Optimization and Practice of Support Working Resistance in Fully-Mechanized Top Coal Caving in Shallow Thick Seam

Abstract

:1. Introduction

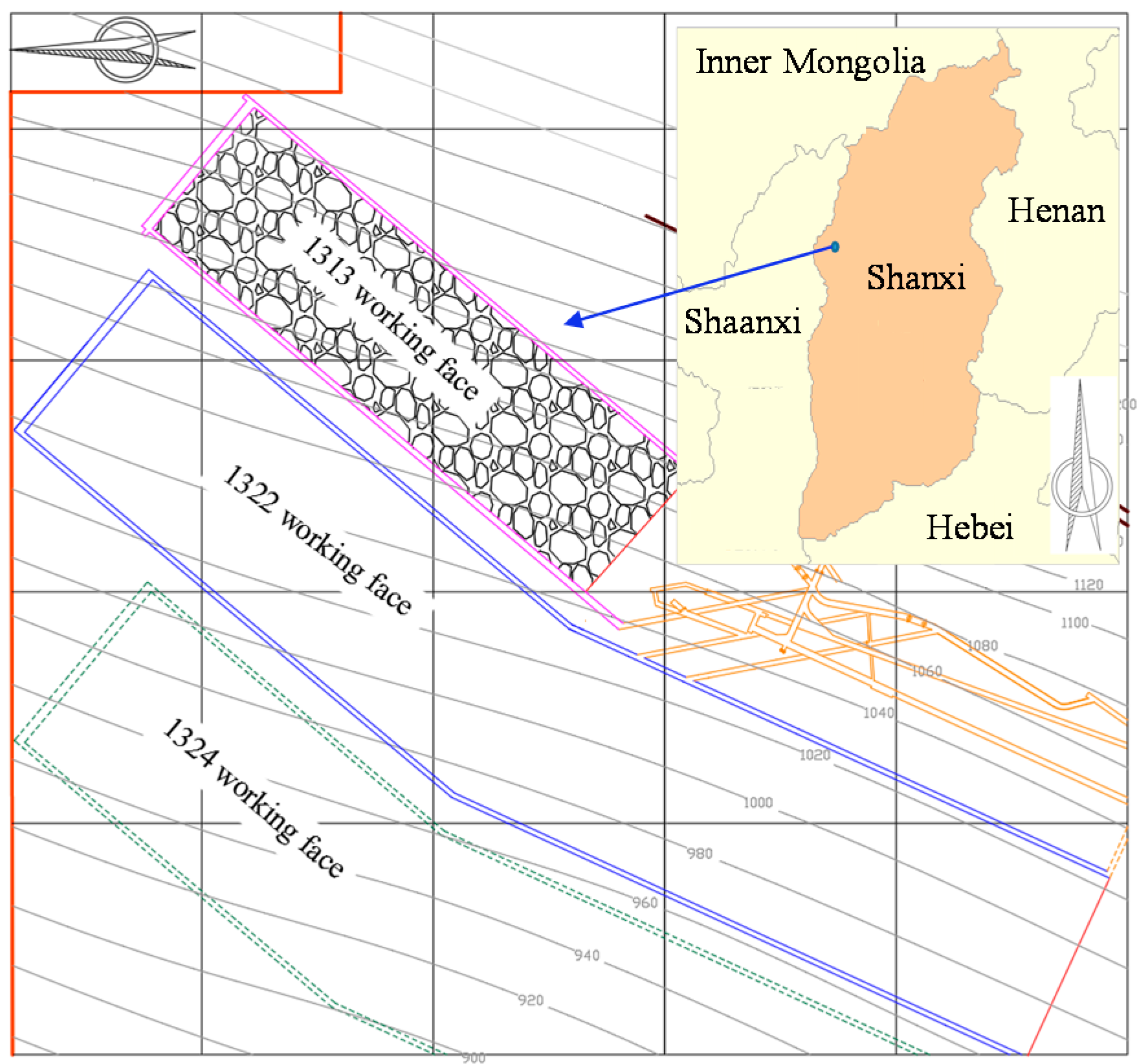

2. Engineering Background

2.1. General Situation of 1311 Caving Working Face

2.2. General Situation of 1311 Caving Working Face

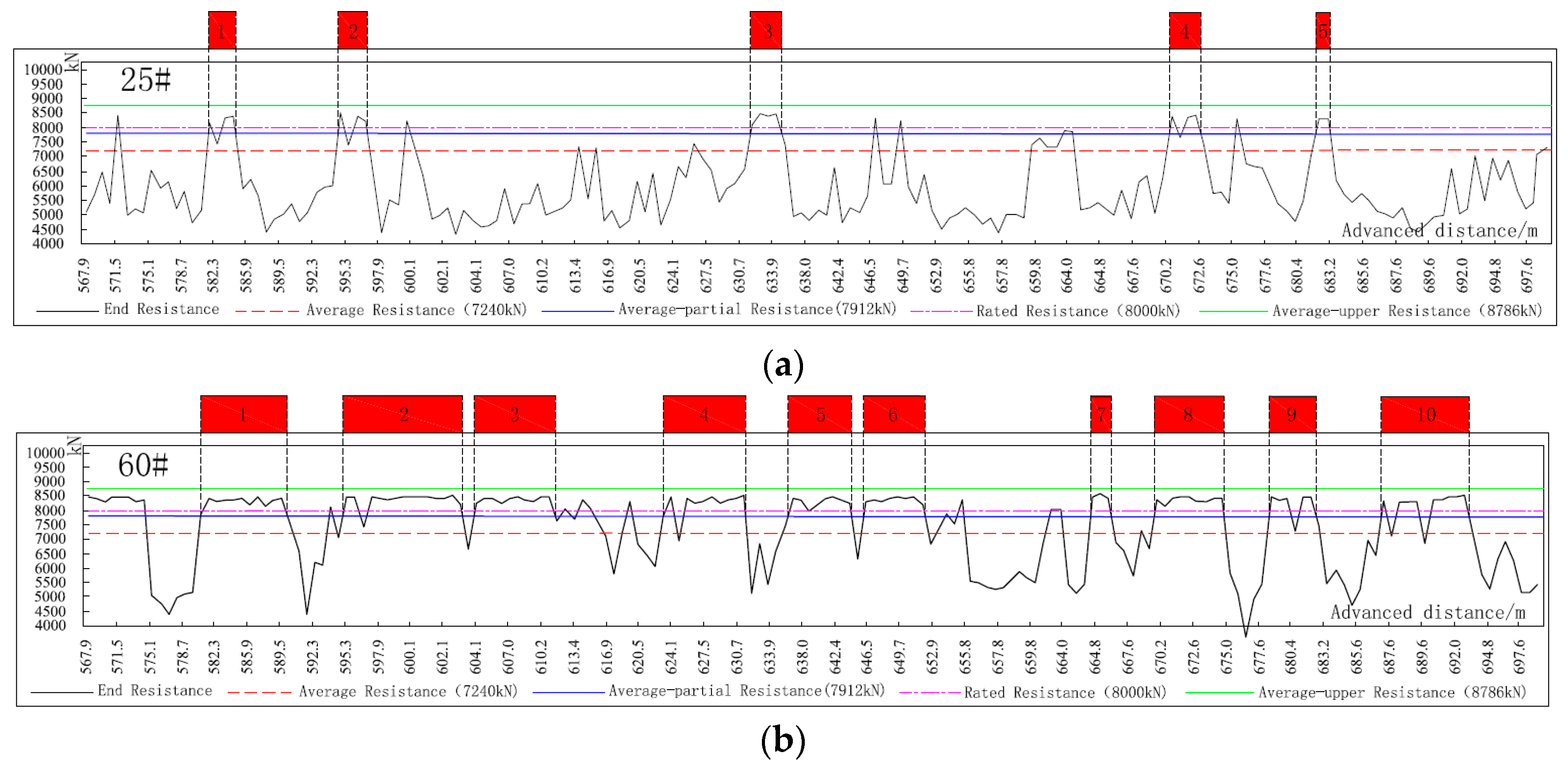

2.3. Mine Pressure Behavior of 1311 Caving Working Face

