Development and Optimization of a Building Energy Simulation Model to Study the Effect of Greenhouse Design Parameters

Abstract

:1. Introduction

2. Materials and Methods

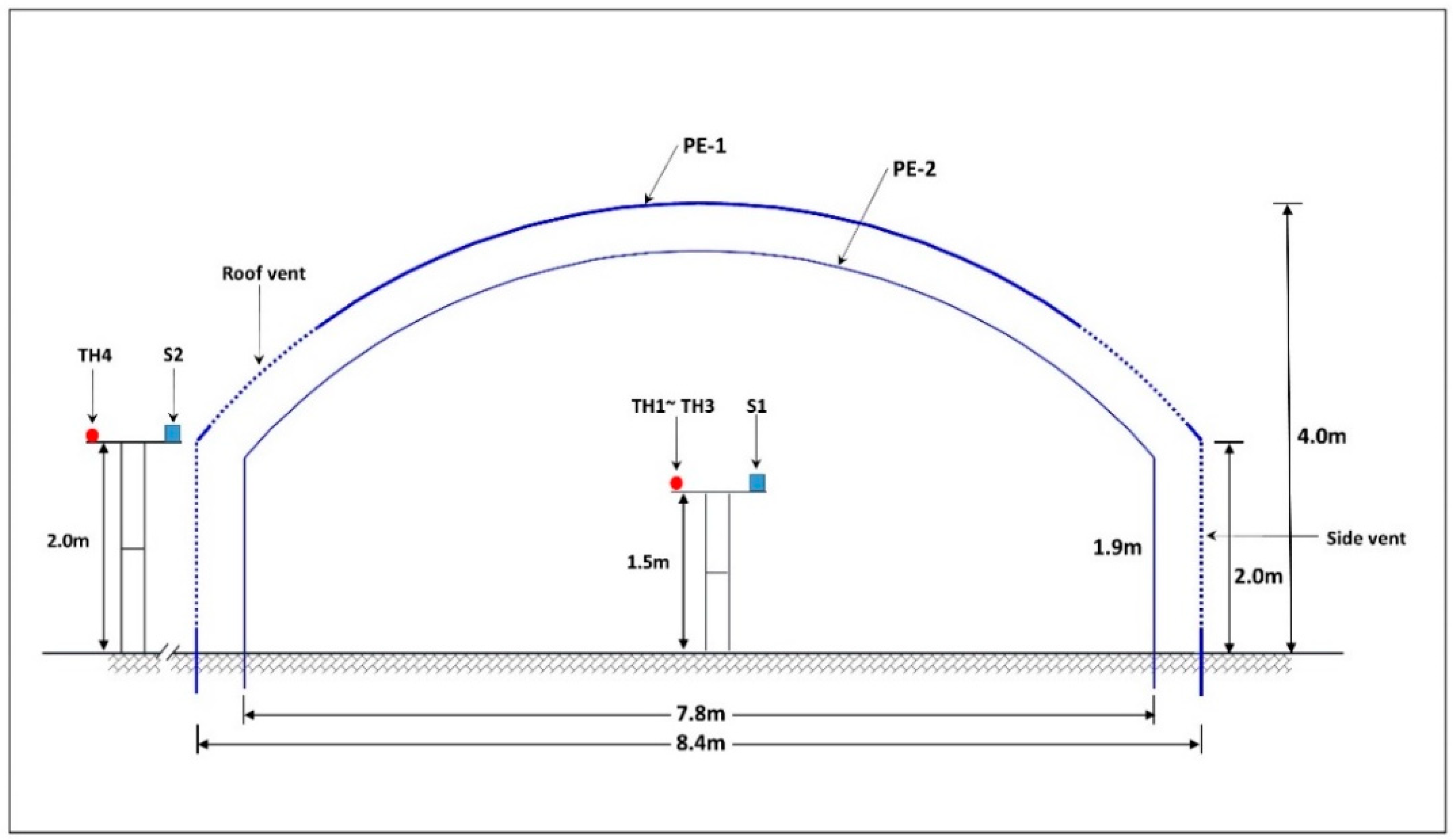

