A Three-Coil Inductively Power Transfer System with Constant Voltage Output

Abstract

:1. Introduction

2. Theoretical Analysis

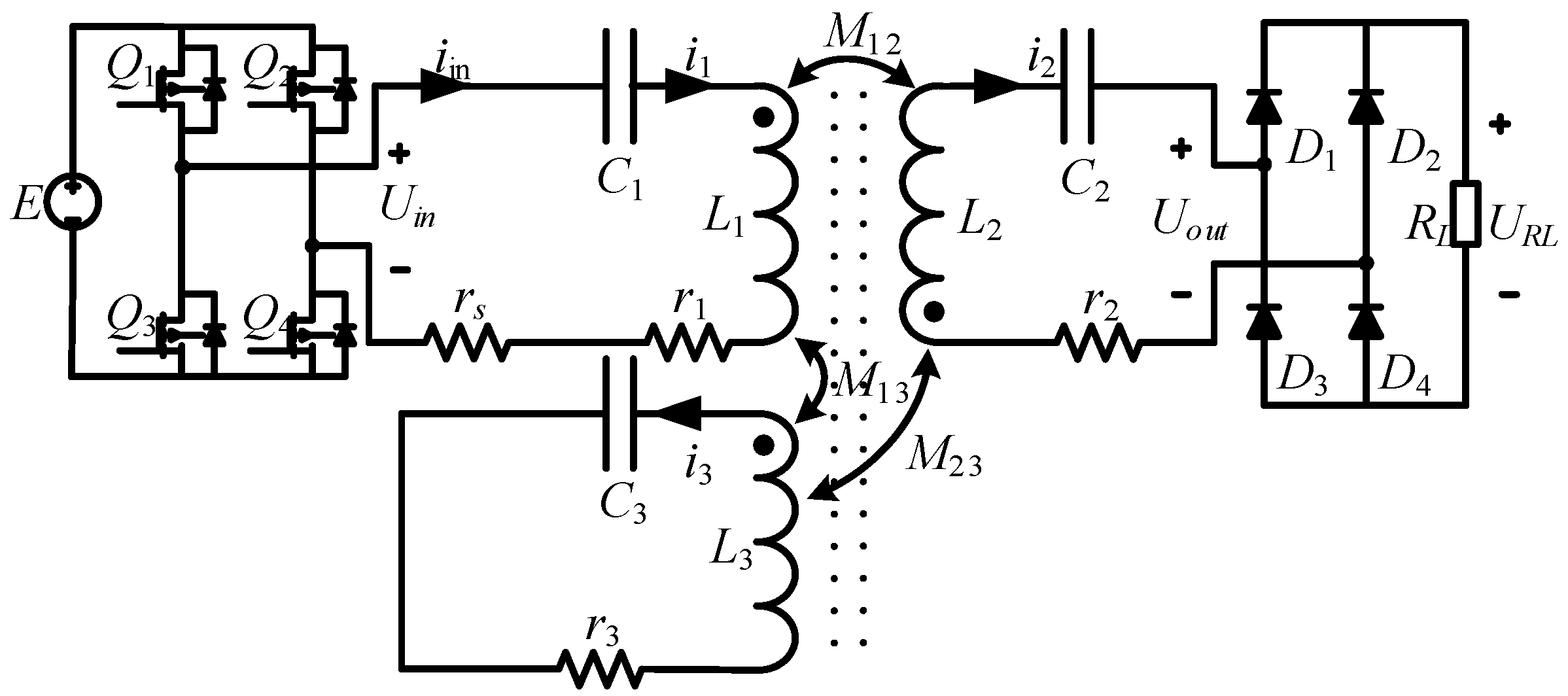

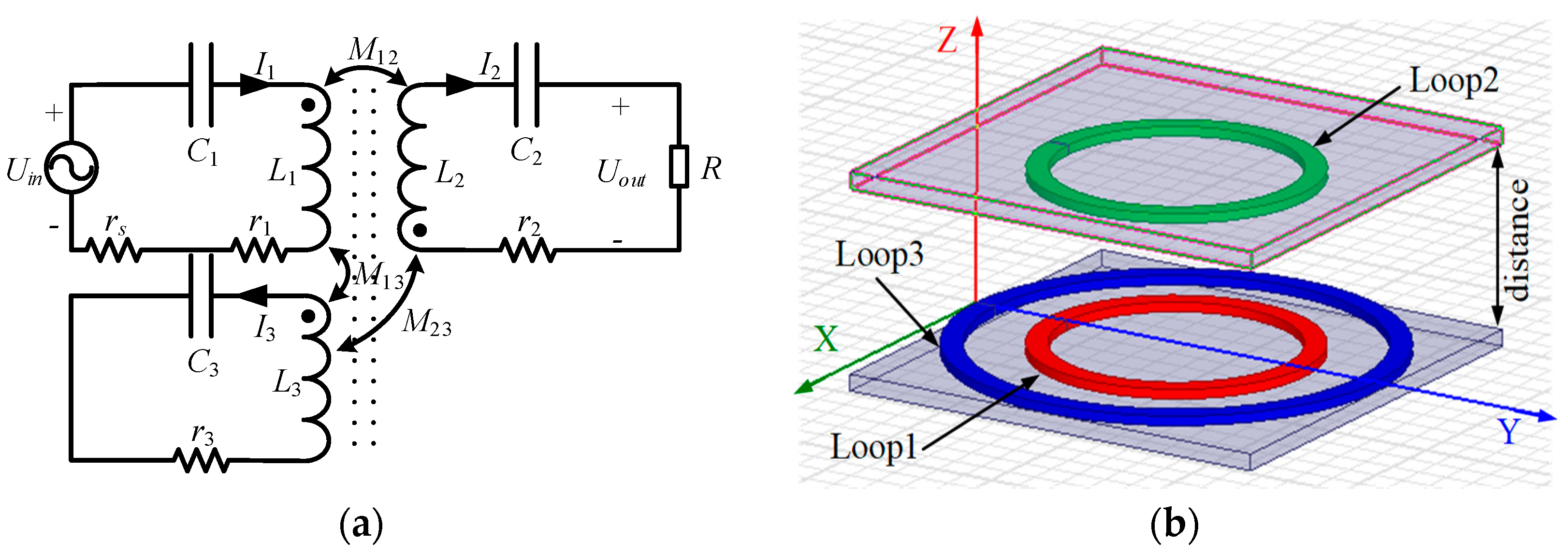

2.1. Overview of the Series-Series 3-Coil IPT System

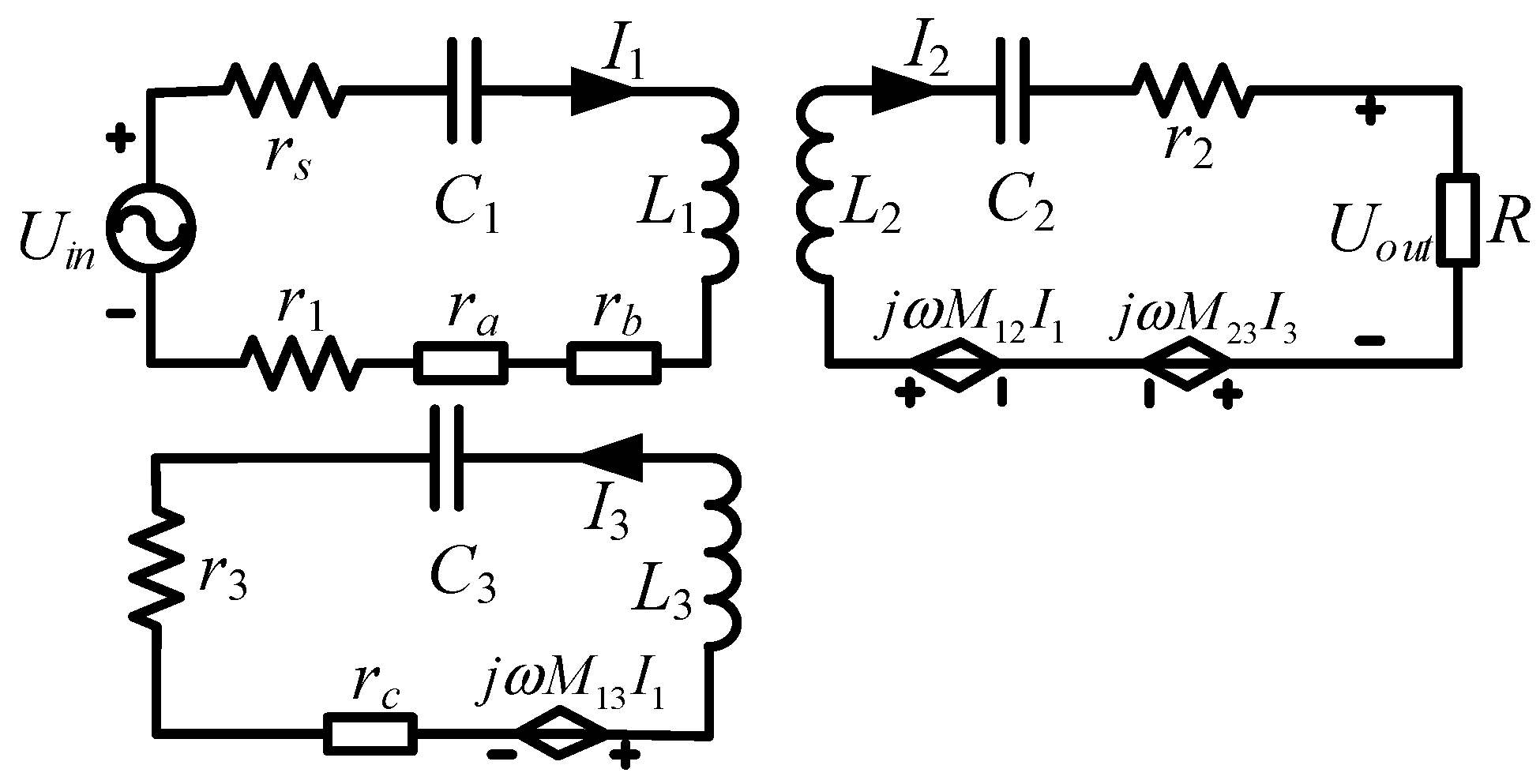

2.1.1. Equivalent Circuits and Fundamental Analysis

2.1.2. Voltage Gain and Methodology for CV Mode

