Research on a Novel Hydraulic/Electric Synergy Bus

Abstract

:1. Introduction

- (1)

- When the vehicle is running, energy can be converted both from thermal to electric or thermal to hydraulic;

- (2)

- When the vehicle is running, energy can be converted bi-directionally between electric and hydraulic.

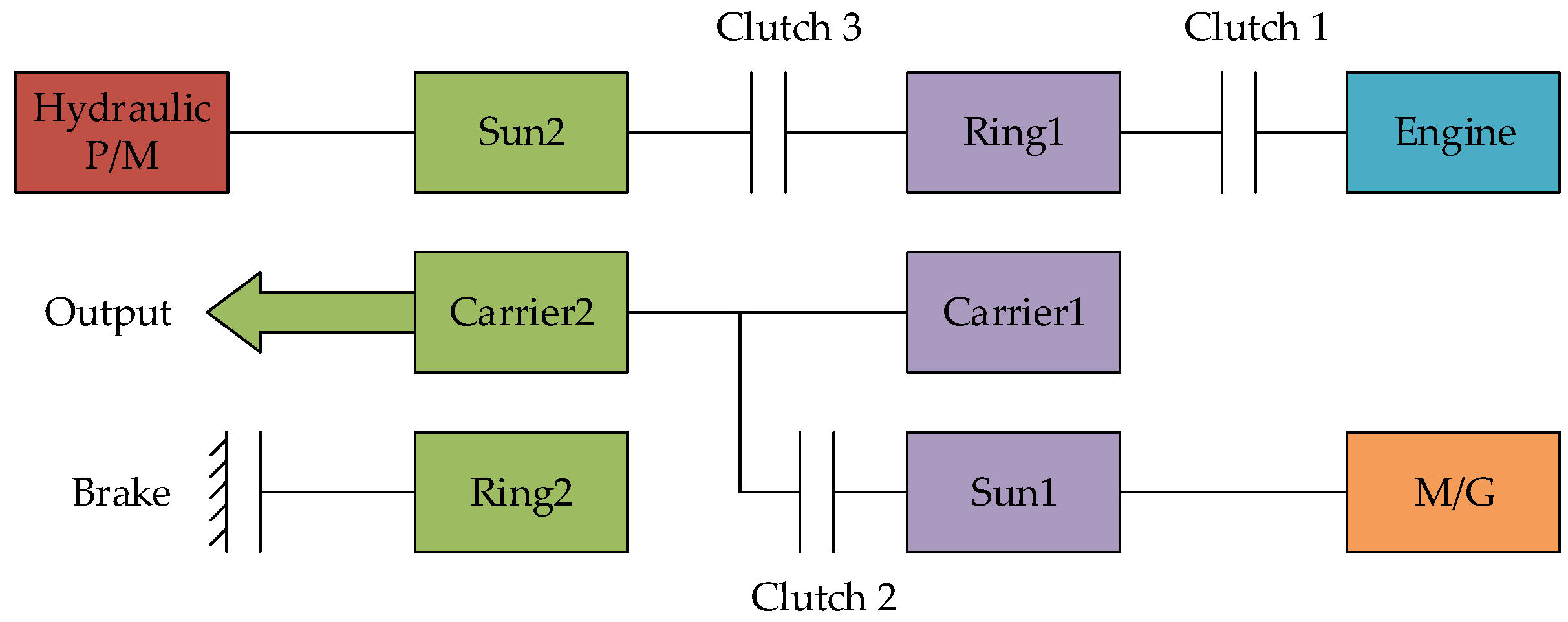

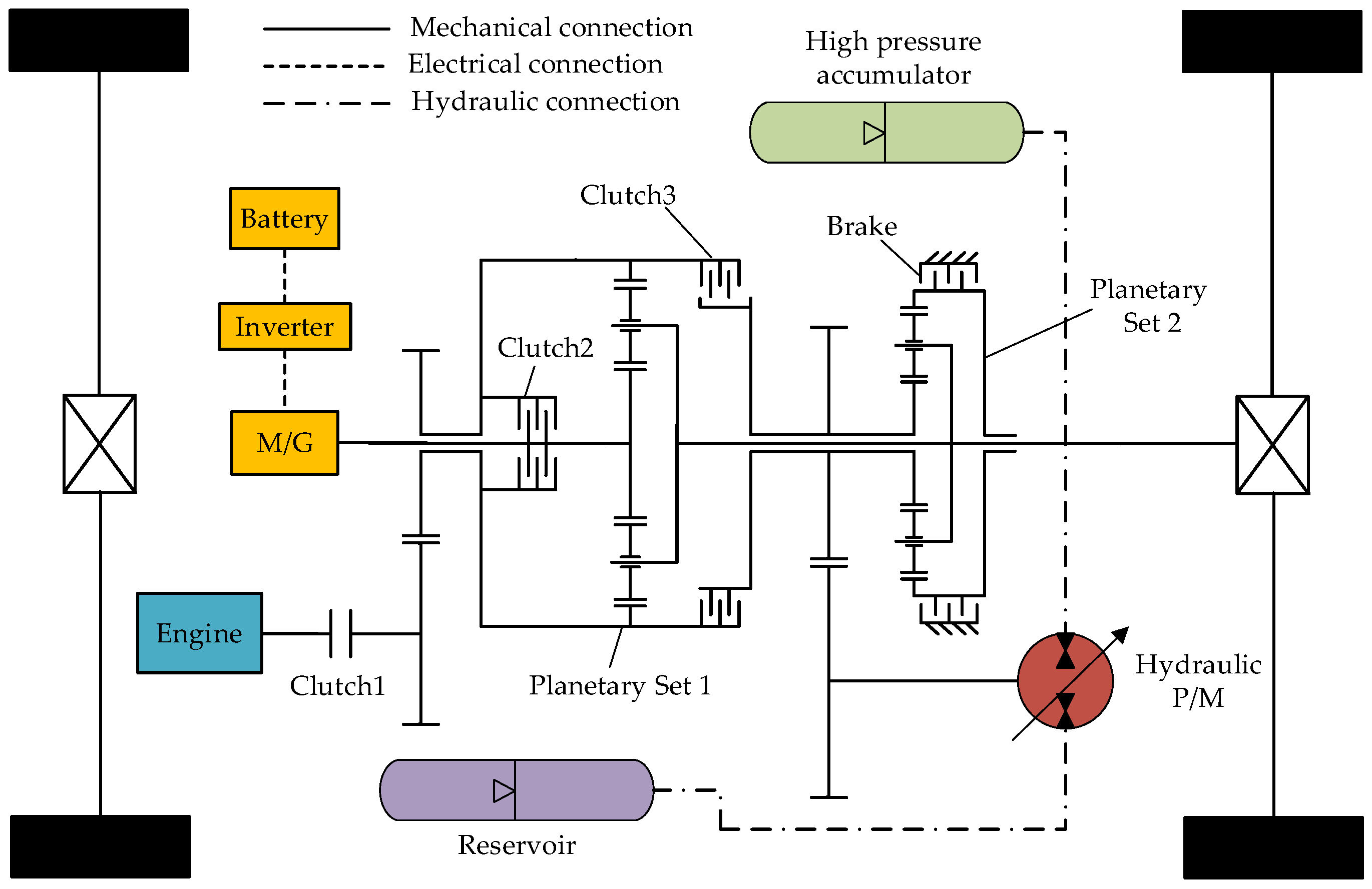

2. The Novel Hydraulic/Electric Synergy Powertrain

2.1. Start-Up Conditions

2.2. Urban Conditions