2.1. Experimental Greenhouse

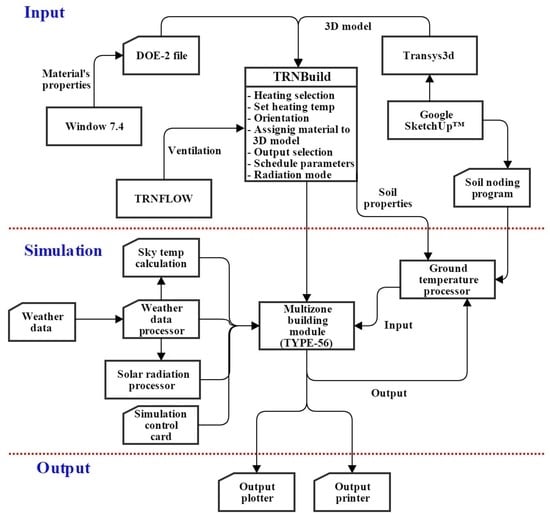

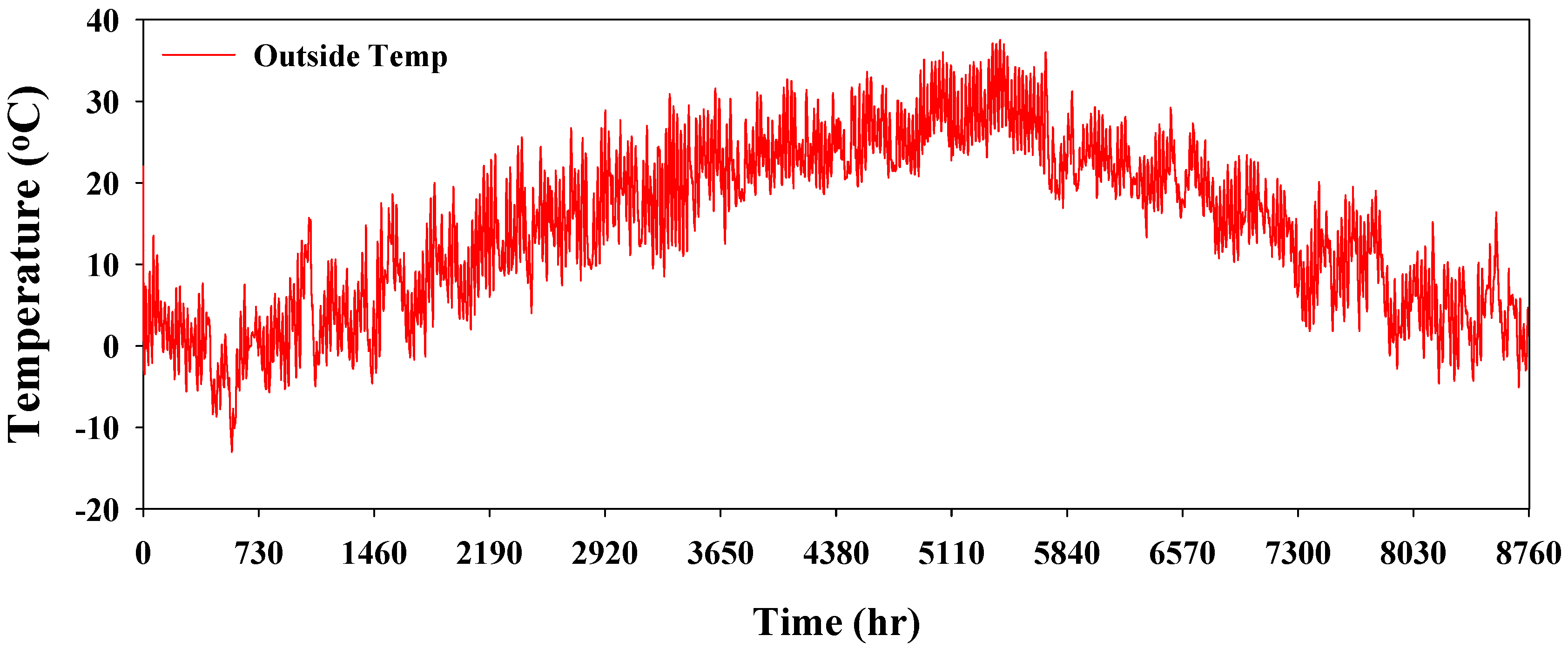

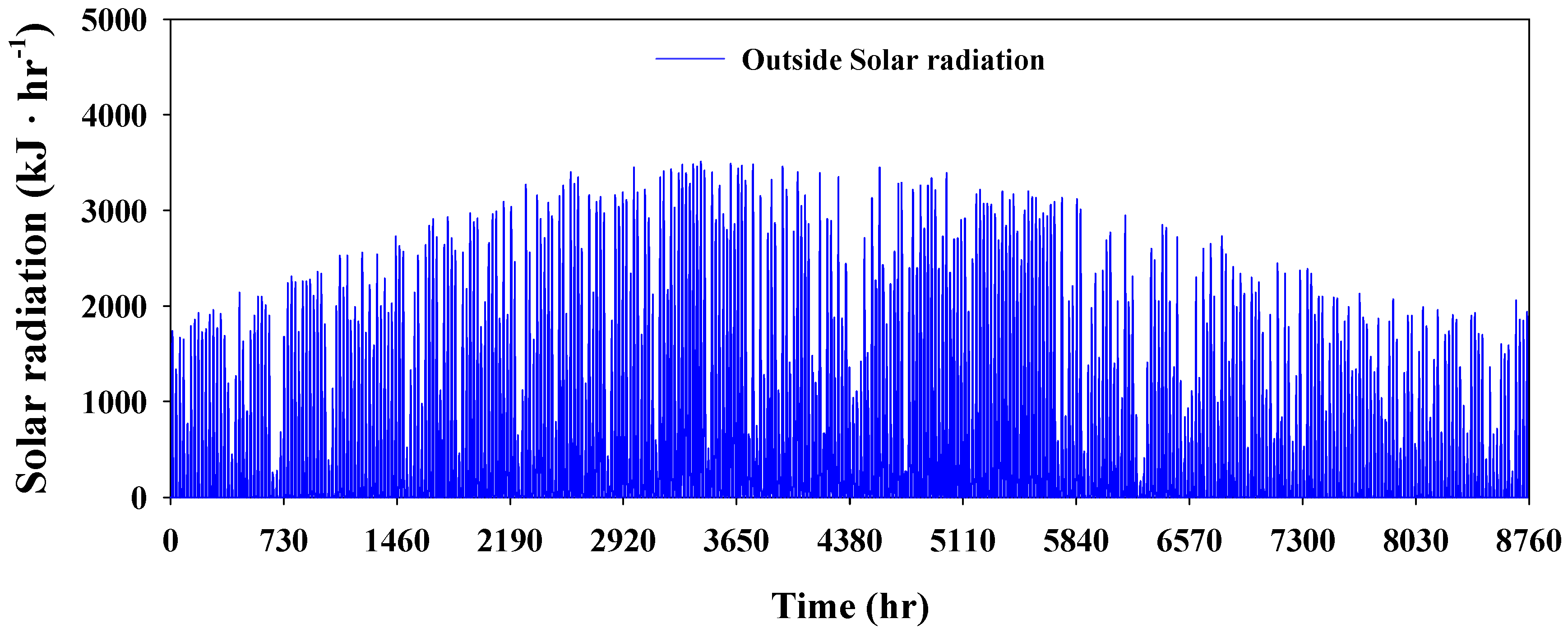

2.2. Building Energy Simulation (BES)

