Symbolic Analysis of the Cycle-to-Cycle Variability of a Gasoline–Hydrogen Fueled Spark Engine Model

Abstract

:1. Introduction

2. Quasi-Dimensional Simulation Model

2.1. Combustion Model

2.2. Chemical Reactions

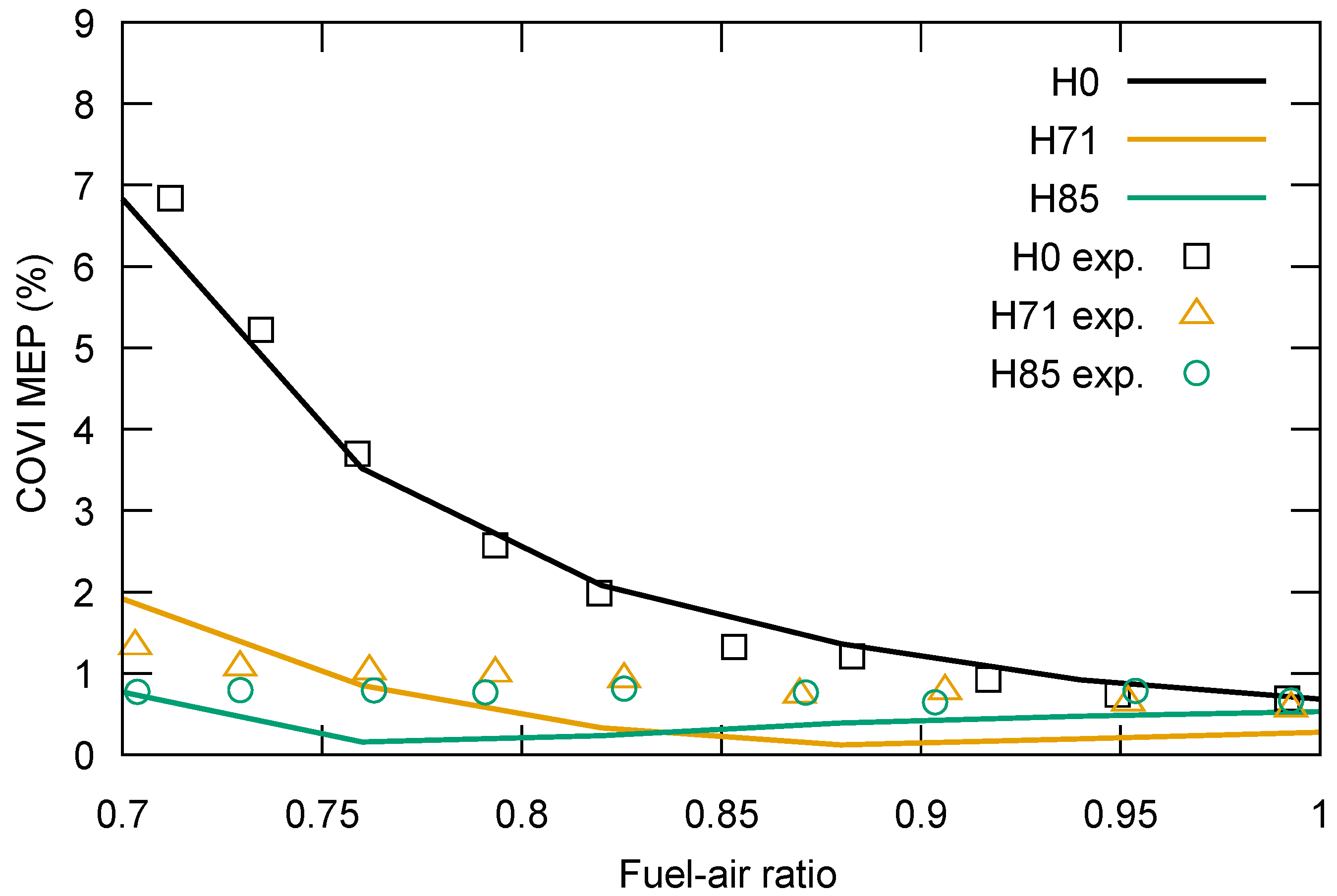

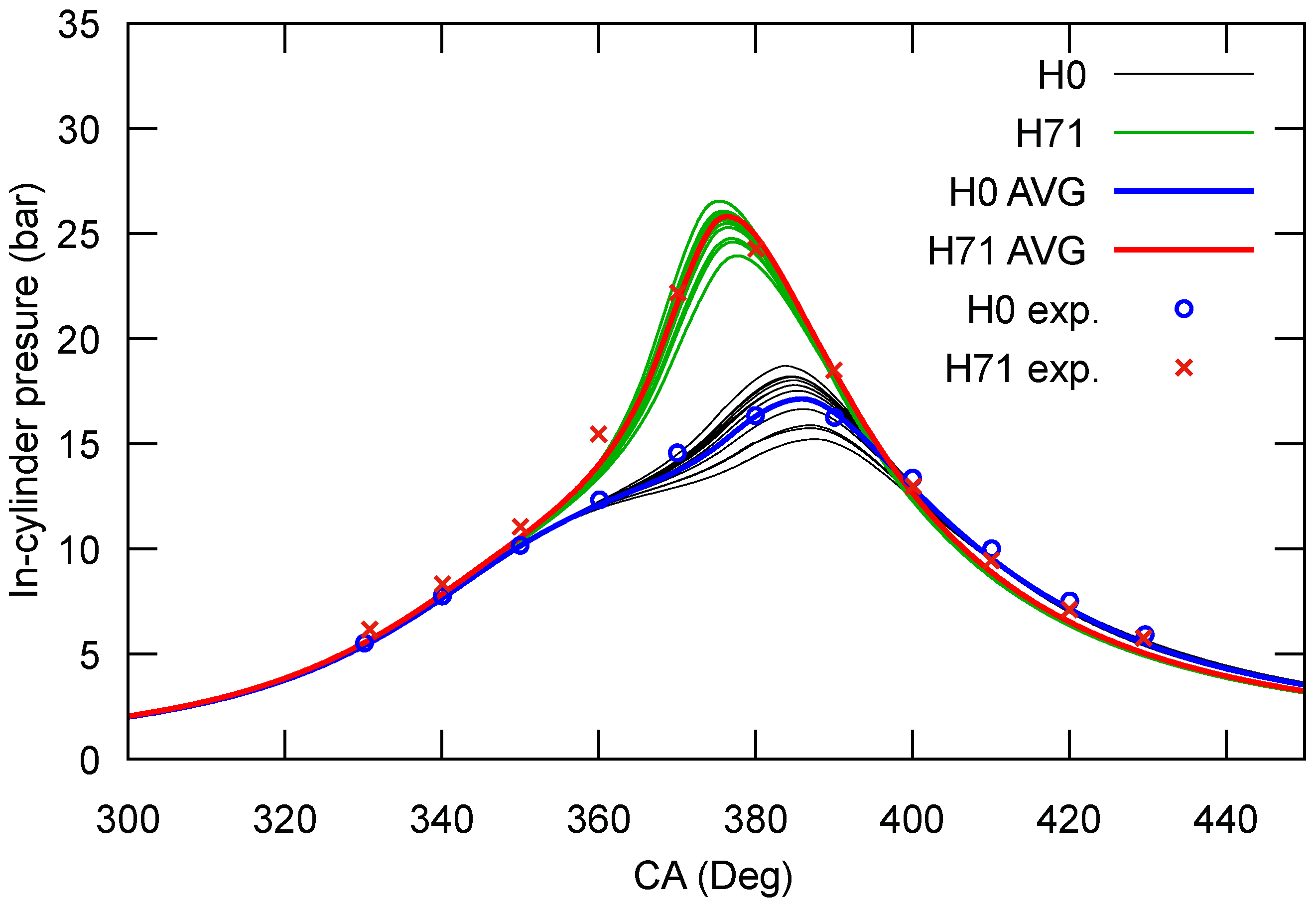

2.3. Simulation Validation and Heat Release Time Series Computation

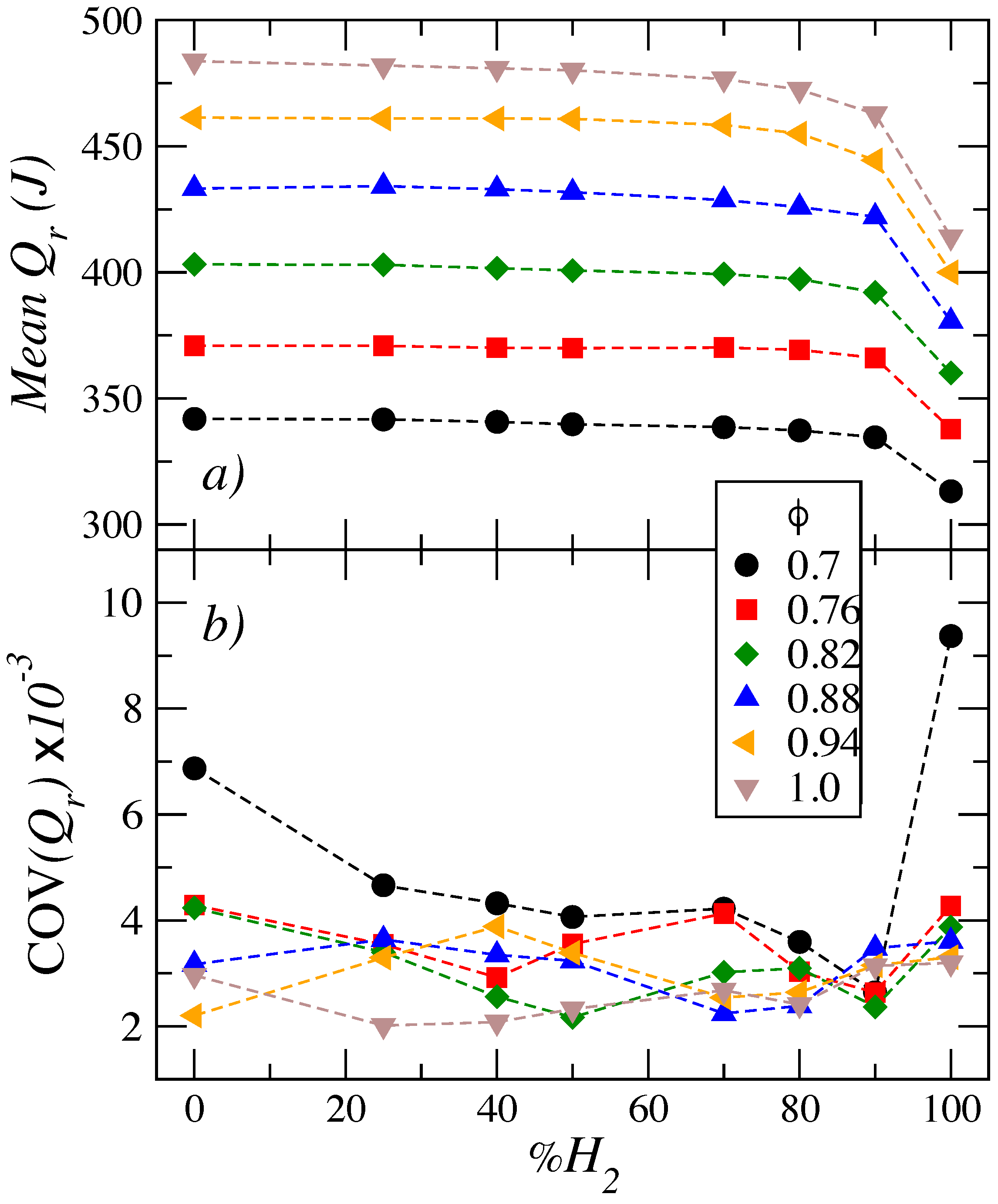

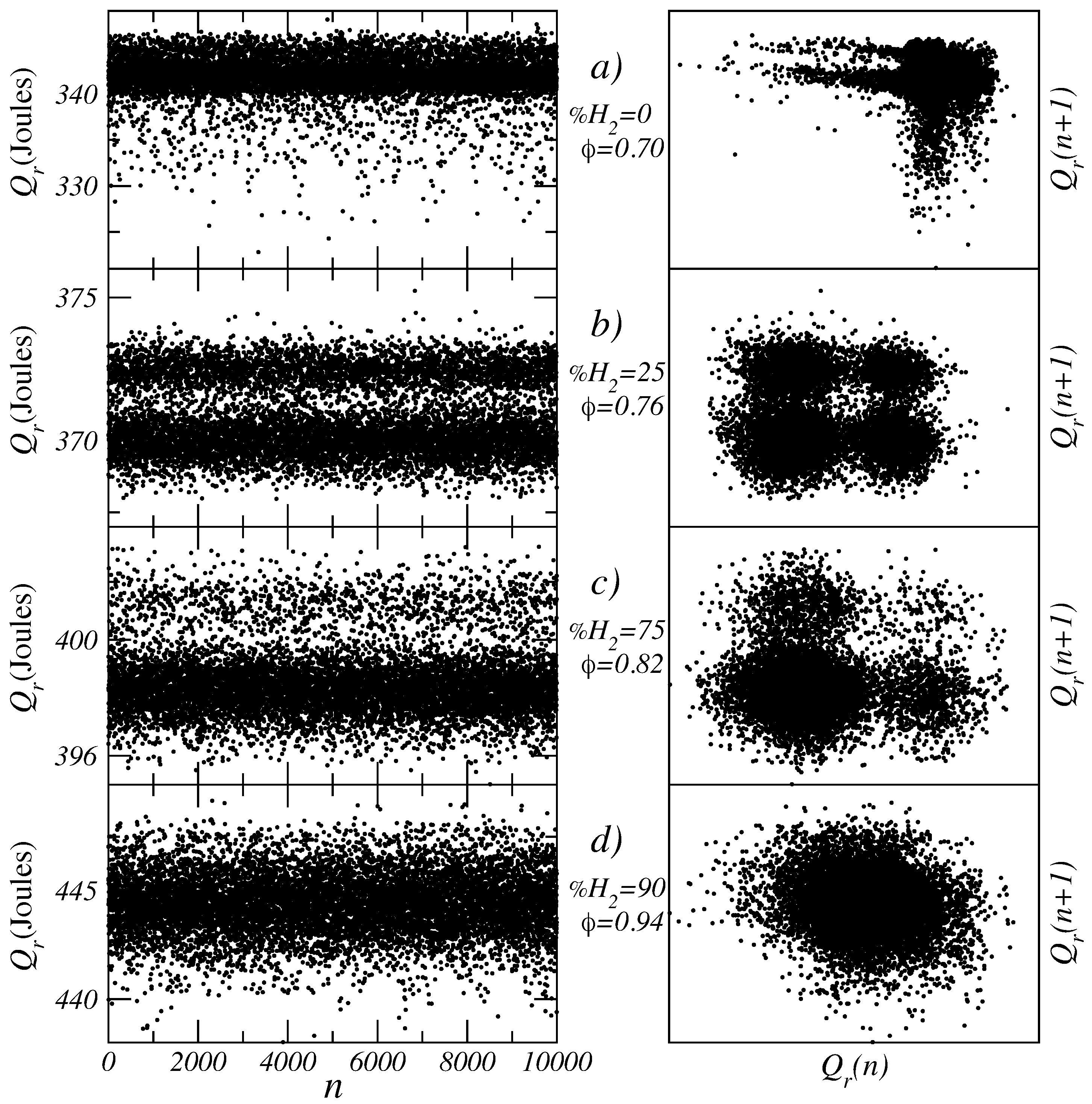

3. Simulated Heat Release Time Series

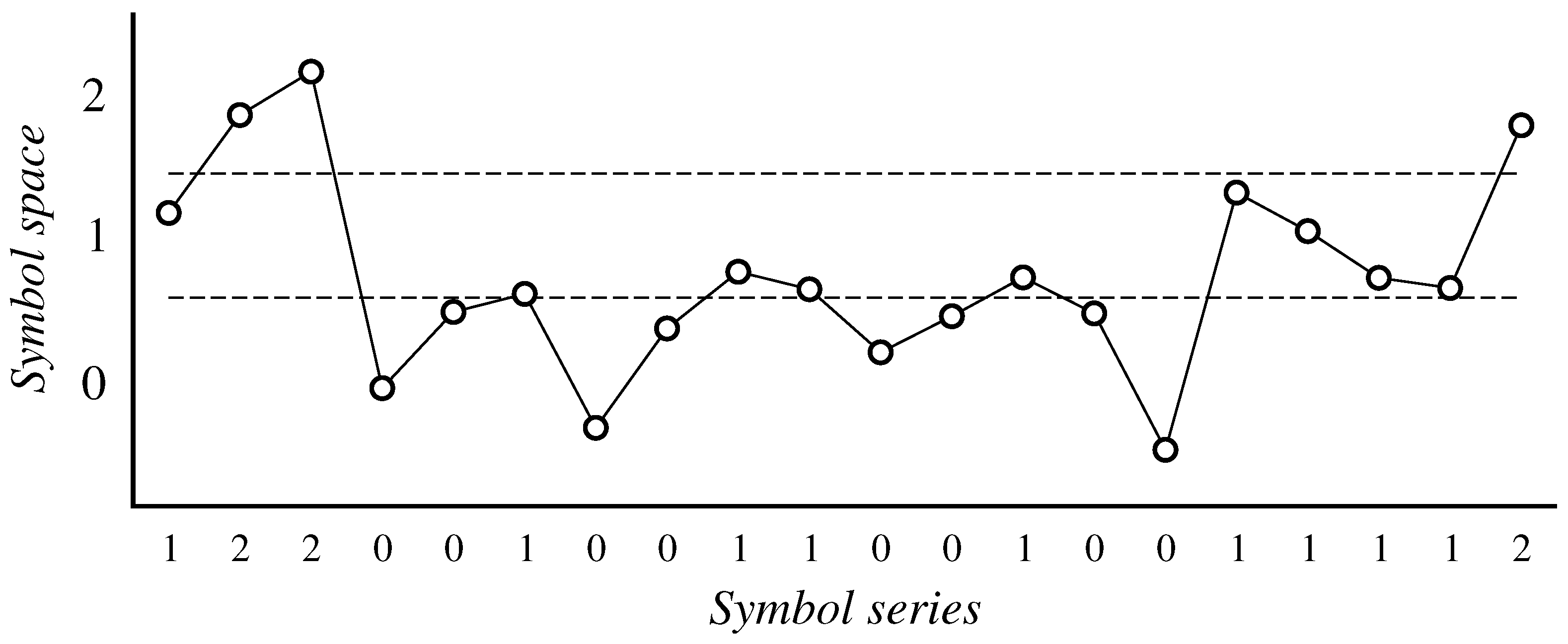

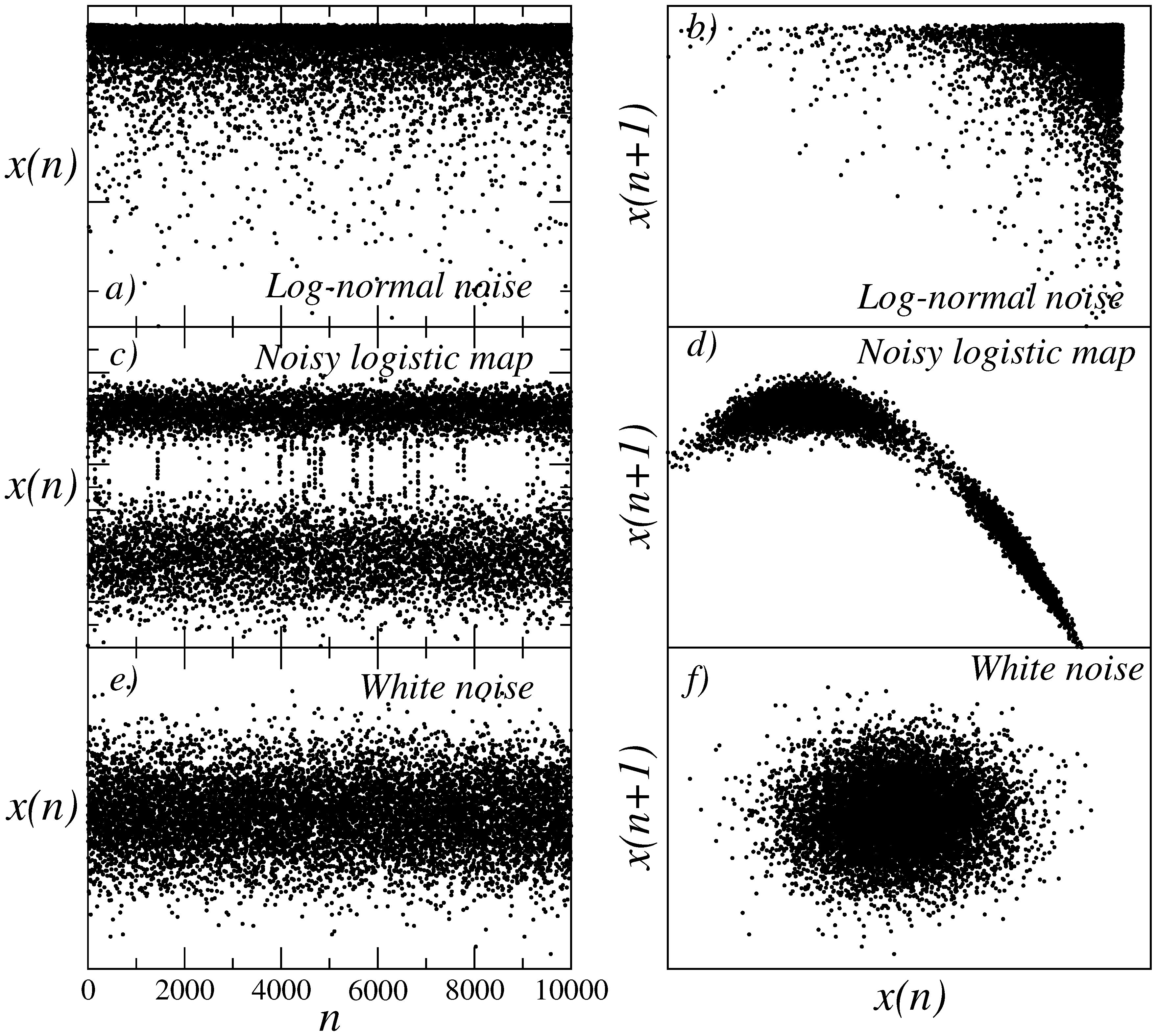

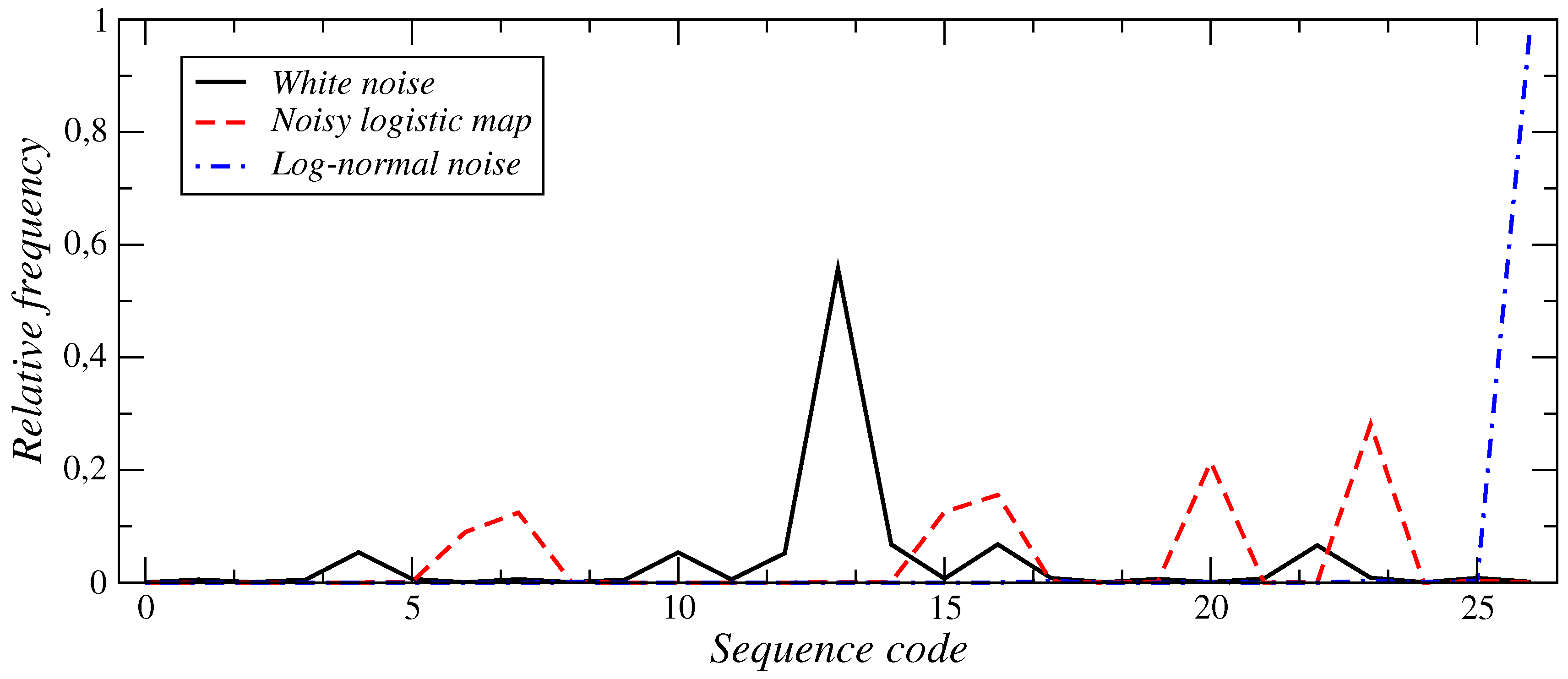

