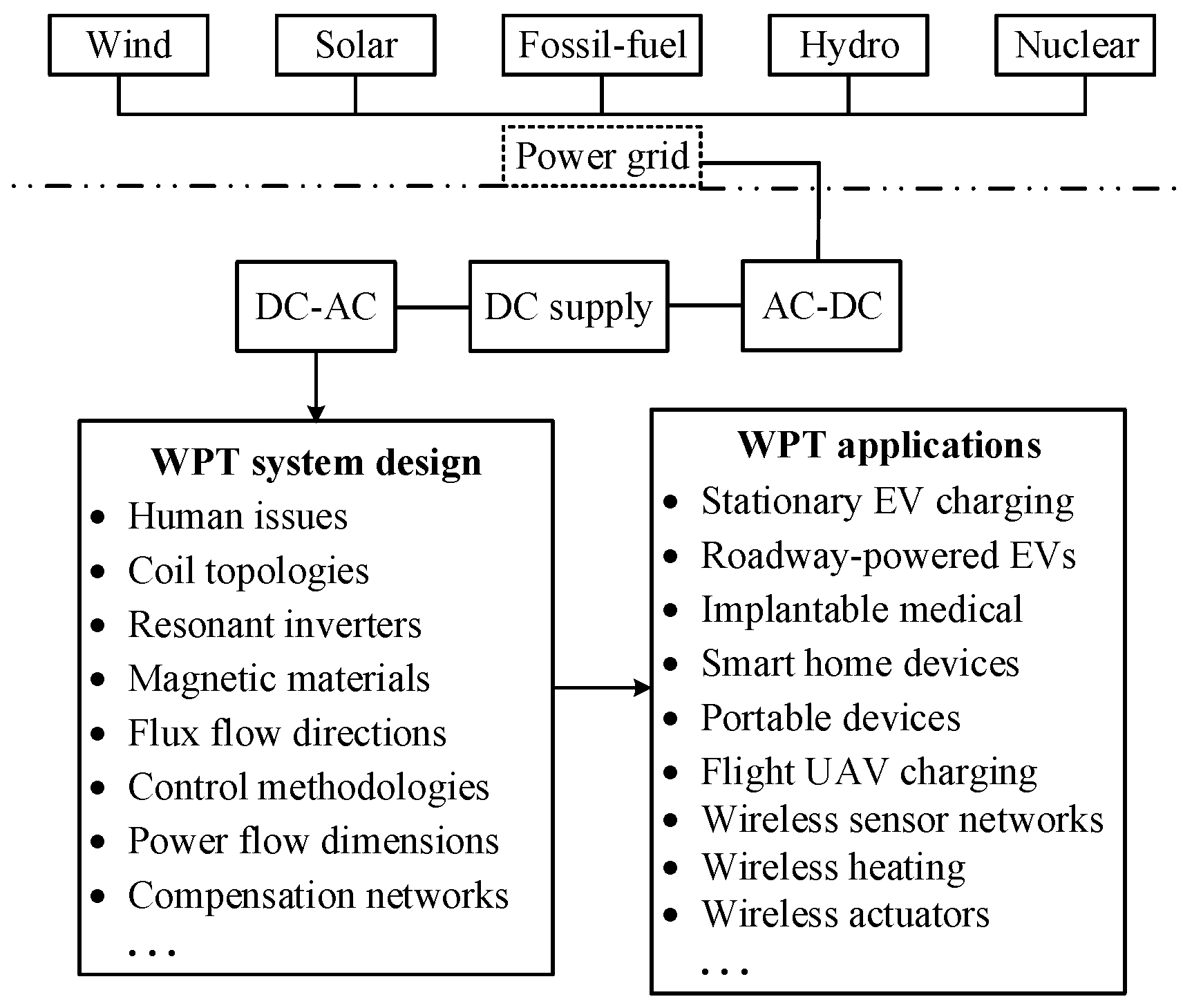

An Overview of Resonant Circuits for Wireless Power Transfer

Abstract

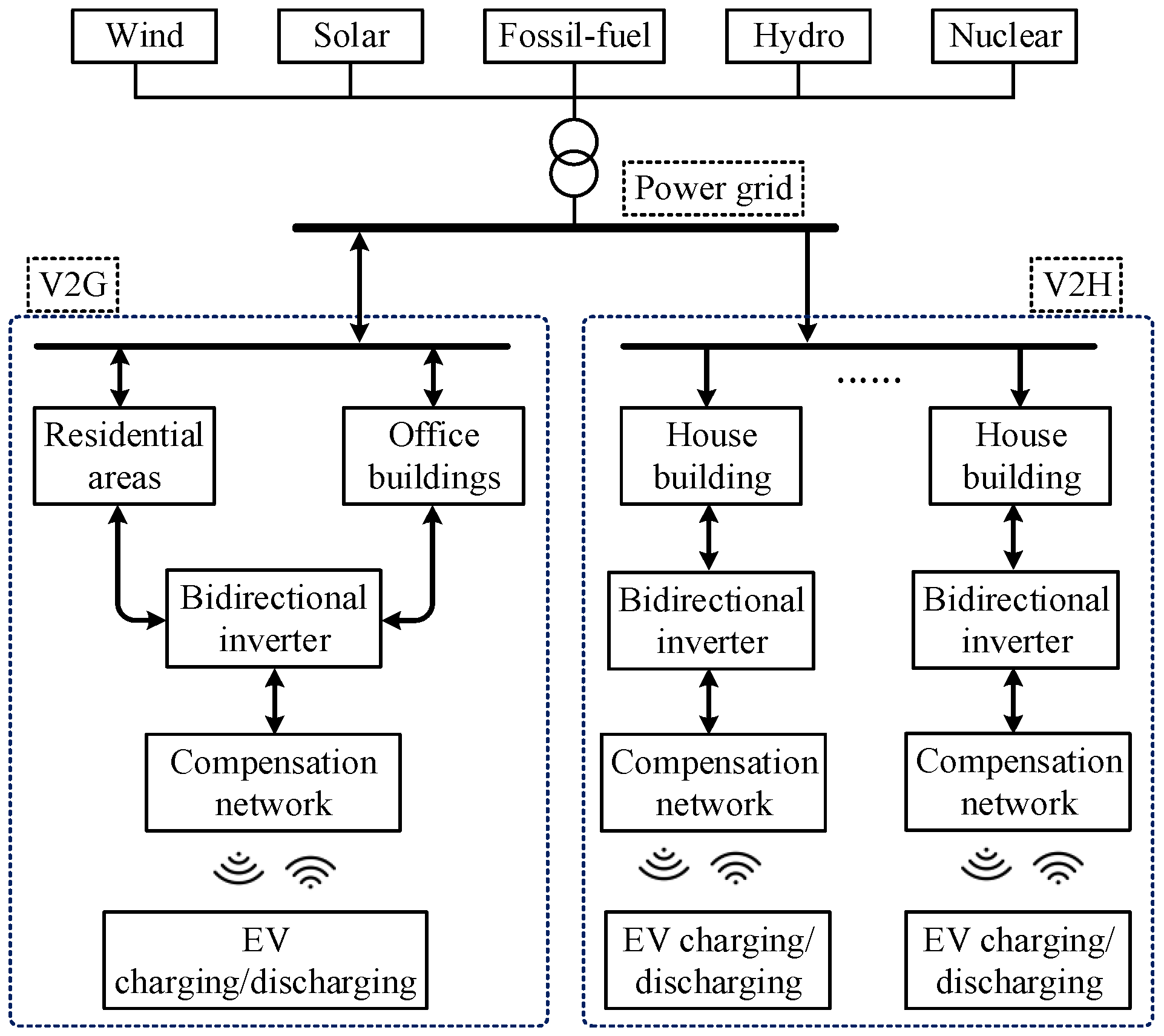

