The Innovative Concept of Cold District Heating Networks: A Literature Review

Abstract

:1. Introduction

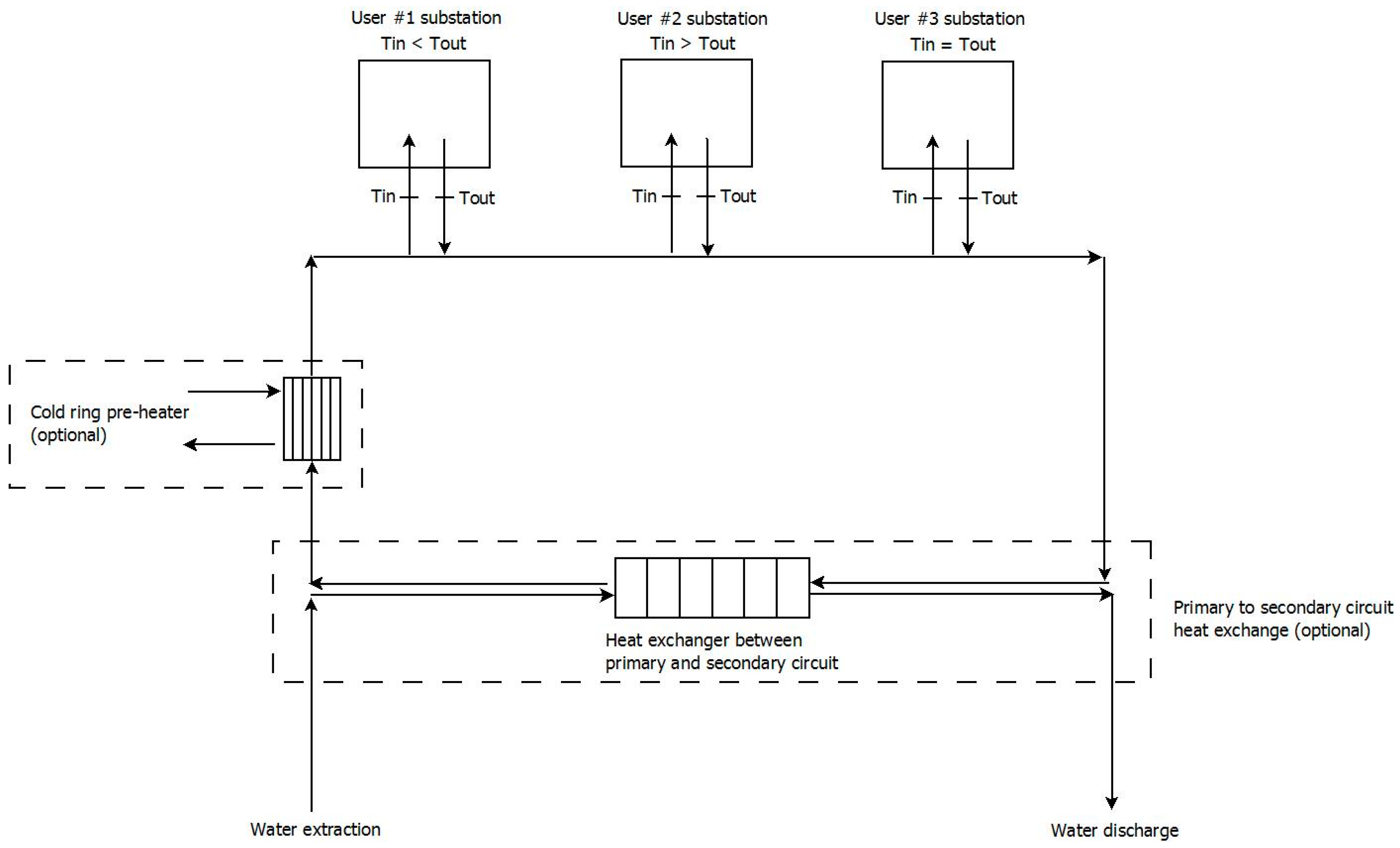

2. Cold District Heating Networks

2.1. Cold Water Sources

2.2. The “Cold Ring”

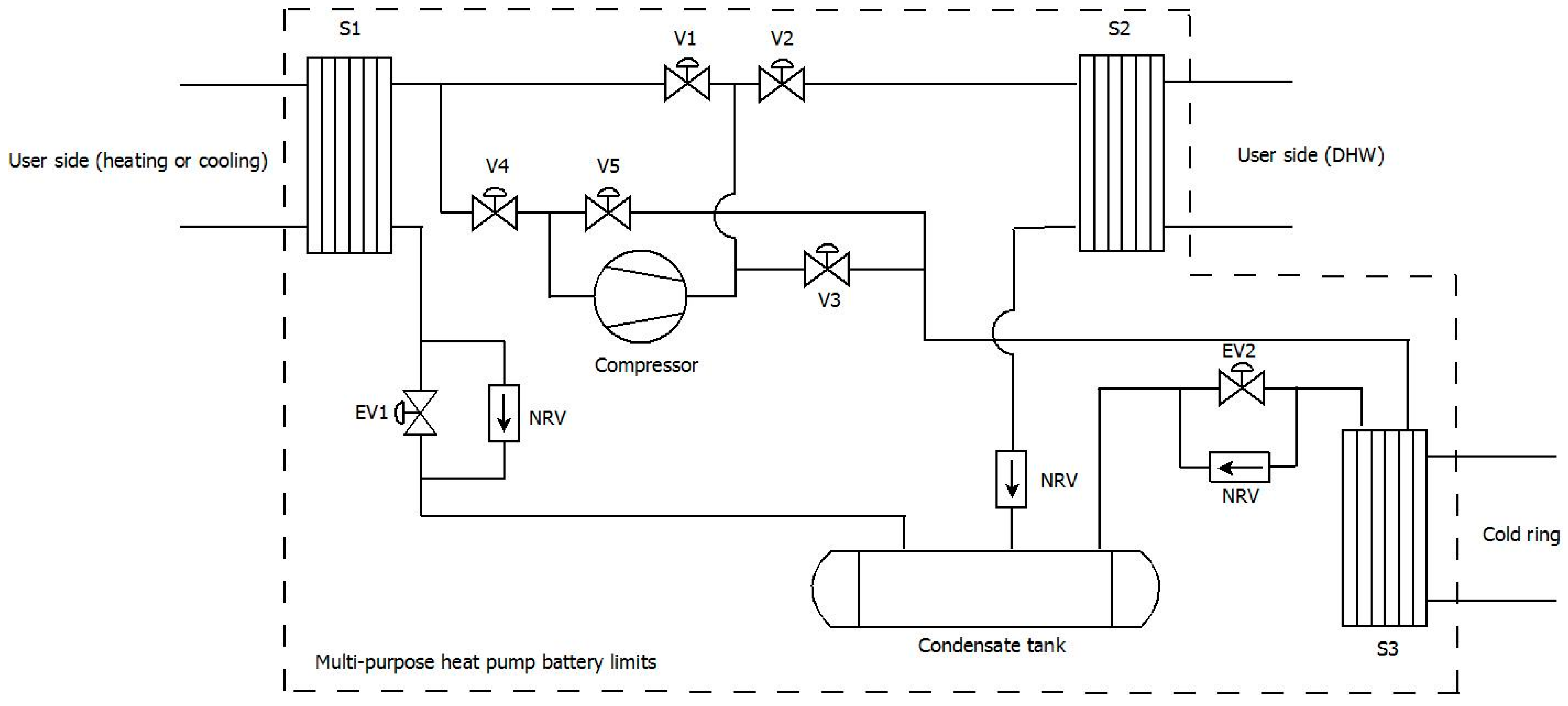

2.3. Substation Configuration: Multipurpose Heat Pumps

2.4. Intelligent Control and Metering of the Network Performance

