The Maximum-Allowable Well Depth While Drilling of Extended-Reach Wells Targeting to Offshore Depleted Reservoirs

Abstract

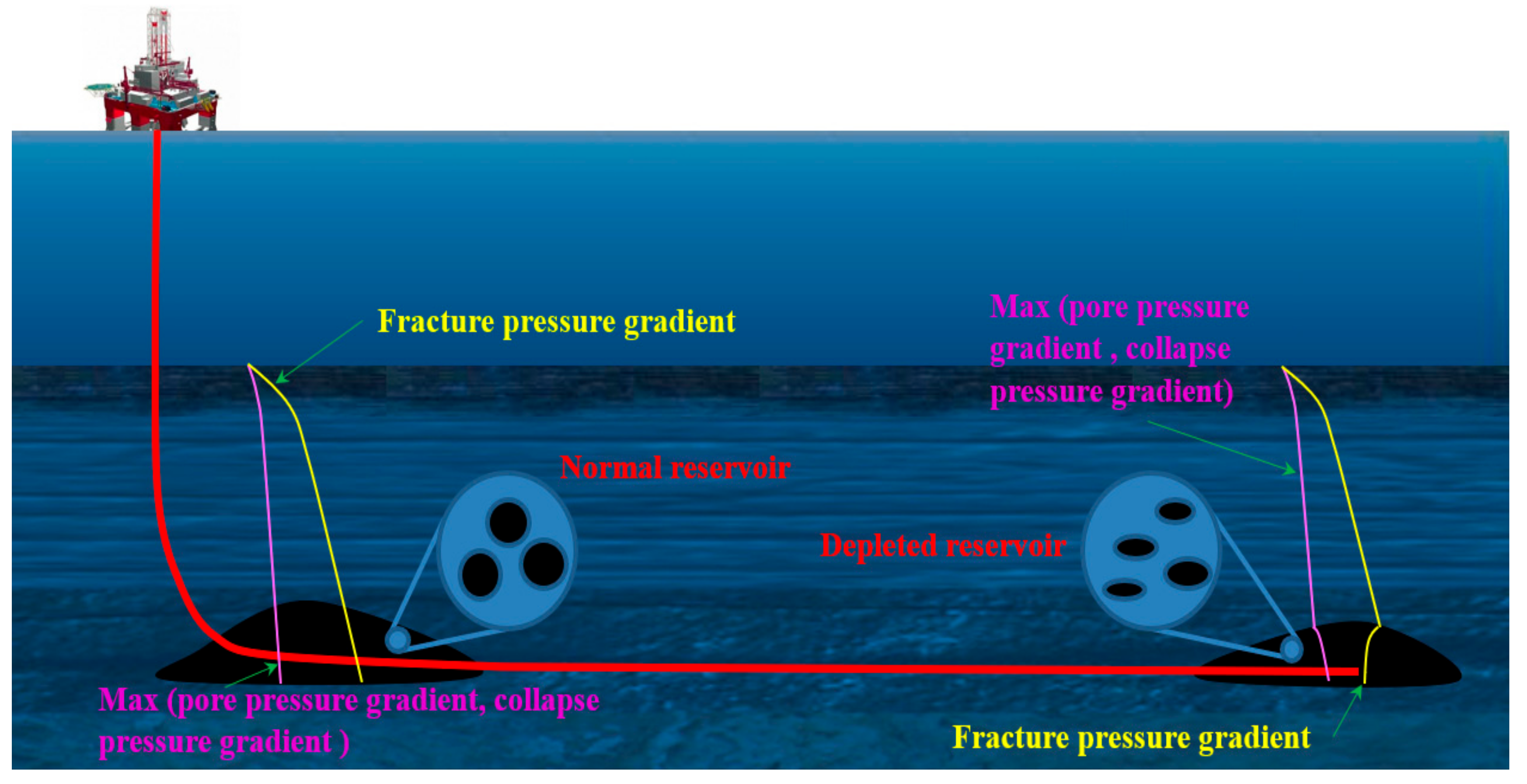

:1. Introduction

2. Model and Methodology

2.1. Effect of Depletion on In Situ Stresses

2.2. Stresses Distribution around an Inclined Wellbore Considering Depletion and Seepage Effects

2.3. The Model of MAMD While Drilling of ERWs Targeting to Depleted Reservoirs

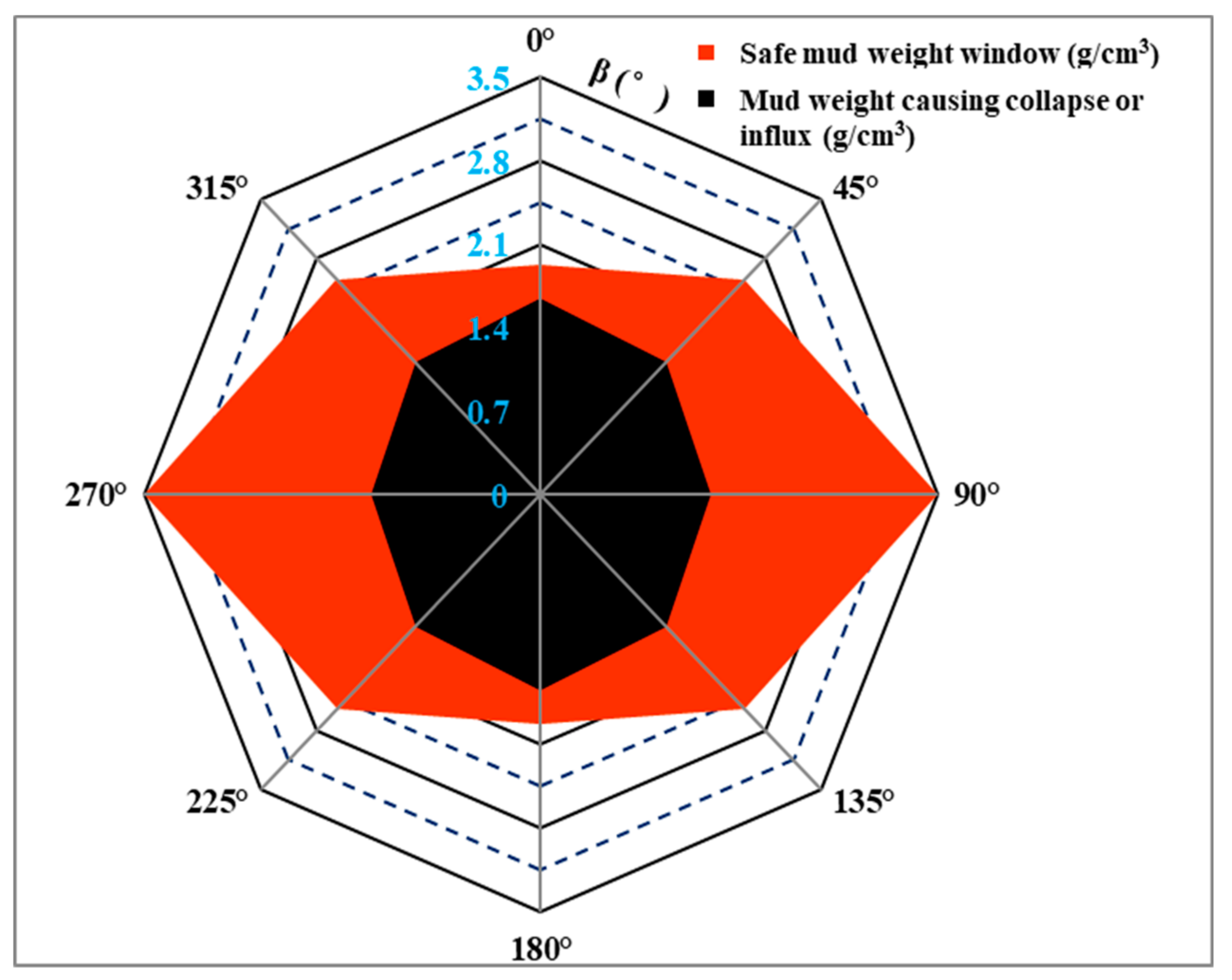

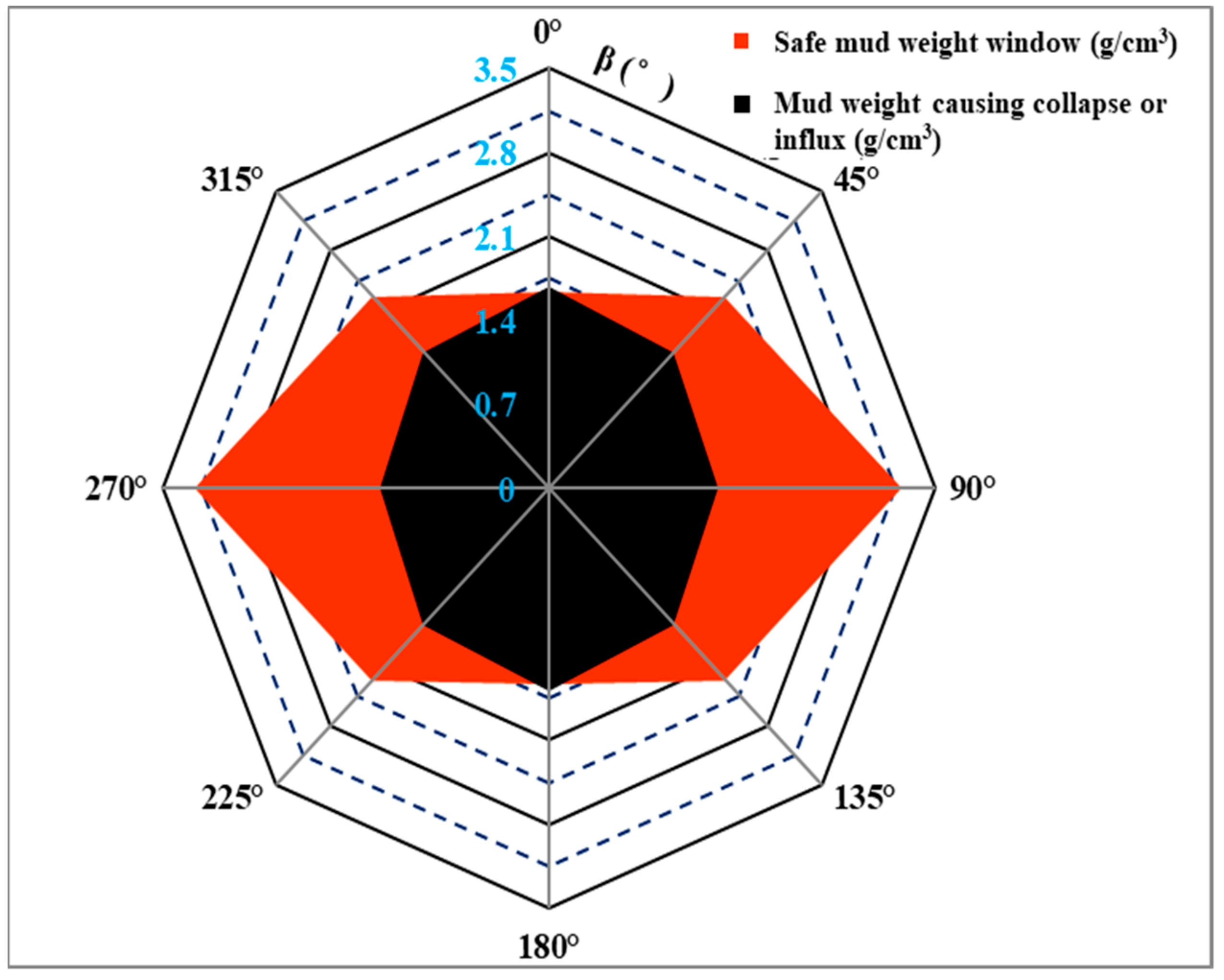

