Hanging Wall Pressure Relief Mechanism of Horizontal Section Top-Coal Caving Face and Its Application—A Case Study of the Urumqi Coalfield, China

Abstract

:1. Introduction

2. HSTCC Method

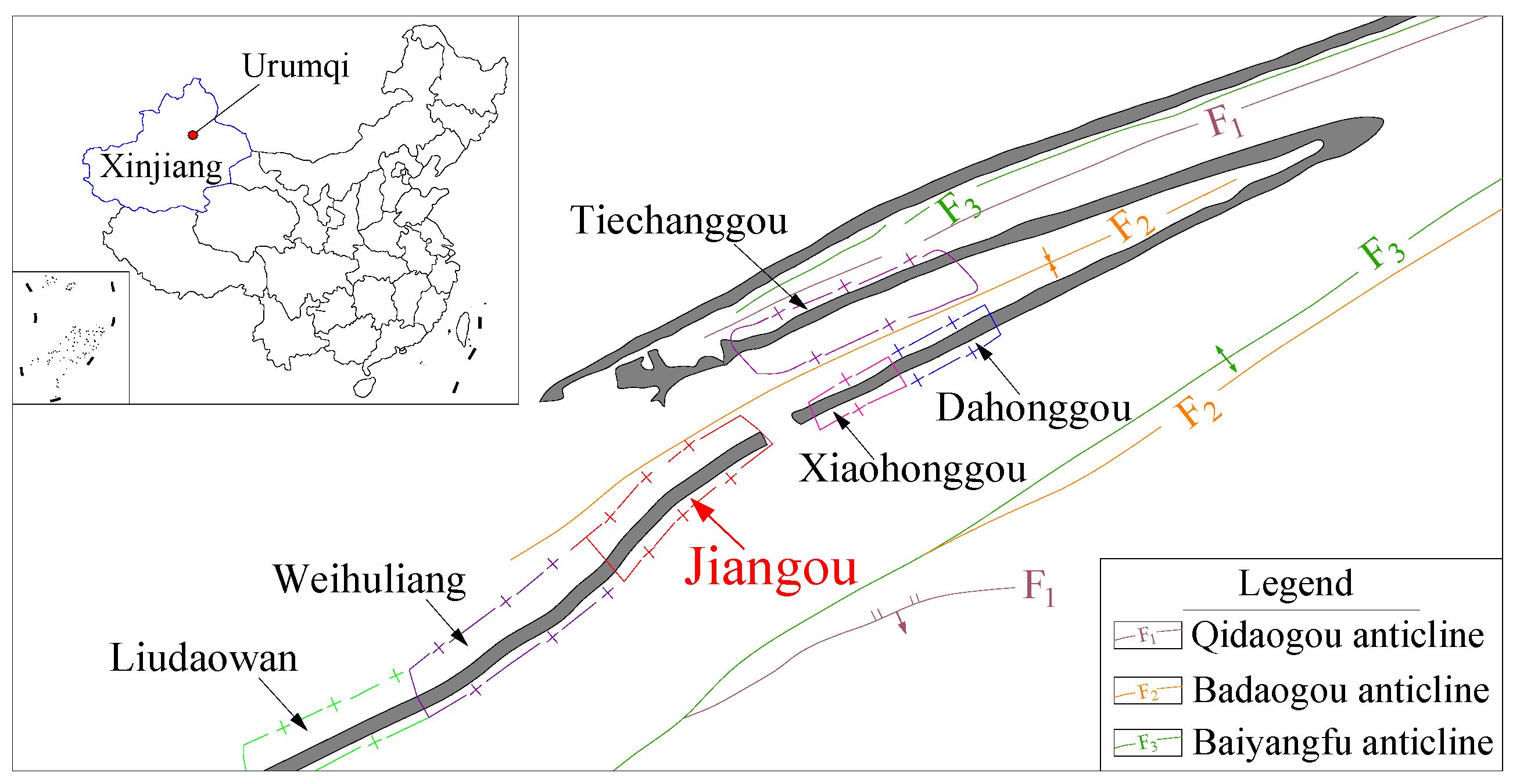

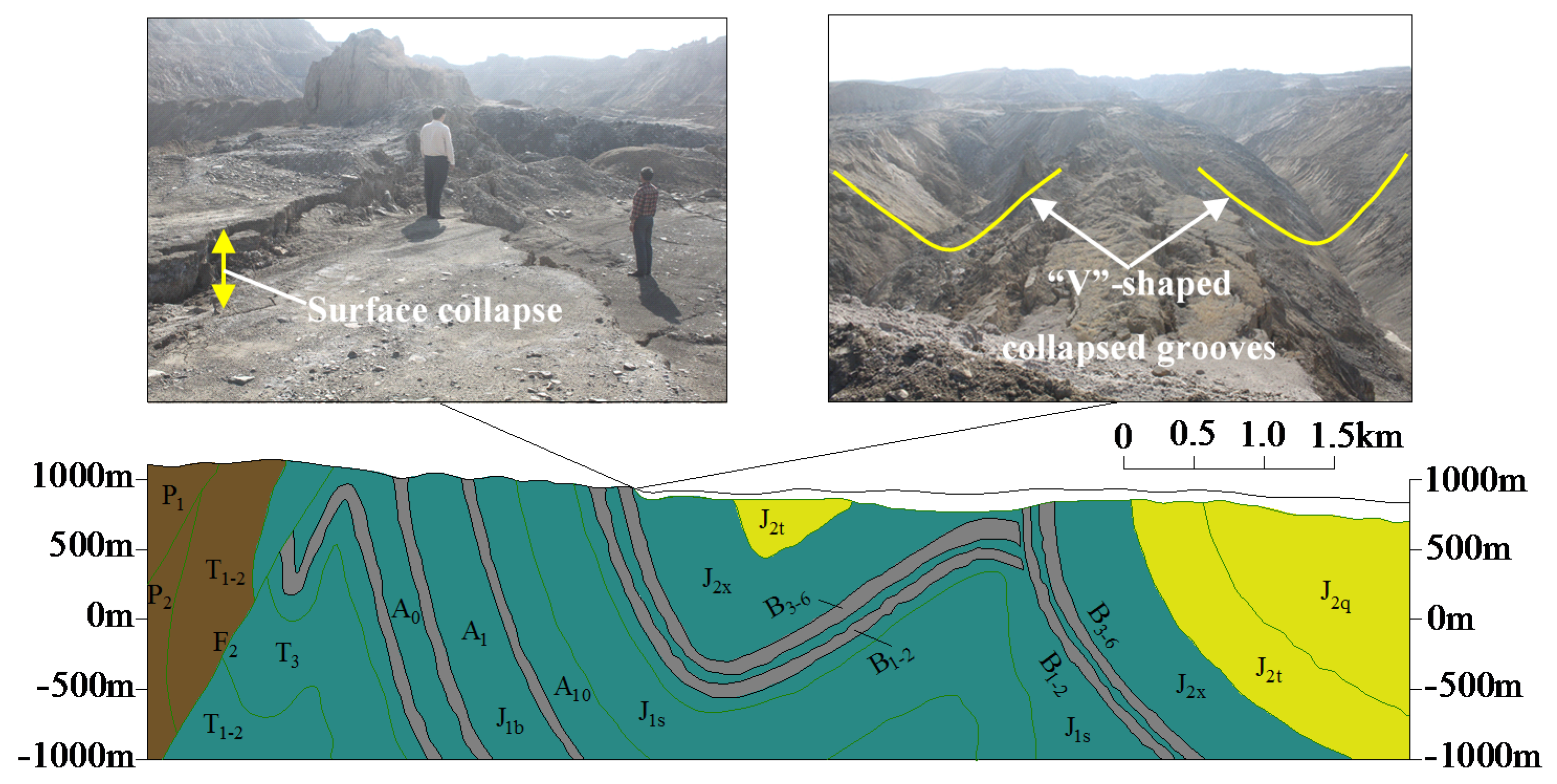

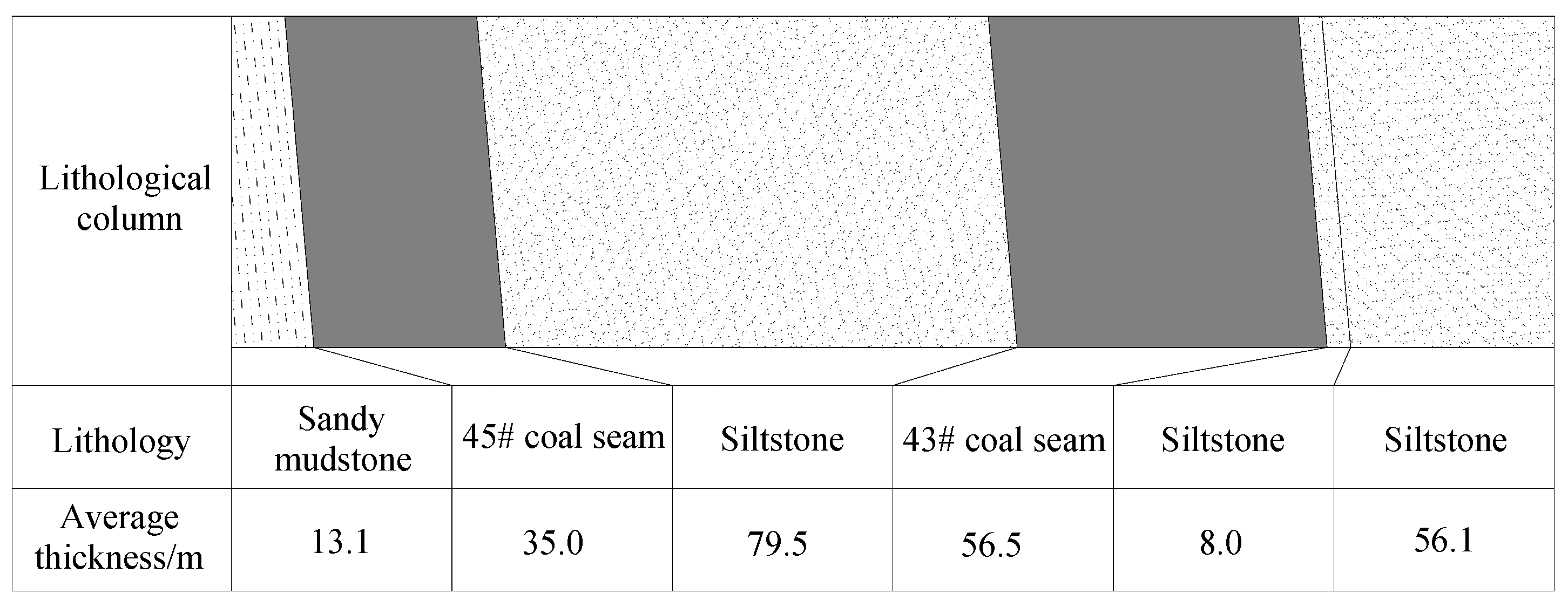

2.1. Geology Conditions

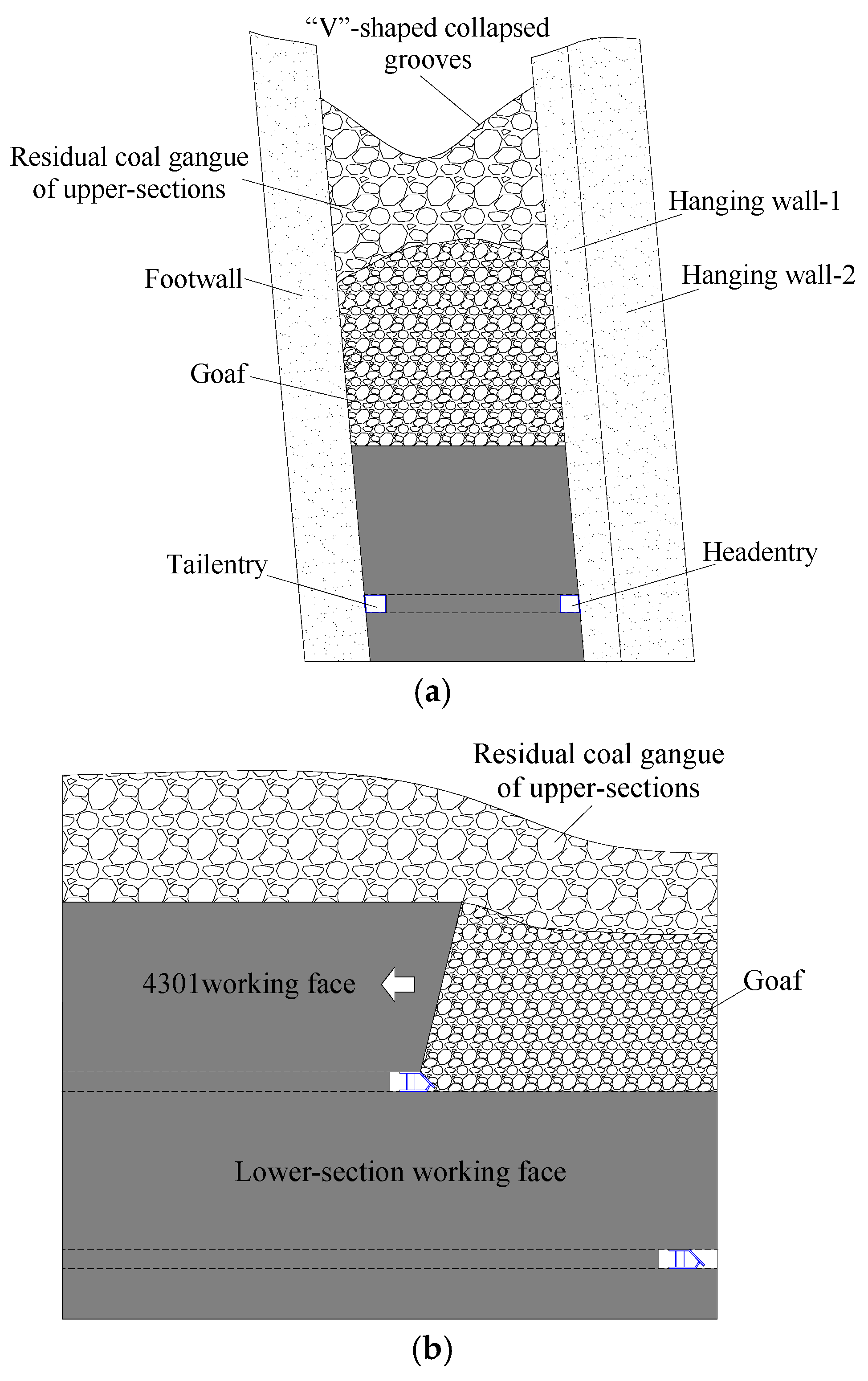

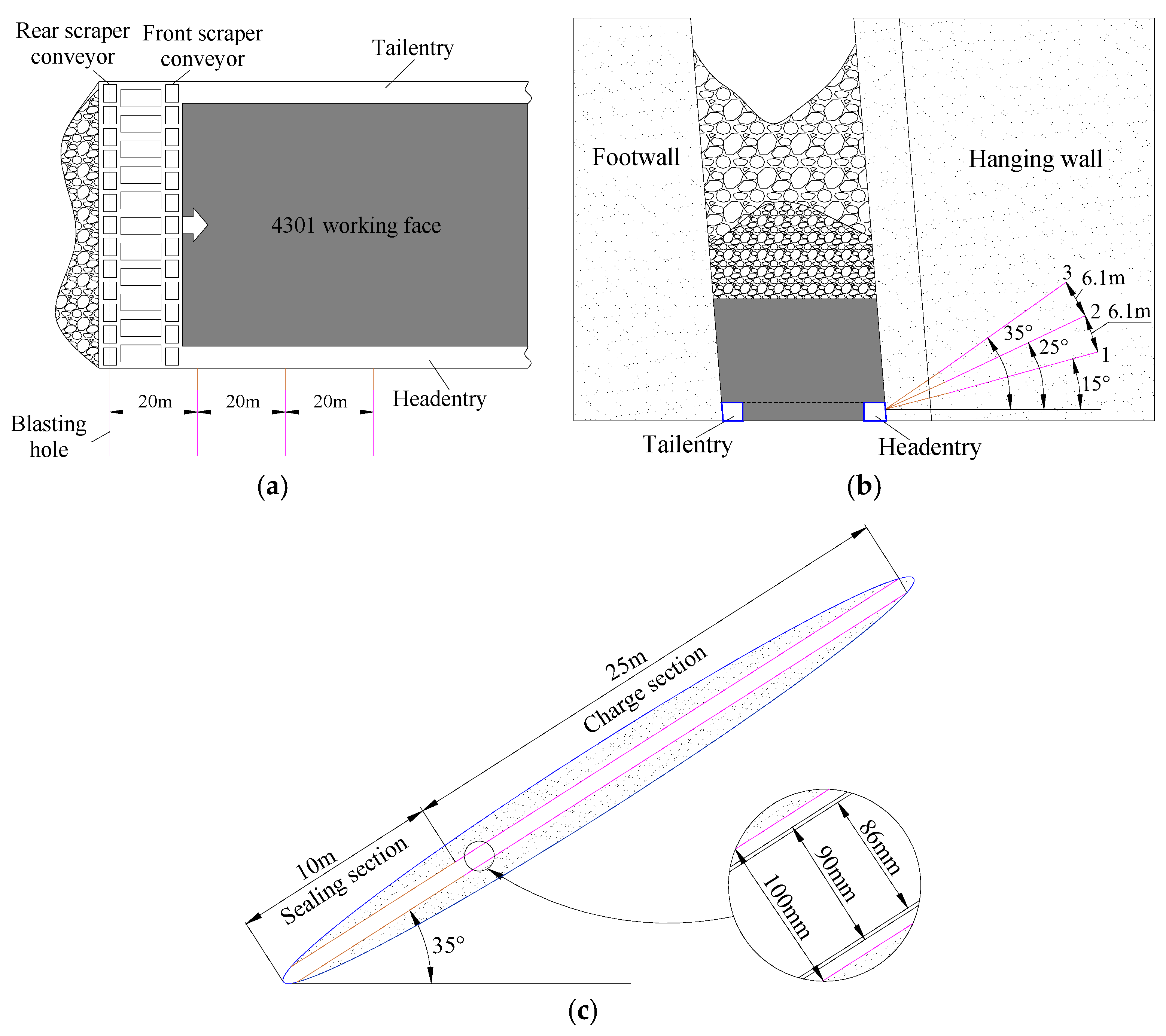

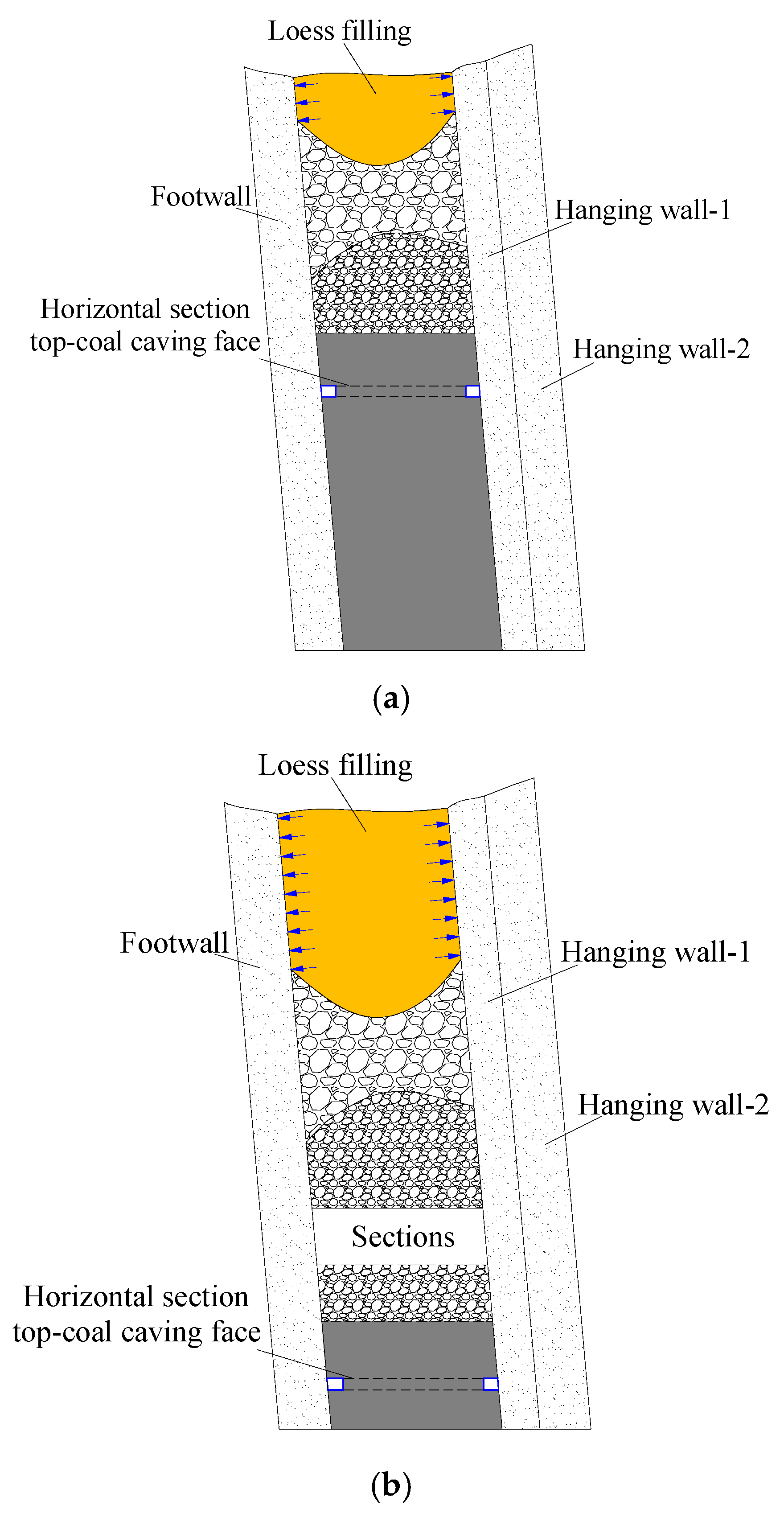

2.2. Mining Method

2.2.1. Mining Conditions

2.2.2. Face Layout

3. Deformation Behavior of HSTCC Face’s Hanging Wall

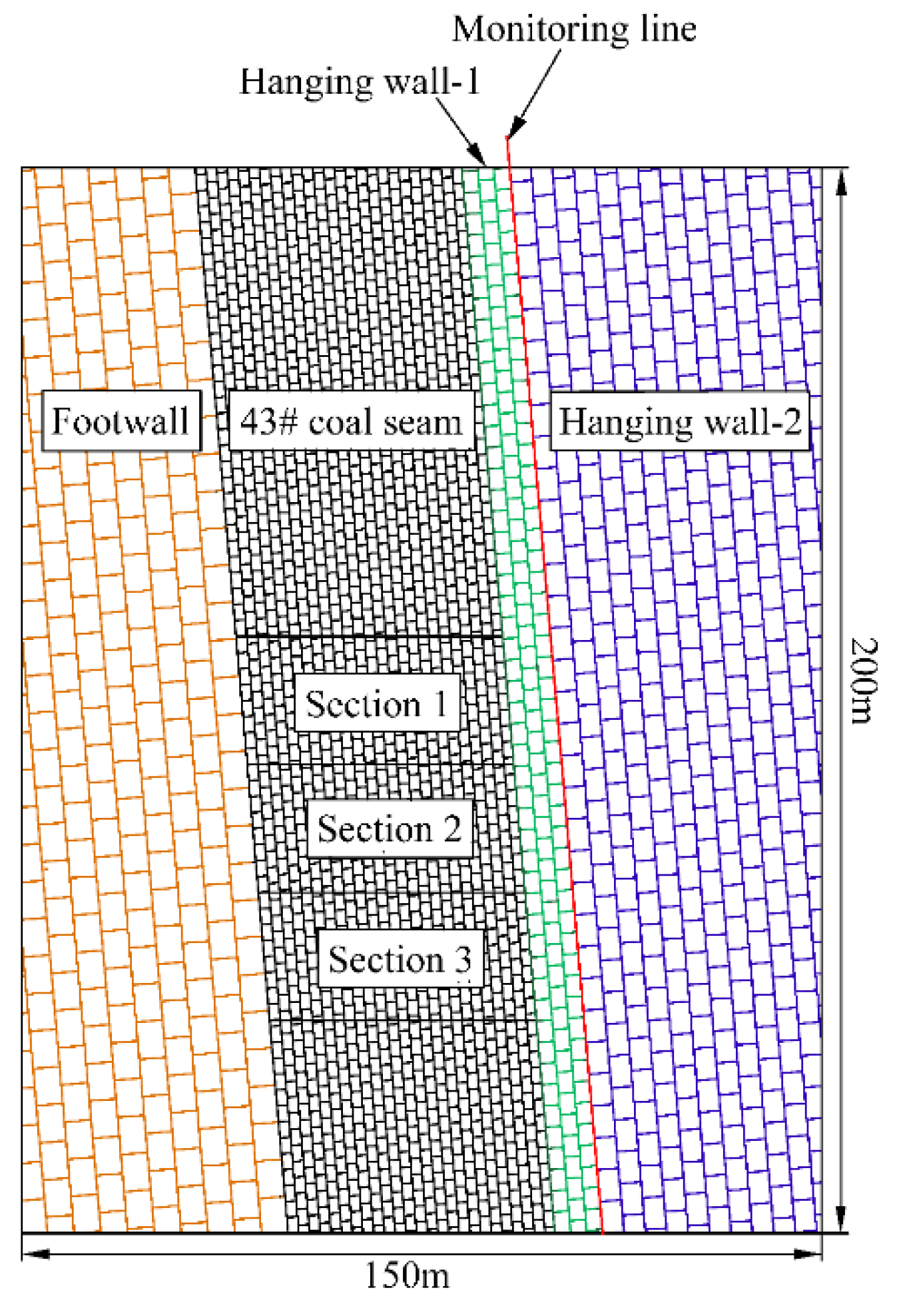

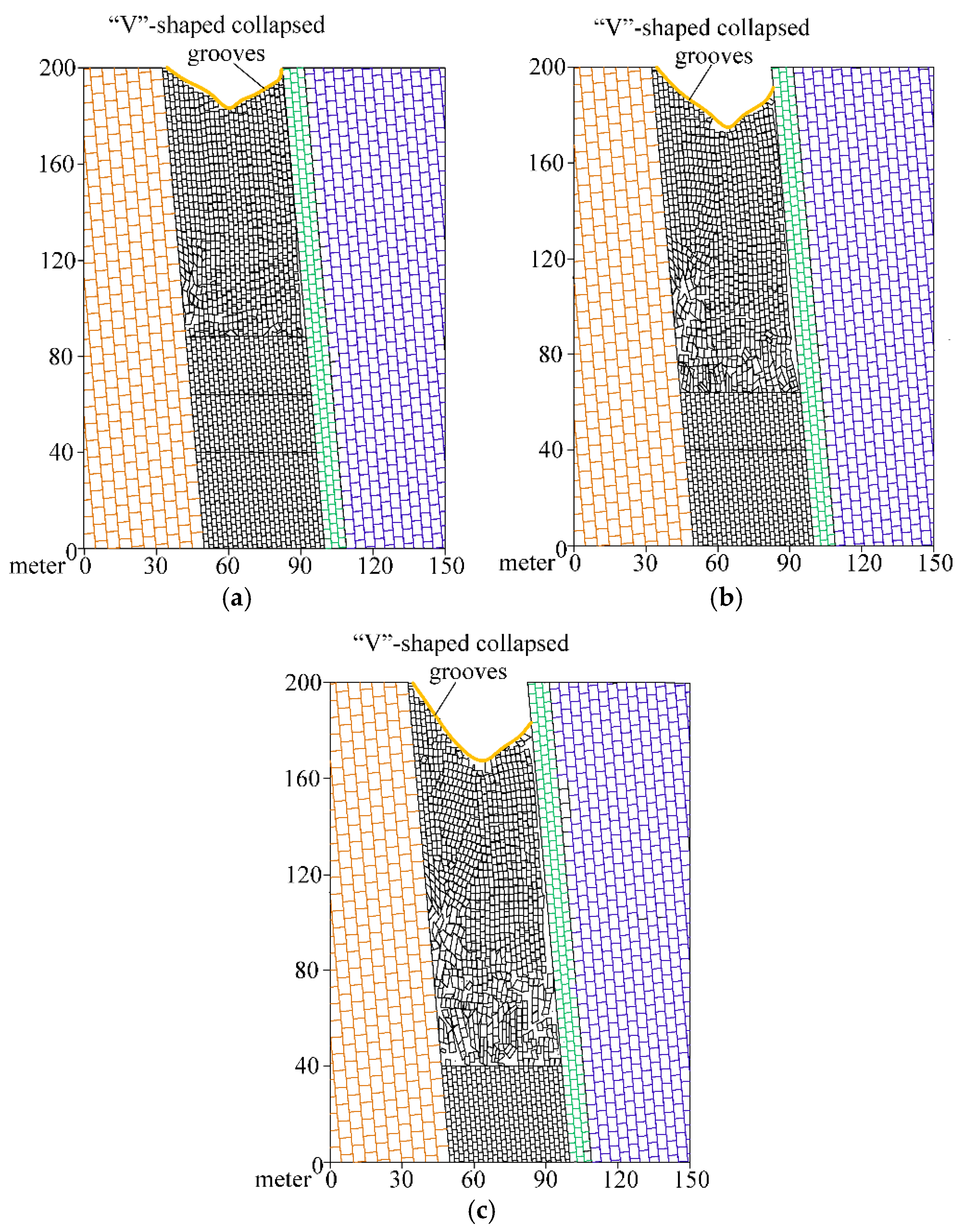

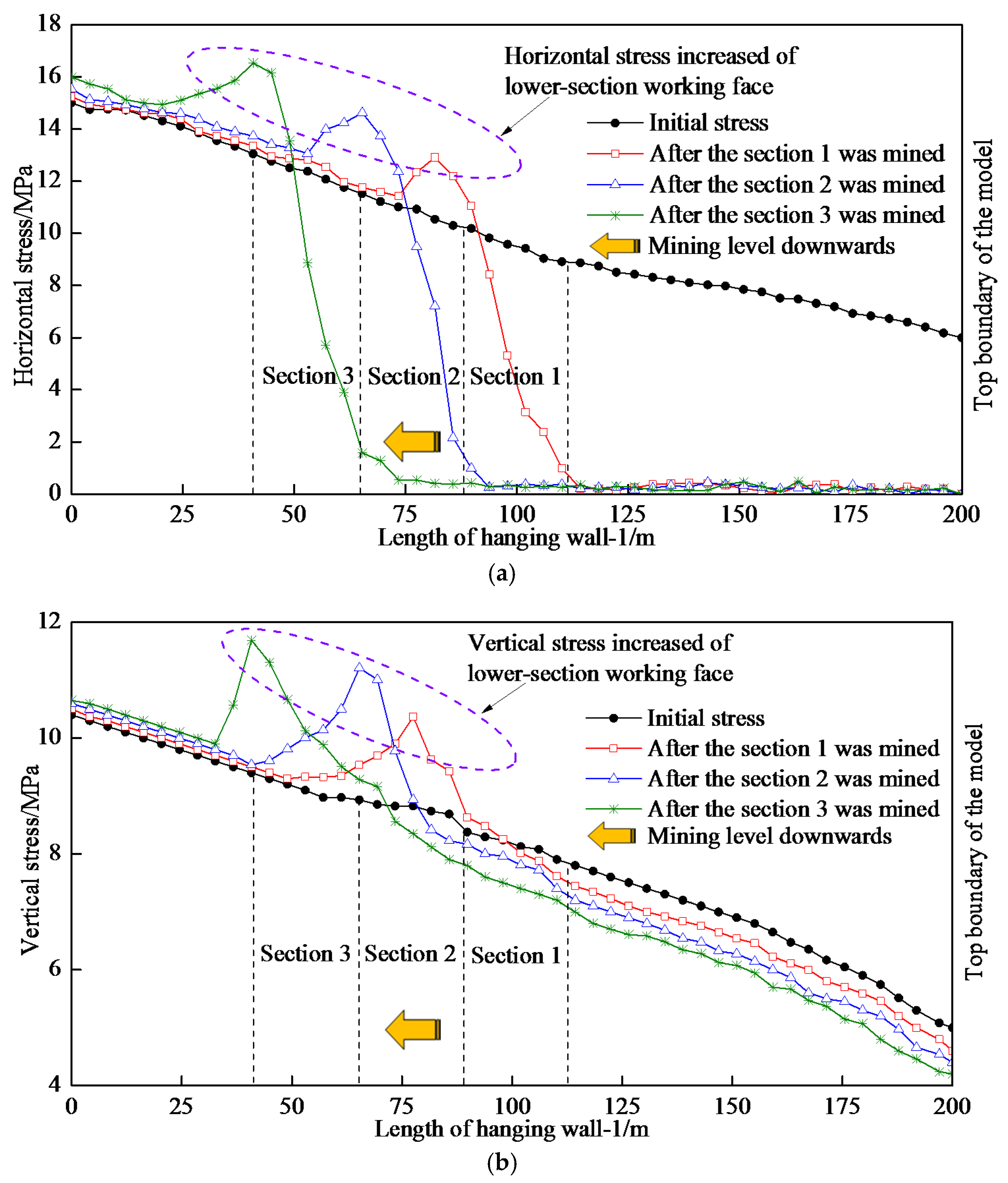