3. Cold District Heating and Cooling Network State of the Art

3.1. Switzerland

3.2. Germany

3.3. Italy

3.4. The Netherlands

4. Drawback-Benefit Analysis

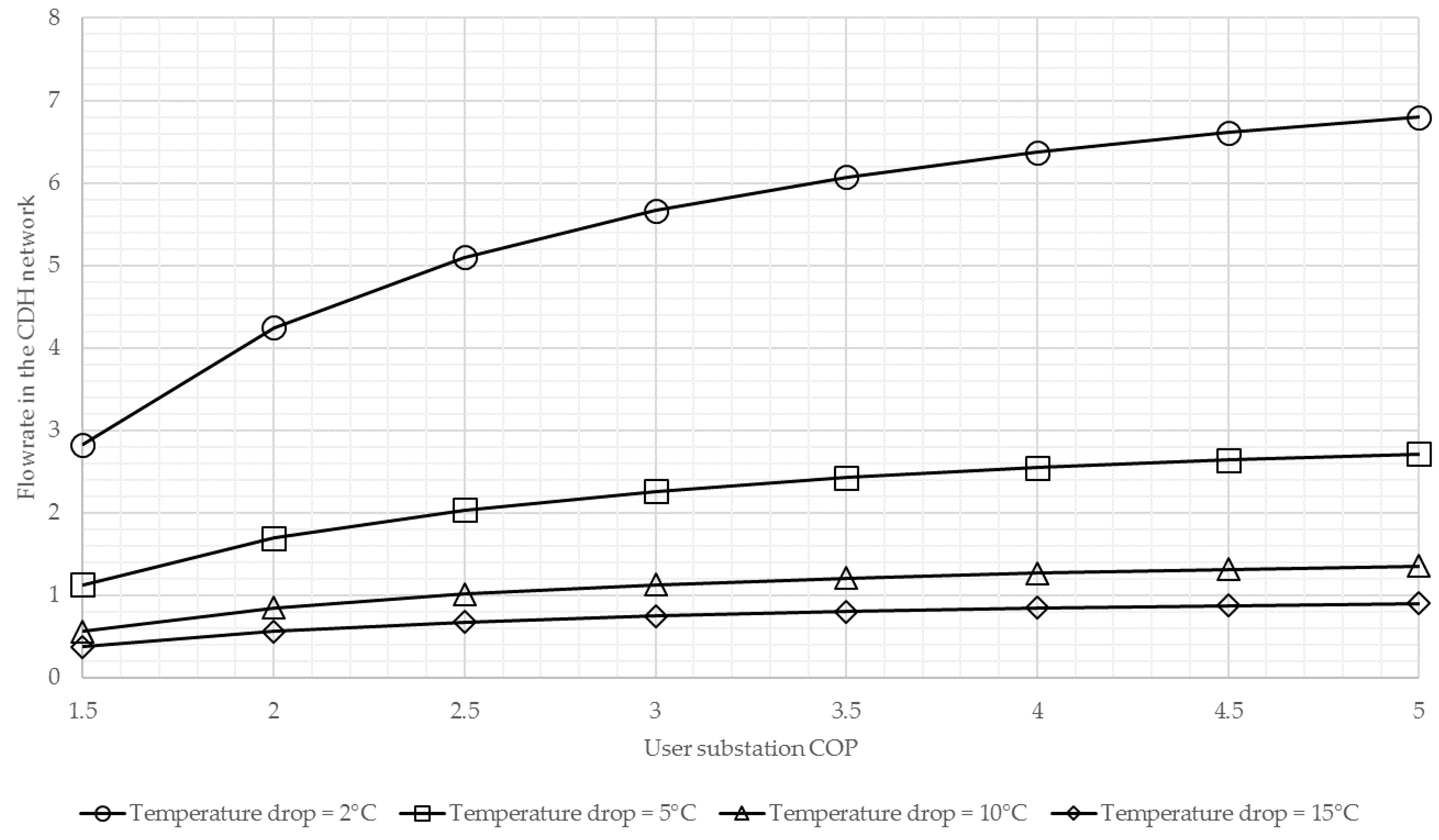

4.1. Cold Water Sources: Flowrate and Temperature Limitations

4.2. Low Thermal Losses in the Distribution Network

4.3. Primary Energy Saving

4.4. Pipeline Design

4.5. Substation Design

4.6. Ability to Utilize Renewable Energy and Create a Smart Energy System

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Østergaard, P.A.; Mathiesen, B.V.; Möller, B.; Lund, H. A renewable energy scenario for Aalborg municipality based on low-temperature geothermal heat, wind power and biomass. Energy 2010, 35, 4892–4901. [Google Scholar] [CrossRef]

- Lund, H. Renewable energy strategies for sustainable development. Energy 2007, 32, 912–919. [Google Scholar] [CrossRef]

