Integrated Sizing and Energy Management for Four-Wheel-Independently-Actuated Electric Vehicles Considering Realistic Constructed Driving Cycles

Abstract

:1. Introduction

1.1. Motivation

1.2. Literature Review

1.3. Contributions of This Study

1.4. Orgnization of This Paper

2. Powertrain Architecture and System Modeling

2.1. Powertrain Architecture

- The employed in-wheel motors are identical and with the same characteristics;

- There are no time delays during motor control implementation.

2.2. System Modeling

2.2.1. Vehicle Model

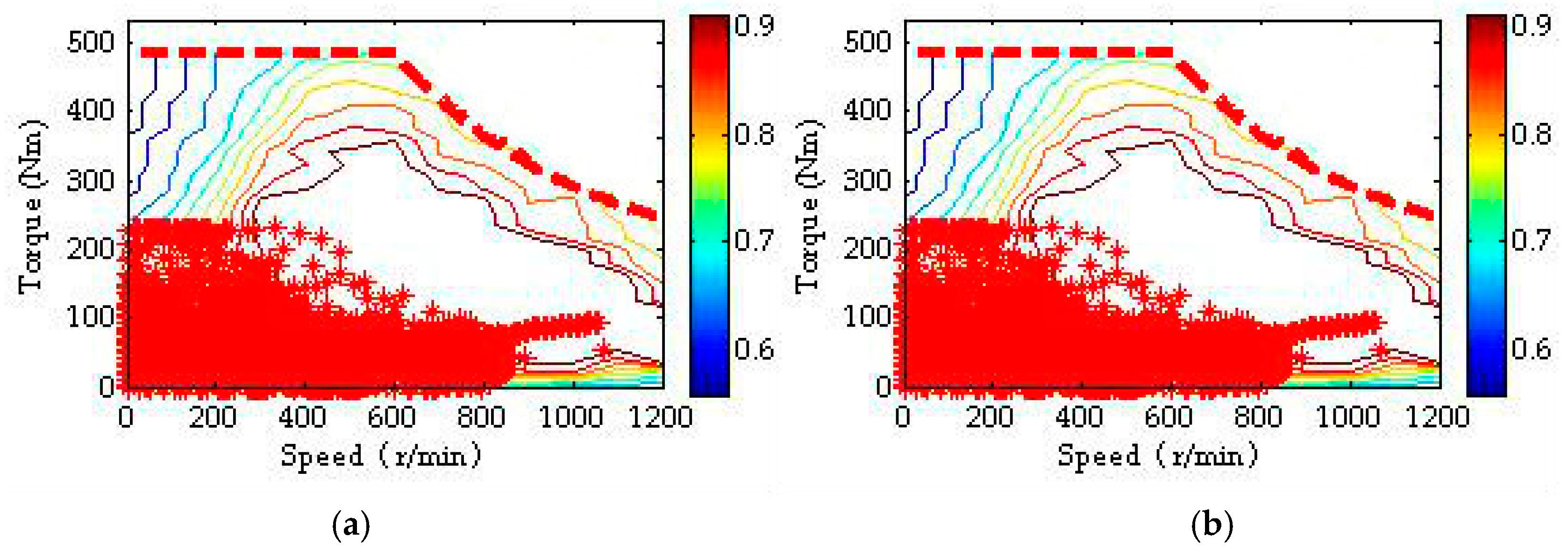

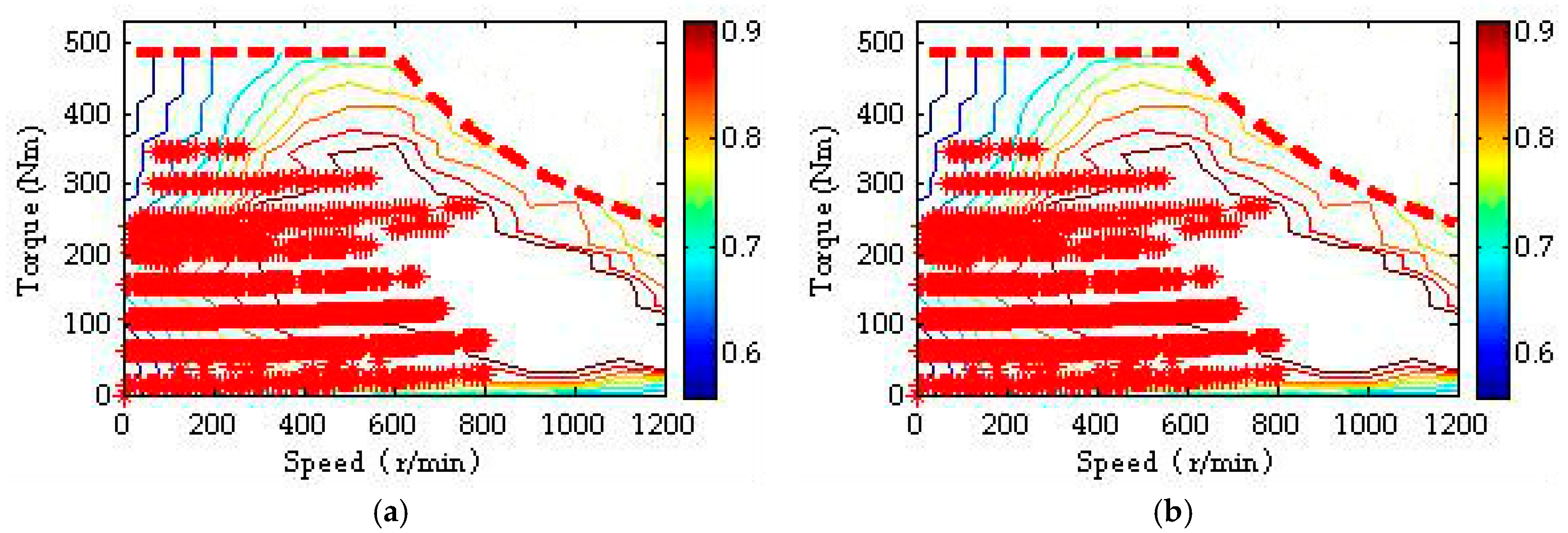

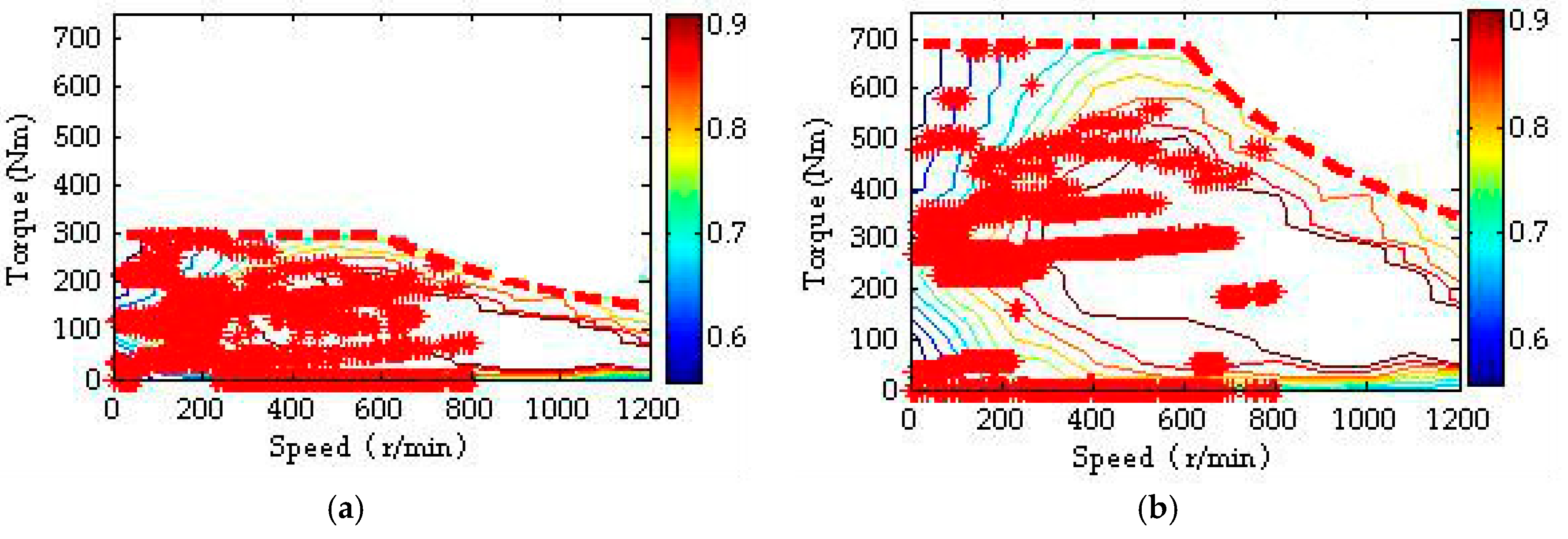

2.2.2. Motor Model

2.2.3. Battery Model

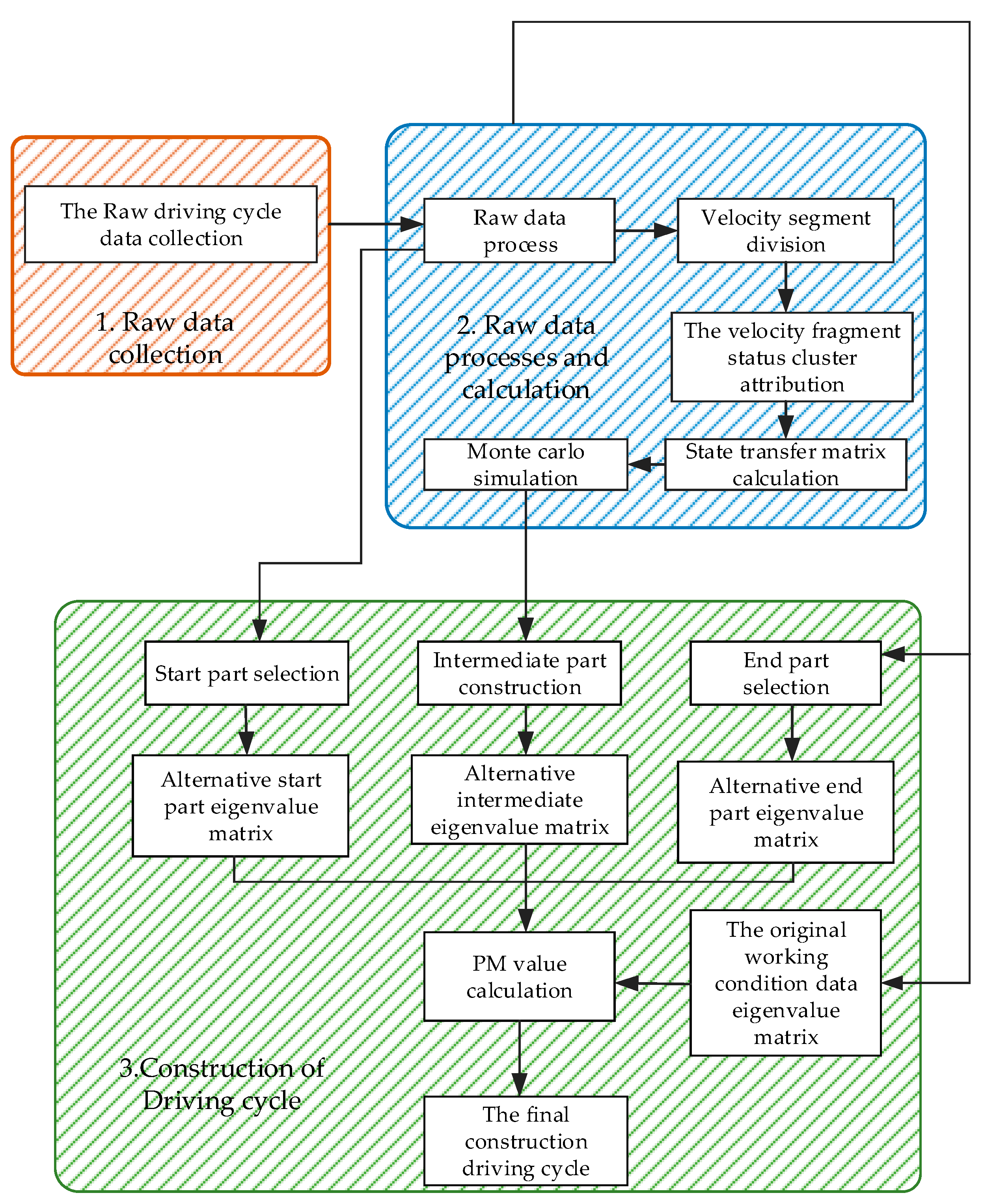

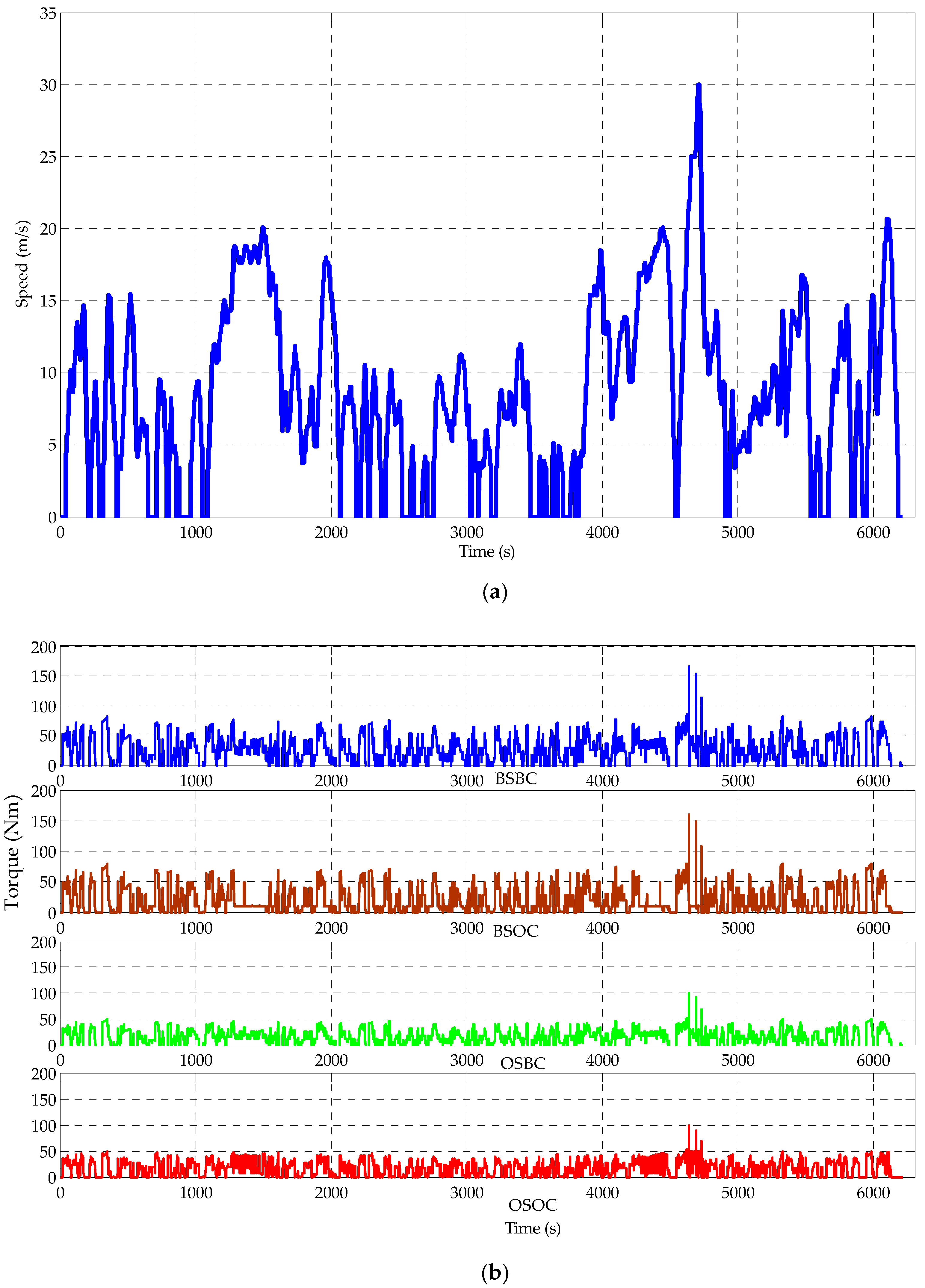

3. Driving Cycle Construction Based on the Markov Chain