4. Symbolic Analysis Framework

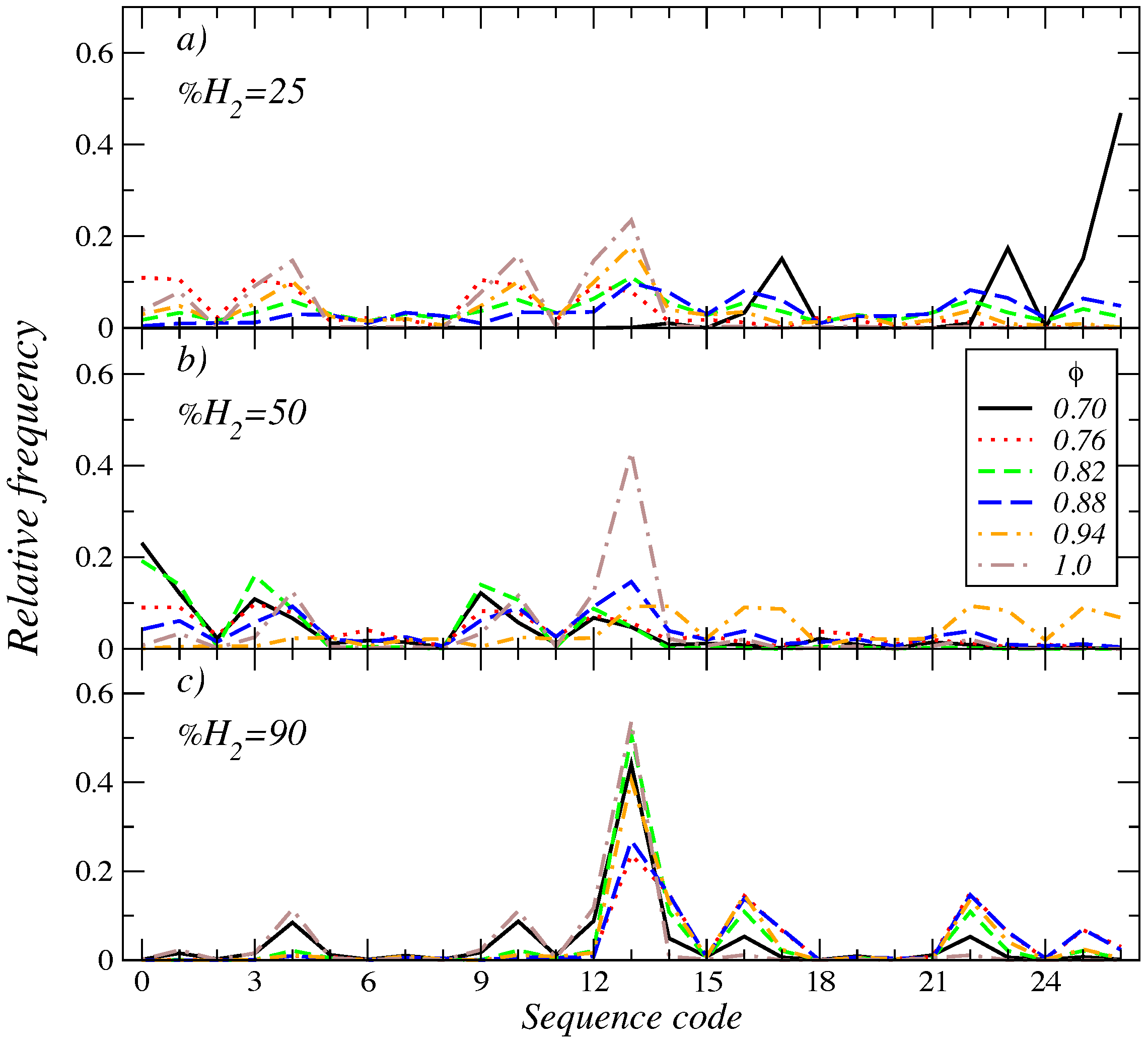

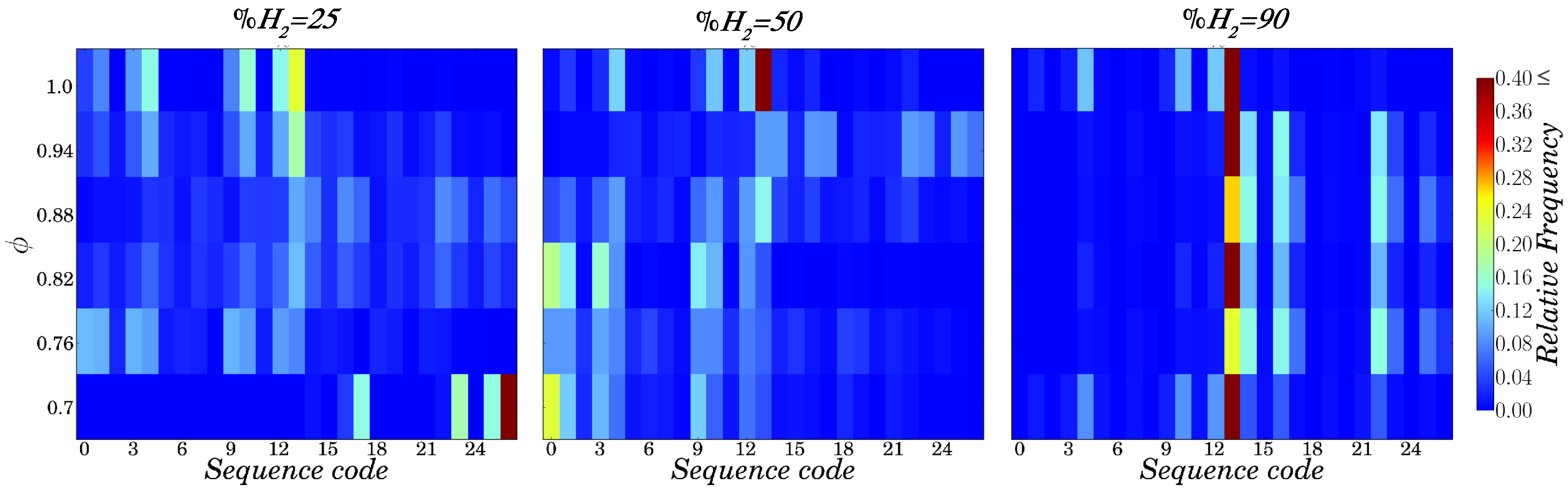

5. Discussion of Symbolic Analysis Findings

6. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Al-Durra, A.; Canova, M.; Yurkovich, S. A real-time pressure estimation algorithm for closed-loop combustion control. Mech. Syst. Signal Process. 2013, 38, 411–427. [Google Scholar] [CrossRef]

- Maurya, R.K.; Pal, D.D.; Agarwal, A.K. Digital signal processing of cylinder pressure data for combustion diagnostics of HCCI engine. Mech. Syst. Signal Process. 2013, 36, 95–109. [Google Scholar] [CrossRef]

