Cyclic CH4 Injection for Enhanced Oil Recovery in the Eagle Ford Shale Reservoirs

Abstract

:1. Introduction

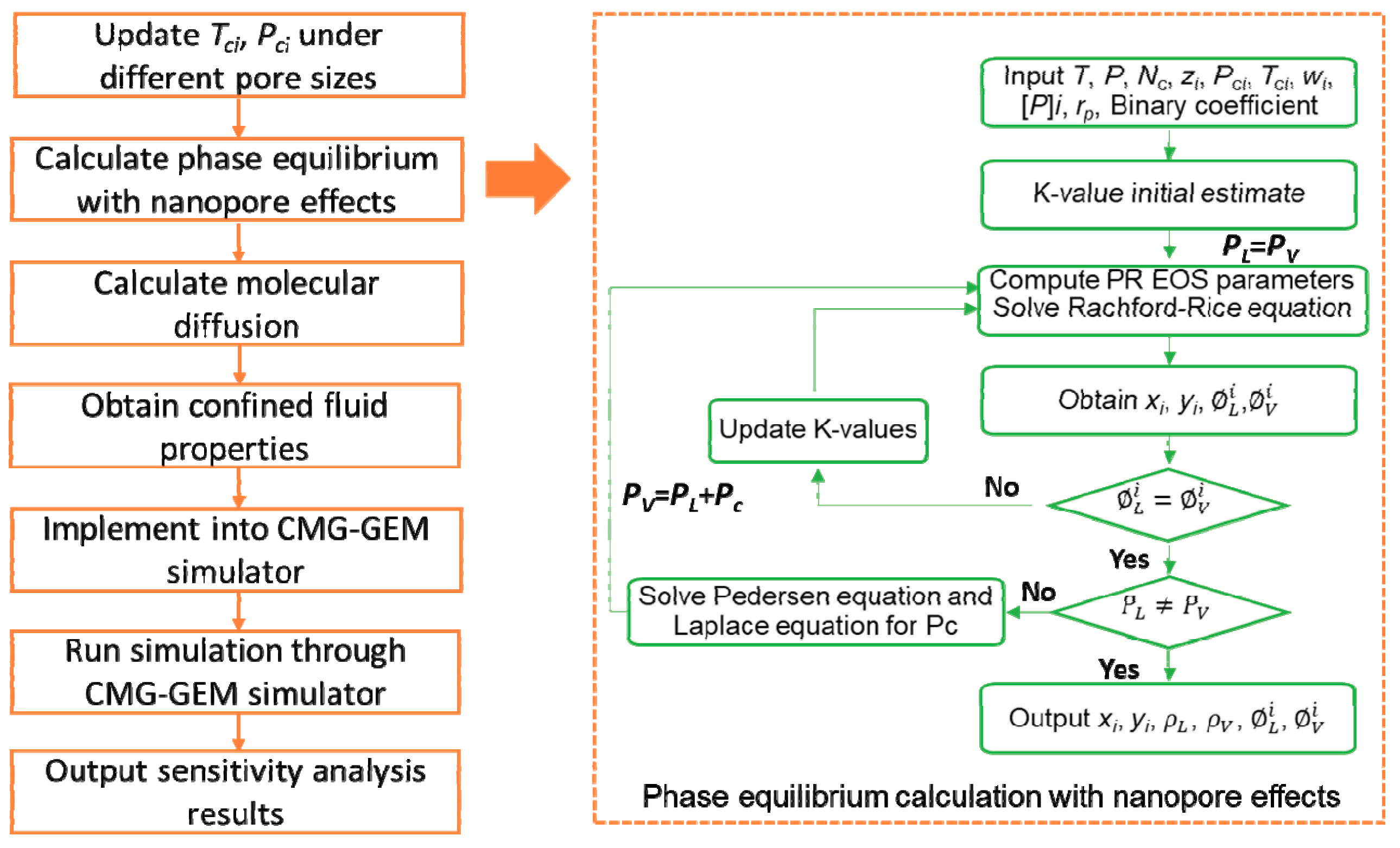

2. Methodology

2.1. Shifts of Critical Properties

