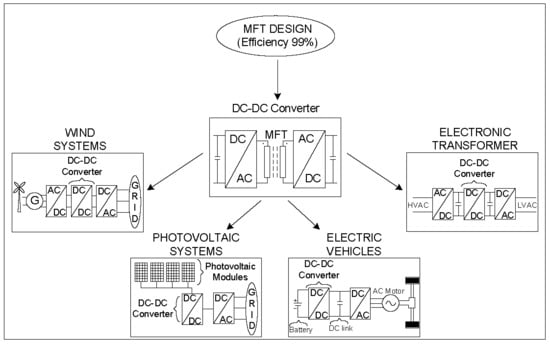

The three-section methodology centers in the design procedure of the MFTs. The sections are (1) the selection of magnetic materials, (2) the MFT design procedure, and (3) the implementation of the MFT–DAB system.

2.2. Design Procedure

The MFTs design procedure developed in this work introduces new ideas, but also involves a key modification of the well-known product-of-the-areas method [

22]. This modification, detailed in full in this section, is in the context of estimation of core losses. With this new estimation approach, the calculation of the effects of core losses on the MFT efficiency are more precise. This efficiency estimation value is close to the efficiency achieved experimentally with the MFT lab prototype.

Figure 2 presents the flow diagram of the proposed design process. After this process is completed, the parameters for the MFT design are determined.

