Comparison of the Energy Conversion Efficiency of a Solar Chimney and a Solar PV-Powered Fan for Ventilation Applications

Abstract

:1. Introduction

1.1. Solar Chimneys

1.2. Solar-Powered Electric Motors

1.3. Scope of the Study

2. Solar Chimney Scenario

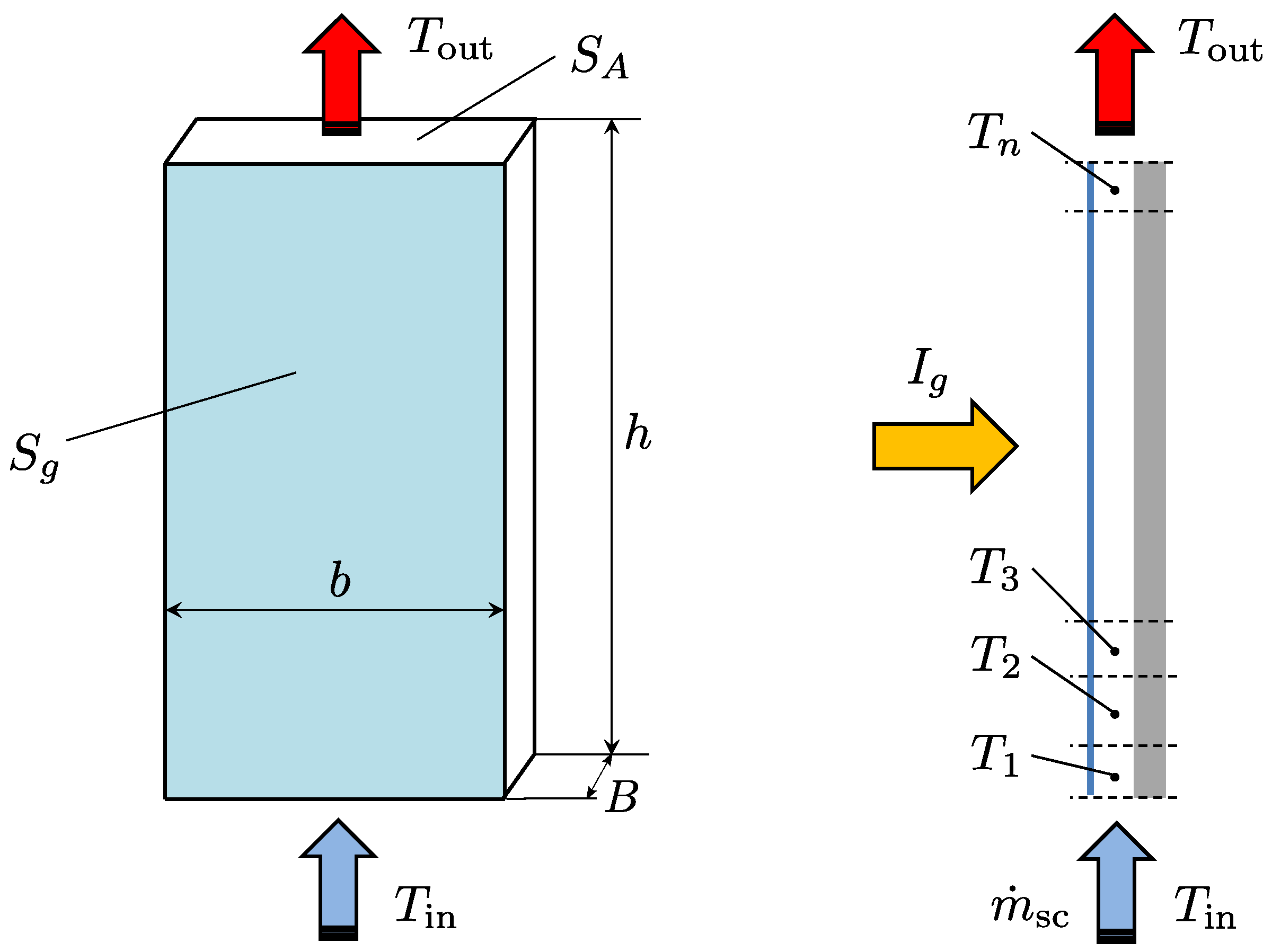

3. Computer Model of Solar Chimney

3.1. Basic Considerations and Governing Equations

3.2. Numerical Discretization

4. Scenario with the Fan Powered by Solar PV

4.1. Solar Panel

4.2. DC Fan

5. Computer Model of the PV Panel with the DC Fan

5.1. Model of PV Panels

5.2. Model of the DC Fan

6. Comparison of Performance and Discussion

6.1. Mass Flow Rates

6.2. Energy Conversion Efficiency

6.3. Economic Considerations

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | ideality factor |

| b | width |

| B | depth |

| specific heat at constant pressure | |

| D | equivalent diameter |

| f | friction factor |

| h | height |

| g | standard gravity |

| I | current |

| incident radiation | |

| k | Boltzmann constant |

| K | overall resistance coefficient |

| mass flow rate | |

| number of cells | |

| p | pressure |

| q | charge of electron |

| Q | volume flow rate |

| heat flux | |

| r | gas constant |

| R | electric resistance |

| area of glazing | |

| cross-section area of chimney | |

| T | temperature |

| V | voltage |

| w | air velocity |

| absorptivity | |

| local loss coefficient | |

| density | |

| transmissivity | |

| speed |

References

- Mullett, L.B. The solar chimney—Overall efficiency, design and performance. Int. J. Ambient Energy 1987, 8, 35–40. [Google Scholar] [CrossRef]