2.3. High-Speed Conditions

2.4. Braking Conditions

2.5. Parking Conditions

3. Dynamic Parameter Matching

3.1. Target Vehicle

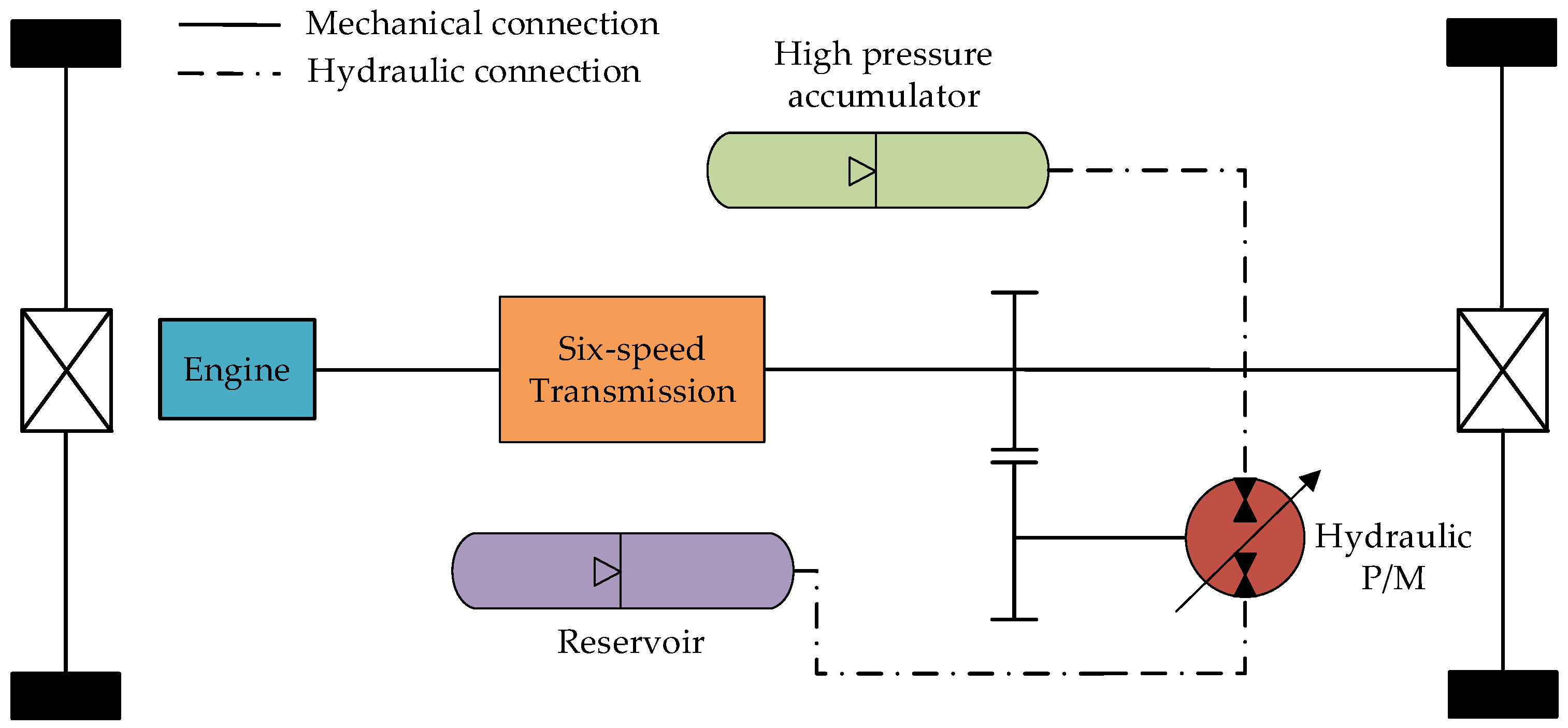

3.2. Hydraulic Hybrid Vehicle

3.3. Hybrid Electric Vehicle

3.4. Hydraulic/Electric Synergy Vehicle

3.5. Comparison of Dynamic Performance

4. Modeling

4.1. Engine

4.2. Electric System

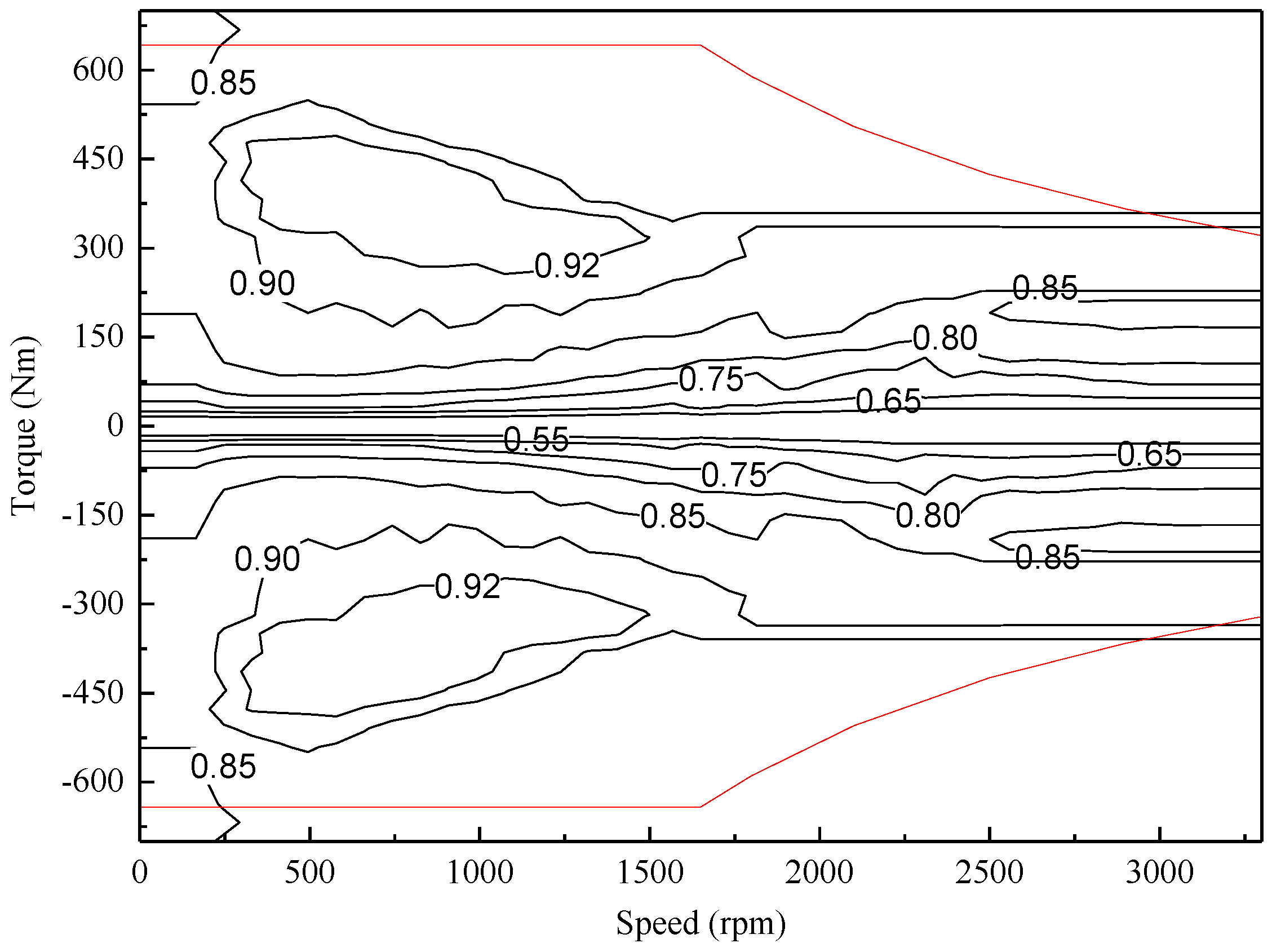

4.3. Hydraulic System

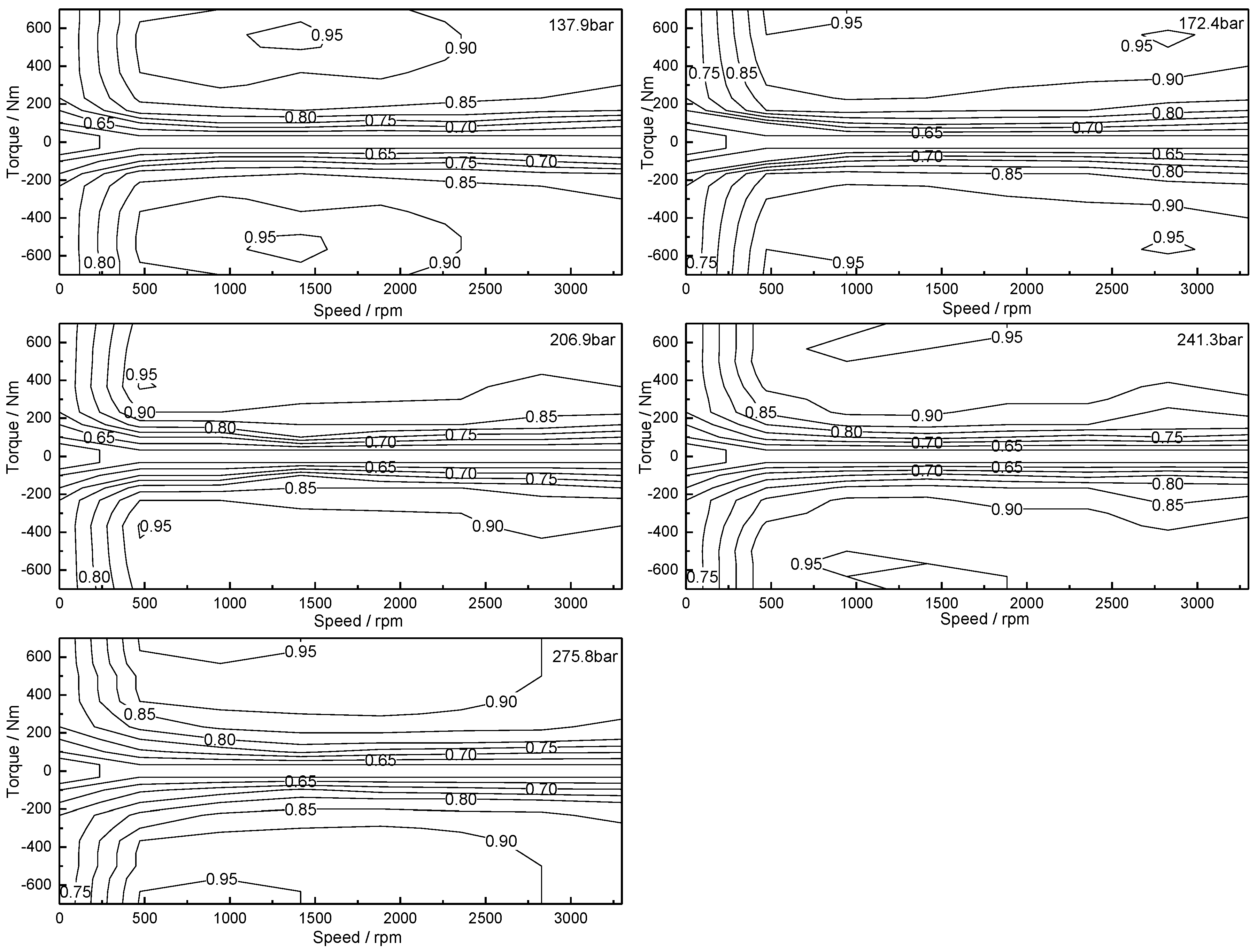

4.4. Transmission Components

