Thermal Characteristics of an Oscillating Heat Pipe Cooling System for Electric Vehicle Li-Ion Batteries

Abstract

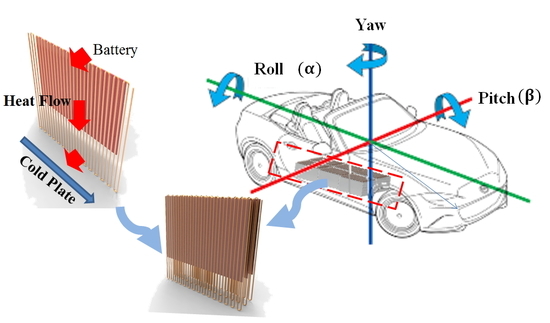

:1. Introduction

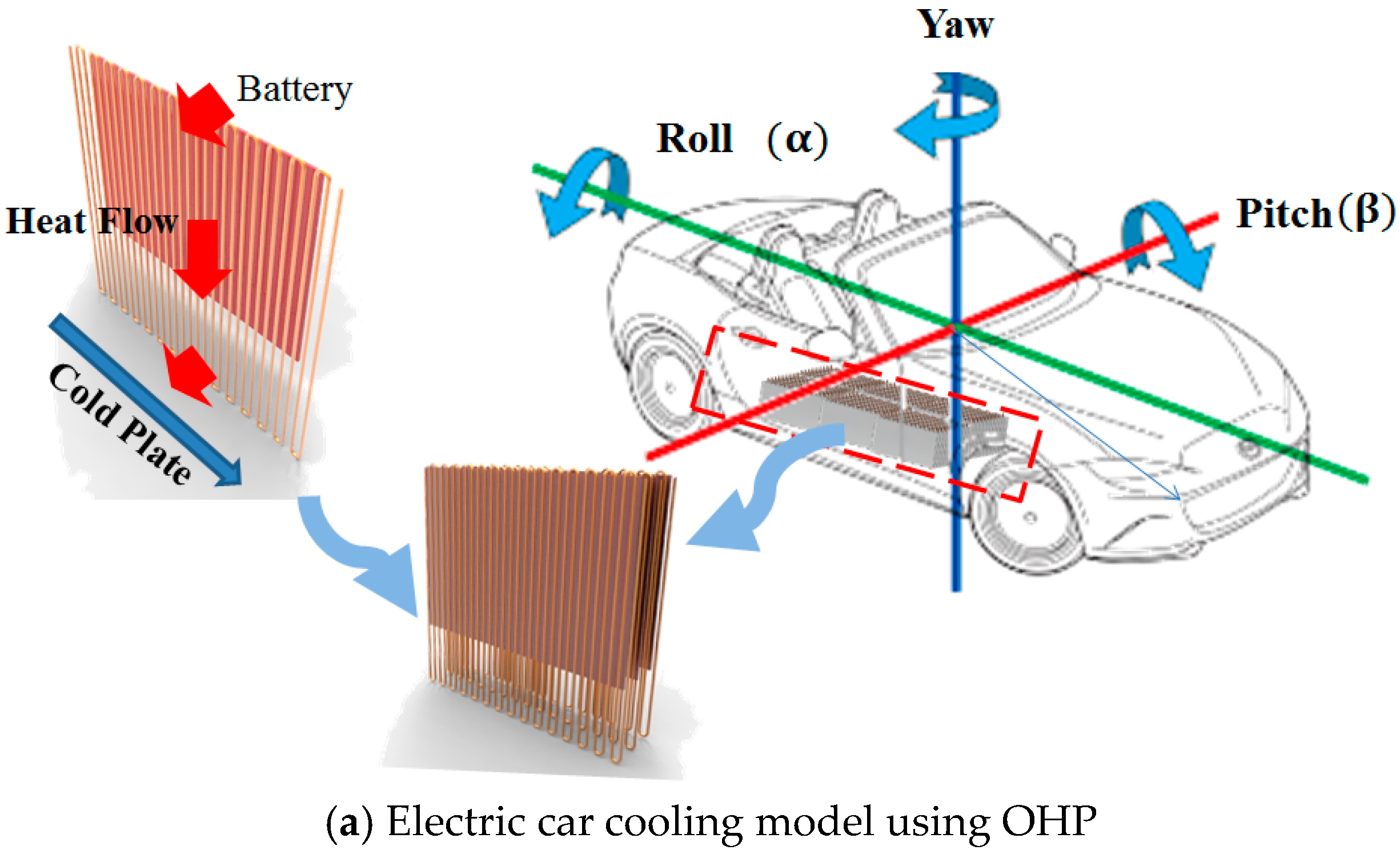