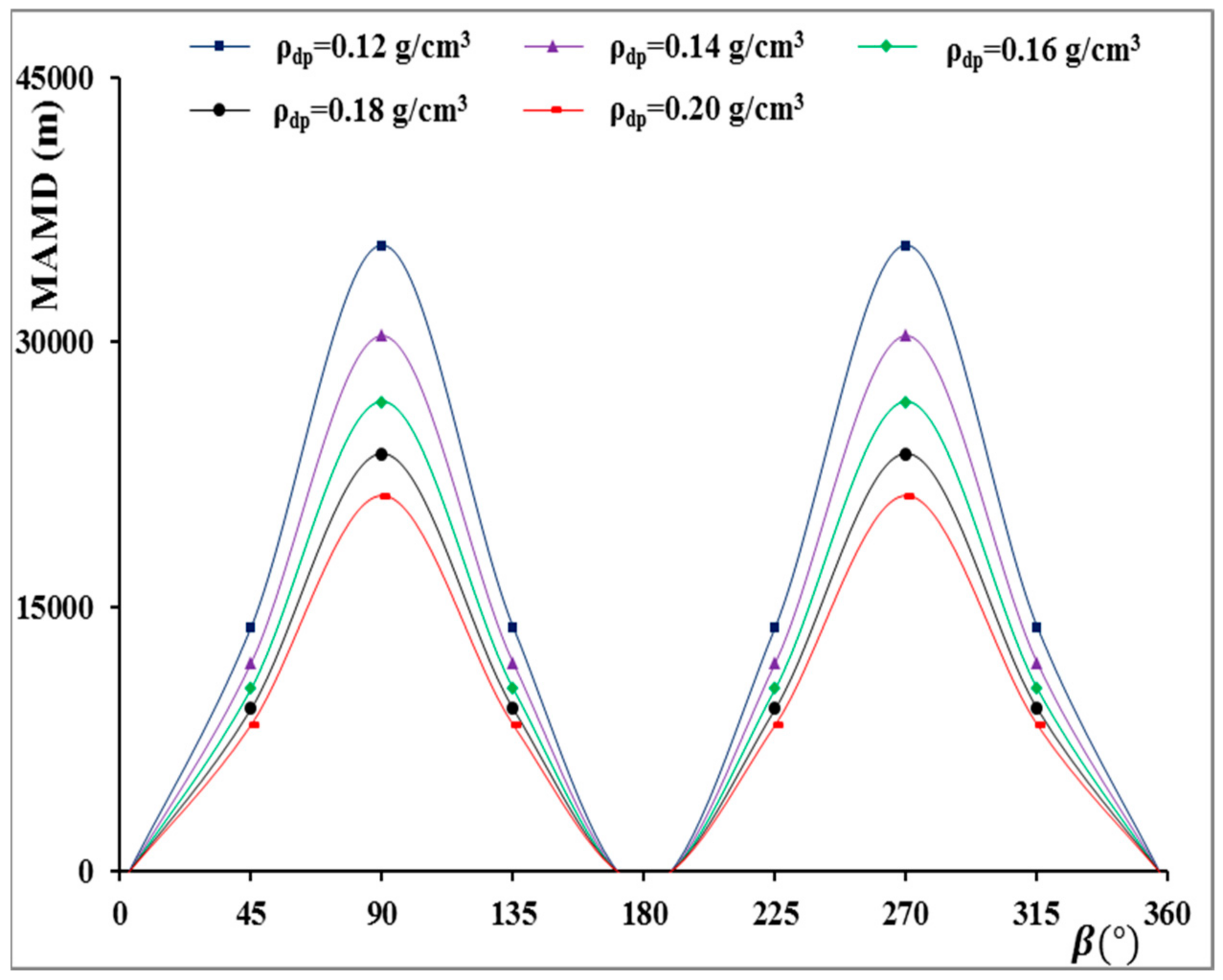

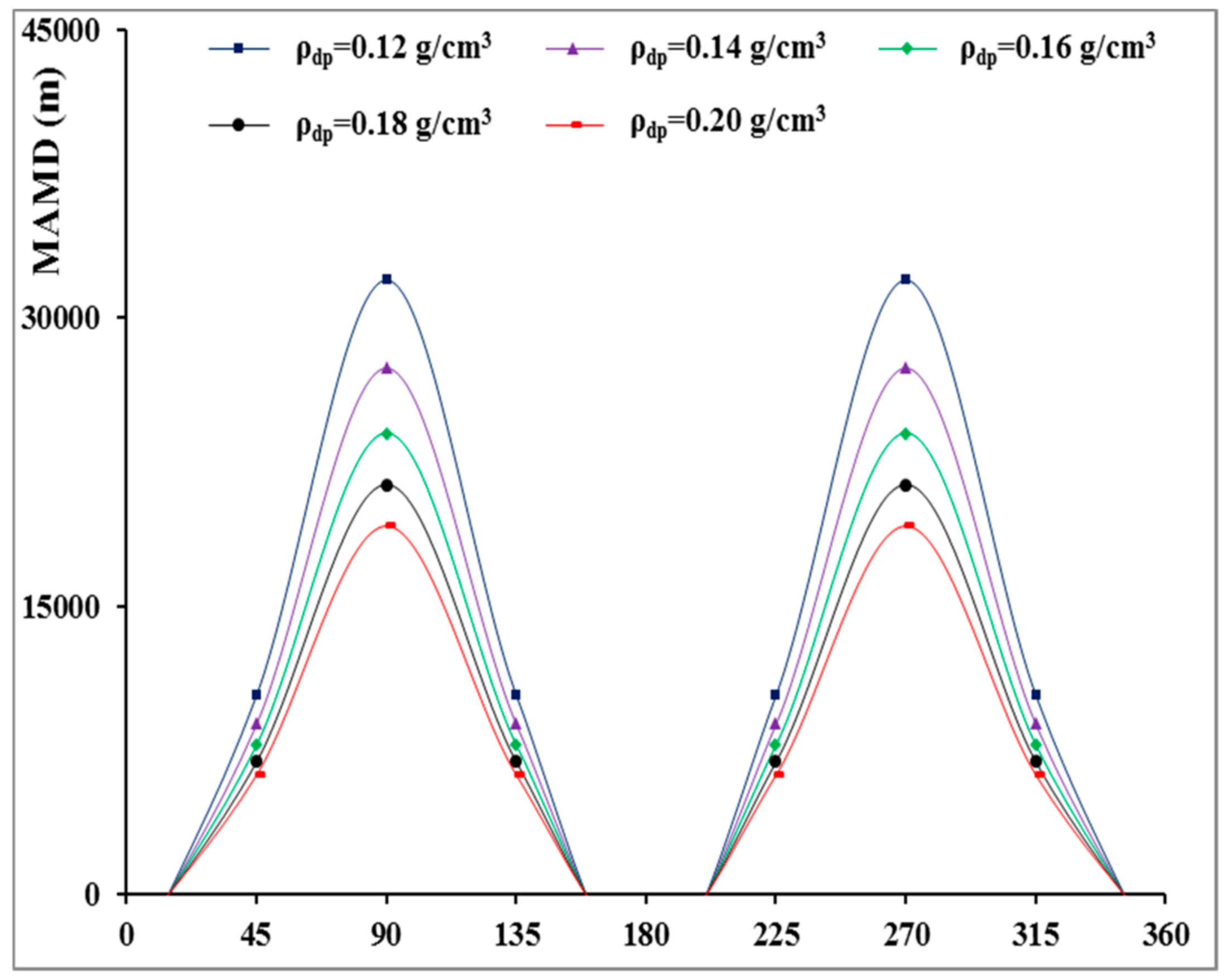

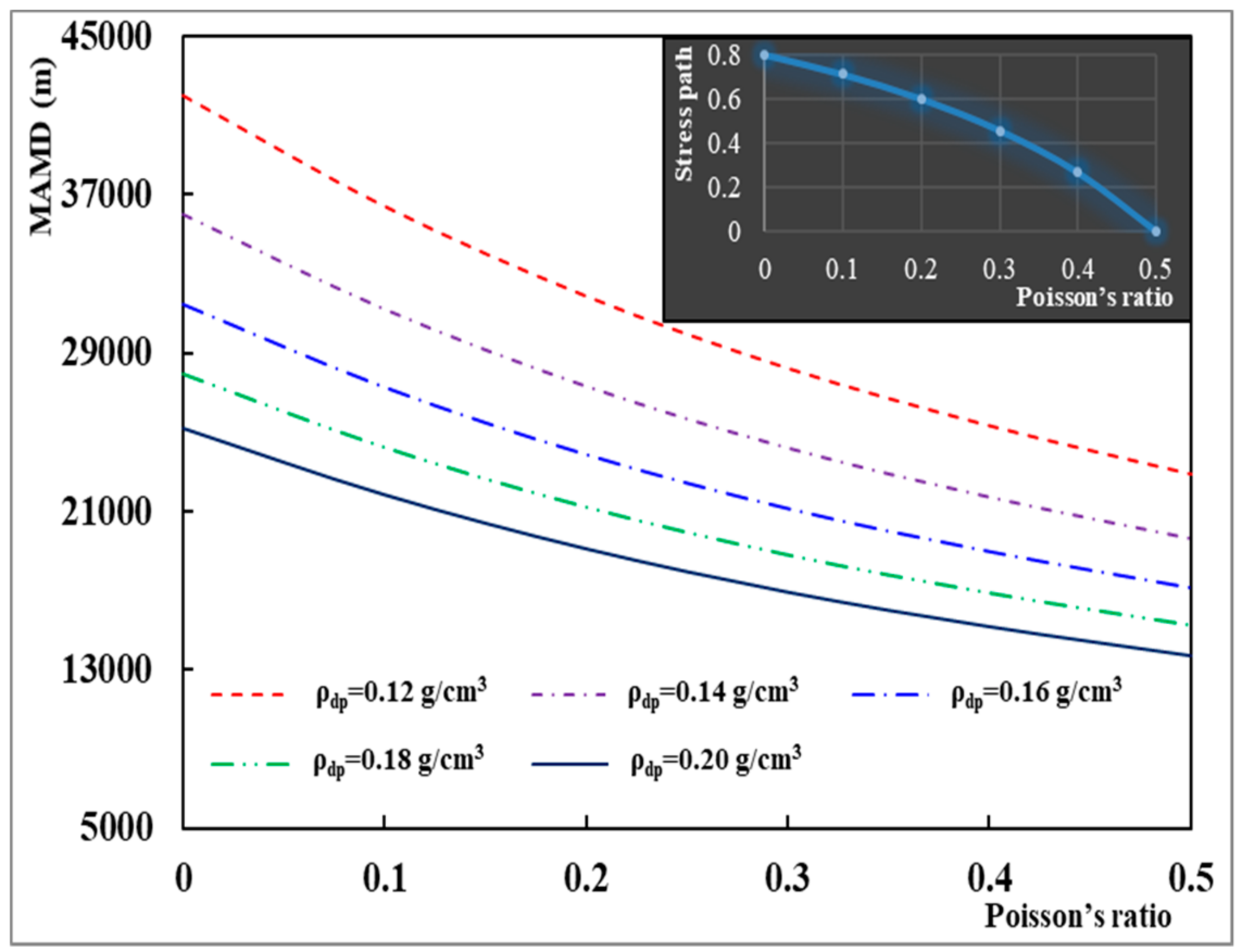

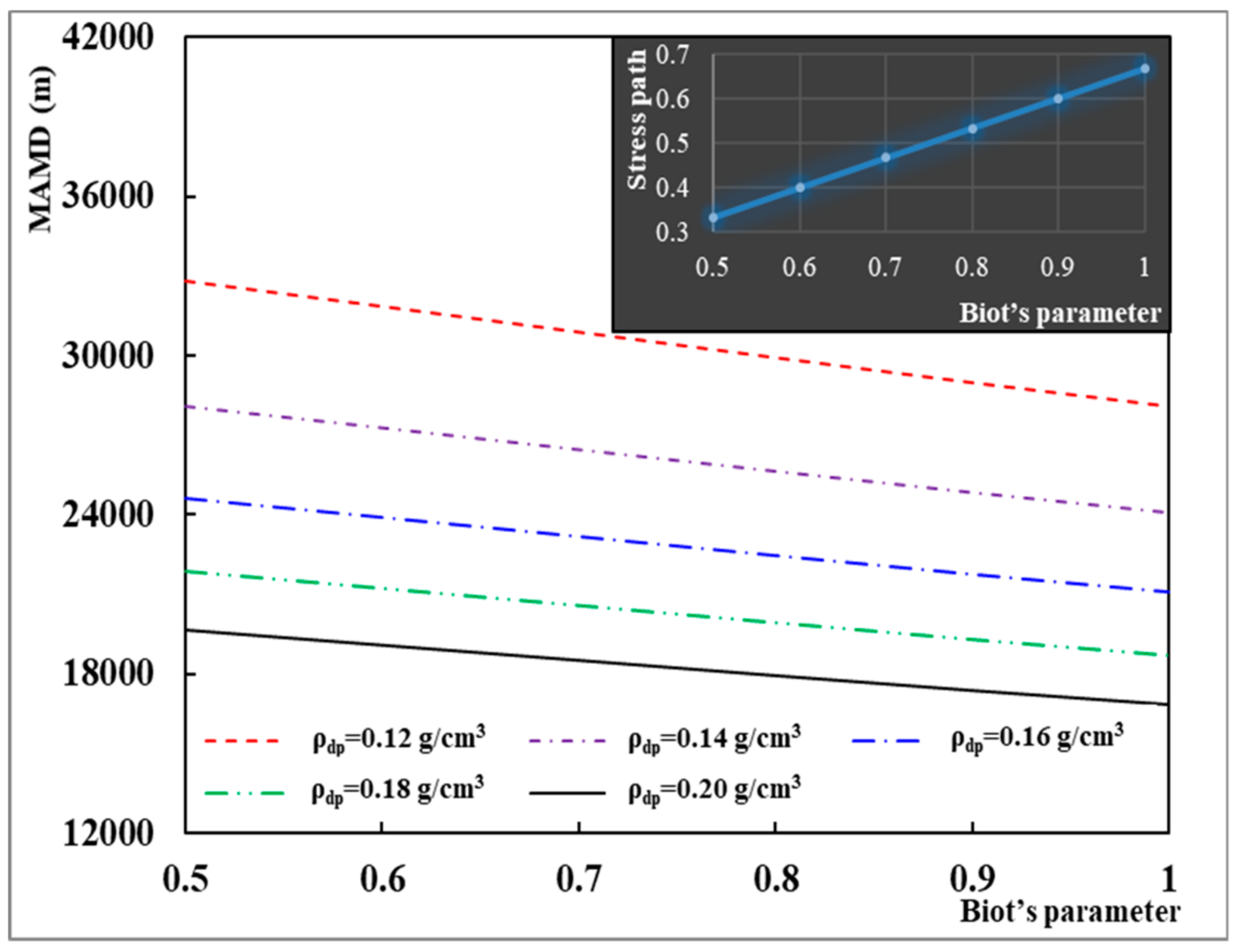

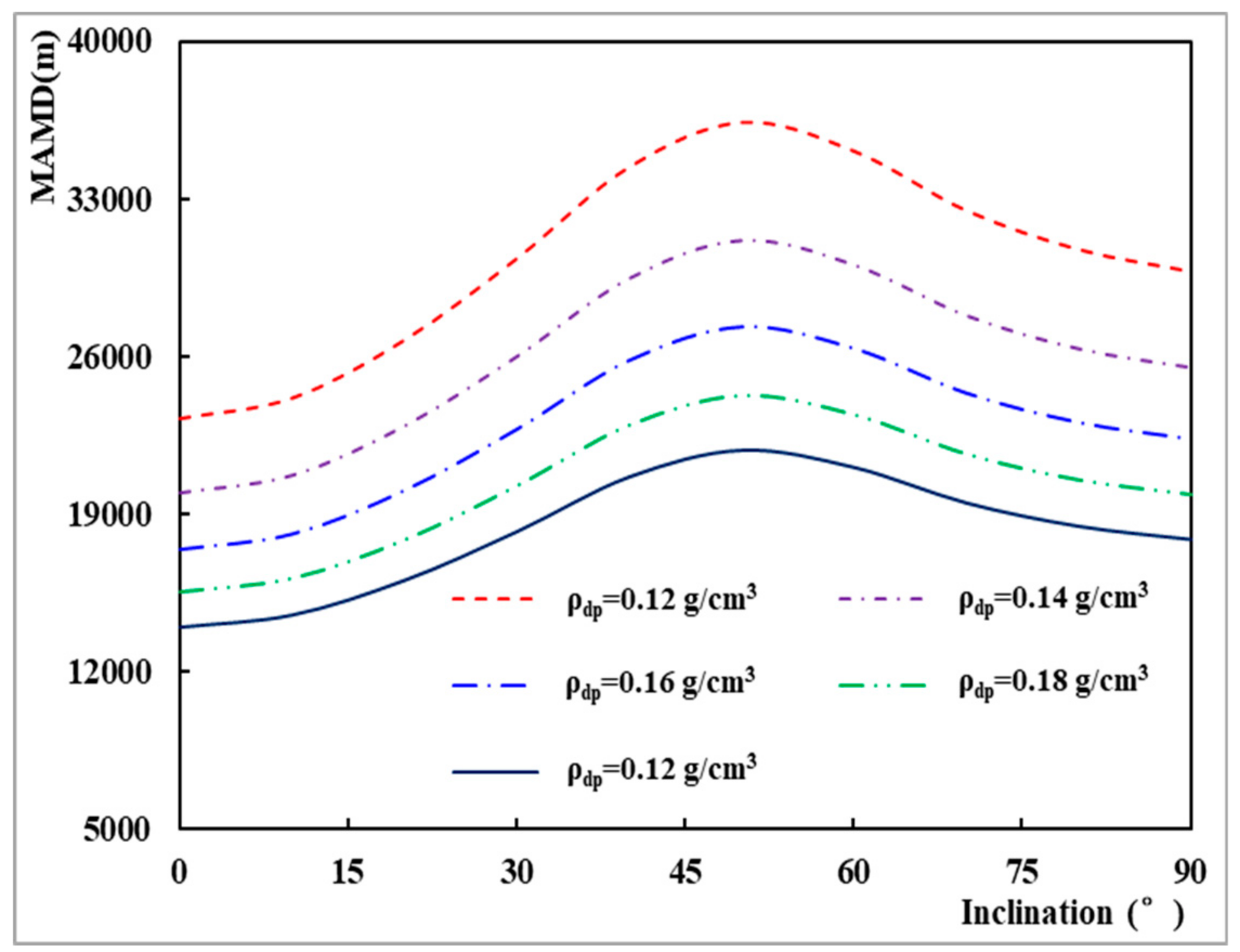

3. Results and Discussions

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Stress path |

| c | Cohesion strength of rock, MPa |

| cw | Cohesion strength in weak plane, MPa |

| E | Young’s modulus, MPa |

| Ex, Ey, Ez | Young’s modulus in the x, y, and z directions, MPa |

| g | Gravitational acceleration, m/s2 |

