Research on Economic Comprehensive Control Strategies of Tractor-Planter Combinations in Planting, Including Gear-Shift and Cruise Control

Abstract

:1. Introduction

2. Model

2.1. Dynamic Model of Tractor-Planter Combination Unit

2.2. Powertrain Model

2.3. Seed Metering System Model

3. Control Strategies

3.1. Generation of Gear-Shift Schedule

- Let vref = 4.1;

- Let k = 1 and Tq(1) = 10010, calculate the optimal values of g(1) and ne(1) which guarantee J(1) = minQ(1);

- Let k = k + 1, determine appropriate x(k) under the object J(k) = minQ(k);

- Repeating the step 3 until k = N, then let vref = vref + 0.1;

- Repeating the steps 2–4 until vref = 18.

3.2. Cruise Control Strategy

- Starting and transiting: In this stage, the tractor needs to start smoothly and accelerate quickly to around the target speed by manipulating clutches and transmission manually or automatically.

- Automatic cruise control: In this stage, the gear-shift and engine throttle are controlled by the control system based on the working load and speed demands.

- Stopping and turning: While reaching the edge of the field, the tractor needs to be quickly decelerated and change travel direction.

3.3. Control Strategy of Precision Seed Metering Device

3.4. Simulation Method

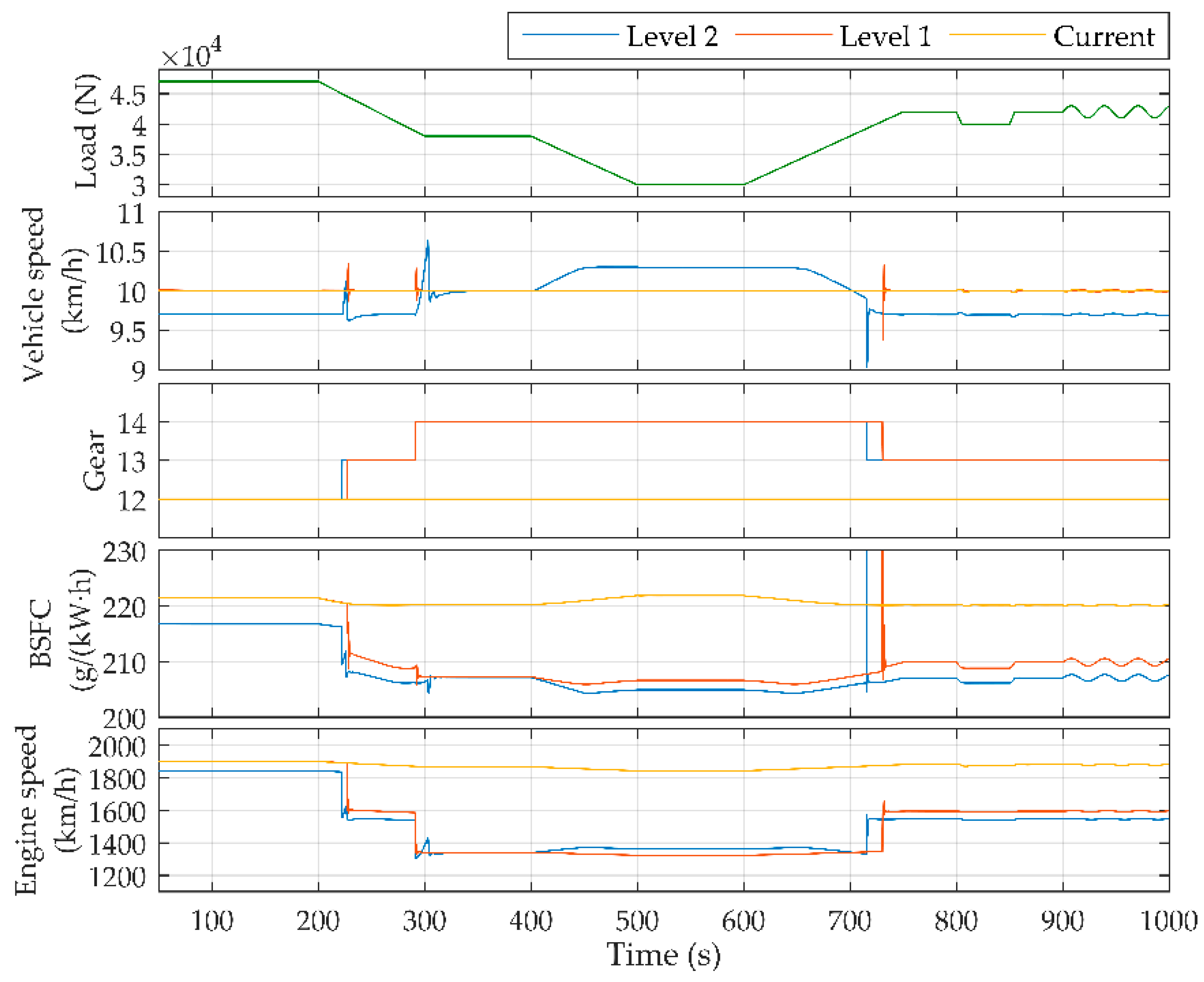

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- McBratney, A.; Whelan, B.; Ancev, T.; Bouma, J. Future directions of precision agriculture. Precis. Agric. 2005, 6, 7–23. [Google Scholar] [CrossRef]

- Li, M.; Imou, K.; Wakabayashi, K.; Yokoyama, S. Review of research on agricultural vehicle autonomous guidance. Int. J. Agric. Biol. Eng. 2009, 2, 1–16. [Google Scholar] [CrossRef]

- Backman, J.; Oksanen, T.; Visala, A. Navigation system for agricultural machines: Nonlinear model predictive path tracking. Comput. Electron. Agric. 2012, 82, 32–43. [Google Scholar] [CrossRef]

- Derrick, J.B.; Bevly, D.M. Adaptive steering control of a farm tractor with varying yaw rate properties. J. Field Robot. 2009, 26, 519–536. [Google Scholar] [CrossRef]

- Li, Y.; Efatmaneshnik, M.; Dempster, A.G. Attitude determination by integration of MEMS inertial sensors and GPS for autonomous agriculture applications. GPS Solut. 2012, 16, 41–52. [Google Scholar] [CrossRef]