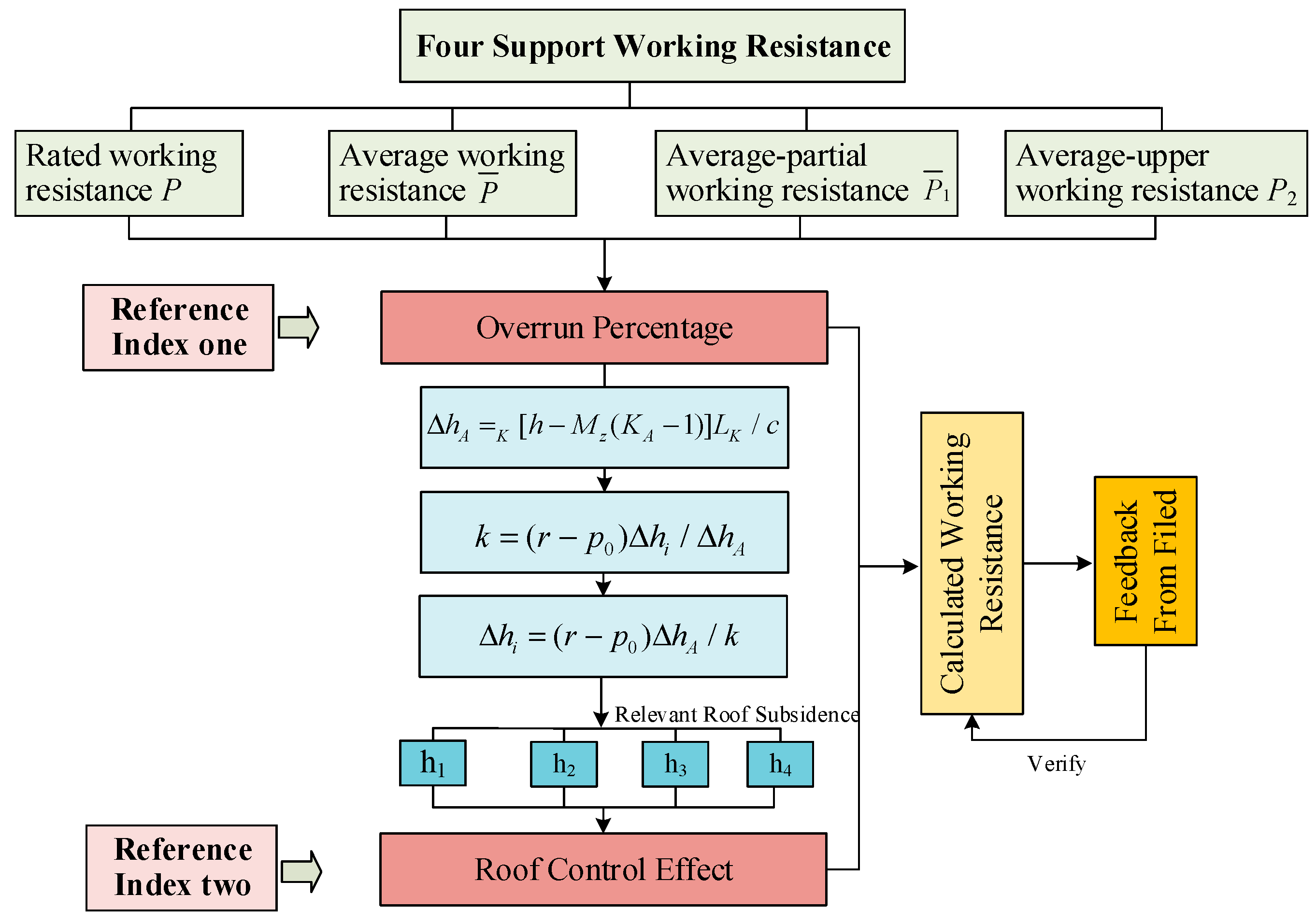

3. An Inversion Optimizing Method

3.1. Four Support Working Resistance

- (1)

- Rated working resistance pThe rated working resistance is the maximum force that the hydraulic support exerts onto the roof.

- (2)

- Average working resistanceAverage working resistance is the average of the end working resistance during the roof weighting stage.where the end working resistance is , kN; the circulation number of roof weighting is n.

- (3)

- Average-partial working resistanceAverage-partial working resistance was defined as the sum of average working resistance and the mean square error.where the mean standard deviation is , kN.

- (4)

- Average-upper working resistance p2The average-upper working resistance is defined as the sum of average working resistance and the double mean square error.