3.1. Numerical Simulation of HSTCC

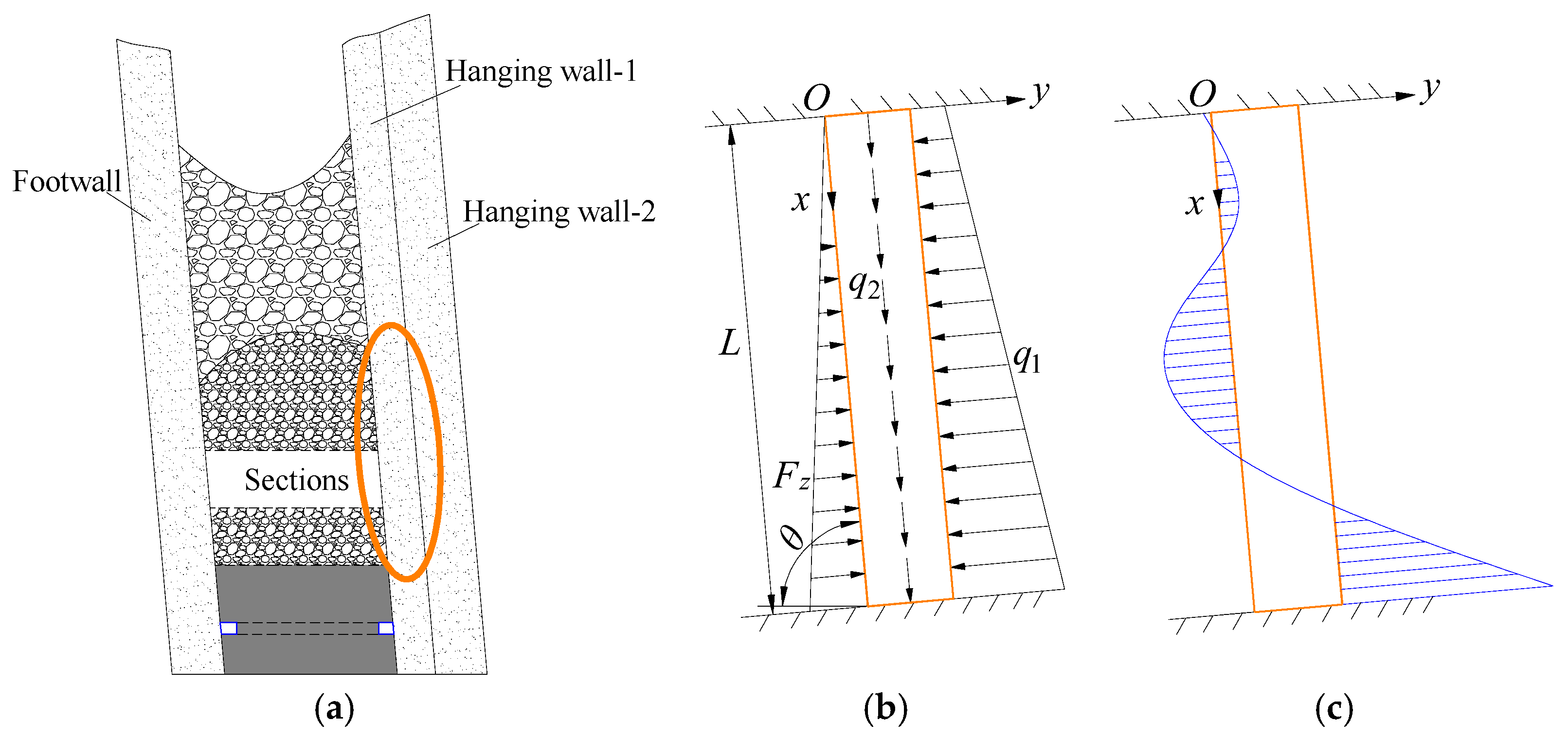

3.2. Mechanical Model of HSTCC Face’s Hanging Wall

- q1 is the normal load exerted on the hanging wall-1 by the hanging wall-2 (kN/m3);

- q2 is the tangential load on the hanging wall-1 (kN/m3);

- γ is the bulk density of the hanging wall strata (kN/m3);

- θ is the dip of hanging wall strata;

- Lj is the total thickness of the hanging wall-1 and hanging wall-2 (m);

- Fz is the supporting force exerted on the hanging wall-1 by the caved gangue (kN);

- Ld is the height of the goaf after several sections were mined (m);

- λ is lateral pressure coefficient;

