A 120 W Class-E Power Module with an Adaptive Power Combiner for a 6.78 MHz Wireless Power Transfer System

Abstract

:1. Introduction

2. Design of the Class-E Power Module

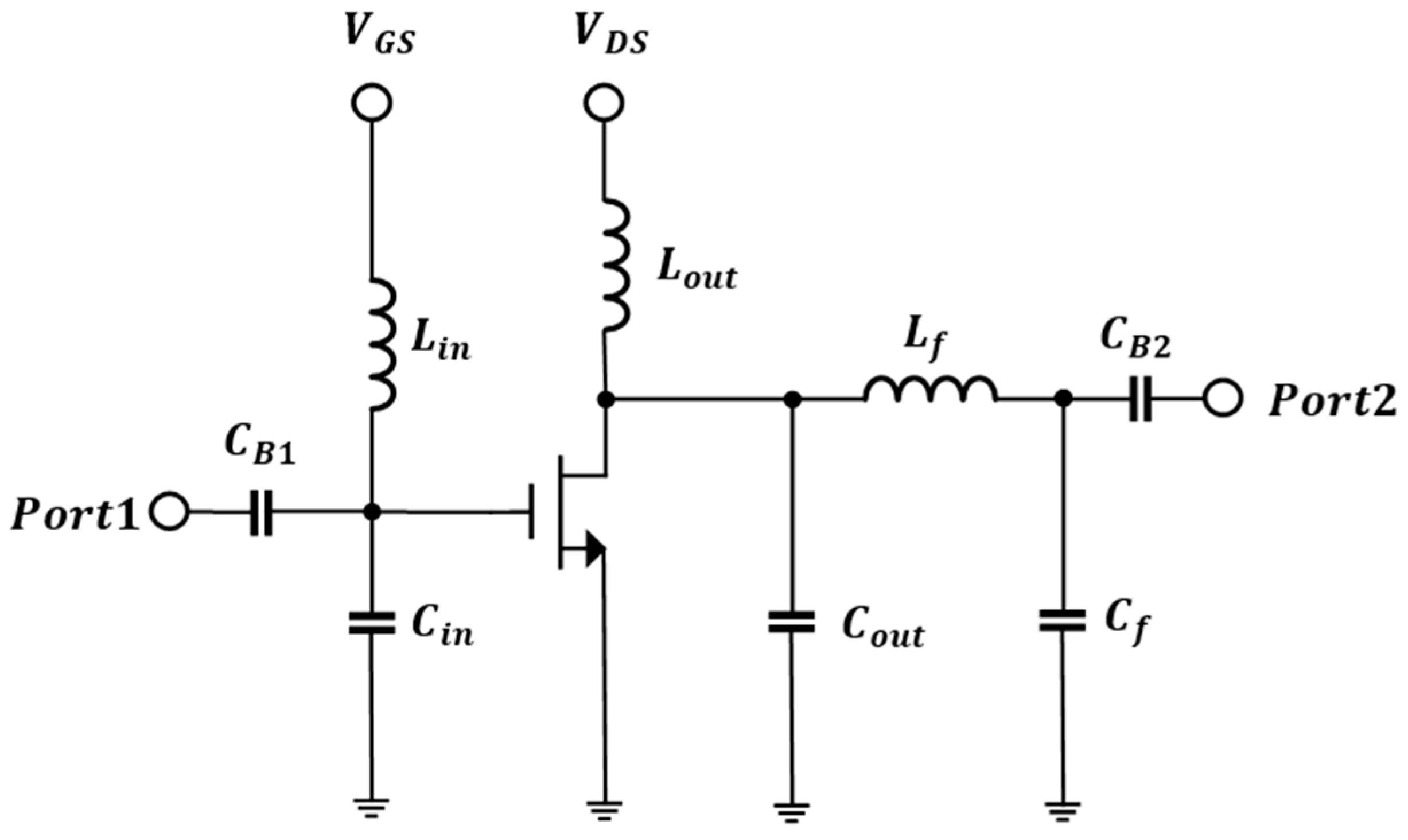