- Karim, G.A. Hydrogen as a spark ignition engine fuel. Int. J. Hydrogen Energy 2003, 28, 569–577. [Google Scholar] [CrossRef]

- White, C.M.; Steeper, R.R.; Lutz, A.E. The hydrogen-fueled internal combustion engine: A technical review. Int. J. Hydrogen Energy 2006, 31, 1292–1305. [Google Scholar] [CrossRef]

- Verhelst, S.; Wallner, T. Hydrogen-fueled internal combustion engines. Prog. Energy Combust. Sci. 2009, 35, 490. [Google Scholar] [CrossRef]

- D’Andrea, T.; Henshawa, P.F.; Tingb, D.S.-K. The addition of hydrogen to a gasoline-fuelled SI engine. Int. J. Hydrogen Energy 2004, 29, 1541–1552. [Google Scholar] [CrossRef]

- Ji, C.; Wang, S. Effect of hydrogen addition on the idle performance of a spark ignited gasoline engine at stoichiometric condition. Int. J. Hydrogen Energy 2009, 34, 3546–3556. [Google Scholar] [CrossRef]

- Ji, C.; Wang, S. Effect of hydrogen addition on combustion and emissions performance of a spark ignition gasoline engine at lean conditions. Int. J. Hydrogen Energy 2009, 34, 7823–7834. [Google Scholar] [CrossRef]

- Ji, C.; Wang, S.; Zhang, B. Effect of spark timing on the performance of a hybrid hydrogen-gasoline