2. Experiments

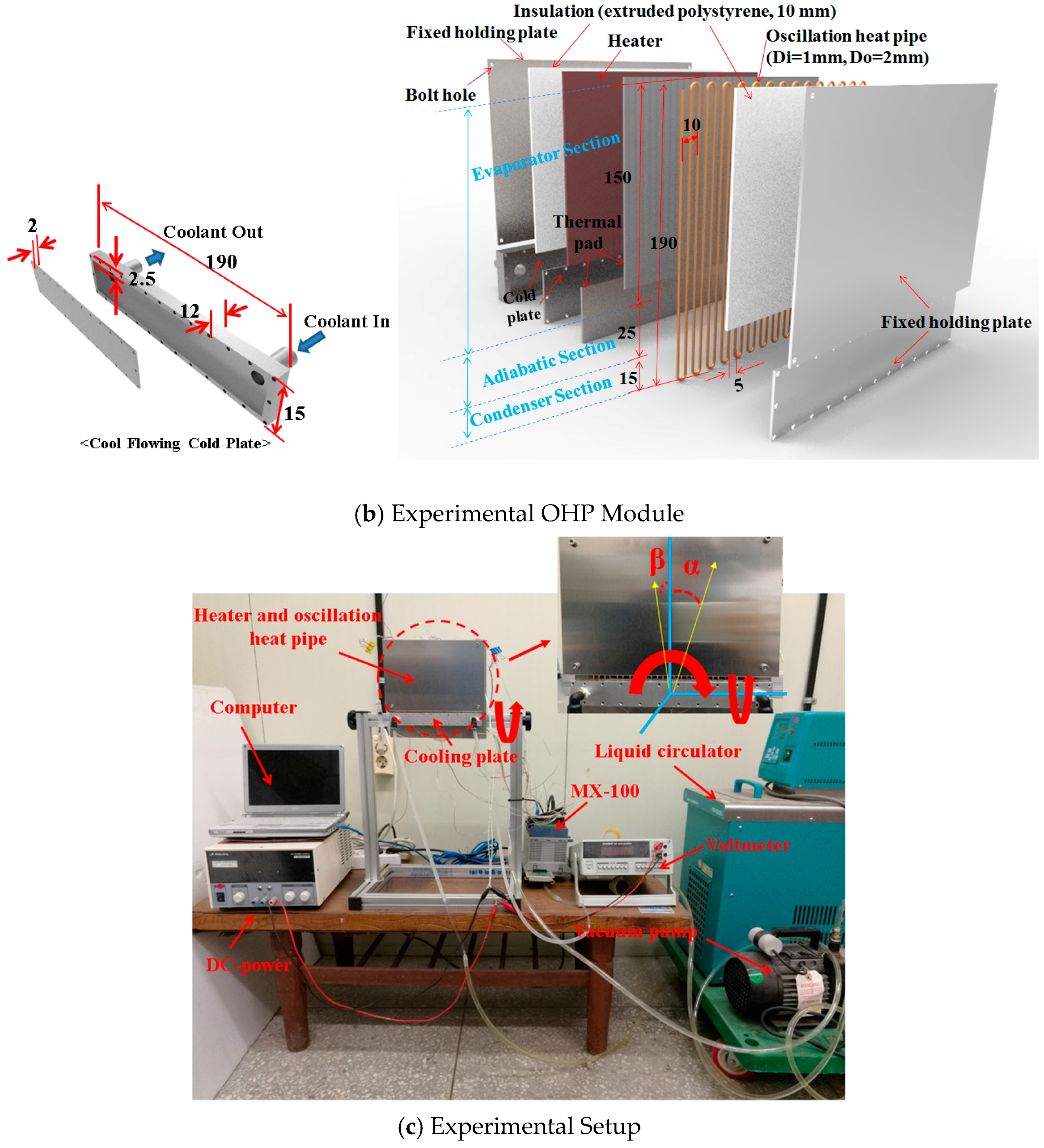

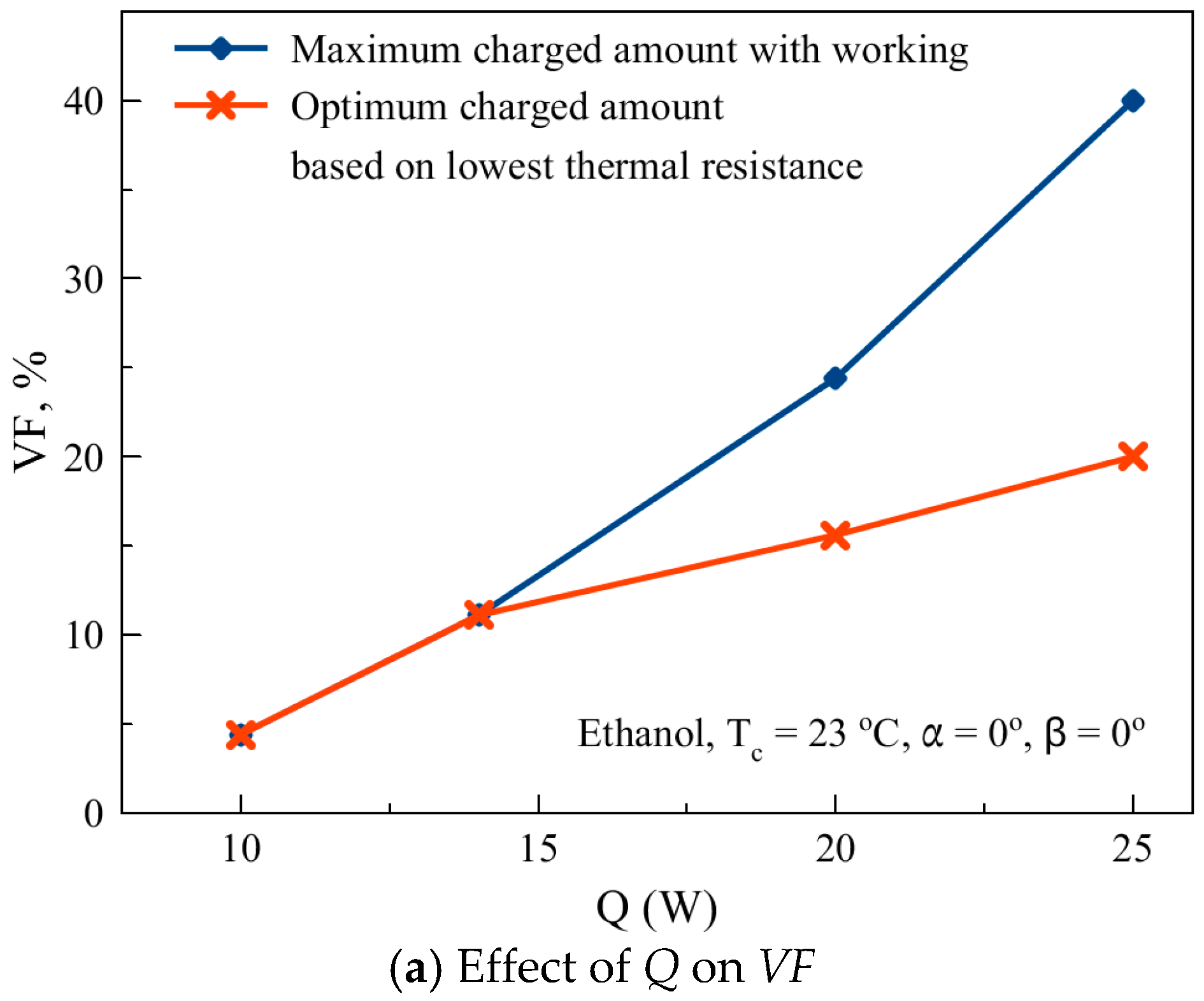

3. Results and Discussion

4. Conclusions

- -

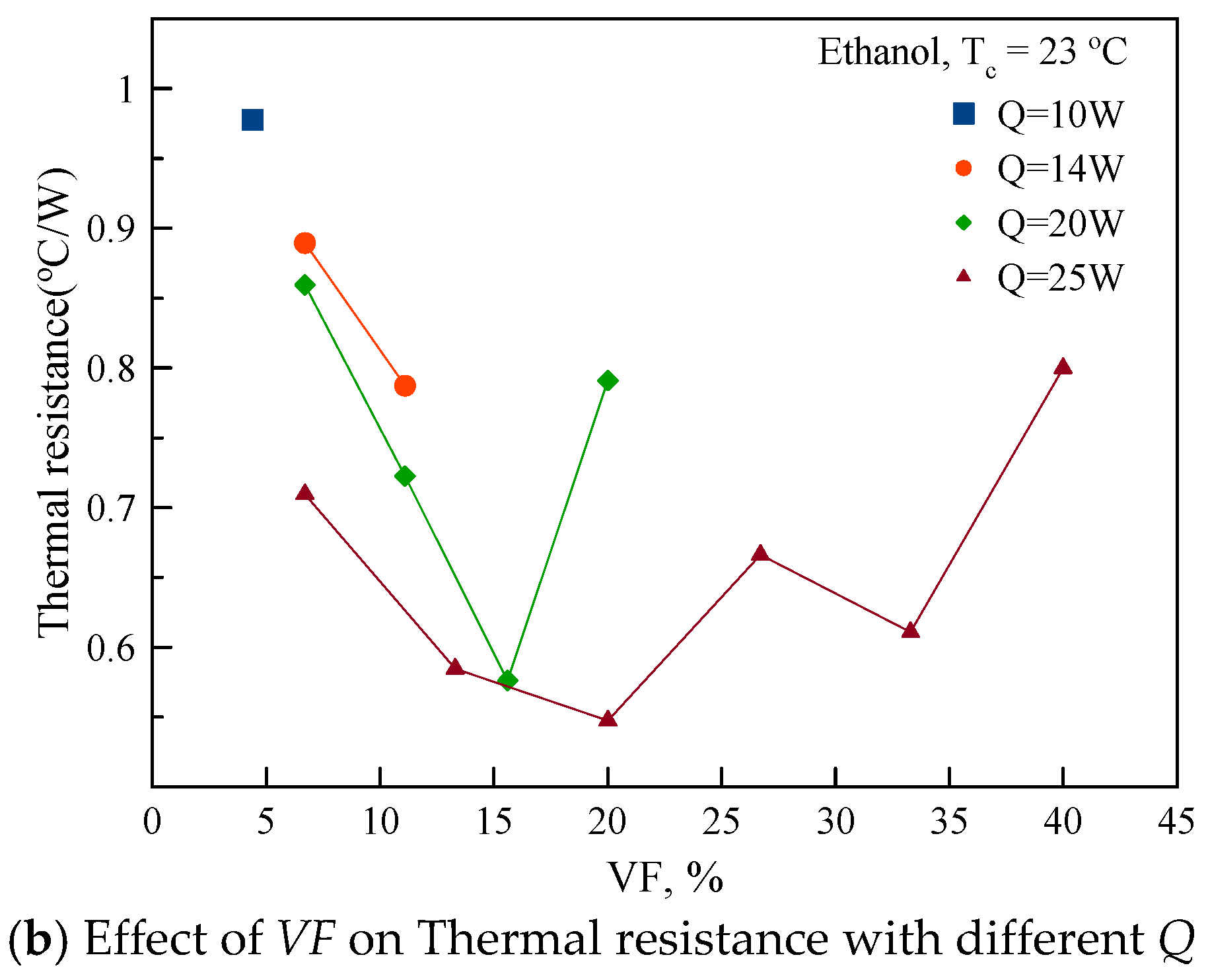