- Amiri, S.; Weinberger, G. Increased cogeneration of renewable electricity through energy cooperation in a Swedish district heating system—A case study. Renew. Energy 2018, 116, 866–877. [Google Scholar] [CrossRef]

- Olsthoorn, D.; Haghighat, F.; Mirzaei, P.A. Integration of storage and renewable energy into district heating systems: A review of modelling and optimization. Sol. Energy 2016, 136, 49–64. [Google Scholar] [CrossRef]

- Wang, D.; Orehounig, K.; Carmeliet, J. Investigating the potential for district heating networks with locally integrated solar thermal energy supply. Energy Proc. 2017, 122, 1057–1062. [Google Scholar] [CrossRef]

- Sepponen, M.; Heimonen, I. Business concepts for districts’ Energy hub systems with maximised share of renewable energy. Energy Build. 2016, 124, 273–280. [Google Scholar] [CrossRef]

- Collins, J.F. The history of district heating. Dist. Heat. 1976, 62, 154–161. [Google Scholar]

- Vesterlund, M.; Toffolo, A. Design Optimization of a District Heating Network Expansion, a Case Study for the Town of Kiruna. Appl. Sci. 2017, 7, 488. [Google Scholar] [CrossRef]

- Werner, S. International review of district heating and cooling. Energy 2017, 137, 617–631. [Google Scholar] [CrossRef]

- Danielewicz, J.; Śniechowska, B.; Sayegh, M.A.; Fidorów, N.; Jouhara, H. Three-dimensional numerical model of heat losses from district heating network pre-insulated pipes buried in the ground. Energy 2016, 108, 172–184. [Google Scholar] [CrossRef]

- Comakli, K.; Yuksel, B.; Comakli, O. Evaluation of energy and exergy losses in district heating network. Appl. Therm. Eng. 2004, 24, 1009–1017. [Google Scholar] [CrossRef]

- Kecebas, A.; Alkan, M.A.; Bayhan, M. Thermo-economic analysis of pipe insulation for district heating piping systems. Appl. Therm. Eng. 2011, 31, 3929–3937. [Google Scholar] [CrossRef]

- Nussbaumer, T.; Thalmann, S. Influence of system design on heat distribution costs in district heating. Energy 2016, 101, 496–505. [Google Scholar] [CrossRef]

- Tereshchenko, T.; Nord, N. Importance of Increased Knowledge on Reliability of District Heating Pipes. Proc. Eng. 2016, 146, 415–423. [Google Scholar] [CrossRef] [Green Version]

- Winterscheid, C.; Holler, S.; Dalenback, J.O. Integration of solar thermal systems into existing district heating systems. Energy Proc. 2017, 116, 158–169. [Google Scholar] [CrossRef]

- Ion, I.V.; Popescu, F.; Dimofte, E. Integration of biomass resources into existent district heating system. In Proceedings of the 6th International Conference on Thermal Equipment, Renewable Energy and Rural Development, Moieciu de Sus, Romania, 8–10 June 2017. [Google Scholar]

- Christenson, M.; Manz, H.; Gyalistras, D. Climate warming impact on degree-days and building energy demand in Switzerland. Energy Convers. Manag. 2006, 47, 671–686. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Q. Impact of Climate Change Heating and Cooling Energy Use in Buildings in the United States. Energy Build. 2014, 82, 428–436. [Google Scholar] [CrossRef]

- Worm, J.; Jorgensen, H.; Thorsen, J.E.; Bennetsen, J.; Ting Larsen, C.; Juhl, O.; Lang, S.; Rosenberg, F.; Kaarup Olsen, P.; Lambertsen, H.; et al. Udvikling og Demonstration af Lavenergifjernvarme til Lavenergibyggeri (Development and Demonstration of Low-Energy District Heating for Low-Energy Housing); Teknologisk Institut: Taastrup, Denmark, 2011. [Google Scholar]

- Østergaard, D.; Svendsen, S. Space heating with ultra-low-temperature district heating—A case study of four single-family houses from the 1980s. Energy Proc. 2017, 116, 226–235. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Svendsen, S. Evaluations of different domestic hot water preparing methods with ultra-low-temperature district heating. Energy 2016, 109, 248–259. [Google Scholar] [CrossRef]