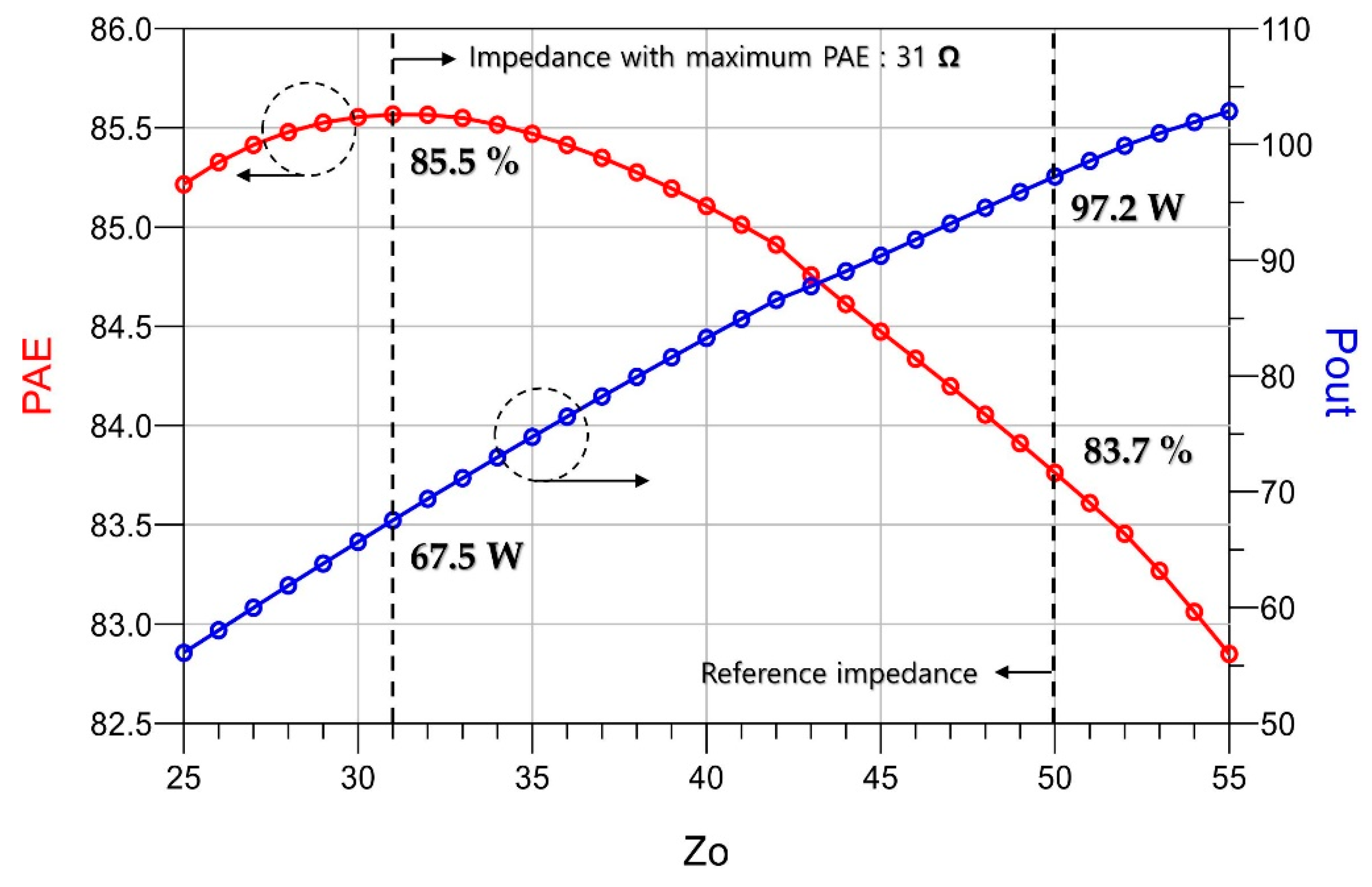

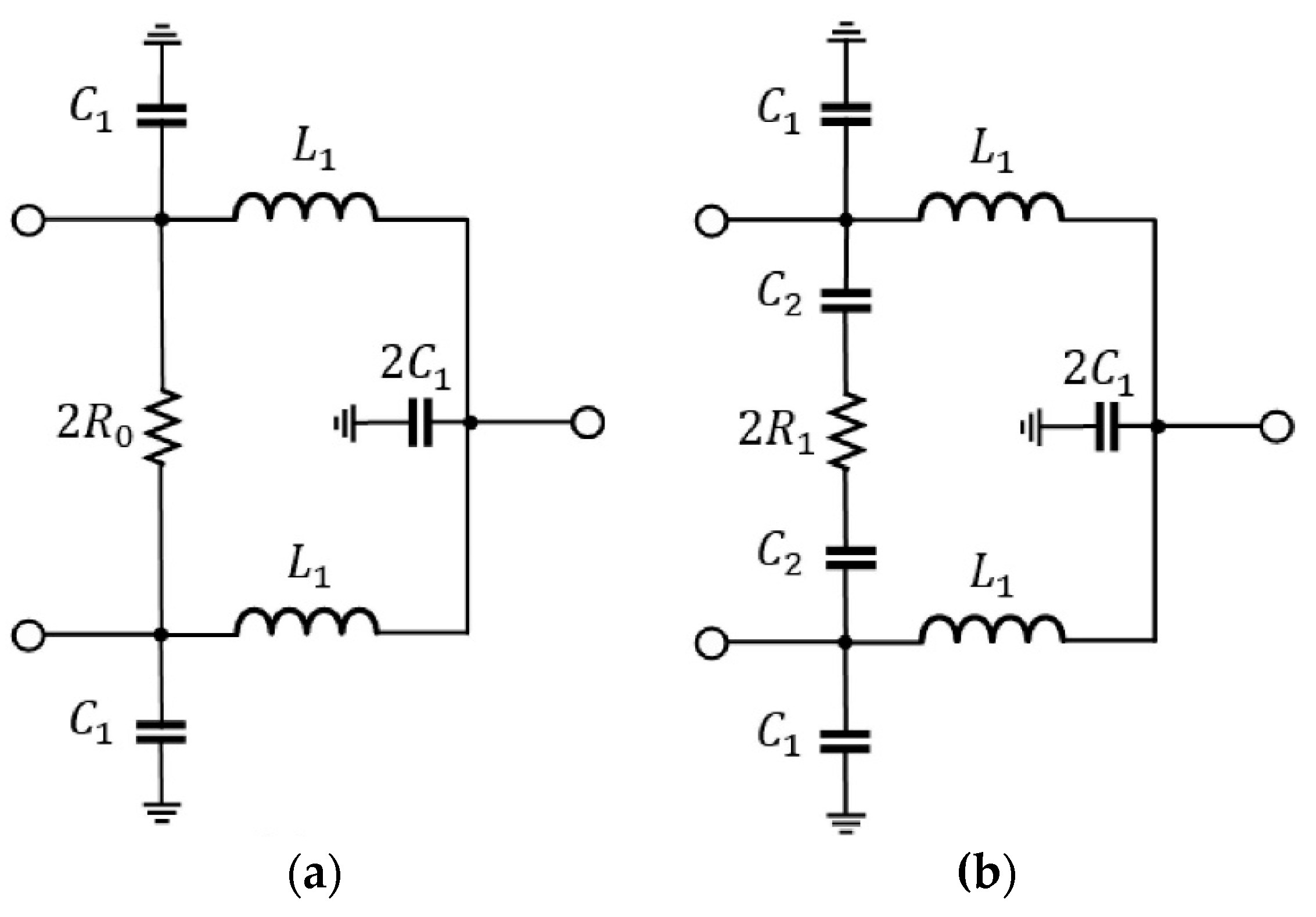

2.1. Class-E Power Amplifiers Using an L-Type Matching Network

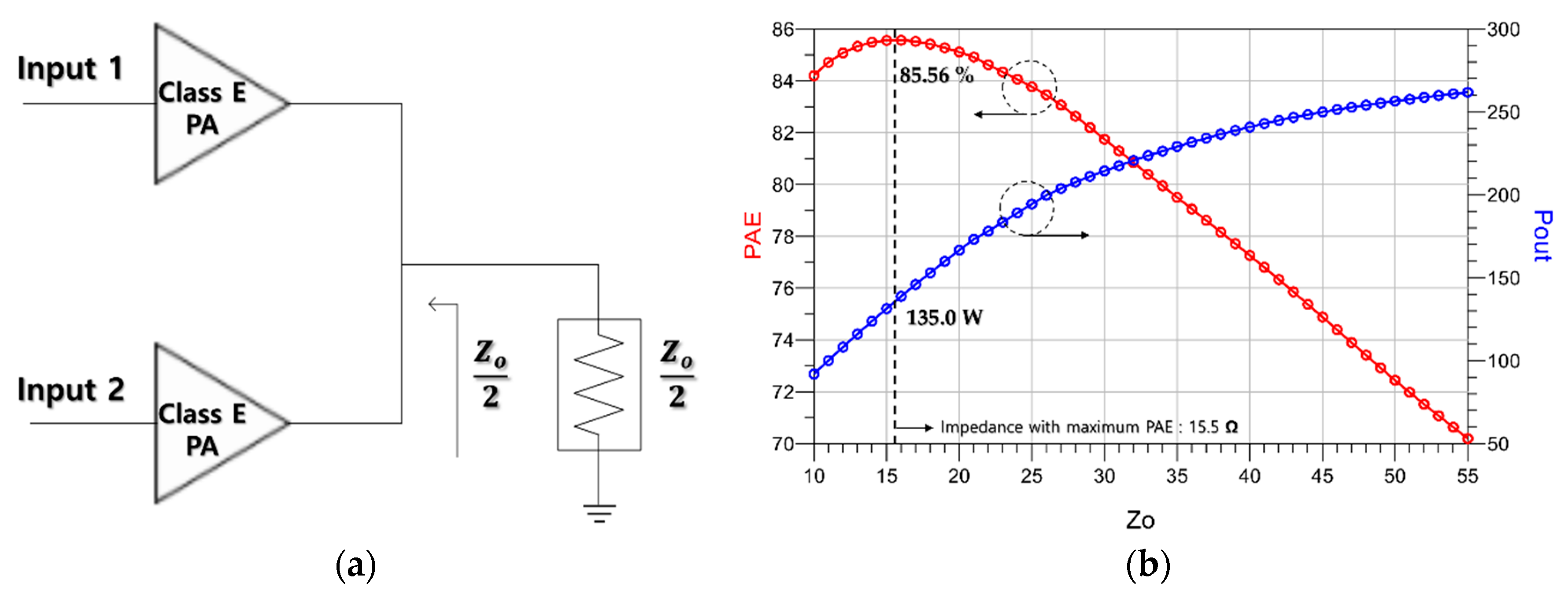

