Comparative Study of Electric Energy Storages and Thermal Energy Auxiliaries for Improving Wind Power Integration in the Cogeneration System

Abstract

:1. Introduction

2. Methodology

2.1. Operation Characteristic of Combined Heat and Power (CHP) Units

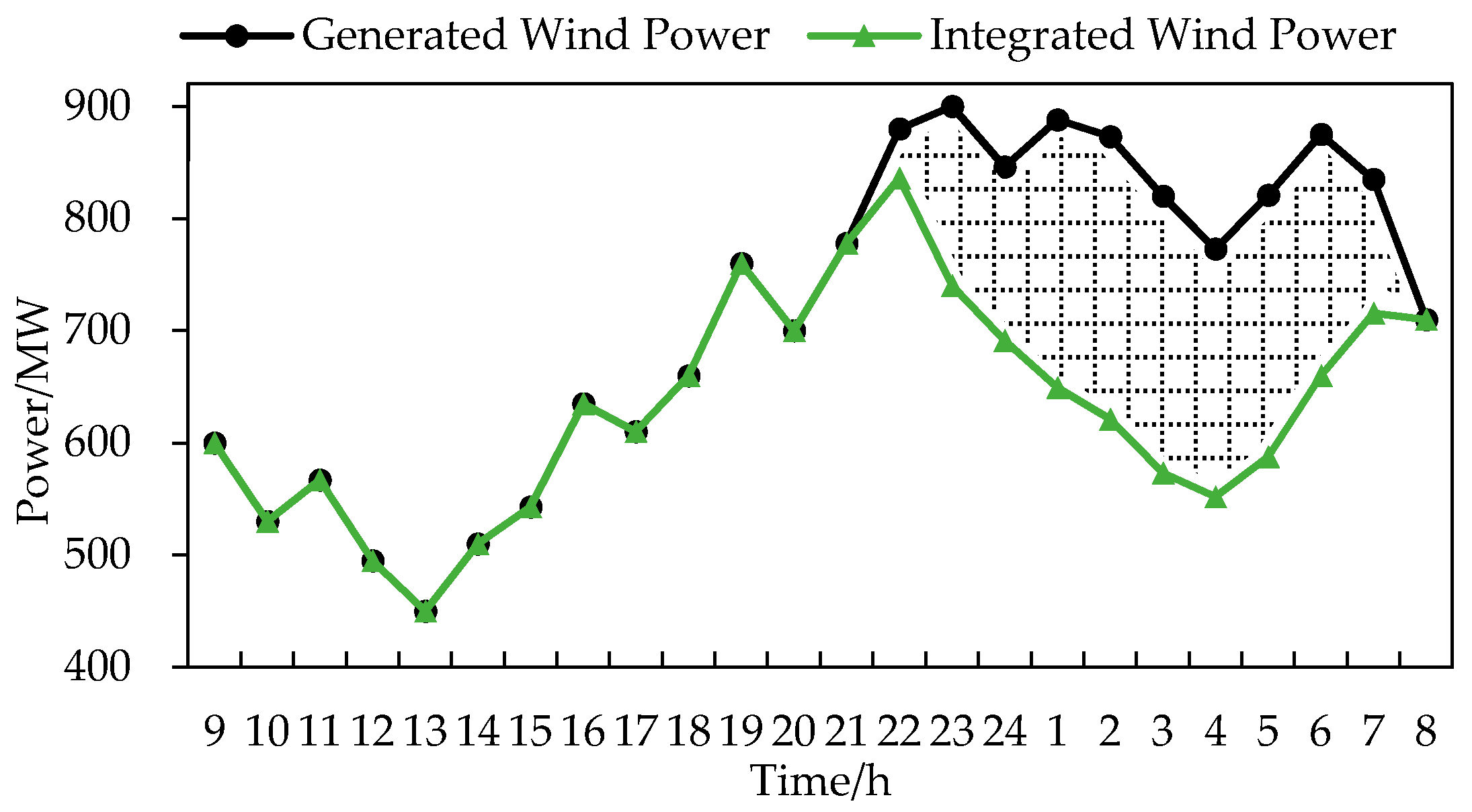

2.2. Wind-Thermal Conflicting Expression (WTCE)

2.3. Additional Equipment for the Promotion of Wind Power Integration

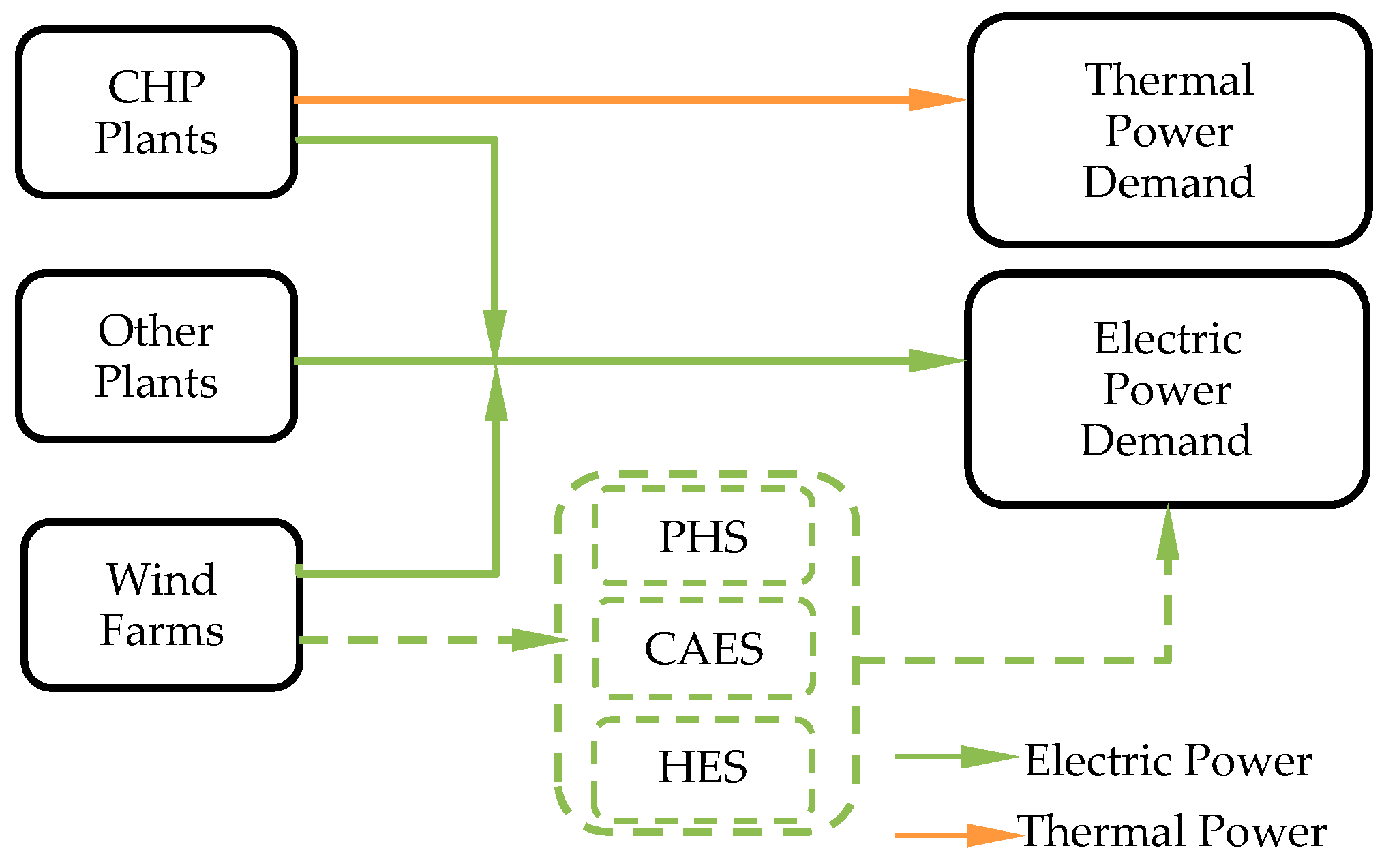

2.3.1. Electric Energy Storages

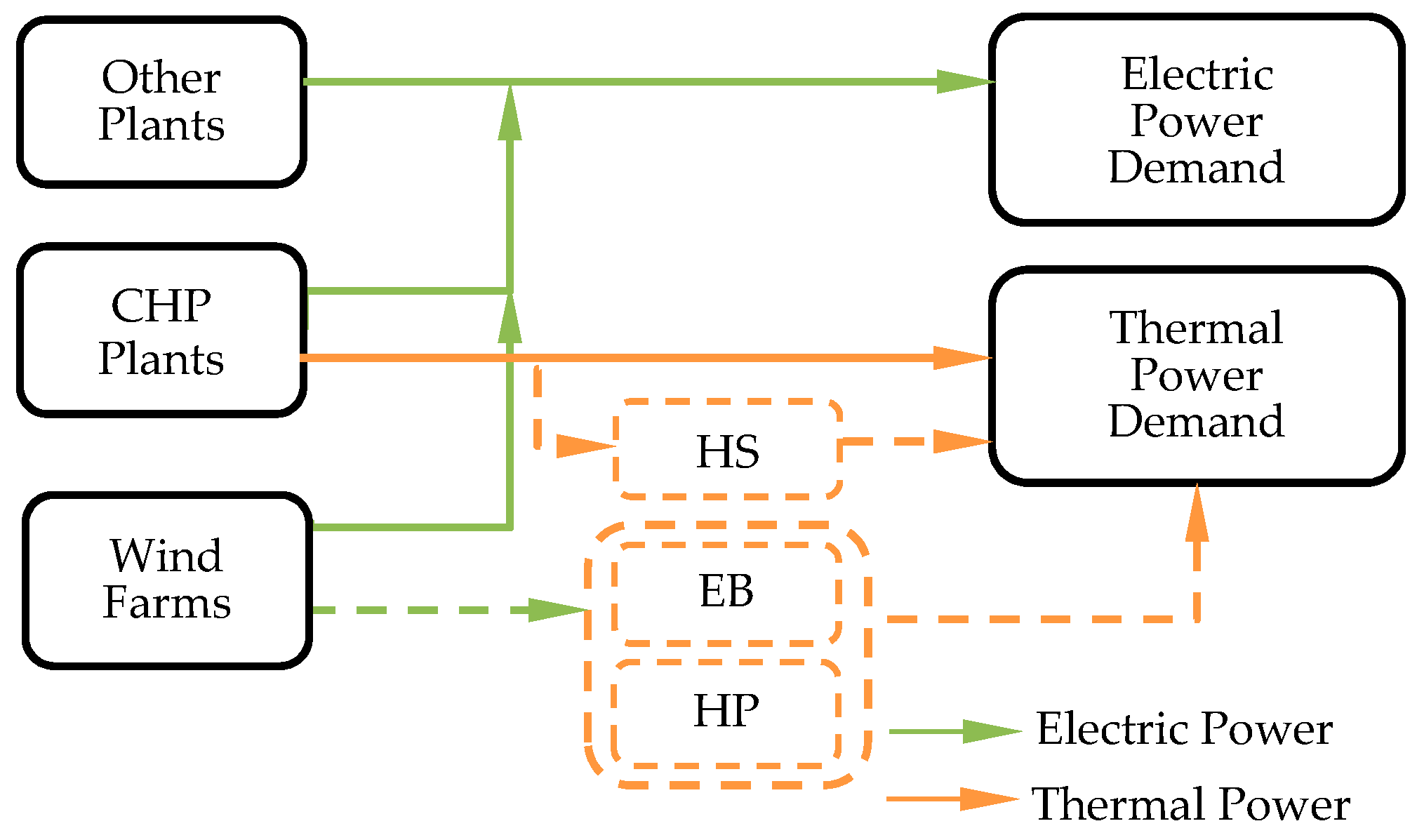

2.3.2. Thermal Energy Auxiliaries

3. Case Studies

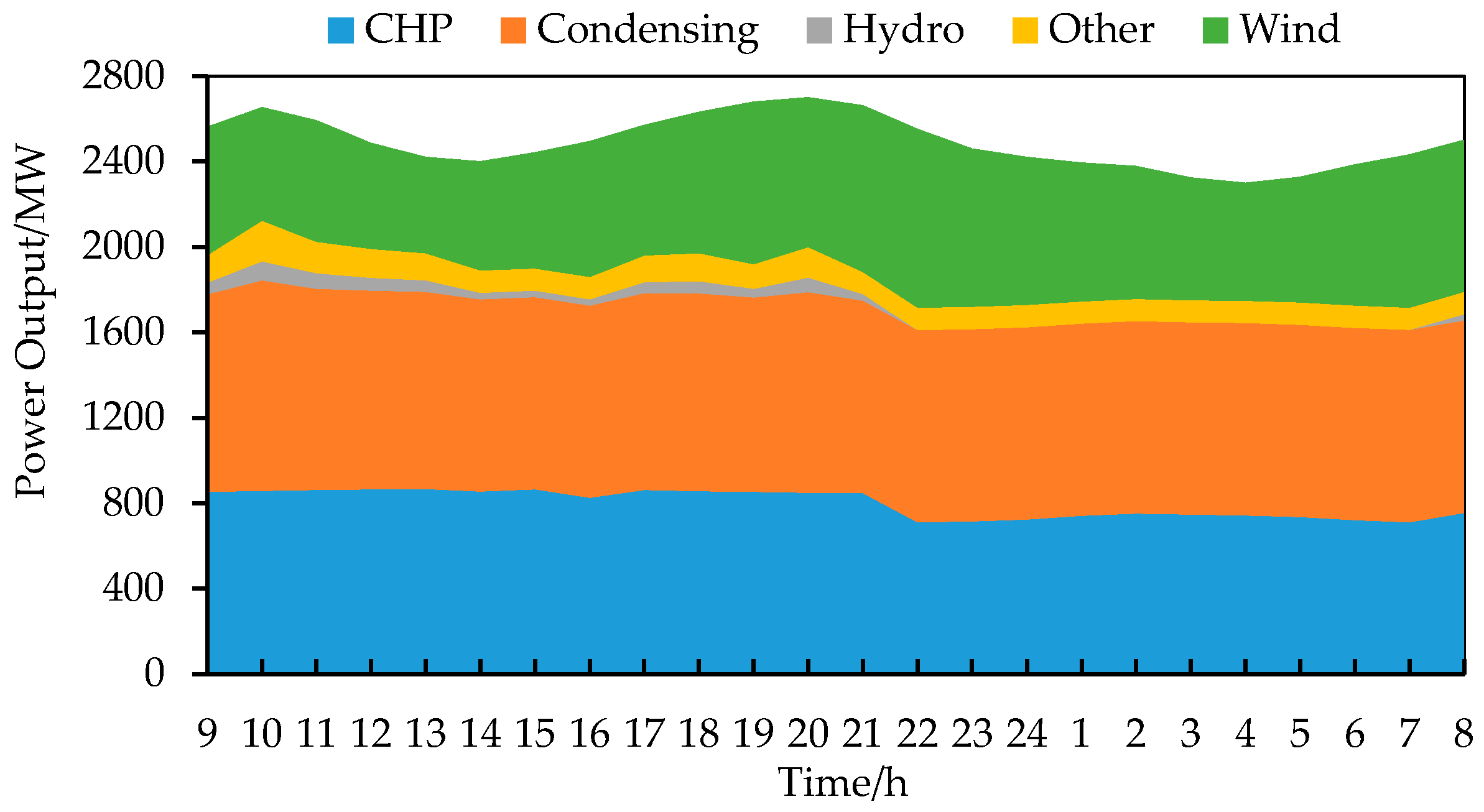