2.2.1. Modeling

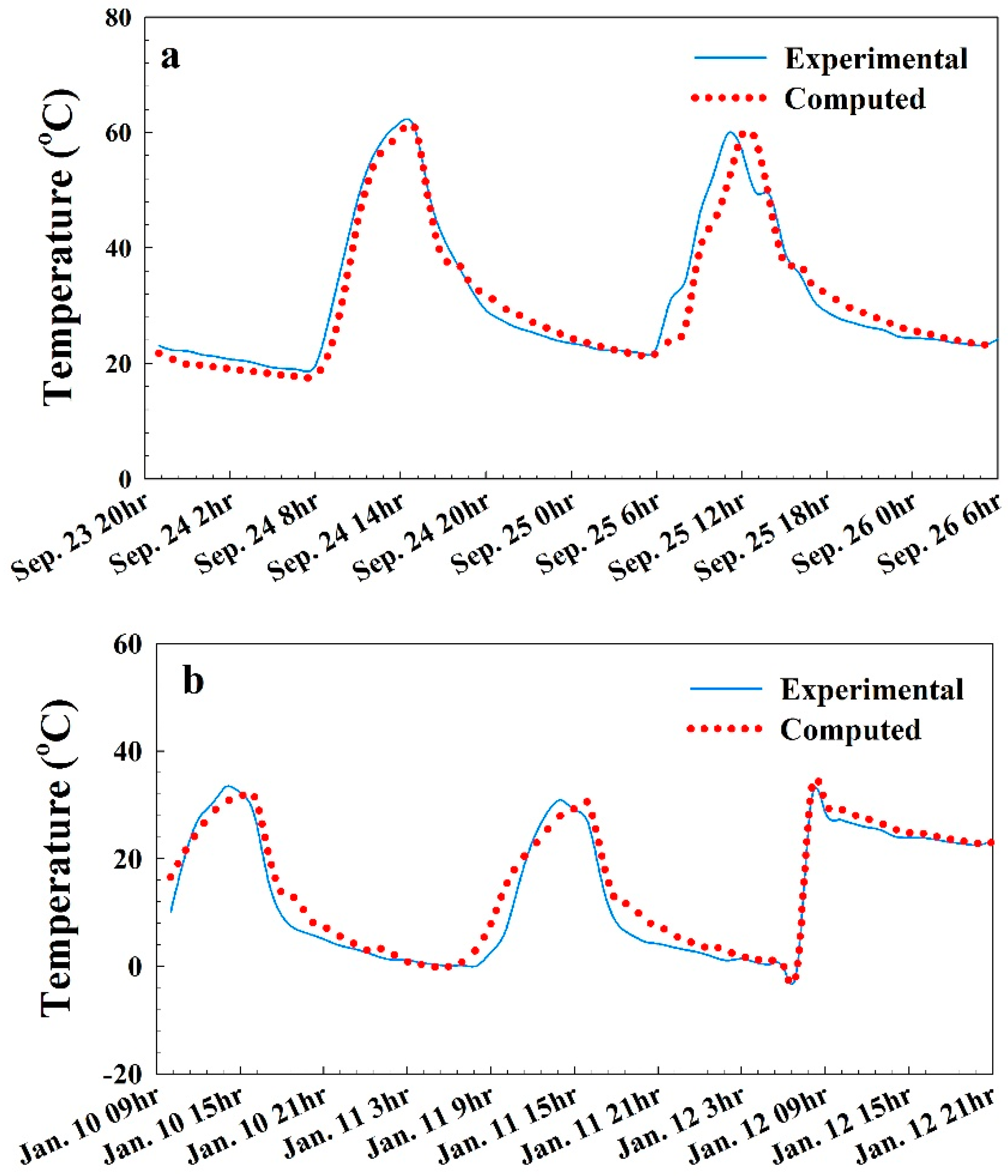

2.2.2. Statistical Analysis of the BES Model

2.2.3. Calibration

2.2.4. Validation

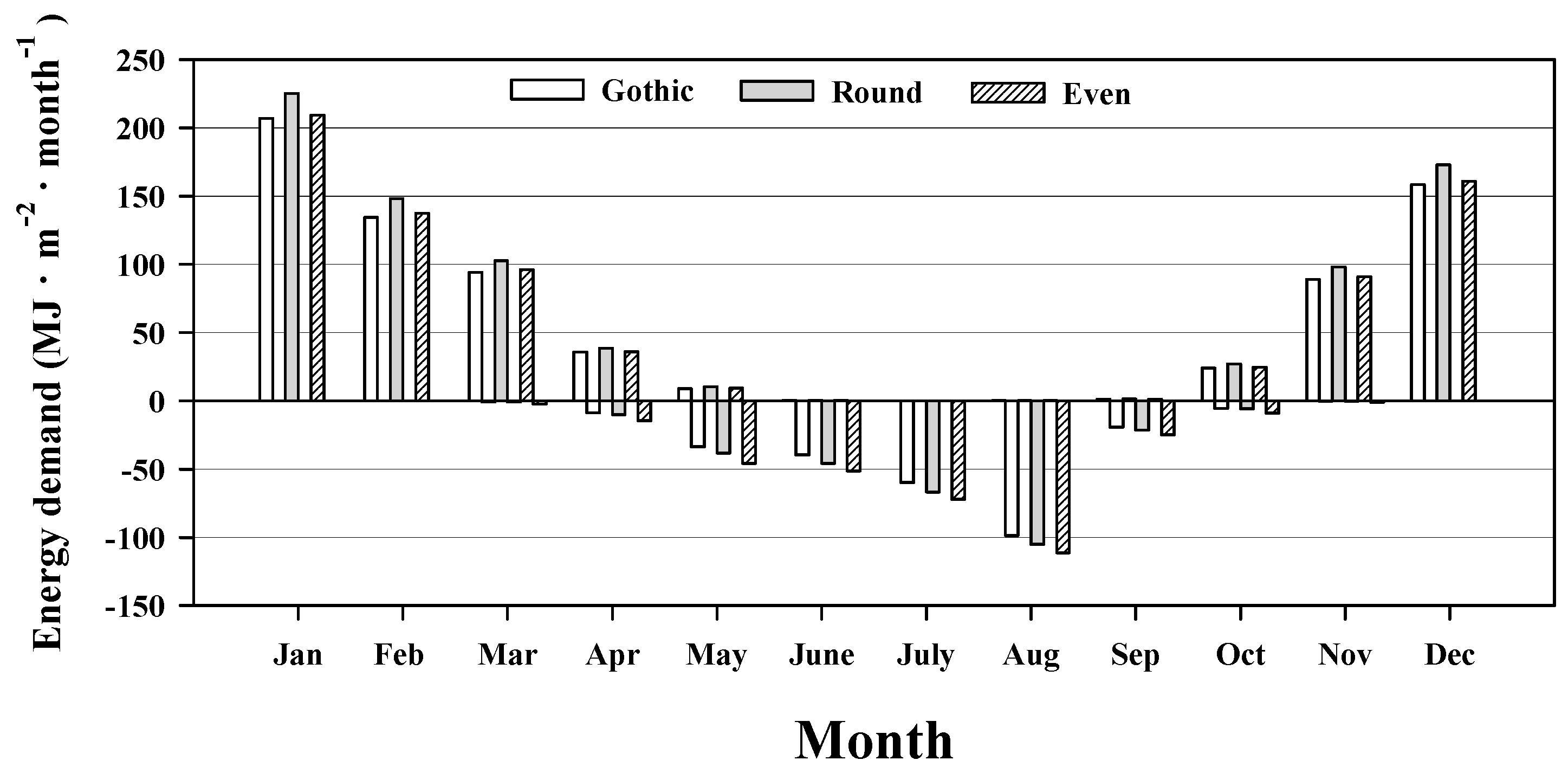

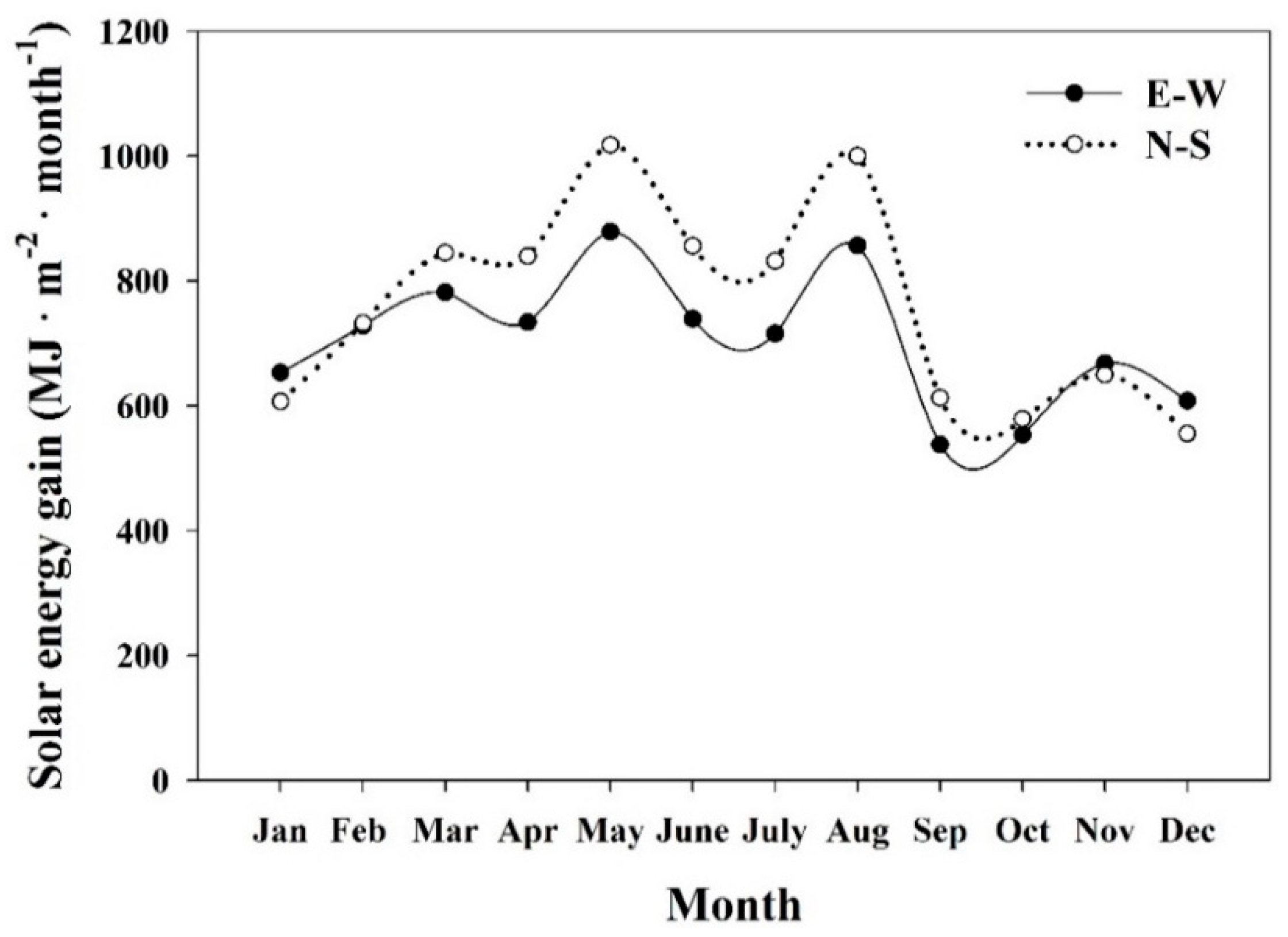