- Lund, H.; Werner, S.; Wiltshire, R.; Svendsen, S.; Thorsen, J.E.; Hvelplund, F.; Mathisen, B.V. 4th Generation District Heating (4GDH) Integrating smart thermal grids into future sustainable energy systems. Energy 2014, 68, 1–11. [Google Scholar] [CrossRef]

- Paiho, S.; Reda, F. Towards next generation district heating in Finland. Renew. Sustain. Energy Rev. 2016, 65, 915–924. [Google Scholar] [CrossRef]

- Li, H.; Wang, S.J. Challenges in Smart Low-Temperature District Heating Development. Energy Proc. 2014, 61, 1472–1475. [Google Scholar] [CrossRef] [Green Version]

- Tunzi, M.; Ostergaard, D.S.; Svendsen, S.; Boukhanouf, R.; Cooper, E. Method to investigate and plan the application of low temperature district heating to existing hydraulic radiator systems in existing buildings. Energy 2016, 113, 413–421. [Google Scholar] [CrossRef]

- Li, H.; Svendsen, S. Energy and exergy analysis of low temperature district heating network. Energy 2012, 45, 237–246. [Google Scholar] [CrossRef]

- Brand, M.; Thorsen, J.E.; Svendsen, S. Numerical modelling and experimental measurements for a low-temperature district heating substation for instantaneous preparation of DHW with respect to service pipes. Energy 2012, 41, 392–400. [Google Scholar] [CrossRef]

- Cirule, D.; Pakere, I.; Blumberga, D. Legislative framework for sustainable development of 4th generation district heating system. Energy Proc. 2016, 95, 344–350. [Google Scholar] [CrossRef]

- Ziemele, J.; Gravelsins, A.; Blumberga, A.; Vigants, G.; Blumberga, D. System dynamics model analysis of pathway to 4th generation district heating in Latvia. Energy 2016, 110, 85–94. [Google Scholar] [CrossRef]

- Ziemele, J.; Gravelsins, A.; Blumberga, A.; Blumberga, D. Combining energy efficiency at source and at consumer to reach 4th generation district heating: Economic and system dynamics analysis. Energy 2017, 137, 595–606. [Google Scholar] [CrossRef]

- Castro Flores, J.F.; Lacarriere, B.; Chiu, J.N.W.; Martin, V. Assessing the techno-economic impact of low-temperature subnets in conventional district heating networks. Energy Proc. 2017, 116, 260–272. [Google Scholar] [CrossRef]

- Kofinger, M.; Basciotti, D.; Schmidt, R.R.; Meissner, E.; Doczekal, C.; Giovannini, A. Low temperature district heating in Austria: Energetic, ecologic and economic comparison of four case studies. Energy 2016, 110, 95–104. [Google Scholar] [CrossRef]

- Baldvinsson, I.; Nakata, T. A feasibility and performance assessment of a low temperature district heating system—A North Japanese case study. Energy 2016, 95, 155–174. [Google Scholar] [CrossRef]

- Schmidt, D.; Kallert, A.; Blesl, M.; Svendsen, S.; Li, H.; Nord, N.; Sipila, K. Low temperature district heating for future energy systems. Energy Proc. 2017, 116, 26–38. [Google Scholar] [CrossRef]

- Brand, M.; Svendsen, S. Renewable-based low-temperature district heating for existing buildings in various stages of refurbishment. Energy 2013, 62, 311–319. [Google Scholar] [CrossRef]

- Nord, N.; Ingebretsen, M.E.; Tryggestad, I.S. Possibilities for Transition of Existing Residential Buildings to Low Temperature District Heating System in Norway. In Proceedings of the 12th REHVA World Congress, Aalborg, Denmark, 22–25 May 2016. [Google Scholar]

- Bunning, F.; Wetter, M.; Fuchs, M.; Muller, D. Bidirectional low temperature district energy systems with agent-based control: Performance comparison and operation optimization. Appl. Energy 2018, 209, 502–515. [Google Scholar] [CrossRef]

- Yang, X.; Li, H.; Svendsen, S. Decentralized substations for low-temperature district heating with no Legionella risk, and low return temperatures. Energy 2016, 110, 65–74. [Google Scholar] [CrossRef]

- Palm, J.; Gustafsson, S. Barriers to and enablers of district cooling expansion in Sweden. J. Clean. Prod. 2018, 172, 39–45. [Google Scholar] [CrossRef]