3.1. Data and System Configuration

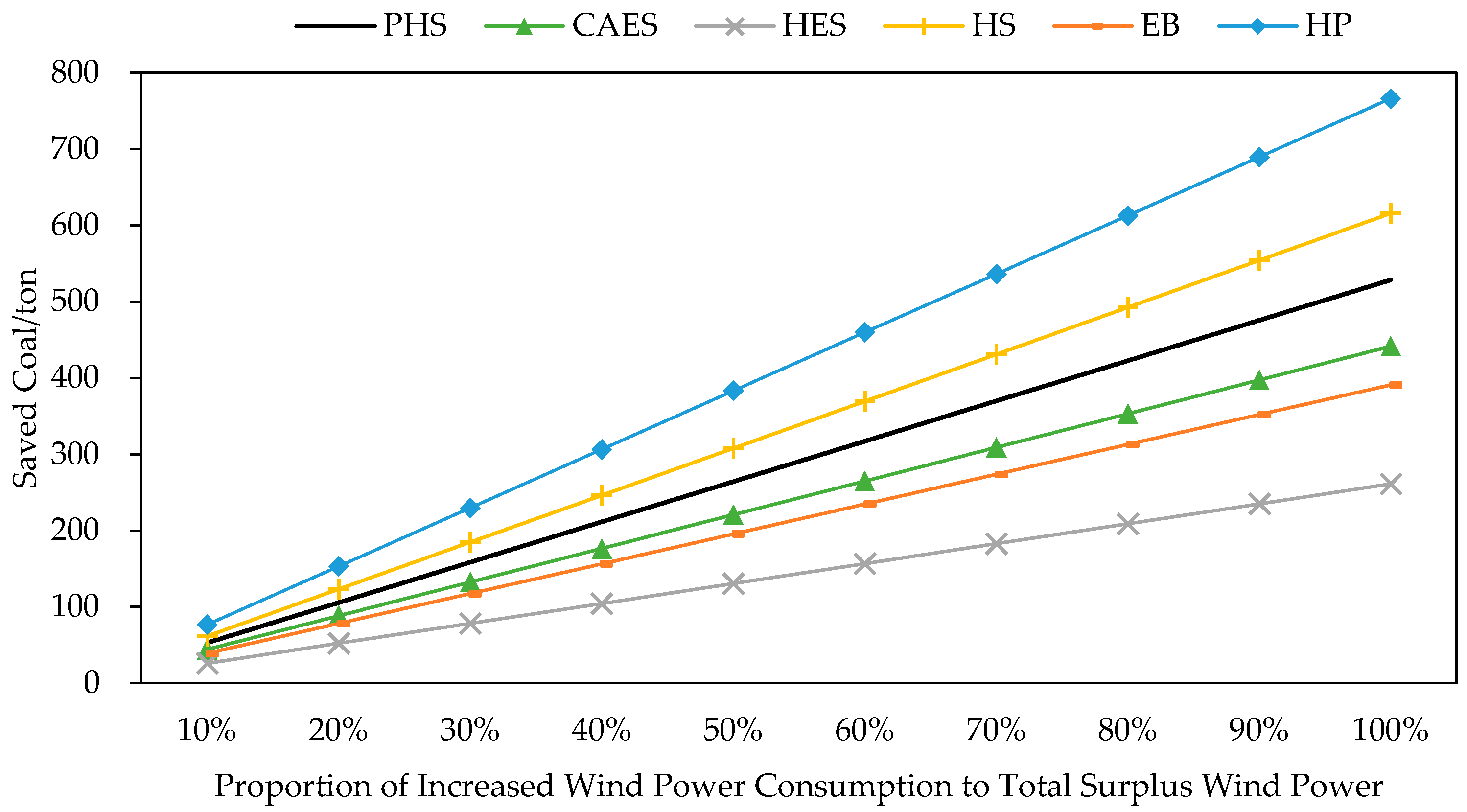

3.2. Comparison of the Six Candidates with Varying Integrated Wind Power

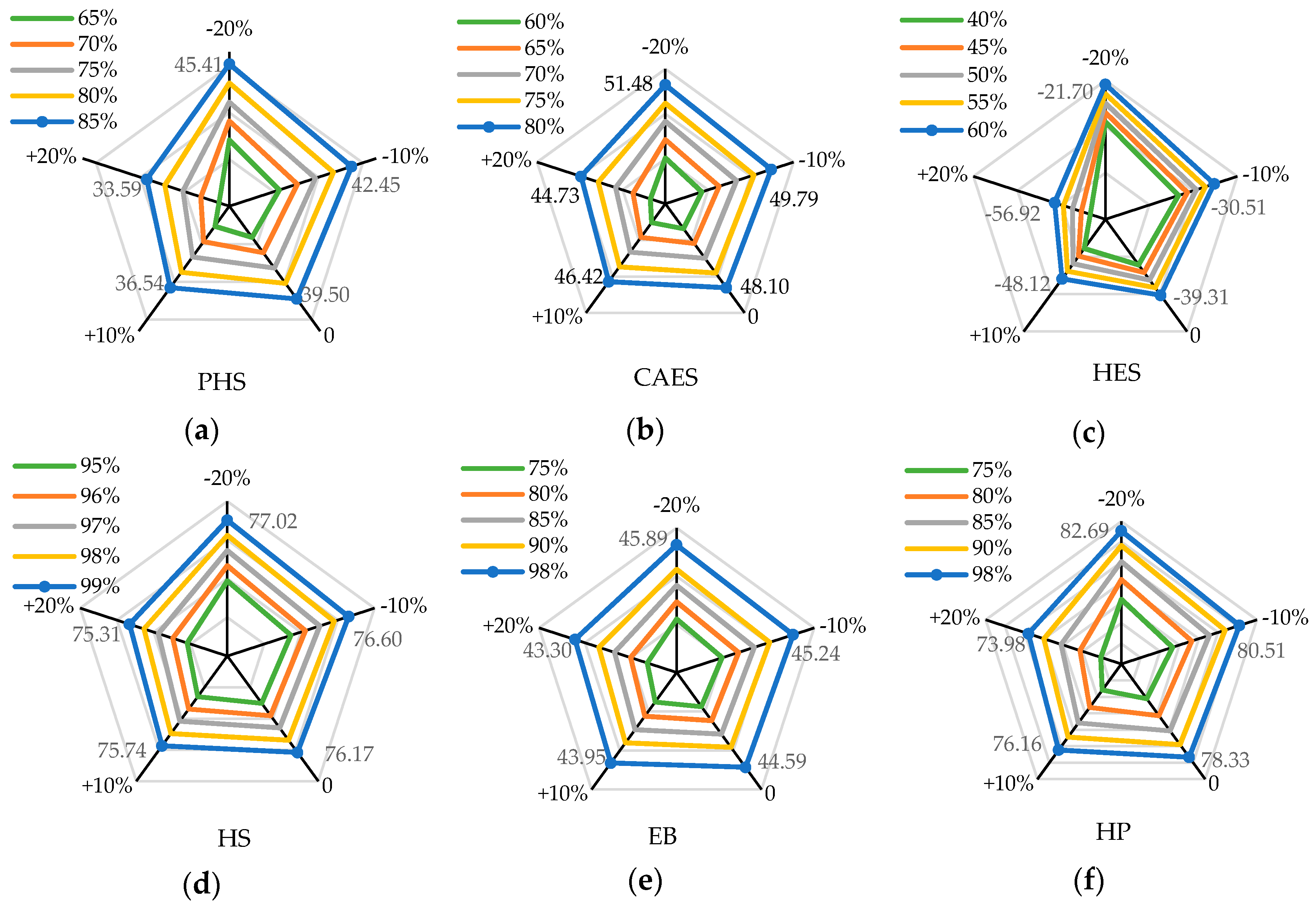

3.3. Further Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Abbreviation | |||

| CHP | Combined heat and power | SMES | Superconducting magnetic energy storage |

| PHS | Pumped hydro storage | HS | Heat storage |

| CAES | Compressed air energy storage | EB | Electric boiler |

| HES | Hydrogen-based energy storage | HP | Heat pump |

| BES | Battery energy storage | WTCE | Wind-thermal conflicting expression |