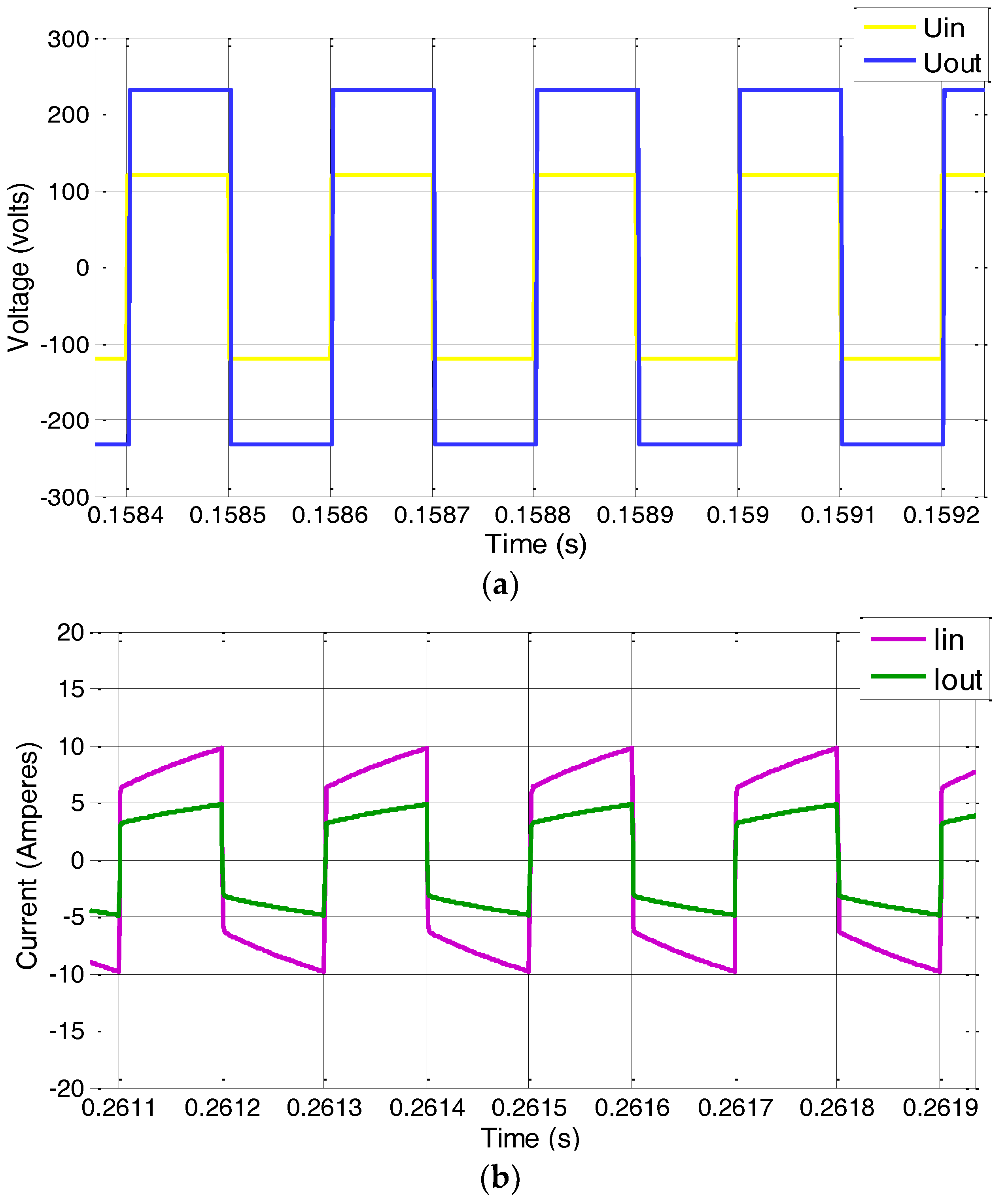

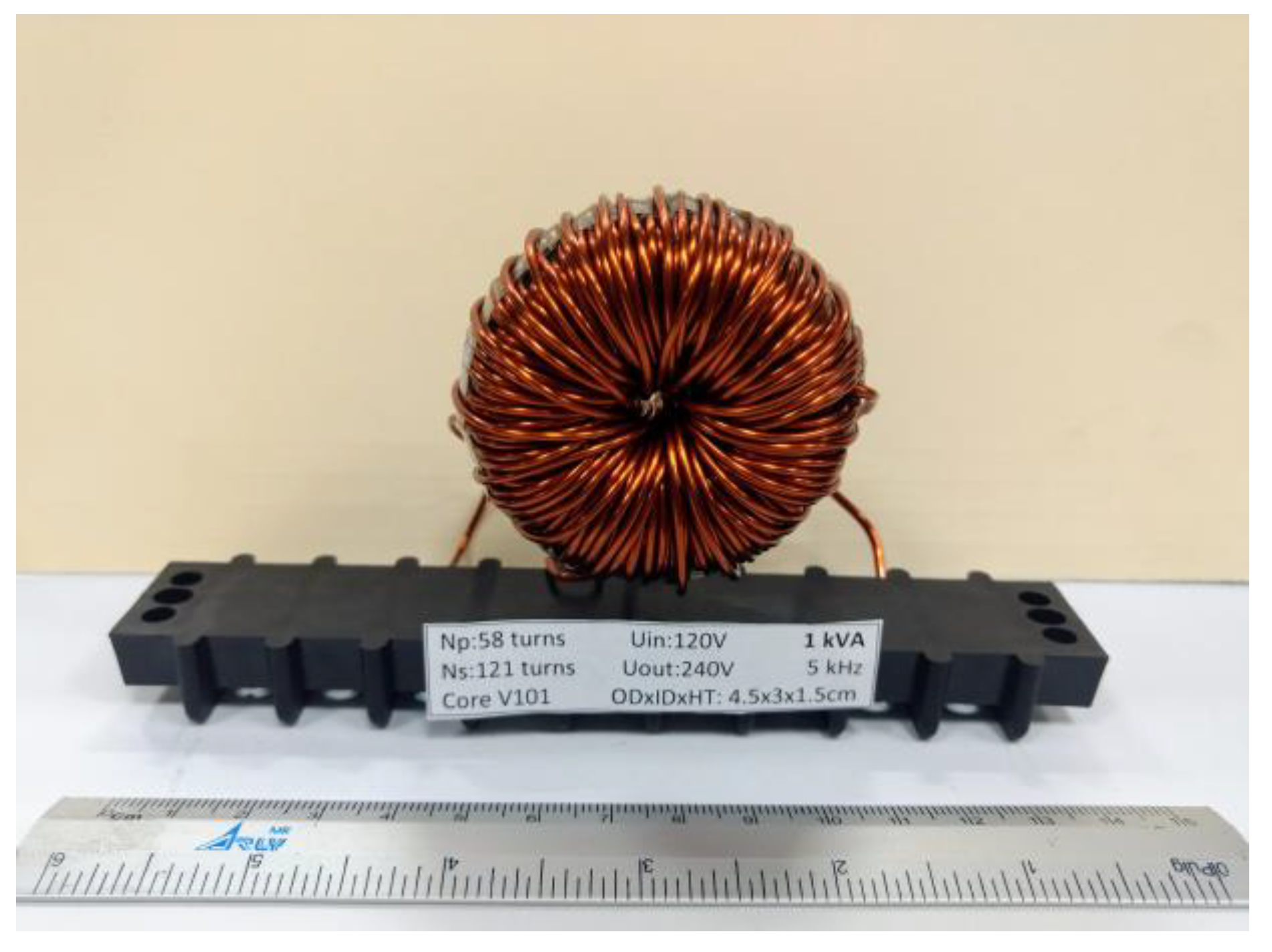

As the first step, the initial values of variables, such as input and output voltage (Uin and Uout, respectively), output current (Iout), frequency (f), current density (J), turns ratio (n), waveform coefficient (kf), window utilization factor (ku), and output power (Pout) are chosen.

The second step is the selection of the core material, according to the required nominal operation frequency. For the purpose of this work, the frequency is 5 kHz and the core is nanocrystalline.