2.2. Phase Equilibrium Calculation Considering Nanopore Confinement

3. Base Case

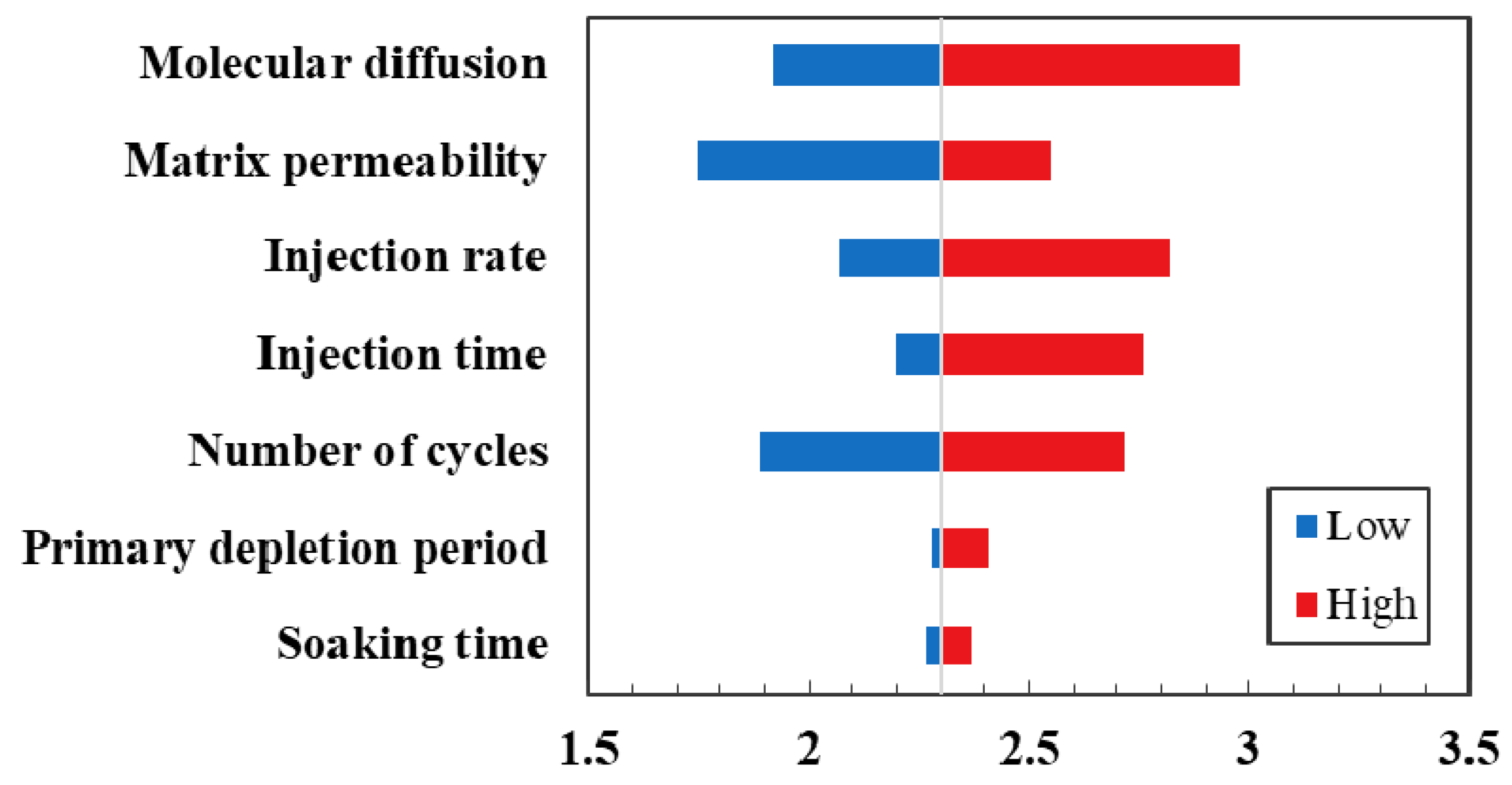

4. Results and Discussions

4.1. Effect of Confinement in Nanopores

4.2. Molecular Diffusion

4.3. Effect of Primary Depletion Period