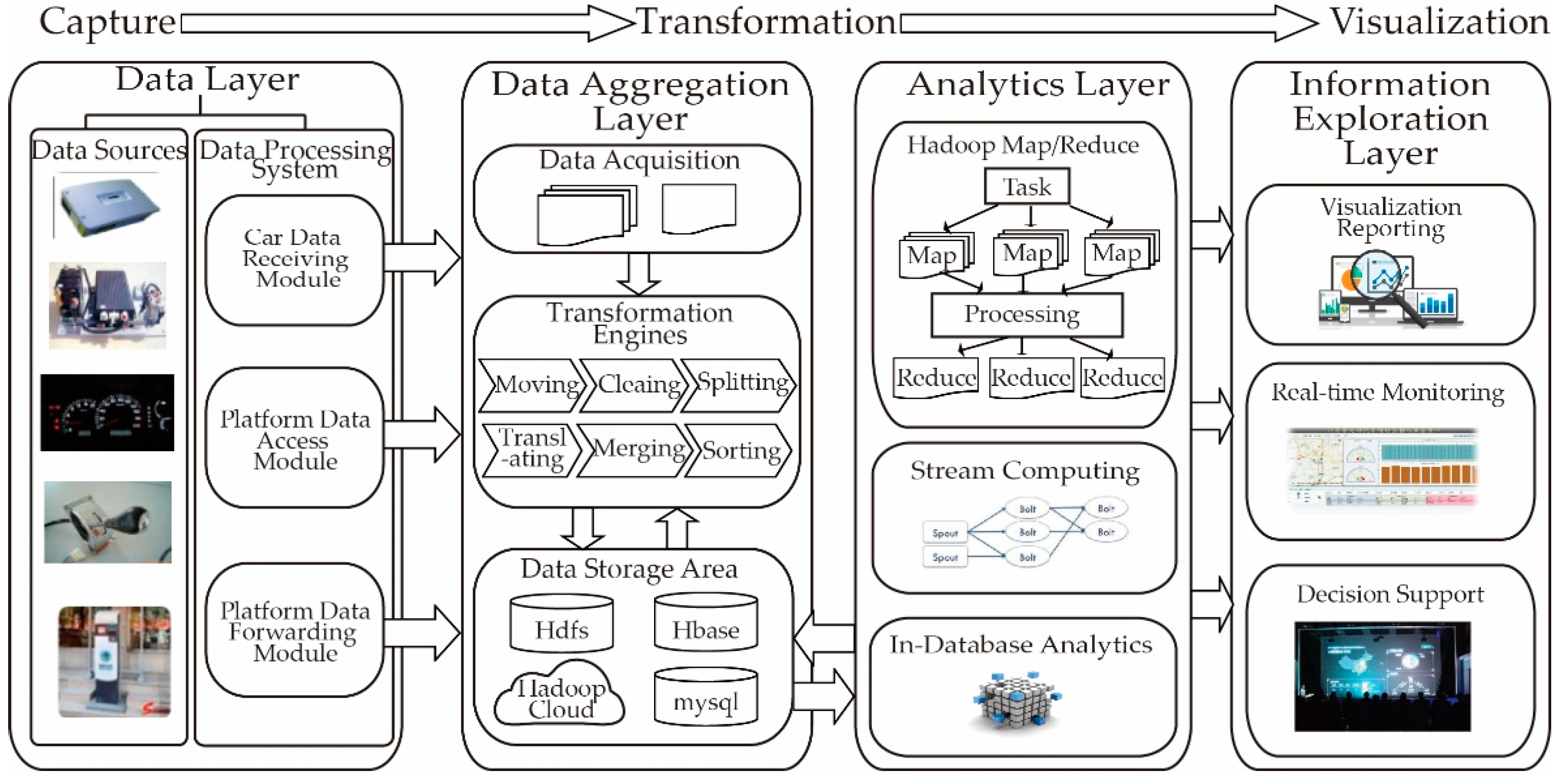

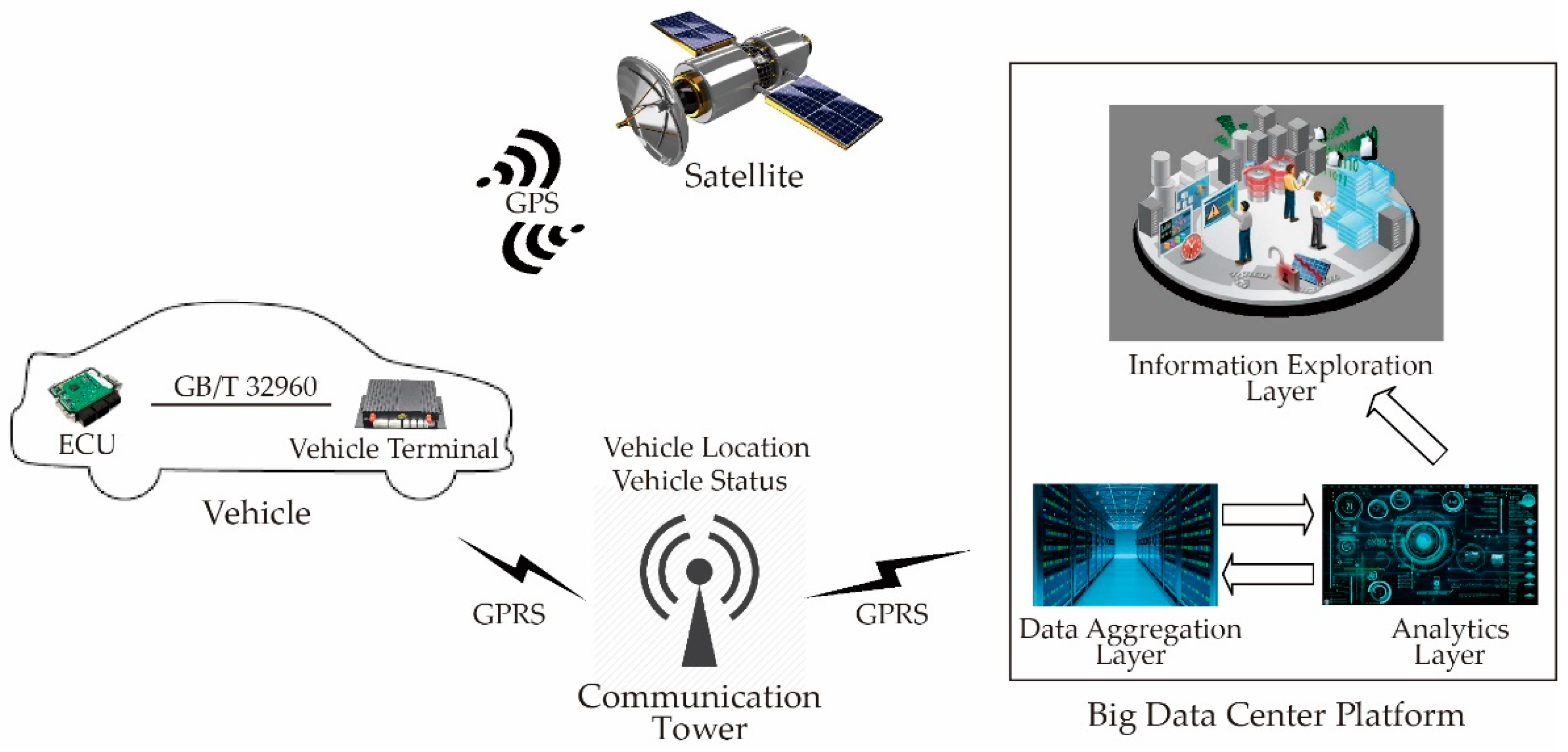

3.1. Raw Data Collection

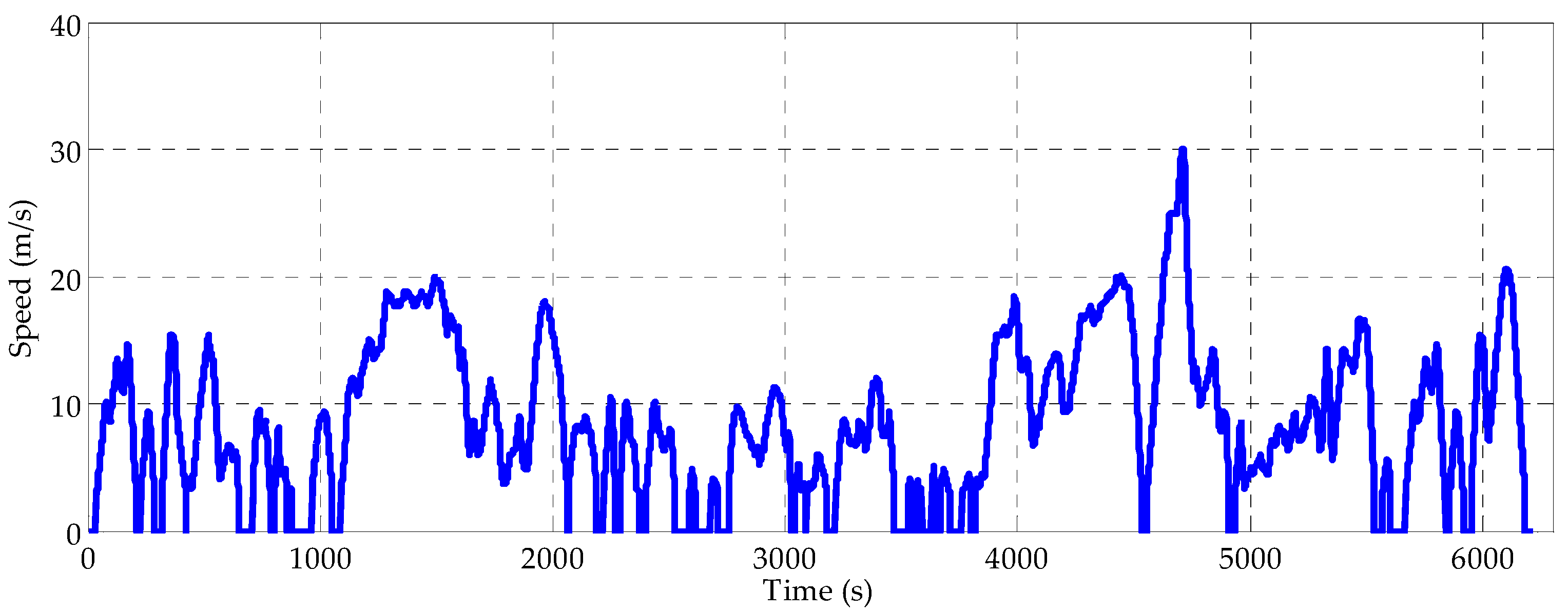

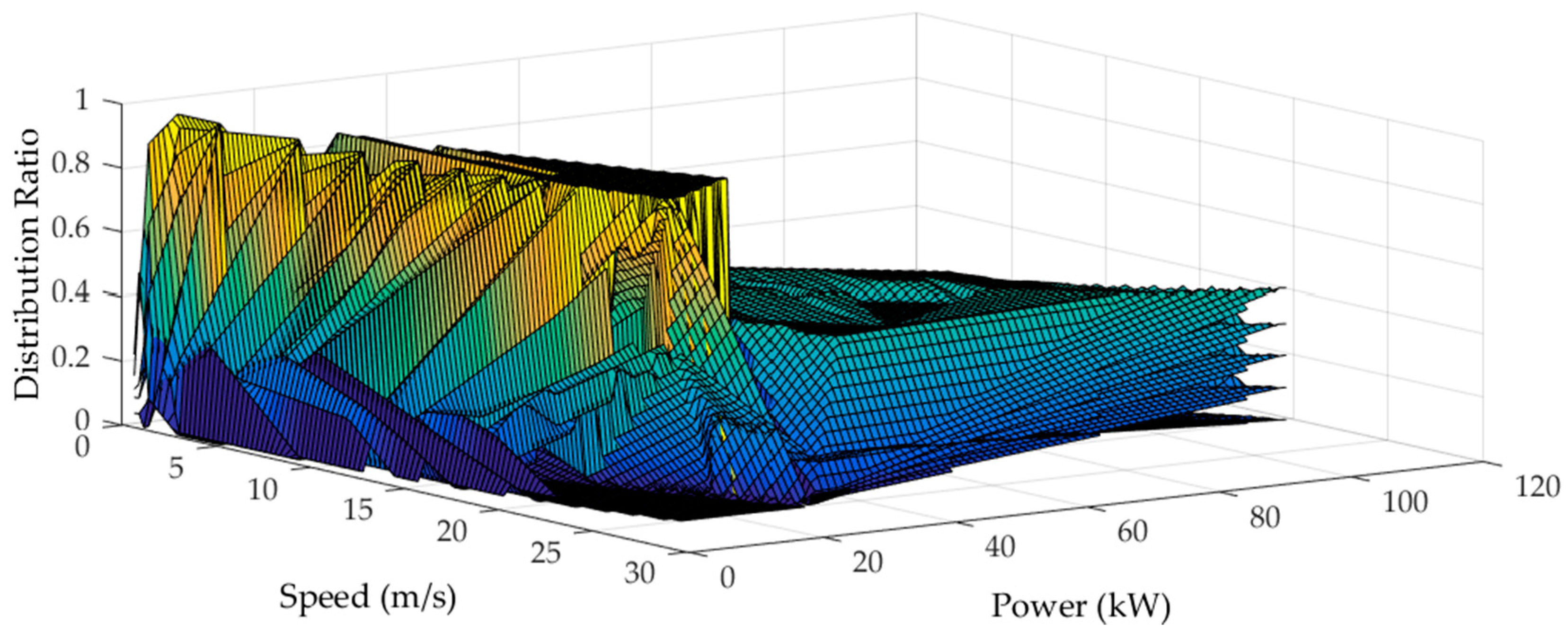

3.2. Data Processing and Calculation

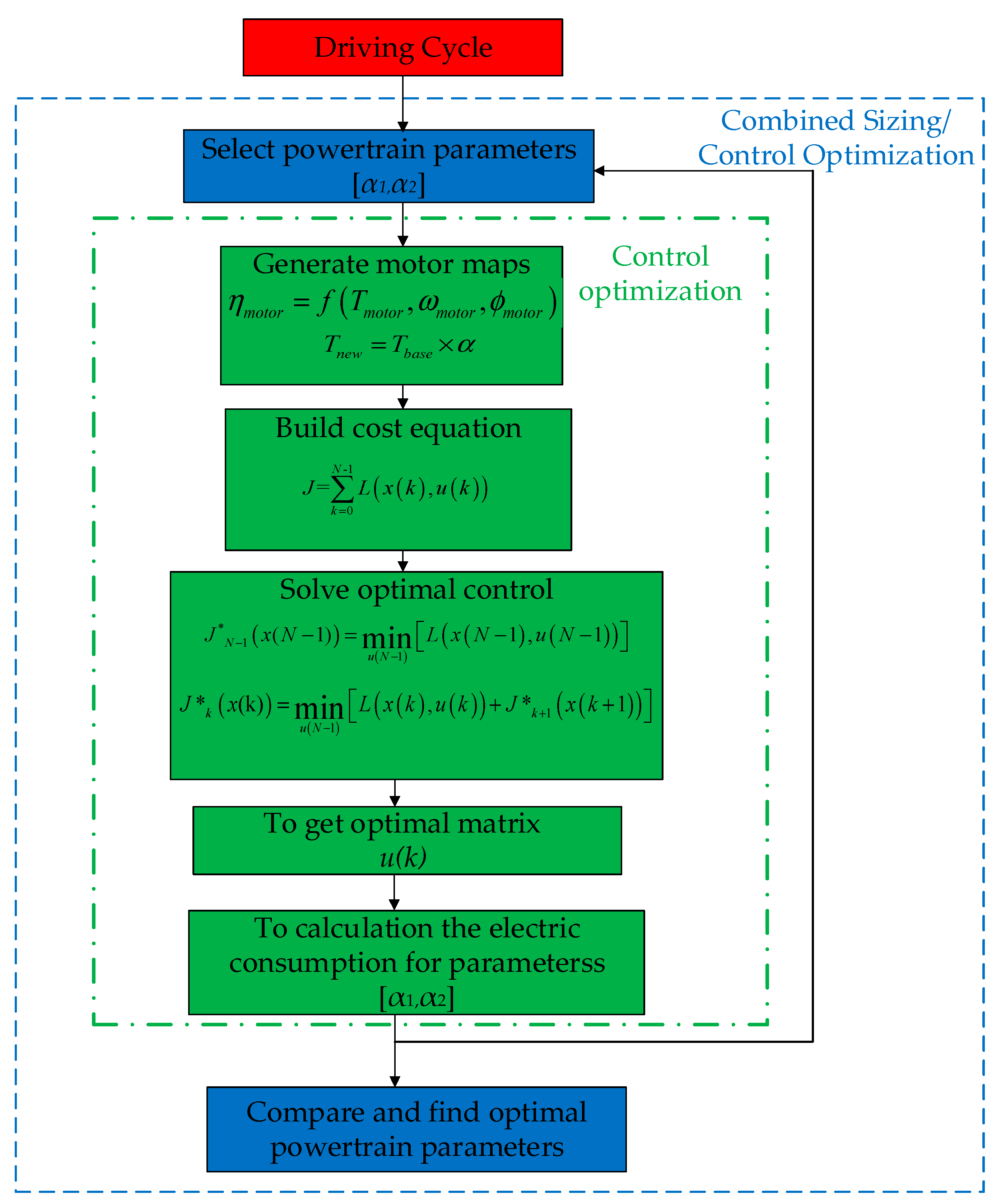

4. Integrated Sizing/Control Optimization of the Four-Wheel-Independently-Actuated Electric Vehicles (FWIA EVs)

4.1. Control Optimization of the FWIA EV

4.1.1. Problem Formulation

4.1.2. The Dynamic Programming Implementation

4.1.3. Rule Extraction

4.2. Combined Sizing/Control Optimization of the FWIA EV

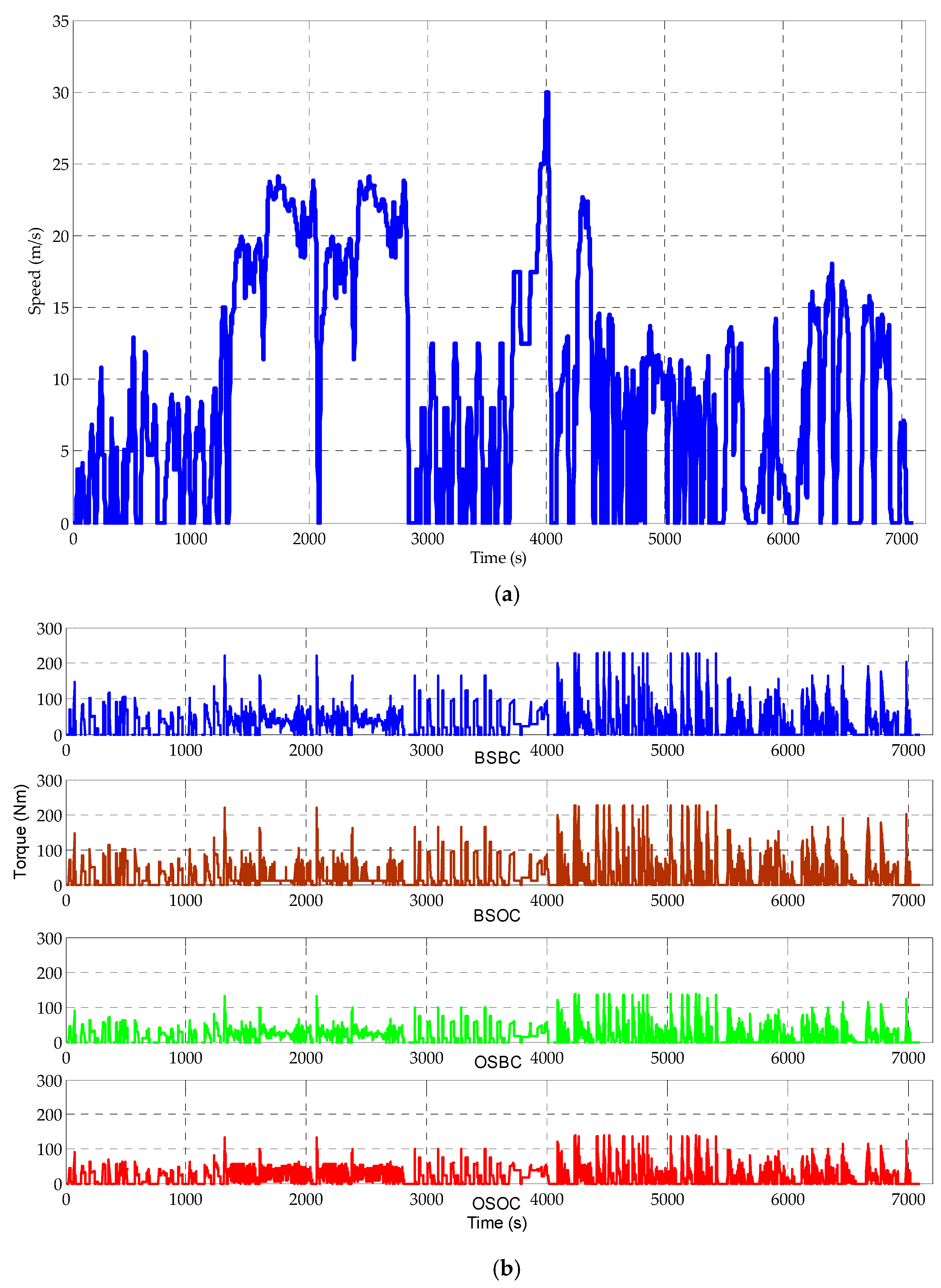

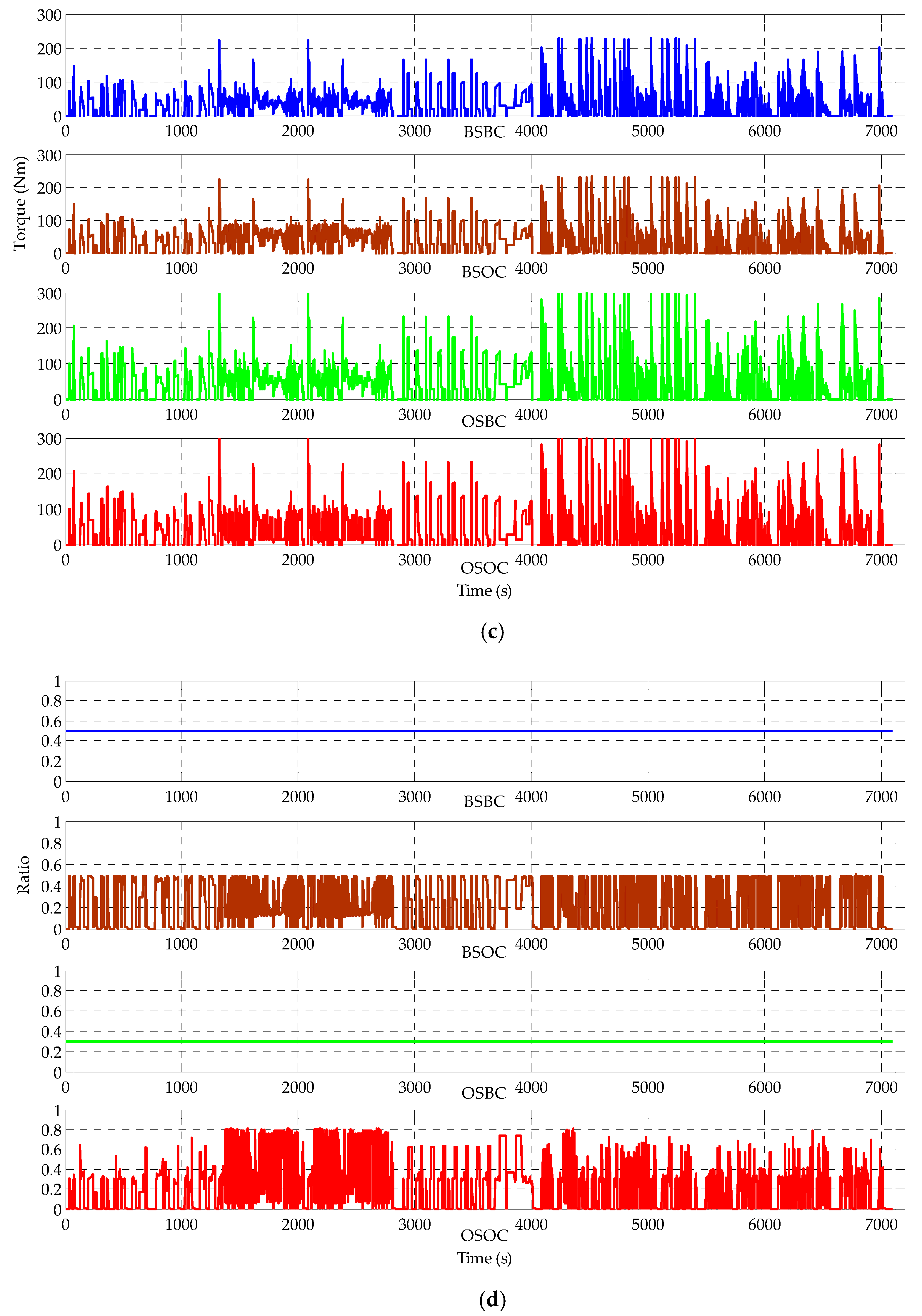

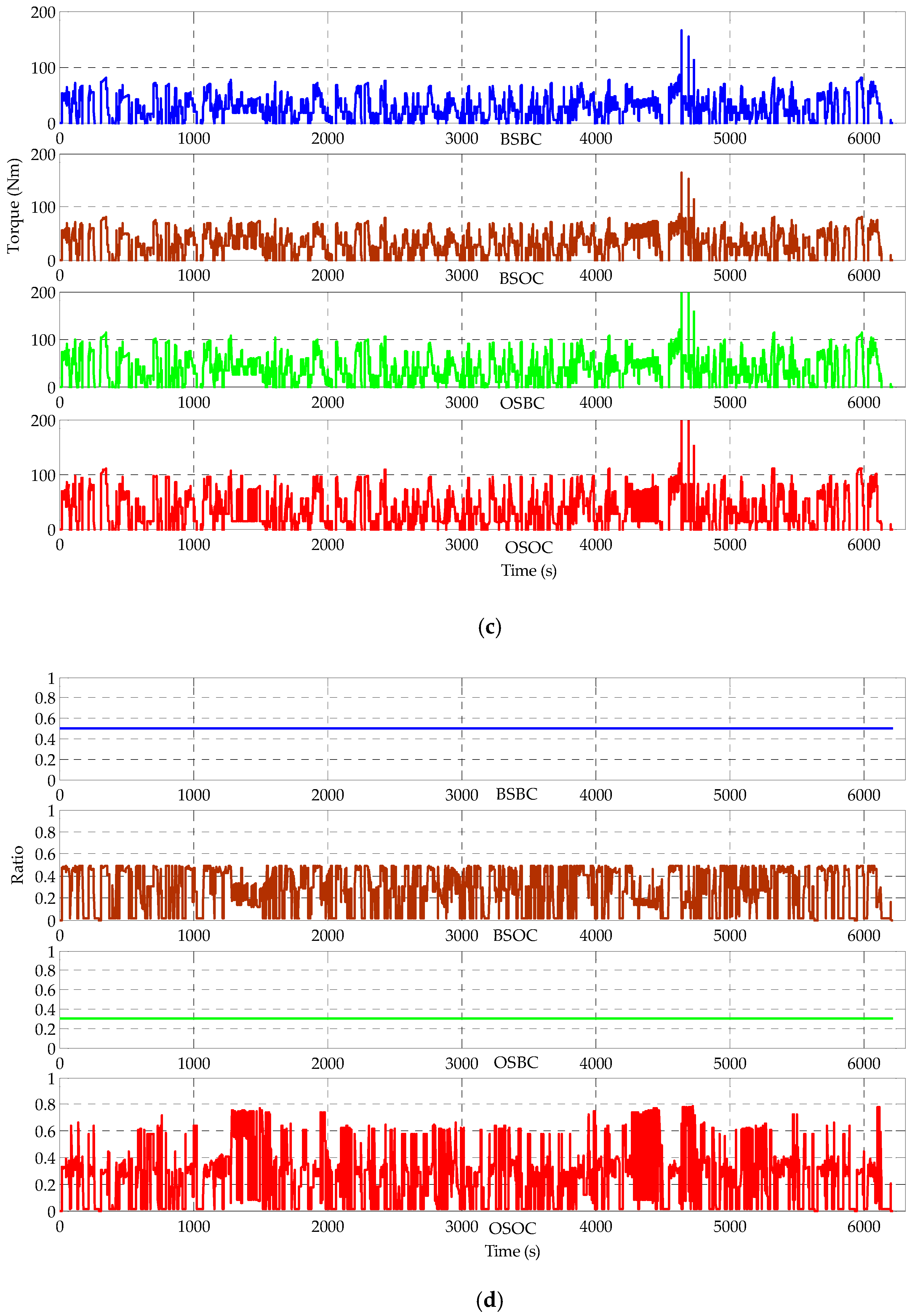

5. Simulation Results and Discussions