:1. Introduction

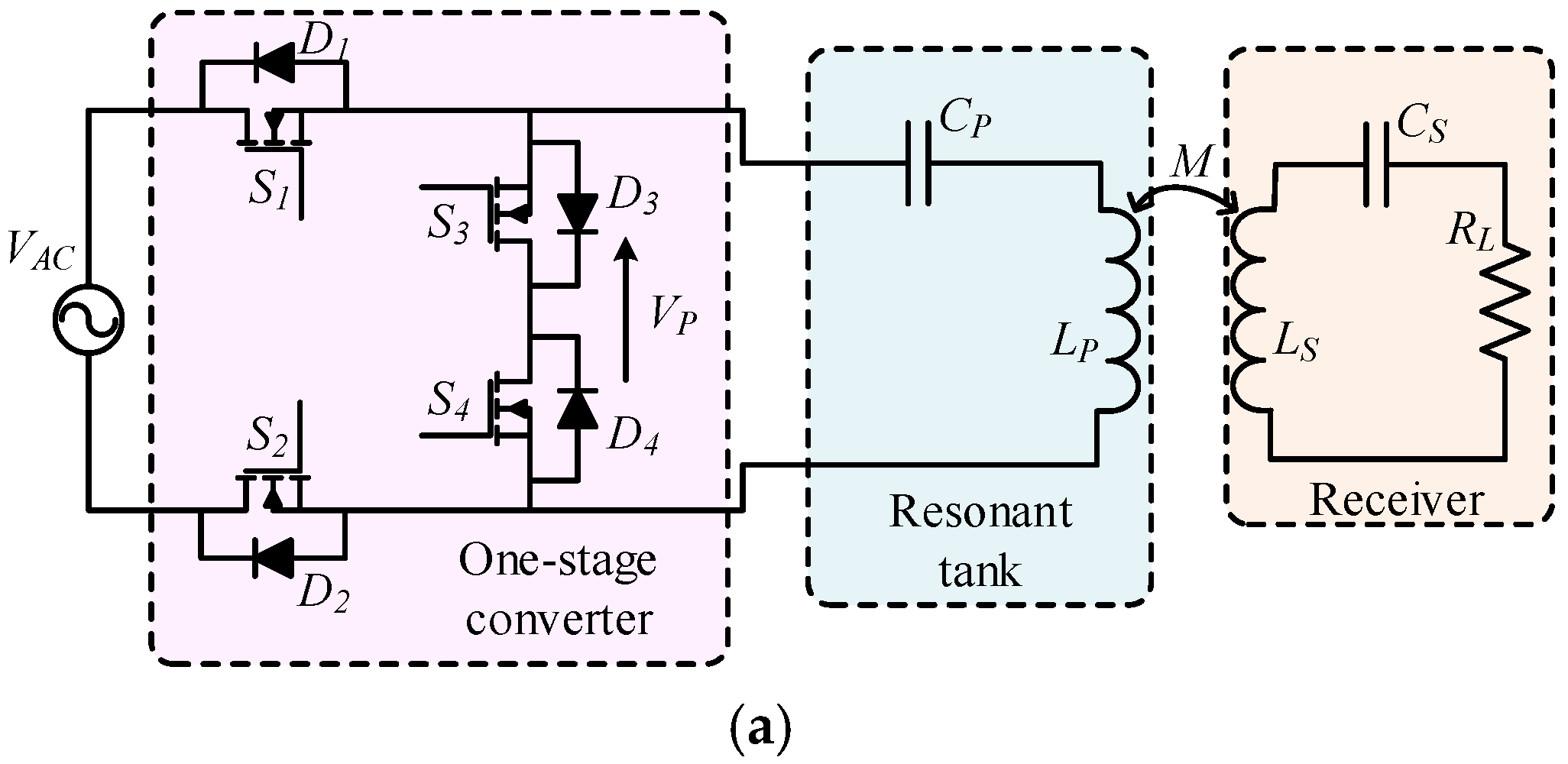

2. Non-Resonant Converters with Resonant Tank

2.1. Single-Phase AC-AC Converter