4.4. Effect of Injection Rate

4.5. Effect of Injection Time

4.6. Effect of Soaking Time

4.7. Effect of Number of Cycles

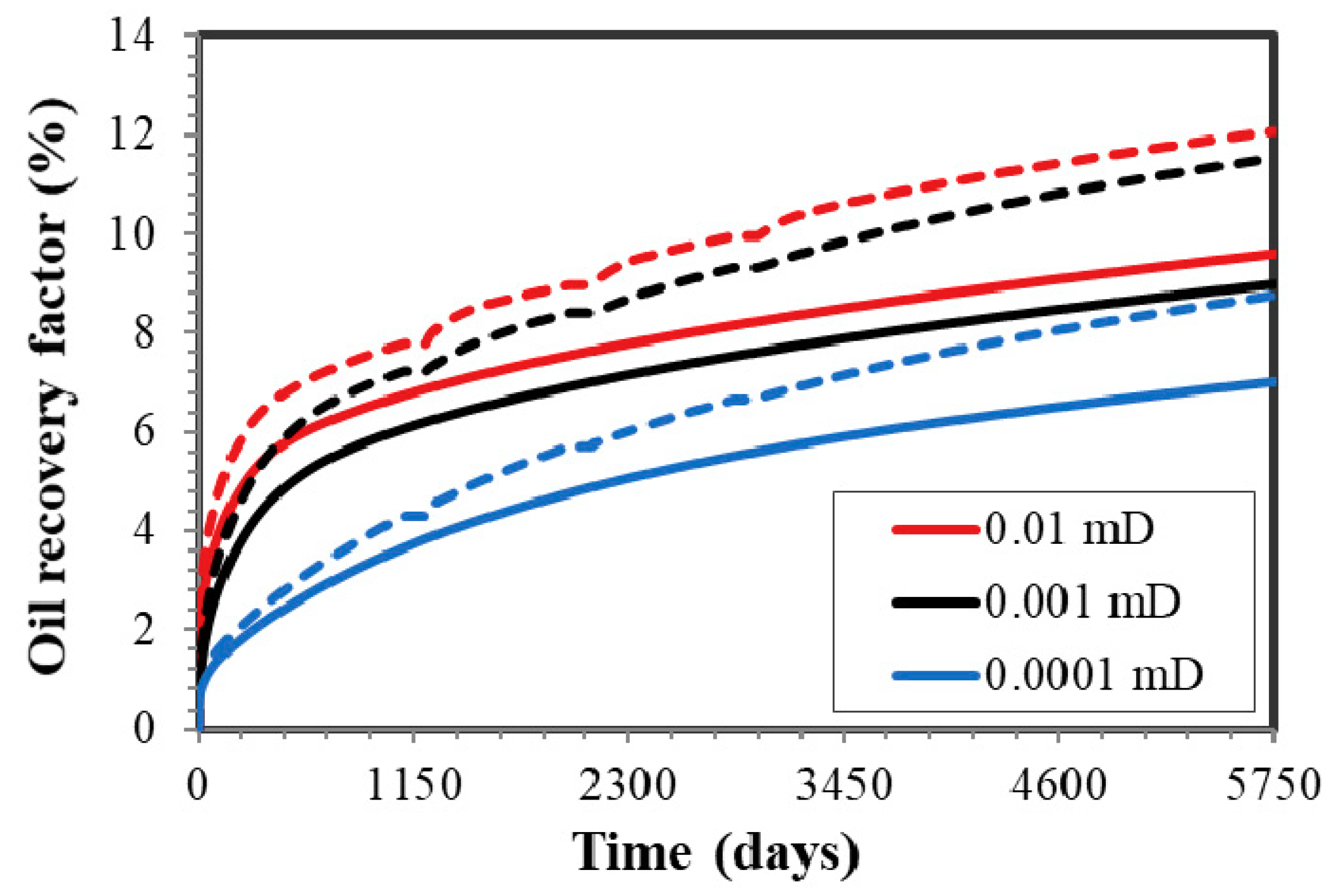

4.8. Effect of Matrix Permeability

5. Conclusions

- (1)

