Experimental and Numerical Vibrational Analysis of a Horizontal-Axis Micro-Wind Turbine

Abstract

:1. Introduction

2. The Facilities and the Methods

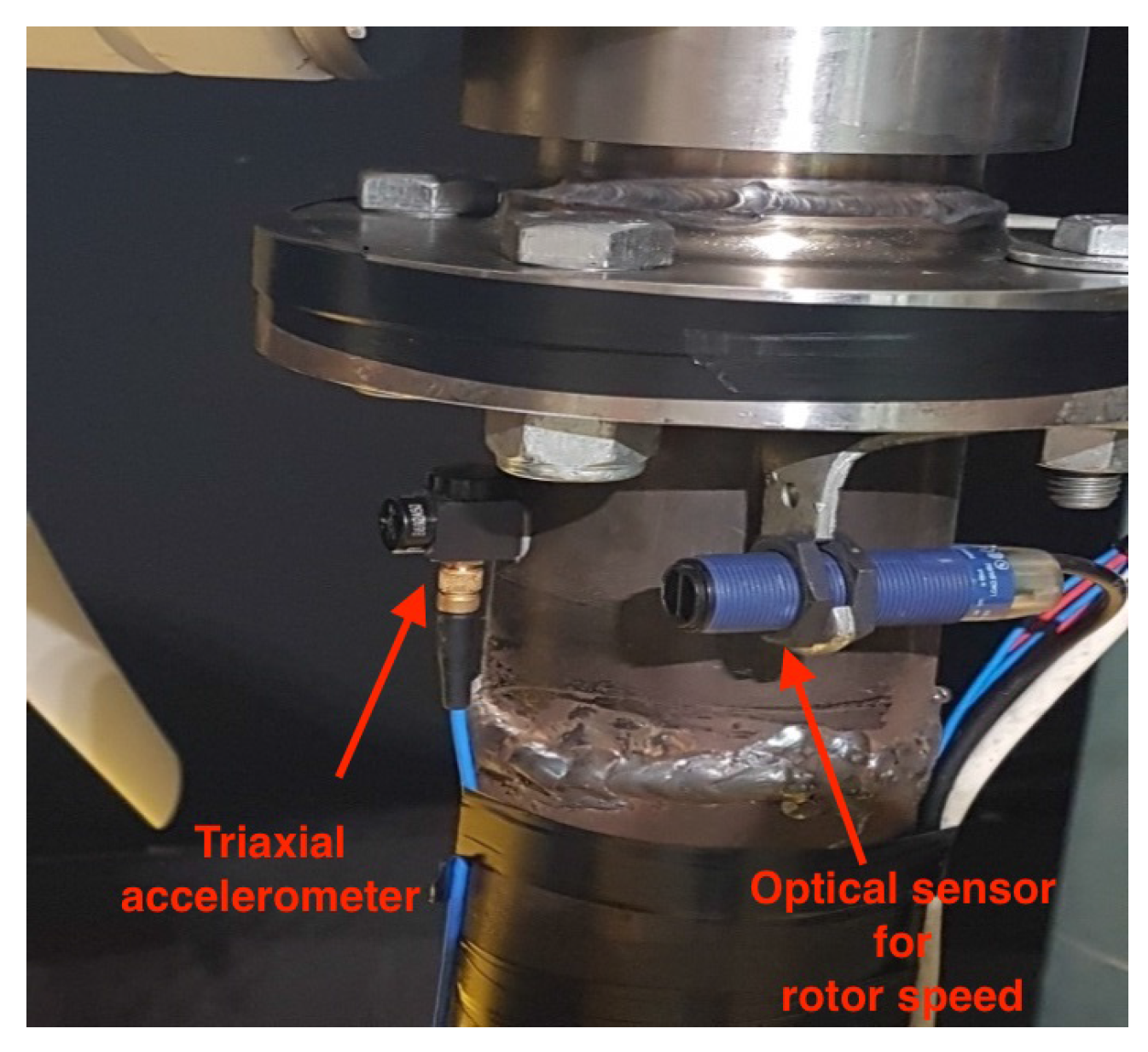

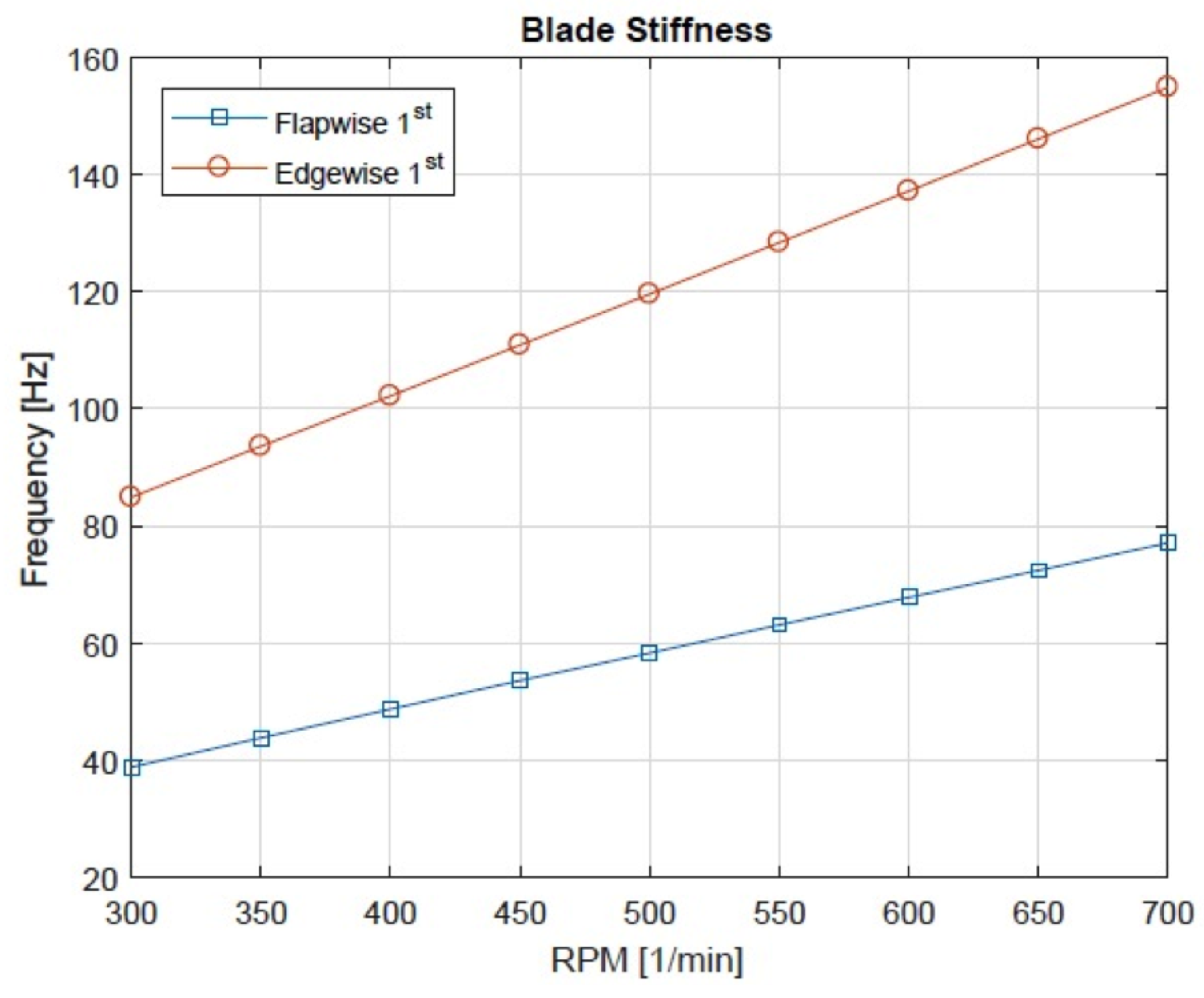

2.1. The Wind Turbine