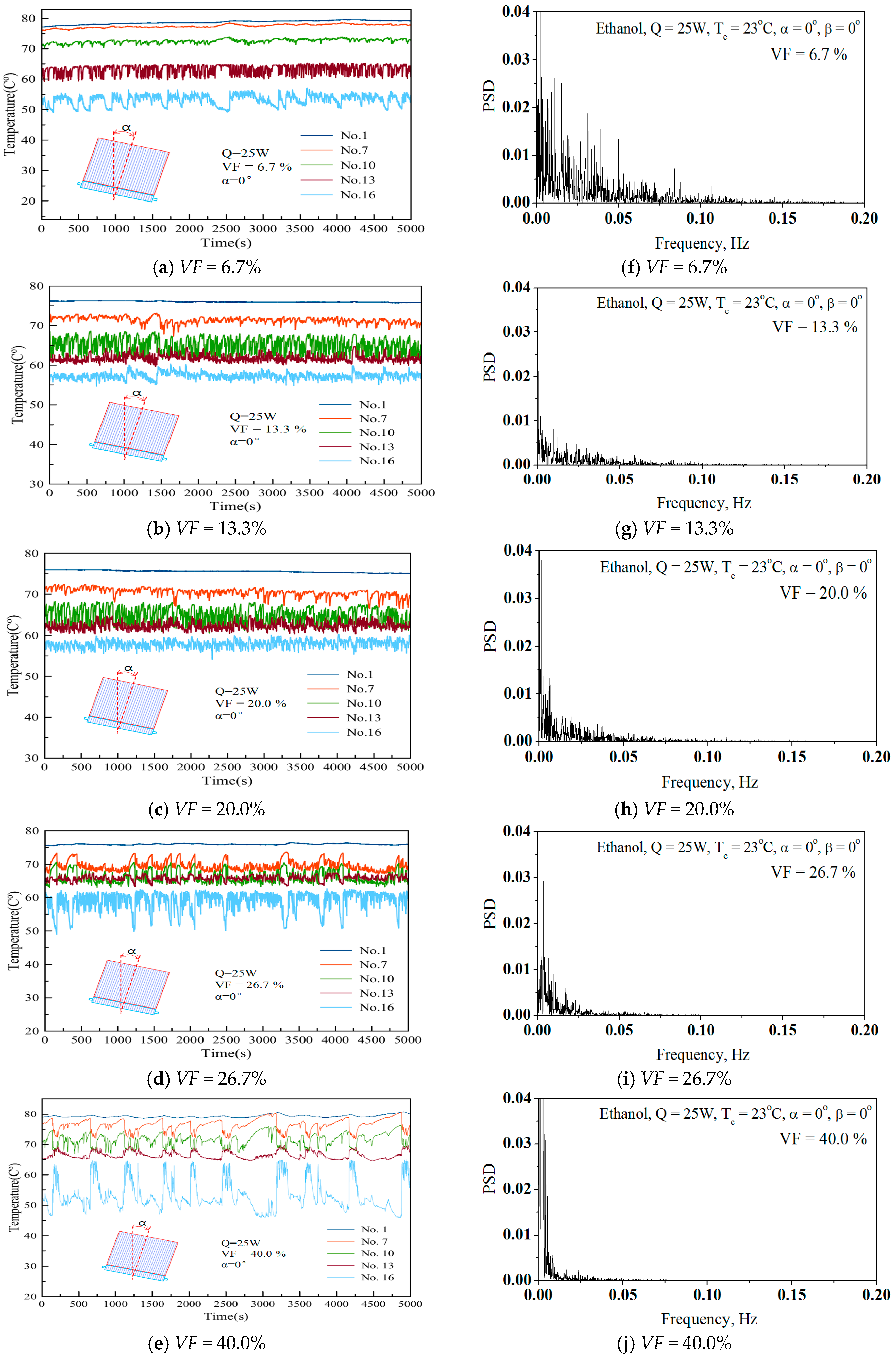

- The thermal performance was mainly dominantly dependent on the amount of working fluid charged. The system worked properly with a low charged VF of around 10% of the total volume.