- The effect of confinement in the nanopores is a significant factor in the simulation model to capture the real mechanism during the cyclic CH4 injection;

- (2)

- A series of simulations were performed to evaluate the impacts of key parameters on the process of enhanced oil recovery, concluding that molecular diffusion is the most sensitive, followed by matrix permeability, injection rate, injection time, and number of cycles;

- (3)

- The impacts of primary depletion period and soaking time are less favorable for the cyclic CH4 injection process;

- (4)

- This work provides a better understanding of factors affecting the efficiency of cyclic CH4 injection, which can hopefully guide the operations in the shale reservoir.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Salahshoor, S.; Fahes, M.; Teodoriu, C. A review on the effect of confinement on phase behavior in tight formations. J. Nat. Gas Sci. Eng. 2018, 51, 89–103. [Google Scholar] [CrossRef]

- Mullen, J. Petrophysical characterization of the Eagle Ford shale in South Texas. In Proceedings of the Canadian Unconventional Resources & International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Shelley, R.F.; Saugier, L.D.; Al-Tailji, W.; Guliyev, N.; Shah, K. Understanding hydraulic fracture stimulated horizontal Eagle Ford completions. In Proceedings of the SPE/EAGE European Unconventional Resources Conference and Exhibition, Vienna, Austria, 20–22 March 2012. [Google Scholar]

- Zhang, L.; Kou, Z.; Wang, H.; Zhao, Y.; Dejam, M.; Guo, J.; Du, J. Performance analysis for a model of a multi-wing hydraulically fractured vertical well in a coalbed methane gas reservoir. J. Pet. Sci. Eng. 2018, 166, 104–120. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Semi-analytical solution for pressure transient analysis of a hydraulically fractured vertical well in a bounded dual-porosity reservoir. J. Hydrol. 2018, 565, 289–301. [Google Scholar] [CrossRef]

- Xu, Z.H.; Zhao, P.Q.; Wang, Z.L.; Ostadhassan, M.; Pan, Z.H. Characterization and consecutive prediction of pore structures in tight oil reservoirs. Energies 2018, 11, 2705. [Google Scholar] [CrossRef]

- Qian, K.; Yang, S.L.; Dou, H.E.; Wang, Q.; Wang, L.; Huang, Y. Experimental investigation on microscopic residual oil distribution during CO2 Huff-and-Puff process in tight oil reservoirs. Energies 2018, 11, 2843. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Pre-Darcy flow in porous media. Water Resour. Res. 2017, 53, 8187–8210. [Google Scholar] [CrossRef]

- Dejam, M.; Hassanzadeh, H.; Chen, Z. Pre-Darcy flow in tight and shale formations. In Proceedings of the 70th Annual Meeting of the APS (American Physical Society) Division of Fluid Dynamics, Denver, CO, USA, 19–21 November 2017. [Google Scholar]

- Hawthorne, S.B.; Gorecki, C.D.; Sorensen, J.A.; Steadman, E.N.; Harju, A.J.; Melzer, S. Hydrocarbon mobilization mechanisms from upper, middle, and lower Bakken reservoir rocks exposed to CO2. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 5–7 November 2013. [Google Scholar]

- Ren, B.; Ren, S.; Zhang, L.; Chen, G.; Zhang, H. Monitoring on CO2 migration in a tight oil reservoir during CCS-EOR in Jilin Oilfield China. Energy 2016, 98, 108–121. [Google Scholar] [CrossRef]

- Sheng, J.J. Critical review of field EOR projects in shale and tight reservoirs. J. Pet. Sci. Eng. 2017, 159, 654–665. [Google Scholar] [CrossRef]