- k is the distribution factor of the supporting force applied to the hanging wall-1 by the caved gangue (kN/m3).

3.2.1. Deformation Caused by the Normal Load

3.2.2. Deformation Caused by the Tangential Load

4. The DHB Technology for Pressure Relief

4.1. Mechanism of Pressure Relief by DHB

4.2. Theoretical Analysis of DHB and Numerical Simulation

4.2.1. Theoretical Analysis of DHB

- rb and rc are the radii of blasting holes and explosive charge, respectively (m);

- ρ and ρ0 are hanging wall rock density and explosive density, respectively (kg/m3);

- Cp and Dv are speed of sound in the rock blasted and detonation velocity (m/s);

- a is the attenuation coefficient of load;

- b is lateral stress coefficient;

- ud is the dynamic Poisson’s ratio of the rock, ud = 0.8u; in which u is the Poisson’s ratio of the rock;

- K is the radial decoupling coefficient of charge, K = rb/rc;

- lc is the axial decoupling coefficient of charge, lc = 1;

- n is the coefficient of pressure on blasting holes wall due to the impact of the expanding detonation products, normally n = 10;

- γ is the adiabatic expansion coefficient of the detonation products, usually set at 3;

- σcd and σtd are the dynamic compressive strength and tensile strength of the rock, respectively; σcd = ε1/3σc and σtd = ε1/3σd, in which σc and σd are compressive strength and tensile strength of the rock, respectively; ε is the strain rate of the load (s−1), normally ε = 10 s−1.