2.1.3. Efficiency Analysis

2.1.4. Parameter Value Design

2.2. Parameter Design for S-LCL Compensated 2-Coil System

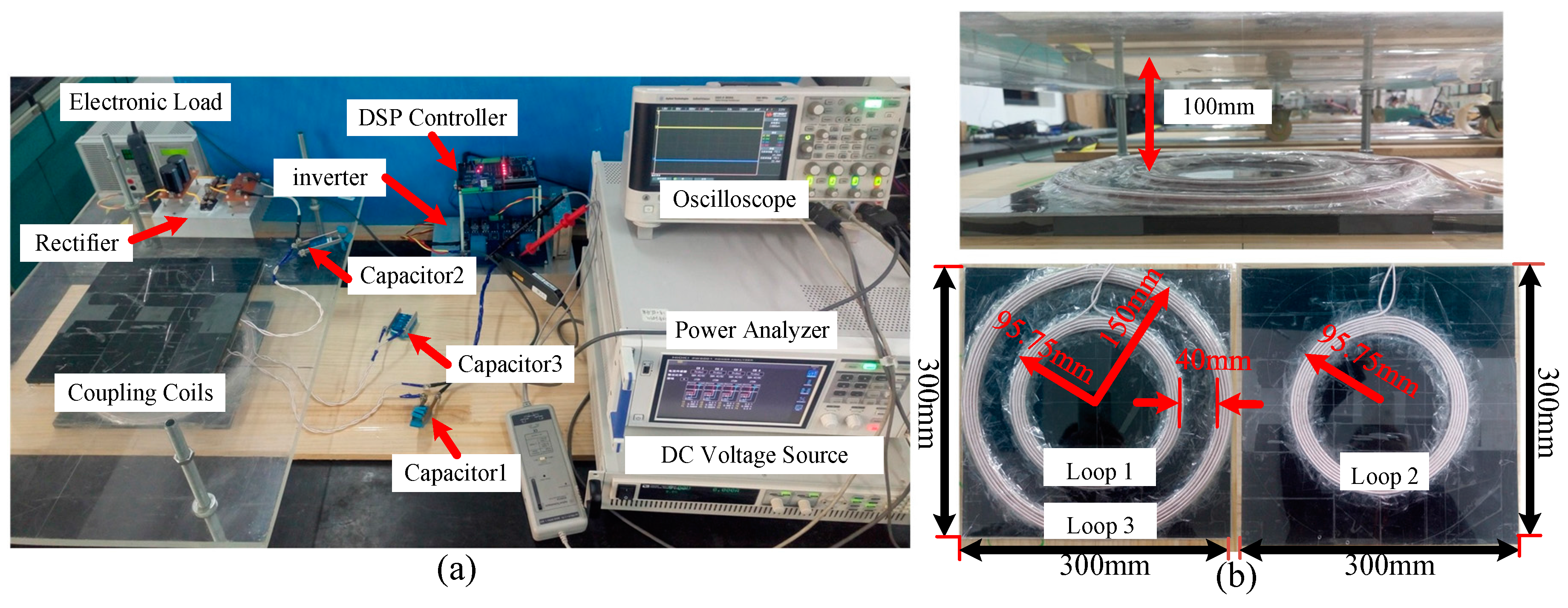

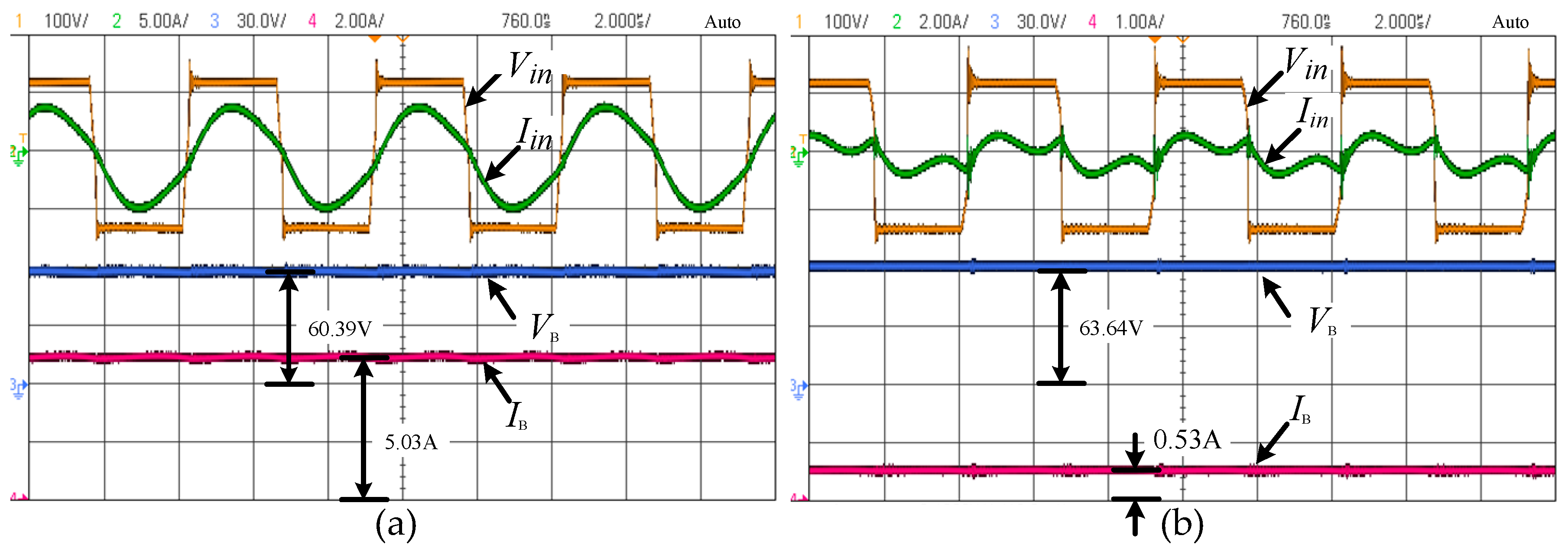

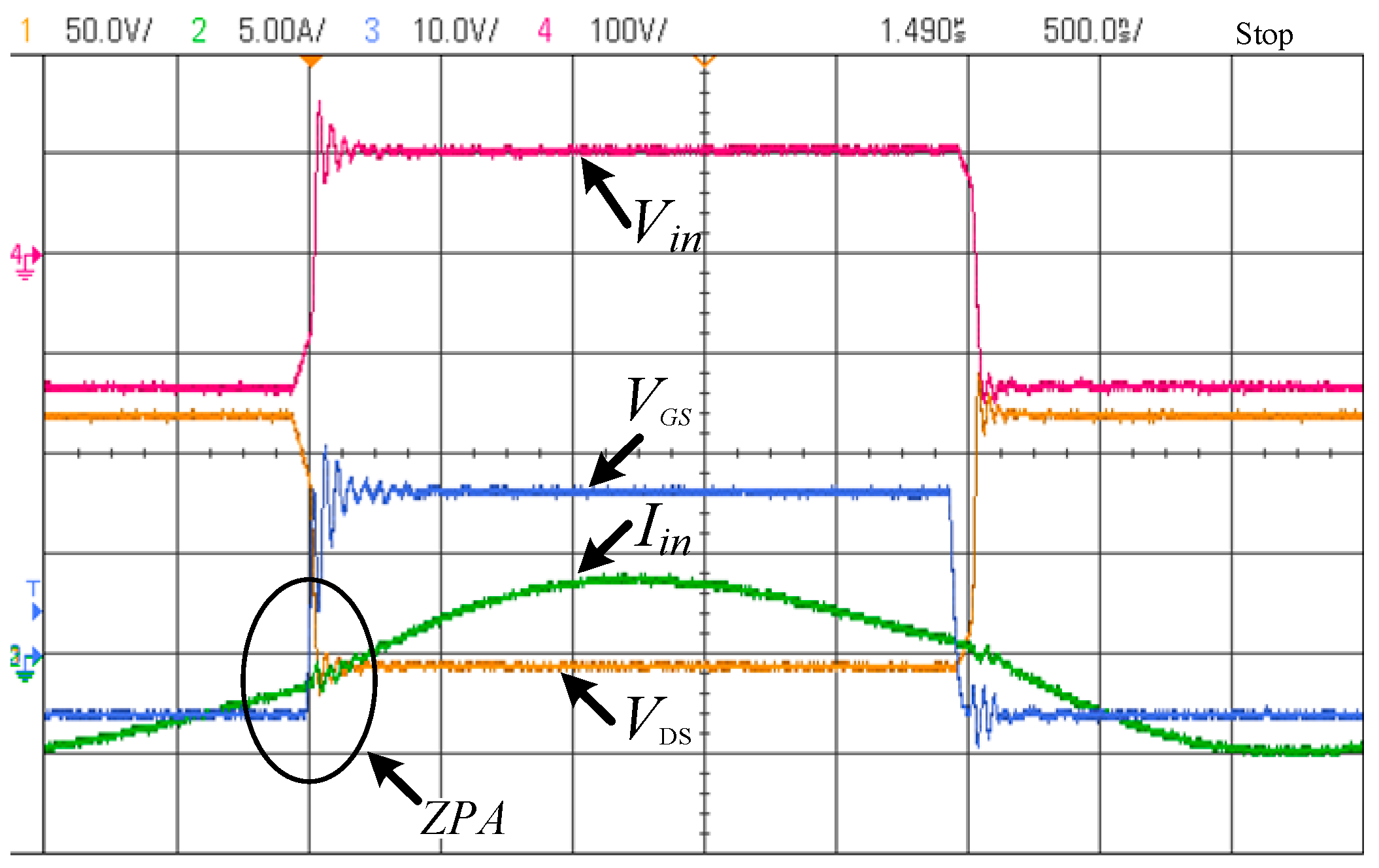

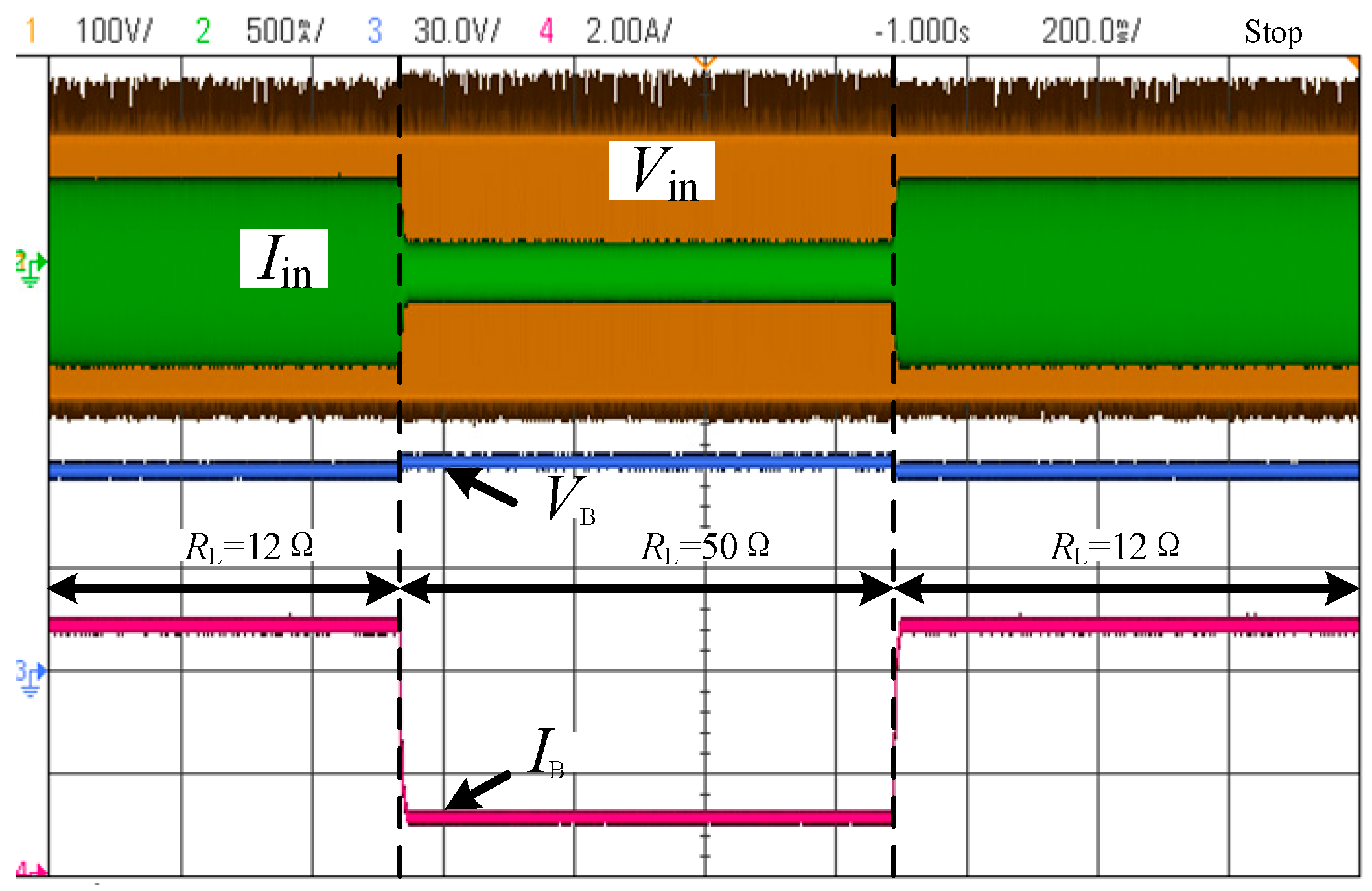

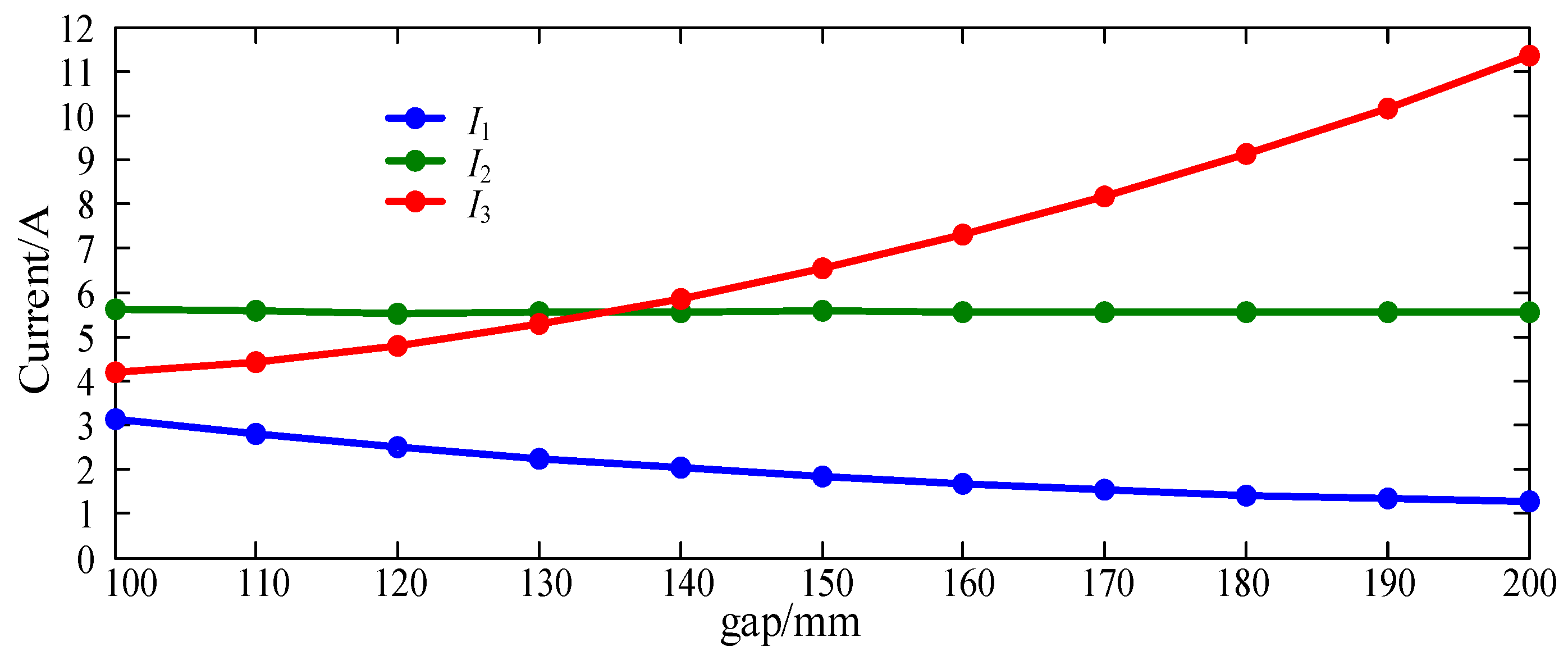

3. Experimental Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, X.; Yang, Q.; Chen, H.; Li, Y.; Cai, Y.; Jin, L. Modeling