- Wang, X.; Luo, P.; Er, V.; Huang, S.S. Assessment of CO2 flooding potential for Bakken Formation, Saskatchewan. In Proceedings of the Canadian Unconventional Resources & International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Sanchez-Rivera, D.; Mohanty, K.; Balhoff, M. Reservoir simulation and optimization of Huff-n-Puff operations in the Bakken shale. Fuel 2015, 147, 82–94. [Google Scholar] [CrossRef]

- Alfarge, D.; Wei, M.; Bai, B. Feasibility of CO2-EOR in shale-oil reservoirs: Numerical simulation study and pilot tests. In Proceedings of the Carbon Management Technology Conference, Houston, TX, USA, 17–20 July 2017. [Google Scholar]

- Meng, X.; Yu, Y.; Sheng, J.J.; Watson, M.; Mody, F. An experimental study on huff-n-puff gas injection to enhance condensate recovery in shale gas reservoirs. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015. [Google Scholar]

- Shi, R.; Kantzas, A. Enhanced heavy oil recovery on depleted long core system by CH4 and CO2. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 20–23 October 2008. [Google Scholar]

- Gamadi, T.D.; Elldakli, F.; Sheng, J.J. Compositional simulation evaluation of EOR potential in shale oil reservoirs by cyclic natural gas injection. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 25–27 August 2014. [Google Scholar]

- Shen, Z.; Sheng, J.J. Experimental study of asphaltene aggregation during CO2 and CH4 injection in shale oil reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Sigmund, P.M.; Dranchuk, P.M.; Morrow, N.R.; Purvis, R.A. Retrograde condensation in porous media. SPE J. 1973, 13, 93–104. [Google Scholar] [CrossRef]

- Brusilovsky, A.I. Mathematical simulation of phase behavior of natural multicomponent systems at high pressures with an equation of state. SPE Res. Eng. 1992, 7, 117–122. [Google Scholar] [CrossRef]

- Du, L.; Chu, L. Understanding anomalous phase behavior in unconventional oil reservoirs. In Proceedings of the SPE Canadian Unconventional Resources Conference, Calgary, AB, Canada, 30 October–1 November 2012. [Google Scholar]

- Nojabaei, B.; Johns, R.T.; Chu, L. Effect of capillary pressure on phase behavior in tight rocks and shales. SPE Res. Eval. Eng. 2013, 16, 281–289. [Google Scholar] [CrossRef]

- Sanaei, A.; Jamili, A.; Callard, J.; Mathur, A. Production modeling in the Eagle Ford gas condensate window: Integrating new relationships between core permeability, pore size, and confined PVT properties. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 16–18 April 2014. [Google Scholar]

- Zhang, Y.; Lashgari, H.R.; Di, Y.; Sepehrnoori, K. Capillary pressure effect on hydrocarbon phase behavior in unconventional reservoirs. In Proceedings of the SPE Low Perm Symposium, Denver, CO, USA, 5–6 May 2016. [Google Scholar]

- Wang, L.; Parsa, E.; Gao, Y.; Ok, J.T.; Neeves, K.; Yin, X.; Ozkan, E. Experimental study and modeling of the effect of nanoconfinement on hydrocarbon phase behavior in unconventional reservoirs. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 16–18 April 2014. [Google Scholar]

- Yang, G.; Fan, Z.; Li, X. Determination of confined fluid phase behavior using modified Peng-Robinson equation of state. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar]

- Luo, S.; Nasrabadi, H.; Lutkenhaus, J.L. Effect of confinement on the bubble points of hydrocarbons in nanoporous media. AIChE J. 2016, 62, 1772–1780. [Google Scholar] [CrossRef]

- Alfi, M.; Nasrabadi, H.; Banerjee, D. Effect of confinement on bubble point temperature shift of hydrocarbon mixtures: Experimental investigation using nanofluidic devices. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar]

- Yu, W.; Lashgari, H.R.; Wu, K.; Sepehrnoori, K. CO2 injection for enhanced oil recovery in Bakken tight oil reservoirs. Fuel 2015, 159, 354–363. [Google Scholar] [CrossRef]