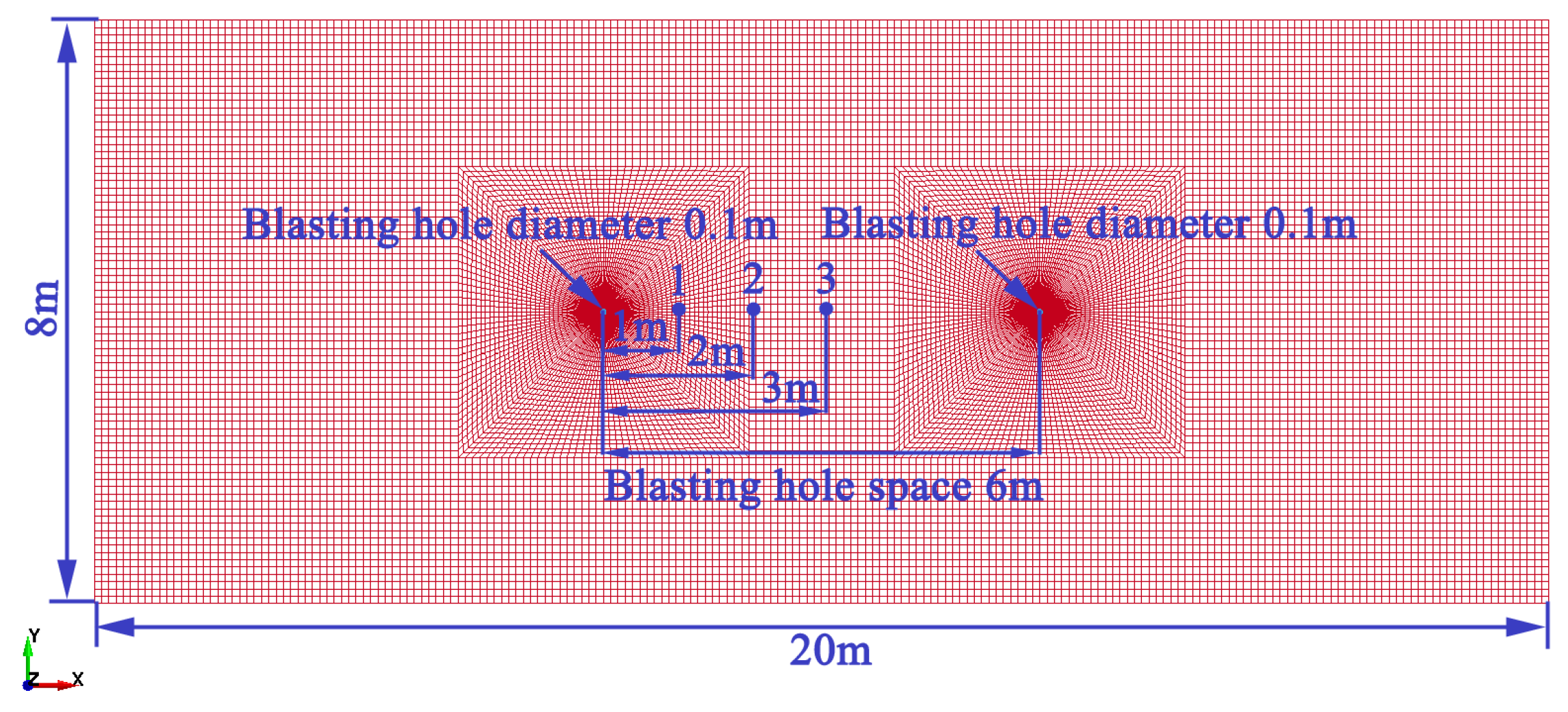

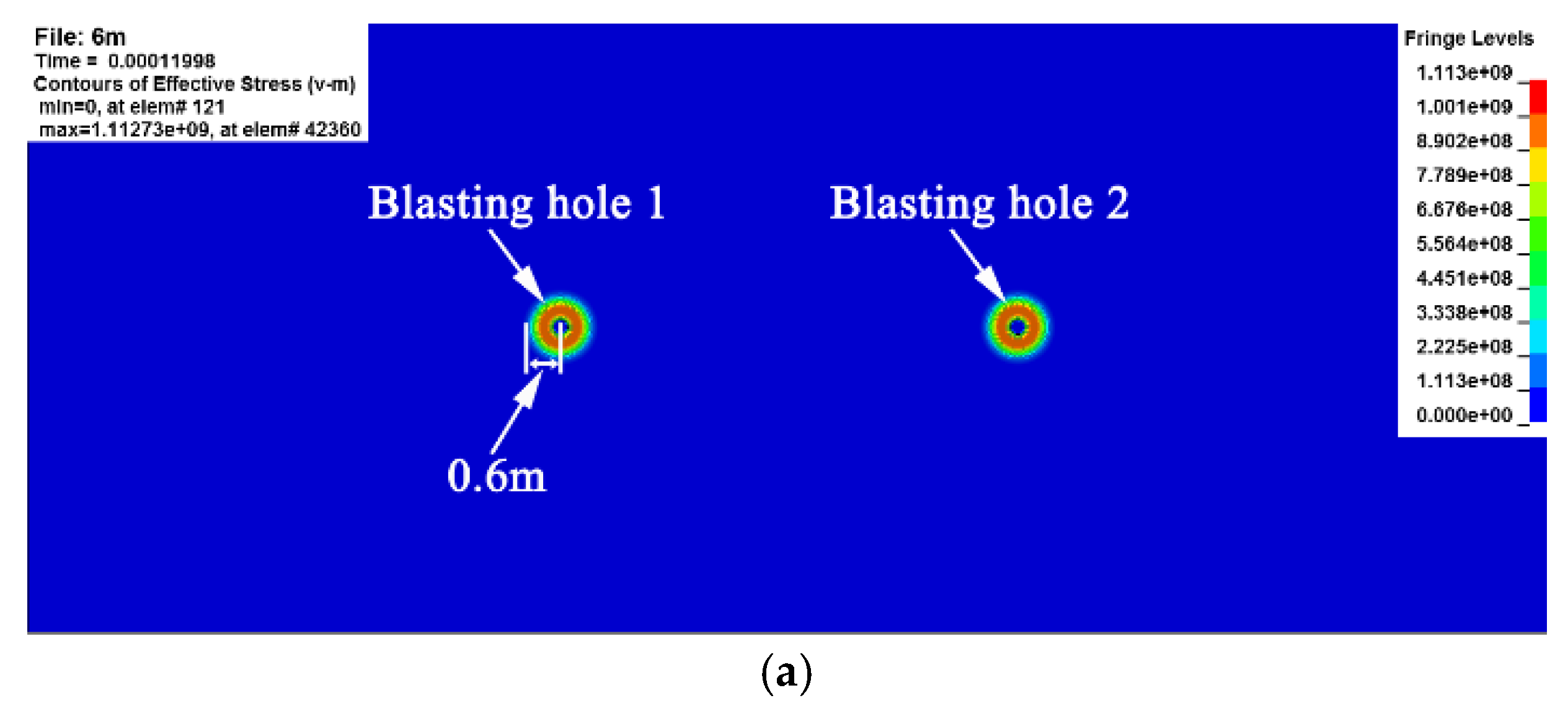

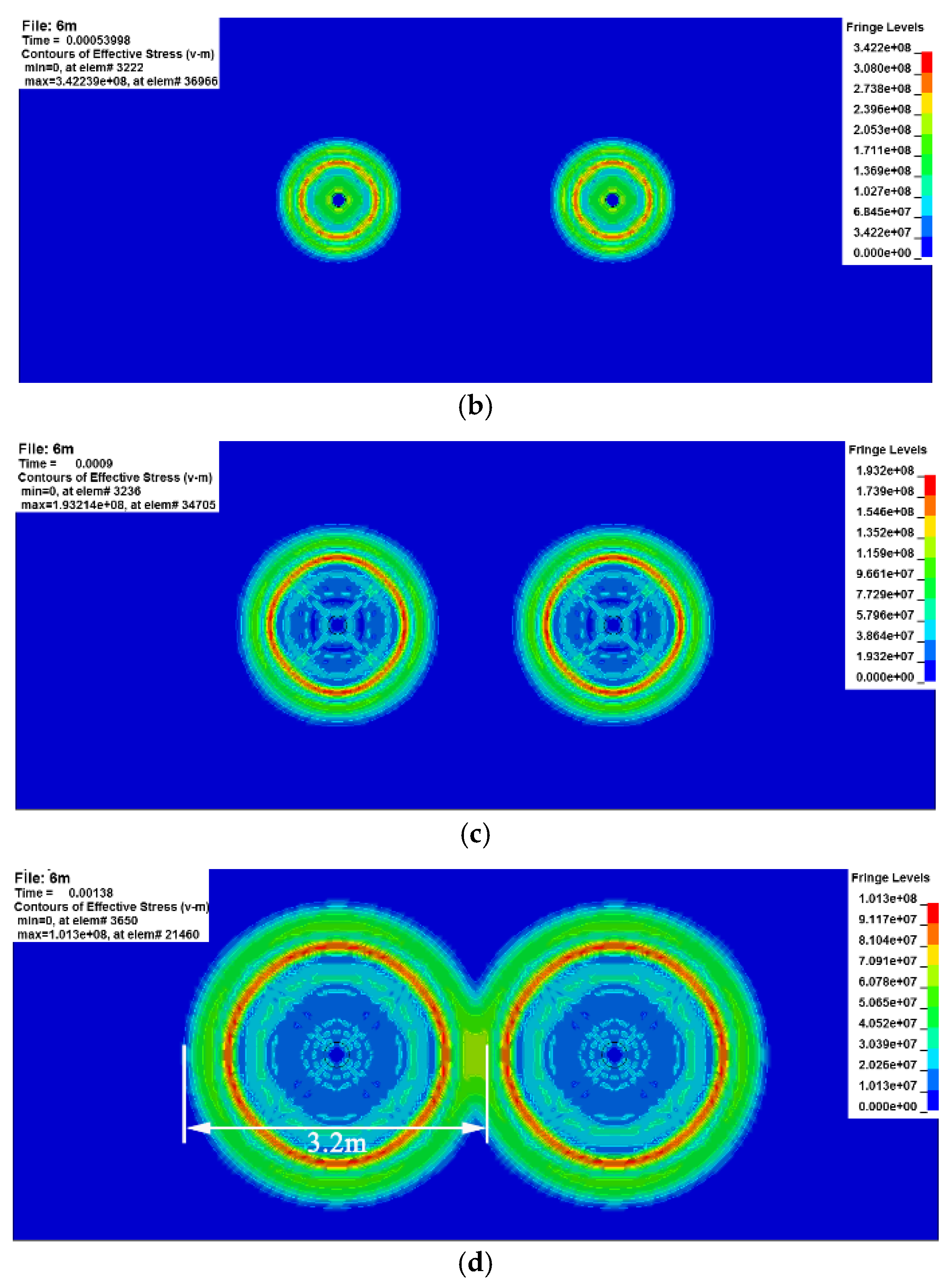

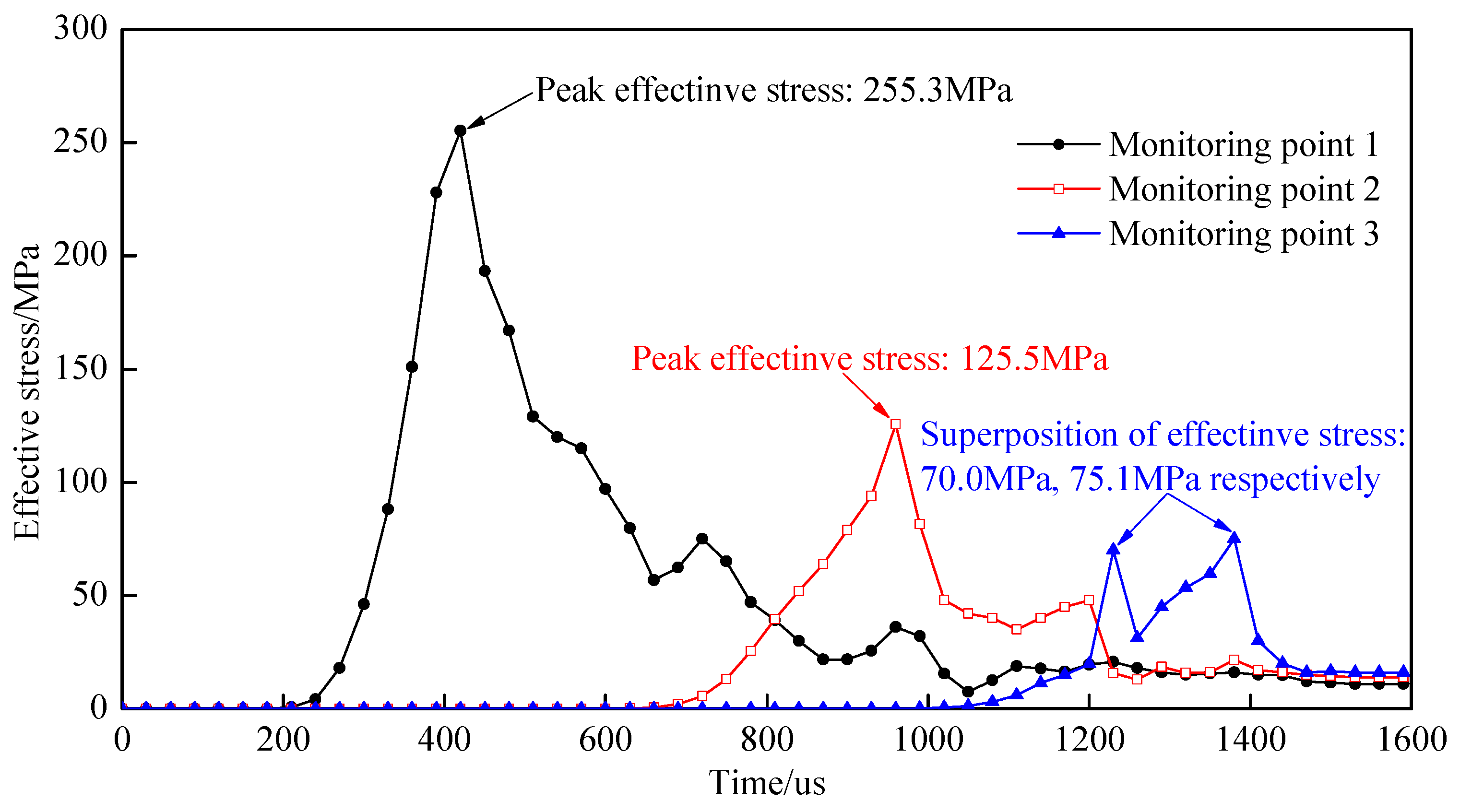

4.2.2. Numerical Simulation of DHB

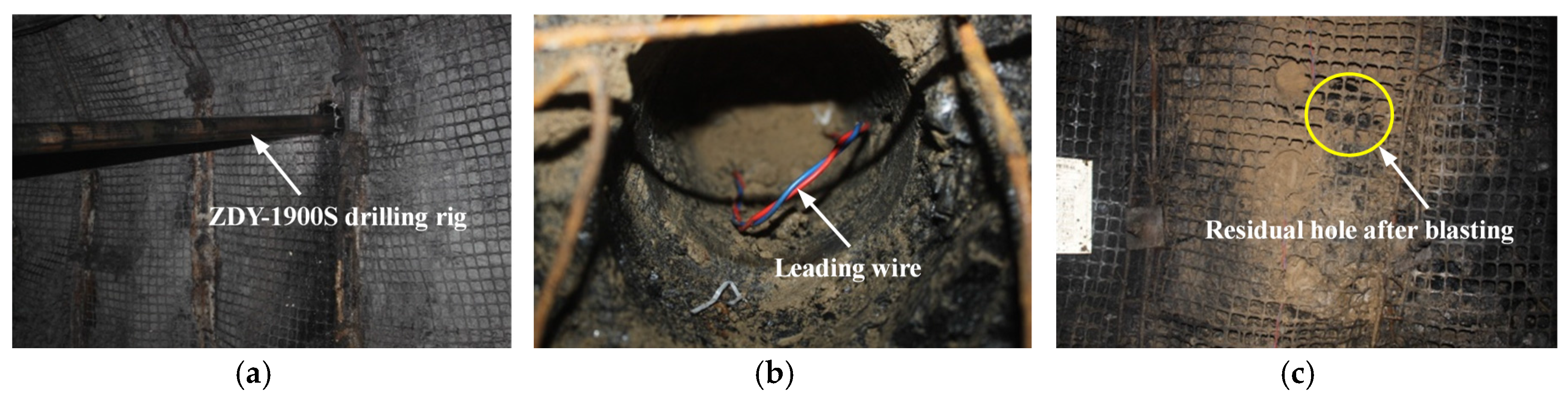

5. Engineering Application

5.1. Determination of Blasting Parameters

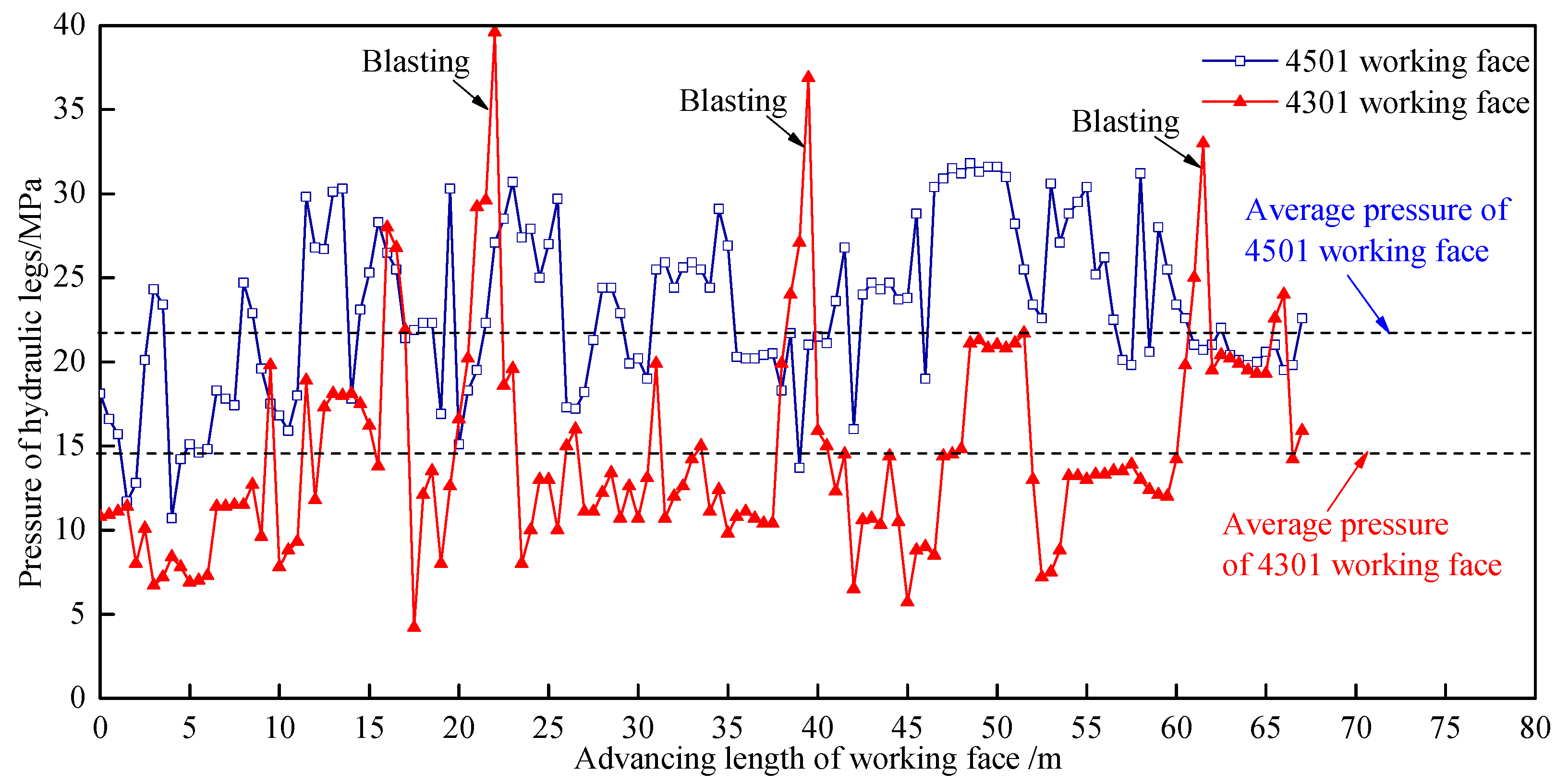

5.2. Effectiveness of DHB in Hanging Wall Pressure Relief

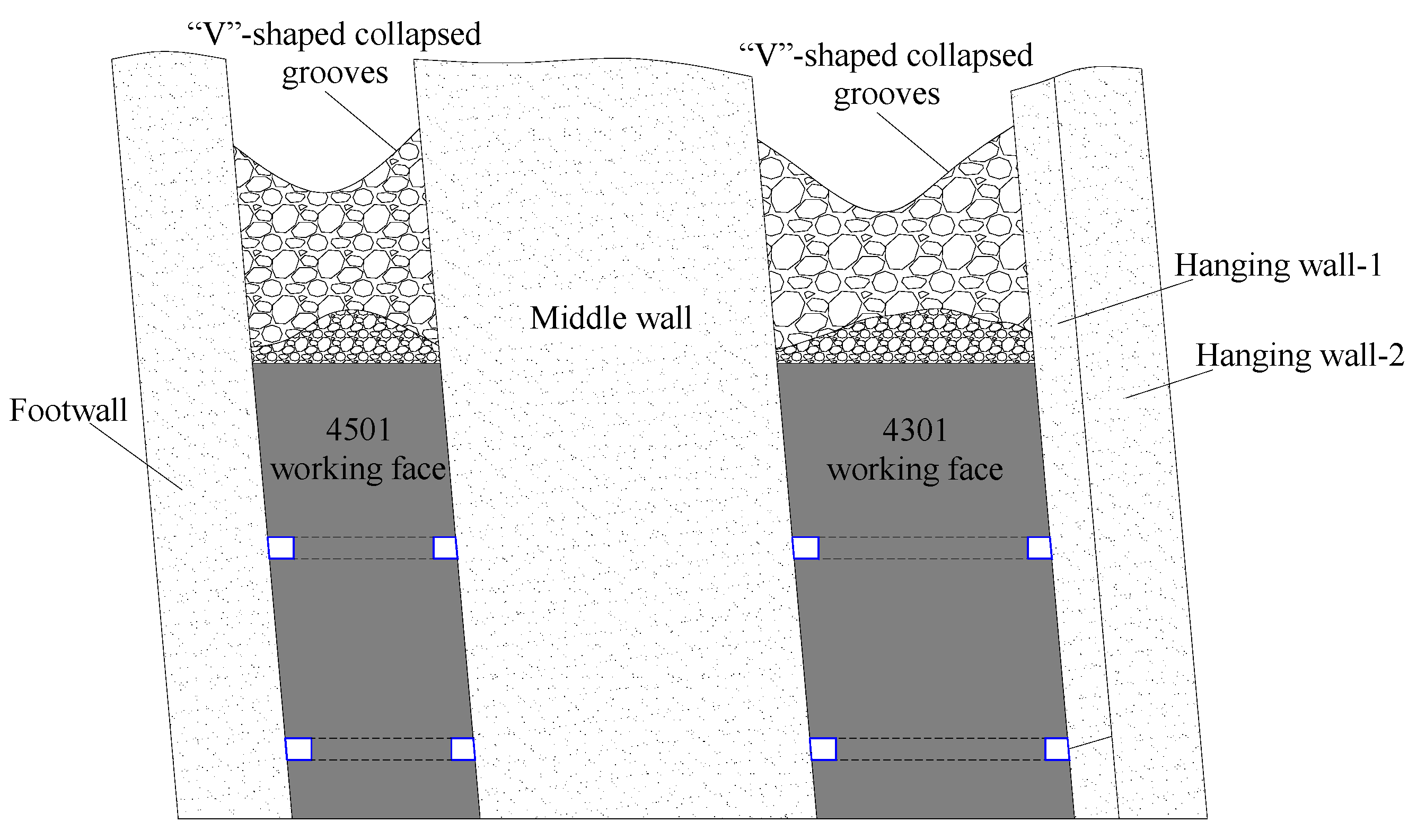

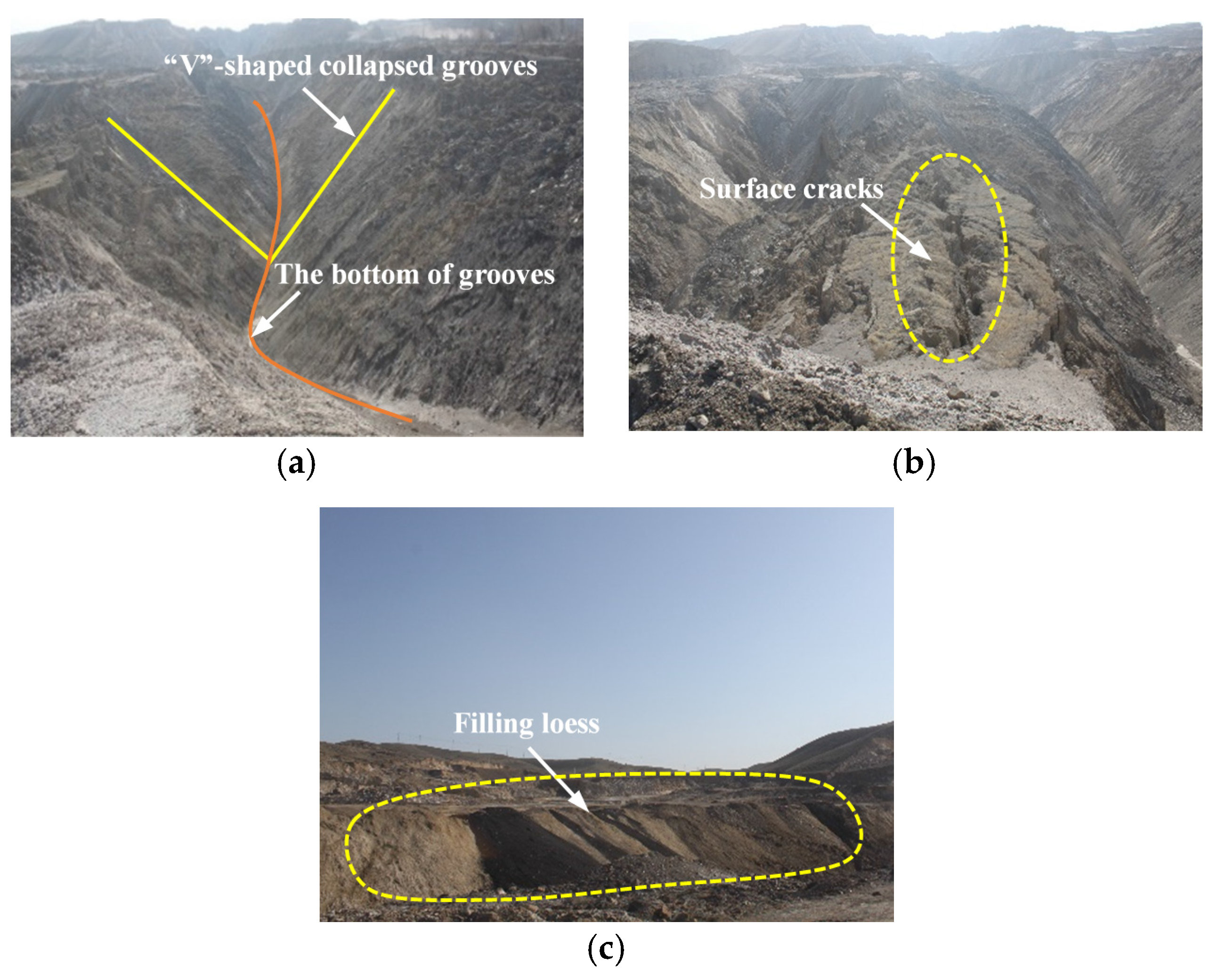

5.3. Loess Filling to Constrain Surface Collapsed Grooves

6. Discussion

- (1)

- The steeply-dipping thick seams group in the Urumqi coalfield was the product of local tectonic movements. Lateral tectonic movements exert a control role on the formation of in-situ stress. The study found that the rocks in this region are subject primarily to horizontal stresses. Therefore, the effect of tectonic stress should be considered when analyzing deformation behavior of HSTCC face’s hanging wall. In this study, a lateral pressure coefficient of 0.3 was included in the mechanical model presented above to account for the effect of tectonic stress [46].

- (2)

- Major factors influencing the effectiveness of DHB include blasting holes diameter, length, and space, blasting interval, etc. While blasting holes diameter and length and blasting interval depend primarily on the equipment available, geological conditions, and actual production situation, blasting holes space is easily adjustable and has a direct influence on the effectiveness of DHB in pressure relief. For this reason, the numerical analysis of the effectiveness of DHB focused on the influence of blasting holes space.

- (3)

- The blasting site was set right above the rear scraper conveyor behind the face, meaning that the explosive was detonated when the rear scraper conveyor reached the position under the blasting holes. In this way, the blasting energy was largely released into the goaf behind the face, thereby reducing the influence of blasting on the face as well as the headentry and tailentry along it.

- (4)