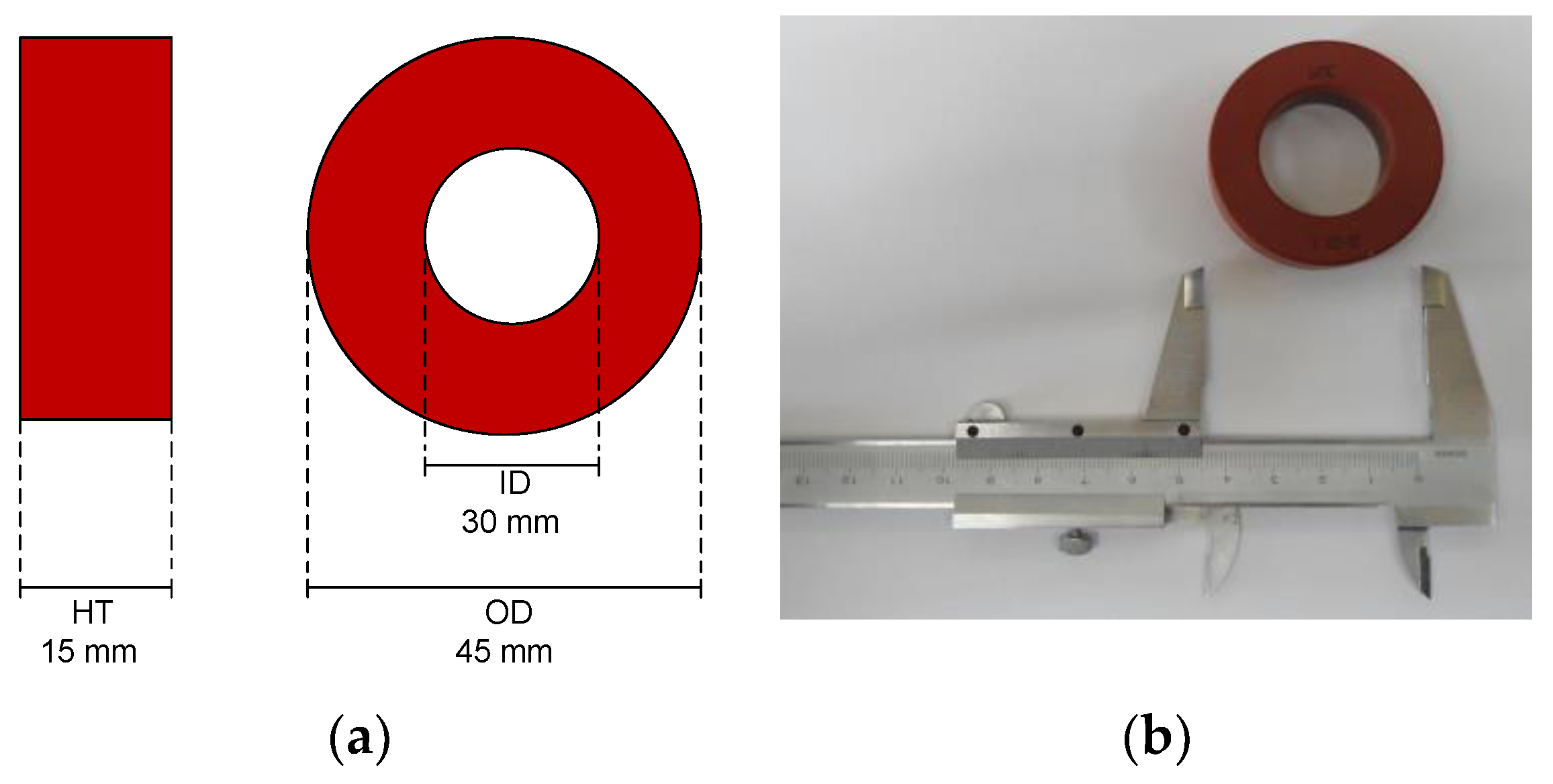

The third step is the computation of the physical dimensions of the MFT core, which include the outer diameter (OD), inner diameter (ID), core length (HT), window area (Wa), effective cross-section of the core (Ac), and the area product (Ap). With the physical dimensions at hand, the flow density (Bac) is then computed. If Bac > Bmax (maximum allowable flow density), then Ap is incremented, and steps 2 and 3 are repeated.

Step 4, reached once Bac < Bmax, is the computation of the winding and insulation characteristics. This calculation involves the primary turns (Np), secondary turns (Ns), primary wire area (Awp), secondary wire area (Aws), input current (Iin), minimum distance between conductors (dins), required insulation voltage (Uins), insulation dielectric rigidity (Eins), and safety margin (v).

In step 5, the main variables needed for determining the efficiency of the MFT are calculated. These are the primary windings resistance (Rp), the secondary windings resistance (Rs), the primary windings losses (Pp), the secondary windings losses (Ps), the copper losses (Pcu), the core losses (Pfe), total losses (Ptot), the magnetization inductance (Lm), and the dispersion inductance (Ld).