- Baseline motor sizing + baseline control (BSBC). Four in-wheel motors with the same rated power of 30 kW are used, and a basic control strategy in which a constant proportion of power allocation for the front- and rear-axle motors is adopted as:

- Baseline sizing + optimal control (BSOC). Four in-wheel motors with the same rated power of 30 kW are also selected. However, the DP algorithm described in the study is adopted for optimal power allocation;

- Optimal sizing + baseline control (OSBC). The baseline control strategy described by Equation (21) is used, and the sizes of both the front- and rear-axle motors are left for optimization;

- Optimal sizing + optimal control (OSOC). This presents the combined sizing/control optimization described in the previous section.

6. Conclusions

- Simulation results indicate that the improvement in energy consumption in three cases, i.e., BSOC, OSBC and OSOC, compared with that in the BSBC case is 1.3603%, 14.3633%, and 15.0908% in the hybrid driving cycle and 1.8021%, 12.1679%, and 13.3355% in the constructed driving cycle, respectively.

- The optimal total motor power is searched to be 1.3 times of the motor baseline power in our example via the proposed method.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| m | Vehicle mass | V | Vehicle velocity |

| Cd | Aerodynamic drag coefficient | Ftotal | Total driving force |

| ρ | Air density | Af | Frontal area of the vehicle |

| g | Gravitational acceleration | Cr | Rolling resistance coefficient |

| λ | Axle distribution coefficient | θ | Road grade |

| T1 | Front-left baseline motor | Fi | Driving force of the i-th wheel |

| T3 | Rear-left baseline motor | T2 | Front-right baseline motor |

| ω1 | Angular velocity of the front-left baseline motor | T4 | Rear-right baseline motor |