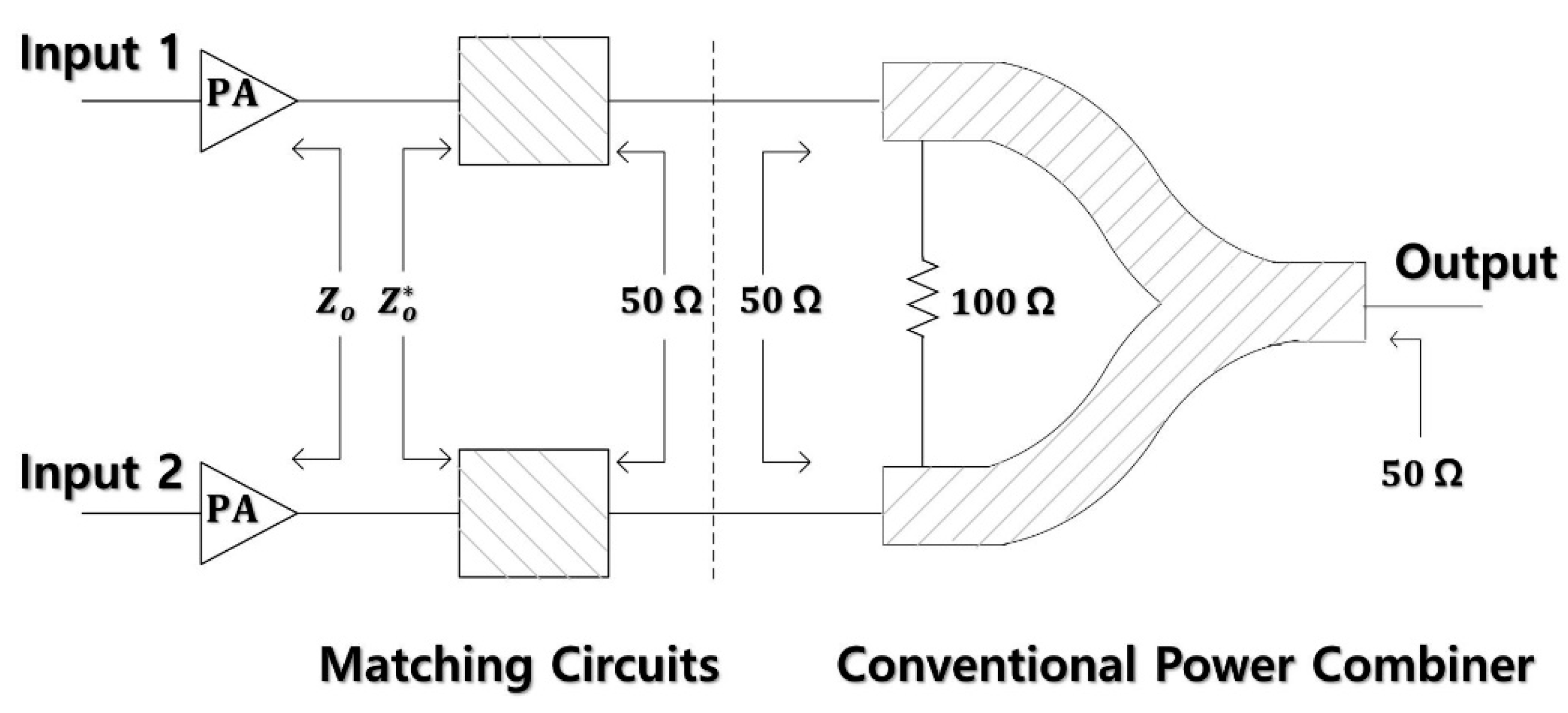

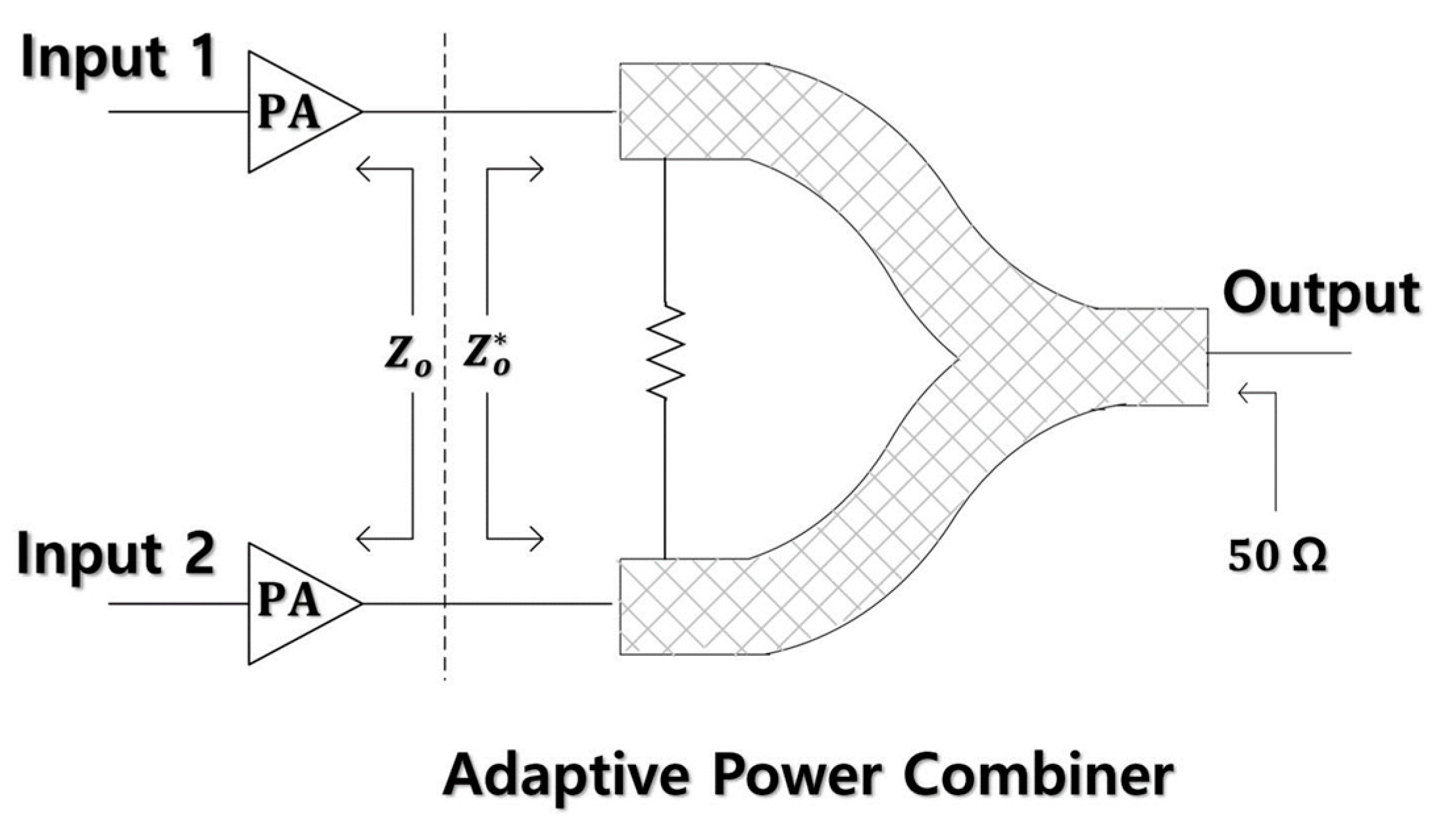

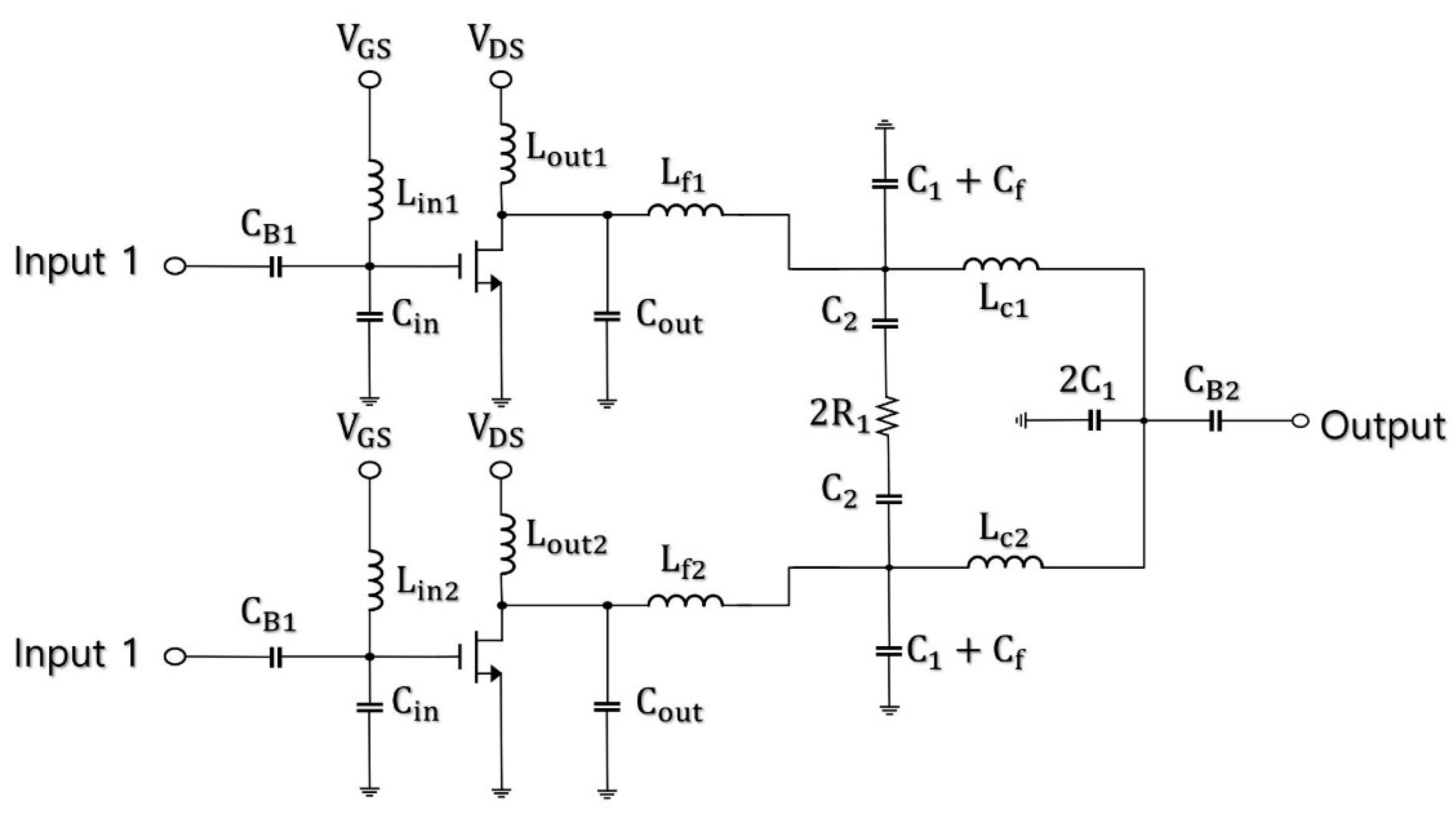

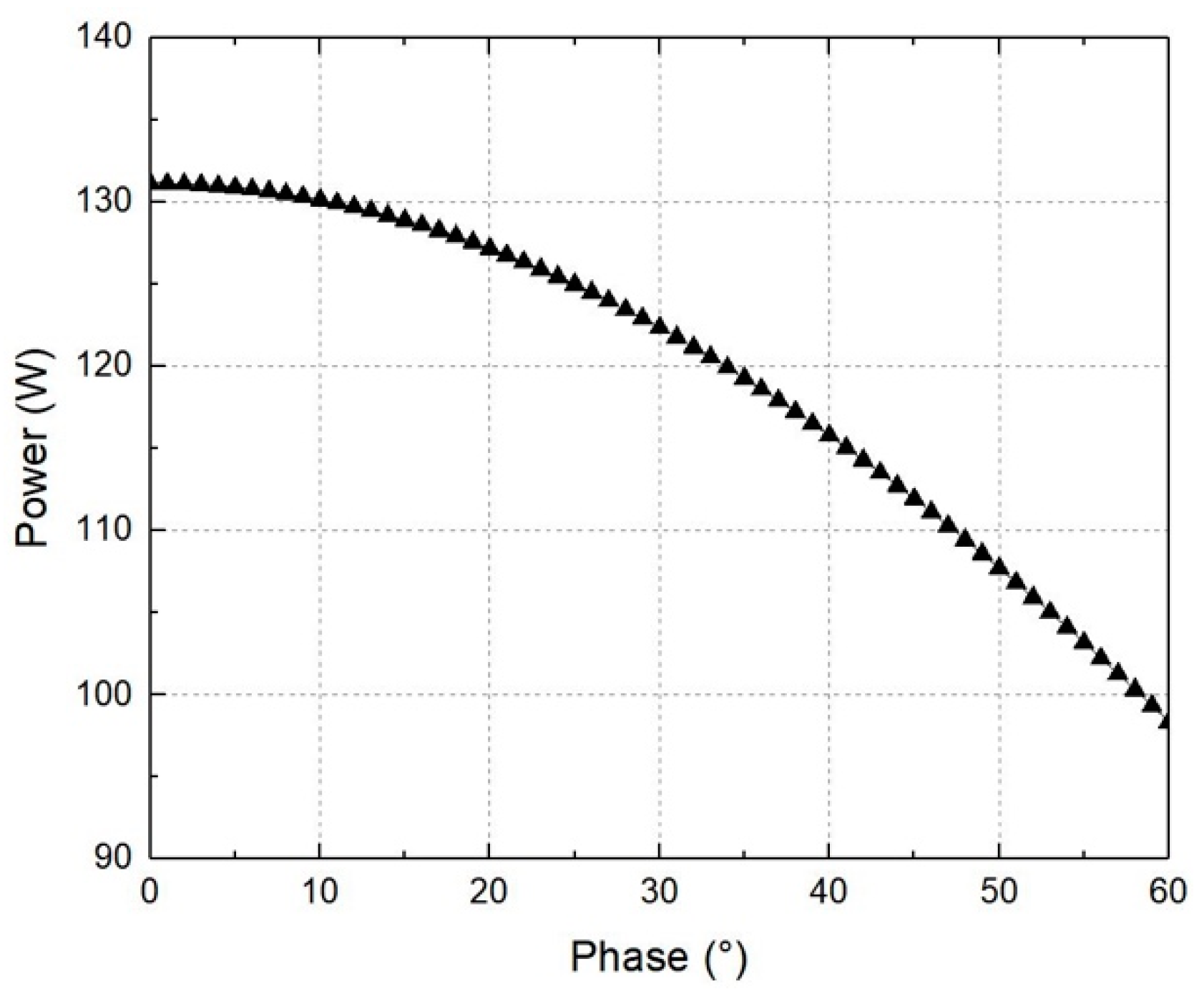

2.2. Proposed Power Module with an Adaptive Power Combiner