- Pérez-Ruiz, M.; Carballido, J.; Agüera, J.; Gil, J.A. Assessing GNSS correction signals for assisted guidance systems in agricultural vehicles. Precis. Agric. 2011, 12, 639–652. [Google Scholar] [CrossRef]

- Han, K.; Zhu, Z.; Mao, E.; Song, Z.; Hu, F.; Xu, L. Cruise control system of tractor based on automated mechanical transmission. Trans. Chin. Soc. Agric. Eng. 2012, 28, 21–26. (In Chinese) [Google Scholar] [CrossRef]

- Marsden, G.; McDonald, M.; Brackstone, M. Towards an understanding of adaptive cruise control. Transp. Res. C Emerg. Technol. 2001, 9, 33–51. [Google Scholar] [CrossRef]

- Milanes, V.; Shladover, S.E.; Spring, J.; Nowakowski, C.; Kawazoe, H.; Nakamura, M. Cooperative adaptive cruise control in real traffic situations. IEEE Trans. Intell. Transp. Syst. 2014, 15, 296–305. [Google Scholar] [CrossRef]

- Moon, S.; Moon, I.; Yi, K. Design, tuning, and evaluation of a full-range adaptive cruise control system with collision avoidance. Control Eng. Pract. 2009, 17, 442–455. [Google Scholar] [CrossRef]

- Coen, T.; Saeys, W.; Missotten, B.; De Baerdemaeker, J. Cruise control on a combine harvester using model-based predictive control. Biosyst. Eng. 2008, 99, 47–55. [Google Scholar] [CrossRef]

- Coen, T.; Anthonis, J.; De Baerdemaeker, J. Cruise control using model predictive control with constraints. Comput. Electron. Agric. 2008, 63, 227–236. [Google Scholar] [CrossRef]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A fuzzy control strategy for the forward speed of a combine harvester based on KDD. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar] [CrossRef]

- Na, G.; Jingtao, H. Variable universe adaptive fuzzy-PID control of traveling speed for rice transplanter. Trans. Chin. Soc. Agric. Mach. 2013, 44, 245–251. (In Chinese) [Google Scholar] [CrossRef]

- Grzesikiewicz, W.; Knap, L.; Makowski, M.; Pokorski, J. Study of the Energy Conversion Process in the Electro-Hydrostatic Drive of a Vehicle. Energies 2018, 11, 348. [Google Scholar] [CrossRef]

- Karbaschian, M.A.; Soeffker, D. Review and Comparison of Power Management Approaches for Hybrid Vehicles with Focus on Hydraulic Drives. Energies 2014, 7, 3512–3536. [Google Scholar] [CrossRef]

- Wang, J.; Lei, Y.; Ge, A.; Lu, X. Shift Strategy Research on Off-Road Vehicle; Technical Report; SAE International: Warrendale, PA, USA. [CrossRef]