4.5. Vehicle Dynamics

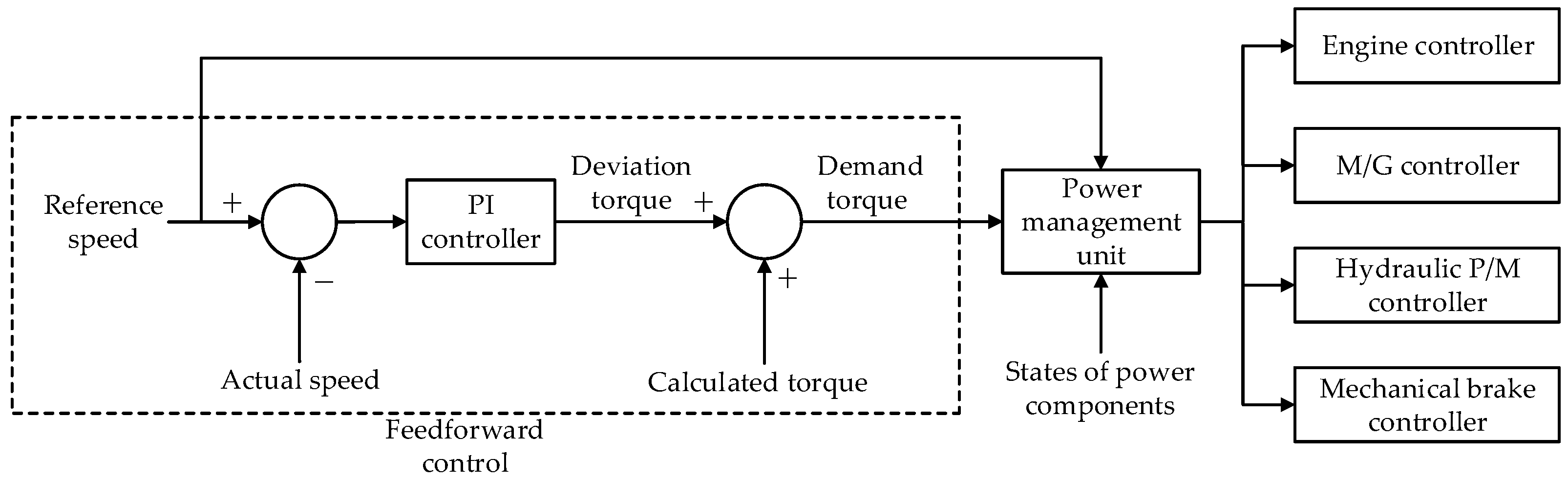

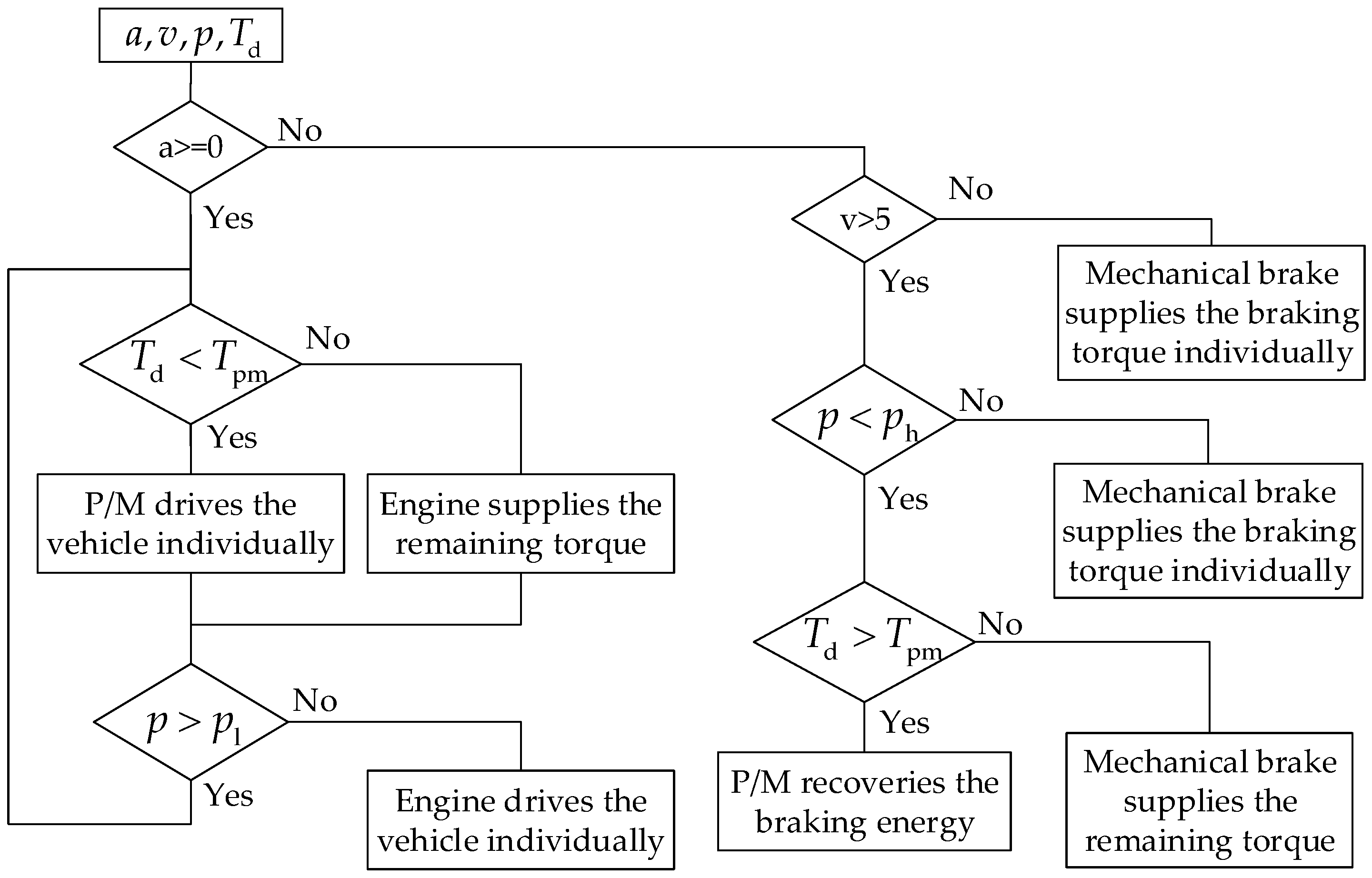

5. Control Strategy

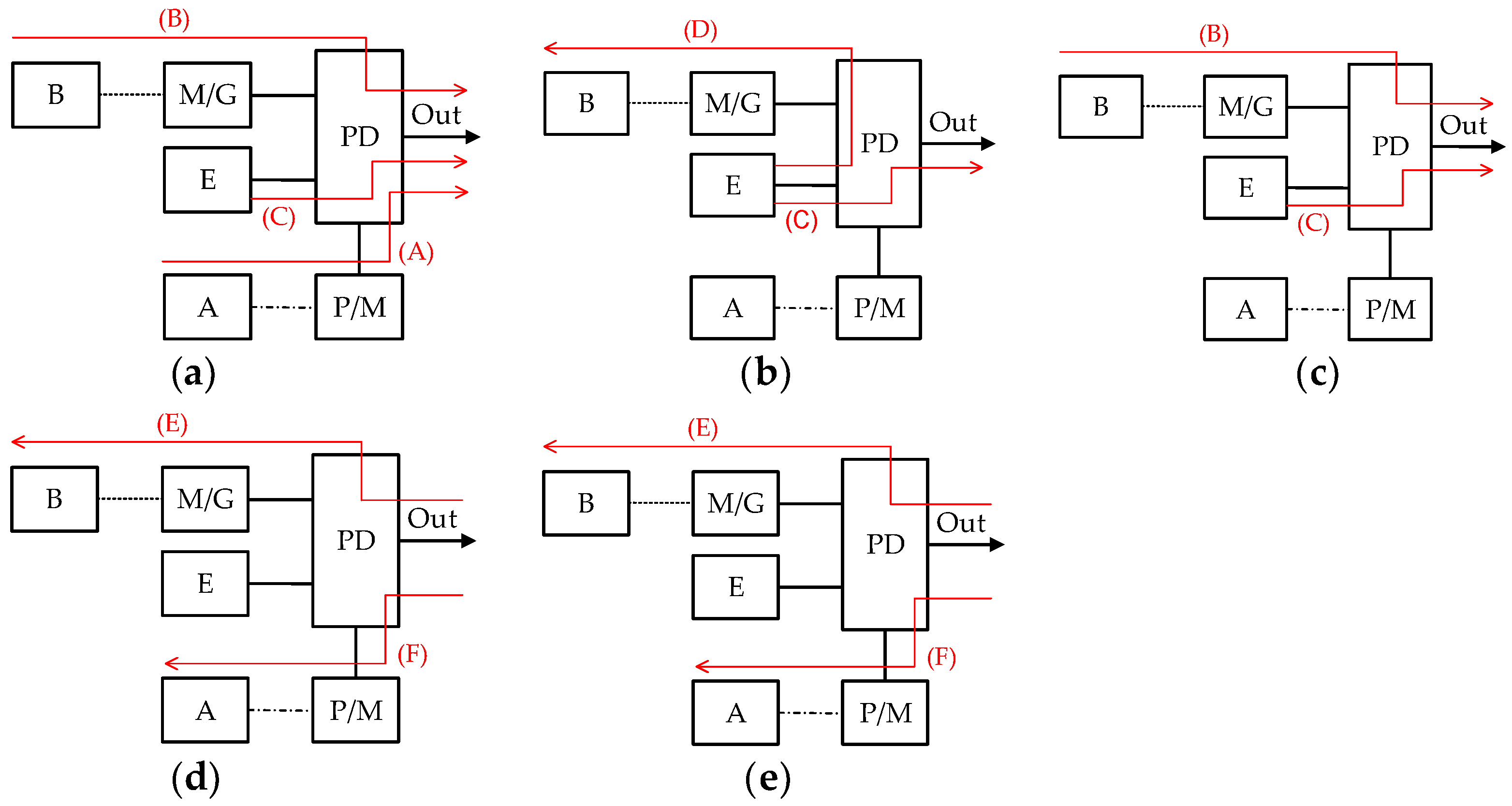

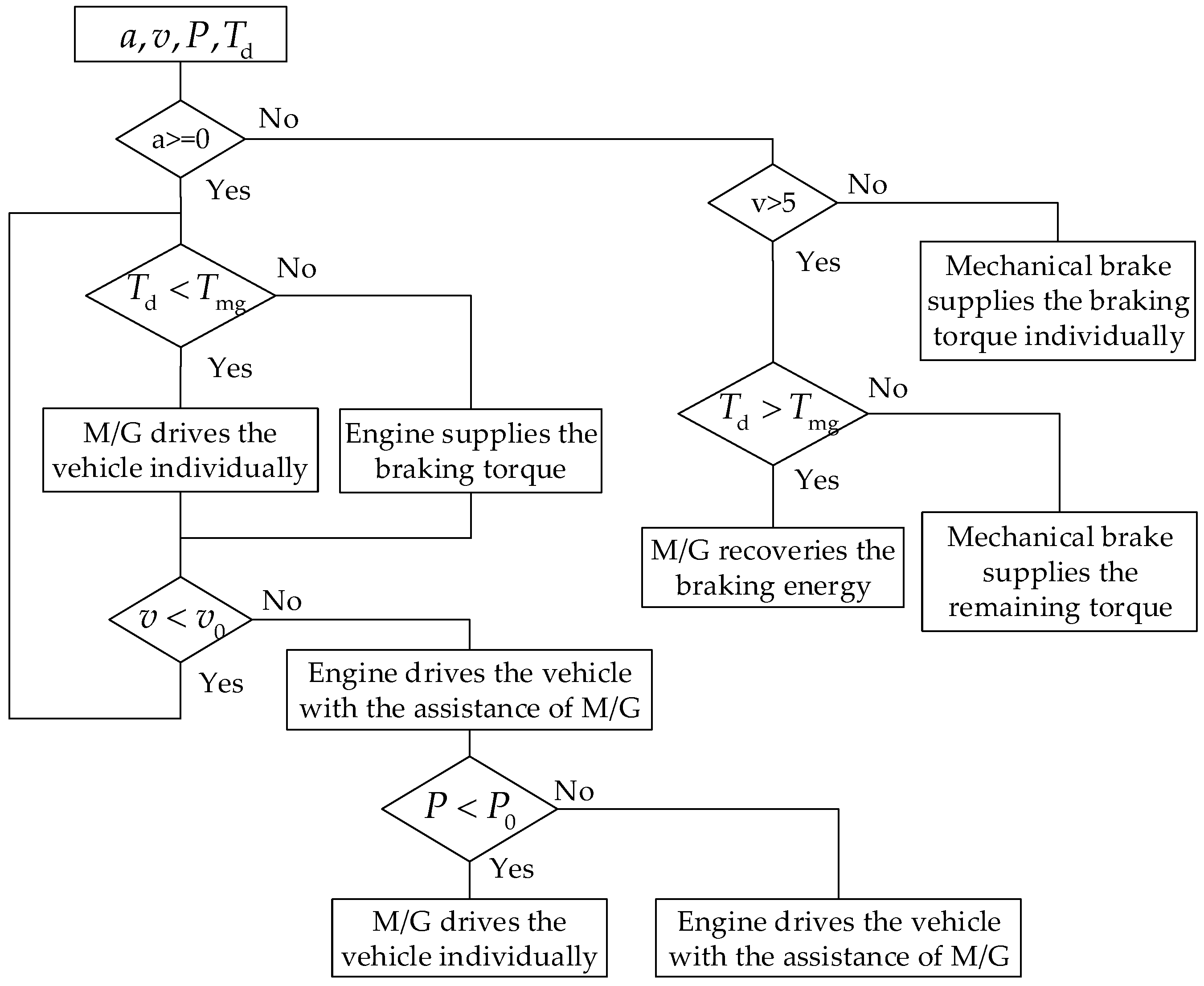

5.1. Power Management Strategy of the HHV

5.2. Power Management Strategy of the HEV

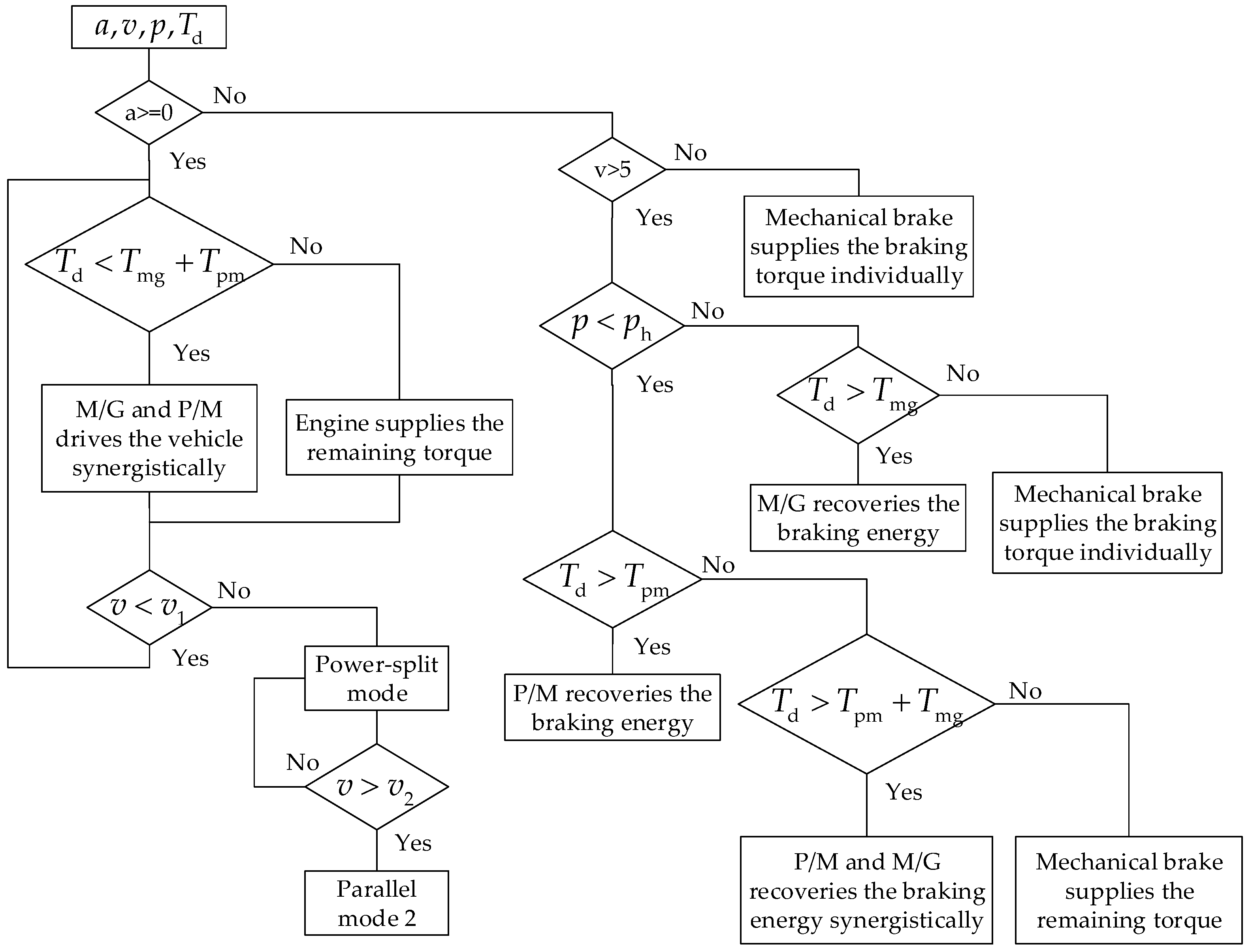

5.3. Power Management Strategy of the HESV

6. Simulation Results

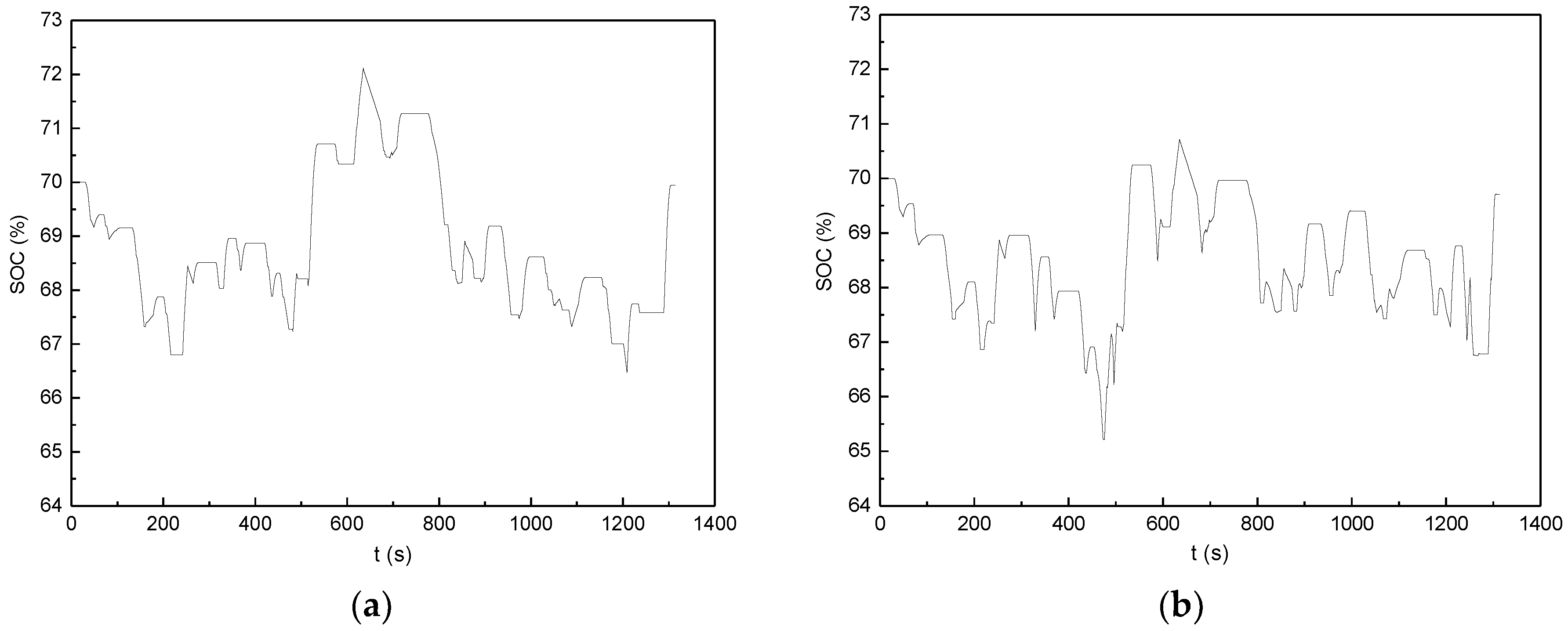

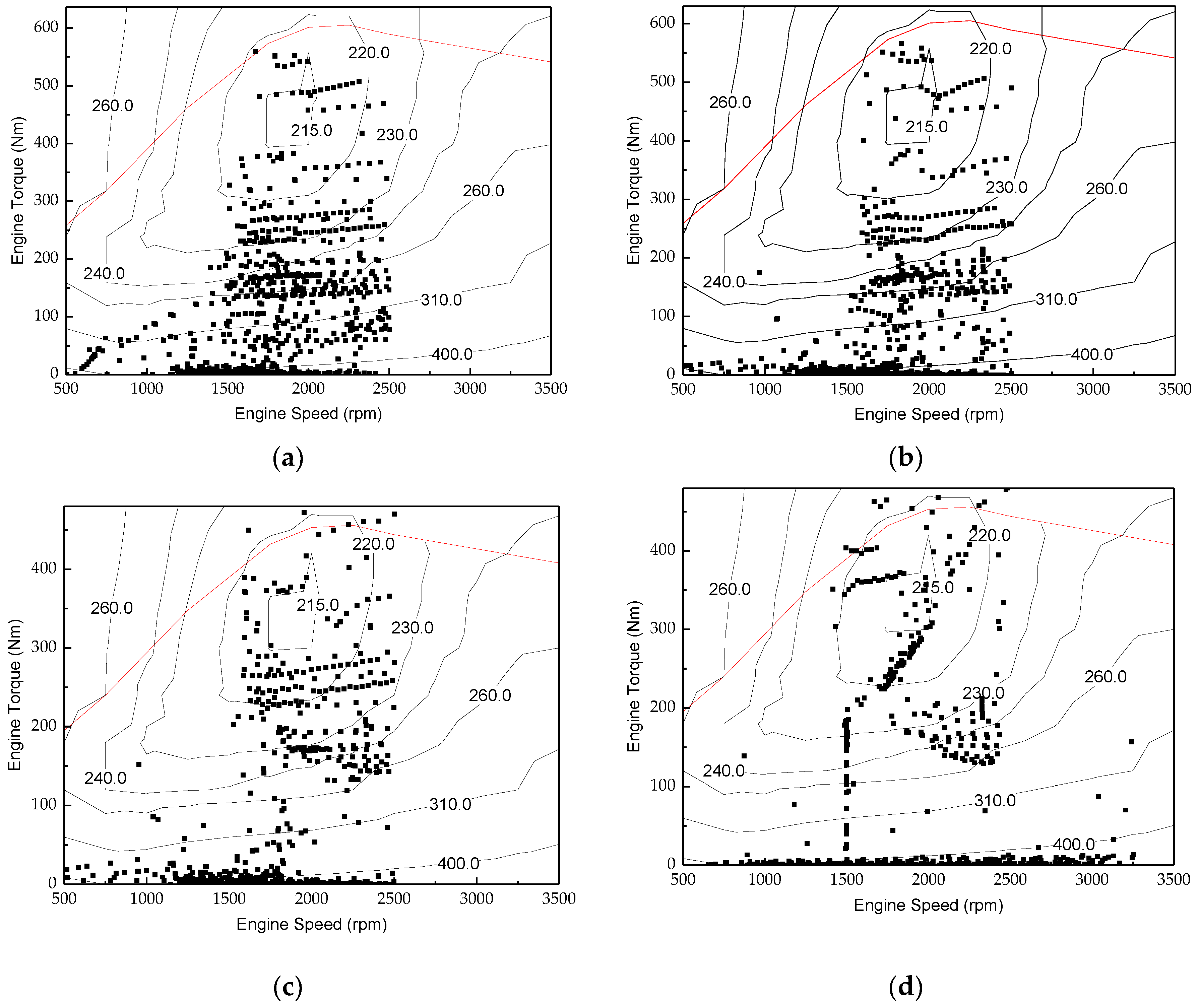

6.1. Fuel Economy Analysis