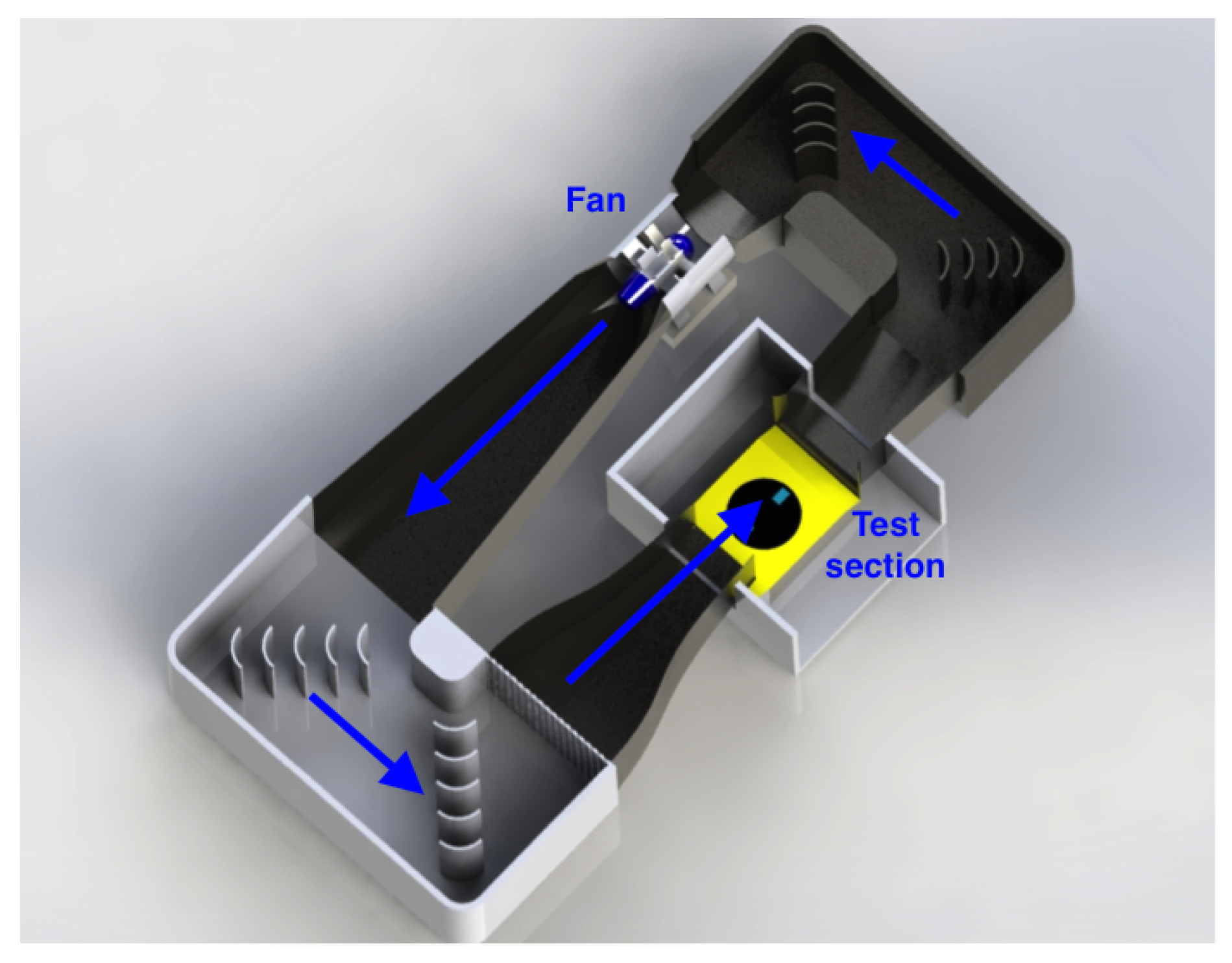

2.2. The Wind Tunnel

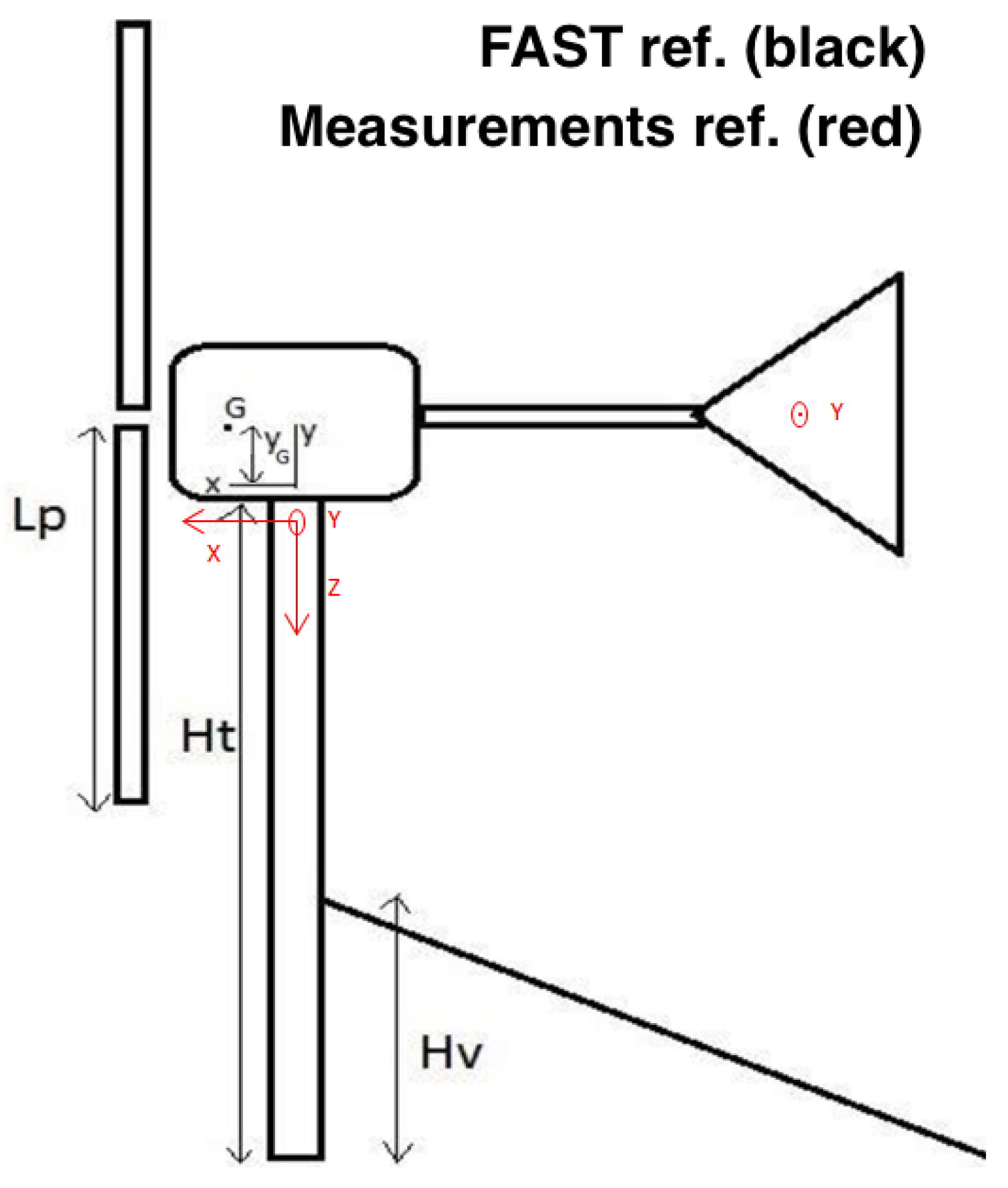

2.3. The FAST Code

2.4. The Methods

3. Results

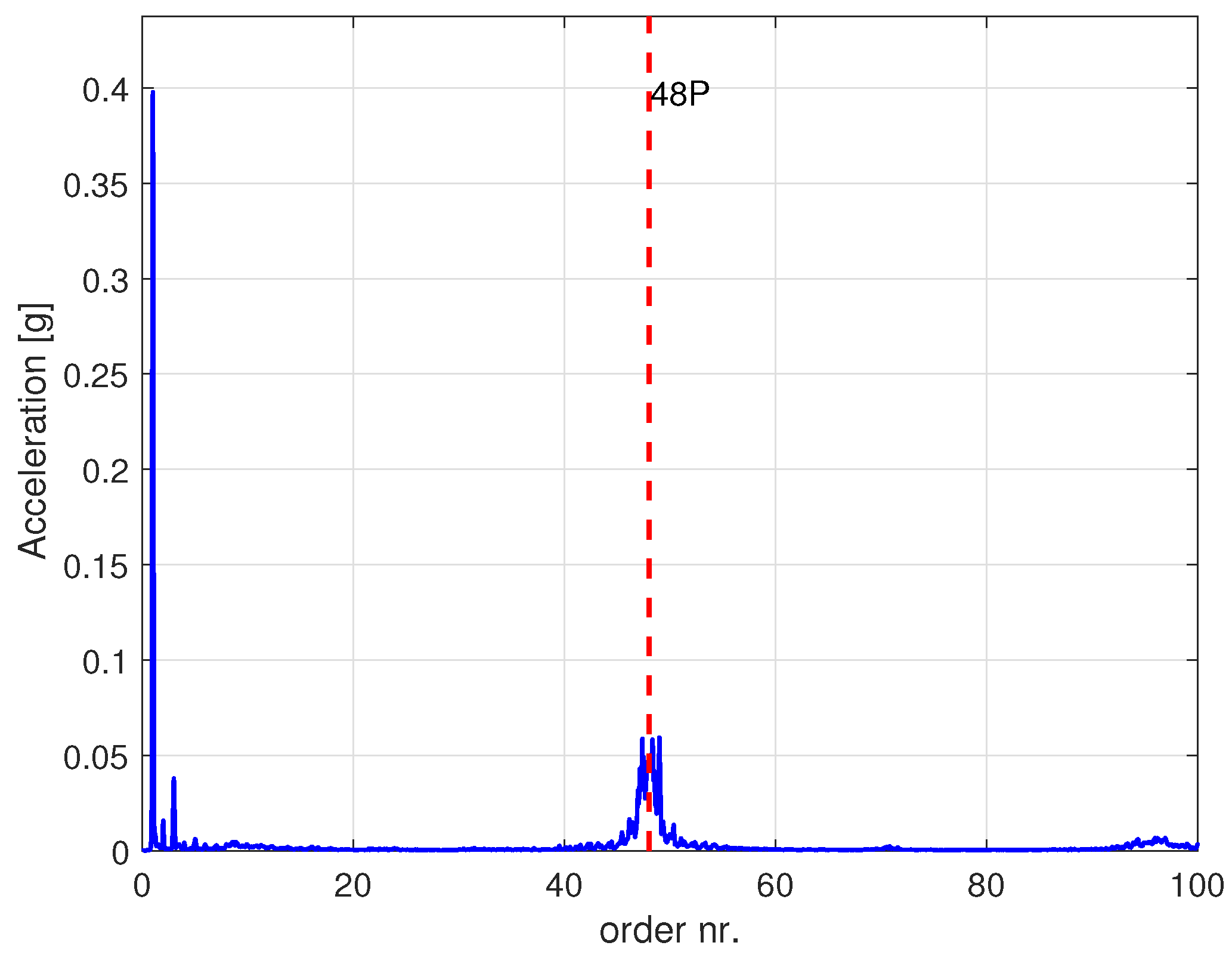

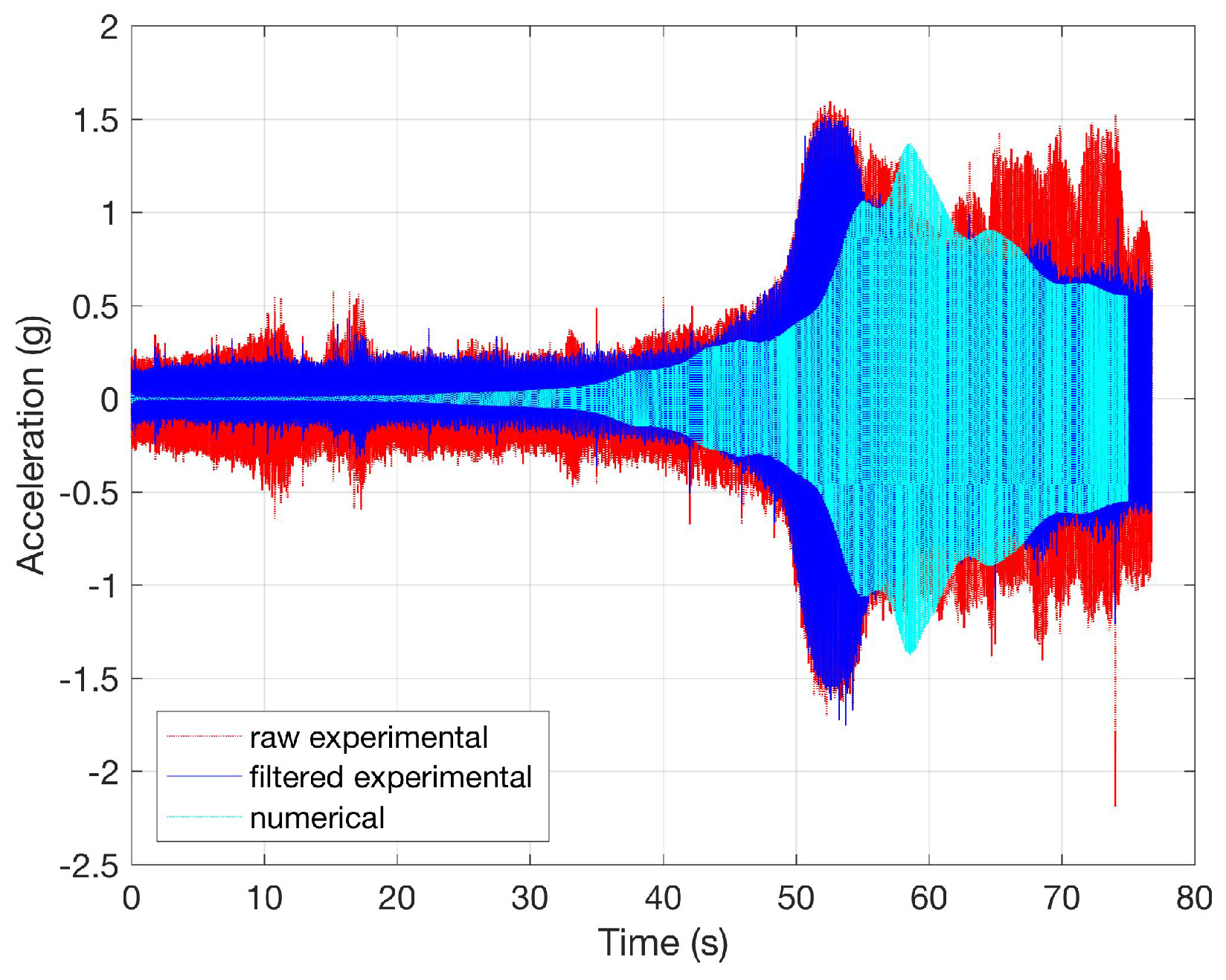

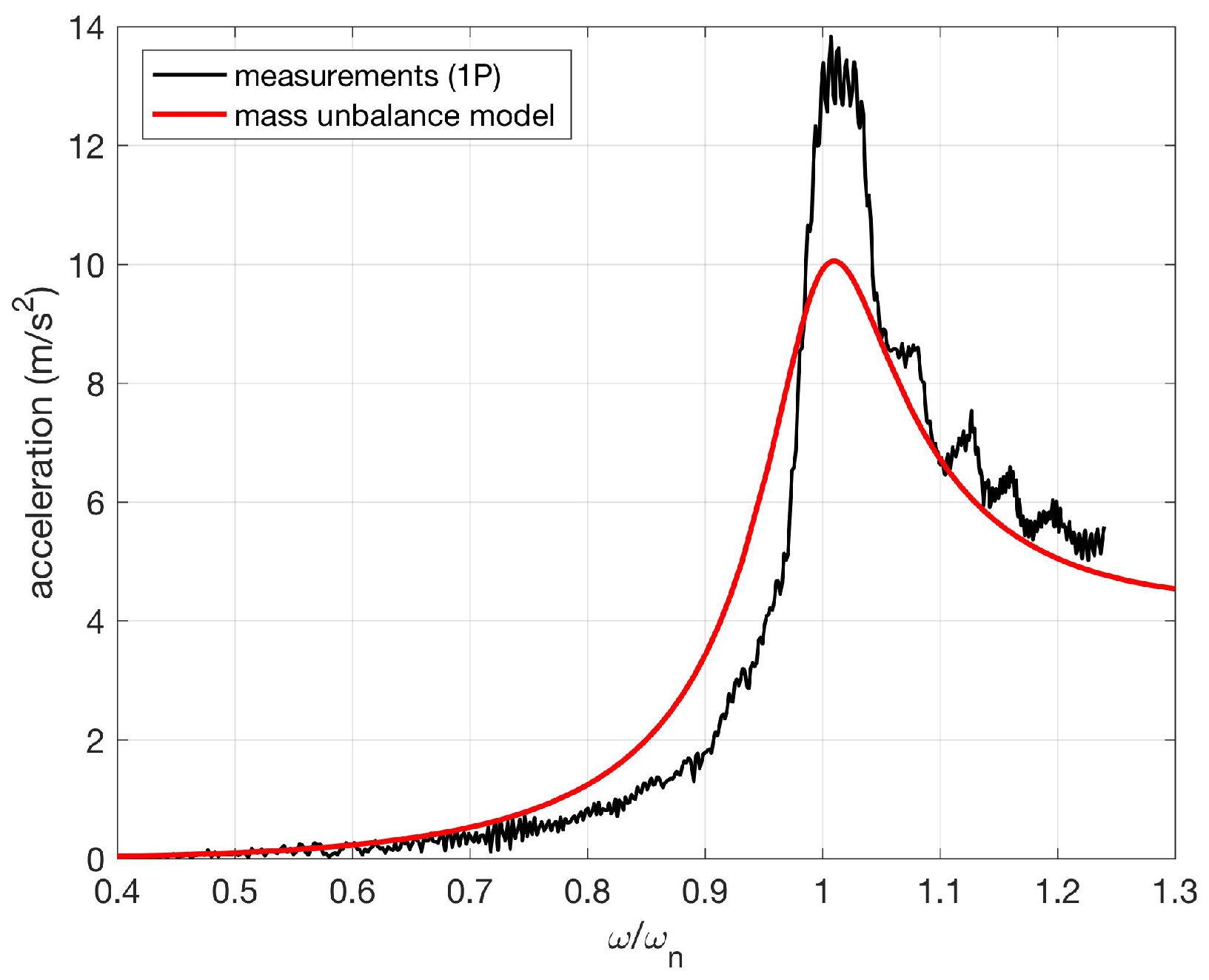