- Du, X.D.; Gu, M.; Duan, S.; Xian, X.F. Investigation of CO2–CH4 displacement and transport in shale for enhanced shale gas recovery and CO2 sequestration. J. Energy Resour. Technol. 2017, 139, 012909. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, W.; Li, Z.; Sepehrnoori, K. Simulation study of factors affecting CO2 Huff-n-Puff process in tight oil reservoirs. J. Pet. Sci. Eng. 2018, 163, 264–269. [Google Scholar] [CrossRef]

- Wu, K.; Li, X.; Guo, C.; Wang, C.; Chen, Z. A unified model for gas transfer in nanopores of shale-gas reservoirs: Coupling pore diffusion and surface diffusion. SPE J. 2016, 21, 1583–1611. [Google Scholar] [CrossRef]

- Chen, C.; Gu, M. Investigation of cyclic CO2 huff-and-puff recovery in shale oil reservoirs using reservoir simulation and sensitivity analysis. Fuel 2017, 188, 102–111. [Google Scholar] [CrossRef]

- Simpson, M.D.; Patterson, R.; Wu, K. Study of stress shadow effects in Eagle Ford Shale: Insight from field data analysis. In Proceedings of the 50th U.S. Rock Mechanics/Geomechanics Symposium, American Rock Mechanics Association, Houston, TX, USA, 26–29 June 2016. [Google Scholar]

- Singh, S.K.; Sinha, A.; Deo, G.; Singh, J.K. Vapor-liquid phase coexistence, critical properties, and surface tension of confined alkanes. J. Phys. Chem. C 2009, 113, 7170–7180. [Google Scholar] [CrossRef]

- Jin, L.C.; Ma, Y.X.; Jamili, A. Investigating the effect of pore proximity on phase behavior and fluid properties in shale formations. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Campos, M.D.; Akkutlu, I.Y.; Sigal, R.F. A molecular dynamics study on natural gas solubility enhancement in water confined to small pores. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Devegowda, D.; Sapmanee, K.; Civan, F.; Sigal, R.F. Phase behavior of gas condensates in shales due to pore proximity effects: Implications for transport, reserves and well productivity. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Zarragoicoechea, G.J.; Kuz, V.A. Critical shift of a confined fluid in a nanopore. Fluid Phase Equilib. 2004, 220, 7–9. [Google Scholar] [CrossRef]

- Adamson, A.W. Capillarity. In Physical Chemistry of Surfaces, 5th ed.; John Wiley & Sons: New York City, NY, USA, 1990. [Google Scholar]

- Pedersen, K.S.; Christensen, P.L. Flash and phase envelope calculations. In Phase Behavior of Petroleum Reservoir Fluids, 1st ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2006. [Google Scholar]

- Peng, D.Y.; Robinson, D.B. A new two-constant equation of state. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- CMG. GEM-GEM User’s Guide; Computer Modeling Group Ltd.: Calgary, AB, Canada, 2012. [Google Scholar]

- Condon, S.M.; Dyman, T.S. Geologic Assessment of Undiscovered Conventional Oil and Gas Resources in the Upper Cretaceous Navarro and Taylor Groups, Western Gul Province; Texas: USGS Digital Data Series; USGU: Reston, VG, USA, 2006. [Google Scholar]

- Mohebbinia, S.; Wong, T. Molecular diffusion calculations in simulation of gasfloods in fractured reservoirs. In Proceedings of the SPE Reservoir Simulation Conference, Montgomery, AL, USA, 20–22 February 2017. [Google Scholar]

- Orangi, A.; Nagarajan, N.R.; Honarpour, M.M.; Rosenzweig, J.J. Unconventional shale oil and gas-condensate reservoir production, impact of rock, fluid, and hydraulic fractures. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 24–26 January 2011. [Google Scholar]

| Properties | Value | Unit |

|---|---|---|

| Initial reservoir pressure | 8125 | psi |

| Reservoir temperature | 270 | °F |

| Reservoir thickness | 100 | ft |

| Water saturation | 17% | - |

| Porosity | 12% | - |

| Average matrix permeability | 0.001 | mD |

| Fracture half-length | 210 | ft |

| Fracture spacing | 80 | ft |

| Components | Mole Fraction (%) | Critical Temperature (K) | Critical Pressure (atm) | Acentric Factor | Molecular Weight (g/mol) |