and Design and Experimental Verification of Contactless Power Transmission Systems via Electromagnetic Resonant Coupling. Proc. CSEE 2012, 32, 153–158. (In Chinese) [Google Scholar]

- González-González, J.M.; Triviño-Cabrera, A.; Aguado, J.A. Design and Validation of a Control Algorithm for a SAE J2954-Compliant Wireless Charger to Guarantee the Operational Electrical Constraints. Energies 2018, 11, 604. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, A.P. Study of Power Flow in an IPT System Based on Poynting Vector Analysis. Energies 2018, 11, 165. [Google Scholar] [CrossRef]

- Fan, X.; Mo, X.; Zhang, X. Research Status and Application of Wireless Power Transmission Technology. Proc. CSEE 2015, 35, 2584–2600. (In Chinese) [Google Scholar]

- Li, Y.; Mai, R.; Lu, L.; He, Z. Active and Reactive Currents Decomposition based Control of Angle and Magnitude of Current for a Parallel Multi-Inverter IPT System. IEEE Trans. Power Electron. 2017, 32, 1602–1614. [Google Scholar] [CrossRef]

- Hu, G.; Zhang, J.; Wang, J.; Fang, Z.; Cai, C.; Lin, Z. Combination of Compensations and Multi-Parameter Coil for Efficiency Optimization of Inductive Power Transfer System. Energies 2017, 10, 2088. [Google Scholar] [CrossRef]