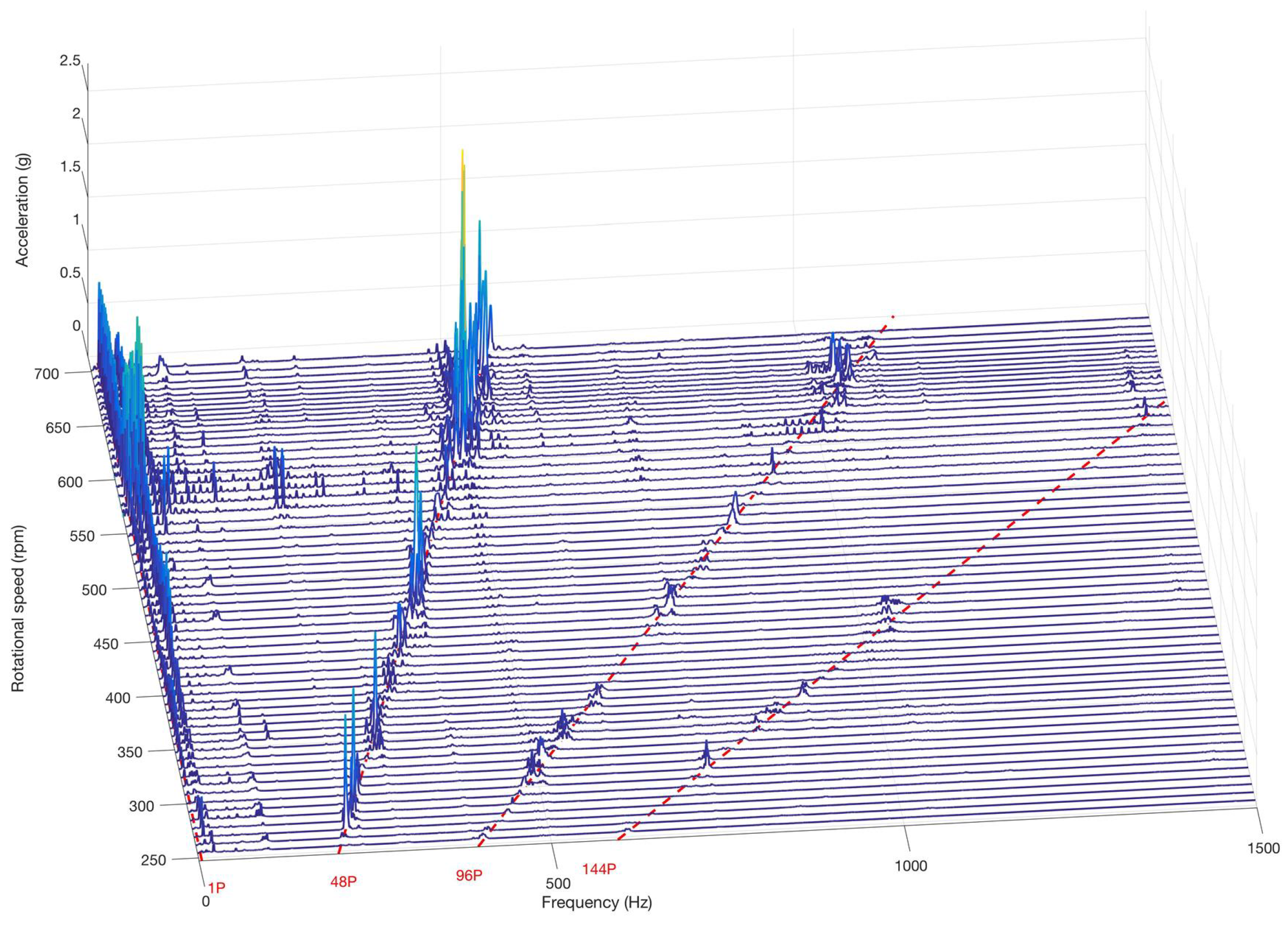

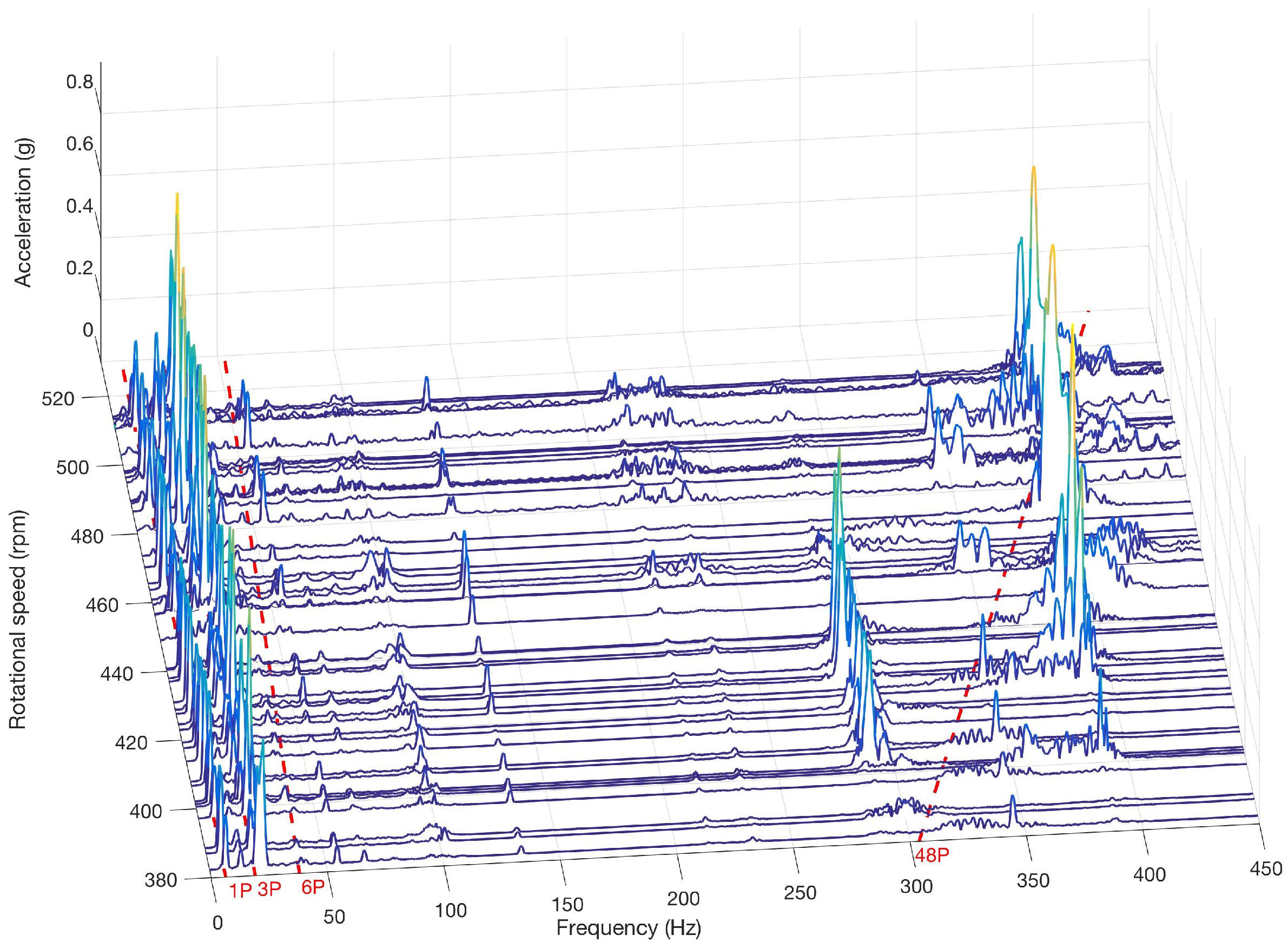

3.1. Tower Vibrations

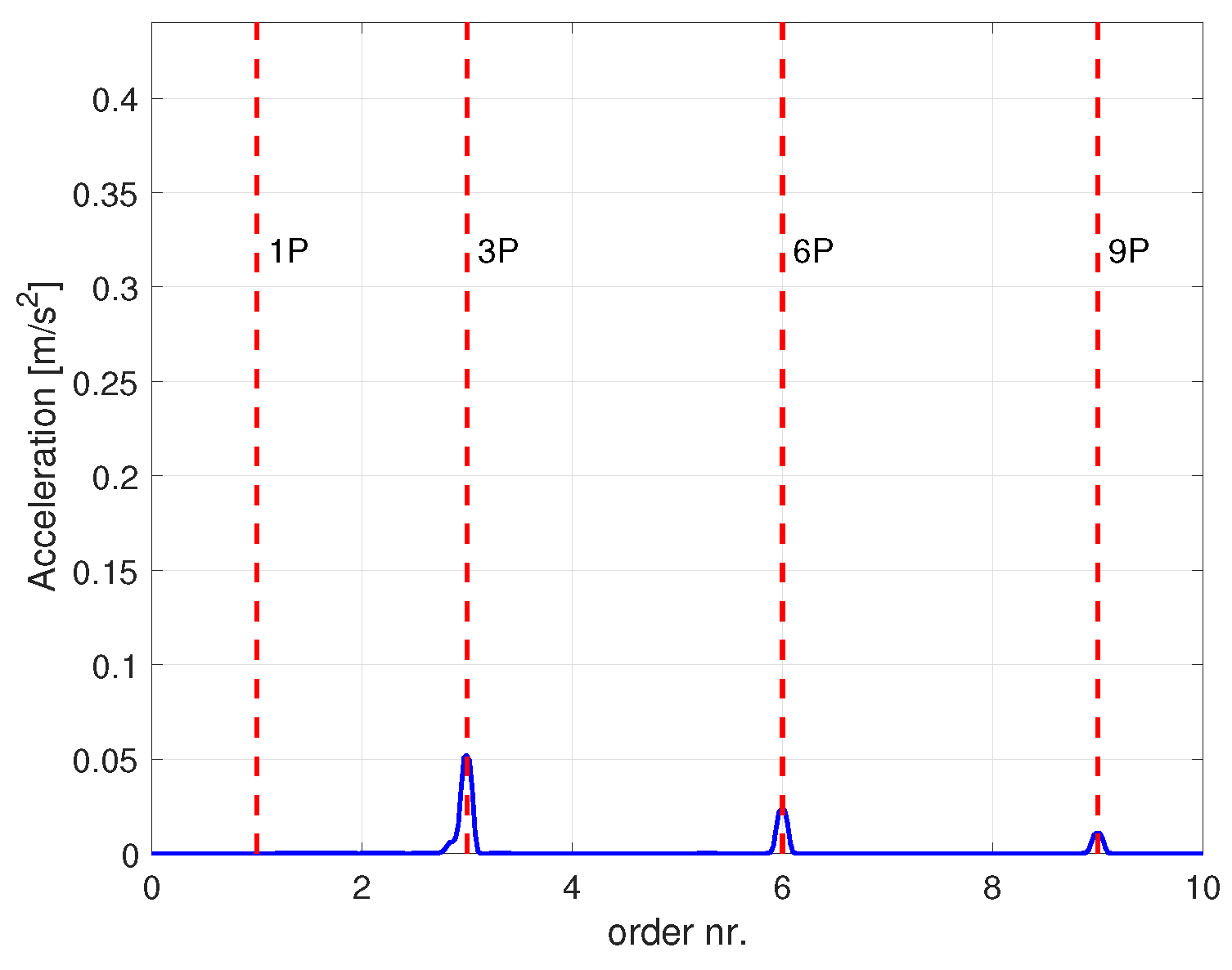

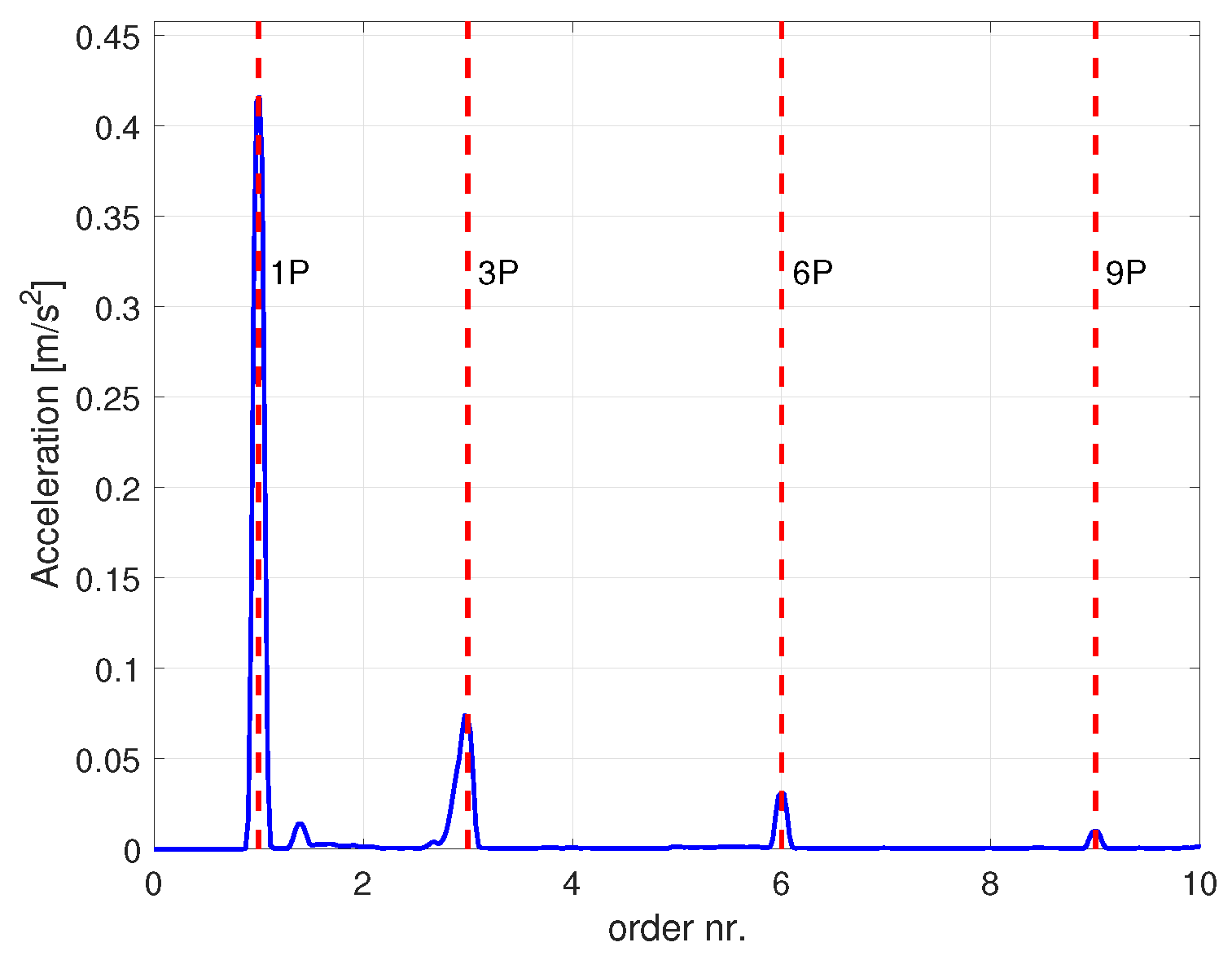

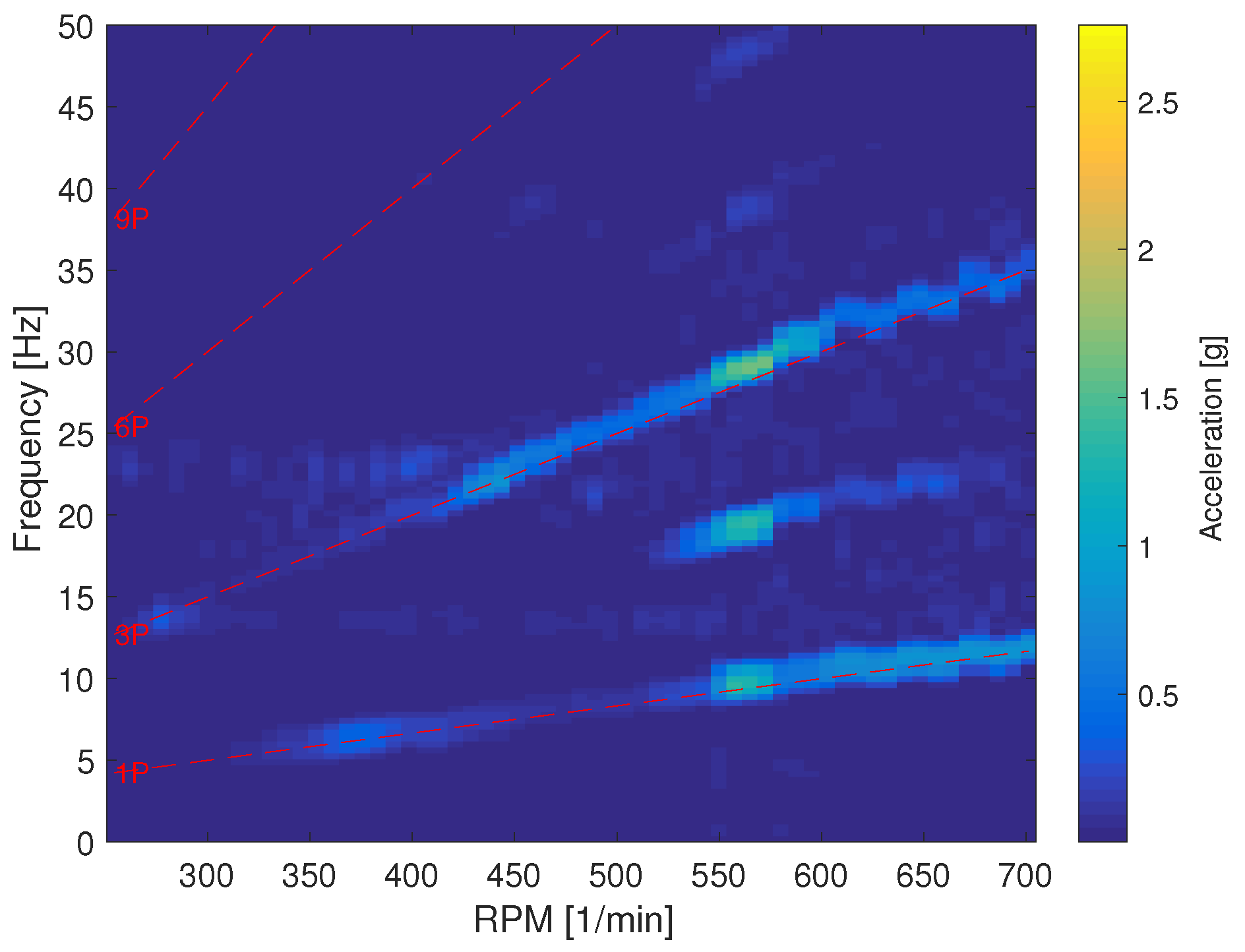