- Suárez-López, M.J.; Blanco-Marigorta, A.M.; Gutiérrez-Trashorras, A.J.; Pistono-Favero, J.; Blanco-Marigorta, E. Numerical simulation and exergetic analysis of building ventilation solar chimneys. Energy Convers. Manag. 2015, 96, 1–11. [Google Scholar] [CrossRef]

- Naraghi, M.H.; Blanchard, S. Twenty-four hour simulation of solar chimneys. Energy Build. 2015, 94, 218–226. [Google Scholar] [CrossRef]

- Imran, A.A.; Jalil, J.M.; Ahmed, S.T. Induced flow for ventilation and cooling by a solar chimney. Renew. Energy 2015, 78, 236–244. [Google Scholar] [CrossRef]

- He, G.; Zhang, J.; Hong, S. A new analytical model for airflow in solar chimneys based on thermal boundary layers. Sol. Energy 2016, 136, 614–621. [Google Scholar] [CrossRef]

- Sudprasert, S.; Chinsorranant, C.; Rattanadecho, P. Numerical study of vertical solar chimneys with moist air in a hot and humid climate. Int. J. Heat Mass Transf. 2016, 102, 645–656. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, G.; Cheng, X.; Guo, Y.; Wang, J.; Chew, M.Y.L. Developing an empirical model for roof solar chimney based on experimental data from various test rigs. Build. Environ. 2016, 110, 115–128. [Google Scholar] [CrossRef]

- Saleem, A.A.; Bady, M.; Ookawara, S.; Abdel-Rahman, A.K. Achieving standard natural ventilation rate of dwellings in a hot-arid climate using solar chimney. Energy Build. 2016, 133, 360–370. [Google Scholar] [CrossRef]

- Badescu, V. Dynamic model of a complex system including PV cells, electric battery, electrical motor and water pump. Energy 2003, 28, 1165–1181. [Google Scholar] [CrossRef]

- Atlam, O.; Kolhe, M. Performance evaluation of directly photovoltaic powered DC PM (direct current permanent magnet) motor—Propeller thrust system. Energy 2013, 57, 692–698. [Google Scholar] [CrossRef]

- Gupta, B.L.; Bhatnagar, M.; Marhur, J. Optimum sizing of PV panel, battery capacity and insulation thickness for a photovoltaic operated domestic refrigerator. Sustain. Energy Technol. Assess. 2014, 7, 55–67. [Google Scholar] [CrossRef]

- Hosien, M.A.; Selim, S.M. Effects of the geometrical and operational parameters and alternative outer cover materials on the performance of solar chimney used for natural ventilation. Energy Build. 2017, 138, 355–367. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, Y.; Wang, F.; Wang, X. Enhancement of natural ventilation of a novel roof solar chimney with perforated absorber plate for building energy conservation. Appl. Therm. Eng. 2016, 107, 653–661. [Google Scholar] [CrossRef]

- Khanal, R.; Lei, C. An experimental investigation of an inclined passive wall solar chimney for natural ventilation. Sol. Energy 2014, 107, 461–474. [Google Scholar] [CrossRef]

- Odeh, N.; Grassie, T.; Henderson, D.; Muneer, T. Modelling of flow rate in a photovoltaic-driven roof slate-based solar ventilation air preheating system. Energy Convers. Manag. 2006, 47, 909–925. [Google Scholar] [CrossRef]

- Sera, D.; Teodorescu, R.; Rodriguez, P. PV panel model based on datasheet values. In Proceedings of the IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 June 2007; pp. 2392–2396. [Google Scholar] [CrossRef]

- Hadj Arab, A.; Chenlo, F.; Benghanem, M. Loss-of-load probability of photovoltaic water pumping systems. Sol. Energy 2004, 76, 713–723. [Google Scholar] [CrossRef]

- Eurostat—Statistics Explained, Electricity Price Statistics. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Electricity_price_statistics (accessed on 3 April 2018).

| Parameter | Value | Description |

|---|---|---|

| 0.95 | absorptivity of the solar absorber plate | |

| B | 0.2 m | depth of the chimney cavity |

| 1005 J/kg·K | specific heat of air at constant pressure | |

| 1.19 kg/m | density of ambient (inlet) air | |

| 1.3 m | area of glazing | |

| 20 C | inlet air temperature | |

| 0.91 | transmissivity of glazing |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klimeš, L.; Charvát, P.; Hejčík, J. Comparison of the Energy Conversion Efficiency of a Solar Chimney and a Solar PV-Powered Fan for Ventilation Applications. Energies 2018, 11, 912. https://doi.org/10.3390/en11040912

Klimeš L, Charvát P, Hejčík J. Comparison of the Energy Conversion Efficiency of a Solar Chimney and a Solar PV-Powered Fan for Ventilation Applications. Energies. 2018; 11(4):912. https://doi.org/10.3390/en11040912

Chicago/Turabian StyleKlimeš, Lubomír, Pavel Charvát, and Jiří Hejčík. 2018. "Comparison of the Energy Conversion Efficiency of a Solar Chimney and a Solar PV-Powered Fan for Ventilation Applications" Energies 11, no. 4: 912. https://doi.org/10.3390/en11040912