An Experimental Investigation of Hydraulic Fracturing in Shale Considering Anisotropy and Using Freshwater and Supercritical CO2

Abstract

:1. Introduction

2. Experimental Methodology

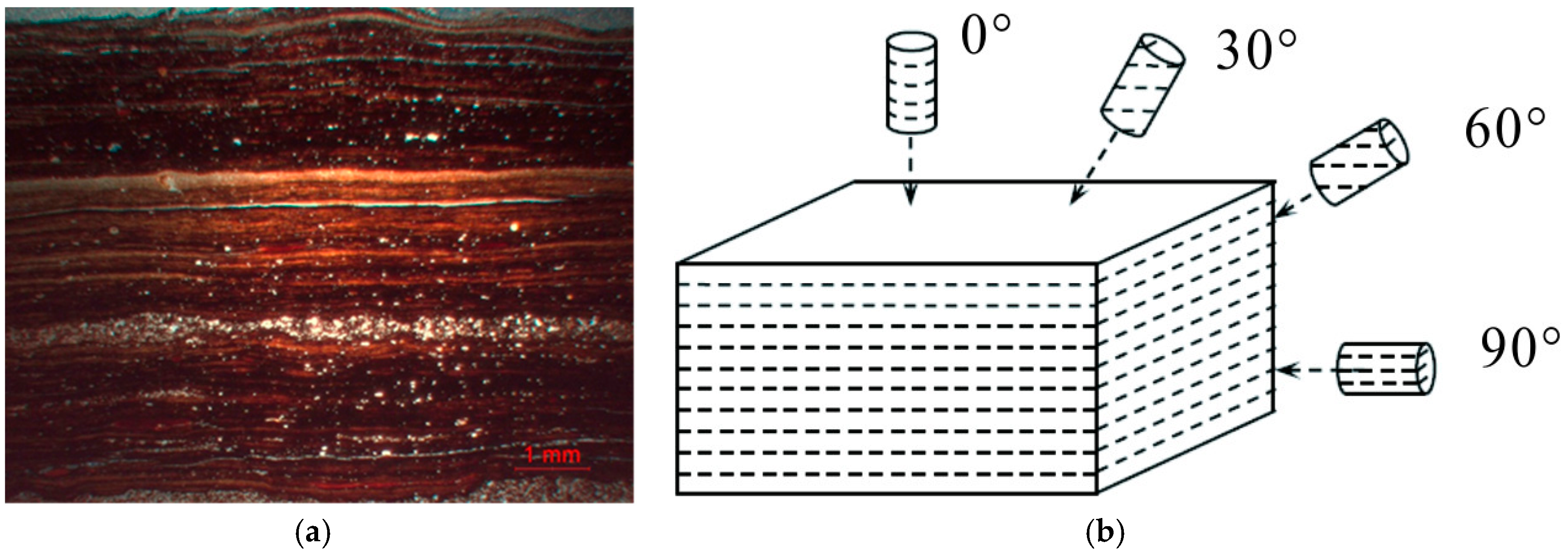

2.1. Sample Preparation

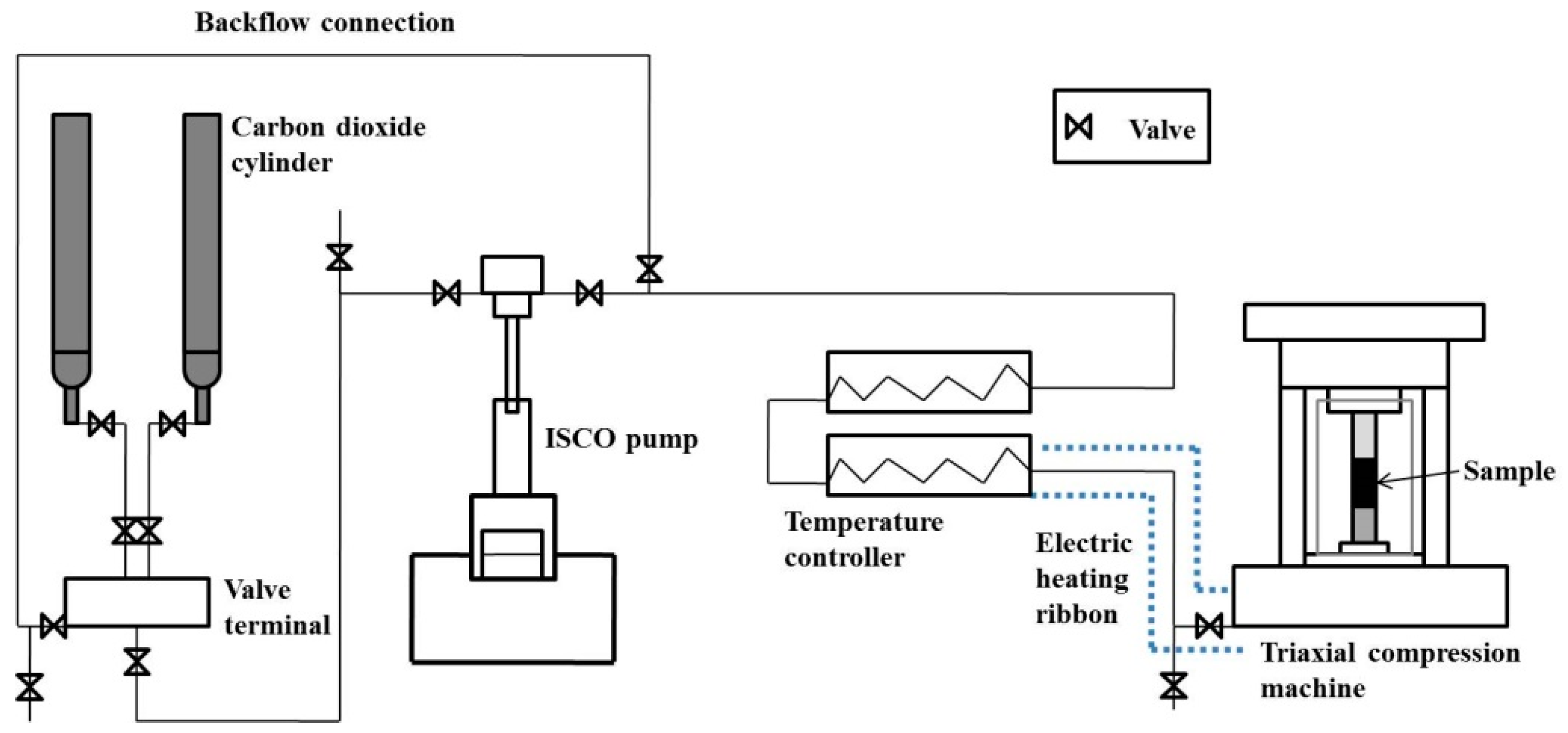

2.2. Experimental Procedures

3. Results and Discussion

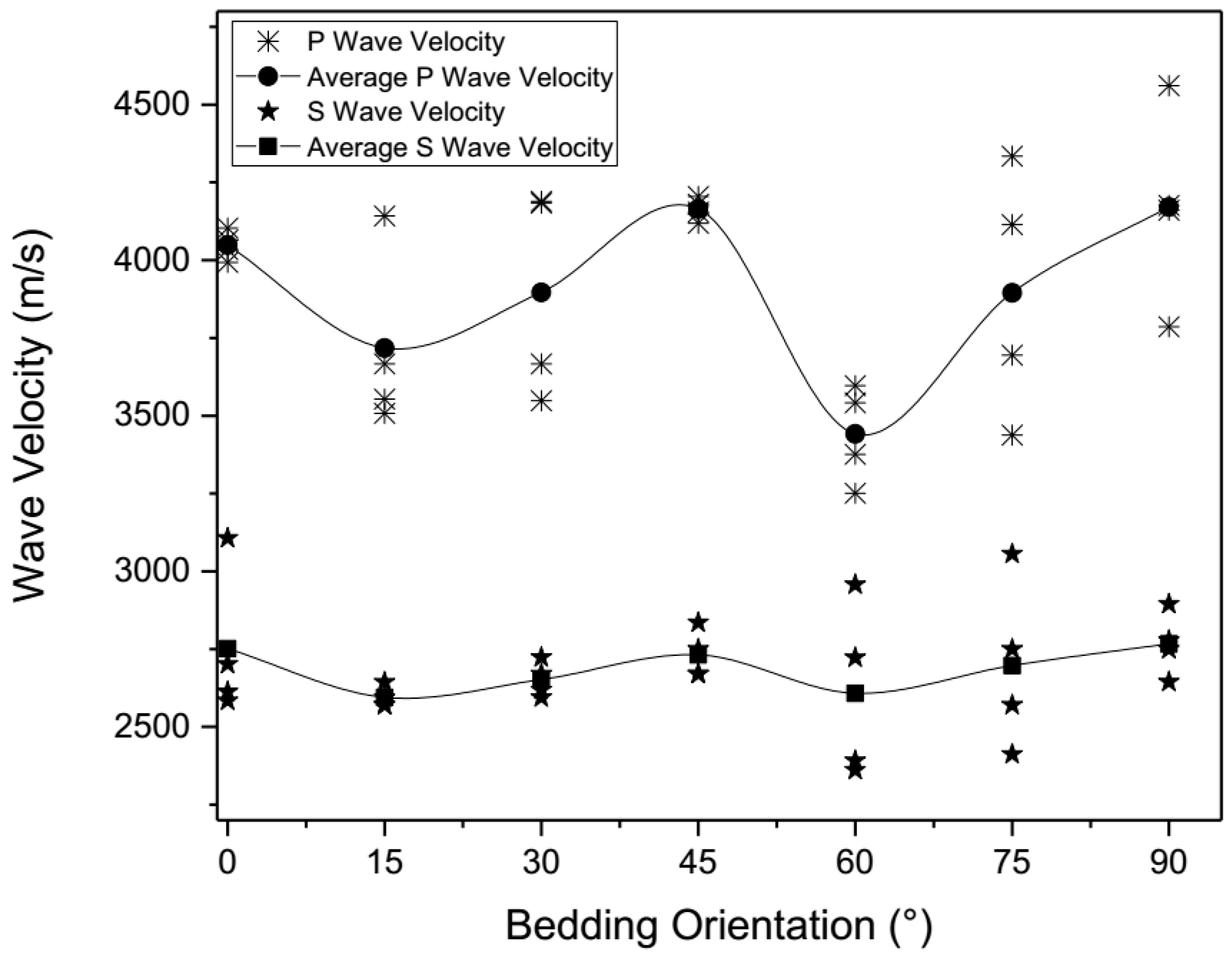