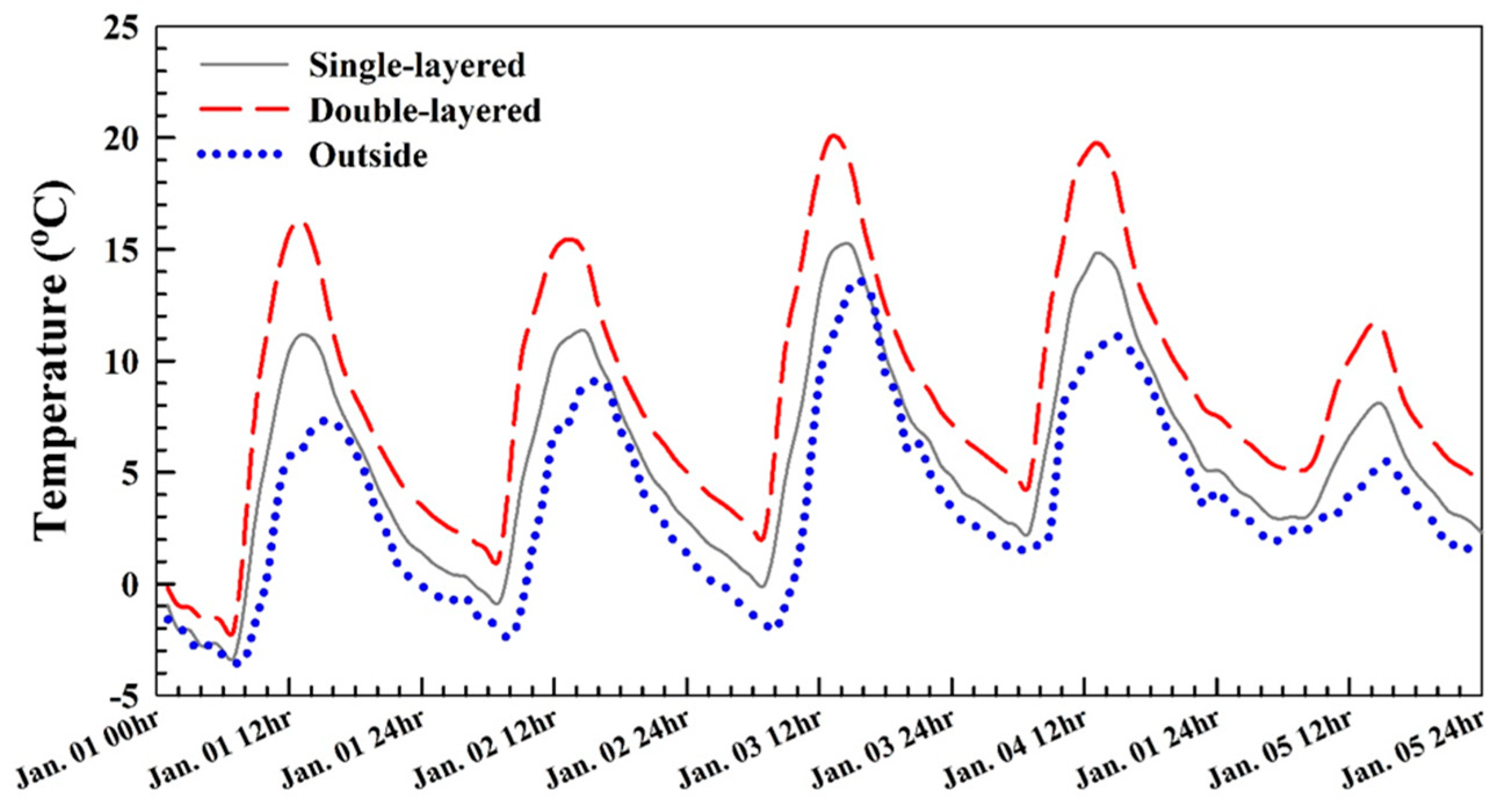

3. Results and Discussion

4. Conclusions

Supplementary Materials

Supplementary File 1Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Subscripts | |