- -

- Increasing the heat input, the working range of the charged amount varied in the 10–26% range.

- -

- The optimum charged amount with supplied heat input should be determined by the thermal resistance behavior.

- -

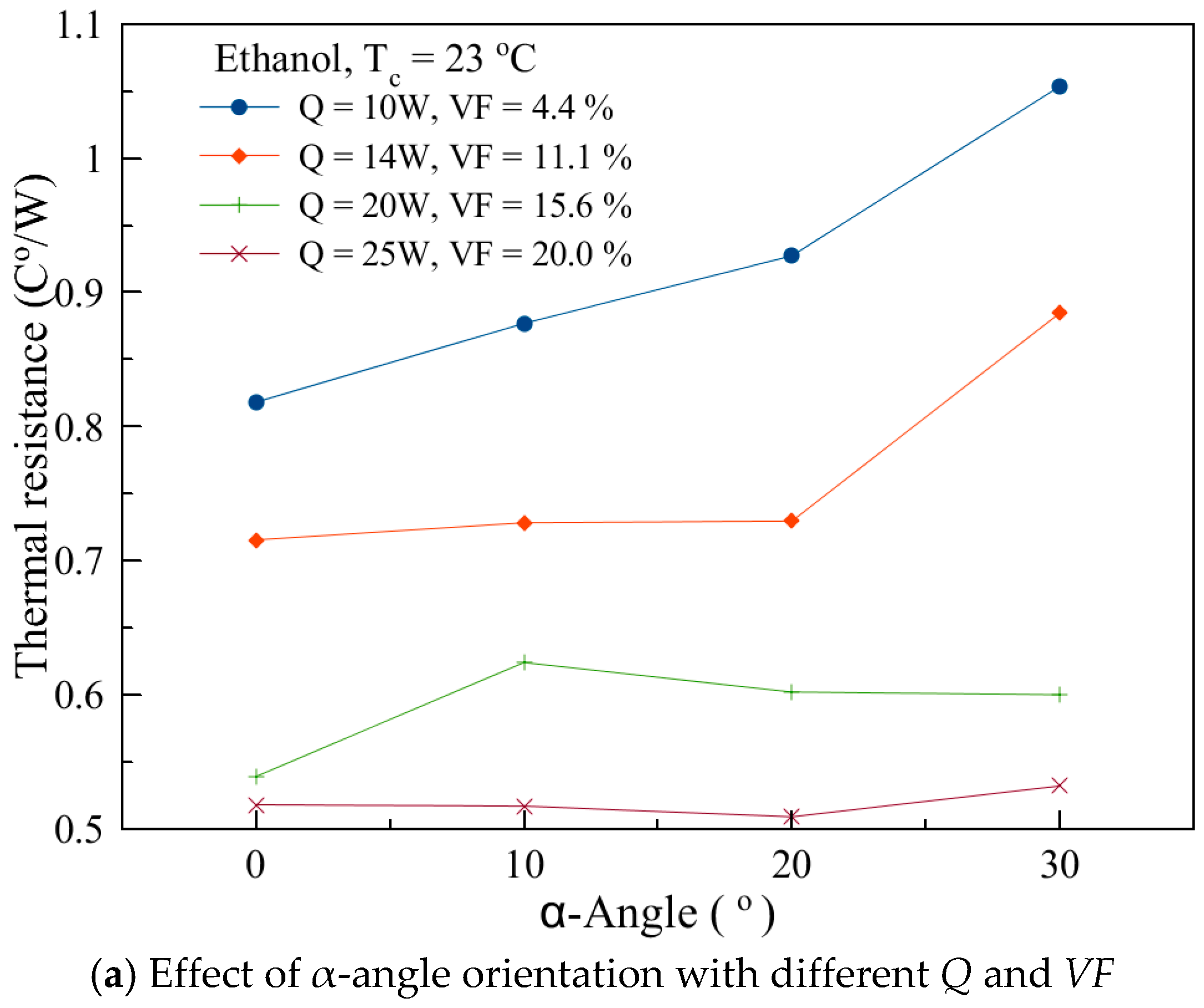