3.1. Anisotropic Characteristics of the Shale

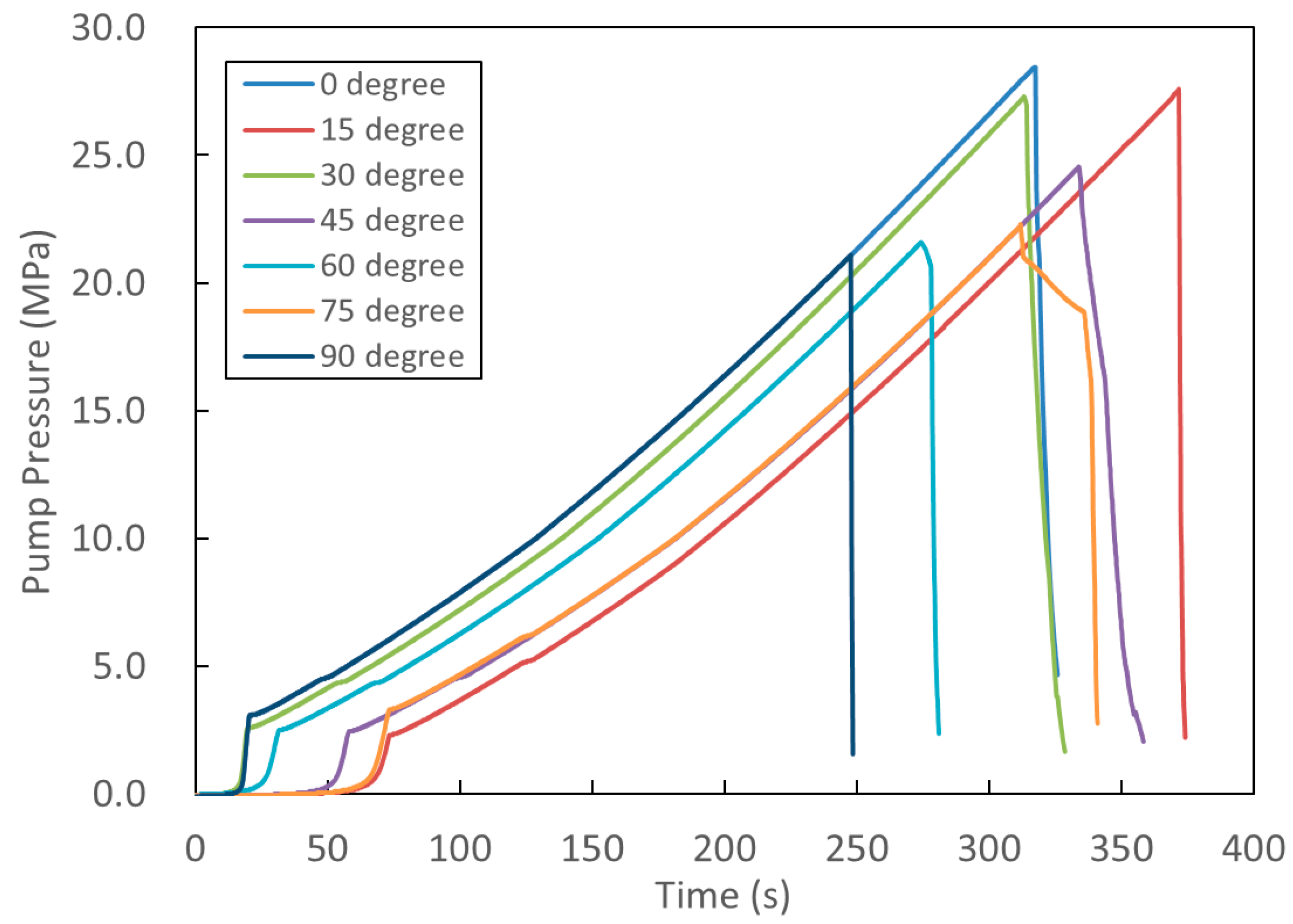

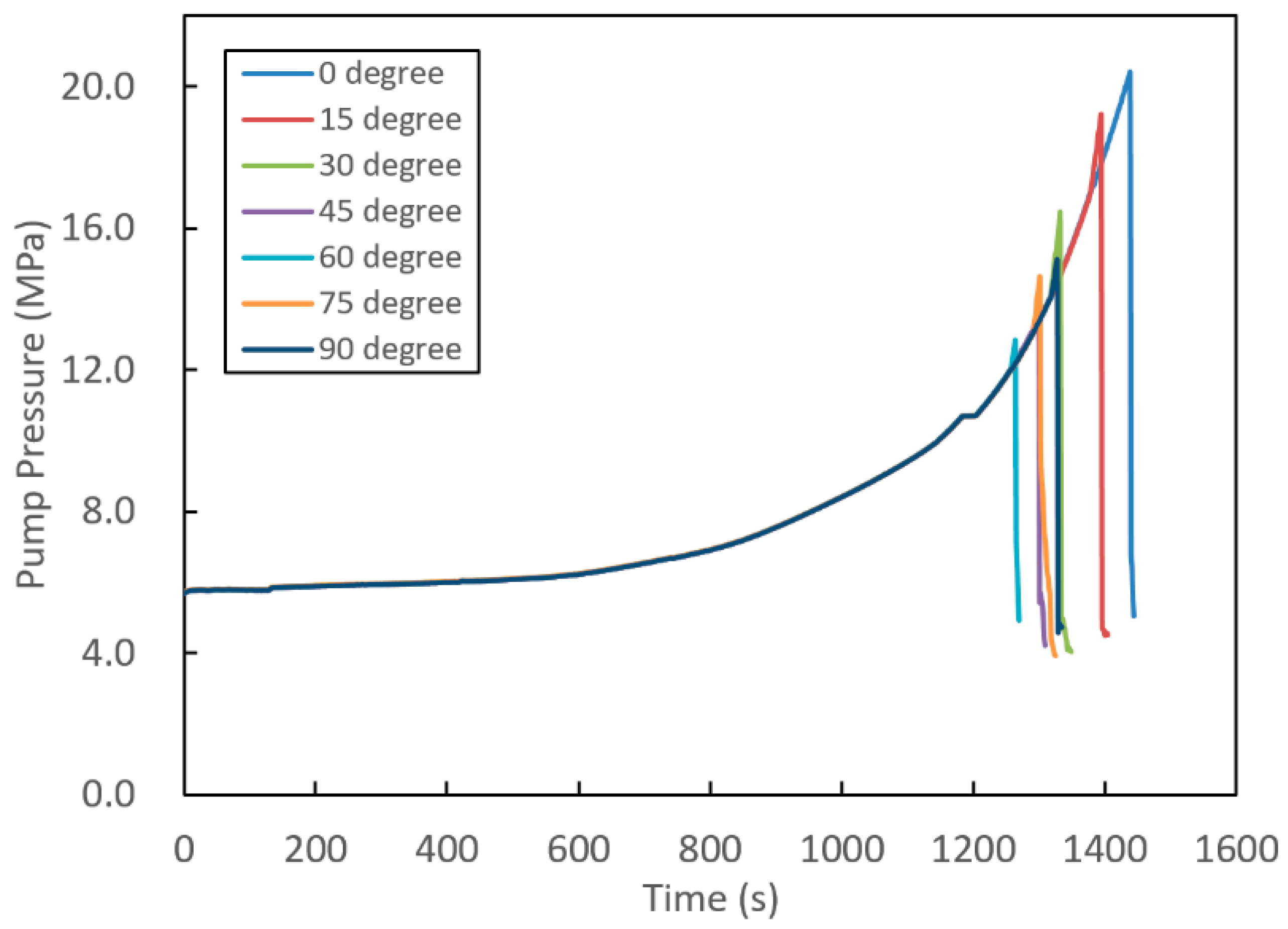

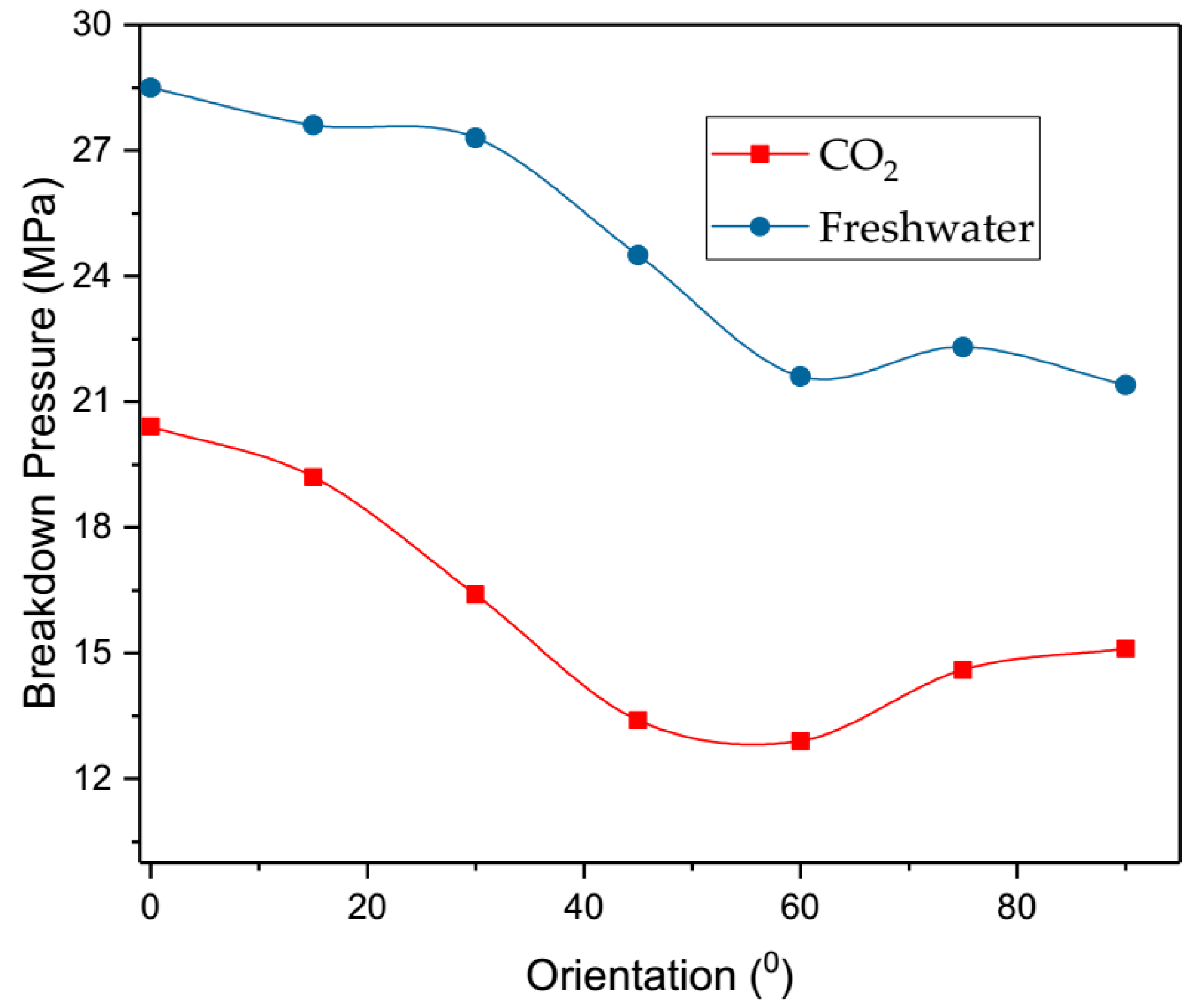

3.2. Experimental Monitoring of Hydraulic Fracturing

3.3. Fracture Propagation of Hydraulic Fracturing

- Curved fractures: these cracks are slightly curved and deviated from the loading direction.

- Layer-activated fractures: these are straight or slightly straight fractures that propagated along the bedding plane and the rock matrix.

- Central-linear fractures: fractures that propagated along the loading direction.