- The DHB technology was intended to relieve the hanging wall stress arising from hanging wall deformation after the working face was mined and thereby ensure safe production. The loess filling technology was proposed as a way to constrain surface “V”-shaped collapsed grooves resulting from SDTCS mining by HSTCC method. It uses loess to constrain the surrounding rock on the sides of the grooves area, so as to prevent rock failure and minimize ecological damage. The two technologies can be used in combination to guarantee green mining of SDTCS.

7. Conclusions

- (1)

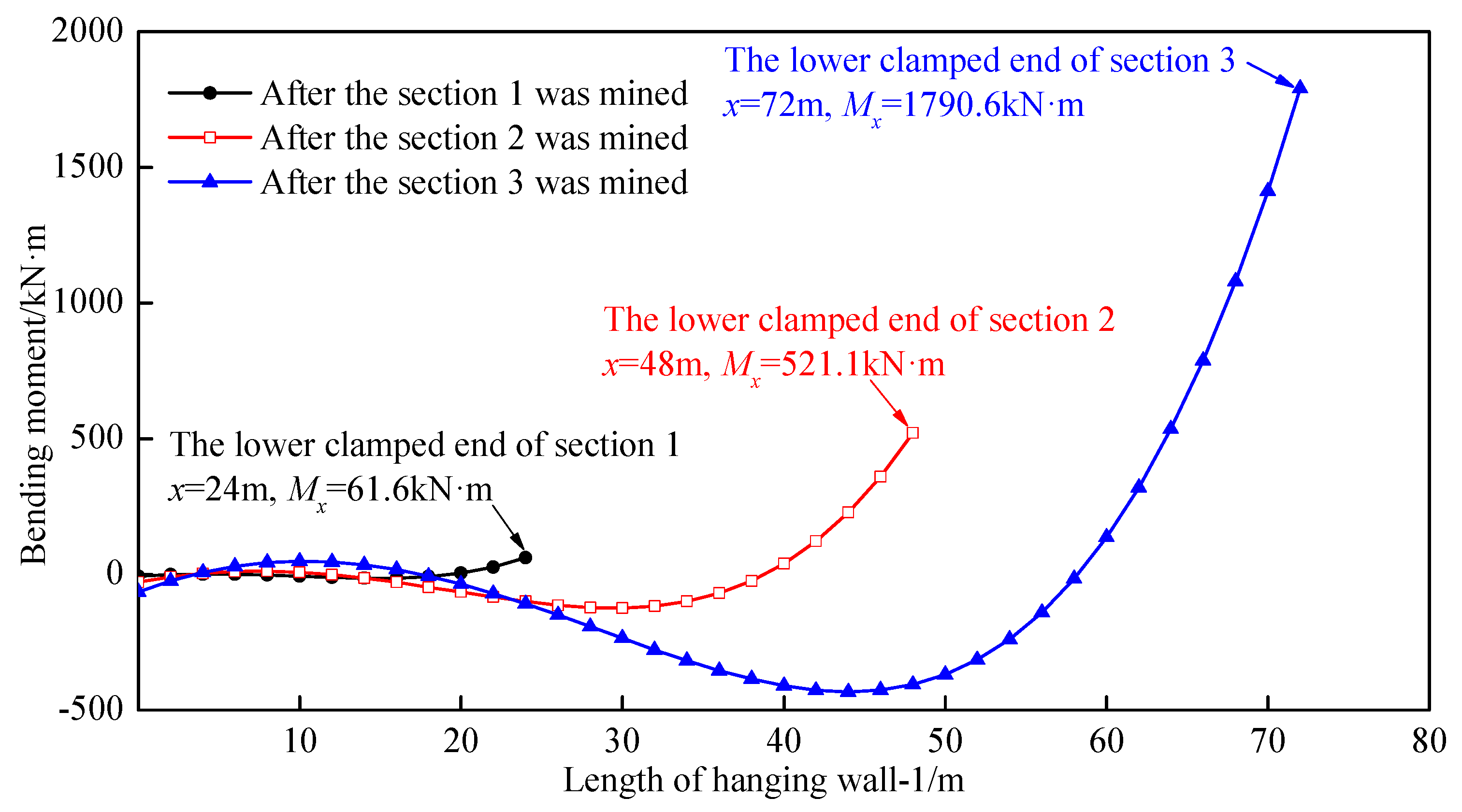

- The mining process of HSTCC was simulated in this study. It was found that the hanging wall of the HSTCC face was nearly-vertical and did not fracture easily after the working face was mined. The hanging wall-1 of the HSTCC face was modeled with a clamped-clamped elastic beam model to analyze its deformation behavior. The results show that after the section 2 was mined, the maximum bending moment in the hanging wall-1 increased 8.5-fold compared with that observed after of the section 1 was mined. After the section 3 was mined, the maximum bending moment increased 29.1-fold from that observed after the section 1 was mined. These suggest that, as the mining level downwards, the bending moment in the hanging wall-1 increased and its effect on the lower-section working face grew gradually.

- (2)

- The pressure relief mechanism of DHB was theoretically analyzed, and its effectiveness was examined by numerical simulation. The results suggest that blasting holes space of 6 m can ensure effective weakening of hanging wall. This technology was then applied to the 4301 working face of the Jiangou coal mine. The average pressure of hydraulic supports’ legs measured at this face decreased by about 34% compared to that measured at the 4501 face, which DHB was not applied.

- (3)