engine at lean conditions. Int. J. Hydrogen Energy 2010, 35, 2203–2212. [Google Scholar] [CrossRef]

- Wang, S.; Ji, C.; Zhang, B.; Liu, X. Realizing the part load control of a hydrogen-blended gasoline engine at the wide open throttle condition. Int. J. Hydrogen Energy 2014, 39, 7428–7436. [Google Scholar] [CrossRef]

- Wang, S.; Ji, C.; Zhang, B.; Liu, X. Lean burn performance of a hydrogen-blended gasoline engine at the wide open throttle condition. Appl. Energy 2014, 136, 43–50. [Google Scholar] [CrossRef]

- Ji, C.; Liu, X.; Gao, B.; Wang, S.; Yang, J. Numerical investigation on the combustion process in a spark-ignition engine fueled with hydrogen-gasoline blends. Int. J Hydrogen Energy 2013, 38, 11149–11155. [Google Scholar] [CrossRef]

- Ji, C.; Liu, X.; Wang, S.; Gao, B.; Yang, J. Development and validation of a laminar flame speed correlation for the CFD simulation of hydrogen-enriched gasoline engines. Int. J. Hydrogen Energy 2013, 38, 1997–2006. [Google Scholar] [CrossRef]

- Sen, A.; Longwic, R.; Litak, G.; Gorski, K. Analysis of cycle-to-cycle pressure oscillations in a diesel engine. Mech. Syst. Signal Process. 2008, 22, 362–373. [Google Scholar] [CrossRef]