| ω3 | Angular velocity of the rear-left baseline motor | ω2 | Angular velocity of the front-right baseline motor |

| ηmotor | Efficiency of the motor | ω4 | Angular velocity of the rear-right baseline motor |

| α | Scaling factor | Rating power of the motor | |

| Tbase | Torque of the baseline motor | Pout,total | Total driving power |

| α2 | Scaling factor for rear-axle motors | α1 | Scaling factor for the front-axle motors |

| η2 | Efficiencies of the rear-axle motors | η1 | Efficiencies of the front -axle motors |

| Pbatt | Output power | Ibatt | Discharging current |

| Rbatt | Internal resistance | Voc | Terminal voltage |

| L | Instantaneous cost | N | Time length of the driving cycle |

References

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D. A review of supercapacitor modeling, estimation, and applications: A control/management perspective. Renew. Sustain. Energy Rev. 2018, 81, 1868–1878. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Deng, J.; Dorrell, D. Multiobjective optimal sizing of hybrid energy storage system for electric vehicles. IEEE Trans. Veh. Technol. 2018, 67, 1027–1035. [Google Scholar] [CrossRef]

- Amini, M.; Karabasoglu, O. Optimal operation of interdependent power systems and electrified transportation networks. Energies 2018, 11, 196. [Google Scholar] [CrossRef]

- Mumtaz, S.; Ali, S.; Ahmad, S.; Khan, L.; Hassan, S.Z.; Kamal, T. Energy management and control of plug-in hybrid electric vehicle charging stations in a grid-connected hybrid power system. Energies 2017, 10, 1923. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Zhang, L.; Liu, M.; Zhu, J. Lateral stability enhancement based on a novel sliding mode prediction control for a four-wheel-independently-actuated electric vehicle. IET Intell. Transp. Syst. 2018. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, J.; Zhang, L.; Wang, Y. Vehicle sideslip angle estimation for a four-wheel-independent-drive electric vehicle based on a hybrid estimator and a moving polynomial Kalman smoother. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2018. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Zhang, L.; Liu, M. Vehicle stability enhancement through hierarchical control for a four-wheel-independently-actuated electric vehicle. Energies 2017, 10, 947. [Google Scholar] [CrossRef]

- Wang, Z.; Qu, C.; Zhang, L.; Xue, X.; Wu, J. Optimal component sizing of a four-wheel independently-actuated electric vehicle with a real-time torque distribution strategy. IEEE Access 2018. [Google Scholar] [CrossRef]