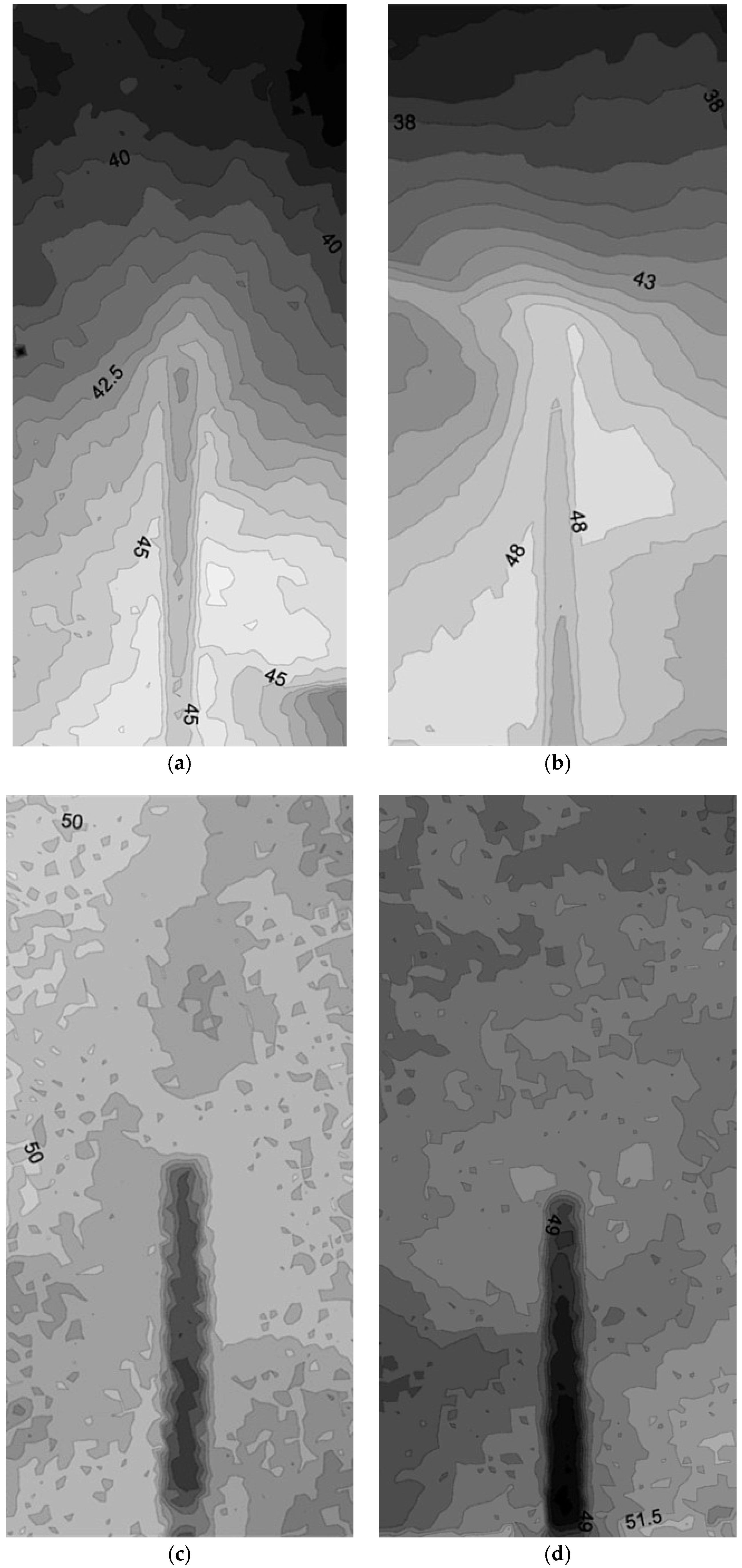

3.4. Assessment of the the Fracture Surface

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chen, L.; Kang, Q.; Dai, Z.; Viswanathan, H.S.; Tao, W. Permeability prediction of shale matrix reconstructed using the elementary building block model. Fuel 2015, 160, 346–356. [Google Scholar] [CrossRef]

- Singh, H.; Javadpour, F. Langmuir slip-Langmuir sorption permeability model of shale. Fuel 2016, 164, 28–37. [Google Scholar] [CrossRef]

- Warpinski, N.R.; Teufel, L.W. Influence of geologic discontinuities on hydraulic fracture propagation (includes associated papers 17011 and 17074). J. Pet. Technol. 1987, 39, 209–220. [Google Scholar] [CrossRef]

- Scanlon, B.R.; Reedy, R.C.; Nicot, J.-P. Comparison of water use for hydraulic fracturing for unconventional oil and gas versus conventional oil. Environ. Sci. Technol. 2014, 48, 12386–12393. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, G.; Shen, Z. A Feasibility analysis on shale gas exploitation with supercritical carbon dioxide. Energy Sources Part A Recover. Util. Environ. Eff. 2012, 34, 1426–1435. [Google Scholar] [CrossRef]

- Jackson, R.E.; Gorody, A.W.; Mayer, B.; Roy, J.W.; Ryan, M.C.; Van Stempvoort, D.R. Groundwater protection and unconventional gas extraction: The critical need for field-based hydrogeological research. Groundwater 2013, 51, 488–510. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Lau, H.C.; Huang, S. Coalbed Methane Development in China: Engineering Challenges and Opportunities. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition (APOGCE), Jakarta, Indonesia, 17–19 October 2017. [Google Scholar]

- Middleton, R.; Viswanathan, H.; Currier, R.; Gupta, R. CO2 as a fracturing fluid: Potential for commercial-scale shale gas production and CO2 sequestration. Energy Procedia 2014, 63, 7780–7784. [Google Scholar] [CrossRef]

- Li, X.; Feng, Z.; Han, G.; Elsworth, D.; Marone, C.; Saffer, D. Hydraulic Fracturing in Shale with H2O, CO2 and N2. In Proceedings of the 49th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 28 June–1 July 2015. ARMA 15-786. [Google Scholar]

- Ishida, T.; Aoyagi, K.; Niwa, T.; Chen, Y.; Murata, S.; Chen, Q.; Nakayama, Y. Acoustic emission monitoring of hydraulic fracturing laboratory experiment with supercritical and liquid CO2. Geophys. Res. Lett. 2012, 39, L16309. [Google Scholar] [CrossRef]

- Ishida, T.; Nagaya, Y.; Inui, S.; Aoyagi, K.; Nara, Y.; Chen, Y.; Chen, Q.; Nakayama, Y. AE Monitoring of Hydraulic Fracturing Experiments Conducted Using CO2 and water. In Rock Mechanics for Resources, Energy and Environment; CRC Press: Boca Raton, FL, USA, 2013; pp. 957–962. ISBN 978-1-138-00080-3. [Google Scholar]

- Kizaki, A.; Tanaka, H.; Ohashi, K.; Sakaguchi, K.; Matsuki, K. Hydraulic Fracturing in Inada Granite and Ogino Tuff with Super Critical Carbon Dioxide. In Proceedings of the ISRM Regional Symposium-7th Asian Rock Mechanics Symposium (ARMS7), Seoul, Korea, 15–19 October 2012. [Google Scholar]