- Gang, W.; Wang, S.; Xiao, F.; Gao, D. District cooling systems: Technology integration, system optimization, challenges and opportunities for applications. Renew. Sustain. Energy Rev. 2016, 53, 253–264. [Google Scholar] [CrossRef]

- Adnot, J. Energy Efficiency and Certification of Central Air Conditioners (EECCAC); Technical Report; Armines: Paris, France, 2003. [Google Scholar]

- Spinoni, J.; Vogt, J.; Barbosa, P. European degree-day climatologies and trends for the period 1951–2011. Int. J. Climatol. 2015, 35, 25–36. [Google Scholar] [CrossRef]

- Conte, B.; Bruno, J.C.; Coronas, A. Optimal Cooling Load Sharing Strategies for Different Types of Absorption Chillers in Trigeneration Plants. Energies 2016, 9, 573. [Google Scholar] [CrossRef]

- Arabkoohsar, A.; Andresen, G.B. Supporting district heating and cooling networks with a bifunctional solar assisted absorption chiller. Energy Convers. Manag. 2017, 148, 184–196. [Google Scholar] [CrossRef]

- Liu, M.; Shi, Y.; Fang, F. Combined cooling, heating and power systems: A survey. Renew. Sustain. Energy Rev. 2014, 35, 1–22. [Google Scholar] [CrossRef]

- Yu, Q.D. Theory of energy level and its application in water-loop heat pump system. Appl. Therm. Eng. 2017, 119, 269–274. [Google Scholar] [CrossRef]

- Polzot, A.; Dipasquale, C.; D’Agaro, P.; Cortella, G. Energy benefit assessment of a water loop heat pump system integrated with a CO2 commercial refrigeration unit. Energy Proc. 2017, 123, 36–45. [Google Scholar] [CrossRef]

- Lee, K.S. A Review on Concepts, Applications, and Models of Aquifer Thermal Energy Storage Systems. Energies 2010, 3, 1320–1334. [Google Scholar] [CrossRef]

- Bloemendal, M.; Olsthoorn, T.; Boons, F. How to achieve optimal and sustainable use of the subsurface for Aquifer Thermal Energy Storage. Energy Policy 2014, 66, 104–114. [Google Scholar] [CrossRef]

- Buyukalaca, O.; Ekinci, F.; Yilmaz, T. Experimental investigation of Seyhan River and dam lake as heat source–sink for a heat pump. Energy 2003, 28, 157–169. [Google Scholar] [CrossRef]

- Liu, Z.; Tan, H.; Li, Z. Heating and Cooling Performances of River-Water Source Heat Pump System for Energy Station in Shanghai. Proc. Eng. 2017, 205, 4074–4081. [Google Scholar] [CrossRef]

- Song, Y.; Akashi, Y.; Yee, J.J. Effects of utilizing seawater as a cooling source system in a commercial complex. Energy Build. 2007, 39, 1080–1087. [Google Scholar] [CrossRef]

- Elías-Maxil, J.A.; van der Hoek, J.P.; Hofman, J.; Rietveld, L. Energy in the urban water cycle: Actions to reduce the total expenditure of fossil fuels with emphasis on heat reclamation from urban water. Renew. Sustain. Energy Rev. 2014, 30, 808–820. [Google Scholar] [CrossRef] [Green Version]

- Fiore, S.; Genon, G. Heat recovery from municipal wastewater: Evaluation and proposals. Environ. Eng. Manag. J. 2014, 13, 1595–1604. [Google Scholar]

- Kahraman, A.; Celebi, A. Investigation of the Performance of a Heat Pump Using Waste Water as a Heat Source. Energies 2009, 2, 697–713. [Google Scholar] [CrossRef]

- De Pasquale, A.M.; Giostri, A.; Romano, M.C.; Chiesa, P.; Demeco, T.; Tani, S. District heating by drinking water heat pump: Modelling and energy analysis of a case study in the city of Milan. Energy 2017, 118, 246–263. [Google Scholar] [CrossRef]

- Manfren, M.; Caputo, P.; Costa, G. Paradigm shift in urban energy systems through distributed generation: Methods and models. Appl. Energy 2011, 88, 1032–1048. [Google Scholar] [CrossRef]