| ai | Internal air |

| si | Internal surface |

| Abbreviations | |

| TRNSYS | Transient Systems Simulation |

| PE | Polyethylene |

| PVC | Polyvinyl chloride |

| HG | Horticulture glass |

| PMMA | Polymethylmethacrylate |

| PC | Polycarbonate |

| BES | Building energy simulation |

| KMA | Korean Meteorological Administration |

| NSE | Nash–Sutcliffe efficiency coefficient |

| Symbols | |

| T | Temperature |

| H | Humidity |

| S | Solar radiation |

| W | wind speed |

| hi | Internal convective heat transfer coefficient |

| he | External convective heat transfer coefficient |

| Tsi | Internal surface temperature |

| Ibt | Beam radiation on tilted surface |

| Igt | Reflected radiation tilted surface |

| Idt | Diffuse radiation tilted surface |

| Ib | Beam radiation on the horizontal surface |

| Id | Diffuse radiation on the horizontal surface |

| Rb | geometric factor |

| Incidence angle of beam radiation on the tilt surface | |

| Solar zenith angle | |

| β | Slope of a surface |

| Surface azimuth angle | |

| Solar azimuth angle | |

| Reflectance of the ground surface | |

| AI | Anisotropy index |

| f | Modulating factor |

| I | Total radiation on horizontal surface |

| θac | Angular location of circumsolar region |

| Yr | Year |

References

- Vadiee, A.; Martin, V. Solar blind system-solar energy utilization and climate mitigation in glassed buildings. Energy Procedia 2014, 57, 2023–2032. [Google Scholar] [CrossRef]

- Yang, S.H.; Lee, C.G.; Lee, W.K.; Ashtiani, A.A.; Kim, J.Y.; Lee, S.D.; Rhee, J.Y. Heating and cooling system for utilization of surplus air thermal energy in greenhouse and its control logic. J. Biosyst. Eng. 2012, 37, 19–27. [Google Scholar] [CrossRef]

- Carlini, M.; Castellucci, S. Modelling and simulation for energy production parametric dependence in greenhouses. Math. Probl. Eng. 2010, 2010. [Google Scholar] [CrossRef]

- Xaman, J.; Hernandez-Perez, I.; Arce, J.; Alvarez, G.; Ramirez-Davila, L.; Noh-Pat, F. Numerical study of earth-to-air heat exchanger: The effect of thermal insulation. Energy Build. 2014, 85, 356–361. [Google Scholar] [CrossRef]

- Sethi, V.P.; Sumathy, K.; Lee, C.; Pal, D.S. Thermal modeling aspects of solar greenhouse microclimate control: A review on heating technologies. Sol. Energy 2013, 96, 56–82. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Lin, W.D. Advanced applications of solar energy in agricultural greenhouses. Renew. Sustain. Energy Rev. 2016, 54, 989–1001. [Google Scholar] [CrossRef]

- Adnan, R.; Jong Won, L.; Hyun Woo, L. A review of greenhouse energy management by using building energy simulation. Prot. Hortic. Plant Fact. 2015, 24, 317–325. [Google Scholar]

- Calise, F. High temperature solar heating and cooling systems for different mediterranean climates: Dynamic simulation and economic assessment. Appl. Therm. Eng. 2012, 32, 108–124. [Google Scholar] [CrossRef]

- Voulgaraki, S.I.; Papadakis, G. Simulation of a Greenhouse Solar Heating System with Seasonal Storage in Greece. In Proceedings of the International Society for Horticultural Science (ISHS), Leuven, Belgium, 1 September 2008; pp. 757–764. [Google Scholar]

- Carlini, M.; Honorati, T.; Castellucci, S. Photovoltaic greenhouses: Comparison of optical and thermal behaviour for energy savings. Math. Probl. Eng. 2012, 2012. [Google Scholar] [CrossRef]

- Attar, I.; Naili, N.; Khalifa, N.; Hazami, M.; Farhat, A. Parametric and numerical study of a solar system for heating a greenhouse equipped with a buried exchanger. Energy Convers. Manag. 2013, 70, 163–173. [Google Scholar] [CrossRef]

- Asdrubali, F.; Cotana, F.; Messineo, A. On the evaluation of solar greenhouse efficiency in building simulation during the heating period. Energies 2012, 5, 1864. [Google Scholar] [CrossRef]

- Chargui, R.; Sammouda, H.; Farhat, A. Geothermal heat pump in heating mode: Modeling and simulation on trnsys. Int. J. Refrig. 2012, 35, 1824–1832. [Google Scholar] [CrossRef]

- Lee, S.; Lee, I.; Hwang, H.; Hong, S.; Seo, I.; Kwon, K.; Ha, T. Design and assessment of greenhouse using ground source heat pump system, Energy, biomass and biological residues. In Proceedings of the International Conference of Agricultural Engineering-CIGR-AgEng 2012: Agriculture and Engineering for a Healthier Life, Valencia, Spain, 8–12 July 2012; p. 1248. [Google Scholar]

- Hoes, H.; Desmedt, J.; Goen, K.; Wittemans, L. The geskas project, closed greenhouse as energy source and optimal growing environment. In Proceedings of the International Society for Horticultural Science (ISHS), Leuven, Belgium, 1 September 2008; pp. 1355–1362. [Google Scholar]

- Vadiee, A.; Martin, V. Energy analysis and thermoeconomic assessment of the closed greenhouse—the largest commercial solar building. Appl. Energy 2013, 102, 1256–1266. [Google Scholar] [CrossRef]

- Dalamagkidis, K.; Saridakis, G.; Kolokotsa, D. Development of simulation algorithms for control scheme optimization in greenhouses. In Proceedings of the Dynastee Scientific Conference, Athens, Greece, 12–14 October 2005. [Google Scholar]