3.2. The Partition of Roof Control Effect Level

3.3. Working Resistance Design Flow

3.4. Reasonable Working Resistance Calculation

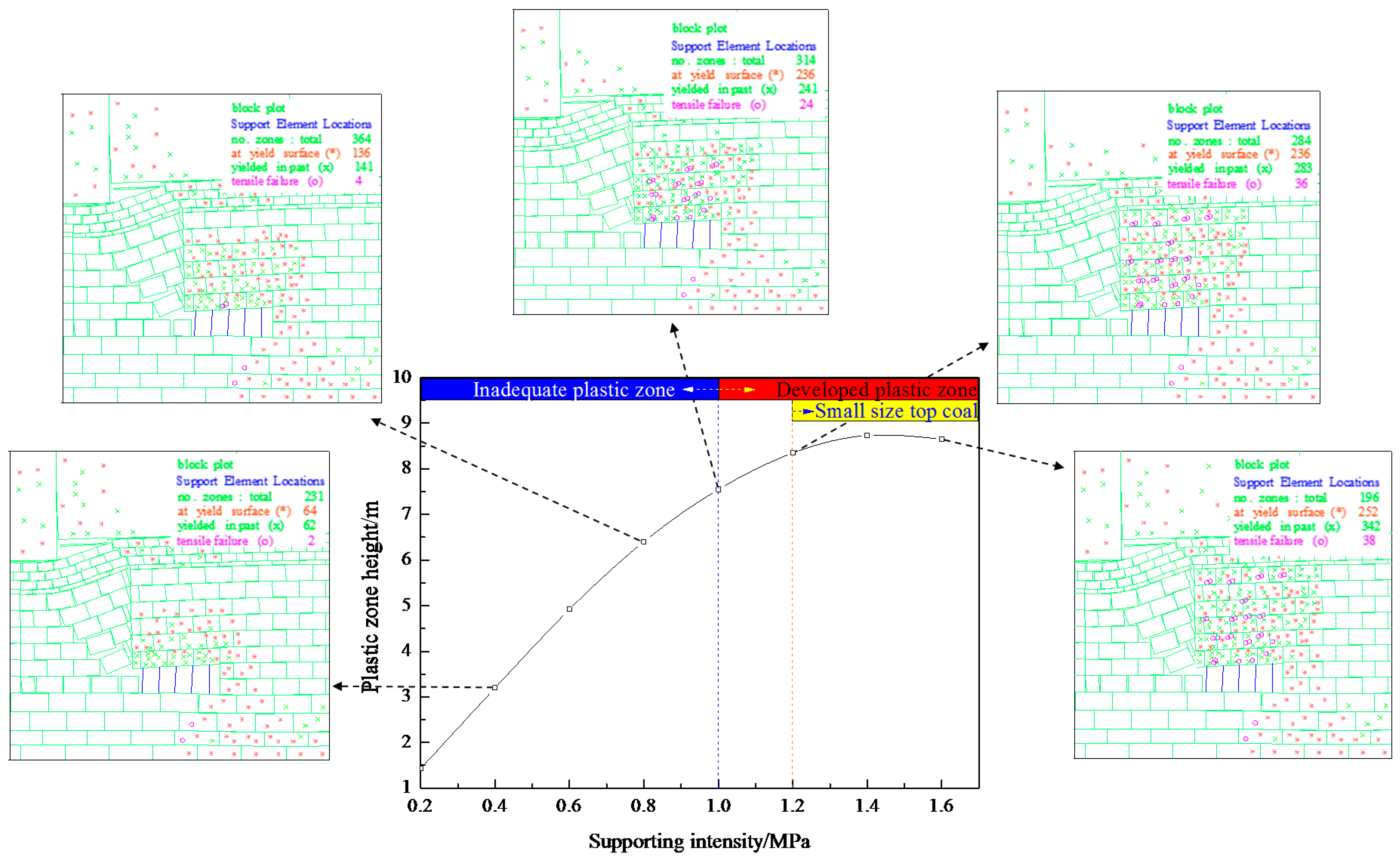

4. Top Coal Cavability and Roof Subsidence under Different Supporting Strengths

4.1. Top Coal Cavability under Different Supporting Strength

4.2. Roof Subsidence under Different Supporting Strength

5. Engineering Practice

5.1. General Situation of 1322 Caving Working Face

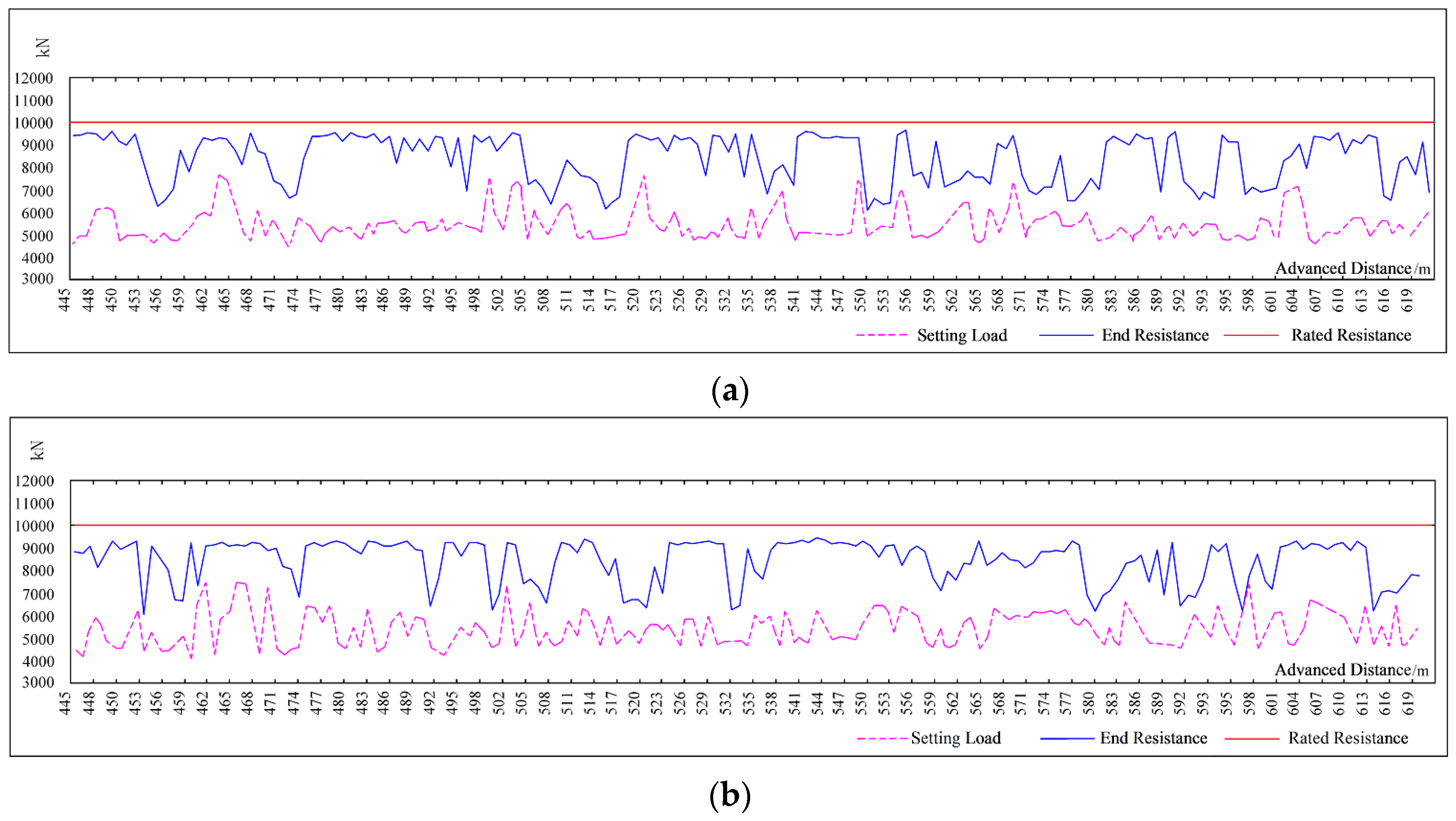

5.2. Mine Pressure Behavior of 1322 Caving Working Face

6. Conclusions

- (1)

- An inversion optimizing method and design flow of working resistance in fully-mechanized top coal caving in shallow thick seam was put forward by considering two very important reference indexes-roof control effect and working resistance overrun percentage. This method and design flow were applied to calculate the working resistance of 1313 working face and 1322 working face and were determined to be with 8786 kN and 10,000 kN. The applied working resistance (8000 kN) is lower than the calculated working resistance (8000 kN) in the 1313 working face which resulted in pillar shrinkage. Therefore, for the 1322 working face, 10,000 kN was determined as the required working resistance.