| Gxy, Gxz, Gyz | Three components of shear modulus, MPa |

| K | Module of elasticity, dimensionless |

| MAMD | Maximum allowable measured depth, m |

| pc | Wellbore collapse pressure of the formation to be drilled, MPa |

| pcθ | Critical borehole pressure causing collapse at a given point that defined by the circumferential angle θ, MPa |

| pf | Wellbore fracture pressure of the formation to be drilled, MPa |

| pfθ | Critical borehole pressure causing fracture at a given point that defined by the circumferential angle θ, MPa |

| pfp | The far field pore pressure, MPa |

| pp | Pore pressure, MPa |

| ∆pp | Change in pore pressure, MPa |

| pw | Mud pressure, MPa |

| Q | Coordinate transformation matrix |

| r | Radial distance, m |

| rw | Wellbore radius, m |

| St | Tensile strength, MPa |

| TVDf | True vertical depth of the depleted formation to be drilled, m |

| α | Well inclination, degree |

| αp | Biot’s parameter, dimensionless |

| β | Angle between the azimuth of borehole and the azimuth of maximum horizontal in-situ stress, degree |

| γxy, γxz, γyz | Three components of shear strain, dimensionless |

| δ | Coefficient of seepage effect, if the borehole wall is impermeable δ = 0, and if the borehole wall is permeable δ = 1 (Chen et al., 2008), dimensionless |

| ε | Normal strain, dimensionless |

| εx, εy, εz | Normal strain in the x, y, and z directions, dimensionless |

| θ | Circumferential angle around borehole measured counter-clockwise from the x-axis, degree |

| λ | The angle between σ1 and the normal to the weakness plane, rad |

| Poisson’s ratio, dimensionless | |

| Poisson’s Ratio in horizontal plane, dimensionless | |

| Poisson’s Ratio in vertical plane-toward maximum horizontal in-situ stress, dimensionless | |

| Poisson’s Ratio in vertical plane-toward minimum horizontal in-situ stress, dimensionless | |

| , , | Poisson’s Ratio in the x, y, and z directions, dimensionless |

| ρc | Equivalent density of collapse pressure of the formation to be drilled, g/cm3 |

| ρdp | Equivalent density of drilling fluid friction pressure loss in annulus, g/cm3 |