- Roberts, J.B.; Peyton Jones, J.C.; Landsborough, K.J. Stochastic modelling and estimation for cyclic pressure variations in spark ignition engines. Mech. Syst. Signal Process. 2001, 15, 419–438. [Google Scholar] [CrossRef]

- Martínez, S.; Irimescu, A.; Merola, S.S.; Lacava, P.; Curto-Risso, P.L. Flame front propagation in an optical GDI engine under stoichiometric and lean burn conditions. Energies 2017, 10, 1337. [Google Scholar]

- Srivastav, A.; Ray, A.; Gupta, S. An information-theoretic measure for anomaly detection in complex dynamical systems. Mech. Syst. Signal Process. 2009, 23, 358–371. [Google Scholar] [CrossRef]

- Wagner, R.M.; Drallmeier, J.A.; Daw, C.S. Prior-Cycle Effects in Lean Spark Ignition Combustion-Fuel/Air Charge Considerations; SAE Paper 981047; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Finney, C.E.; Kaul, B.C.; Daw, C.S.; Wagner, R.M.; Edwards, K.D.; Green, J.B., Jr. Invited review: A review of deterministic effects in cyclic variability of internal combustion engines. Int. J. Engine Res. 2015, 16, 366–378. [Google Scholar] [CrossRef]

- Sen, A.K.; Litak, G.; Finney, C.E.A.; Daw, C.S.; Wagner, R.M. Analysis of heat release dynamics in an internal combustion engine using multifractals and wavelets. Appl. Energy 2010, 87, 1736–1743. [Google Scholar] [CrossRef]

- Ma, F.; Li, S.; Zhao, J.; Qi, Z.; Deng, J.; Naeve, N.; He, Y.; Zhao, S. A fractal-based quasi-dimensional combustion model for SI engines fuelled by hydrogen enriched compressed natural gas. Int. J. Hydrogen Energy 2012, 37, 9892–9901. [Google Scholar] [CrossRef]

- Curto-Risso, P.L.; Medina, A.; Calvo Hernández, A.; Guzmán-Vargas, L.; Angulo-Brown, F. Monofractal and multifractal analysis of simulated heat release fluctuations in a spark ignition heat engine. Physica A 2010, 389, 5662–5670. [Google Scholar] [CrossRef]

- Sen, A.K.; Medina, A.; Curto-Risso, P.L.; Calvo Hernández, A. Effect of ethanol addition on cyclic variability in a simulated spark igntion engine. Meccanica 2014, 49, 2285–2297. [Google Scholar] [CrossRef]

- Daw, C.S.; Kennel, M.B.; Finney, C.E.A.; Connolly, F.T. Observing and modeling nonlinear dynamics in an internal combustion engine. Phys. Rev. E 1998, 57, 2811–2819. [Google Scholar] [CrossRef]

- Ghazimirsaied, A.; Shahbakhti, M.; Koch, C.R. HCCI engine combustion phasing prediction using a symbolic-statistics approach. J. Eng. Gas Turbines Power 2010, 132, 082805. [Google Scholar] [CrossRef]

- Ghazimirsaied, A.; Koch, C.R. Controlling cyclic combustion timing variations using a symbol-statistics predictive approach in an hcci engine. Appl. Energy 2012, 92, 133–146. [Google Scholar] [CrossRef]

- Chen, Y.; Dong, G.; Mack, J.H.; Butt, R.H.; Chen, J.Y.; Dibble, R.W. Cyclic variations and prior-cycle effects of ion current sensing in an hcci engine: A time-series analysis. Appl. Energy 2016, 168, 628–635. [Google Scholar] [CrossRef]

- Li, F.; Wang, H.; Zhou, G.; Yu, D.; Li, J.; Gao, H. Anomaly detection in gas turbine fuel systems using a sequential symbolic method. Energies 2017, 10, 724. [Google Scholar] [CrossRef]

- Curto-Risso, P.L.; Medina, A.; Calvo Hernández, A. Optimizing the geometrical parameters of a spark ignition engine: Simulation and theoretical tools. Appl. Therm. Eng. 2011, 31, 803–810. [Google Scholar] [CrossRef]

- Curto-Risso, P.L.; Medina, A.; Calvo Hernández, A.; Guzmán-Vargas, L.; Angulo-Brown, F. On cycle-to-cycle heat release variations in a simulated spark ignition heat engine. Appl. Energy 2011, 88, 1557–1567. [Google Scholar] [CrossRef]

- Martínez-Boggio, S.; Curto-Risso, P.L.; Medina, A.; Calvo Hernández, A. Simulation of cycle-to-cycle variations on spark ignition engines fueled with gasoline-hydrogen blends. Int. J. Hydrogen Energy 2016, in press. [Google Scholar]

- Tang, X.Z.; Tracy, E.R.; Boozer, A.D.; Brown, R. Symbol sequence statistics in noisy chaotic signal reconstruction. Phys. Rev. E 1995, 51, 3871. [Google Scholar] [CrossRef]

- Daw, C.S.; Finney, C.E.A.; Kennel, M.B. Symbolic approach for measuring temporal irreversibility. Phys. Rev. E 2000, 62, 1912–1921. [Google Scholar] [CrossRef]

- Daw, C.S.; Finney, C.E.A.; Tracy, E.R. A review of symbolic analysis of experimental data. Rev. Sci. Instrum. 2003, 74, 915–930. [Google Scholar] [CrossRef]

- Curto-Risso, P.L.; Medina, A.; Calvo Hernández, A. Optimizing the operation of a spark ignition engine: Simulation and theoretical tools. J. Appl. Phys. 2009, 105, 094904. [Google Scholar] [CrossRef]

- Medina, A.; Curto-Risso, P.L.; Calvo Hernández, A.; Guzmán-Vargas, L.; Angulo-Brown, F.; Sen, A.K. Quasi-Dimensional Simulation of Spark Ignition Engines; Springer: Berlin, Germany, 2014. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988; Appendix C; p. 906. [Google Scholar]