- Kolokotsa, D.; Saridakis, G.; Dalamagkidis, K.; Dolianitis, S.; Kaliakatsos, I. Development of an intelligent indoor environment and energy management system for greenhouses. Energy Convers. Manag. 2010, 51, 155–168. [Google Scholar] [CrossRef]

- Serir, L.; Bournet, P.E.; Benmoussa, H.; Mesmoudi, K. Thermal simulation of a greenhouse under a semi-arid climate. In Proceedings of the International Society for Horticultural Science (ISHS), Leuven, Belgium, 1 July 2012; pp. 635–642. [Google Scholar]

- Lee, S.-B.; Lee, I.-B.; Homg, S.-W.; Seo, I.-H.; Bitog, P.J.; Kwon, K.-S.; Ha, T.-H.; Han, C.-P. Prediction of greenhouse energy loads using building energy simulation (bes). J. Korean Soc. Agric. Eng. 2012, 54, 113–124. [Google Scholar] [CrossRef]

- Ishigami, Y.; Goto, E.; Watanabe, M.; Takahashi, T.; Okushima, L. Development of a simulation model to evaluate environmental controls in a tomato greenhouse. Acta Hortic. 2014, 1037, 93–98. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, P.; Mao, J.; Tang, X.; Li, Z.; Shi, J. A low cost seasonal solar soil heat storage system for greenhouse heating: Design and pilot study. Appl. Energy 2015, 156, 213–222. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, S.N.; Lee, I.B. Calculation of heating and cooling loads for plastic film greenhouse utilizing power plant hot water by using building energy simulation. In Proceedings of the Korean Society for Bio-Environment Control Conference, Cheongju, Korea, 7–8 October 2015; pp. 31–32. [Google Scholar]

- Gupta, M.J.; Chandra, P. Effect of greenhouse design parameters on conservation of energy for greenhouse environmental control. Energy 2002, 27, 777–794. [Google Scholar] [CrossRef]

- Gupta, R.; Tiwari, G.; Kumar, A.; Gupta, Y. Calculation of total solar fraction for different orientation of greenhouse using 3d-shadow analysis in auto-cad. Energy Build. 2012, 47, 27–34. [Google Scholar] [CrossRef]

- Sethi, V.P. On the selection of shape and orientation of a greenhouse: Thermal modeling and experimental validation. Sol. Energy 2009, 83, 21–38. [Google Scholar] [CrossRef]

- Watts, D.; Jara, D. Statistical analysis of wind energy in chile. Renew. Energy 2011, 36, 1603–1613. [Google Scholar] [CrossRef]

- Valera, M.D.; Molina, A.F.; Alvarez, M.A. Protocolo de Auditoría Energética en Invernaderos. Auditoría Energética de un Invernadero para Cultivo de flor Cortada en Mendigorría; Instituto Para La Diversificación Y Ahorro De La Energía: Madrid, Spain, 15 June 2011. (In Spanish) [Google Scholar]

- Rasheed, A.; Lee, J.W.; Lee, H.W. Development of a model to calculate the overall heat transfer coefficient of greenhouse covers. Span. J. Agric. Res. 2017, 15, 4. [Google Scholar] [CrossRef]

- Klein, S.A. Trnsys, a Transient System Simulation Program; Solar Energy Laborataory, University of Wisconsin: Madison, WI, USA, 2012; pp. 92–95. [Google Scholar]

- Liu, B.; Jordan, R. Daily insolation on surfaces tilted towards equator. ASHRAE J. 1961, 10, 53–59. [Google Scholar]

- Hay, J.E.; Davies, J.A. Calculation of the Solar Radiation Incident on an Inclined Surface. In Proceedings of the First Canadian Solar Radiation Data Workshop; Hay, J.E., Won, T.K., Eds.; Ministry of Supply and Services Canada: Toronto, ON, Canada, 1980. [Google Scholar]

- Reindl, D.T.; Beckman, W.A.; Duffie, J.A. Evaluation of hourly tilted surface radiation models. Sol. Energy 1990, 45, 9–17. [Google Scholar] [CrossRef]

- Perez, R.; Seals, R.; Ineichen, P.; Stewart, R.; Menicucci, D. A new simplified version of the perez diffuse irradiance model for tilted surfaces. Sol. Energy 1987, 39, 221–231. [Google Scholar] [CrossRef] [Green Version]

- Iqbal, M. An Introduction to Solar Radiation; Elsevier: Toronto, ON, Canada, 2012; Available online: https://books.google.com.hk/books?id=3_qWce_mbPsC&printsec=frontcover&hl=zh-TW&source=gbs_ge_summary_r&cad=0#v=onepage&q&f=false (accessed on 14 November 2017).

- Noorian, A.M.; Moradi, I.; Kamali, G.A. Evaluation of 12 models to estimate hourly diffuse irradiation on inclined surfaces. Renew. Energy 2008, 33, 1406–1412. [Google Scholar] [CrossRef]

- Nam, S. Roof ventilation structures and ridge vent effect for single span greenhouses of arch shape. CNU J. Agric. Sci. 2001, 28, 99–107. [Google Scholar]

- Gan, G. Thermal transmittance of multiple glazing: Computational fluid dynamics prediction. Appl. Therm. Eng. 2001, 21, 1583–1592. [Google Scholar] [CrossRef]

| Weather Parameter | Unit | Time Interval | Sensor | Data Recorded |

|---|---|---|---|---|

| Temperature | °C | 10 min | TR-76Ui-H, TECPEL | Field recorded |

| Relative humidity | % | 10 min | TR-76Ui-H, TECPEL | Field recorded |

| Solar radiation | kW | 10 min | CMP3, Kipp & Zonen | Field recorded |

| Wind speed | ms–1 | 1 h | JY-WS161B, Jingang | KMA |

| Wind direction | degree | 1 h | JY-WS161B, Jingang | KMA |

| Ambient pressure | hPa | 1 h | PTB-220TS, VAISALA | KMA |

| Parameter | Test Condition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Roof shape | Gothic | Round | Even roof | |||||||||

