An Experiment on Heat Recovery Performance Improvements in Well-Water Heat-Pump Systems for a Traditional Japanese House

Abstract

:1. Introduction

2. Methods

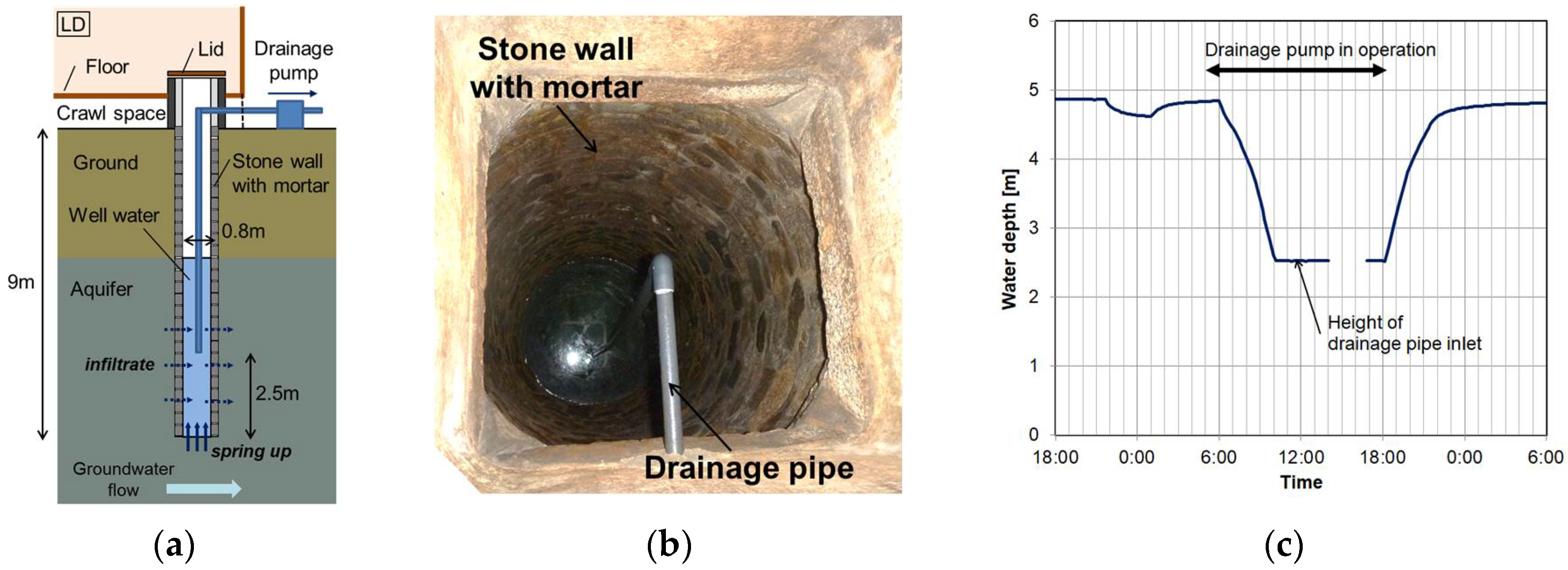

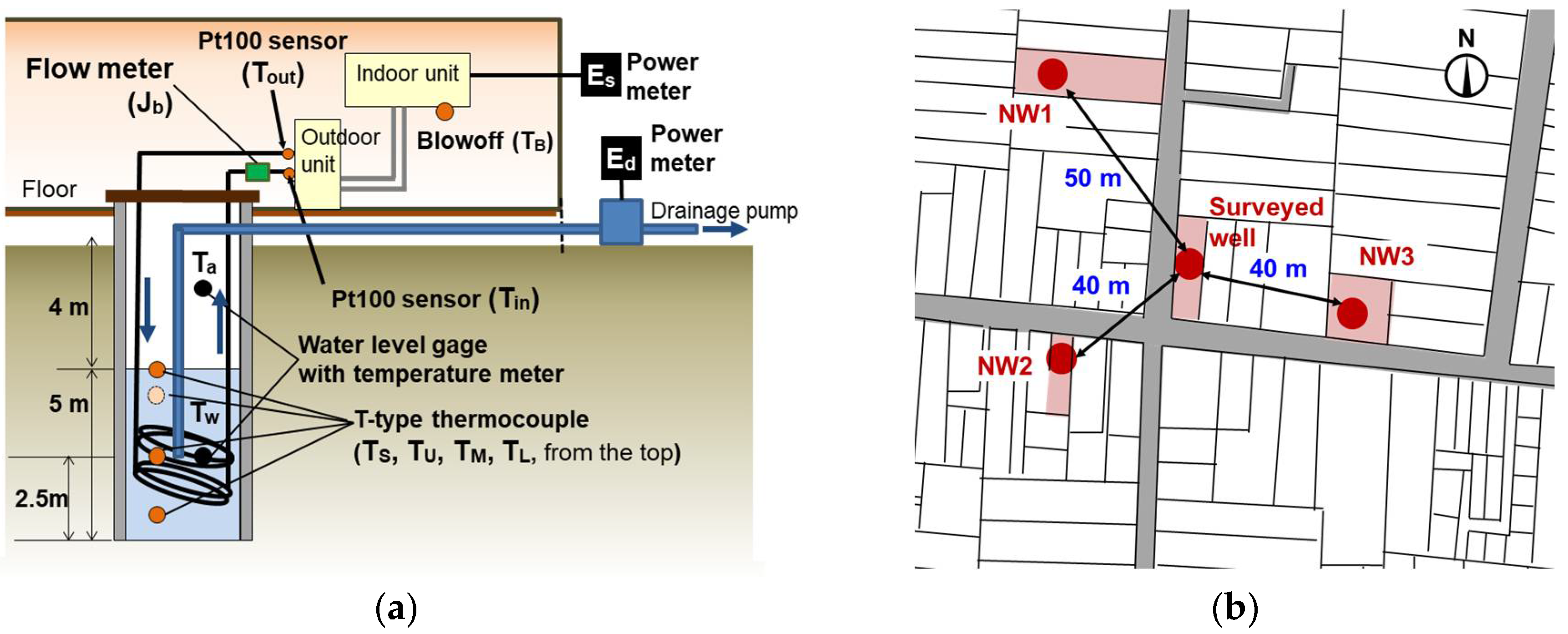

2.1. Surveyed Dwelling and Heat-Pump Heating System

2.2. Measurement Items

2.3. Operation Patterns

3. Results

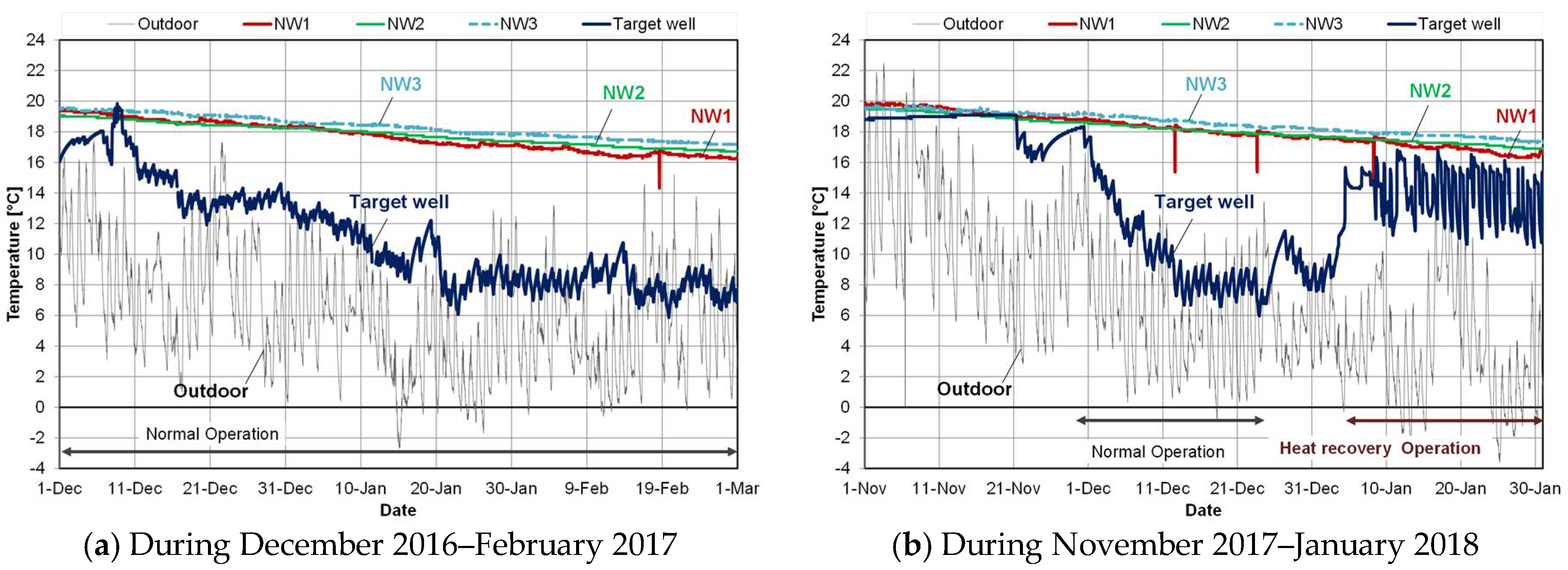

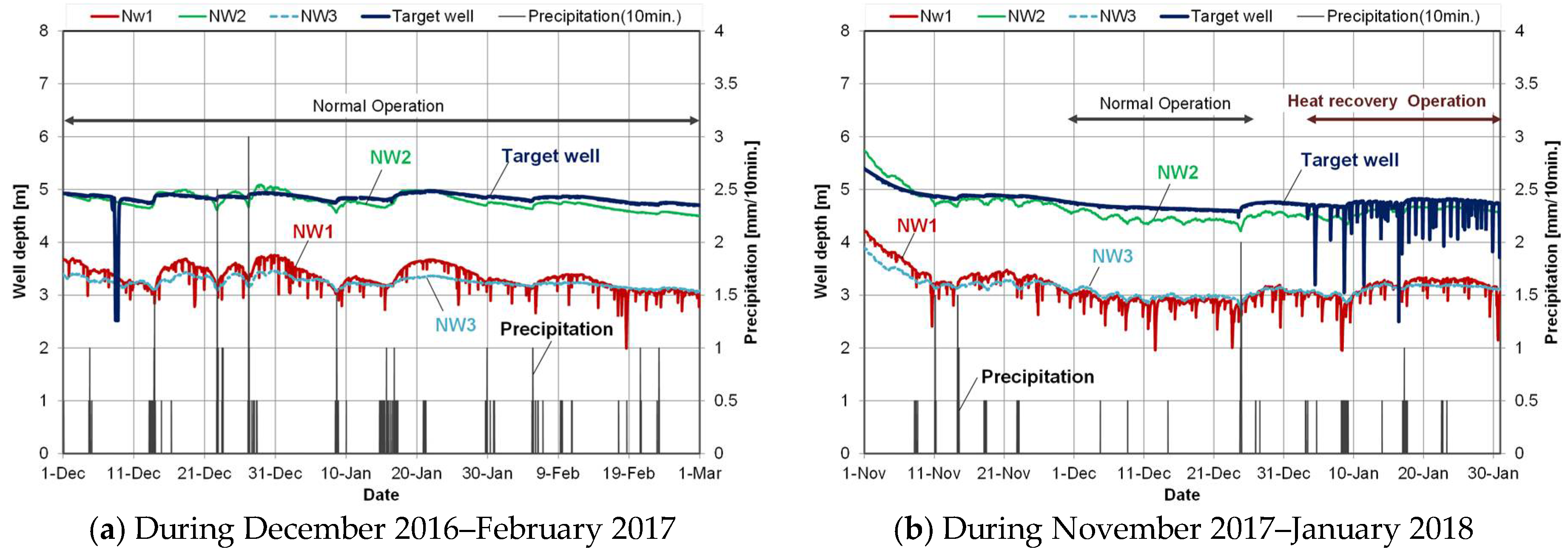