- Gadd, H.; Werner, S. Heat load patterns in district heating substations. Appl. Energy 2013, 108, 176–183. [Google Scholar] [CrossRef]

- Zabasta, A.; Selmanovs-Pless, V.; Kunicina, N.; Ribickis, L. Wireless Sensor Networks for Optimisation of District Heating. J. Energy Power Eng. 2013, 7, 1362–1369. [Google Scholar]

- Liu, L.; Fu, L.; Jiang, Y. A new “wireless on-off control” technique for adjusting and metering household heat in district heating system. Appl. Therm. Eng. 2012, 36, 202–209. [Google Scholar] [CrossRef]

- Xue, P.; Zhou, Z.; Fang, X.; Chen, X.; Liu, L.; Liu, Y.; Liu, J. Fault detection and operation optimization in district heating substations based on data mining techniques. Appl. Energy 2018, 144, 20–30. [Google Scholar] [CrossRef]

- Ma, Z.; Xie, J.; Li, H.; Sun, Q.; Si, Z.; Zhang, J.; Guo, J. The Role of Data Analysis in the Development of Intelligent Energy Networks. IEEE Netw. 2017, 31, 88–95. [Google Scholar] [CrossRef]

- Razmara, M.; Bharati, G.R.; Shahbakhti, M.; Paudyal, S.; Robinett, R.D. Bidirectional optimal operation of smart building-to-grid systems. Am. Control Conf. 2015, 288–293. [Google Scholar] [CrossRef]

- Rybach, L.; Wilhelm, J.; Gorhan, H. Geothermal use of tunnel waters—A Swiss speciality. In Proceedings of the International Geothermal Conference, Reykjavík, Iceland, 14–17 September 2003. [Google Scholar]

- Pietruschka, D.; Brennenstuhl, M.; Matthiss, B.; Binder, J. Decentralised heat pumps and small electricity storages as active components in a virtual power plant for smart grid services. In Proceedings of the 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015. [Google Scholar]

- Sanner, B. Market and potential for geothermal energy in Europe. In Proceedings of the GeoEnergi 2015, Bergen, Norway, 2–3 September 2015. [Google Scholar]

- Stubler, A.; Bestenlehner, D.; Druck, H. Energy saving potentials of cold district heating networks. In Proceedings of the 17th EWA Symposium during IFAT 2014, München, Germany, 6–7 May 2014. [Google Scholar]

- Molinari, F.C.; Tarantino, P. New Projects for Geothermal District Heating and Cooling Systems in the Brescia Province-Northern Italy. In Proceedings of the Workshop on Geothermal Energy Status and Future in the Peri–Adriatic Area, Veli Lošinj, Croatia, 25–27 August 2014. [Google Scholar]

- Bianchini, A.; Pellegrini, M.; Saccani, C. Wide use of sustainable energy from aquifers in Italy: Pilot plant design and implementation. In Proceedings of the 22nd Summer School Francesco Turco, Palermo, Italy, 13–15 September 2017. [Google Scholar]

- Chmutina, K.; Goodier, C.I. Case Study Analysis of Urban Decentralised Energy Systems. In Climate-Smart Technologies; Leal Filho, W., Mannke, F., Mohee, R., Schulte, V., Surroop, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-37752-5. [Google Scholar]

- Brielmann, H.; Griebler, C.; Schmidt, S.I.; Michel, R.; Lueders, T. Effects of thermal energy discharge on shallow groundwater ecosystems. FEMS Microbiol. Ecol. 2009, 68, 273–286. [Google Scholar] [CrossRef] [PubMed]

- Madden, N.; Lewis, A.; Davis, M. Thermal effluent from the power sector: An analysis of once-through cooling system impacts on surface water temperature. Environ. Res. Lett. 2013, 8, 1–8. [Google Scholar] [CrossRef]

- Ni, Z.; van Gaans, P.; Smit, M.; Rijnaarts, H.; Grotenhuis, T. Combination of aquifer thermal energy storage and enhanced bioremediation: Resilience of reductive dechlorination to redox changes. Appl. Microbiol. Biotechnol. 2015, 100, 3767–3780. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Duanmu, L.; Li, X.; Lahdelma, R. Optimizing the District Heating Primary Network from the Perspective of Economic-Specific Pressure Loss. Energies 2017, 10, 1095. [Google Scholar] [CrossRef]