| FES | Flywheel energy storage | ||

| Index sets | |||

| i | Index set of the CHP units | p | Index set of electric energy storage |

| t | Index set of dispatch time interval | q | Index set of thermal energy auxiliaries |

| Symbols | |||

| Increased amount of wind power integration at time t, MWh | Insufficient amount of heating power supply, MWh | ||

| Electric power reduction of the i-th CHP unit, MWh | Thermal power reduction of the i-th CHP unit, MWh | ||

| Electric power reduction of CHPs, MWh | Thermal power reduction of CHPs, MWh | ||

| Standard coal required for electric power production, kg/MWh | Standard coal required for thermal power production, kg/MWh | ||

| Energy capacity of the electric energy storage, MWh | Unemployed power capacity of the EB/HP, MW | ||

| Energy Capacity of the heat storage, MWh | Power capacity of the EB/HP, MW | ||

| Economic benefit, $ | Energy efficiency, % | ||

| Investment cost, $ | Maintenance cost ratio, % | ||

| Comprehensive benefit, $ | r | Bank lending rate, % | |

| Cost of the standard coal, $/ton | y | Life time, year | |

| Cost of the CO2 emission, $/ton | D | Running days per year, day | |

| CO2 emission coefficient of standard coal | |||

References

- Li, Z.; Wu, W.; Shahidehpour, M.; Wang, J.; Zhang, B. Combined heat and power dispatch considering pipeline energy storage of district heating network. IEEE Trans. Sustain. Energy 2016, 7, 12–22. [Google Scholar] [CrossRef]

- Petchers, N. Combined Heating, Cooling & Power Handbook: Technologies & Applications an Integrated Approach to Energy Resource Optimization; The Fairmont Press Inc.: Lilburn, GA, USA, 2003. [Google Scholar]

- National Energy Administration. 2010 Statistics of Wind Power Development. Available online: http://www.nea.gov.cn/2011-07/05/c_131086514.htm (accessed on 5 July 2011).