2.2. Three-Phase AC-AC Converter

2.3. DC Fed Energy Injection Converter

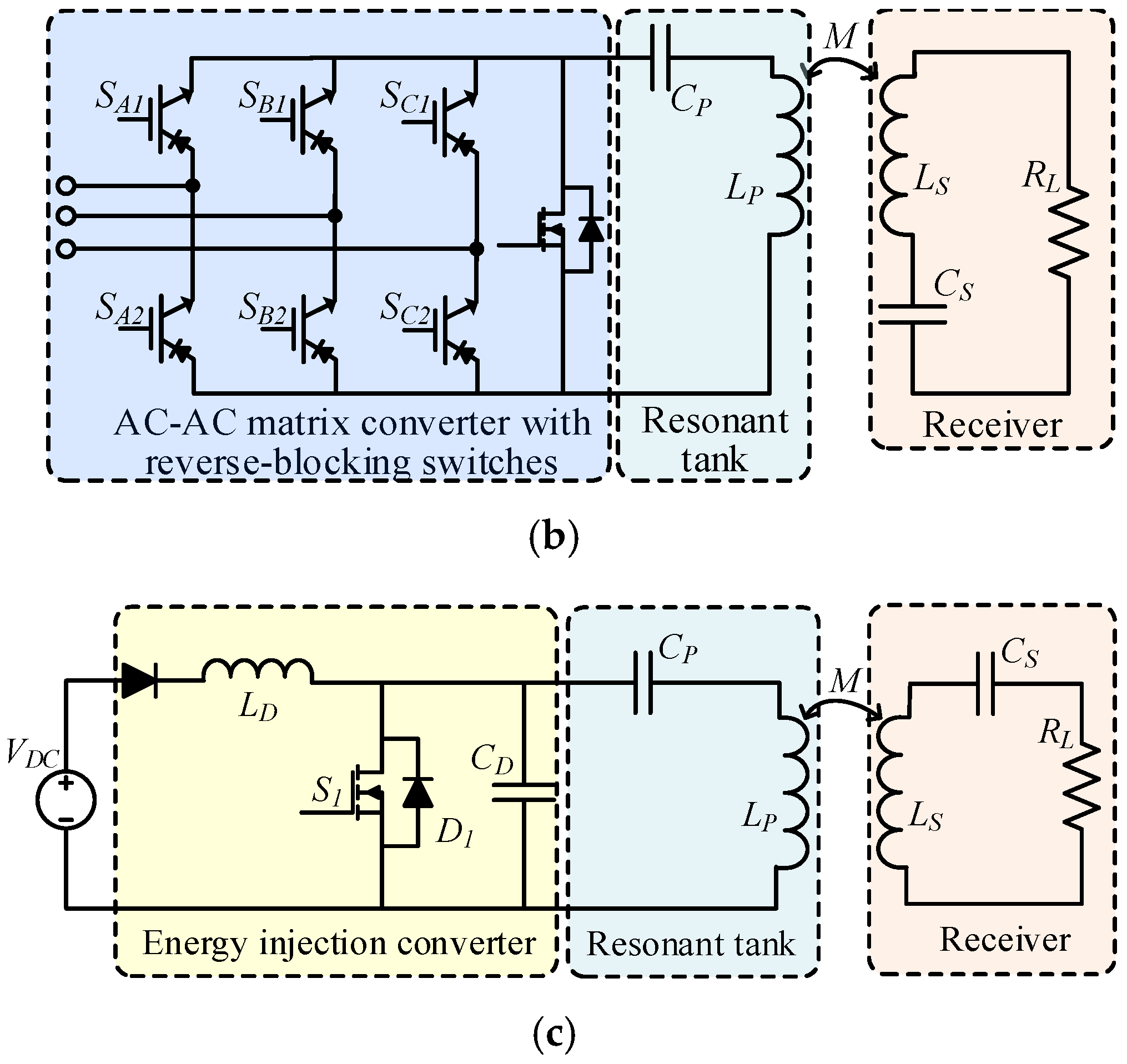

3. Resonant Inverters with Resonant Tank