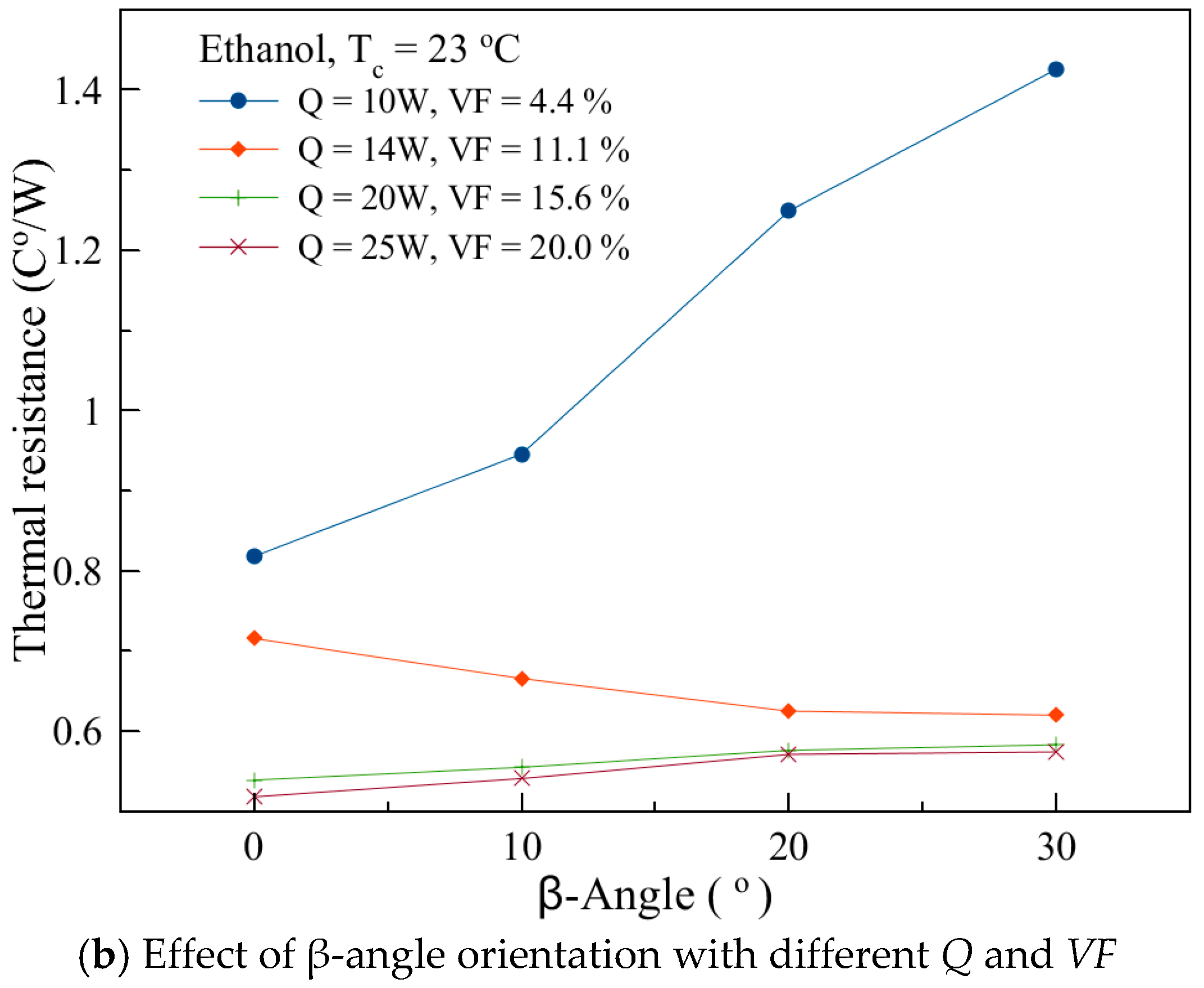

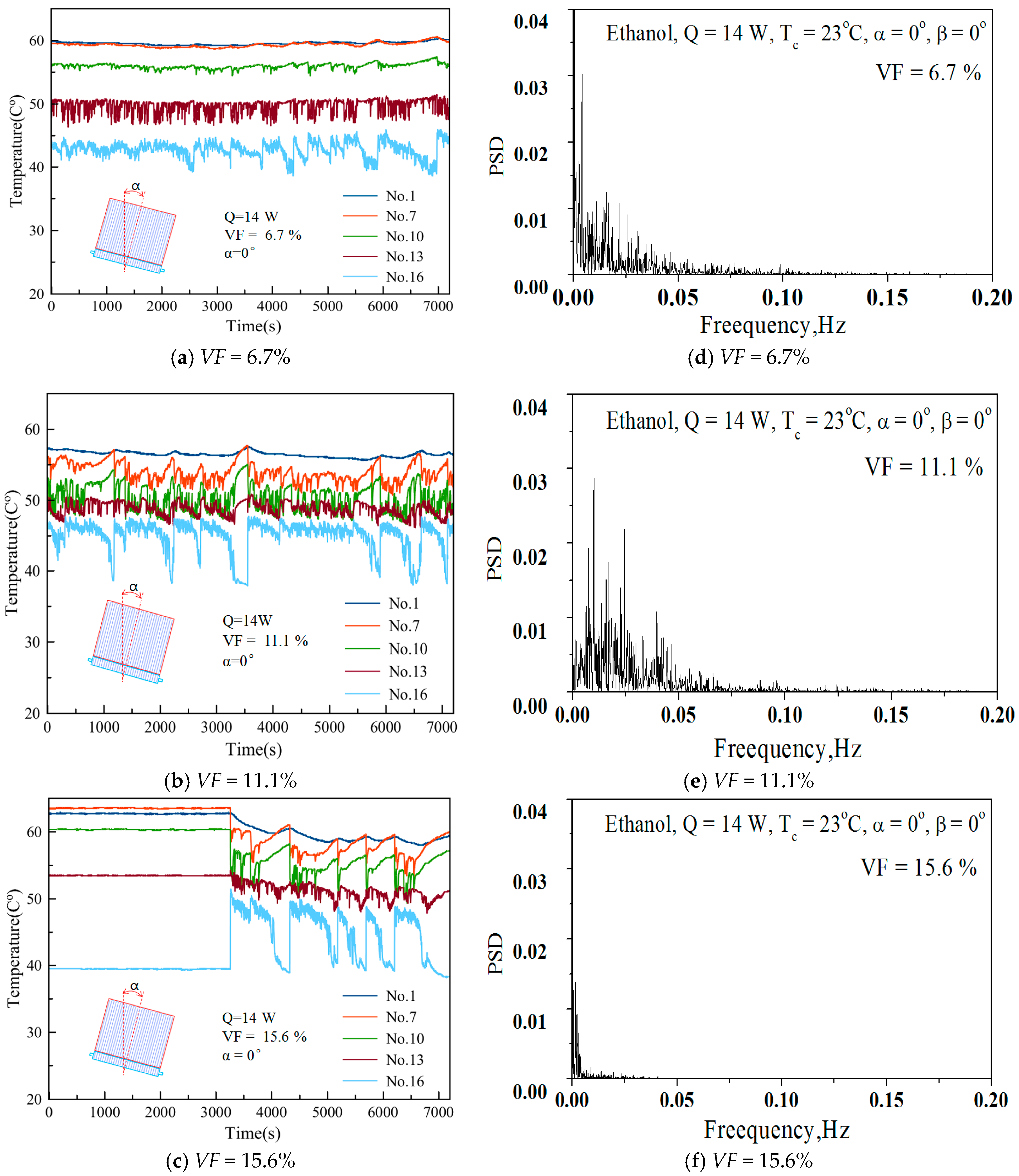

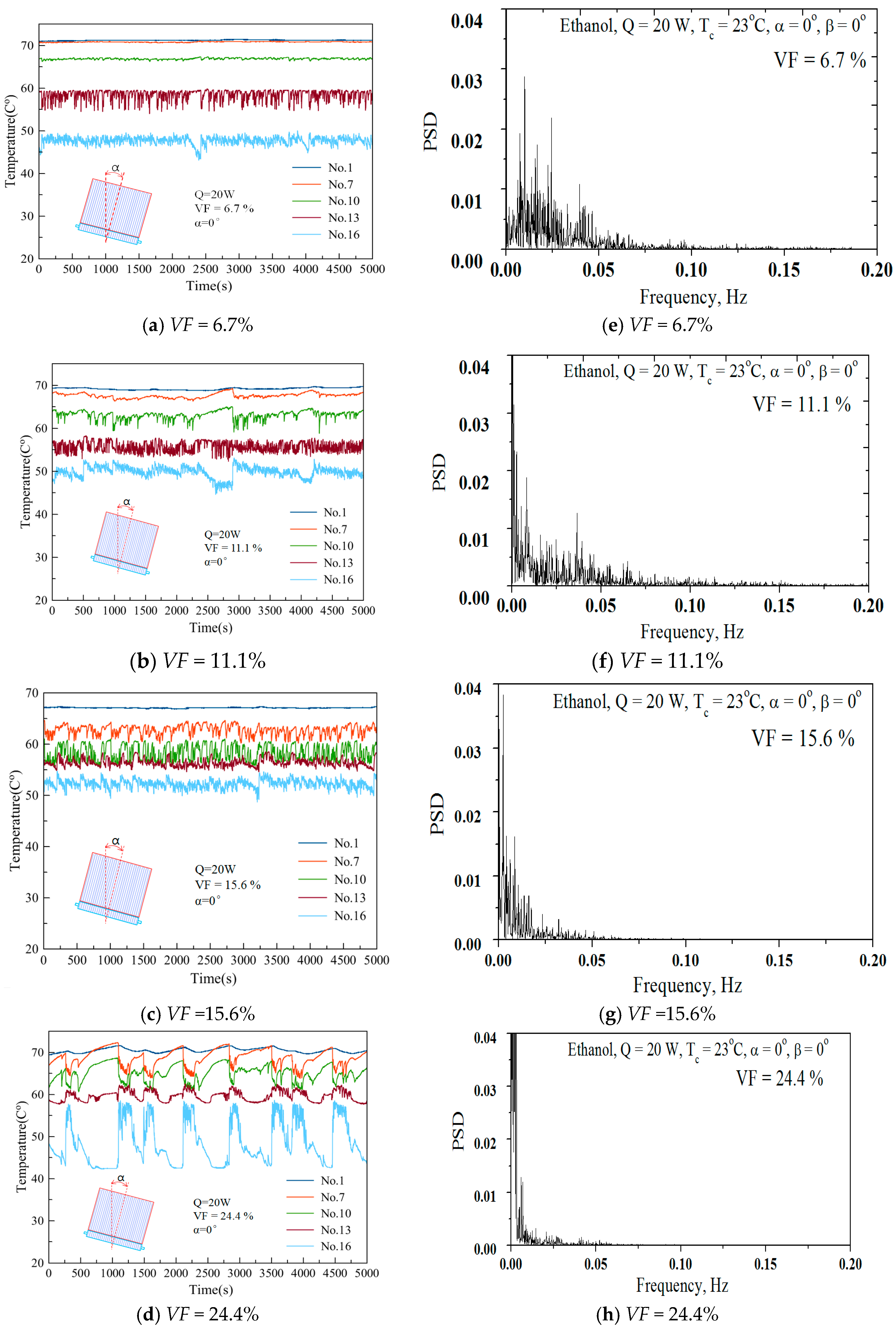

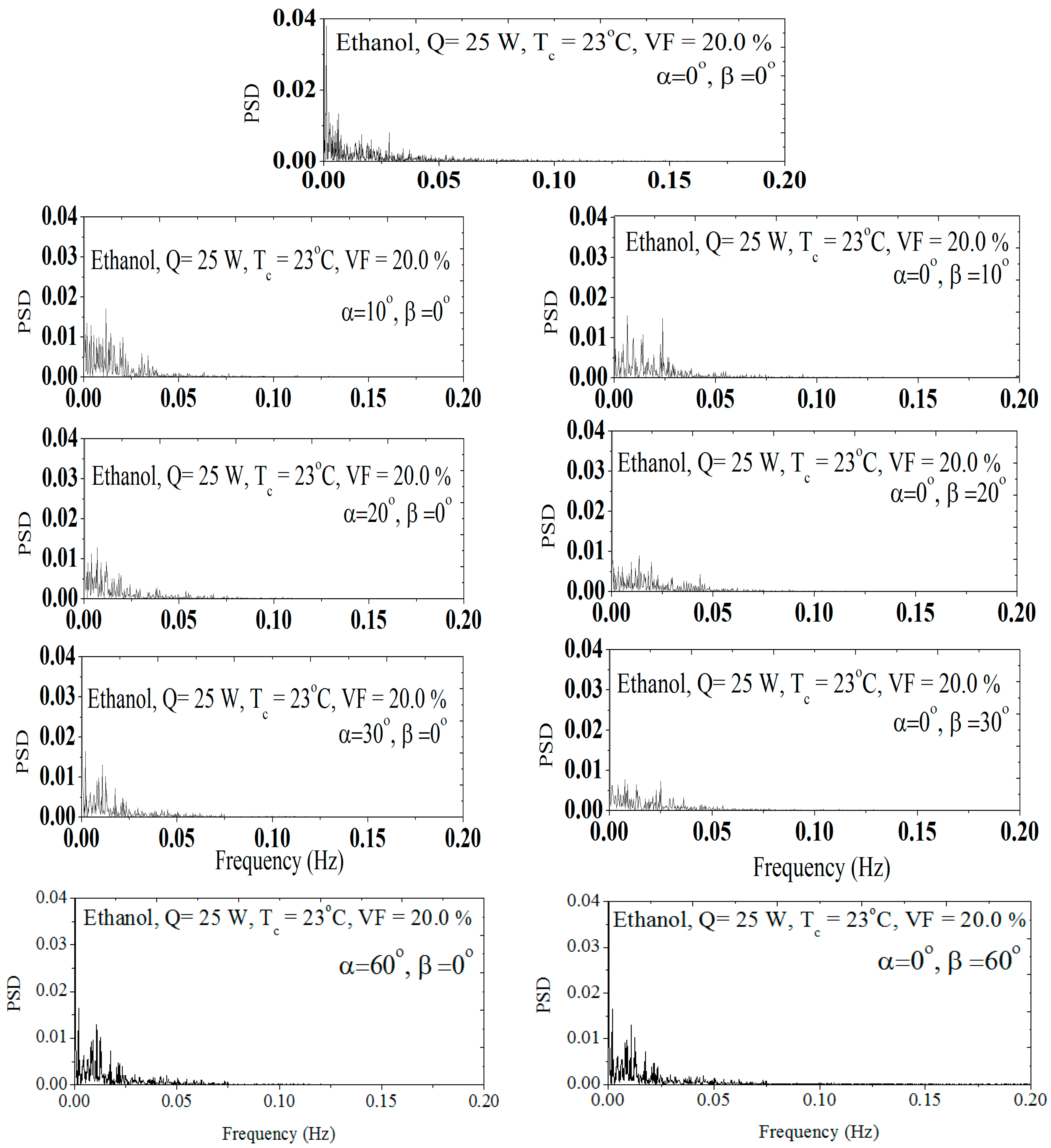

- The α and β-angle inclination of the OHP system minimally influenced the thermal resistance with a high heat input, but at a low heat, the thermal resistance sharply increased when the α and β-angles increased. However, the working behavior with FFT analysis was not significantly affected by the orientation.