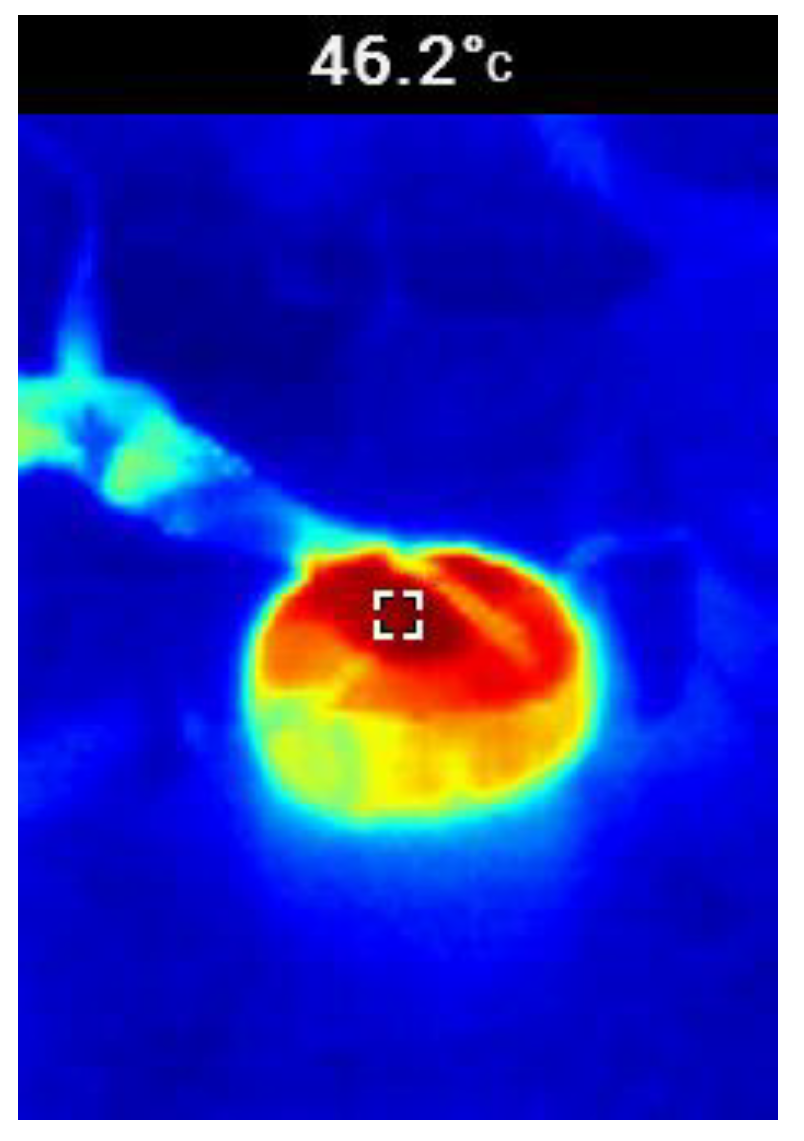

The calculation of the temperature (Tr) increase is carried out as step 6. If Tr > 80 °C, then Ap is increased, and steps 2, 3, 4, and 5 are recalculated. If Tr < 80 °C, then the required minimum efficiency is verified. Nanocrystalline materials can withstand temperatures between 105 °C and 120 °C, depending the specific material, which is the reason of choosing the reference set point at Tr = 80 °C.

If the resulting efficiency is lower than 98%, then the goal is not achieved. Therefore, Ap is decreased, and steps 2, 3, 4, 5, and 6 are recalculated. On the other hand, if the resulting efficiency is greater than 98%, then the goal is achieved, and step 7, as well as the design procedure altogether, is over.

All of the results obtained from the design procedure are organized into core dimensions (Wa, Ac, Ap), winding characteristics (Np, Awp, Ns, Aws), and insulation dimensions. Additional data include the distance between primary and secondary windings (Diso), the minimum insulation distance between primary conductors (Dins1), and the minimum insulation distance between secondary conductors (Dins2). Using these data, the MFT behavior is simulated in Matlab-Simulink (The MathWorks, v2014a, Mexico City, Mexico). Afterwards, the MFT lab prototype is built.

2.2.1. Core Geometry

The DAB, toroidal-core, high/medium-frequency transformers have a great opportunity niche in modern power electronics structures. An example of this is the DAB. The main advantages of this type of transformer are the reduction of its weight and volume, as well as obtaining a very low magnetic dispersion flow compared to transformers with different core geometries. In medium-power applications of a DAB converter to power grids, such as an electronic transformer for medium- and low-power grids, high-power density and high transformer efficiency are two key criteria of designing MFTs. In this research work, toroidal core geometry was selected.

2.2.2. Insulation Design

The required minimum insulation distance between conductors for dry insulation of the MFT in DABs [

14] is

where

v, is the safety margin,

Eins is the dielectric rigidity of the insulation material, and

Uins is the voltage between the conductors to be isolated. If the insulation calculation is wrong, then the total MFT losses can be higher than initially expected, and recalculation must be carried out. The insulation value that is calculated influences the dispersion inductance value, as is shown in

Section 2.2.3.

2.2.3. Dispersion Inductance

The classic mathematical approach to calculate the dispersion is Equation (2) [

22]. Another approach is to use Equation (3) [

24], which includes data such as the dimensions of the core, the windings, and the insulation material. As part of this research work, results obtained from Equation (3) were compared to those from (i) simulations using the finite element method (FEM) and (ii) the classic Equation (2) for a frequency range of 0 kHz to 200 kHz.

The technique outlined in [

24] affords greater accuracy than Equation (2). However, at 5 kHz—the frequency of interest in this paper for simulations and the prototype—both techniques provide nearly the same output:

where

| = vacuum permeability | diso = isolation distance |

| dins1 = insulation distance between the layers of the primary | NL1 = turns per layer |

| dins2 = insulation distance between the layers of the secondary | hw = winding height |

| m1 = number of layers in the primary | dpri = thickness of the primary |

| m2 = number of layers in the secondary | dsec = thickness of the secondary |

| MLTiso = mean length of the isolation distance | ∆1 = penetration ratio of the primary, |

| MLTpri = mean length turns of primary portion | ∆2 = penetration ratio of the primary, |

| MLTsec = mean length turns of secondary portion | where is the skin depth |

The calculation of the dispersion inductance of the lab prototype uses Equations (2) and (3). As initially expected, the theoretical and experimental results are almost the same.