- Lu, F.; Zhang, H.; Mi, C. A Review on the Recent Development of Capacitive Wireless Power Transfer Technology. Energies 2017, 10, 1752. [Google Scholar] [CrossRef]

- Mai, R.; Li, Y.; He, Z.; Yang, M.; Lu, L.; Liu, Y.; Chen, Y.; Lin, T.; Xu, D. Wireless Power Transfer Technology and Its Research Progress In Rail Transportration. J. Southwest Jiaotong Univ. 2016, 51, 446–461. (In Chinese) [Google Scholar]

- Sallán, J.; Villa, J.L.; Llombart, A.; Sanz, J.F. Optimal Design of ICPT Systems Applied to Electric Vehicle Battery Charge. IEEE Trans. Ind. Electron. 2009, 56, 2140–2149. [Google Scholar] [CrossRef]

- Mai, R.; Ma, L. Research on Inductive Power Transfer Systems with Dual Pick-up Coils. Proc. CSEE 2016, 36, 5192–5199. (In Chinese) [Google Scholar]

- Fareq, M.; Fitra, M.; Irwanto, M.; Syafruddin, H.S.; Gomesh, N.; Farrah, S.; Rozailan, M. Solar wireless Power Transfer Using Inductive Coupling for Mobile Phone Charger. In Proceedings of the 2014 IEEE 8th International Power Engineering and Optimization Conference (PEOCO2014), Langkawi, Malaysia, 24–25 March 2014; pp. 473–476. [Google Scholar]

- Xu, W.; Liang, W.; Peng, J.; Liu, Y.; Wang, Y. Maximizing Charging Satisfaction of Smartphone Users via Wireless Energy Transfer. IEEE Trans. Mob. Comput. 2017, 16, 990–1004. [Google Scholar] [CrossRef]

- Kang, W.; Alexander, Z.; Jun, H.; Park, Y.; Pack, J. Exposure Assessment for a Wireless Multi-Phone Charger. In Proceedings of the 2014 International Symposium on Electronmagnetic Compatibility, Tokyo, Japan, 12–16 May 2014; pp. 198–201. [Google Scholar]

- Chung, E.; Lee, J.; Ha, J. System Conditions Monitoring Method for a Wireless Cellular Phone Charger. In Proceedings of the 2014 International Power Electronics and Application Conference and Exposition, Shanghai, China, 5–8 November 2014; pp. 639–643. [Google Scholar]

- Li, H.; Li, J.; Wang, K.; Chen, W.; Yang, X. A maximum Efficiency Point Tracking Control Scheme for Wireless Power Transfer Systems Using Magnetic Resonant Coupling. IEEE Trans. Power Electron. 2015, 30, 3998–4008. [Google Scholar] [CrossRef]

- Mai, R.; Zhang, Y.; Chen, Y.; Kou, Z.; He, Z. Study on IPT Charging System with Hybrid Topology for Configurable Charge Currents. Proc. CSEE 2017. (In Chinese) [Google Scholar] [CrossRef]

- Boys, J.T.; Covic, G.A.; Xu, Y. DC Analysis Technique for Inductive Power Transfer Pick-ups. IEEE Power Electron. Lett. 2003, 1, 51–53. [Google Scholar] [CrossRef]

- Vu, V.B.; Doan, V.T.; Pham, V.L.; Choi, W. A new method to implement the constant Current-Constant Voltage charge of the Inductive Power Transfer system for Electric Vehicle applications. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Busan, Korea, 1–4 June 2016; pp. 449–453. [Google Scholar]

- Wu, H.H.; Gilchrist, A.; Sealy, K.D.; Bronson, D. A High Efficiency 5 kW Inductive Charger for EVs Using Dual Side Control. IEEE Trans. Ind. Inform. 2012, 8, 585–595. [Google Scholar] [CrossRef]

- Mai, R.; Chen, Y.; Liu, Y. Compensation Capacitor alteration Based IPT Battery Charging Application with Constant Current and Constant Voltage Control. Proc. CSEE 2016, 36, 5816–5821. (In Chinese) [Google Scholar]

- Mai, R.; Chen, Y.; Zhang, Y.; Li, Y.; He, Z. Study on Secondary Compensation Capacitor alteration Based IPT Charging System. Proc. CSEE 2017, 33, 3263–3269. (In Chinese) [Google Scholar]

- Mai, R.; Chen, Y.; Li, Y.; Zhang, Y.; Cao, G.; He, Z. Inductive Power Transfer for Massive Electric Bicycles Charging Based on Hybrid Topology Switching with A Single Inverter. IEEE Trans. Power Electron. 2017, 8, 5897–5906. [Google Scholar] [CrossRef]

- Kiani, M.; Jow, U.M.; Ghovanloo, M. Design and optimization of a 3-coil inductive link for efficient wireless power transmission. IEEE Trans. Biomed. Circuits Syst. 2011, 5, 579–591. [Google Scholar] [CrossRef] [PubMed]

- Tran, D.H.; Vu, V.; Choi, W. Design of a High Efficiency Wireless Power Transfer System with Intermediate Coils for the On-board Chargers of Electric Vehicles. IEEE Trans. Power Electron. 2017, 1, 175–187. [Google Scholar] [CrossRef]

- Kurs, A.; Karalis, A.; Moffatt, R.; Joannopoulos, J.D.; Fisher, P.; Soljacic, M. Wireless power transfer via strongly coupled magnetic resonances. Science 2007, 317, 83–86. [Google Scholar] [CrossRef] [PubMed]

- Beh, T.C.; Kato, M.; Imura, T.; Oh, S.; Hori, Y. Automated Impedance Matching System for Robust Wireless Power Transfer via Magnetic Resonance Coupling. IEEE Trans. Ind. Electron. 2013, 60, 3689–3698. [Google Scholar] [CrossRef]