| ρecd | Equivalent circulating density (ECD) of drilling fluid, g/cm3 |

| ρesd | Equivalent static density (ESD) of drilling fluid, g/cm3 |

| ρf | Equivalent density of fracture pressure of the formation to be drilled, g/cm3 |

| ρp | Equivalent density of pore pressure of the formation to be drilled, g/cm3 |

| ∆ρp | Equivalent density of pore pressure change of the depleted formation |

| ρs | Drilling fluid density for supporting a safe drilling, g/cm3 |

| σ | Normal stress, MPa |

| σ1 | The maximum principal stess, MPa |

| σ3 | The minimum principal stress, MPa |

| σv | Overburden pressure, MPa |

| σh | Minimum horizontal in-situ stress, MPa |

| ∆σh | Change of minimum horizontal in-situ stress due to pore pressure change, MPa |

| σH | Maximum horizontal in-situ stress, MPa |

| ∆σH | Change of maximum horizontal in-situ stress due to pore pressure change, MPa |

| σxx, σyy, σzz | x, y and z axial stress, MPa |

| σr | Radial stress around borehole include thermal and seepage effects, MPa |

| σθ | Hoop stress around borehole include thermal and seepage effects, MPa |

| σz | Axial stress around borehole include thermal and seepage effects, MPa |

| τxy, τyz, τzx | Three components of shear stress, MPa |

| τrθ, τrz, τθz | Three components of shear stress around borehole include seepage effects, MPa |

| φ | Porosity, dimensionless |

| ϕ | Intrinsic friction angle, rad |

| ϕw | Friction angle in the plane of weakness, rad |

References

- Poedjono, B.; Rawlins, S.A.; Maus, S. Addressing Wellbore Position Challenges in Ultra-Extended-Reach Drilling in Russia. In Proceedings of the SPE Russian Oil and Gas Exploration and Production Technical Conference and Exhibition, Moscow, Russia, 16–18 October 2012. [Google Scholar]

- Chen, X.; Gao, D. The Maximum-Allowable Well Depth While Performing Ultra-Extended-Reach Drilling From Shallow Water to Deepwater Target. SPE J. 2018, 23, 224–236. [Google Scholar] [CrossRef]

- Basak, D.; Gurses, S. Advanced Intelligent Completion Solution for Extended Reach Wells. In Proceedings of the SPE Middle East Intelligent Oil & Gas Conference & Exhibition, Abu Dhabi, UAE, 15–16 September 2015. [Google Scholar]

- Chamat, E.; Cuadros, G.; Trejo, E.; Scrofina, J.; Cermeno, E.; Rodriguez, O. Performance Step Change in Shallow Extended Reach Wells in Venezuela Enables Drilling Optimization and Increased Heavy Oil Production. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 9–11 June 2015. [Google Scholar]

- Rui, Z.; Lu, J.; Zhang, Z.; Guo, R.; Ling, K.; Zhang, R.; Patil, S. A quantitative oil and gas reservoir evaluation system for development. J. Nat. Gas Sci. Eng. 2017, 42, 31–39. [Google Scholar] [CrossRef]

- Chen, X.; Gao, D.; Guo, B. A Method for Optimizing Jet-Mill-Bit Hydraulics in Horizontal Drilling. SPE J. 2016, 21, 416–422. [Google Scholar] [CrossRef]

- Chen, X.; Gao, D.; Guo, B.; Feng, Y. Real-time optimization of drilling parameters based on mechanical specific energy for rotating drilling with positive displacement motor in the hard formation. J. Nat. Gas Sci. Eng. 2016, 35, 686–694. [Google Scholar] [CrossRef]

- Nakaten, N.C.; Kempka, T. Techno-Economic Comparison of Onshore and Offshore Underground Coal Gasification End-Product Competitiveness. Energies 2017, 10, 1643. [Google Scholar] [CrossRef]

- Rui, Z.; Li, C.; Peng, P.; Ling, K.; Chen, G.; Zhou, X.; Chang, H. Development of Industry performance metrics for offshore oil and gas project. J. Nat. Gas Sci. Eng. 2017, 39, 44–53. [Google Scholar] [CrossRef]

- Rui, Z.; Wang, X.; Zhang, Z.; Lu, J.; Chen, G.; Zhou, X.; Patil, S. A realistic and integrated model for evaluating oil sands development with steam assisted gravity drainage technology in Canada. Appl. Energy 2018, 213, 76–91. [Google Scholar] [CrossRef]

- Chen, X.; Fan, H.; Guo, B.; Gao, D.; Wei, H.; Ye, Z. Real-time prediction and optimization of drilling performance Based on A New mechanical specific energy model. Arabian J. Sci. Eng. 2014, 39, 8221–8231. [Google Scholar] [CrossRef]

- Zhao, K.; Han, J.; Dou, L.; Feng, Y. Moderate Collapse in a Shale Cap of a Nearly Depleted Reservoir. Energies 2017, 10, 1820. [Google Scholar] [CrossRef]

- Aadnoy, B.S.; Kaarstad, E. History Model for Sand Production During Depletion. In Proceedings of the SPE EUROPEC/EAGE Annual Conference and Exhibition, Barcelona, Spain, 14–17 June 2010. [Google Scholar]

- Lu, Y.; Cheng, Y.; Ge, Z.; Cheng, L.; Zuo, S.; Zhong, J. Determination of Fracture Initiation Locations during Cross-Measure Drilling for Hydraulic Fracturing of Coal Seams. Energies 2016, 9, 358. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, X.; Liang, Y.; Li, M.; Li, G.; Ma, T.; Nie, W. Mechanical Behavior and Permeability Evolution of Reconstituted Coal Samples under Various Unloading Confining Pressures-Implications for Wellbore Stability Analysis. Energies 2017, 10, 292. [Google Scholar] [CrossRef]