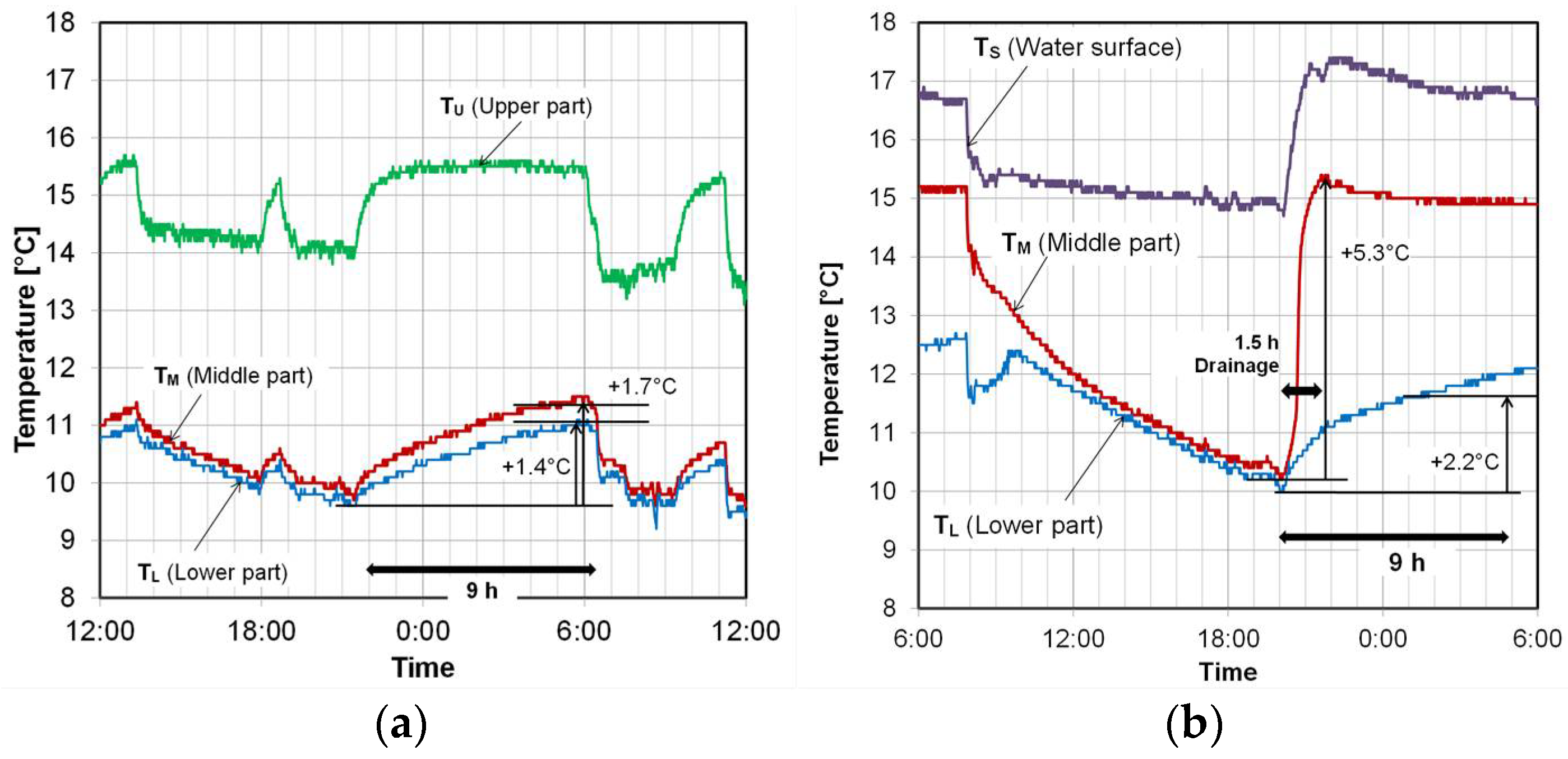

3.1. Time Profile of Well-Water Temperature and Water Depth during Winter

3.2. Measurement Results in each Pattern Focusing on a Certain Day

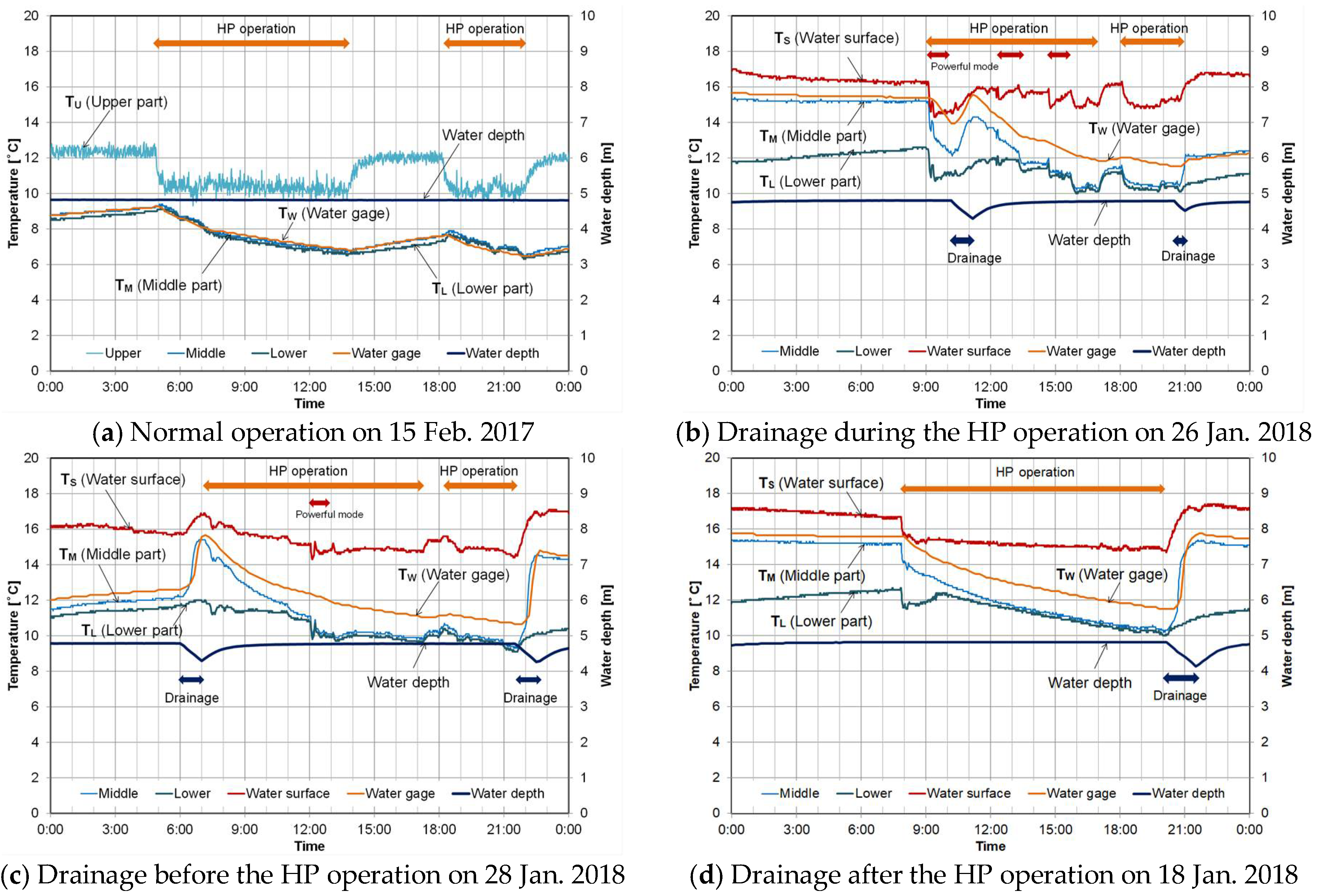

3.2.1. Well-Water Temperature Changes at Different Heights and Water Depths

3.2.2. Temperature and Flowrate of Antifreeze Solution and Heating Blowoff Temperature

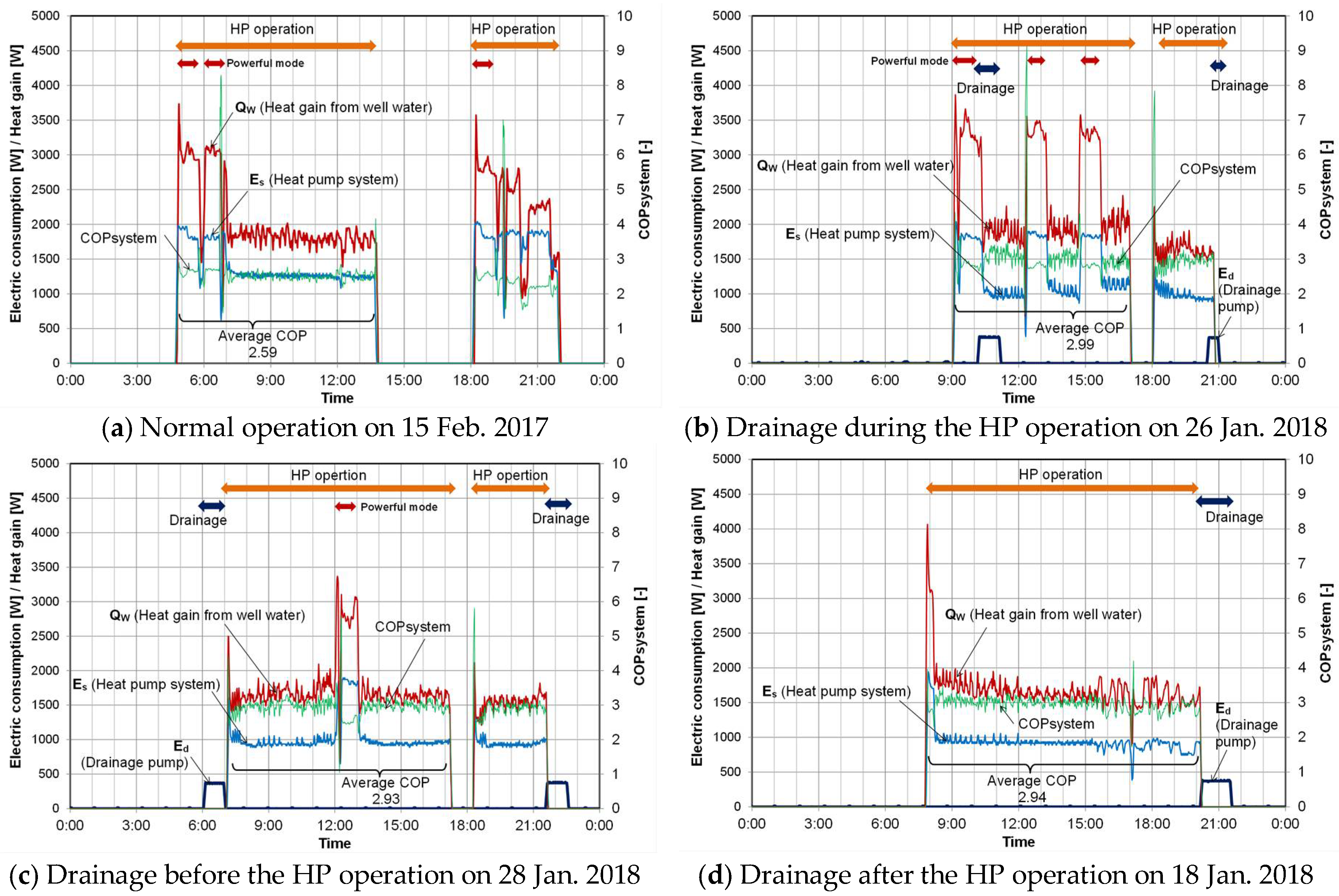