- Zhong, W.X.; Zhang, C.; Liu, X.; Hui, S.Y.R. A Methodology for Making a Three-Coil Wireless Power Transfer System More Energy Efficient Than a Two-Coil Counterpart for Extended Transfer Distance. IEEE Trans. Power Electron. 2015, 30, 933–942. [Google Scholar] [CrossRef]

- Moon, S.; Kim, B.C.; Cho, S.Y.; Ahn, C.H.; Moon, G.W. Analysis and design of a wireless power transfer system with an intermediate coil for high efficiency. IEEE Trans. Ind. Electron. 2014, 61, 5861–5870. [Google Scholar] [CrossRef]

- Kim, J.W.; Son, H.C.; Kim, K.H.; Park, Y.J. Efficiency analysis of magnetic resonance wireless power transfer with intermediate resonant coil. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 389–392. [Google Scholar] [CrossRef]

- Zhang, F.; Hackworth, S.A.; Fu, W.; Li, C.; Mao, Z.; Sun, M. Relay effect of wireless power transfer using strongly coupled magnetic resonances. IEEE Trans. Magn. 2011, 47, 1478–1481. [Google Scholar] [CrossRef]

- Moon, S.; Moon, G.W. Wireless Power Transfer System with an Asymmetric Four-Coil Resonator for Electric Vehicle Battery Chargers. IEEE Trans. Ind. Electron. 2016, 31, 6844–6854. [Google Scholar]

- Ahn, D.J.; Hong, S.C. A study on magnetic field repeater in wireless power transfer. IEEE Trans. Ind. Electron. 2013, 60, 360–371. [Google Scholar] [CrossRef]

- Kamineni, G.; Covic, A.; Boys, J.T. Analysis of Coplanar Intermediate Coil Structures in Inductive Power Transfer Systems. IEEE Trans. Power Electron. 2015, 30, 6141–6154. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Frequency f/kHz | 200 | Capacitor C2/nF | 13.681 |

| Input voltage E/V | 120 | Capacitor C3/nF | 6.701 |

| Self-inductance L1/uH | 53.76 | Transfer distance gap/mm | 100 |

| Self-inductance L2/uH | 56.69 | Outer radius of Loop 1 R1/mm | 95.75 |

| Self-inductance L3/uH | 94.497 | Outer radius of Loop 2 R2/mm | 95.75 |

| Mutual inductance M12/uH | 9.5425 | Outer radius of Loop 3 R3/mm | 150 |

| Mutual inductance M13/uH | 23.255 | Number of turns for Loop 1 N1 | 10 |

| Mutual inductance M23/uH | 12.675 | Number of turns for Loop 2 N2 | 10 |

| Capacitor C1/nF | 11.779 | Number of turns for Loop 3 N3 | 10 |

| Model | gap/mm | 100.00 | 110.00 | 120.00 | 130.00 | 140.00 | 150.00 | 160.00 | 170.00 | 180.00 | 190.00 | 200.00 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 coil | L1/uH | 62.51 | 62.23 | 61.94 | 61.87 | 61.73 | 61.64 | 61.49 | 61.54 | 61.54 | 61.46 | 61.56 |

| L2/uH | 62.57 | 62.35 | 61.96 | 61.98 | 61.82 | 61.61 | 61.57 | 61.73 | 61.65 | 61.71 | 61.61 | |

| L3/uH | 107.14 | 106.82 | 106.20 | 106.26 | 105.53 | 105.54 | 105.57 | 105.37 | 105.25 | 105.42 | 105.32 | |

| M12/uH | 9.93 | 8.38 | 7.13 | 6.09 | 5.23 | 4.52 | 3.92 | 3.41 | 2.98 | 2.61 | 2.30 | |

| M13/uH | 23.66 | 23.20 | 22.91 | 22.71 | 22.51 | 22.40 | 22.34 | 22.27 | 22.28 | 22.19 | 22.16 | |

| M23/uH | 13.04 | 11.46 | 10.09 | 8.92 | 7.88 | 7.00 | 6.23 | 5.55 | 4.96 | 4.44 | 3.98 | |

| 2 coil | L1/uH | 216.98 | 215.45 | 213.96 | 213.54 | 212.29 | 211.99 | 211.75 | 211.46 | 211.34 | 211.27 | 211.19 |

| L2/uH | 62.57 | 62.35 | 61.96 | 61.98 | 61.82 | 61.61 | 61.57 | 61.73 | 61.65 | 61.71 | 61.61 | |

| M/uH | 22.97 | 19.84 | 17.22 | 15.00 | 13.11 | 11.52 | 10.16 | 8.96 | 7.94 | 7.05 | 6.28 |

| Model | gap/mm | 100.00 | 110.00 | 120.00 | 130.00 | 140.00 | 150.00 | 160.00 | 170.00 | 180.00 | 190.00 | 200.00 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

