineering Handbook; U.S. Department of Energy Office of Scientific and Technical Information (OSTI): Washington, DC, USA, 1987.

- Hansen, L.; Durdevic, P.; Jepsen, K.L.; Yang, Z. Plant-wide Optimal Control of an Offshore De-oiling Process Using MPC Technique. IFAC-PapersOnLine 2018, 51, 144–150. [Google Scholar] [CrossRef]

- Yang, M. Measurement of oil in produced water. In Produced Water; Springer: New York, NY, USA, 2011. [Google Scholar]

- Jorin Particle Detection. 2018. Available online: http://www.jorin.co.uk/technology/detection/ (accessed on 14 June 2018).

| Name | Type | Description | Range/size |

|---|---|---|---|

| WP | Grundfos CRNE 3 | Centrifugal water feed pump | 1 L/s at 162.7 m, max 25 bar |

| H | Vortoil liner | Up to 2 industrial hydrocyclone liners | 1.4” |

| Siemens Sitrans P200 | Piezo-resistive pressure measuring cell | (0–16) bar | |

| AC | — | Air compressor | 8.5 bar |

| LT | Rosemount 3051SAL | Scalable Level Transmitter | 6 mHO @4C-g |

| Rosemount 8732 | Electromagnetic flow transmitter | DN50 (0–25.97) L/s @ 12 m/s | |

| Bailey-Fischer-Porter 10DX4311C | Electromagnetic flow transmitter | DN15 (0–1.64) L/s | |

| Micro-Motion Coriolis Elite (CMFS010) | Coriolis flow transmitter | DN10 L/s | |

| Turner-Design TD-4100XDC | Fluorescence measurement OiW monitor | (0 ppb–5000 ppm) | |

| MPS | Milton Roy Mixing, 77212 AVON Cedex, FRANCE | Motorized Propeller Stirrer | 750/h, 1.1 KW, 137 RPM, Propeller D = 550 mm |

| Tank | Custom made | Stainless steel tank | 3 m |

| Bürkert 2301+8696 | Pneumatic Globe valve | mm mm | |

| Bürkert 2301+8696 | Pneumatic Globe valve | mm mm | |

| Bürkert 8626 | Mass flow controller | 20–1500 /min, @ 1.013 bar and 0 C |

| Name | Type | Description | Company |

|---|---|---|---|

| Oil | MIDLAND NON DETERGENT 30 | SAE 30 API SB | Oel-Brack AG |

| Air | From compressor | ≈8 bars | – |

| Water | From tap | ≈23.5 C | – |

| Experiment Name | Aim |

|---|---|

| Dynamic-Tracking Capability | Evaluate the instruments dynamic and static performance |

| Controller Evaluation 1 | Evaluate the de-oiling efficiency () during fluctuating flow |

| Controller Evaluation 2 | Evaluate the instruments dynamic and static performance |

| Controller | Amount | Unit |

|---|---|---|

| PID control solution [] | 827.46 | L |

| H control solution [] | 714.73 | L |

| PID control solution [] | 0.302 | kg |

| H control solution [] | 0.281 | kg |

| PID control solution [] | 78.92 | % |

| H control solution [] | 71.8 | % |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durdevic, P.; Yang, Z. Dynamic Efficiency Analysis of an Off-Shore Hydrocyclone System, Subjected to a Conventional PID- and Robust-Control-Solution. Energies 2018, 11, 2379. https://doi.org/10.3390/en11092379

Durdevic P, Yang Z. Dynamic Efficiency Analysis of an Off-Shore Hydrocyclone System, Subjected to a Conventional PID- and Robust-Control-Solution. Energies. 2018; 11(9):2379. https://doi.org/10.3390/en11092379

Chicago/Turabian StyleDurdevic, Petar, and Zhenyu Yang. 2018. "Dynamic Efficiency Analysis of an Off-Shore Hydrocyclone System, Subjected to a Conventional PID- and Robust-Control-Solution" Energies 11, no. 9: 2379. https://doi.org/10.3390/en11092379