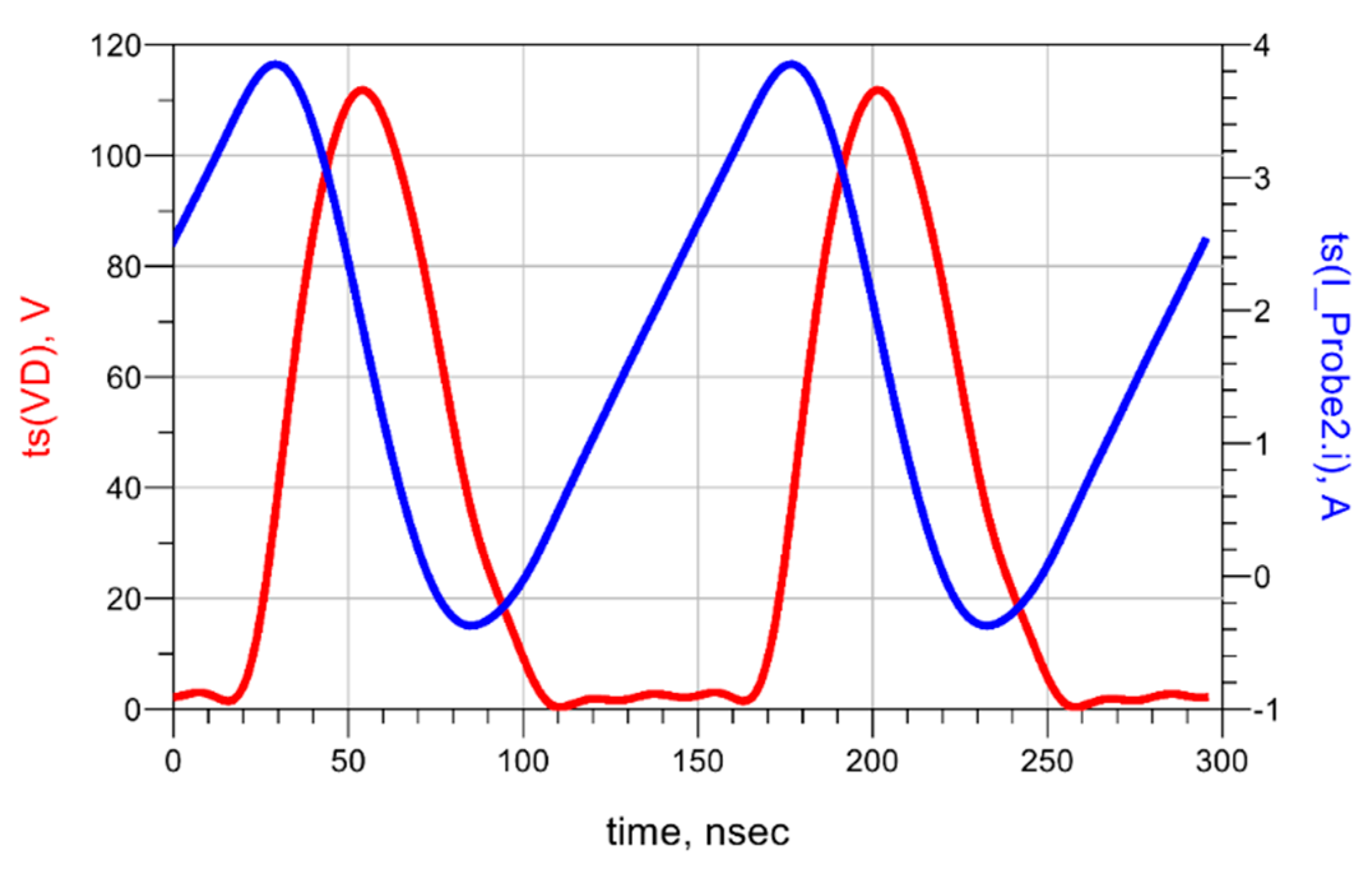

2.3. Electromagnetic Field and Radio Frequency Circuit Co-Simulation

3. Results

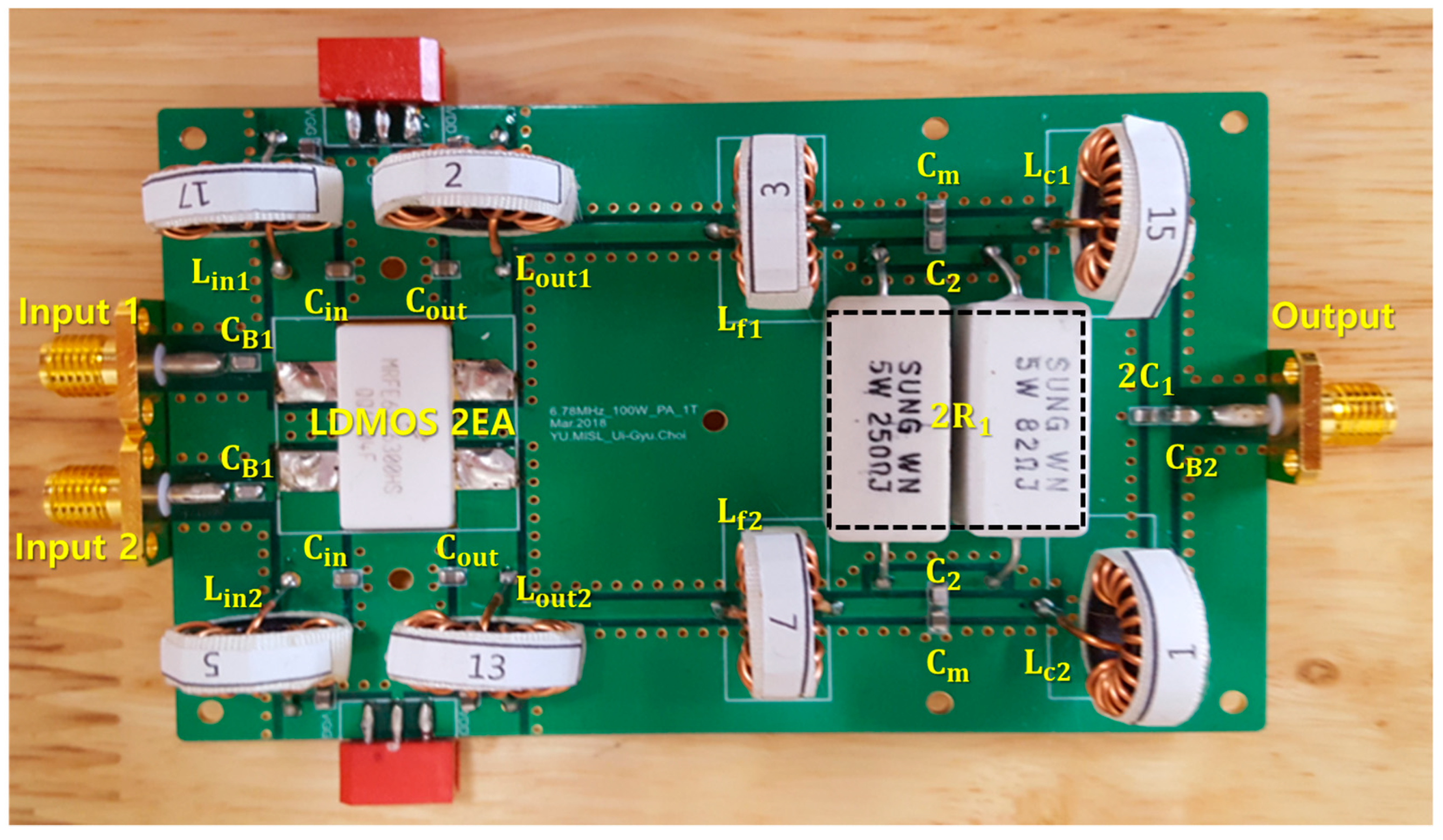

3.1. Implementation of the Proposed Power Module