3.2.3. Electric Power Consumption of the HP System and the Drainage Pump and Coefficient of Performance

4. Discussion

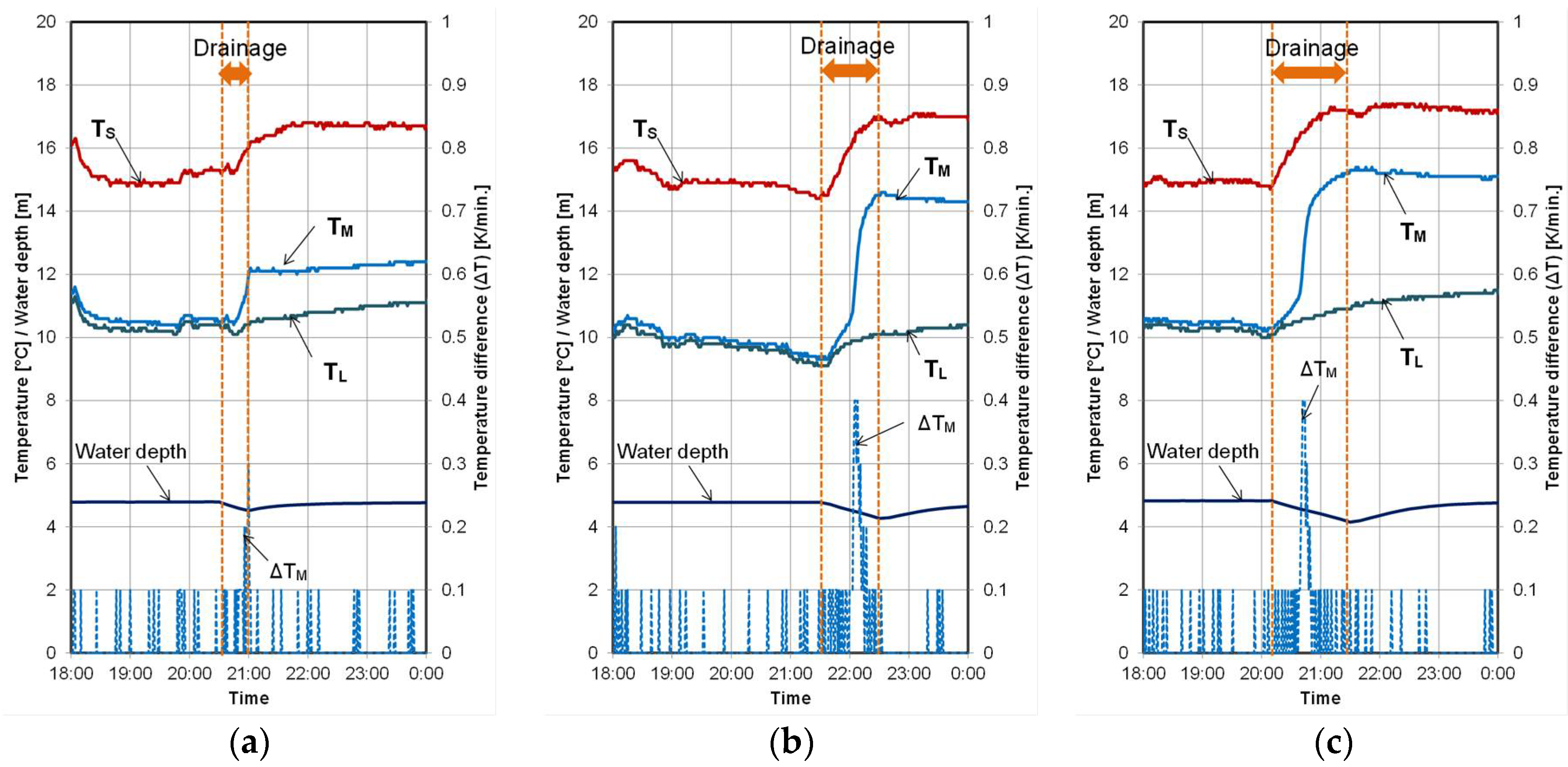

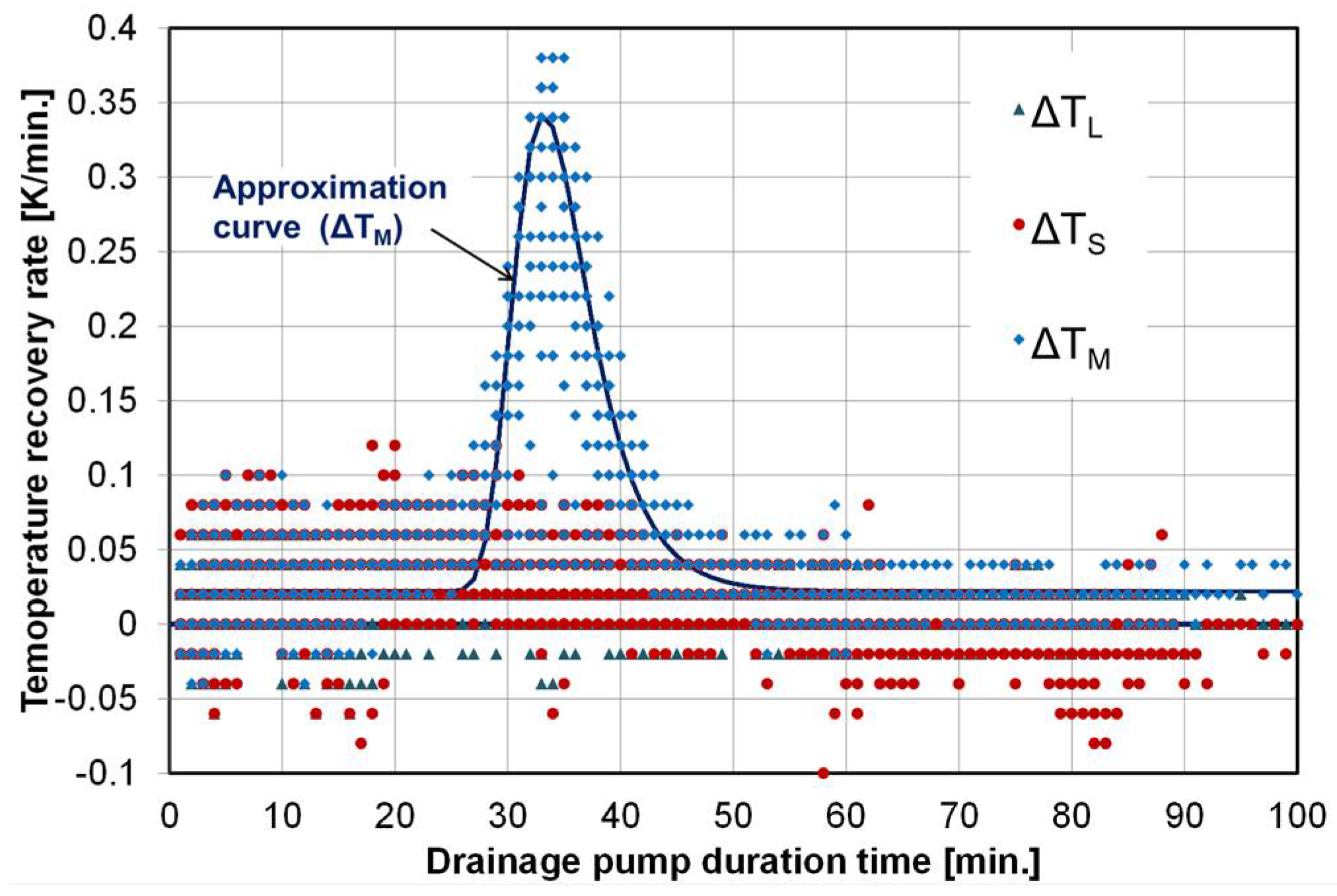

4.1. Well-Water Increase Caused by Operating Drainage Pump

4.2. Improvement of Heat Gain and Energy Efficiency

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Sanner, B.; Nordell, B. Underground thermal energy storage with heat pumps—An International Overview. IEA Heat Pump Centre Newslett. 