|---|---|---|---|---|---|

| CO2 | 1.18 | 304.20 | 72.8 | 0.225 | 44.01 |

| N2 | 0.16 | 126.20 | 33.5 | 0.040 | 28.01 |

| CH4 | 11.54 | 190.60 | 45.4 | 0.008 | 16.04 |

| C2-nC5 | 26.44 | 274.74 | 36.5 | 0.172 | 52.02 |

| C6-C10 | 38.09 | 438.68 | 25.1 | 0.284 | 103.01 |

| C11+ | 22.59 | 740.29 | 17.5 | 0.672 | 267.15 |

| Component | CO2 | N2 | CH4 | C2-nC5 | C6-C10 | C11+ |

|---|---|---|---|---|---|---|

| CO2 | 0 | −0.020 | 0.1030 | 0.1299 | 0.1500 | 0.1500 |

| N2 | −0.020 | 0 | 0.0310 | 0.0820 | 0.1200 | 0.1200 |

| CH4 | 0.1030 | 0.0310 | 0 | 0.0174 | 0.0462 | 0.1110 |

| C2-nC5 | 0.1299 | 0.0820 | 0.0174 | 0 | 0.0073 | 0.0444 |

| C6-C10 | 0.1500 | 0.1200 | 0.0462 | 0.0073 | 0 | 0.0162 |

| C11+ | 0.1500 | 0.1200 | 0.1110 | 0.0444 | 0.0162 | 0 |

| Components | Critical Temperatures (K) | Critical Pressures (Bar) | ||||||

|---|---|---|---|---|---|---|---|---|

| Bulk | 15 nm | 10 nm | 5 nm | Bulk | 15 nm | 10 nm | 5 nm | |

| CO2 | 304.2 | 296.7 | 293.1 | 282.2 | 73.8 | 72.0 | 71.1 | 68.4 |

| N2 | 126.2 | 123.2 | 121.7 | 117.4 | 33.9 | 33.1 | 32.7 | 31.6 |

| CH4 | 190.6 | 185.9 | 183.6 | 176.8 | 46.0 | 44.9 | 44.3 | 42.7 |

| C2-nC5 | 274.7 | 266.6 | 262.5 | 250.6 | 37.0 | 35.9 | 35.3 | 33.7 |

| C6-C10 | 438.7 | 421.4 | 413.0 | 388.1 | 25.4 | 24.4 | 24.0 | 22.5 |

| C11+ | 740.3 | 701.4 | 682.4 | 627.0 | 17.7 | 16.8 | 16.3 | 15.0 |

| Parameters | Minimum | Medium | Maximum |

|---|---|---|---|

| Molecular diffusion/cm2/s | 0.0001 | 0.001 | 0.01 |

| Primary depletion period/year | 2 | 3 | 5 |

| Injection time/day | 30 | 60 | 90 |

| Injection rate, Mscf/day | 2000 | 5000 | 8000 |

| Soaking time/day | 30 | 60 | 90 |

| Number of cycles | 1 | 3 | 5 |

| Matrix permeability, mD | 0.001 | 0.01 | 0.1 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Di, Y.; Shi, Y.; Hu, J. Cyclic CH4 Injection for Enhanced Oil Recovery in the Eagle Ford Shale Reservoirs. Energies 2018, 11, 3094. https://doi.org/10.3390/en11113094

Zhang Y, Di Y, Shi Y, Hu J. Cyclic CH4 Injection for Enhanced Oil Recovery in the Eagle Ford Shale Reservoirs. Energies. 2018; 11(11):3094. https://doi.org/10.3390/en11113094

Chicago/Turabian StyleZhang, Yuan, Yuan Di, Yang Shi, and Jinghong Hu. 2018. "Cyclic CH4 Injection for Enhanced Oil Recovery in the Eagle Ford Shale Reservoirs" Energies 11, no. 11: 3094. https://doi.org/10.3390/en11113094