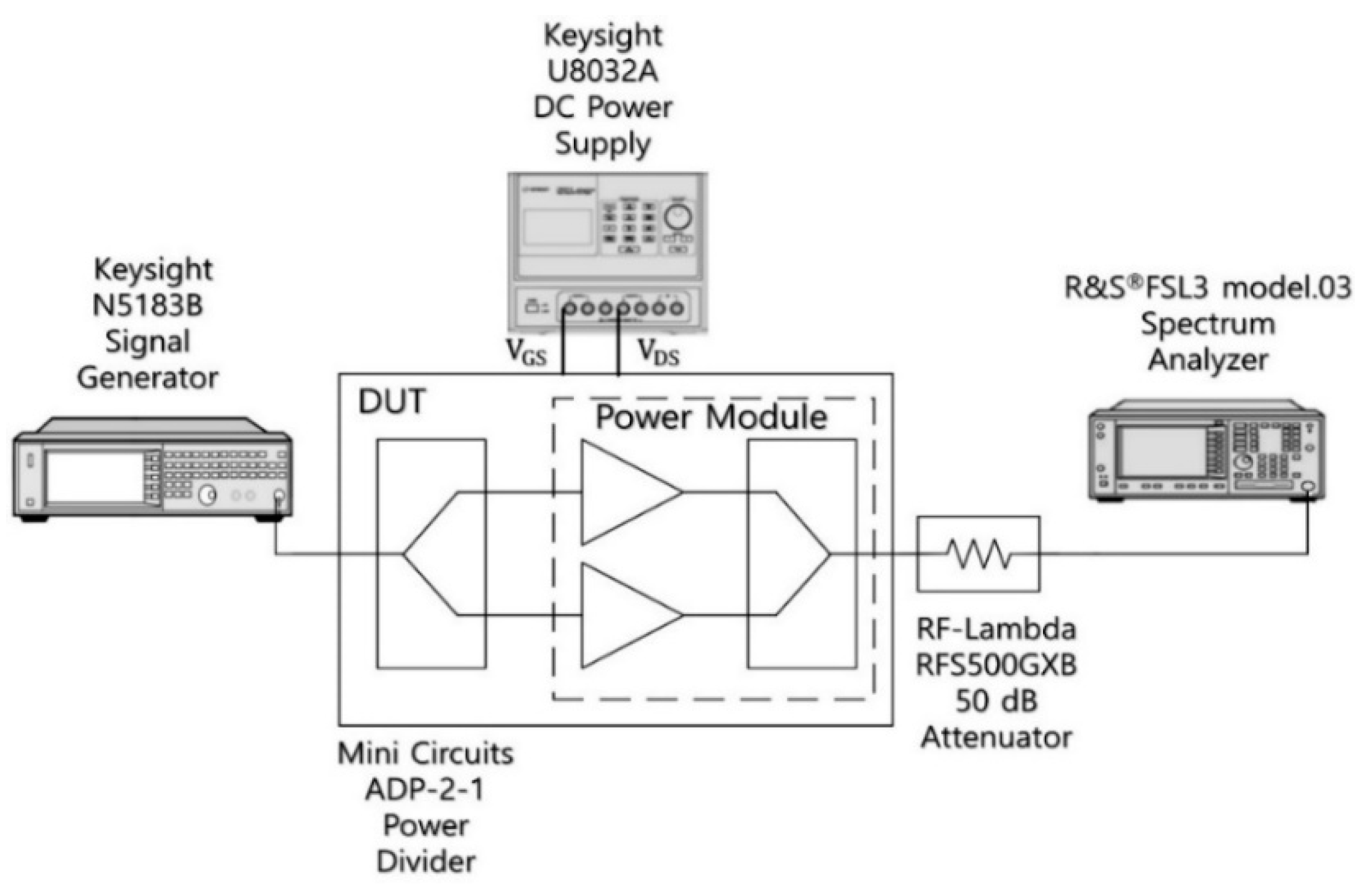

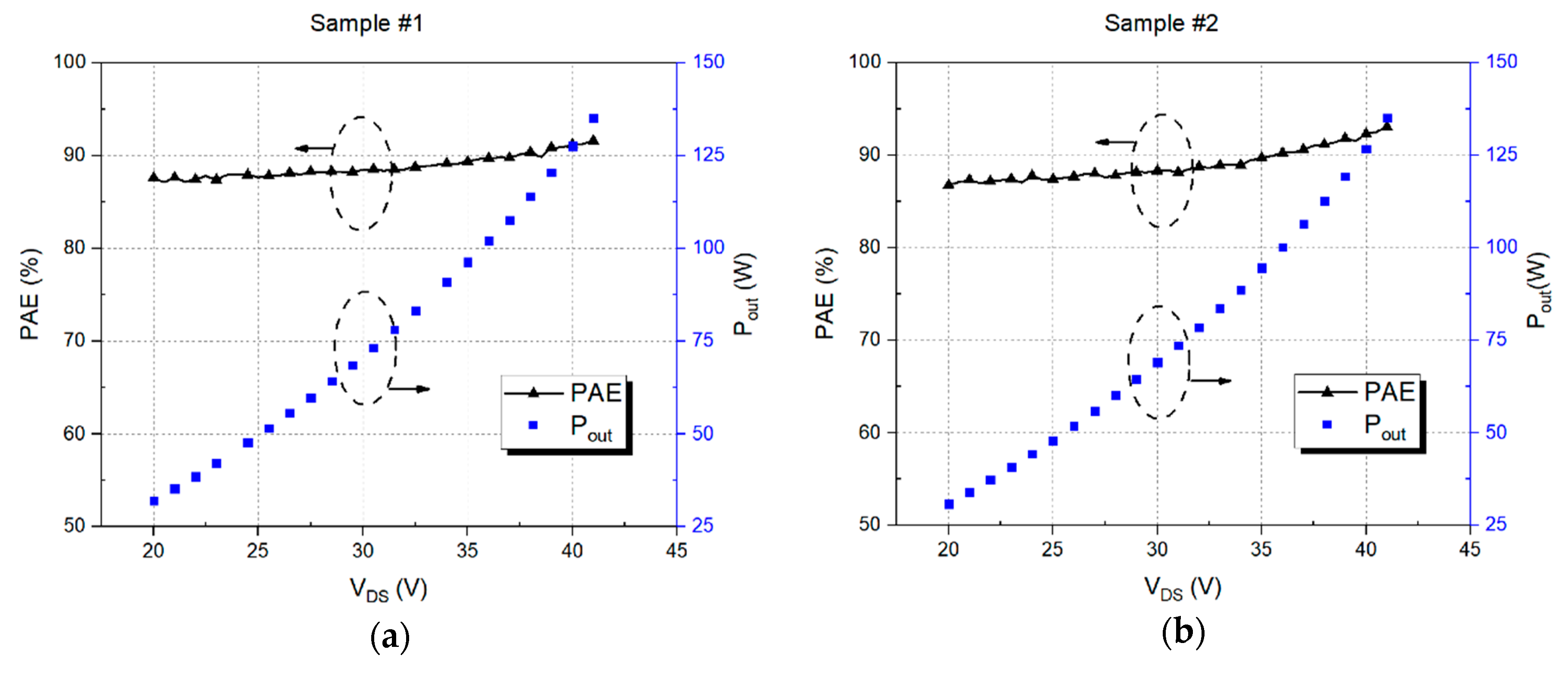

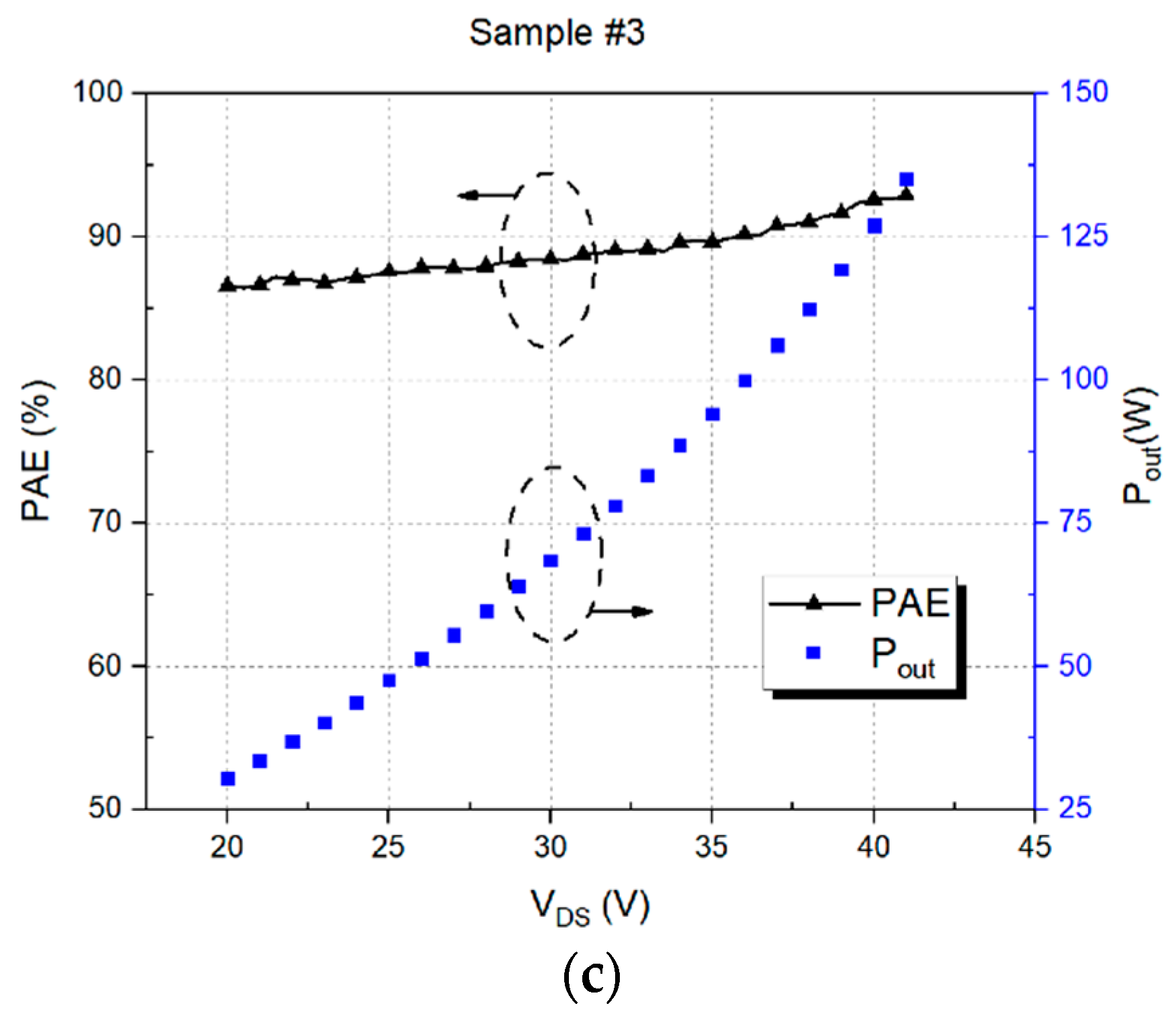

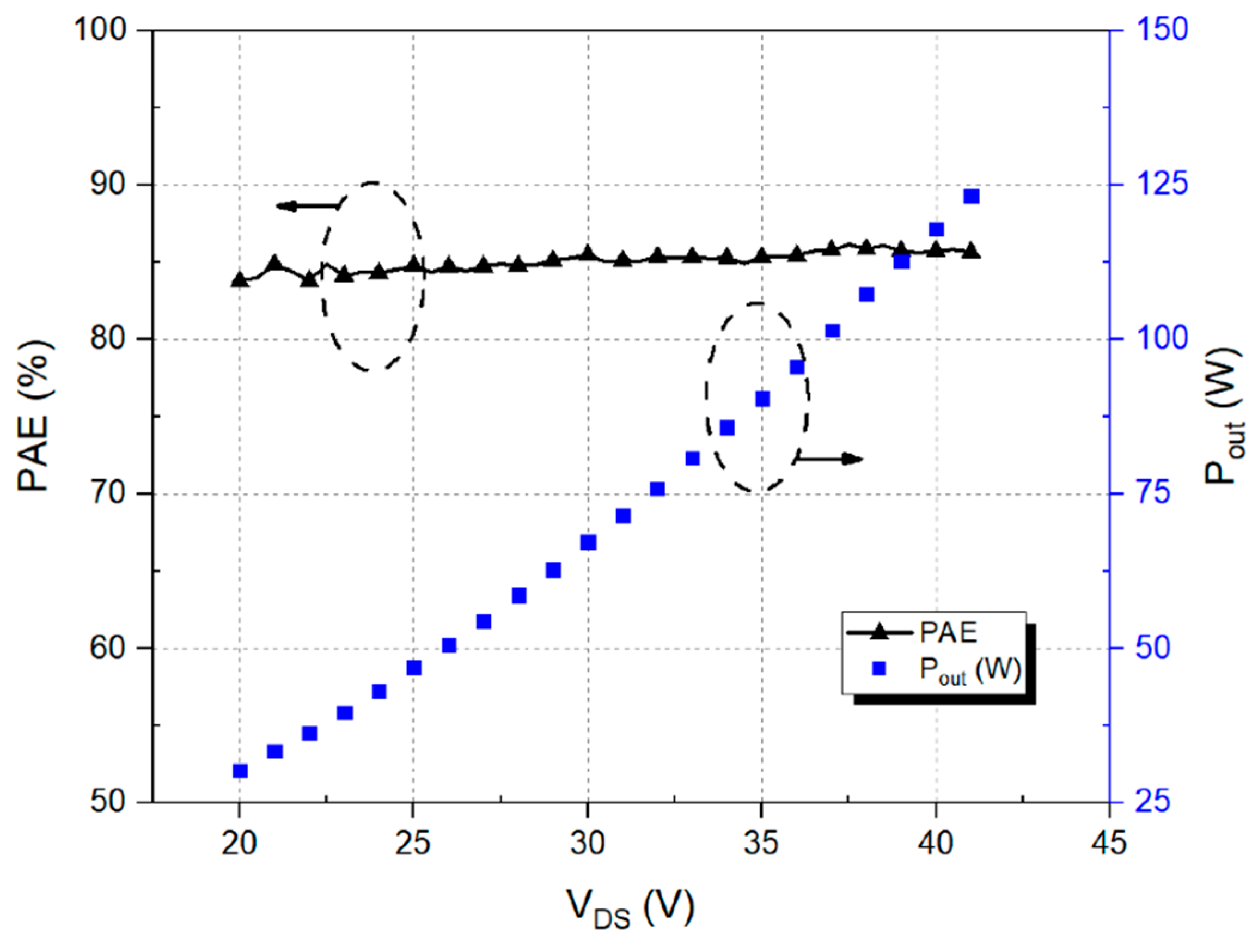

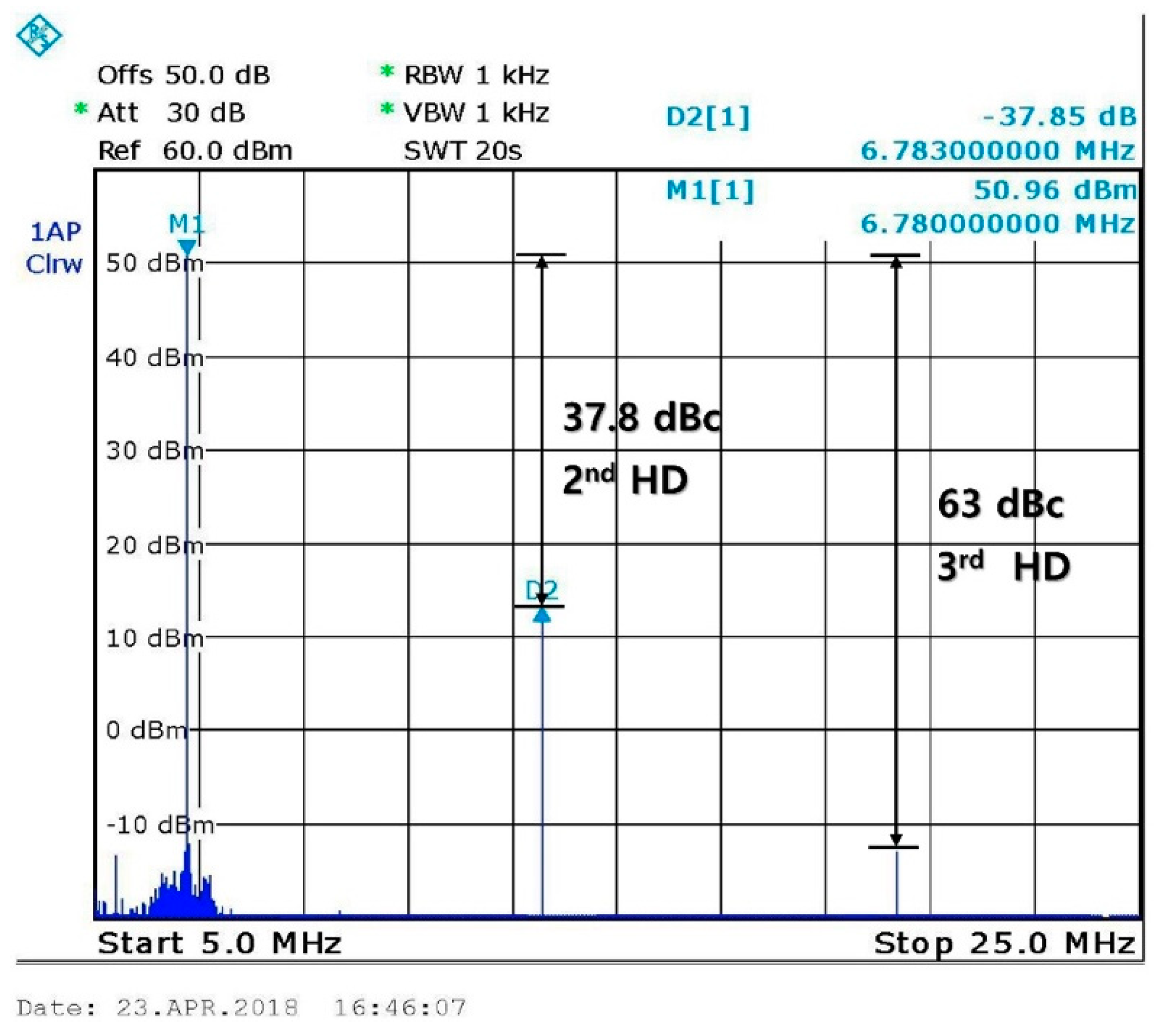

3.2. Measurement Results

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- André, K.; Karalis, A.; Moffatt, R.; Joannopoulos, J.D.; Fisher, P.; Soljai, M. Wireless power transfer via strongly coupled magnetic resonances. Science 2007, 317, 83–86. [Google Scholar]

- Inventions & Experiments of Nikola Tesla. Available online: https://teslaresearch.jimdo.com/wireless-transmission-of-energy-1/ (accessed on 16 June 2018).