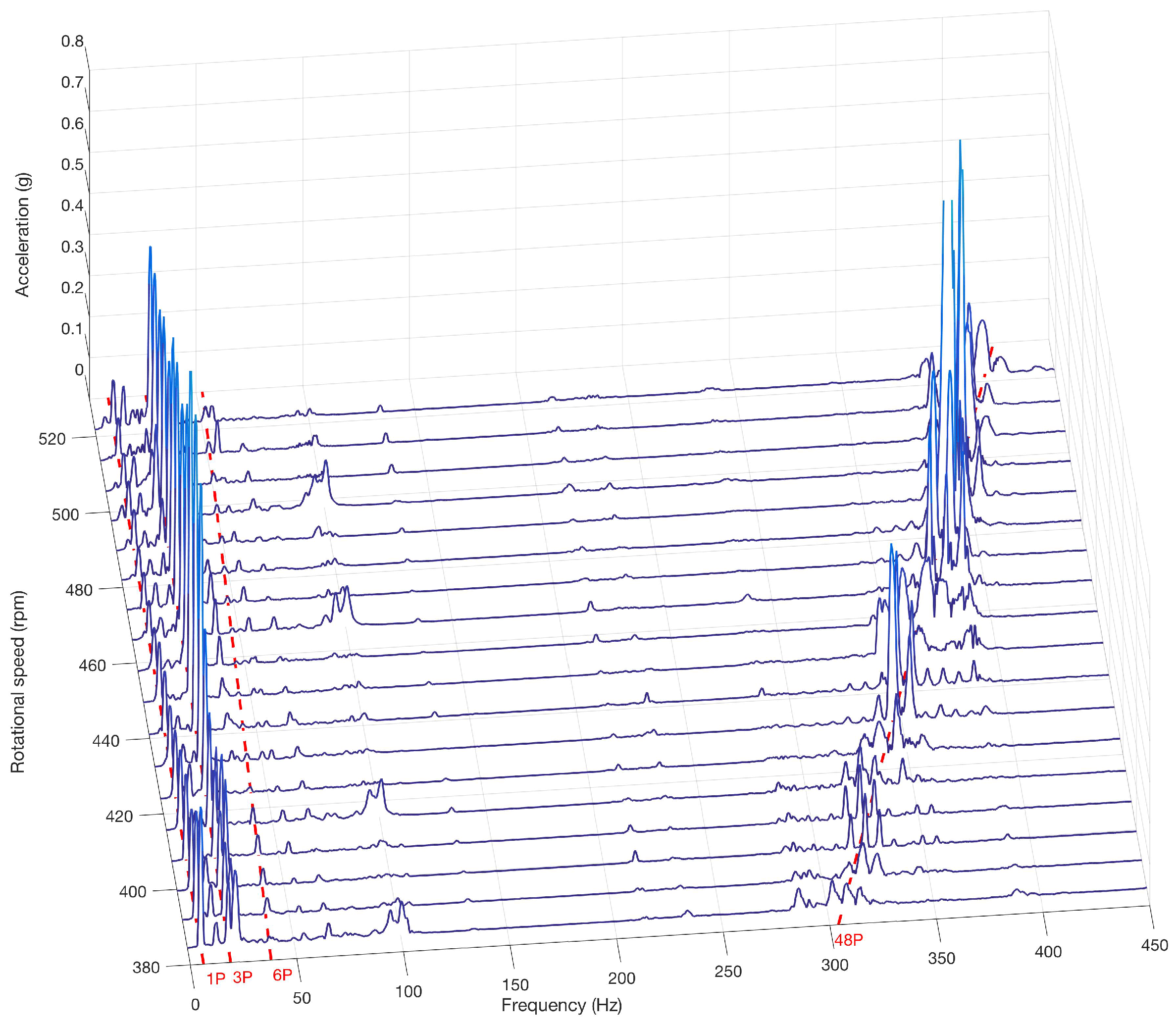

3.2. Tail Fin Vibrations

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sauter, R.; Watson, J. Strategies for the deployment of micro-generation: Implications for social acceptance. Energy Policy 2007, 35, 2770–2779. [Google Scholar] [CrossRef]

- Xie, W.; Zeng, P.; Lei, L. Wind tunnel experiments for innovative pitch regulated blade of horizontal axis wind turbine. Energy 2015, 91, 1070–1080. [Google Scholar] [CrossRef]

- Bai, C.J.; Chen, P.W.; Wang, W.C. Aerodynamic design and analysis of a 10 kW horizontal-axis wind turbine for Tainan, Taiwan. Clean Technol. Environ. Policy 2016, 18, 1151–1166. [Google Scholar] [CrossRef]

- Scappatici, L.; Bartolini, N.; Castellani, F.; Astolfi, D.; Garinei, A.; Pennicchi, M. Optimizing the design of horizontal-axis small wind turbines: From the laboratory to market. J. Wind Eng. Ind. Aerodyn. 2016, 154, 58–68. [Google Scholar] [CrossRef]

- Lanzafame, R.; Messina, M. Power curve control in micro wind turbine design. Energy 2010, 35, 556–561. [Google Scholar] [CrossRef]