1998, 16, 10–14. [Google Scholar]

- Sanner, B.; Karytsas, C.; Mendrinos, D.; Rybach, L. Current status of ground source heat pumps and underground thermal energy storage in Europe. Geothermics 2003, 32, 579–588. [Google Scholar] [CrossRef]

- Hamada, Y.; Nakamura, M.; Ochifuji, K.; Nagano, K.; Yokoyama, S. Field performance of a Japanese low energy home relying on renewable energy. Energy Build. 2001, 33, 805–814. [Google Scholar] [CrossRef]

- Nagano, K.; Katsura, T.; Takeda, S. Development of a design and performance prediction tool for the ground source heat pump system. Appl. Therm. Eng. 2006, 26, 1578–1592. [Google Scholar] [CrossRef]

- Tarnawski, V.R.; Leong, W.H.; Momose, T.; Hamada, Y. Analysis of ground source heat pumps with horizontal ground heat exchangers for northern Japan. Renew. Energy 2009, 34, 127–134. [Google Scholar] [CrossRef]

- Congedo, G.S.P.M.; Colangelo, G. Horizontal Heat Exchangers for GSHPs. Efficiency and Cost Investigation for Three Different Applications. In Proceedings of the ECOS 2005 the 18th International Conference on Efficiency, Cost, Optimization, Simulation, and Environmental Impact of Energy Systems, Trondheim, Norway, 20–22 June 2005. [Google Scholar]

- Congedo, P.M.; Colangelo, G.; Starace, G. CFD simulations of horizontal ground heat exchangers: A comparison among different configurations. Appl. Therm. Eng. 2012, 33–34, 24–32. [Google Scholar] [CrossRef]

- D’Arpa, S.; Colangelo, G.; Starace, G.; Petrosillo, I.; Bruno, D.E.; Uricchio, V.; Zurlini, G. Heating requirements in greenhouses farming in southern Italy: Evaluation of ground-source heat pump utilization compared to traditional heating systems. Energy Effic. 2016, 9, 1065–1085. [Google Scholar] [CrossRef]