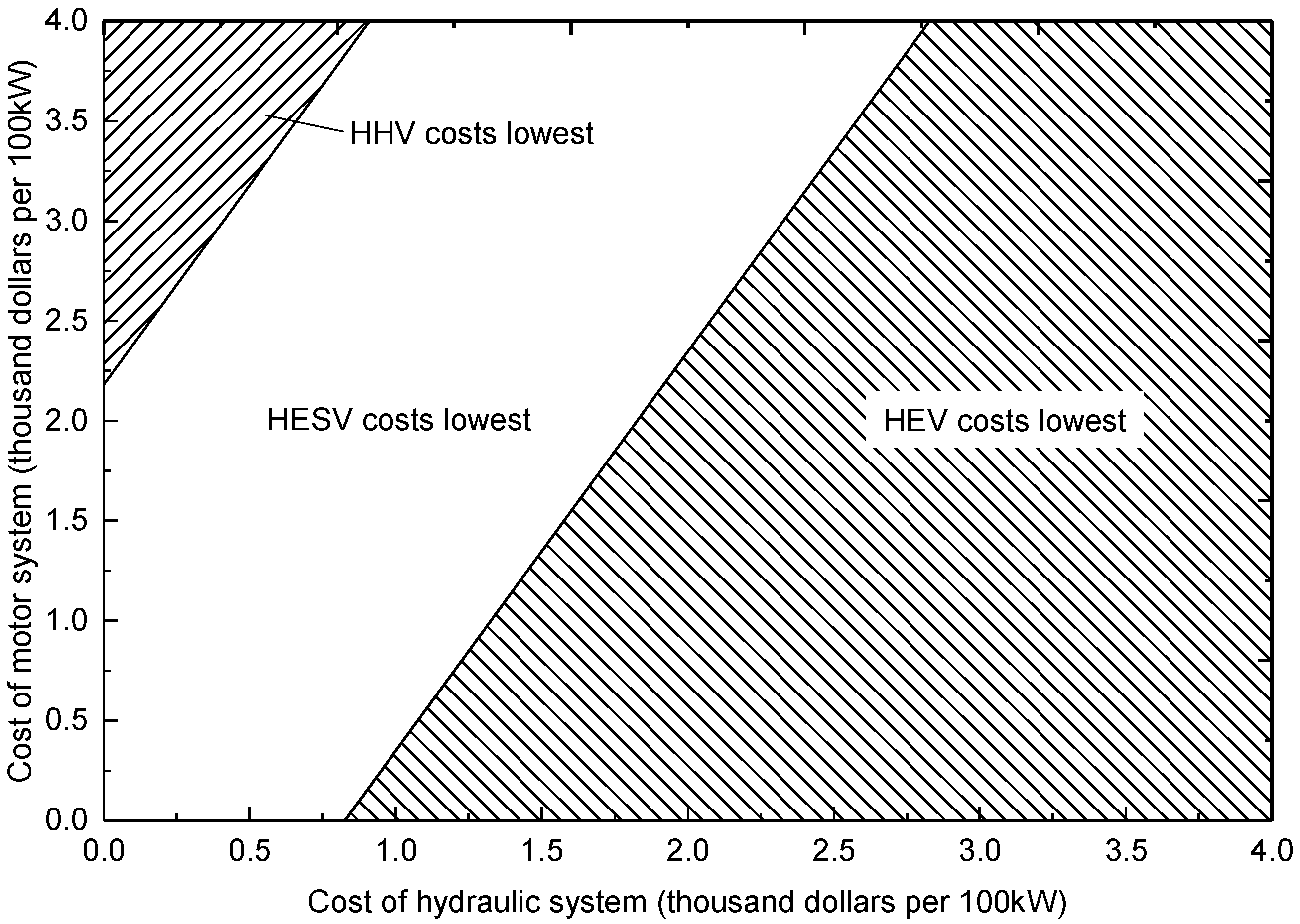

6.2. Total Operating Cost Estimation in Five Years

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Filipi, Z.; Louca, L.; Daran, B.; Lin, C.C.; Yildir, U.; Wu, B.; Kokkolaras, M.; Assanis, M.; Peng, H.; Stein, J.; et al. Combined optimisation of design and power management of the hydraulic hybrid propulsion system for the 6 × 6 medium truck. Int. J. Heavy Veh. Syst. 2004, 11, 372–402. [Google Scholar] [CrossRef]