- Yang, W.; Wu, G.; Dang, J. Research and Development of Automatic Transmission Electronic Control System. In Proceedings of the 2007 IEEE International Conference on Integration Technology, Las Vegas, NV, USA, 13–15 August 2007. [Google Scholar]

- Shen, W.; Yu, H.; Hu, Y.; Xi, J. Optimization of Shift Schedule for Hybrid Electric Vehicle with Automated Manual Transmission. Energies 2016, 9, 220. [Google Scholar] [CrossRef] [Green Version]

- Zoz, F.M.; Grisso, R.D. Traction and tractor performance. In Proceedings of the 2003 Agricultural Equipment Technology Conference, Louisville, KY, USA, 9–11 February 2003. [Google Scholar]

- Dwyer, M.J. The tractive performance of wheeled vehicles. J. Terramech. 1984, 21, 19–34. [Google Scholar] [CrossRef]

- ASABE Standards. Available online: http://elibrary.asabe.org/standards.asp (accessed on 15 January 2018).

- Molari, G.; Sedoni, E. Experimental evaluation of power losses in a power-shift agricultural tractor transmission. Biosyst. Eng. 2008, 100, 177–183. [Google Scholar] [CrossRef]

- Zhai, J.; Xia, J.; Zhou, Y.; Zhang, S. Design and experimental study of the control system for precision seed-metering device. Int. J. Agric. Biol. Eng. 2014, 7, 13–18. [Google Scholar] [CrossRef]

- Lei, Y.; Fu, Y.; Liu, K.; Li, X.; Liu, Z.; Zhang, Y.; Fu, X. Research on Optimal Gearshift Strategy for Stepped Automatic Transmission Based on Vehicle Power Demand; Technical Report; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Baglione, M.; Duty, M.; Ni, J.; Assanis, D. Reverse dynamic optimization methodology for maximizing powertrain system efficiency. IFAC Proc. Vol. 2007, 40, 17–24. [Google Scholar] [CrossRef]

- Ngo, D.V.; Hofman, T.; Steinbuch, M.; Serrarens, A.; Merkx, L. Improvement of fuel economy in Power-Shift Automated Manual Transmission through shift strategy optimization—An experimental study. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Ang, K.H.; Chong, G.; Li, Y. PID control system analysis, design, and technology. IEEE Trans. Control Syst. Technol. 2005, 13, 559–576. [Google Scholar] [CrossRef]

- Emission Test Cycles. Available online: https://www.dieselnet.com/standards/cycles/index.php (accessed on 15 January 2018).

| Mode | Maximum Deviation Proportion dr | Target Speed Band |

|---|---|---|

| Level 1 | 0% | [vref, vref] |

| Level 2 | 3% | [0.97vref, 1.03vref] |

| Level 3 | 6% | [0.94vref, 1.06vref] |

| Level 4 | 9% | [0.91vref, 1.09vref] |

| Parameters | Value |

|---|---|

| Rated power of engine (kW) | 191 |

| Rolling radius of wheels (m) | 0.95 |

| Mass of tractor with counter weight (kg) | 11,000 |

| Mechanical efficiency of drive system ηm1 | 0.87 |

| Mechanical efficiency of PTO ηm2 | 0.97 |

| Parameters | Value |

|---|---|

| Rated speed (rpm) | 3000 |

| Maximum speed (rpm) | 4000 |

| Rated power (W) | 60 |

| Rated voltage (V) | 12 |

| Rated current (A) | 3.28 |

| Maximum current (A) | 6.56 |

| Rated torque (N·m) | 0.192 |

| Control Mode | Mean Fuel Consumption (L/km) | Mean Time (s/km) |

|---|---|---|

| Current | 2.768 | 411.4 |

| Level 1 | 2.668 | 410.8 |

| Level 2 | 2.644 | 414.1 |

| Level 3 | 2.613 | 417.9 |

| Level 4 | 2.579 | 421.7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Sun, D.; Hu, M.; Liu, J. Research on Economic Comprehensive Control Strategies of Tractor-Planter Combinations in Planting, Including Gear-Shift and Cruise Control. Energies 2018, 11, 686. https://doi.org/10.3390/en11030686

Li B, Sun D, Hu M, Liu J. Research on Economic Comprehensive Control Strategies of Tractor-Planter Combinations in Planting, Including Gear-Shift and Cruise Control. Energies. 2018; 11(3):686. https://doi.org/10.3390/en11030686

Chicago/Turabian StyleLi, Baogang, Dongye Sun, Minghui Hu, and Junlong Liu. 2018. "Research on Economic Comprehensive Control Strategies of Tractor-Planter Combinations in Planting, Including Gear-Shift and Cruise Control" Energies 11, no. 3: 686. https://doi.org/10.3390/en11030686