- Hagihara, K.; Iba, C.; Hokoi, S. Effective use of a ground-source heat-pump system in traditional Japanese “Kyo-machiya” residences during winter. Energy Build. 2016, 128, 262–269. [Google Scholar] [CrossRef]

- Fukumiya, K.; Hirao, N. Performance Characteristics of Geothermal Heat Pump System by Using an Old Well. J. Jpn. Soc. Agric. Mach. 2012, 74, 4–8. (In Japanese) [Google Scholar]

- Wang, Y.; Liu, K.W.Q.; Jin, Y.; Tu, J. Improvement of energy efficiency for an open-loop surface water source heat pump system via optimal design of water-intake. Energy Build. 2012, 51, 93–100. [Google Scholar] [CrossRef]

- Alberti, L.; Antelmi, M.; Angelotti, A.; Formentin, G. Geothermal heat pumps for sustainable farm climatization and field irrigation. Agric. Water Manag. 2018, 195, 187–200. [Google Scholar] [CrossRef]

| Type/Use | Split type (Indoor Unit/Outdoor Unit) Heating and Cooling | |

|---|---|---|

| Rated Value for the System | Heating capacity | 5.0 kW |

| Heating electric power consumption | 1389 W | |

| Heating COP | 3.60 * | |

| Compressor type/Refrigerant type | Rotary compressor/R410A | |

| Rated Value for the Compressor | Rated electric power | 1239 W |

| Heating COP | 4.04 (Evaporation Temp: 7~8 °C; Condensation Temp: 49~50 °C) | |

| Heat Extraction Pipe | Antifreeze Solution | ||

|---|---|---|---|

| Material designation | PE100; Allowable maximum pressure 1.60 MPa @20 °C | Material | propylene glycol 30% diluent |

| Size | Outer diameter 32 mm, pipe thickness 3 mm, 26.0 m length (16.0 m spirally set in the well water) | Density | 1020 (kg/m3) |

| Pipe thermal conductivity | 0.46–0.50 (W/mK) | Specific heat | 4010 (J/kg·K) |

| Apparatus | Range | Accuracy | Resolution | Note |

|---|---|---|---|---|

| Pressure-type level gage | 0–4 m | ±0.3 cm | 0.14 cm | in water level |

| −20 °C to +50 °C | ±0.44°C from 0 °C to 50 °C | 0.1°C @ 20 °C | in temperature | |

| T-type thermocouple | −200 °C to +300 °C | ±0.5 °C | - | - |

| Pt100 sensor | −200 °C to +100 °C | ±(0.30 + 0.005t) °C | - | B-class |

| clamp-type wattmeter | 0–10 kW | ±3% | 0.1 W | - |

| Pattern | Drainage Pump | Representative Date | HP Operation Duration | Drainage Pump Duration * |

|---|---|---|---|---|

| Normal | No operation | 15 February 2017 | 9 h | - |

| Heat recovery | During the HP operation | 26 January 2018 | 8 h | 1 h |

| Before the HP operation | 28 January 2018 | 10 h | 1 h | |

| After the HP operation | 18 January 2018 | 12 h | 1.5 h |

| Pattern | Drainage Pump | Average COP (COPex) | Cumulative HP Energy Consumption (kWh) (Eex) | HP Energy Consumption * (kWh) Assumed at COPim = 2.59 | Drainage Pump Energy Consumption (kWh) (EDP) | Energy Saving Effect (kWh) (ΔE) |

|---|---|---|---|---|---|---|

| Normal | No operation | 2.59 | 12.35 at 9 h | 12.35 | 0 | 0 |

| Heat recovery | During the HP operation | 2.99 | 10.69 at 8 h | 12.34 | 0.365 at 1 h | −1.29 |

| Before the HP operation | 2.93 | 10.50 at 10 h | 11.88 | 0.339 at 1 h | −1.40 | |

| After the HP operation | 2.94 | 11.50 at 12 h | 13.05 | 0.501 at 1.5 h | −1.05 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iba, C.; Takano, S.; Hokoi, S. An Experiment on Heat Recovery Performance Improvements in Well-Water Heat-Pump Systems for a Traditional Japanese House. Energies 2018, 11, 1023. https://doi.org/10.3390/en11051023

Iba C, Takano S, Hokoi S. An Experiment on Heat Recovery Performance Improvements in Well-Water Heat-Pump Systems for a Traditional Japanese House. Energies. 2018; 11(5):1023. https://doi.org/10.3390/en11051023

Chicago/Turabian StyleIba, Chiemi, Shun Takano, and Shuichi Hokoi. 2018. "An Experiment on Heat Recovery Performance Improvements in Well-Water Heat-Pump Systems for a Traditional Japanese House" Energies 11, no. 5: 1023. https://doi.org/10.3390/en11051023