- (2)

- The simulation model of fully-mechanized top coal caving working face is built by using the UDEC software to justify the method of calculating working resistance with analyzing the top coal cavability and roof subsidence. The roof subsidence under supporting strength of 1.2 MPa (10,000 kN) is 120 mm, which falls within the ‘Good’ range of roof control effect partial. The plastic zone of top coal developed well under supporting strength of 1.2 MPa (10,000 kN), which benefits top coal caving.

- (3)

- The top-cave hydraulic support (ZF10000/23/35) is selected to employ in 1322 plane. The working resistance was monitored during the working face advanced distance is from 445 m to 619 m. The working resistance is 80–90% of working rated resistance. The practice shows that the support worked well and no support pillar shrinkage and crushing happened, which justify the method of calculating working resistance with field feedback.

- (4)

- There are a large number of shallow coal mines where top coal caving method has been applied in the western region of China. Large mining height, special overburden structure, and shallow depth coal seam, many problems were induced in top coal mining working face, such as roof shear, support crushing, and threatened safety of the working face. The research achievements of this paper provide a new support working resistance design flow to guarantee safety mining in those coal mines working face.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yasitli, N.E.; Unver, B. 3D numerical modeling of longwall mining with top-coal caving. Int. J. Rock Mech. Min. Sci. 2005, 42, 219–235. [Google Scholar] [CrossRef]

- Atkinson, T. Thick, steep and irregular coal seam mining. Min. Eng. Lond. 1979, 139, 421–431. [Google Scholar]

- Senkal, S.; Kose, H.; Ermisoglu, N. A study on coal losses and dilution problems in the mining method applied at GLI Tuncbilek Colliery, Madencilik. Bull. Chamb. Min. Eng. Turk. 1988, 27, 5–11. (In Turkish) [Google Scholar]

- Schweitzer, R. Thick seam winning methods in French coal mines. In Proceedings of the International Symposium on Thick Seam Mining Dhanbad; Paper No. 3; Department of Mining Engineering Indian School of Mines: Dhanbad, India, 1977. [Google Scholar]

- Ahcan, R. Mechanization and concentration of thick coal seams mining in SFR Yugoslavia. In Proceedings of the International Symposium on Thick Seam Mining Dhanbad; Paper No. 4; Department of Mining Engineering Indian School of Mines: Dhanbad, India, 1977. [Google Scholar]

- Garg, P.C.; Nath, P.D. Choice of methods for mining thick coal seams in India. In Proceedings of the International Symposium on Thick Seam Mining Dhanbad; Paper No. 10; Department of Mining Engineering Indian School of Mines: Dhanbad, India, 1977. [Google Scholar]

- Yasitli, N.E. Numerical Modeling of Longwall with Top Coal Caving. Master’s Thesis, Hacettepe University, Ankara, Turkey, 2002; p. 148. (In Turkish). [Google Scholar]

- Unver, B.; Yasitli, N.E. Simulation of Sublevel Caving Method Used in thick Coal Seam by Computer; Project No. 0002602008; Hacettepe University Scientific Research Unit: Ankara, Turkey, 2002; p. 148. (In Turkish) [Google Scholar]

- Unver, B.; Yasitli, N.E. Modelling of strata movement with a special reference to caving mechanism in thick seam coal mining. Int. J. Coal Geol. 2006, 66, 227–252. [Google Scholar] [CrossRef]

- Tien, J. Longwall caving in thick seams. Coal Age 1998, 103, 52–61. [Google Scholar]

- Xie, H.P.; Wang, J.H.; Shen, B.H.; Liu, J.Z.; Jiang, P.F.; Zhou, H.W.; Liu, H.; Wu, G. New idea of coal mining: Scientific mining and sustainable mining capacity. J. China Coal Soc. 2012, 37, 1069–1079. [Google Scholar]

- Xu, J.L.; Zhu, W.B.; Wang, X.Z.; Yi, M.S. Classification of key strata structure of overlying strata in shallow coal seam. J. China Coal Soc. 2009, 7, 865–870. [Google Scholar]