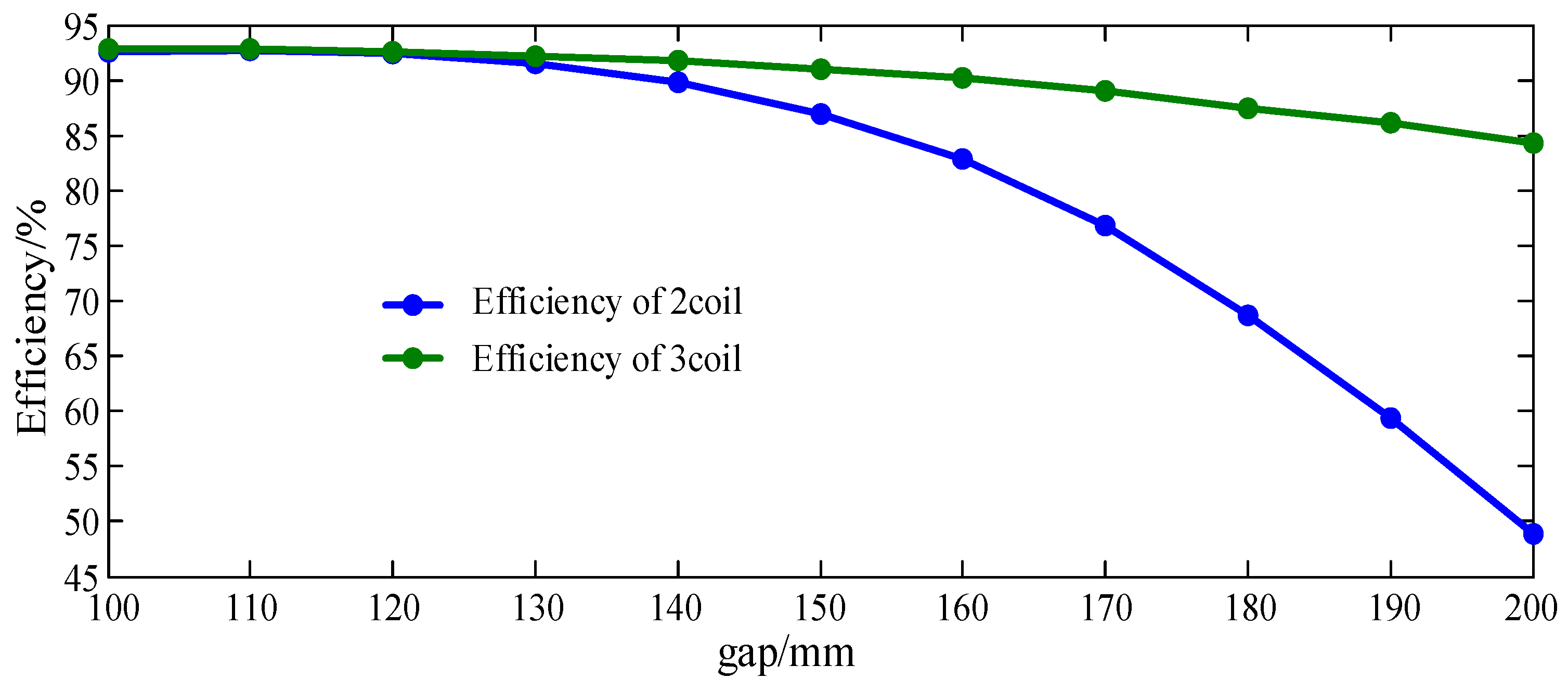

| 3 coil | Pin/w | 329.80 | 325.70 | 323.10 | 326.40 | 327.60 | 331.90 | 332.60 | 336.10 | 344.40 | 347.70 | 356.20 |

| Pout/w | 306.30 | 302.20 | 299.20 | 301.10 | 300.70 | 301.90 | 300.10 | 299.10 | 301.30 | 299.60 | 300.10 | |

| η/% | 92.89 | 92.78 | 92.62 | 92.24 | 91.79 | 90.96 | 90.24 | 88.99 | 87.50 | 86.15 | 84.26 | |

| URL/V | 60.62 | 60.22 | 59.92 | 60.11 | 60.07 | 60.19 | 60.01 | 59.91 | 60.13 | 59.96 | 60.01 | |

| E/V | 117.20 | 129.50 | 144.10 | 161.80 | 181.00 | 203.00 | 226.50 | 253.00 | 284.00 | 315.00 | 351.00 | |

| I1/A | 3.13 | 2.80 | 2.50 | 2.25 | 2.03 | 1.84 | 1.67 | 1.53 | 1.42 | 1.33 | 1.27 | |

| I2/A | 5.61 | 5.58 | 5.53 | 5.57 | 5.56 | 5.57 | 5.56 | 5.55 | 5.57 | 5.55 | 5.56 | |

| I3/A | 4.21 | 4.43 | 4.78 | 5.28 | 5.87 | 6.56 | 7.30 | 8.16 | 9.14 | 10.17 | 11.34 | |

| 2 coil | Pin/w | 325.00 | 324.20 | 325.40 | 328.40 | 334.60 | 345.50 | 362.30 | 390.80 | 435.80 | 504.50 | 613.60 |

| Pout/w | 301.00 | 300.50 | 300.70 | 300.70 | 300.70 | 300.50 | 300.10 | 300.20 | 299.30 | 299.30 | 300.20 | |

| η/% | 92.61 | 92.69 | 92.41 | 91.57 | 89.87 | 86.98 | 82.81 | 76.81 | 68.67 | 59.33 | 48.92 | |

| URL/V | 60.10 | 60.05 | 60.07 | 60.07 | 60.07 | 60.05 | 60.01 | 60.02 | 59.93 | 59.93 | 60.02 | |

| E/V | 117.20 | 129.50 | 144.10 | 161.80 | 181.00 | 203.00 | 226.50 | 253.00 | 284.00 | 315.00 | 351.00 | |

| I1/A | 3.12 | 2.82 | 2.55 | 2.33 | 2.33 | 2.01 | 1.88 | 1.80 | 1.76 | 1.81 | 1.96 | |

| I2/A | 3.53 | 4.54 | 5.86 | 7.58 | 9.74 | 12.47 | 15.81 | 20.04 | 25.41 | 31.76 | 39.75 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mai, R.; Zhang, Y.; Dai, R.; Chen, Y.; He, Z. A Three-Coil Inductively Power Transfer System with Constant Voltage Output. Energies 2018, 11, 673. https://doi.org/10.3390/en11030673

Mai R, Zhang Y, Dai R, Chen Y, He Z. A Three-Coil Inductively Power Transfer System with Constant Voltage Output. Energies. 2018; 11(3):673. https://doi.org/10.3390/en11030673

Chicago/Turabian StyleMai, Ruikun, Youyuan Zhang, Ruimin Dai, Yang Chen, and Zhengyou He. 2018. "A Three-Coil Inductively Power Transfer System with Constant Voltage Output" Energies 11, no. 3: 673. https://doi.org/10.3390/en11030673