- -

- The average heater surface temperature was maintained around 60 °C for heat fluxes under Q = 20 W.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Dcr | Critical diameter [m] |

| Di | Inner diameter [m] |

| Do | Outer diameter [m] |

| Gravitational acceleration [m/s2] | |

| I | Electric current [A] |

| P | Power Spectrum Density [Energy/frequency] |

| Evaporator section of average temperature [°C] | |

| Temperature of cooling water [°C] | |

| Condition section of average temperature [°C] | |

| R | Thermal resistance [W/°C] |

| Heating of heater [W] | |

| Voltage [W] | |

| Volume fraction, ((Volume of charged working fluid)/ (Total volume of OHP))100 | |

| Greek Letters | |

| α | Rolling angle [°] |

| β | Pitching Angle [°] |

| σ | Turface Tension [N/m] |

| Density of liquid [kg/m³] | |

| Density of gas [kg/m³] | |

| Temperature difference [°C] |

References

- Cui, S.M. New Energy Vehicle Technology; Peking University Press: Beijing, China, 2009. [Google Scholar]

- Li, Y. Thermoelectric Power Generation Study-Based Automobile Exhaust Waste Heat Recovery; University of Electronic Science and Technology of China: Chengdu, China, 2010. [Google Scholar]

- China New Energy Chamber of Commerce. Hanergy, Global New Energy Development Report 2015; China New Energy Chamber of Commerce: Beijing, China, 2015. [Google Scholar]

- Linden, R.T.B. Handbook of Batteries; McGraw-Hill: New York, NY, USA, 2002; Volume 36, p. 265. ISBN 13 978-0071624213. [Google Scholar]

- Li, H.; Su, J. Cycle-life prediction model studies of lithium-ion batteries. Chin. J. Power Sources 2008, 32, 242–246. [Google Scholar]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Experimental and theoretical investigations of heat generation rates for a water cooled LiFePO4 battery. Int. J. Heat Mass Transf. 2016, 101, 1093–1102. [Google Scholar] [CrossRef]

- Xu, X.; He, R. Review on the heat dissipation performance of battery pack with different structures and operation conditions. Renew. Sustain. Energy 2014, 29, 301–315. [Google Scholar] [CrossRef]

- Wang, T.; Tseng, K.; Zhao, J.; Wei, Z. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Mohammadian, S.K.; Zhang, Y. Thermal management optimization of an air cooled Li-ion battery module using pin-fin heat sinks for hybrid electric vehicles. J. Power Sources 2015, 273, 431–439. [Google Scholar] [CrossRef]

- Fan, L.; Khodadadi, J.; Pesaran, A. A parametric study on thermal management of an air-cooled lithium-ion battery module for plug-in hybrid electric vehicles. J. Power Sources 2013, 238, 301–312. [Google Scholar] [CrossRef]

- Giuliano, M.R.; Prasad, A.K.; Advani, S.G. Experimental study of an air-cooled thermal management system for high capacity lithium-titanate batteries. J. Power Sources 2012, 216, 345–352. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.H.; Huo, Y.; Liu, X.J.; Li, Y.M. Thermal management of cylindrical power battery module for extending the life of new energy electric vehicles. Appl. Therm. Eng. 2015, 85, 33–43. [Google Scholar] [CrossRef]

- Jin, L.; Lee, P.; Kong, X.; Fan, Y.; Chou, S. Ultra-thin minichannel LCP for EV battery thermal management. Appl. Energy Eng. 2014, 113, 1786–1794. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z.; Liu, X.; Zhao, J. Investigation of power battery thermal management by using mini-channel cold plate. Energy Convers. Manag. 2015, 89, 387–395. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Uneven temperature and voltage distributions due to rapid discharge rates and different boundary conditions for series-connected LiFePO4 batteries. Int. Commun. Heat Mass Transf. 2017, 81, 210–217. [Google Scholar] [CrossRef]

- Putra, N.; Ariantara, B.; Pamungkas, R.A. Experimental investigation on performance of lithium-ion battery thermal management system using flat plate loop heat pipe for electric vehicle application. Appl. Therm. Eng. 2016, 99, 784–789. [Google Scholar] [CrossRef]

- Greco, A.; Cao, D.; Jiang, X.; Yang, H. A theoretical and computational study of lithium-ion battery thermal management for electric vehicles using heat pipes. J. Power Sources 2014, 257, 344–355. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Xue, Q.F.; Sun, H.L.; Li, B. Experimental investigation on EV battery cooling and heating by heat pipes. Appl. Therm. Eng. 2015, 88, 54–60. [Google Scholar] [CrossRef]

- Zhao, J.; Lv, P.; Rao, Z. Experimental study on the thermal management performance of phase change material coupled with heat pipe for cylindrical power battery pack. Exp. Therm. Fluid Sci. 2017, 82, 182–188. [Google Scholar] [CrossRef]

- Ye, Y.; Saw, L.H.; Shi, Y.; Tay, A.A.O. Numerical analyses on optimizing a heat pipe thermal management system for lithium-ion batteries during fast charging. Appl. Therm. Eng. 2015, 86, 281–291. [Google Scholar] [CrossRef]

- Akachi, H. Structure of a Heat Pipe. U.S. Patent No. 4921041, 1 May 1990. [Google Scholar]

- Akachi, H. Pulsating Heat Pipes. In Proceedings of the 5th International Heat Pipe Symposium, Melbourne, Australia, 17–20 November 1996; pp. 208–217. [Google Scholar]

- Khandekar, S. An Insight into Thermos-Hydrodynamic Coupling in Closed Loop PHPs. Int. J. Therm. Sci. 2004, 43, 13–20. [Google Scholar] [CrossRef]

- Miyazaki, Y. Oscillatory Flow in the OHP. In Proceedings of the 11th IHPC, Tokyo, Japan, 12–16 September 1999; pp. 367–372. [Google Scholar]

- Shafii, M.B.; Faghri, A. Thermal Modeling of Unlooped and Looped PHPs. J. Heat Transf. 2001, 123, 1159–1172. [Google Scholar] [CrossRef]

- Nikolayev, V. A Dynamic Film Model of the Pulsating Heat pipe. J. Heat Transf. 2011, 113, 081504. [Google Scholar] [CrossRef]

- Nikolayev, V. Oscillatory Instability of the Gas-Liquid Meniscus in a Capillary under the Imposed Temperature Difference. Int. J. Heat Mass Transf. 2013, 64, 313–321. [Google Scholar] [CrossRef]

- Tong, B.Y.; Wong, T.N.; Ooi, K.T. Closed-loop pulsating heat pipe. Appl. Therm. Eng. 2001, 21, 1845–1862. [Google Scholar] [CrossRef]

- Qu, W.; Ma, T. Experimental investigation on flow and heat transfer of a pulsating heat pipe. In Proceedings of the 12th International Heat Pipe Conference, Grenoble, France, 8–23 August 2002; pp. 226–231. [Google Scholar]