- Yildirim, N.; Toksoy, M.; Gokcen, G. Piping network design of geothermal district heating systems: Case study for a university campus. Energy 2010, 35, 3256–3262. [Google Scholar] [CrossRef]

- Nord, N.; Schmidt, D.; Dagmar Kallert, A.M. Necessary measures to include more distributed renewable energy sources into district heating systems. Energy Proc. 2017, 116, 48–57. [Google Scholar] [CrossRef]

- Werner, S. District heating and cooling in Sweden. Energy 2017, 126, 419–429. [Google Scholar] [CrossRef]

- Lund, H. Renewable Energy Systems: A Smart Energy Systems Approach to the Choice and Modelling of 100% Renewable Solutions, 2nd ed.; Academic Press: Burlington, ON, Canada, 2014; ISBN 978-0-12-410423-5. [Google Scholar]

- Bianchini, A.; Guzzini, A.; Pellegrini, M.; Saccani, C. Photovoltaic/thermal (PV/T) solar system: Experimental measurements, performance analysis and economic assessment. Renew. Energy 2017, 111, 543–555. [Google Scholar] [CrossRef]

- Hassine, I.B.; Eicker, U. Control aspects of decentralized solar thermal integration into district heating networks. Energy Proc. 2014, 48, 1055–1064. [Google Scholar] [CrossRef]

- Ancona, M.A.; Branchini, L.; De Pascale, A.; Melino, F. Smart district heating: Distributed generation systems’ effects on the network. Energy Proc. 2015, 75, 1208–1213. [Google Scholar] [CrossRef]

- Hwang, J.; Choi, M.; Lee, T.; Jeon, S.; Kim, S.; Park, S.; Park, S. Energy Prosumer Business Model Using Blockchain System to Ensure Transparency and Safety. Energy Proc. 2017, 141, 194–198. [Google Scholar] [CrossRef]

- Mengelkamp, E.; Garttner, J.; Rock, K.; Kessler, S.; Orsini, L.; Weinhardt, C. Designing microgrid energy markets: A case study: The Brooklyn Microgrid. Appl. Energy 2018, 210, 870–880. [Google Scholar] [CrossRef]

- Reynolds, J.; Rezgui, Y.; Hippolyte, J. Upscaling energy control from building to districts: Current limitations and future perspectives. Sustain. Cities Soc. 2017, 35, 816–829. [Google Scholar] [CrossRef]

- Koirala, B.P.; Chaves Ávila, J.P.; Gómez, T.; Hakvoort, R.A.; Herder, P.M. Local Alternative for Energy Supply: Performance Assessment of Integrated Community Energy Systems. Energies 2016, 9, 981. [Google Scholar] [CrossRef]

- Goop, J.; Odenberger, M.; Johnsson, F. The effect of high levels of solar generation on congestion in the European electricity transmission grid. Appl. Energy 2017, 205, 1128–1140. [Google Scholar] [CrossRef]

- Zhang, G.; Cao, Y.; Cao, Y.; Li, D.; Wang, L. Optimal Energy Management for Microgrids with Combined Heat and Power (CHP) Generation, Energy Storages, and Renewable Energy Sources. Energies 2017, 10, 1288. [Google Scholar] [CrossRef]

- Wu, Q.H.; Zheng, J.; Jing, Z. Coordinated Scheduling of Energy Resources for Distributed DHCs in an Integrated Energy Grid. J. Power Energy Sources 2015, 1, 95–103. [Google Scholar] [CrossRef]

- Badami, M.; Fonti, A.; Carpignano, A.; Grosso, D. Design of district heating networks through an integrated thermo-fluid dynamics and reliability modelling approach. Energy 2018, 144, 826–838. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pellegrini, M.; Bianchini, A. The Innovative Concept of Cold District Heating Networks: A Literature Review. Energies 2018, 11, 236. https://doi.org/10.3390/en11010236

Pellegrini M, Bianchini A. The Innovative Concept of Cold District Heating Networks: A Literature Review. Energies. 2018; 11(1):236. https://doi.org/10.3390/en11010236

Chicago/Turabian StylePellegrini, Marco, and Augusto Bianchini. 2018. "The Innovative Concept of Cold District Heating Networks: A Literature Review" Energies 11, no. 1: 236. https://doi.org/10.3390/en11010236