- Wu, B.; Lin, C.C.; Filipi, Z.; Peng, H.; Assanis, D. Optimal Power Management for a Hydraulic Hybrid Delivery Truck. Veh. Syst. Dyn. 2004, 42, 23–40. [Google Scholar] [CrossRef]

- Pregelj, B.; Vrecko, D.; Petrovcic, J.; Jovan, V.; Dolanc, G. A model-based approach to battery selection for truck onboard fuel cell-based APU in an anti-idling application. Appl. Energy 2015, 137, 64–76. [Google Scholar] [CrossRef]

- Bubna, P.; Brunner, D.; Advani, S.G.; Prasad, A.K. Prediction-based optimal power management in a fuel cell/battery plug-in hybrid vehicle. J. Power Sources 2010, 195, 6699–6708. [Google Scholar] [CrossRef]

- Santucci, A.; Sorniotti, A.; Lekakou, C. Power split strategies for hybrid energy storage systems for vehicular applications. J. Power Sources 2014, 258, 395–407. [Google Scholar] [CrossRef]

- Yu, Q.; Xiong, R.; Lin, C.; Shen, W.; Deng, J. Lithium-ion Battery Parameters and State-of-Charge Joint Estimation Based on H-Infinity and Unscented Kalman Filters. IEEE Trans. Veh. Technol. 2017, 207, 8693–8701. [Google Scholar] [CrossRef]

- Sun, H.; Jiang, J.H.; Wang, X. Torque control strategy for a parallel hydraulic hybrid vehicle. J. Terramechan. 2009, 46, 259–265. [Google Scholar]

- Sun, H.; Yang, L.; Jing, J.; Luo, Y. Control strategy of hydraulic/electric synergy system in heavy hybrid vehicles. Energy Convers. Manag. 2011, 52, 668–674. [Google Scholar]

- Huang, X.; Zhao, K.; Luo, Y.; Liu, W. Study on a new split type of HEV powertrains. Int. J. Veh. Des. 2005, 38, 96–105. [Google Scholar]