- Inui, S.; Ishida, T.; Nagaya, Y.; Nara, Y.; Chen, Y.; Chen, Q. AE monitoring of Hydraulic Fracturing Experiments in Granite Blocks Using Supercritical CO2, Water and Viscous Oil. In Proceedings of the 48th U.S. Rocks Mechanics/Geomechanics Symposium, Minneapolis, MN, USA, 1–4 June 2014. [Google Scholar]

- Chen, Y.; Nagaya, Y.; Ishida, T. Observations of Fractures Induced by Hydraulic Fracturing in Anisotropic Granite. Rock Mech. Rock Eng. 2015, 48, 1455–1461. [Google Scholar] [CrossRef]

- Skurtveit, E.; Aker, E.; Soldal, M.; Angeli, M.; Wang, Z. Experimental investigation of CO2 breakthrough and flow mechanisms in shale. Pet. Geosci. 2012, 18, 3–15. [Google Scholar] [CrossRef]

- Lamont, N.; Jessen, F.W. The effects of existing fractures in rocks on the extension of hydraulic fractures. J. Pet. Technol. 1963, 15, 203–209. [Google Scholar] [CrossRef]

- Blanton, T.L. An Experimental Study of Interaction between Hydraulically Induced and Pre-Existing Fractures. In Proceedings of the SPE Unconventional Gas Recovery Symposium, Pittsburgh, PA, USA, 6–18 May 1982; pp. 559–571. [Google Scholar]

- Gale, J.F.W.; Reed, R.M.; Holder, J. Natural fractures in the Barnett Shale and their importance for hydraulic fracture treatments. AAPG Bull. 2007, 91, 603–622. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, M.; Jin, Y.; Zhang, G. Analysis of fracture propagation behavior and fracture geometry using a tri-axial fracturing system in naturally fractured reservoirs. Int. J. Rock Mech. Min. Sci. 2008, 45, 1143–1152. [Google Scholar] [CrossRef]

- Dehghan, A.N.; Goshtasbi, K.; Ahangari, K.; Jin, Y. Experimental investigation of hydraulic fracture propagation in fractured blocks. Bull. Eng. Geol. Environ. 2015, 74, 887–895. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, M.; Zhang, G. Analysis of the influence of a natural fracture network on hydraulic fracture propagation in carbonate formations. Rock Mech. Rock Eng. 2014, 47, 575–587. [Google Scholar] [CrossRef]

- Chuprakov, D.; Melchaeva, O.; Prioul, R. Injection-sensitive mechanics of hydraulic fracture interaction with discontinuities. Rock Mech. Rock Eng. 2014, 47, 1625–1640. [Google Scholar] [CrossRef]

- Gupta, A.P.; Gupta, A.; Langlinais, J. Feasibility of Supercritical Carbon Dioxide as a Drilling Fluid for Deep Underbalanced Drilling Operation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 22–25 October 1995. [Google Scholar]

- Olson, J.E.; Bahorich, B.; Holder, J. Examining Hydraulic Fracture: Natural Fracture Interaction in Hydrostone Block Experiments. In Proceedings of the 2012 SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 6–8 February 2012. [Google Scholar]

- Guo, T.; Zhang, S.; Qu, Z.; Zhou, T.; Xiao, Y.; Gao, J. Experimental study of hydraulic fracturing for shale by stimulated reservoir volume. Fuel 2014, 128, 373–380. [Google Scholar] [CrossRef]

- Fan, T.; Zhang, G. Laboratory investigation of hydraulic fracture networks in formations with continuous orthogonal fractures. Energy 2014, 74, 164–173. [Google Scholar] [CrossRef]

- Bennour, Z.; Ishida, T.; Nagaya, Y.; Chen, Y.; Nara, Y.; Chen, Q.; Sekine, K.; Nagano, Y. Crack extension in hydraulic fracturing of shale cores using viscous oil, water, and liquid carbon dioxide. Rock Mech. Rock Eng. 2015, 48, 1463–1473. [Google Scholar] [CrossRef] [Green Version]

- Alabbad, E.A.; Olson, J.E. Examining the Geomechanical Implications of Pre-Existing Fractures and Simultaneous-Multi-Fracturing Completions on Hydraulic Fractures: Experimental Insights into Fracturing Unconventional Formations. In Proceedings of the 2016 SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 9–11 February 2016; pp. 6–8. [Google Scholar]

- Liu, E. Effects of fracture aperture and roughness on hydraulic and mechanical properties of rocks: Implication of seismic characterization of fractured reservoirs. J. Geophys. Eng. 2005, 2, 38. [Google Scholar] [CrossRef]

- Renard, F.; Bernard, D.; Desrues, J.; Ougier-Simonin, A. 3D imaging of fracture propagation using synchrotron X-ray microtomography. Earth Planet. Sci. Lett. 2009, 286, 285–291. [Google Scholar] [CrossRef]

- Stanchits, S.; Mayr, S.; Shapiro, S.; Dresen, G. Fracturing of porous rock induced by fluid injection. Tectonophysics 2011, 503, 129–145. [Google Scholar] [CrossRef]