- Maosen, Y.I. Study and Application of Key Strata Theory in Shallow Seam of Shendong Mining Area; China University of Mining and Technology: Xuzhou, China, 2008. [Google Scholar]

- Yan, S.H.; Yin, X.W. Discussing about the main theoretical problems of long wall with top coal caving. J. China Coal Soc. 2008, 33, 481–484. [Google Scholar]

- Cai, Y.; Hebblewhite, B.; Onder, U.; Xu, B.; Kelly, M.; Wright, B.; Kraemer, I.; Hebblewhite, B.K. Application of Longwall Top Coal Caving to Australian Operations; CSIRO–ACARP Report C11040; Australian Coal Association Research Program: Brisbane, Australia, 2003. [Google Scholar]

- Mao, D.; Yao, J. Adaptability of longwall top coal caving with high cutting height. J. China Coal Soc. 2010, 35, 1837–1841. [Google Scholar]

- Mao, D.; Kang, L. Longwall top coal caving mining with higher mining height and its feasibility. Coal Min. Technol. 2003, 8, 11–14. [Google Scholar]

- Alehossein, H.; Poulsen, B.A. Stress analysis of longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2010, 47, 30–41. [Google Scholar] [CrossRef]

- Wang, J. Present status and development tendency of fully mechanized coal mining technology and equipment with high cutting height in China. Coal Sci. Technol. 2006, 34, 4–7. [Google Scholar]

- Xiong, R. Investigation of mechanism of roof failure due to weighting over great extent. J. China Coal Soc. 1995, 20, 38–39. [Google Scholar]

- Xu, G. Influence of Initial Support Force on Strata Behavior; Coal Industry Press: Beijing, China, 2011; pp. 247–250. [Google Scholar]

- Xu, G. Cause analysis of large area weighting of full mechanized mining face under non hard roof based on actual measurement data. Coal Min. Technol. 2014, 19, 98–100. [Google Scholar]

- Xu, G. Cause and prevention of powered support jammed in full-mechanized top coal caving mining face in ultra thick seam with watery roof. Coal Sci. Technol. 2016, 44, 1–5. [Google Scholar]

- Zhang, L.; Li, Z.; Jie, X. Mechanism study prevention technology of large area support crushing in fully mechanized top coal caving face of supper thick coal seam. Coal Eng. 2015, 11, 67–69. [Google Scholar]

- Yin, X. Analysis on crushed cause of hydraulic support in fully-mechanized high cutting coal mining face and prevention countermeasures. Coal Sci. Technol. 2014, 42, 26–29. [Google Scholar]

- Yan, S.; Xu, G.; Zhang, X.; Zhan, Z. Reason analyses on large area roof shearting and collapse of hydraulic supports at fully-mechanized top coal caving mining face in ultra thick coal seams. Coal Sci. Technol. 2015, 43, 14–18. [Google Scholar]

- Zhang, D.; Qian, M.; Zhai, M.; Yang, Z. Structural patterns and strata behavior of overlying strata in fully mechanized caving face. Mine Press. Roof Manag. 1994, 4, 13–17. [Google Scholar]

- He, J.; Dou, L.; He, H.; Lu, Z.; Lu, C.; Guo, X. Mechanism study of overlying strata movement inducing rock rurst on top-coal caving face. Chin. J. Mech. Eng. 2011, 30, 3920–3927. [Google Scholar]

- Singh, G.S.P.; Singh, U.K. A numerical modeling approach for assessment of progressive caving of strata and performance of hydraulic powered support in longwall workings. Comput. Geotech. 2009, 36, 1142–1156. [Google Scholar] [CrossRef]

- Singh, G.S.P.; Singh, U.K. Prediction of caving behavior of strata and optimum rating of hydraulic powered support for longwall workings. Int. J. Rock Mech. Min. Sci. 2010, 47, 1–16. [Google Scholar] [CrossRef]

- Su, D.W.H.; Hasenfusgj, M. Geomechanical criteria of longwall face support selection at Consol mines. In Proceedings of the 23rd International Conference on Ground Control in Mining, Morgantown, WV, USA, 3–5 August 2004; pp. 1–10. [Google Scholar]

- Chen, J.S.; Peng, S.S. Design of longwall face support by use of neural network models. Trans. Inst. Min. Metal. Sect. A 1999, 108, A143–A151. [Google Scholar]