- Kang, J.; Choi, W.; Kim, H. Development of a control strategy based on the transmission efficiency with mechanical loss for a dual mode power split-type hybrid electric vehicle. Int. J. Automot. Technol. 2012, 13, 825–833. [Google Scholar] [CrossRef]

- Grewe, T.M.; Conlon, B.M.; Holmes, A.G. Defining the General Motors 2-Mode Hybrid Transmission. In Proceedings of the 2007 World Congress, Detroit, MI, USA, 16–19 April 2007. [Google Scholar]

- Mashadi, B.; Emadi, S.A.M. Dual-Mode Power-Split Transmission for Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2010, 59, 3223–3232. [Google Scholar] [CrossRef]

- GB/T 19754-2015. Test Methods for Energy Consumption of Heavy-Duty Hybrid Electric Vehicles; China Standard Press: Beijing, China, 2015. [Google Scholar]

- Yan, Y.; Liu, G.; Chen, J. Integrated Modeling and Optimization of a Parallel Hydraulic Hybrid Bus. Int. J. Automot. Technol. 2010, 11, 97–104. [Google Scholar] [CrossRef]

- Wang, B.H.; Luo, Y.G.; Zhang, J.W. Simulation of City Bus Performance Based on Actual Urban Driving Cycle in China. Int. J. Automot. Technol. 2008, 9, 501–507. [Google Scholar] [CrossRef]

- Zhao, Z.G.; He, N.; Zhu, Y.; Yu, Z.P. Mode Transition Control for Four Wheel Drive Hybrid Electric Car. J. Mech. Eng. 2011, 47, 100–109. [Google Scholar] [CrossRef]

- Chen, J.S. Energy Efficiency Comparison between Hydraulic Hybrid and Hybrid Electric Vehicles. Energies 2015, 8, 4697–4723. [Google Scholar] [CrossRef]

- Kim, Y.; Filipi, Z. Simulation Study of a Series Hydraulic Hybrid Propulsion System for a Light Truck. In Proceedings of the Commercial Vehicle Engineering Congress and Exhibition, Rosemont, IL, USA, 30 October–1 November 2007. [Google Scholar]

- Johri, R.; Filipi, Z. Low-Cost Pathway to Ultra Efficient City Car: Series Hydraulic Hybrid System with Optimized Supervisory Control. SAE Int. J. Engines 2010, 2, 505–520. [Google Scholar] [CrossRef] [Green Version]

- Senger, R.; Merkle, M.; Nelson, D. Validation of ADVISOR as a Simulation Tool for a Series Hybrid Electric Vehicle. In Proceedings of the International Congress and Exposition, Detroit, MI, USA, 23–26 February 1998. [Google Scholar]

- Tremblay, O.; Dessaint, L.A. Experimental Validation of a Battery Dynamic Model for EV Applications. In Proceedings of the International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Stavanger, Norway, 13–16 May 2009. [Google Scholar]

- Xiong, R.; Zhang, Y.; He, H.; Zhou, X.; Pecht, M.G. A double-scale, particle-filtering, energy state prediction algorithm for lithium-ion batteries. IEEE Trans. Ind. Electron. 2017, 65, 1526–1538. [Google Scholar] [CrossRef]

- Serrao, L.; Onori, S.; Sciarretta, A.; Guezennec, Y.; Rizzoni, G. Optimal energy management of hybrid electric vehicles including battery aging. In Proceedings of the 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011. [Google Scholar]

- Spagnol, P.; Onori, S.; Madella, N.; Guezennec, Y.; Neal, J. Aging and Characterization of Li-Ion Batteries in a HEV Application for Lifetime Estimation. IFAC Proc. Vol. 2010, 43, 186–191. [Google Scholar] [CrossRef]

- Yang, Y.; Luo, C.; Li, P. Regenerative Braking Control Strategy of Electric-Hydraulic Hybrid (EHH) Vehicle. Energies 2017, 10, 1038. [Google Scholar] [CrossRef]

- Alson, J.; Barba, D.; Bryson, J.; Doorlag, M.; Haugen, D.; Kargul, J. Progress Report on Clean and Efficient Automotive Technologies under Development at EPA; EPA420-R-04-002; United States Environmental Protection Agency: Washington, DC, USA, 2004.

- Mou, L.; Yin, G.; Yang, S. A dynamic simulation model to simulate shifting transients of off-highway vehicles. China Mech. Eng. 2005, 16, 60–63. [Google Scholar]

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

| Working Modes | Engine | M/G | Hydraulic P/M | Clutch1 | Clutch2 | Clutch3 | Brake |

|---|---|---|---|---|---|---|---|

| Parallel Mode 1 | Off | On | On | D | D | E | E |

| On | On | On | E | D | E | E | |

| Parallel Mode 2 | On | On | Off | E | E | D | E |

| Power-split Mode | On | On | Off | E | D | D | E |

| Regeneration 1 | Off | On | On | E | E | D | E |

| Regeneration 2 | Off | On | On | D | D | E | E |

| Parking | On | Off | On | E | D | E | D |

| On | On | Off | E | D | D | D |

| Parameters | Value |

|---|---|

| Gross weight (kg) | 15,500 |

| Wheel radius (m) | 0.51 |

| Gear ratios | 6.765, 3.794, 2.26, 1.424, 1, 0.879 |

| Final drive ratio | 7.46 |

| Engine (kW/rpm) | 199/3300 |

| Dynamic Performance Index | TV | HHV | HEV | HESV |

|---|---|---|---|---|

| 0–40 km/h acceleration time (s) | 8.03 | 4.78 | 5.87 | 5.69 |

| Maximum climbing degree at 15 km/h (%) | 24.48 | 31.13 | 24.22 | 25.71 |

| Maximum speed (km/h) | 96.69 | 96.69 | 96.69 | 96.69 |

| Gear | GUP (km/h) | GDN (km/h) |

|---|---|---|

| 1↔2 | 9.5 | 8.1 |

| 2↔3 | 17.0 | 13.7 |

| 3↔4 | 28.5 | 21.7 |

| 4↔5 | 45.2 | 30.9 |

| 5↔6 | 64.4 | 35.2 |

| Parameters | TV | HHV | HEV | HESV |

|---|---|---|---|---|

| Engine fuel consumption (L/100 km) | 31.8 | 22.7 | 22.0 | 21.7 |

| Equivalent fuel consumption (L/100 km) | — | — | 22.0 | 21.9 |

| Equivalent battery life (cycle) | — | — | 22,591 | 14,269 |

| Fuel economy improvement (%) | — | 28.8 | 30.9 | 31.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, K.; Liang, Z.; Huang, Y.; Wang, H.; Khajepour, A.; Zhen, Y. Research on a Novel Hydraulic/Electric Synergy Bus. Energies 2018, 11, 34. https://doi.org/10.3390/en11010034

Zhao K, Liang Z, Huang Y, Wang H, Khajepour A, Zhen Y. Research on a Novel Hydraulic/Electric Synergy Bus. Energies. 2018; 11(1):34. https://doi.org/10.3390/en11010034

Chicago/Turabian StyleZhao, Kegang, Zhihao Liang, Yanjun Huang, Hong Wang, Amir Khajepour, and Yuke Zhen. 2018. "Research on a Novel Hydraulic/Electric Synergy Bus" Energies 11, no. 1: 34. https://doi.org/10.3390/en11010034