- Hung, Y.-H.; Wu, C.-H. A combined optimal sizing and energy management approach for hybrid in-wheel motors of EVs. Appl. Energy 2015, 139, 260–271. [Google Scholar] [CrossRef]

- Gu, J.; Ouyang, M.; Lu, D.; Li, J.; Lu, L. Energy efficiency optimization of electric vehicle driven by in-wheel motors. Int. J. Automot. Technol. 2013, 14, 763–772. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J. Fast and global optimal energy-efficient control allocation with applications to over-actuated electric ground vehicles. IEEE Trans. Control Syst. Technol. 2012, 20, 1202–1211. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, J. Torque distribution strategy for a front-and rear-wheel-driven electric vehicle. IEEE Trans. Veh. Technol. 2012, 61, 3365–3374. [Google Scholar] [CrossRef]

- Nam, K.; Hori, Y.; Lee, C. Wheel slip control for improving traction-ability and energy efficiency of a personal electric vehicle. Energies 2015, 8, 6820–6840. [Google Scholar] [CrossRef]

- Zhang, X.; Göhlich, D.; Li, J. Energy-efficient toque allocation design of traction and regenerative braking for distributed drive electric vehicles. IEEE Trans. Veh. Technol. 2018, 67, 285–295. [Google Scholar] [CrossRef]

- Hu, X.; Murgovski, N.; Johannesson, L.M.; Egardt, B. Comparison of three electrochemical energy buffers applied to a hybrid bus powertrain with simultaneous optimal sizing and energy management. IEEE Trans. Intell. Transp. Syst. 2014, 15, 1193–1205. [Google Scholar] [CrossRef]

- Zou, Y.; Sun, F.; Hu, X.; Guzzella, L.; Peng, H. Combined optimal sizing and control for a hybrid tracked vehicle. Energies 2012, 5, 4697–4710. [Google Scholar] [CrossRef]

- Kim, N.; Cha, S.W.; Peng, H. Optimal equivalent fuel consumption for hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2012, 20, 817–825. [Google Scholar]

- Scordia, J.; Desbois-Renaudin, M.; Trigui, R.; Jeanneret, B.; Badin, F. Global optimisation of energy management laws in hybrid vehicles using dynamic programming. Int. J. Veh. Des. 2005, 39, 349–367. [Google Scholar] [CrossRef]

- Moura, S.J.; Callaway, D.S.; Fathy, H.K.; Stein, J.L. Tradeoffs between battery energy capacity and stochastic optimal power management in plug-in hybrid electric vehicles. J. Power Sour. 2010, 195, 2979–2988. [Google Scholar] [CrossRef]

- Wang, H.; Huang, Y.; Khajepour, A.; Song, Q. Model predictive control-based energy management strategy for a series hybrid electric tracked vehicle. Appl. Energy 2016, 182, 105–114. [Google Scholar] [CrossRef]

- Sun, C.; Hu, X.; Moura, S.J.; Fun, F. Velocity predictors for predictive energy management in hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2015, 23, 1197–1204. [Google Scholar]

- Amjad, S.; Neelakrishnan, S.; Rudramoorthy, R. Review of design considerations and technological challenges for successful development and deployment of plug-in hybrid electric vehicles. Renew. Sustain. Energy Rev. 2010, 14, 1104–1110. [Google Scholar] [CrossRef]

- He, H.; Guo, J.; Peng, J.; Tan, H.; Sun, C. Real-time global driving cycle construction and the application to economy driving pro system in plug-in hybrid electric vehicles. Energy 2018, 152, 95–107. [Google Scholar]

- Lee, T.-K.; Adornato, B.; Filipi, Z. Synthesis of real-world driving cycles and their use for estimating phev energy consumption and charging opportunities: Case study for Midwest/U.S. IEEE Trans. Veh. Technol. 2011, 60, 4153–4163. [Google Scholar] [CrossRef]

- Brady, J.; O’Mahony, M. Development of a driving cycle to evaluate the energy economy of electric vehicles in urban areas. Appl. Energy 2016, 177, 165–178. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Ouyang, M. Energy consumption of electric vehicles based on real-world driving patterns: A case study of Beijing. Appl. Energy 2015, 157, 710–719. [Google Scholar] [CrossRef]

- Lukic, S.M.; Emado, A. Modeling of electric machines for automotive applications using efficiency maps. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Technology Conference, Indianapolis, IN, USA, 25–25 September 2003. [Google Scholar]

| Velocity State Cluster | 1 | 2 | … | 6 | 7 |

|---|---|---|---|---|---|

| Velocity interval (km/h) | [0, 15) | [15, 30) | … | [75, 90) | [90, +∞) |

| Power Ratio | Energy Consumption (J) |

|---|---|

| 0.1 | 3.6905 × 107 |

| 0.2 | 3.6784 × 107 |

| 0.3 | 3.5878 × 107 |

| 0.4 | 3.6773 × 107 |

| 0.5 | 3.6892 × 107 |

| Power Ratio | Energy Consumption (J) |

|---|---|

| 0.1 | 2.3761 × 107 |

| 0.2 | 2.3653 × 107 |

| 0.3 | 2.2746 × 107 |

| 0.4 | 2.3647 × 107 |

| 0.5 | 2.3746 × 107 |

| Driving Cycle | Specific Energy Consumption in Four Cases (Wh/km) | Energy Improvement (%) (2) to (1) (3) to (1) (4) to (1) |

|---|---|---|

| Hybrid | (1) 186.7565 (2) 184.2159 (3) 159.9320 (4) 158.5735 | 1.3603% 14.3633% 15.0908% |

| Construction | (1) 143.6563 (2) 141.0674 (3) 126.1764 (4) 124.4990 | 1.8021% 12.1679% 13.3355% |

| Total Power (kW) | Optimal Sizing Results | Energy Consumption (Wh/km) | ||||

|---|---|---|---|---|---|---|

| α1 | α2 | |||||

| Hybrid | Construction | Hybrid | Construction | Hybrid | Construction | |

| 1 | 0.3 | 0.3 | 0.7 | 0.7 | 158.57 | 124.4990 |

| 1.1 | 0.3 | 0.3 | 0.7 | 0.7 | 160.02 | 126.4101 |

| 1.2 | 0.3 | 0.3 | 0.7 | 0.7 | 161.58 | 128.3831 |

| 1.3 | 0.3 | 0.3 | 0.7 | 0.7 | 163.09 | 130.3923 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Qu, C.; Zhang, L.; Zhang, J.; Yu, W. Integrated Sizing and Energy Management for Four-Wheel-Independently-Actuated Electric Vehicles Considering Realistic Constructed Driving Cycles. Energies 2018, 11, 1768. https://doi.org/10.3390/en11071768

Wang Z, Qu C, Zhang L, Zhang J, Yu W. Integrated Sizing and Energy Management for Four-Wheel-Independently-Actuated Electric Vehicles Considering Realistic Constructed Driving Cycles. Energies. 2018; 11(7):1768. https://doi.org/10.3390/en11071768

Chicago/Turabian StyleWang, Zhenpo, Changhui Qu, Lei Zhang, Jin Zhang, and Wen Yu. 2018. "Integrated Sizing and Energy Management for Four-Wheel-Independently-Actuated Electric Vehicles Considering Realistic Constructed Driving Cycles" Energies 11, no. 7: 1768. https://doi.org/10.3390/en11071768