2.2.4. Temperature Increase

The accurate computation of temperature increase in MFTs is crucial for avoiding MFT overheating and damage. The temperature rise is calculated using Equation (4) [

22]:

where

Tt is the temperature rise in Celsius (°C),

Ptot are the total losses in watts, and

At is the surface area of the transformer in cm

2. Various application examples are well explained in [

22].

2.2.5. Winding Losses

The winding losses are calculated with Equations (5–7) [

22].

where

Rp and

Rs are calculated with Equations (8) and (9), respectively. These are

MLT1 and MLT2 are the mean lengths of the primary and secondary windings, respectively; mΩ/cm1 and mΩ/cm2 are the resistances per centimeter of the primary and secondary winding conductors, respectively.

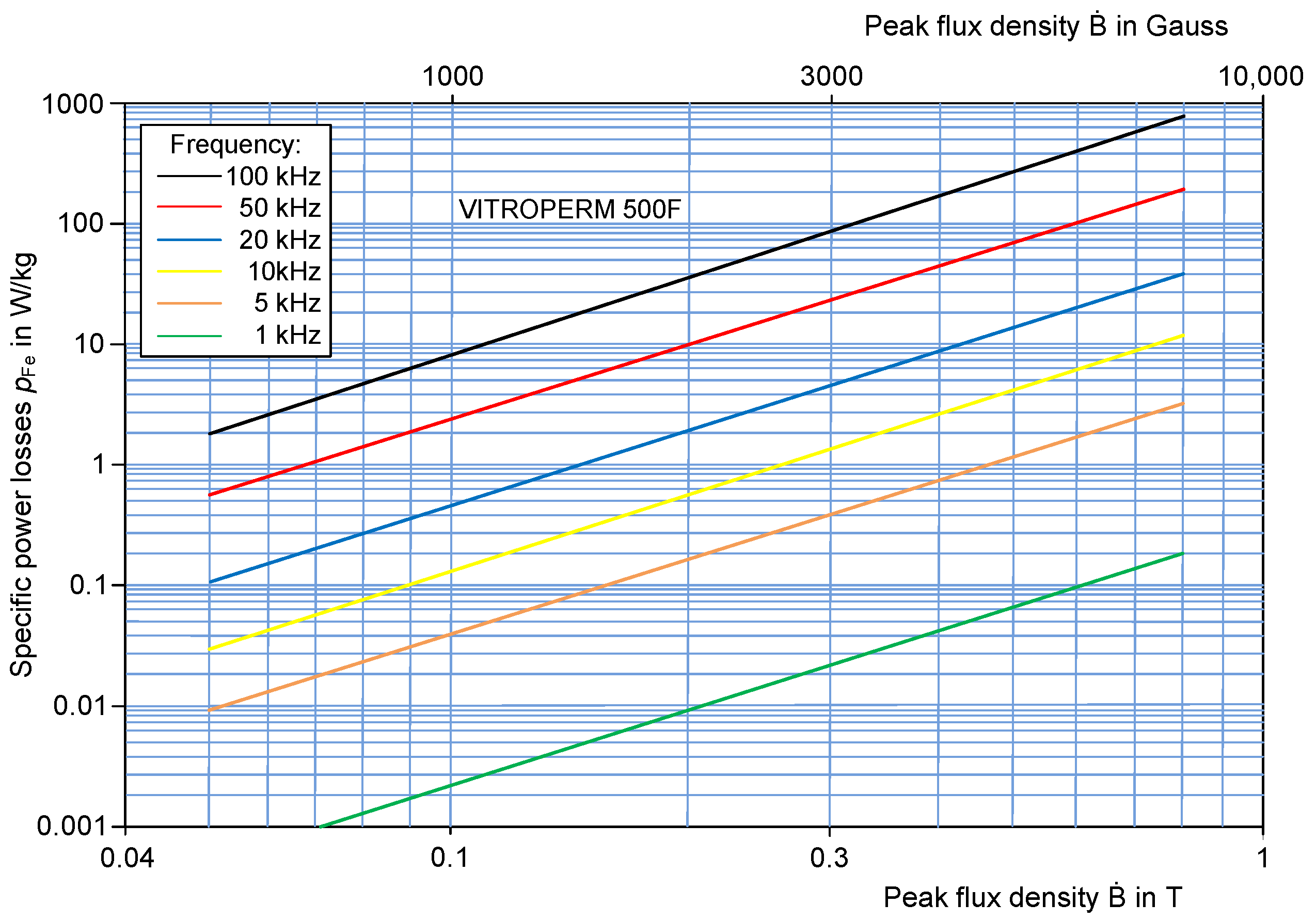

2.2.6. Core Losses

Core losses heavily depend on the core material and the operating frequency of the MFT. At medium frequency (5 kHz), nanocrystalline cores are the common option, because of their low losses and high permeability values.

Figure 3 presented the core losses versus flow density relationship for VITROPERM 500F, a nanocrystalline material. Further detailed characterization of the core losses for nanocrystalline materials over a wider range of frequencies is found in [

23].

The core losses are calculated with Equation (10):

where

Pfe1 are the nanocrystalline material losses (W/kg). In case of VITROPERM 500F, the core losses can be also obtained directly from

Figure 3. In the design of the MFT for this work,

Pfe1 = 5 W/kg. In this case,

Wfe, the core weight (kg), is specified for 1 kVA. It can be noticed that

pFe is directly proportional to the frequency and the flow density.