3.1. Class E Resonant Inverter

3.2. Class D and Class DE Resonant Inverters

3.3. Class EFn Resonant Inverter

3.4. Parallel and Cascaded Inverters

3.5. Other Resonant Inverters

3.6. Comparison of Resonant Circuits

4. Compensation Networks

4.1. Compensation Topologies in Secondary

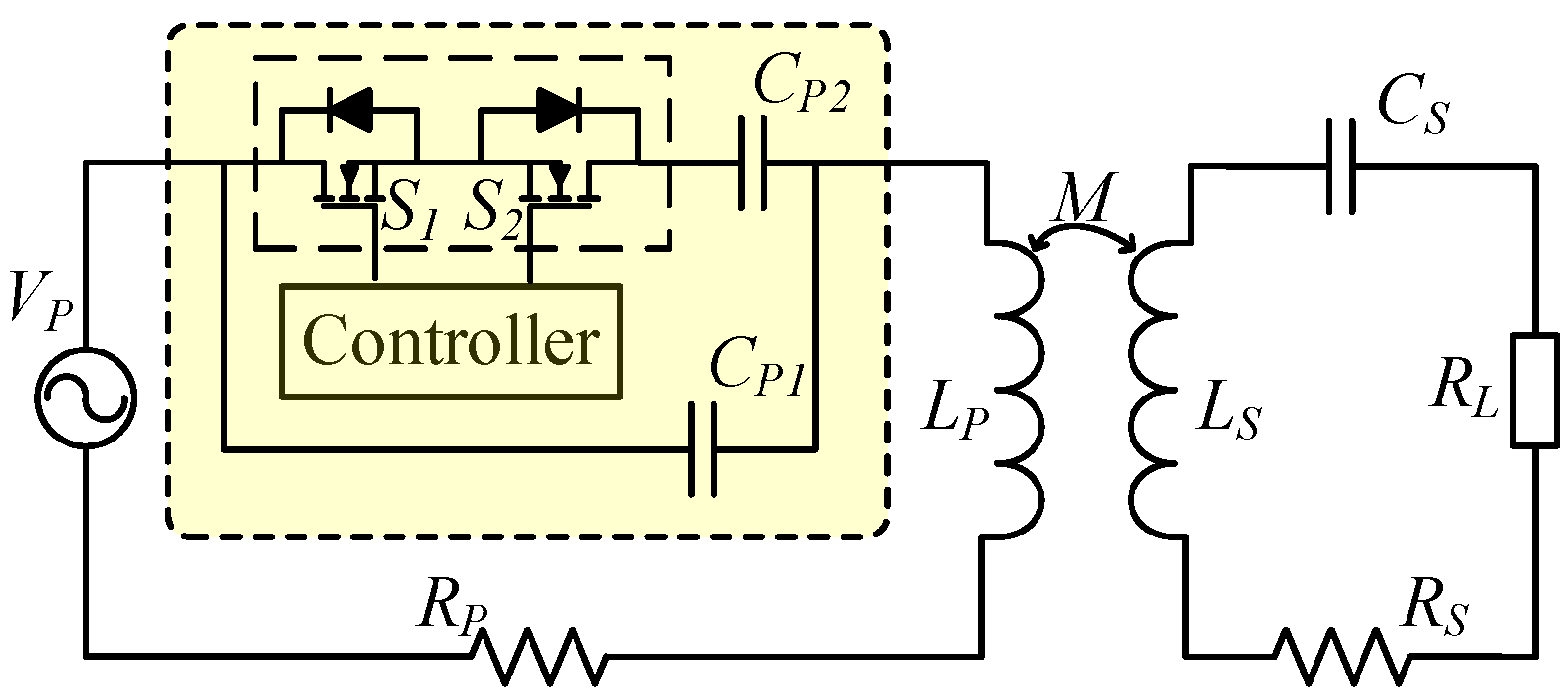