- Barnes-Moss, H.W. A Designer’s Viewpoint in Passenger Car Engines, Conference Proceedings; Institution of Mechanical Engineers: London, UK, 1975; pp. 133–147. [Google Scholar]

- Eichelberg, G. Some new investigations on old combustion-engine problems. Engineering 1939, 148, 463–547. [Google Scholar]

- Bayraktar, H.; Durgun, O. Mathematical modeling of spark-ignition engine cycles. Energy Sources 2003, 25, 439–455. [Google Scholar] [CrossRef]

- Blizard, N.C.; Keck, J.C. Experimental and Theoretical Investigation of Turbulent Burning Model for Internal Combustion Engines; SAE Paper 740191; SAE International: Warrendale, PA, USA, 1974. [Google Scholar]

- Beretta, G.P.; Rashidi, M.; Keck, J.C. Turbulent flame propagation and combustion in spark ignition engines. Combust. Flame 1983, 52, 217–245. [Google Scholar] [CrossRef]

- Heywood, J.B. Combustion and its modeling in spark-ignition engines. In Proceedings of the International Symposium (COMODIA), Yokohama, Japan, 11–14 July 1994; Volume 94. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988; Chapter 14; pp. 771–773. [Google Scholar]

- Metghalchi, M.; Keck, J.C. Laminar burning velocity of propane-air mixture at high temperature and pressure. Combust. Flame 1980, 38, 143. [Google Scholar] [CrossRef]

- Metghalchi, M.; Keck, J.C. Burning velocities of mixtures of air with methanol, isoctane, and indolene at high pressure and temperature. Combust. Flame 1982, 48, 191–210. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988; Chapter 9; pp. 413–427. [Google Scholar]

- Mandilas, C.; Ormsby, M.P.; Sheppard, C.G.W.; Woolley, R. Effects of hydrogen addition on laminar and turbulent premixed methane and iso-octane-air flames. Proc. Combust. Inst. 2007, 31, 1443–1450. [Google Scholar] [CrossRef]

- Emadi, M.; Karkow, D.; Salamesh, T.; Gohil, A.; Raterner, A. Flame structure changes resulting from hydrogen-enrichment and pressurization for low swirl premixed methane-air flames. Int. J. Hydrogen Energy 2012, 37, 10397–10404. [Google Scholar] [CrossRef]

- Ferguson, C.R. Internal Combustion Engines, Applied Thermosciences; John Wiley & Sons: Hoboken, NJ, USA, 1986. [Google Scholar]

- Irimescu, A.; Merona, S.S.; Valentino, G. Application of an entrainment turbulent combustion model with validation based on the distribution of chemical species in an optical spark ignition engine. Appl. Energy 2016, 162, 908–923. [Google Scholar] [CrossRef]

- Ma, F.; Wang, Y.; Wang, M.; Liu, H.; Wang, J.; Dinbg, S.; Zhao, S. Development and validation of a quasi-dimensional combustion model for SI engines fuelled by HCNG with variable hydrogen fractions. Int. J. Hydrogen Energy 2008, 33, 4863–4875. [Google Scholar] [CrossRef]

- Abdi Aghdam, E.; Burluka, A.A.; Hattrell, T.; Liu, K.; Sheppard, G.W.; Neumeister, J.; Crundwell, N. Study of Cyclic Variation in an SI Engine Using Quasi-Dimensional Combustion Model; SAE Paper 2007-01-0939; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Ozdor, N.; Dulger, M.; Sher, E. Cyclic Variability in Spark Ignition Engines. A Literature Survey; SAE Paper 940987; SAE International: Warrendale, PA, USA, 1994. [Google Scholar]

- Heywood, J.B.; Keck, J.C.; Beretta, G.P.; Watts, P.A. Combustion and Operating Characteristics of Spark-Ignition Engines; Technical Report; Massachusetts Institute of Technology: Cambridge, MA, USA, 1980. [Google Scholar]

- Wang, S.; Ji, C.; Zhang, B. Starting a spark-ignited engine with the gasoline-hydrogen mixture. Int. J. Hydrogen Energy 2011, 36, 4461–4468. [Google Scholar] [CrossRef]

| Engine Type | In-Line, 4-Stroke |

|---|---|

| Manufacturer | Beijing Hyundai Motors |

| Bore (mm) | 77.4 |

| Stroke(mm) | 85 |

| Connecting rod (mm) | 141 |

| Displacement (L) | 1.599 |

| Compression ratio | 10:1 |

| Number of valves | 4 per cylinder |

| Manifold absolute pressure | 61.5 kPa |

| Spark advance (°CA BTDC) | 22 |

| IVO (°CA BTDC) | 45 |

| IVC (°CA BTDC) | 135 |

| EVO (°CA ATDC) | 135 |

| EVC (°CA ATDC) | 45 |

| Rated torque (N.m/rpm) | 143/4500 |

| Rated power (kW/rpm) | 82/6000 |

| Engine speed (rpm) | 1400 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reyes-Ramírez, I.; Martínez-Boggio, S.D.; Curto-Risso, P.L.; Medina, A.; Calvo Hernández, A.; Guzmán-Vargas, L. Symbolic Analysis of the Cycle-to-Cycle Variability of a Gasoline–Hydrogen Fueled Spark Engine Model. Energies 2018, 11, 968. https://doi.org/10.3390/en11040968

Reyes-Ramírez I, Martínez-Boggio SD, Curto-Risso PL, Medina A, Calvo Hernández A, Guzmán-Vargas L. Symbolic Analysis of the Cycle-to-Cycle Variability of a Gasoline–Hydrogen Fueled Spark Engine Model. Energies. 2018; 11(4):968. https://doi.org/10.3390/en11040968

Chicago/Turabian StyleReyes-Ramírez, Israel, Santiago D. Martínez-Boggio, Pedro L. Curto-Risso, Alejandro Medina, Antonio Calvo Hernández, and Lev Guzmán-Vargas. 2018. "Symbolic Analysis of the Cycle-to-Cycle Variability of a Gasoline–Hydrogen Fueled Spark Engine Model" Energies 11, no. 4: 968. https://doi.org/10.3390/en11040968