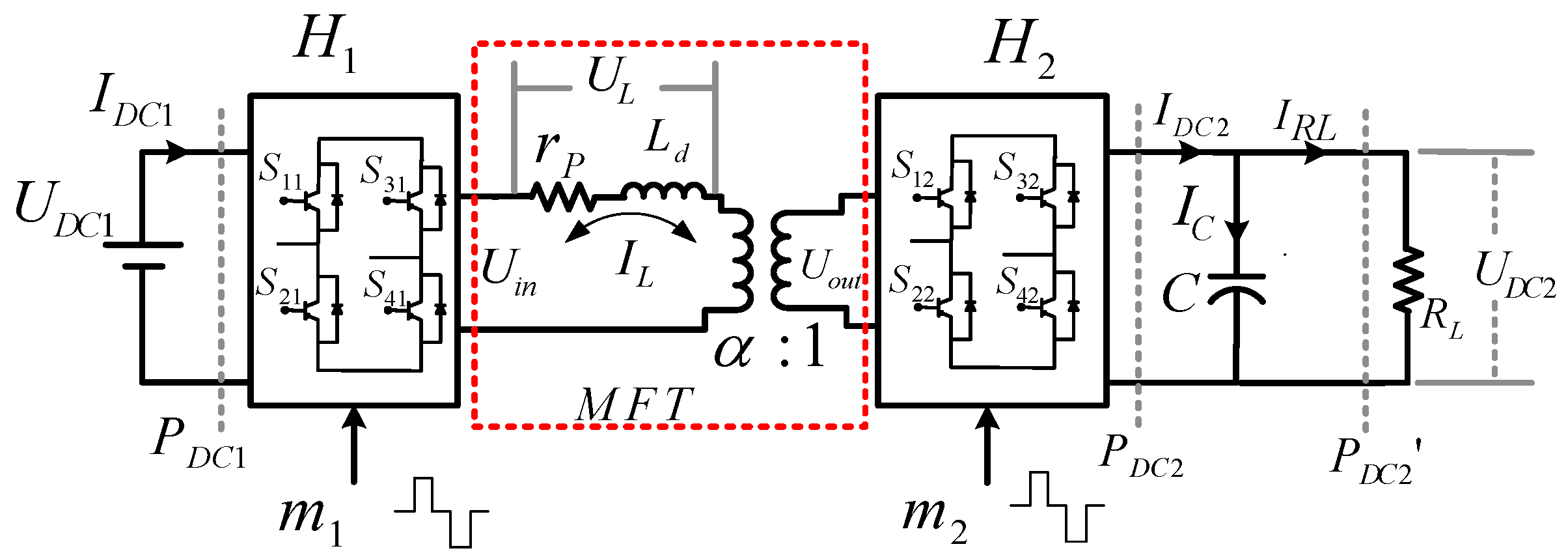

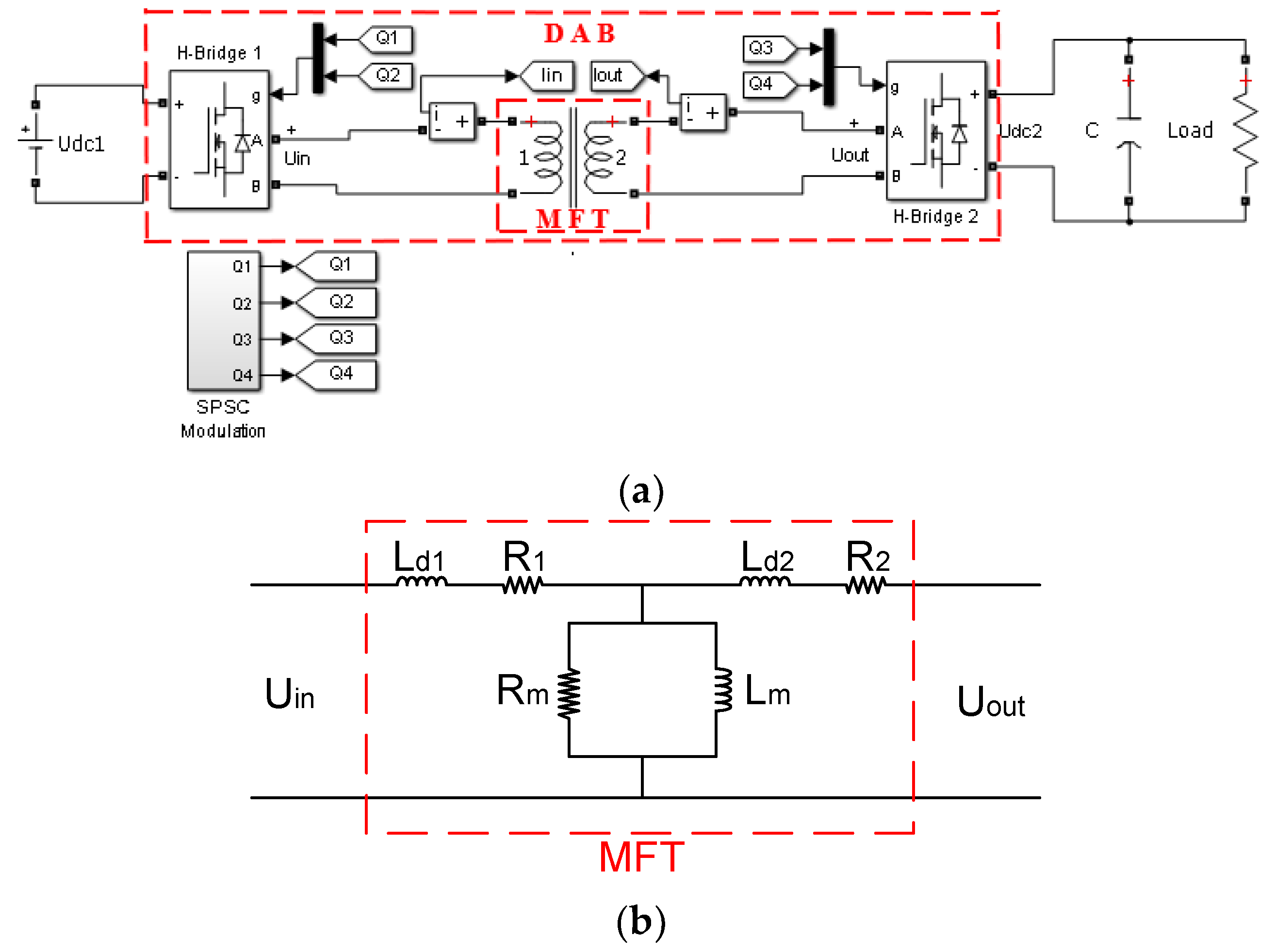

2.3. The Dual Active Bridge Converter and the Medium Frequency Transformer as Prototypes

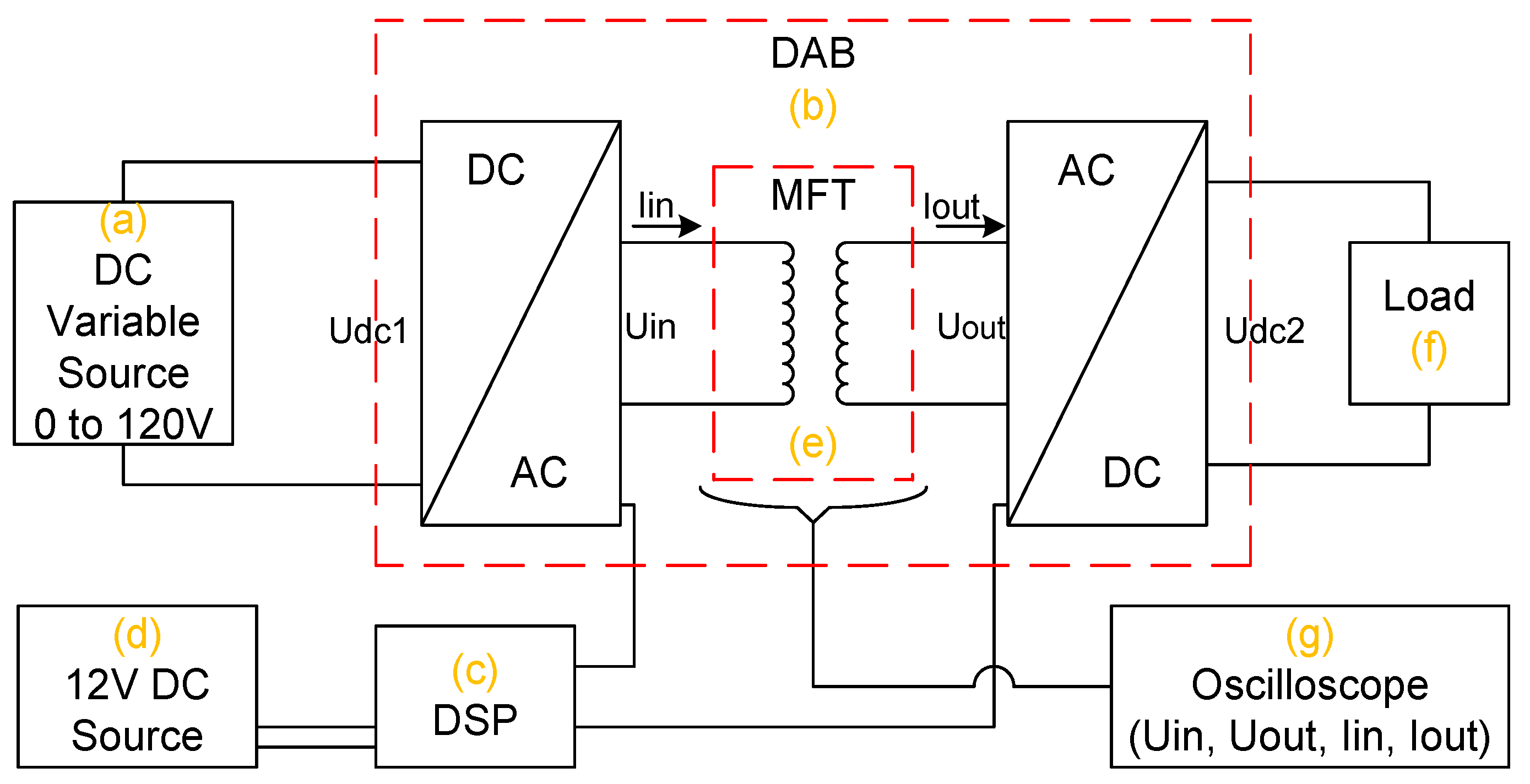

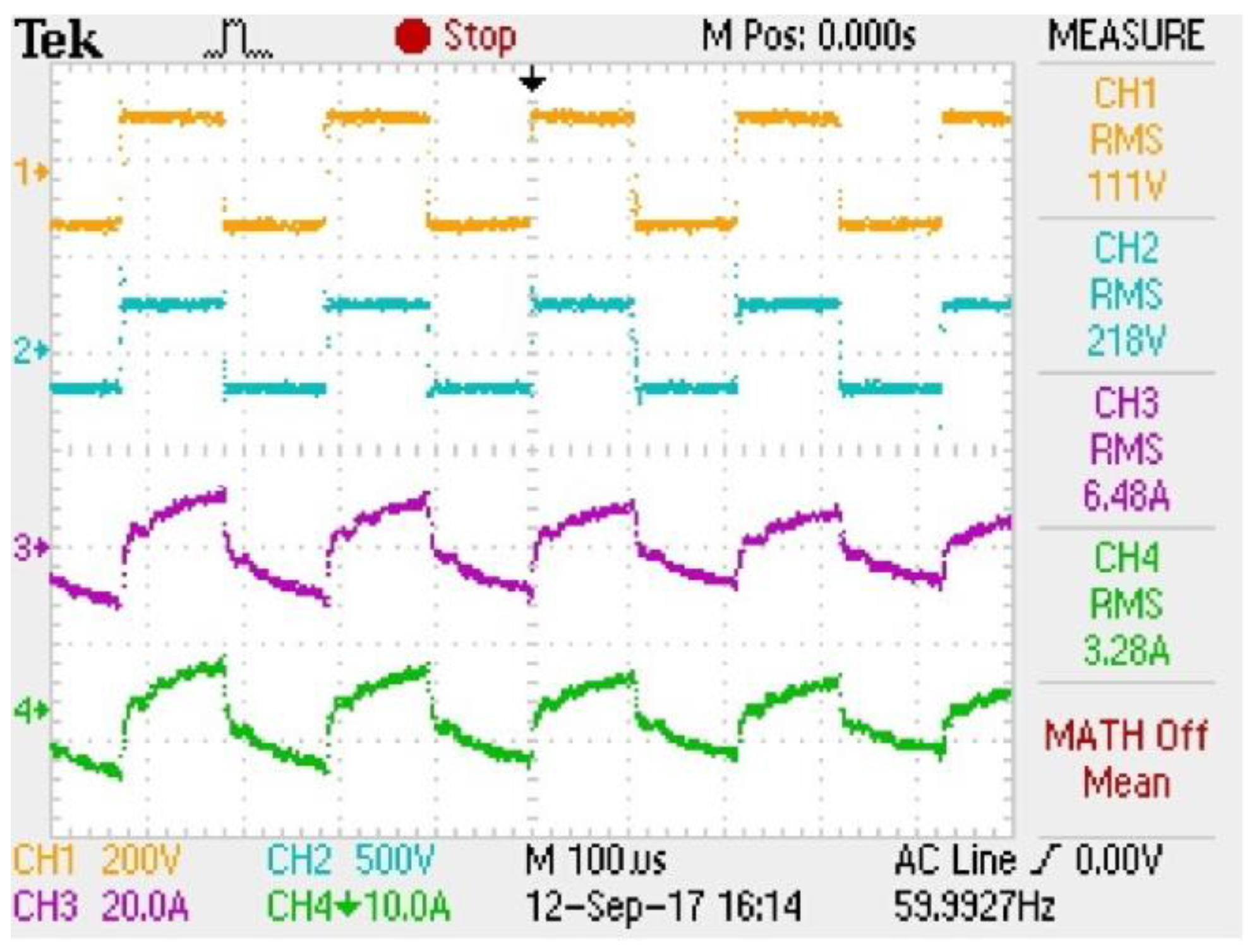

Figure 4 shows the DAB converter topology, where both the input and output ports are each an H-bridge structure (

H1 and

H2) linked together through a MFT.

Uin and

Uout are the AC voltages formed by

H1 and

H2, which in turn rely on the modulation signals

m1 and

m2, as well as on the DC voltages

UDC1 and

UDC2, respectively [

25]. The voltage difference (

UL) between the windings of the MTF produces a current flow

IL, which is dependent upon the leakage inductance,

Ld, the parasitic resistance,

rp, the phase shift carrier (Δ

φ), and the duty ratio (

μ) between the modulation signals

m1 and

m2. Last but not least,

IDC1 and

IDC2 represent the DC currents of the H-Bridge converters. Also notice that

PDC1 and

PDC2 represent the DC powers; more specifically,

PDC2’ represents the power dissipated in the resistive load

RL.

In this paper, the main purpose of the DAB is to help in evaluating the MFT operation, as well as evaluating the overall performance of the DC–DC conversion. The DAB is implemented as a computational model and lab prototype, with the purpose of analyzing the MFT input and output waveforms and MFT efficiency.