- Aqeel, M.J.; Rosdiadee, N.; Sadik, K.G.; Haider, M.J.; Mahamod, I. Opportunities and Challenges for Near-Field Wireless Power Transfer: A Review. Energies 2017, 10, 1022. [Google Scholar]

- Riehl, P.S.; Satyamoorthy, A.; Akram, H.; Yen, Y.C.; Yang, J.C.; Juan, B.; Philip, F.T. Wireless power systems for mobile devices supporting inductive and resonant operating modes. IEEE. Trans. Microw. Theory Tech. 2015, 63, 780–790. [Google Scholar] [CrossRef]

- Kim, C.G.; Seo, D.H.; You, J.S.; Park, J.H.; Cho, B.H. Design of a contactless battery charger for cellular phone. IEEE Trans. Ind. Electron. 2001, 48, 1238–1247. [Google Scholar]

- The 60 Watt Specification. Available online: https://www.wirelesspowerconsortium.com/developers/60-watt-applications.html (accessed on 10 June 2018).

- Zenkner, H.; Khan-Ngern, W. Low loss magnetic design for wireless power transfer. Adv. Sci. Lett. 2015, 21, 2967–2973. [Google Scholar] [CrossRef]

- Mukti, R.J.; Begum, N.P.; Islam, A. Analysis of medium range wireless power transfer system using magnetic resonant coupling. In Proceedings of the International Conference on Informatics, Electronics & Vision, Dhaka, Bangladesh, 23–24 May 2014. [Google Scholar]

- Nair, V.V.; Choi, J.R. An efficiency enhancement technique for a wireless power transmission system based on a multiple coil switching technique. Energies 2016, 9, 156. [Google Scholar] [CrossRef]

- Yang, J.R.; Kim, J.; Park, Y.J. Class E power amplifiers using high-Q inductors for loosely coupled wireless power transfer system. J. Electr. Eng. Technol. 2014, 9, 569–575. [Google Scholar] [CrossRef]

- Cannon, B.L.; Hoburg, J.F.; Stancil, D.D.; Goldstein, S.C. Magnetic resonant coupling as a potential means for wireless power transfer to multiple small receivers. IEEE Trans. Power Electron. 2009, 24, 1819–1825. [Google Scholar] [CrossRef]

- Yang, J.-R. A class E power oscillator for 6.78-MHz wireless power transfer system. J. Electr. Eng. Technol. 2018, 13, 220–225. [Google Scholar]

- Grebennikov, A.V. Switched-mode rf and microwave parallel circuit class E power amplifiers. Int. J. RF Microw. Comput.-Aided Eng. 2004, 14, 21–35. [Google Scholar] [CrossRef]

- Yang, J.-R.; Son, H.-C.; Park, Y.-J. A class E power amplifier with coupling coils for a wireless power transfer system. Prog. Electromagn. Res. C 2013, 35, 13–22. [Google Scholar] [CrossRef]

- Chou, H.L.; Ng, J.C.W.; Liou, R.H.; Jong, Y.C.; Tuan, H.C.; Huang, C.F. The effect of self-heating in ldmosfet expansion regime. IEEE Trans. Electron Dev. 2012, 59, 3042–3047. [Google Scholar] [CrossRef]

- Choi, U.-G.; Yang, J.-R. A 6.78-MHz 100-W class E power amplifier module with an adaptive power combiner. In Proceedings of the IEEE International Symposium on Radio-Frequency Integration Technology, Melbourne, Australia, 15–17 August 2018. [Google Scholar]

- Grebennikov, A.; Sokal, N.O. Switchmode RF Power Amplifiers; Elsevier: Oxford, UK, 2007; ISBN 978-0-7506-7962-6. Available online: https://www.sciencedirect.com/science/book/9780750679626#book-description (accessed on 31 July 2018).

- Duong, T.P.; Lee, J.-W. A Dynamically adaptable impedance-matching system for midrange wireless power transfer with misalignment. Energies 2015, 8, 7593–7617. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering, 4th ed.; John Wiley Sons: Hoboken, NJ, USA, 2011; ISBN 978-0-470-63155-3. Available online: https://www.wiley.com/en-us/Microwave+Engineering%2C+4th+Edition-p-9780470631553 (accessed on 31 July 2018).

- Eccleston, K.W. Efficiency of lossless power combiners. Microw. Opt. Technol. Lett. 1995, 10, 9–12. [Google Scholar] [CrossRef]

| Output Power (W) | Power-Added Efficiency (PAE) (%) | Input Return Loss (dB) | Output Return Loss (dB) | |

|---|---|---|---|---|

| Single PA | 97.2 | 83.7 | 15.2 | 14.0 |

| Dual PAs | 106.2 | 88.6 | 15.3 | 9.7 |

| Difference | 9.0 | 4.9 | 0.1 | −4.3 |

| Components | Value | Components | Value |

|---|---|---|---|

| 2R1 | 62 Ω | CB2 | 20 nF |

| Lin | 305 nH | Cin | 1500 pF |

| Lout | 640 nH | Co | 820 pF |

| Lf | 650 nH | Cm (= C1 + Cf) | 1500 pF |

| Lc1 | 1170 nH | C2 | 120 pF |

| CB1 | 270 pF | 2C1 | 1200 pF |

| Components | Sample #1 | Sample #2 | Sample #3 | |||

|---|---|---|---|---|---|---|

| Inductance [nH] | Q Factor | Inductance [nH] | Q Factor | Inductance [nH] | Q Factor | |

| Lin1 | 307 | 110 | 306 | 107 | 304 | 117 |

| Lin2 | 307 | 110 | 306 | 104 | 304 | 114 |

| Lout1 | 648 | 149 | 649 | 148 | 649 | 140 |

| Lout2 | 648 | 147 | 649 | 155 | 649 | 139 |

| Lf1 | 647 | 141 | 647 | 146 | 647 | 133 |

| Lf2 | 647 | 157 | 647 | 148 | 646 | 138 |

| Lc1 | 1177 | 107 | 1179 | 110 | 1176 | 108 |

| Lc2 | 1177 | 107 | 1179 | 107 | 1176 | 109 |

| Path to the output | Sample #1 [mΩ] | Sample #2 [mΩ] | Sample #3 [mΩ] |

|---|---|---|---|

| From PA 1 | 849.4 | 832.2 | 868.6 |

| From PA 2 | 852.0 | 834.0 | 857.9 |

| Total Resistance | 1701.4 | 1666.2 | 1726.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, U.-G.; Yang, J.-R. A 120 W Class-E Power Module with an Adaptive Power Combiner for a 6.78 MHz Wireless Power Transfer System. Energies 2018, 11, 2083. https://doi.org/10.3390/en11082083

Choi U-G, Yang J-R. A 120 W Class-E Power Module with an Adaptive Power Combiner for a 6.78 MHz Wireless Power Transfer System. Energies. 2018; 11(8):2083. https://doi.org/10.3390/en11082083

Chicago/Turabian StyleChoi, Ui-Gyu, and Jong-Ryul Yang. 2018. "A 120 W Class-E Power Module with an Adaptive Power Combiner for a 6.78 MHz Wireless Power Transfer System" Energies 11, no. 8: 2083. https://doi.org/10.3390/en11082083