| Orientation | 0 (E-W) | 30 | 45 | 60 | 75 | 90 (N-S) | ||||||

| Glazing | Single | Double | ||||||||||

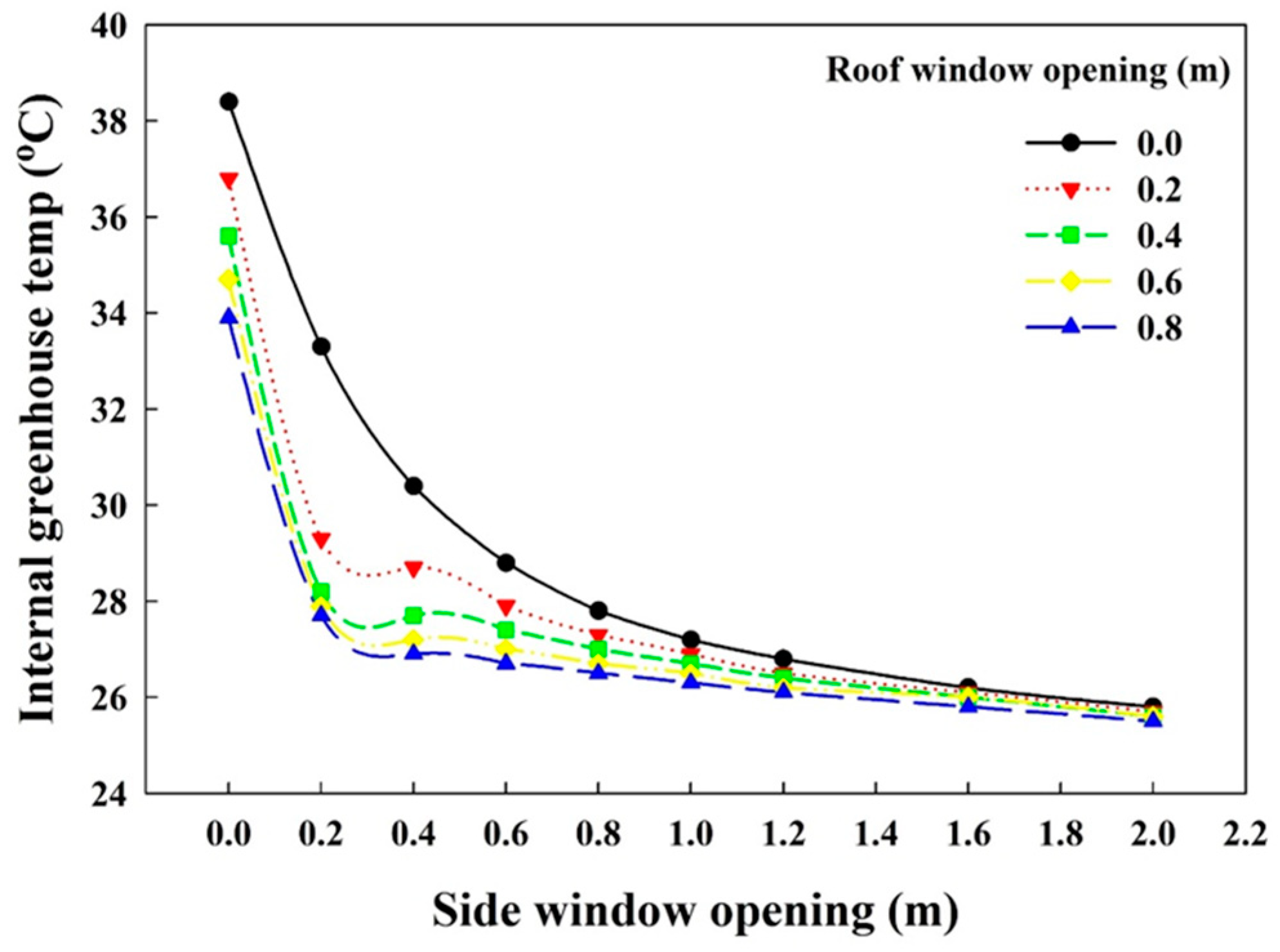

| Natural ventilation | Side vent opening (m) | 0.0 | 0.2 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | 2.0 |