- The loess filling technology was proposed as a way to constrain the surface “V”-shaped collapsed grooves resulting from repeated mining of SDTCS by HSTCC. The large deformation and high mobility of loess enable the loess fill in the grooves to provide constraint and dynamic control on the lateral surrounding rock. Meanwhile, this technology can be used to reduce the ecological damage caused by mining of steeply-dipping seams.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wu, Y.P.; Yun, D.F.; Zhang, M.F. Study on the elementary problems of full-mechanized coal mining in greater pitching seam. J. China Coal Soc. 2000, 25, 465–468. [Google Scholar]

- Shenxin Energy Company Has Achieve the Rapid Development of Extracting Steeply Inclined Thick Coal Seam. Available online: http://scitech.people.com.cn/n/2013/1101/c1057-23394457.html (accessed on 1 September 2017).

- Onica, I.; Mihailescu, V.; Andrioni, F. Economical optimization of the mechanized longwall faces with top coal caving mining, in horizontal slices. Arch. Min. Sci. 2016, 61, 651–676. [Google Scholar] [CrossRef]

- Tu, H.S.; Tu, S.H.; Yuan, Y.; Wang, F.T.; Bai, Q.S. Present situation of fully mechanized mining technology for steeply inclined coal seams in china. Arab. J. Geosci. 2015, 8, 4485–4494. [Google Scholar] [CrossRef]

- Shao, X.P.; Zhang, H.X.; Shi, P.W. Selection of reasonable section heights during top-coal caving to steep seams. J. China Univ. Min. Technol. 2009, 38, 545–549. [Google Scholar]

- Ju, W.J.; Li, W.Z. Fracture mechanical model of main roof along inclined for fully-mechanized top-coal caving in steep and extra-thick coal seam. J. China Coal Soc. 2008, 33, 606–608. [Google Scholar]

- Ma, L.Q.; Zhang, Y.; Zhang, D.S.; Cao, X.Q.; Li, Q.Q.; Zhang, Y.B. Support stability mechanism in a coal face with large angles in both strike and dip. J. S. Afr. Inst. Min. Metall. 2015, 115, 599–606. [Google Scholar] [CrossRef]

- Kulakov, V.N. Geomechanical conditions of mining steep coal beds. J. Min. Sci. 1995, 31, 136–143. [Google Scholar] [CrossRef]

- Kulakov, V.N. Stress state in the face region of a steep coal bed. J. Min. Sci. 1995, 31, 161–168. [Google Scholar] [CrossRef]

- Klishin, V.I.; Klishin, S.V. Coal extraction from thick flat and steep beds. J. Min. Sci. 2010, 46, 149–159. [Google Scholar] [CrossRef]