- Yao, E.; Wang, H.; Liu, L.; Xi, G. A novel constant-pressure pumped hydro combined with compressed air energy storage system. Energies 2014, 8, 154–171. [Google Scholar] [CrossRef]

- Xiong, M.; Gao, F.; Liu, K.; Chen, S.; Dong, J. Optimal real-time scheduling for hybrid energy storage systems and wind farms based on model predictive control. Energies 2015, 8, 8020–8051. [Google Scholar] [CrossRef]

- Long, H.; Xu, R.; He, J. Incorporating the variability of wind power with electric heat pumps. Energies 2011, 4, 1748–1762. [Google Scholar] [CrossRef]

- Rong, S.; Li, W.; Li, Z.; Sun, Y.; Zheng, T. Optimal allocation of thermal-electric decoupling systems based on the national economy by an improved conjugate gradient method. Energies 2016, 9, 17. [Google Scholar] [CrossRef]

- Hozouti, M.A.; Abbaspour, A.; Fotuhi-Firuzabad, M.; Moeini-Aghtaie, M. On the use of pumped storage for wind energy maximization in transmission-constrained power systems. IEEE Trans. Power Syst. 2015, 30, 1017–1025. [Google Scholar] [CrossRef]

- Helseth, A.; Gjelsvik, A.; Mo, B.; Ulfar, L. A model for optimal scheduling of hydro thermal systems including pumped-storage and wind power. IET Gener. Transm. Distrib. 2013, 7, 1426–1434. [Google Scholar] [CrossRef]

- Sousa, J.A.; Teixeira, F.; Faias, S. Impact of a price-maker pumped storage hydro unit on the integration of wind energy in power systems. Energy 2014, 69, 3–11. [Google Scholar] [CrossRef]

- Li, H.; Zheng, C.; Lv, S.; Liu, S.; Huo, C. Research on optimal capacity of wind power based on coordination with pumped storage power. In Proceedings of the 2016 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Xi’an, China, 25–28 October 2016; pp. 1214–1218. [Google Scholar]

- Zhang, N.; Kang, C.; Kirschen, D.S.; Xia, Q.; Xi, W.; Huang, J.; Zhang, Q. Planning pumped storage capacity for wind power integration. IEEE Trans. Sustain. Energy 2013, 4, 393–401. [Google Scholar] [CrossRef]

- Gu, Y.; McCalley, J.; Ni, M.; Bo, R. Economic modeling of compressed air energy storage. Energies 2013, 6, 2221–2241. [Google Scholar] [CrossRef]

- Cleary, B.; Duffy, A.; OConnor, A.; Conlon, M.; Fthenakis, V. Assessing the economic benefits of compressed air energy storage for mitigating wind curtailment. IEEE Trans. Sustain. Energy 2015, 6, 1021–1028. [Google Scholar] [CrossRef]

- Li, N.; Hedman, K.W. Economic assessment of energy storage in systems with high levels of renewable resources. IEEE Trans. Sustain. Energy 2015, 6, 1103–1111. [Google Scholar] [CrossRef]

- Schiebahn, S.; Grube, T.; Robinius, M.; Tietze, V.; Kumar, B.; Stolten, D. Power to gas: Technological overview, systems analysis and economic assessment for a case study in Germany. Int. J. Hydrogen Energy 2015, 40, 4285–4294. [Google Scholar] [CrossRef]

- Ancona, M.A.; Antonioni, G.; Branchini, L.; De Pascale, A.; Melino, F.; Orlandini, V.; Ferraro, M. Renewable energy storage system based on a Power-to-Gas conversion process. Energy Procedia 2016, 101, 854–861. [Google Scholar] [CrossRef]

- Yuan, R.; Ye, J.; Lei, J.; Li, T. Integrated combined heat and power system dispatch considering electrical and thermal energy storage. Energies 2016, 9, 474. [Google Scholar] [CrossRef]

- Melo, D.F.R.; Chang-Chien, L.R. Synergistic control between hydrogen storage system and offshore wind farm for grid operation. IEEE Trans. Sustain. Energy 2014, 5, 18–27. [Google Scholar] [CrossRef]

- Trifkovic, M.; Sheikhzadeh, M.; Nigim, K.; Daoutidis, P. Modeling and control of a renewable hybrid energy system with hydrogen storage. IEEE Tran. Contr. Syst. Technol. 2014, 22, 169–179. [Google Scholar] [CrossRef]

- Jannati, M.; Hosseinian, S.H.; Vahidi, B. A significant reduction in the costs of battery energy storage systems by use of smart parking lots in the power fluctuation smoothing process of the wind farms. Renew. Energy 2016, 87, 1–14. [Google Scholar] [CrossRef]