- Pouria, B.; Amir, H.H.; Adel, M.A.; Hossein, H. A novel model for wellbore stability analysis during reservoir depletion. J. Nat. Gas Sci. Eng. 2016, 35, 935–943. [Google Scholar]

- Addis, M.A. The Stress-Depletion Response of Reservoirs. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar]

- Hillis, R.R. Coupled Changes in Pore Pressure and Stress in Oil Fields and Sedimentary Basins. Pet. Geosci. 2001, 7, 419–425. [Google Scholar] [CrossRef]

- Aadnoy, B.; Looyeh, R. Petroleum Rock Mechanics: Drilling Operations and Well Design; Elsevier Publication: New York, NY, USA, 2010. [Google Scholar]

- Gao, D.; Tan, C.; Tang, H. Limit analysis of extended reach drilling in South China Sea. Pet. Sci. 2009, 6, 166–171. [Google Scholar] [CrossRef]

- Sun, T. Research on Well Trajectory Design & Control in Horizontal Drilling. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2013. [Google Scholar]

- Li, X.; Gao, D.; Zhou, Y.; Zhang, H. Study on open-hole extended-reach limit model analysis for horizontal drilling in shales. J. Nat. Gas Sci. Eng. 2016, 34, 520–533. [Google Scholar] [CrossRef]

- Gercek, H. Poisson’s ratio values for rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 1–13. [Google Scholar] [CrossRef]

- Zhang, J.; Pordel, S.M.; Miska, S.; Majidi, R.; Ozbayoglu, E.; Yu, M. Modified inversion technique for determining the in-situ stress field. In Proceedings of the SPE Western Regional & AAPG Pacific Section Meeting Joint Technical Conference, Monterey, CA, USA, 19–25 April 2013. [Google Scholar]

- Segall, P.; Fitzgerald, S.D. A note on induced stress changes in hydrocarbon and geothermal reservoirs. Tectonophysics 1998, 289, 117–128. [Google Scholar] [CrossRef]

- Chen, M.; Jin, Y.; Zhang, G.Q. Petroleum Related Rock Mechanics; Science Press: Beijing, China, 2008. [Google Scholar]

- Chenevert, M.E.; Gatlin, C. Mechanical anisotropies of laminated sedimentary rocks. SPE J. 1965, 5, 67–77. [Google Scholar] [CrossRef]

- Willson, S.M.; Last, N.C.; Zoback, M.D.; Moos, D. Drilling in South America: A wellbore stability approach for complex geologic conditions. In Proceedings of the Latin American and Caribbean Petroleum Engineering Conference, Caracas, Venezuela, 21–23 April 1999. [Google Scholar]

- Jaeger, J.C.; Cook, N.G.; Zimmerman, R. Fundamentals of Rock Mechanics; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Dokhani, V.; Yu, M.; Bloys, B. A wellbore stability model for shale formations: Accounting for strength anisotropy and fluid induced instability. J. Nat. Gas Sci. Eng. 2016, 32, 174–184. [Google Scholar] [CrossRef]

- Zheng, X.; Duan, C.; Yan, Z.; Ye, H.; Wang, Z.; Xia, B. Equivalent Circulation Density Analysis of Geothermal Well by Coupling Temperature. Energies 2017, 10, 268. [Google Scholar] [CrossRef]

- Rommetveit, R.; Bjorkevoll, K.S. Temperature and Pressure Effects on Drilling Fluid Rheology and ECD in Very Deep Wells. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference, Manama, Bahrain, 23–25 November 1997. [Google Scholar]

- Osisanya, S.O.; Harris, O.O. Evaluation of Equivalent Circulating Density of Drilling Fluids under High Pressure/High Temperature Conditions. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

| Variables | Value |

|---|---|

| TVD of the target (m) | 2500 |

| Overburden pressure (MPa) | 52.616 |

| Maximum horizontal in-situ stress (MPa) | 46.828 |

| Minimum horizontal in-situ stress (MPa) | 37.463 |

| Initial pore pressure (MPa) | 25.235 |

| Depleted pore pressure (MPa) | 15.141 |

| Angle between the azimuth of borehole and the azimuth of maximum horizontal in-situ stress (°) | 70 |

| Well inclination (°) | 86 |

| Wellbore radius (m) | 0.216 |

| Poisson’s ratio (dimensionless) | 0.25 |

| Biot’s parameter (dimensionless) | 0.8 |

| Tensile strength (MPa) | 2 |

| Cohesion strength (MPa) | 7 |

| Young’s modulus (MPa) | 6700 |

| Friction angle (°) | 25 |

| Coefficient of seepage effect (dimensionless) | 1 |

| Porosity (dimensionless) | 0.25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Yang, J.; Gao, D.; Feng, Y.; Li, Y.; Luo, M. The Maximum-Allowable Well Depth While Drilling of Extended-Reach Wells Targeting to Offshore Depleted Reservoirs. Energies 2018, 11, 1072. https://doi.org/10.3390/en11051072

Chen X, Yang J, Gao D, Feng Y, Li Y, Luo M. The Maximum-Allowable Well Depth While Drilling of Extended-Reach Wells Targeting to Offshore Depleted Reservoirs. Energies. 2018; 11(5):1072. https://doi.org/10.3390/en11051072

Chicago/Turabian StyleChen, Xuyue, Jin Yang, Deli Gao, Yongcun Feng, Yanjun Li, and Ming Luo. 2018. "The Maximum-Allowable Well Depth While Drilling of Extended-Reach Wells Targeting to Offshore Depleted Reservoirs" Energies 11, no. 5: 1072. https://doi.org/10.3390/en11051072