- Katpradit, T.; Wongratanaphisan, T.; Terdtoon, P.; Ritthidech, S.; Chareonsawan, P.; Waowaew, S. Effect of aspect ratios and bond number on internal flow patterns of closed end oscillating heat pipe at critical state. In Proceedings of the 13th International Heat Pipe Conference (13th IHPC), Shanghai, China, 21–25 September 2004; pp. 298–303. [Google Scholar]

- Xu, J.L.; Li, Y.X.; Wong, T.N. High speed flow visualization of a closed loop pulsating heat pipe. Int. J. Heat Mass Transf. 2005, 48, 3338–3351. [Google Scholar] [CrossRef]

- Das, S.P.; Nikolayev, V.S.; Lefevre, F.; Pottier, B.; Khandekar, S.; Bonjour, J. Thermally induced two-phase oscillating flow inside a capillary tube. Int. J. Heat Mass Transf. 2010, 53, 3905–3913. [Google Scholar] [CrossRef]

- Soponpongpipat, N.; Sakulchangsatjatai, P.; Saiseub, M.; Terdtoon, P. Time response model of operational mode of closed-loop oscillating heat pipe at normal operating condition. In Proceedings of the 8th International Heat Pipe Symposium, Kumamoto, Japan, 24–27 September 2006; pp. 291–296. [Google Scholar]

- Ma, H.B.; Wilson, C.; Borgmeyer, B.; Park, K.; Yu, Q.; Choi, S.U.S.; Tirumala, M. Effect of nanofluid on the heat transport capability in an oscillating heat pipe. Appl. Phys. Lett. 2006, 88, 143116. [Google Scholar] [CrossRef]

- Ma, H.B.; Wilson, C.; Yu, Q.; Park, K.; Choi, S.U.S.; Tirumala, M. An experimental investigation of heat transport capability in a nanofluid oscillating heat pipe. J. Heat Transf. 2006, 128, 1213–1216. [Google Scholar] [CrossRef]

- Qu, J.; Wu, H.; Cheng, P. Thermal performance of an oscillating heat pipe with Al2O3-water nanofluids. Int. Commun. Heat Mass Transf. 2010, 37, 111–115. [Google Scholar] [CrossRef]

- Qu, J.; Wu, H. Thermal performance comparison of oscillating heat pipes with SiO2/water and Al2O3/water nanofluids. Int. J. Therm. Sci. 2011, 50, 1954–1962. [Google Scholar] [CrossRef]

- Ji, Y.; Wilson, C.; Chen, H.H.; Ma, H.B. Particle shape effect on heat transfer performance in an oscillating heat pipe. Nanoscale Res. Lett. 2011, 6, 296. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.S. Effect of Heat Flux and Filling Ratio on the Thermal Performance of a Pulsating Heat Pipe; Korea Advanced Institute of Science and Technology: Daejeon, Korea, 2012. [Google Scholar]

- Lin, Z.; Wang, S.; Chen, J.; Huo, J.; Hu, Y.; Zhang, W. Experimental study on effective range of miniature oscillating heat pipes. Appl. Therm. Eng. 2011, 31, 880–886. [Google Scholar] [CrossRef]

- Charoensawan, P.; Terdtoon, P. Thermal performance of horizontal closed-loop oscillating heat pipes. Appl. Therm. Eng. 2008, 28, 460–466. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, S.; Ryo, S.; Zhang, L.W. Simulation of a miniature oscillating heat pipe in bottom heating mode using CFD modeling. Int. J. Heat Mass Transf. 2013, 57, 642–656. [Google Scholar] [CrossRef]

- Yang, H.M.; Zhang, C.; Manfred, G. Comparison between Two kinds of Pulsating Heat Pipes (Circle Tube Type and Flat Plate Type with square Channels). Fluid Mach. 2009, 37, 70–72. [Google Scholar]

- Wang, S.F. Effect of Length Ratio of Heating Section to Cooling Section on Properties of Oscillating Heat Pipe. J. South China Univ. Technol. (Nat. Sci. Ed.) 2007, 35, 59–62. [Google Scholar]

- Cao, X.L.; Wang, W.; Chen, J.; Li, X.L.; Yu, S.X. Experimental Investigation on the Start-Up Characteristic of a Pulsating Heat Pipe. Fluid Mach. 2009, 37, 57–60. [Google Scholar]

- Charoensawan, P.; Khandekar, S.; Groll, M. Closed loop pulsating heat pipes: Part A: Parametric experimental investigations. Appl. Therm. Eng. 2003, 23, 2009–2020. [Google Scholar] [CrossRef]

- Han, S.H.; Choi, J.W.; Kim, S.C. Computational analysis of thermal flow with varying the diameter and the number of tubes in pulsating heat pipes. J. Comput. Fluids Eng. 2016, 21, 86–93. [Google Scholar] [CrossRef]

- Wang, Q.C.; Rao, Z.H.; Huo, Y.T.; Wang, S.F. Thermal performance of phase change material/oscillating heat pipe-based battery thermal management system. Int. J. Therm. Sci. 2016, 102, 9–16. [Google Scholar] [CrossRef]

- Khandekar, S.; Groll, M. On the definition of pulsating heat pipes: An overview. In Proceedings of the 5th Minsk International Seminar (Heat Pipes, Heat Pumps and Refrigerators), Minsk, Belarus, 8–11 September 2003. [Google Scholar]

- Rittidech, S.; Terdtoon, P.; Tankakom, P. Evaporation and Working Fluid Properties on Heat Transfer Characteristic of a Closed- end Oscillating Heat Pipe. In Proceedings of the 6th International Heat Pipe Symposium, Chiang Mai, Thailand, 5–9 November 2000. [Google Scholar]

- OriginLab Corp. Help Manual. Available online: https://www.originlab.com/doc/Origin-Help/FFT1-Algorithm (accessed on 13 March 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chi, R.-G.; Chung, W.-S.; Rhi, S.-H. Thermal Characteristics of an Oscillating Heat Pipe Cooling System for Electric Vehicle Li-Ion Batteries. Energies 2018, 11, 655. https://doi.org/10.3390/en11030655

Chi R-G, Chung W-S, Rhi S-H. Thermal Characteristics of an Oscillating Heat Pipe Cooling System for Electric Vehicle Li-Ion Batteries. Energies. 2018; 11(3):655. https://doi.org/10.3390/en11030655

Chicago/Turabian StyleChi, Ri-Guang, Won-Sik Chung, and Seok-Ho Rhi. 2018. "Thermal Characteristics of an Oscillating Heat Pipe Cooling System for Electric Vehicle Li-Ion Batteries" Energies 11, no. 3: 655. https://doi.org/10.3390/en11030655