- Wang, H.; Wu, Y.; Xie, P.; Zhang, Y. Determination of support working resistance of fully-mechanized caving in steeply dipping seam with ultra thick. J. Liaoning Tech. Univ. 2014, 33, 1020–1024. [Google Scholar]

- Yu, L.; Yan, S.; Liu, Q. Determination of support working resistance of top coal caving in extra thick coal seam. J. China Coal Soc. 2012, 37, 737–742. [Google Scholar]

- Kong, L.; Jiang, F.; Wang, C. Study of reasonable working resistance of support in fully-mechanized sub level caving face in extra-thick coal seam. Chin. J. Mech. Eng. 2010, 11, 2312–2318. [Google Scholar]

- Rausand, M.; Arnljot, H. System Reliability Theory: Models, Statistical Methods, and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Qian, M.; Shi, P. Mine Pressure and Rock Formation Control; China University of Mining and Technology Press: Xuzhou, China, 2003. [Google Scholar]

- Peng, S.S. Topical areas of research needs in ground control—A state of the art review on coal mine ground control. Int. J. Min. Sci. Technol. 2015, 25, 1–6. [Google Scholar] [CrossRef]

- Fang, X. Study on stability of support-surrounding rock sand its control in fully-mechanized top-coal caving face. Chin. J. Mech. Eng. 2003, 22, 673–678. [Google Scholar]

- Wang, H.; Wu, Y.; Xie, P.; Cao, P.; Guo, F. Research on strata movement and support stability of fully-mechanized sub level caving work face with variable angle in steeply dipping seam. J. China Univ. Min. Technol. 2017, 3, 1–7. [Google Scholar]

| Serial No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Roof subsidence (mm) | ≤90 | 91–110 | 111–270 | 271–330 | 331–475 | 476–525 | ≥526 |

| Control effect partial | Excellent | Better | Good | Normal | Ordinary | Bad | Poor |

| Serial No. | Four Working Resistance | Value (kN) | Roof Subsidence/mm | Control Effect Partial | Supporting Strength (MPa) | Proportion Type | Overrun Percentage/% | Avg. (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. 25 | No. 50 | No. 60 | No. 70 | No. 90 | No. 110 | - | |||||||

| 1 | 8000 | 329 | Normal | 1.00 | A1 | 16.2 | 32.5 | 60.8 | 55.2 | 0.0 | 3.2 | 28.0 | |

| A2 | 5.7 | 17.7 | 39.1 | 26.4 | 0.0 | 0.8 | 16.9 | ||||||

| 2 | 7240 | 462 | Ordinary | 0.90 | A1 | 32.8 | 76.8 | 82.9 | 85.1 | 67.3 | 17.4 | 60.4 | |

| A2 | 11.5 | 41.8 | 53.3 | 40.7 | 38.5 | 6.4 | 31.7 | ||||||

| 3 | 7912 | 351 | Ordinary | 0.99 | A1 | 18.8 | 37.4 | 65.8 | 55.2 | 0.0 | 6.4 | 30.3 | |

| A2 | 6.6 | 20.3 | 42.3 | 26.4 | 0.0 | 1.1 | 16.1 | ||||||

| 4 | 8786 | 267 | Good | 1.10 | A1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| A2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||

| 5 | Cycle No./n | N = 182 | - | - | - | - | 64 | 99 | 117 | 87 | 104 | 46 | 86 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, P.; Ju, F.; Jessu, K.V.; Xiao, M.; Guo, S. Optimization and Practice of Support Working Resistance in Fully-Mechanized Top Coal Caving in Shallow Thick Seam. Energies 2017, 10, 1406. https://doi.org/10.3390/en10091406

Huang P, Ju F, Jessu KV, Xiao M, Guo S. Optimization and Practice of Support Working Resistance in Fully-Mechanized Top Coal Caving in Shallow Thick Seam. Energies. 2017; 10(9):1406. https://doi.org/10.3390/en10091406

Chicago/Turabian StyleHuang, Peng, Feng Ju, Kashi Vishwanath Jessu, Meng Xiao, and Shuai Guo. 2017. "Optimization and Practice of Support Working Resistance in Fully-Mechanized Top Coal Caving in Shallow Thick Seam" Energies 10, no. 9: 1406. https://doi.org/10.3390/en10091406