| Roof vent opening (m) | 0.0 | 0.2 | 0.4 | 0.6 | 0.8 | |||||||

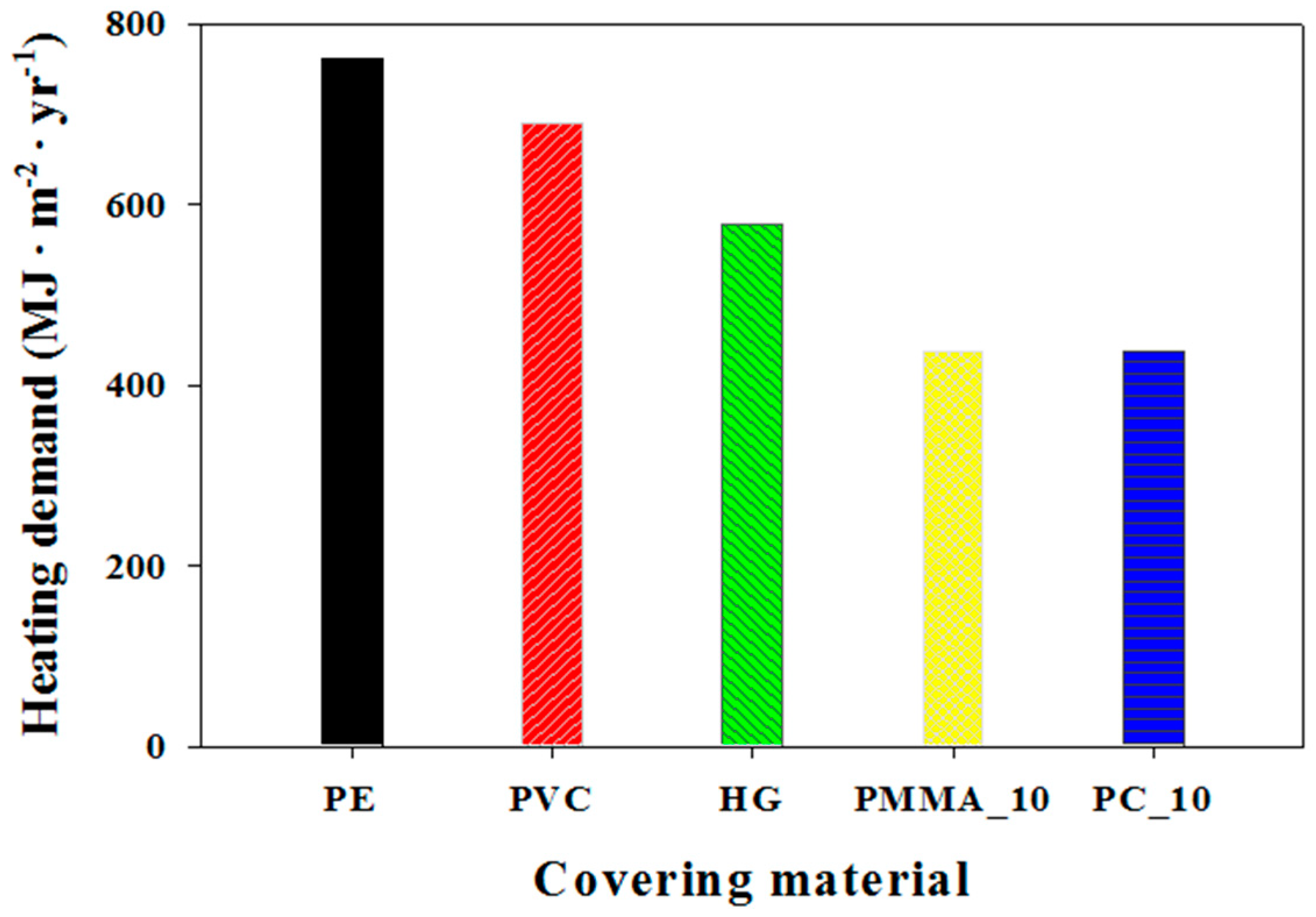

| Covering material | PE | PVC | HG | PMMA | PC | |||||||

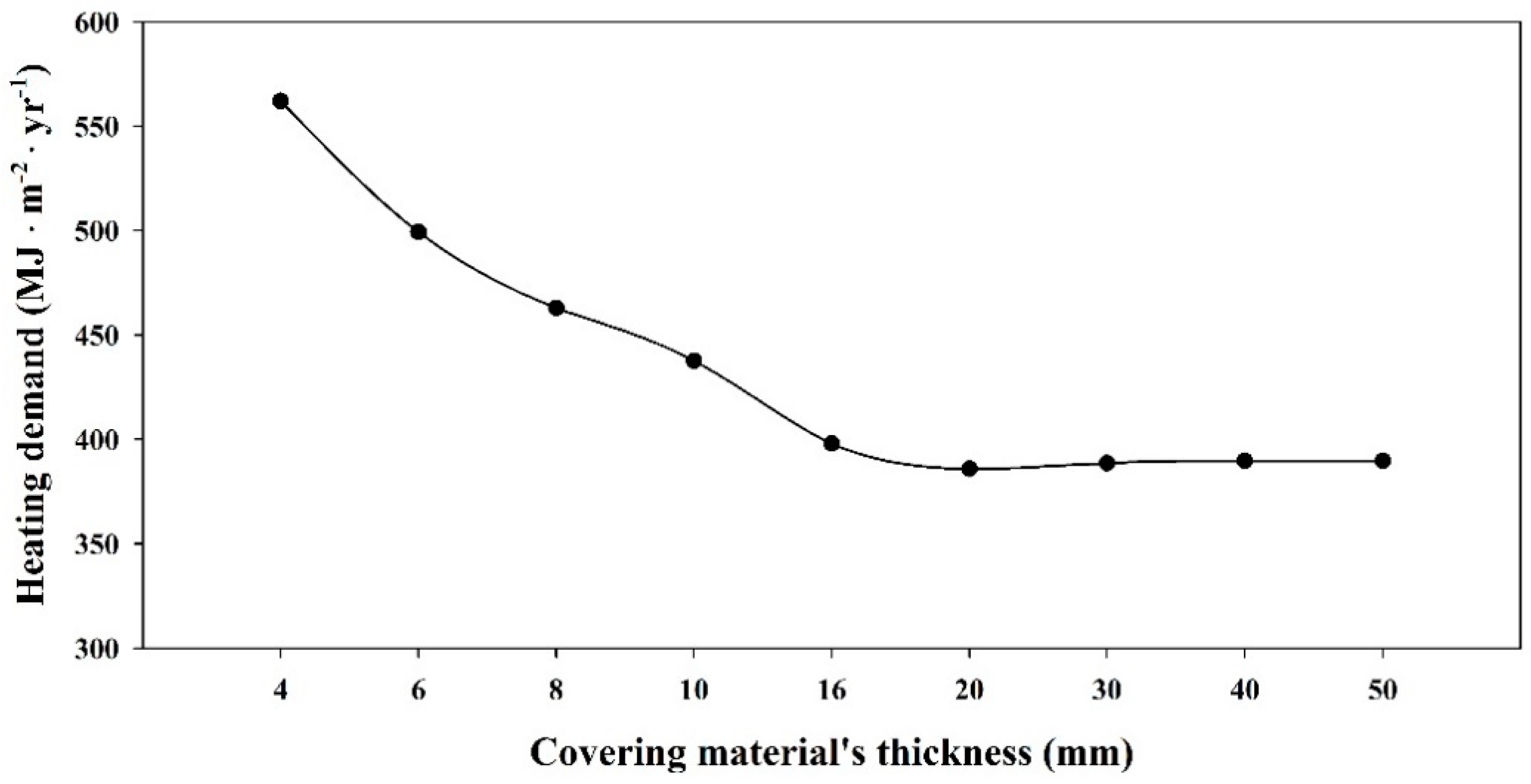

| Thickness of PMMA (mm) | 4 | 6 | 8 | 10 | 16 | 20 | 30 | 40 | 50 | |||

| Cover Characteristics | Greenhouse Covers | ||||

|---|---|---|---|---|---|

| PE | PVC | HG | PMMA | PC | |

| Solar transmittance | 0.86 | 0.91 | 0.89 | 0.82 | 0.78 |

| Solar reflectance | 0.10 | 0.07 | 0.08 | 0.12 | 0.14 |

| Visible radiation transmittance | 0.89 | 0.92 | 0.91 | 0.92 | 0.75 |

| Visible radiation reflectance | 0.08 | 0.14 | 0.08 | 0.07 | 0.15 |

| Thermal radiation transmittance | 0.18 | 0.06 | 0.00 | 0.00 | 0.02 |

| Thermal radiation emission | 0.79 | 0.62 | 0.90 | 0.98 | 0.89 |

| Conductivity (W m−1 K−1) | 0.33 | 0.13 | 0.76 | 0.19 | 0.19 |

| Thickness (mm) | 0.10 | 0.10 | 4.00 | 10 | 10 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasheed, A.; Lee, J.W.; Lee, H.W. Development and Optimization of a Building Energy Simulation Model to Study the Effect of Greenhouse Design Parameters. Energies 2018, 11, 2001. https://doi.org/10.3390/en11082001

Rasheed A, Lee JW, Lee HW. Development and Optimization of a Building Energy Simulation Model to Study the Effect of Greenhouse Design Parameters. Energies. 2018; 11(8):2001. https://doi.org/10.3390/en11082001

Chicago/Turabian StyleRasheed, Adnan, Jong Won Lee, and Hyun Woo Lee. 2018. "Development and Optimization of a Building Energy Simulation Model to Study the Effect of Greenhouse Design Parameters" Energies 11, no. 8: 2001. https://doi.org/10.3390/en11082001