- Abdeltawab, H.H.; Mohamed, Y.A.R.I. Robust energy management of a hybrid wind and flywheel energy storage system considering flywheel power losses minimization and grid-code constraints. IEEE Trans. Ind. Electron. 2016, 63, 4242–4254. [Google Scholar] [CrossRef]

- Zhang, N.; Gu, W.; Yu, H.; Liu, W. Application of coordinated SOFC and SMES robust control for stabilizing tie-line power. Energies 2013, 6, 1902–1917. [Google Scholar] [CrossRef]

- Hossain, J.; Sakib, N.; Hossain, E.; Bayindir, R. Modelling and simulation of solar plant and storage system: A step to microgrid technology. Int. J. Renew. Energy Res. 2017, 7, 723–737. [Google Scholar]

- Rinne, S.; Syri, S. The possibilities of combined heat and power production balancing large amounts of wind power in Finland. Energy 2015, 82, 1034–1046. [Google Scholar] [CrossRef]

- Nielsen, M.G.; Morales, J.M.; Zugno, M.; Pedersen, T.E.; Madsen, H. Economic valuation of heat pumps and electric boilers in the Danish energy system. Appl. Energy 2016, 167, 189–200. [Google Scholar] [CrossRef]

- Hedegaard, K.; Mathiesen, B.V.; Lund, H.; Heiselberg, P. Wind power integration using individual heat pumps–analysis of different heat storage options. Energy 2012, 47, 284–293. [Google Scholar] [CrossRef]

- Nuytten, T.; Claessens, B.; Paredis, K.; Van Bael, J.; Six, D. Flexibility of a combined heat and power system with thermal energy storage for district heating. Appl. Energy 2013, 104, 583–591. [Google Scholar] [CrossRef]

- Yu, Y.J.; Chen, H.K.; Jiang, X.; Tao, Y.B.; Yu, R.Y. Operation strategy for heat storage tank to improve wind power integration. Autom. Electr. Power Syst. 2017, 41, 37–43. [Google Scholar]

- Liu, D.; Zhang, G.; Huang, B.; Liu, W. Optimum electric boiler capacity configuration in a regional power grid for a wind power accommodation scenario. Energies 2016, 9, 144. [Google Scholar] [CrossRef]

- Zidan, A.; Gabbar, H.A. DG mix and energy storage units for optimal planning of self-sufficient micro energy grids. Energies 2016, 9, 616. [Google Scholar] [CrossRef]

- Petrović, S.N.; Karlsson, K.B. Residential heat pumps in the future Danish energy system. Energy 2016, 114, 787–797. [Google Scholar] [CrossRef]

- Cooper, S.J.G.; Hammond, G.P.; McManus, M.C.; Pudjianto, D. Detailed simulation of electrical demands due to nationwide adoption of heat pumps, taking account of renewable generation and mitigation. IET Renew. Power Gener. 2016, 10, 380–387. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Kang, C.; O’Malley, M.; Xia, Q.; Bai, J.; Liu, C.; Li, H. Increasing the flexibility of combined heat and power for wind power integration in China: Modeling and implications. IEEE Trans. Power Syst. 2015, 30, 1848–1857. [Google Scholar] [CrossRef]

- Rong, S.; Li, Z.; Li, W. Investigation of the promotion of wind power consumption using the thermal-electric decoupling techniques. Energies 2015, 8, 8613–8629. [Google Scholar] [CrossRef]

- Wu, C.; Gu, W.; Jiang, P.; Li, Z.; Cai, H.; Li, B. Combined economic dispatch considering the time-delay of a district heating network and multi-regional indoor temperature control. IEEE Trans. Sustain. Energy 2018, 9, 118–127. [Google Scholar] [CrossRef]

- Smallbone, A.; Jülch, V.; Wardle, R.; Roskilly, A.P. Levelised cost of storage for pumped heat energy storage in comparison with other energy storage technologies. Energy Conver. Manag. 2017, 152, 221–228. [Google Scholar] [CrossRef]

- Comodi, G.; Carducci, F.; Sze, J.Y.; Balamurugan, N.; Romagnoli, A. Storing energy for cooling demand management in tropical climates: A techno-economic comparison between different energy storage technologies. Energy 2017, 121, 676–694. [Google Scholar] [CrossRef]

- Hayes, B.P.; Wilson, A.; Webster, R.; Djokic, S.Z. Comparison of two energy storage options for optimum balancing of wind farm power outputs. IET Gener. Transm. Distrib. 2016, 10, 832–839. [Google Scholar] [CrossRef]

- Blarke, M.B. Towards an intermittency-friendly energy system: Comparing electric boilers and heat pumps in distributed cogeneration. Appl. Energy 2012, 91, 349–365. [Google Scholar] [CrossRef]

- Chen, X.; Lu, X.; McElroy, M.B.; Nielsen, C.P.; Kang, C. Synergies of wind power and electrified space heating: Case study for Beijing. Environ. Sci. Technol. 2014, 48, 2016–2024. [Google Scholar] [CrossRef] [PubMed]