- Klishin, S.V.; Klishin, V.I.; Opruk, G.Y. Modeling coal discharge in mechanized steep and thick coal mining. J. Min. Sci. 2013, 49, 932–940. [Google Scholar] [CrossRef]

- Shi, P.W.; Zhang, Y.Z. Structural analysis of arch of spanning strata of top coal caving in steep seam. Chin. J. Rock Mech. Eng. 2006, 25, 79–82. [Google Scholar]

- Lai, X.P.; Sui, H.; Shan, P.F.; Qiu, H.F. Overlying strata ellipsoid-style structure of horizontal section top-coal caving in steeply inclined and extra thick coal seam. J. Min. Saf. Eng. 2014, 31, 716–720. [Google Scholar]

- Huang, B.X.; Liu, C.Y.; Fu, J.H.; Guan, H. Hydraulic fracturing after water pressure control blasting for increased fracturing. Int. J. Rock Mech. Min. Sci. 2011, 48, 976–983. [Google Scholar] [CrossRef]

- Hossain, M.M.; Rahman, M.K. Numerical simulation of complex fracture growth during tight reservoir stimulation by hydraulic fracturing. J. Pet. Sci. Eng. 2008, 60, 86–104. [Google Scholar] [CrossRef]

- Gao, M.F. Numedcal simulation of hard roof processing step. J. Laoning Tech. Univ. 2006, 25, 649–651. [Google Scholar]

- Konicek, P.; Soucek, K.; Stas, L.; Singh, R. Long-hole destress blasting for rockburst control during deep underground coal mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 141–153. [Google Scholar] [CrossRef]

- Wang, K.; Kang, T.H.; Li, H.T.; Han, W.M. Study of control caving methods and reasonable hanging roof length on hard roof. Chin. J. Rock Mech. Eng. 2009, 28, 2320–2327. [Google Scholar]

- Zhang, Z.Z.; Bai, J.B.; Chen, Y.; Hao, S.P. Shallow-hole blasting mechanism and its application for gob-side entry retaining with thick and hard roof. Chin. J. Rock Mech. Eng. 2016, 35, 3008–3016. [Google Scholar]

- Zhang, J.X.; Zhang, Q.; Sun, Q.; Gao, R.; Germain, D.; Abro, S. Surface subsidence control theory and application to backfill coal mining technology. Environ. Earth Sci. 2015, 74, 1439–1448. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, J.X.; Zhang, Q.; Zhao, X. Analysis and prevention of geo-environmental hazards with high-intensive coal mining: A case study in China’s western eco-environment frangible area. Energies 2017, 10, 786. [Google Scholar] [CrossRef]

- Zhou, H.Q.; Hou, C.J.; Sun, X.K.; Qu, Q.D.; Chen, D.J. Solid waste paste filling for none-village-relocation coal mining. J. China Univ. Min. Technol. 2004, 33, 154–158. [Google Scholar]

- Qu, Q.D.; Yao, Q.L.; Li, X.H.; Rong, T.Y. Key factors affecting control surface subsidence in backfilling mining. J. Min. Saf. Eng. 2010, 26, 458–462. [Google Scholar]

- Zhou, Z. Research on goaf filling methods with super high-water material. J. China Coal Soc. 2010, 35, 1963–1968. [Google Scholar]

- Teng, H.; Xu, J.L.; Xuan, D.Y.; Wang, B.L. Surface subsidence characteristics of grout injection into overburden: Case study of Yuandian No. 2 coalmine, China. Environ. Earth Sci. 2016, 75, 530. [Google Scholar] [CrossRef]

- Zhu, W.B.; Xu, J.L.; Lai, W.Q.; Wang, Z.G. Research of isolated section-grouting technology for overburden bed separation space to reduce subsidence. J. China Coal Soc. 2007, 32, 458–462. [Google Scholar]

- Zhang, D.S.; Liu, H.L.; Fan, G.W.; Wang, X.F. Connotation and prospection on scientific mining of large Xinjiang coal base. J. Min. Saf. Eng. 2015, 32, 1–6. [Google Scholar]

- Shao, X.P.; Shi, P.W. Strata behavior in large section face of steep seams. J. Min. Saf. Eng. 2009, 26, 36–40. [Google Scholar]

- Wang, N.B.; Zhang, N.; Cui, F.; Cao, J.T.; Lai, X.P. Characteristics of stope migration and roadway surrounding rock fracture for fully-mechanized top-coal caving face in steeply dipping and extra-thick coal seam. J. China Coal Soc. 2013, 38, 1312–1318. [Google Scholar]

- Lai, X.P.; Li, Y.P.; Wang, N.B.; Liu, Y.H.; Ran, P.J. Roof deformation characteristics with full-mechanized caving face based on beam structure in extremely inclined coal seam. J. Min. Saf. Eng. 2015, 32, 871–876. [Google Scholar]

- Zhang, J.W.; Wang, J.A. Energy distribution characteristics and rock burst control methods of steeper inclined thick coal seam hanging roof. J. China Coal Soc. 2014, 39, 316–324. [Google Scholar]

- Shi, P.W.; Shao, X.P. Function of destruction and instability of basic roof in top coal caving of steep seams. J. Liaoning Tech. Univ. 2006, 25, 325–328. [Google Scholar]

- Lai, X.P.; Sun, H.; Shan, P.F.; Cai, M.; Cao, J.T.; Cui, F. Structure instability forecasting and analysis of giant rock pillars in steeply dipping thick coal seams. Int. J. Miner. Metall. Mater. 2015, 22, 1233–1244. [Google Scholar] [CrossRef]

- Ma, L.Q.; Cao, X.Q.; Li, Q.Q.; Jia, J.L.; Fan, G.W. The support stability mechanism in dip direction of fully mechanised working face with big dip angle considering the strike angle. Int. J. Oil Gas Coal Technol. 2015, 9, 61–78. [Google Scholar] [CrossRef]

- Huang, Y.L.; Li, J.M.; Song, T.Q.; Kong, G.Q.; Li, M. Analysis on filling ratio and shield supporting pressure for overburden movement control in coal mining with compacted backfilling. Energies 2017, 10, 31. [Google Scholar] [CrossRef]

- Chen, J.; Du, J.P.; Zhang, W.S.; Zhang, J.X. An elastic base beam model of overlying strata movement during coal mining with gangue back-filling. J. China Univ. Min. Technol. 2012, 41, 14–19. [Google Scholar]

- Yang, J.X.; Liu, C.Y.; Yang, P.J.; Yang, Y. Research on roadside packing technology for end zone of steep inclined coal seam face. Rock Soil Mech. 2014, 35, 543–550. [Google Scholar]

- Cui, F.; Lai, X.P.; Cao, J.Y. Mining disturbance of horizontal section full-mechanized caving face in steeply inclined coal seam. J. Min. Saf. Eng. 2015, 32, 610–616. [Google Scholar]

- Sanchidrián, J.A.; Segarra, P.; López, L.M. Energy components in rock blasting. Int. J. Rock Mech. Min. Sci. 2007, 44, 130–147. [Google Scholar] [CrossRef]

- Wang, F.T.; Tu, S.H.; Yuan, Y.; Feng, Y.F.; Chen, F.; Tu, H.S. Deep-hole pre-split blasting mechanism and its application for controlled roof caving in shallow depth seams. Int. J. Rock Mech. Min. Sci. 2013, 64, 112–121. [Google Scholar] [CrossRef]

- Shang, X.J.; Su, J.Y. Dynamic Analysis Method and Engineering Example of Ansys/Ls-Dyna; China Water Conservancy and Hydropower Press: Beijing, China, 2008. [Google Scholar]

- Shi, S.Q.; Kang, J.G.; Wang, M.; Liu, Y.; Li, X.D. The Engineering Applications of Ansys/ls-Dyna in the Field of Explosion and Impact; China Construction Industry Press: Beijing, China, 2011. [Google Scholar]

- Gao, K.; Liu, Z.G.; Liu, J.; Deng, D.S.; Gao, X.Y.; Kang, Y.; Huang, K.F. Application of deep borehole blasting to gob-side entry retaining forced roof caving in hard and compound roof deep well. Chin. J. Rock Mech. Eng. 2013, 32, 1588–1594. [Google Scholar]

- Liu, Z.; Cao, A.; Zhu, G.; Wang, C. Numerical simulation and engineering practice for optimal parameters of deep-hole blasting in sidewalls of roadway. Arab. J. Sci. Eng. 2017, 42, 3809–3818. [Google Scholar] [CrossRef]

- Shao, X.P.; Shi, P.W. Stability research of surrounding rock at gob area using large section mining in steep seam. J. Liaoning Tech. Univ. (Nat. Sci.) 2010, 29, 353–356. [Google Scholar]

- Lai, X.-P.; Cai, M.-F.; Ren, F.-H.; Shan, P.-F.; Cui, F.; Cao, J.-T. Study on dynamic disaster in steeply deep rock mass condition in urumchi coalfield. Shock Vib. 2015, 2015, 465017. [Google Scholar] [CrossRef]

| Number | Strata | Thickness (m) | Density (kg/m3) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Cohesion (MPa) | Friction Angle (°) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| 1 | Footwall | 30 | 2530 | 10.8 | 8.1 | 2.8 | 38 | 3.1 |

| 2 | 43# coal seam | 56 | 1400 | 2.9 | 1.3 | 1.2 | 28 | 2.0 |

| 3 | Hanging wall-1 | 8 | 2530 | 10.8 | 8.1 | 2.8 | 38 | 3.1 |

| 4 | Hanging wall-2 | 56 | 2530 | 10.8 | 8.1 | 2.8 | 38 | 3.1 |

| Number | Strata | Thickness (m) | Normal Stiffness (GPa) | Shear Stiffness (GPa) | Cohesion (MPa) | Friction Angle (°) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | Footwall | 30 | 30 | 10 | 2.5 | 30 | 5 |

| 2 | 43# coal seam | 56 | 15 | 8 | 1.0 | 20 | 3 |

| 3 | Hanging wall-1 | 8 | 30 | 10 | 2.5 | 30 | 5 |

| 4 | Hanging wall-2 | 56 | 30 | 10 | 2.5 | 30 | 5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Ma, L.; Wang, Y.; Wang, F. Hanging Wall Pressure Relief Mechanism of Horizontal Section Top-Coal Caving Face and Its Application—A Case Study of the Urumqi Coalfield, China. Energies 2017, 10, 1371. https://doi.org/10.3390/en10091371

Guo J, Ma L, Wang Y, Wang F. Hanging Wall Pressure Relief Mechanism of Horizontal Section Top-Coal Caving Face and Its Application—A Case Study of the Urumqi Coalfield, China. Energies. 2017; 10(9):1371. https://doi.org/10.3390/en10091371

Chicago/Turabian StyleGuo, Jinshuai, Liqiang Ma, Ye Wang, and Fangtian Wang. 2017. "Hanging Wall Pressure Relief Mechanism of Horizontal Section Top-Coal Caving Face and Its Application—A Case Study of the Urumqi Coalfield, China" Energies 10, no. 9: 1371. https://doi.org/10.3390/en10091371