- Chitrala, Y.; Moreno, C.; Sondergeld, C.H.; Rai, C.S. Microseismic Mapping of Laboratory Induced Hydraulic Fractures in Anisotropic Reservoirs. In Proceedings of the 2010 Tight Gas Completions Conference, San Antonio, TX, USA, 2–3 November 2010. [Google Scholar]

- Niandou, H.; Shao, J.F.; Henry, J.P.; Fourmaintraux, D. Laboratory investigation of the mechanical behaviour of Tournemire shale. Int. J. Rock Mech. Min. Sci. 1997, 34, 3–16. [Google Scholar] [CrossRef]

- Sayers, C.M. The effect of anisotropy on the Young’s moduli and Poisson’s ratios of shales. Geophys. Prospect. 2013, 61, 416–426. [Google Scholar] [CrossRef]

- Chuanliang, Y.; Jingen, D.; Lianbo, H.; Zijian, C.; Xinjiang, Y.; Hai, L.; Qiang, T.; Baohua, Y. Brittle failure of shale under uniaxial compression. Arab. J. Geosci. 2015, 8, 2467–2475. [Google Scholar] [CrossRef]

- Cho, J.-W.; Kim, H.; Jeon, S.; Min, K.-B. Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist. Int. J. Rock Mech. Min. Sci. 2012, 50, 158–169. [Google Scholar] [CrossRef]

- He, J.; Afolagboye, L.O. Influence of layer orientation and interlayer bonding force on the mechanical behavior of shale under Brazilian test conditions. Acta Mech. Sin. 2017, 1–10. [Google Scholar] [CrossRef]

- He, J.; Lin, C.; Li, X.; Wan, X. Experimental investigation of crack extension patterns in hydraulic fracturing with shale, sandstone and granite cores. Energies 2016, 9, 1018. [Google Scholar] [CrossRef]

- Vernik, L.; Liu, X. Velocity anisotropy in shales: A petrophysical study. Geophysics 1997, 62, 521–532. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G.; Viete, D.R. Effect of joint orientation on the hydromechanical behavior of singly jointed sandstone experiencing undrained loading. J. Geophys. Res. Solid Earth 2014, 119, 1701–1717. [Google Scholar] [CrossRef]

| Bedding Orientation | Average P Wave Velocity (m/s) | Average S Wave Velocity (m/s) | Uniaxial Compressive Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| 0° | 4049 ± 46.6 | 2752 ± 242.3 | 108.06 ± 1.74 | 7.07 ± 0.99 |

| 15° | 3717 ± 290.8 | 2595 ± 39.4 | 110.85 ± 2.30 | 6.67 ± 1.01 |

| 30° | 3897 ± 337.6 | 2652 ± 57.1 | 111.85 ± 1.95 | 5.63 ± 1.06 |

| 45° | 4164 ± 36.8 | 2731 ± 78.9 | 97.06 ± 1.81 | 4.35 ± 0.98 |

| 60° | 3441 ± 158.0 | 2608 ± 284.6 | 52.29 ± 1.68 | 3.49 ± 0.66 |

| 75° | 3895 ± 404.3 | 2697 ± 276.0 | 91.78 ± 1.43 | 2.91 ± 0.43 |

| 90° | 4171 ± 316.4 | 2767 ± 102.9 | 90.37 ± 1.18 | 3.09 ± 0.37 |

| Bedding Orientation | Fractured Using Freshwater | Fractured Using SCO2 | ||

|---|---|---|---|---|

| Photograph | Sketch | Photograph | Sketch | |

| 0° |  |  |  |  |

| 15° |  |  |  |  |

| 30° |  |  |  |  |

| 45° |  |  |  |  |

| 60° |  |  |  |  |

| 75° |  |  |  |  |

| 90° |  |  |  |  |

| Bedding Orientation | Fractured Using Freshwater | Fractured Using SCO2 | ||

|---|---|---|---|---|

| Real Area | Tortuosity | Real Area | Tortuosity | |

| 30° | 5428.50 | 1.09 | 6229.2 | 1.25 |

| 90° | 5176.44 | 1.04 | 5608.72 | 1.12 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Afolagboye, L.O.; Lin, C.; Wan, X. An Experimental Investigation of Hydraulic Fracturing in Shale Considering Anisotropy and Using Freshwater and Supercritical CO2. Energies 2018, 11, 557. https://doi.org/10.3390/en11030557

He J, Afolagboye LO, Lin C, Wan X. An Experimental Investigation of Hydraulic Fracturing in Shale Considering Anisotropy and Using Freshwater and Supercritical CO2. Energies. 2018; 11(3):557. https://doi.org/10.3390/en11030557

Chicago/Turabian StyleHe, Jianming, Lekan Olatayo Afolagboye, Chong Lin, and Xiaole Wan. 2018. "An Experimental Investigation of Hydraulic Fracturing in Shale Considering Anisotropy and Using Freshwater and Supercritical CO2" Energies 11, no. 3: 557. https://doi.org/10.3390/en11030557