- Lumbreras, C.; Guerrero, J.M.; García, P.; Briz, F.; Reigosa, D.D. Control of a small wind turbine in the high wind speed region. IEEE Trans. Power Electron. 2016, 31, 6980–6991. [Google Scholar] [CrossRef]

- James, P.; Sissons, M.; Bradford, J.; Myers, L.; Bahaj, A.; Anwar, A.; Green, S. Implications of the UK field trial of building mounted horizontal axis micro-wind turbines. Energy Policy 2010, 38, 6130–6144. [Google Scholar] [CrossRef]

- Dayan, E. Wind energy in buildings: Power generation from wind in the urban environment—Where it is needed most. Refocus 2006, 7, 33–38. [Google Scholar] [CrossRef]

- Li, D.; Wang, S.; Yuan, P. A review of micro wind turbines in the built environment. In Proceedings of the Power and Energy Engineering Conference (APPEEC), 2010 Asia-Pacific, Chengdu, China, 28–31 March 2010; pp. 1–4. [Google Scholar]

- Sunderland, K.; Woolmington, T.; Blackledge, J.; Conlon, M. Small wind turbines in turbulent (urban) environments: A consideration of normal and Weibull distributions for power prediction. J. Wind Eng. Ind. Aerodyn. 2013, 121, 70–81. [Google Scholar] [CrossRef]

- Toja-Silva, F.; Colmenar-Santos, A.; Castro-Gil, M. Urban wind energy exploitation systems: Behaviour under multidirectional flow conditions—Opportunities and challenges. Renew. Sustain. Energy Rev. 2013, 24, 364–378. [Google Scholar] [CrossRef]

- Lubitz, W.D. Impact of ambient turbulence on performance of a small wind turbine. Renew. Energy 2014, 61, 69–73. [Google Scholar] [CrossRef]

- Pagnini, L.C.; Burlando, M.; Repetto, M.P. Experimental power curve of small-size wind turbines in turbulent urban environment. Appl. Energy 2015, 154, 112–121. [Google Scholar] [CrossRef]

- Alpman, E. Aerodynamic performance of small-scale horizontal axis wind turbines under two different extreme wind conditions. J. Therm. Eng. 2015, 1, 420–432. [Google Scholar] [CrossRef]

- Joosse, P.; Blanch, M.; Dutton, A.; Kouroussis, D.; Philippidis, T.; Vionis, P. Acoustic emission monitoring of small wind turbine blades. J. Sol. Energy Eng. 2002, 124, 446–454. [Google Scholar] [CrossRef]

- Mollasalehi, E.; Sun, Q.; Wood, D. Contribution of small wind turbine structural vibration to noise emission. Energies 2013, 6, 3669–3691. [Google Scholar] [CrossRef]

- Taylor, J.; Eastwick, C.; Lawrence, C.; Wilson, R. Noise levels and noise perception from small and micro wind turbines. Renew. Energy 2013, 55, 120–127. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S. Numerical and experimental study of aerodynamic noise by a small wind turbine. Renew. Energy 2014, 65, 108–112. [Google Scholar] [CrossRef]

- Tabrizi, A.B.; Whale, J.; Lyons, T.; Urmee, T. Performance and safety of rooftop wind turbines: Use of CFD to gain insight into inflow conditions. Renew. Energy 2014, 67, 242–251. [Google Scholar] [CrossRef]

- Li, Q.; Kamada, Y.; Maeda, T.; Nishida, Y. Experimental investigations of boundary layer impact on the airfoil aerodynamic forces of Horizontal Axis Wind Turbine in turbulent inflows. Energy 2017, 135, 799–810. [Google Scholar] [CrossRef]

- Pourrajabian, A.; Afshar, P.A.N.; Ahmadizadeh, M.; Wood, D. Aero-structural design and optimization of a small wind turbine blade. Renew. Energy 2016, 87, 837–848. [Google Scholar] [CrossRef]

- Evans, S.; Bradney, D.; Clausen, P. Aeroelastic measurements and simulations of a small wind turbine operating in the built environment. J. Phys. Conf. Ser. 2016, 753. [Google Scholar] [CrossRef]

- Bukala, J.; Małachowski, J.; Szafranski, T. Numerical optimization and design study of small wind turbine mast structure. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 5562–5567. [Google Scholar]

- Ochs, D.S.; Miller, R.D.; White, W.N. Simulation of electromechanical interactions of permanent-magnet direct-drive wind turbines using the fast aeroelastic simulator. IEEE Trans. Sustain. Energy 2014, 5, 2–9. [Google Scholar] [CrossRef]

- Tang, D.; Bao, S.; Luo, L.; Mao, J.; Lv, B.; Guo, H. Study on the aeroelastic responses of a wind turbine using a coupled multibody-FVW method. Energy 2017, 141, 2300–2313. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X.; Kolios, A. State of the art in the aeroelasticity of wind turbine blades: Aeroelastic modelling. Renew. Sustain. Energy Rev. 2016, 64, 195–210. [Google Scholar] [CrossRef]

- Jonkman, J.M.; Buhl Jr, M.L. User’s Guide—Updated August 2005; Technical report; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2005.

- Antoni, J. Cyclostationarity by examples. Mech. Syst. Signal Process. 2009, 23, 987–1036. [Google Scholar] [CrossRef]

- Elia, G.; Cocconcelli, M.; Mucchi, E.; Dalpiaz, G. Combining blind separation and cyclostationary techniques for monitoring distributed wear in gearbox rolling bearings. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 1113–1128. [Google Scholar] [CrossRef]

- Dolan, D.S.; Lehn, P.W. Simulation model of wind turbine 3p torque oscillations due to wind shear and tower shadow. IEEE Trans. Energy Convers. 2006, 21, 717–724. [Google Scholar] [CrossRef]

- Hau, E. Wind Turbines: Fundamentals, Technologies, Application, Economics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Battisti, L.; Zanne, L.; Dell’Anna, S.; Dossena, V.; Persico, G.; Paradiso, B. Aerodynamic measurements on a vertical axis wind turbine in a large scale wind tunnel. J. Energy Resour. Technol. 2011, 133, 031201. [Google Scholar] [CrossRef]

- Battisti, L.; Benini, E.; Brighenti, A.; Soraperra, G.; Castelli, M.R. Simulating the dynamic behavior of a vertical axis wind turbine operating in unsteady conditions. J. Phys. Conf. Ser. 2016, 753. [Google Scholar] [CrossRef]

| Quantity | Dimensions (m) |

|---|---|

| 1.00 | |

| 0.98 | |

| 0.55 | |

| 0.13 | |

| 0.20 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castellani, F.; Astolfi, D.; Becchetti, M.; Berno, F.; Cianetti, F.; Cetrini, A. Experimental and Numerical Vibrational Analysis of a Horizontal-Axis Micro-Wind Turbine. Energies 2018, 11, 456. https://doi.org/10.3390/en11020456

Castellani F, Astolfi D, Becchetti M, Berno F, Cianetti F, Cetrini A. Experimental and Numerical Vibrational Analysis of a Horizontal-Axis Micro-Wind Turbine. Energies. 2018; 11(2):456. https://doi.org/10.3390/en11020456

Chicago/Turabian StyleCastellani, Francesco, Davide Astolfi, Matteo Becchetti, Francesco Berno, Filippo Cianetti, and Alessandro Cetrini. 2018. "Experimental and Numerical Vibrational Analysis of a Horizontal-Axis Micro-Wind Turbine" Energies 11, no. 2: 456. https://doi.org/10.3390/en11020456