- Rinne, S.; Syri, S. Heat pumps versus combined heat and power production as CO2 reduction measures in Finland. Energy 2013, 57, 308–318. [Google Scholar] [CrossRef]

- Lund, P.D.; Lindgren, J.; Mikkola, J.; Salpakari, J. Review of energy system flexibility measures to enable high levels of variable renewable electricity. Renew. Sustain. Energy Rev. 2015, 45, 785–807. [Google Scholar] [CrossRef]

- Mathiesen, B.V.; Lund, H. Comparative analyses of seven technologies to facilitate the integration of fluctuating renewable energy sources. IET Renew. Power Gener. 2009, 3, 190–204. [Google Scholar] [CrossRef]

- Lu, C.; Xu, H.; Pan, X.; Song, J. Optimal sizing and control of battery energy storage system for peak load shaving. Energies 2014, 7, 8396–8410. [Google Scholar] [CrossRef]

- Christidis, A.; Koch, C.; Pottel, L.; Tsatsaronis, G. The contribution of heat storage to the profitable operation of combined heat and power plants in liberalized electricity markets. Energy 2012, 41, 75–82. [Google Scholar] [CrossRef]

- Li, P.; Wang, H.; Lv, Q.; Li, W. Combined heat and power dispatch considering heat storage of both buildings and pipelines in district heating system for wind power integration. Energies 2017, 10, 893. [Google Scholar] [CrossRef]

- Nielsen, M.G. Probabilistic Forecasting and Optimization in CHP Systems. Master’s Thesis, Technical University of Denmark, Lyngby, Denmark, 2017. [Google Scholar]

- Evans, A.; Strezov, V.; Evans, T.J. Assessment of utility energy storage options for increased renewable energy penetration. Renew. Sustain. Energy Rev. 2012, 16, 4141–4147. [Google Scholar] [CrossRef]

- Díaz-González, F.; Sumper, A.; Gomis-Bellmunt, O.; Villafáfila-Robles, R. A review of energy storage technologies for wind power applications. Renew. Sustain. Energy Rev. 2012, 16, 2154–2171. [Google Scholar] [CrossRef]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar] [CrossRef]

- Lv, Q.; Li, L.; Zhu, Q.S.; Wang, H.X.; Liu, R.; Li, W.D. Comparison of coal-saving effect and national economic indices of three feasible curtailed wind power accommodating strategies. Autom. Electr. Power Syst. 2015, 39, 75–83. [Google Scholar]

| Parameters | PHS | CAES | HES | HS | EB | HP |

|---|---|---|---|---|---|---|

| Energy Efficiency | 85% | 71% | 42% | 99% | 98% | 3.5 (COP) 1 |

| Life Time | 50 years | 40 years | 15 years | 50 years | 20 years | 20 years |

| Maintenance Cost Ratio 2 | 0.9% | 0.46% | 1% | 0.5% | 0.5% | 1% |

| Unit Cost | 79 $/kWh | 46 $/kWh | 151 $/kWh | 5.8 $/kWh | 150 $/kW | 870 $/kW |

| References | [49,50,51] | [49,50,51] | [50,51] | [25,52] | [44,52] | [25,30,44] |

| Items | Ccoal | Ccarbon | α | Pcoal | Qcoal | r | D | k_av |

|---|---|---|---|---|---|---|---|---|

| Data | 120 $/ton | 4 $/ton | 2.66 | 330 kg/MWh | 153 kg/MWh | 6% | 365 | 0.48 |

| Parameters | PHS | CAES | HES | HS | EB | HP |

|---|---|---|---|---|---|---|

| Energy Efficiency | 65–85% | 60–80% | 40–60% | 95–99% | 75–98% | 2.5–3.5 (COP) |

| Proportion 1 | 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% |

|---|---|---|---|---|---|---|---|---|---|---|

| HP Benefit/k$ | 8.38 | 16.76 | 25.02 | 33.22 | 41.42 | 49.61 | 57.58 | 65.24 | 72.54 | 78.33 |

| CAES&HP Benefit/k$ | 7.95 | 15.90 | 23.78 | 31.57 | 39.36 | 47.15 | 54.85 | 62.44 | 69.64 | 76.62 |

| HS&HP Benefit/k$ | 8.30 | 16.61 | 24.85 | 32.99 | 41.13 | 49.27 | 57.33 | 65.27 2 | 72.89 | 80.48 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Chen, H.; Chen, L. Comparative Study of Electric Energy Storages and Thermal Energy Auxiliaries for Improving Wind Power Integration in the Cogeneration System. Energies 2018, 11, 263. https://doi.org/10.3390/en11020263

Yu Y, Chen H, Chen L. Comparative Study of Electric Energy Storages and Thermal Energy Auxiliaries for Improving Wind Power Integration in the Cogeneration System. Energies. 2018; 11(2):263. https://doi.org/10.3390/en11020263

Chicago/Turabian StyleYu, Yanjuan, Hongkun Chen, and Lei Chen. 2018. "Comparative Study of Electric Energy Storages and Thermal Energy Auxiliaries for Improving Wind Power Integration in the Cogeneration System" Energies 11, no. 2: 263. https://doi.org/10.3390/en11020263