4.2. Compensation Topologies in Primary

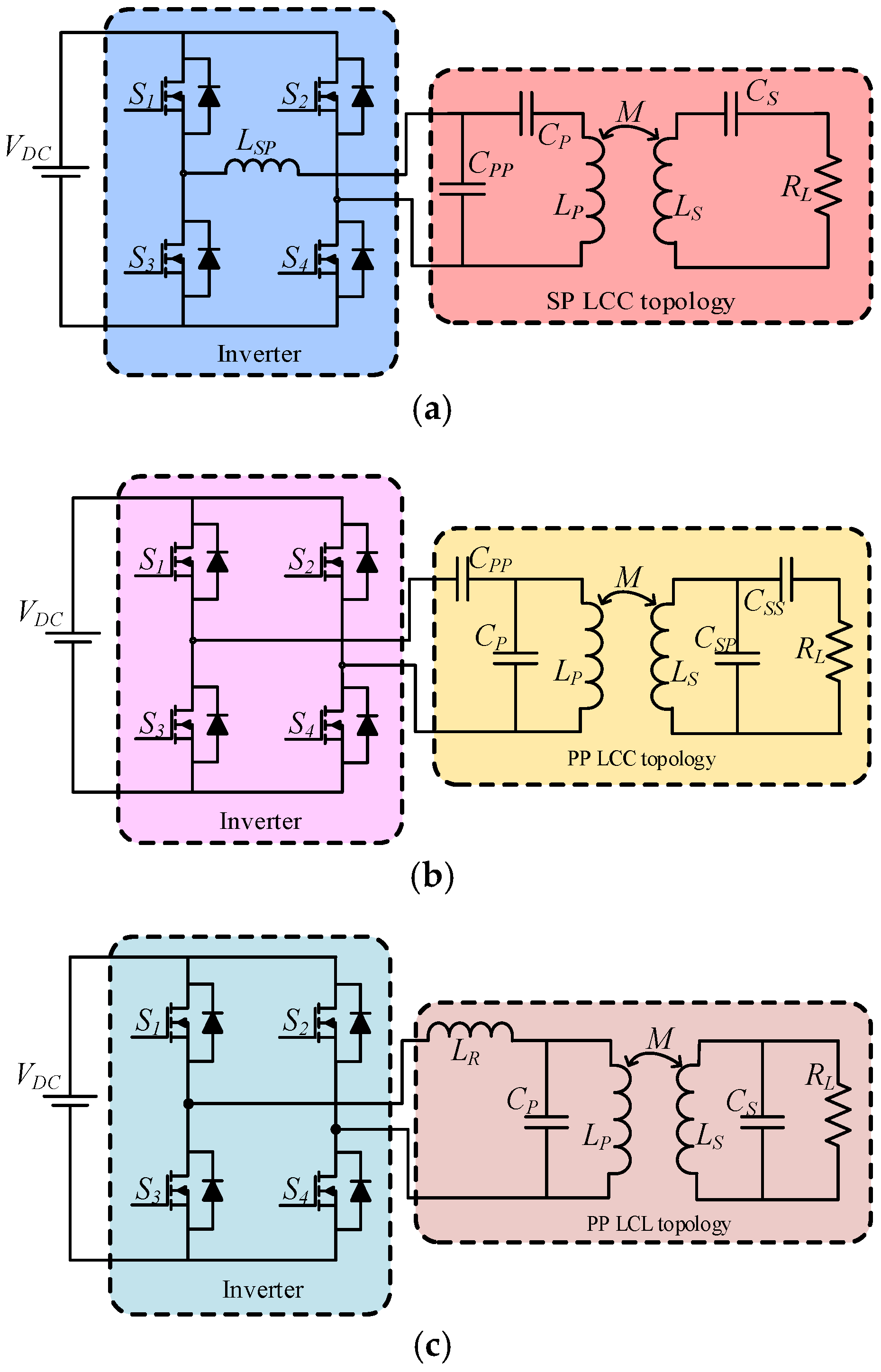

4.3. LCC-Compensation Topology

4.4. LCL-Compensation Topology

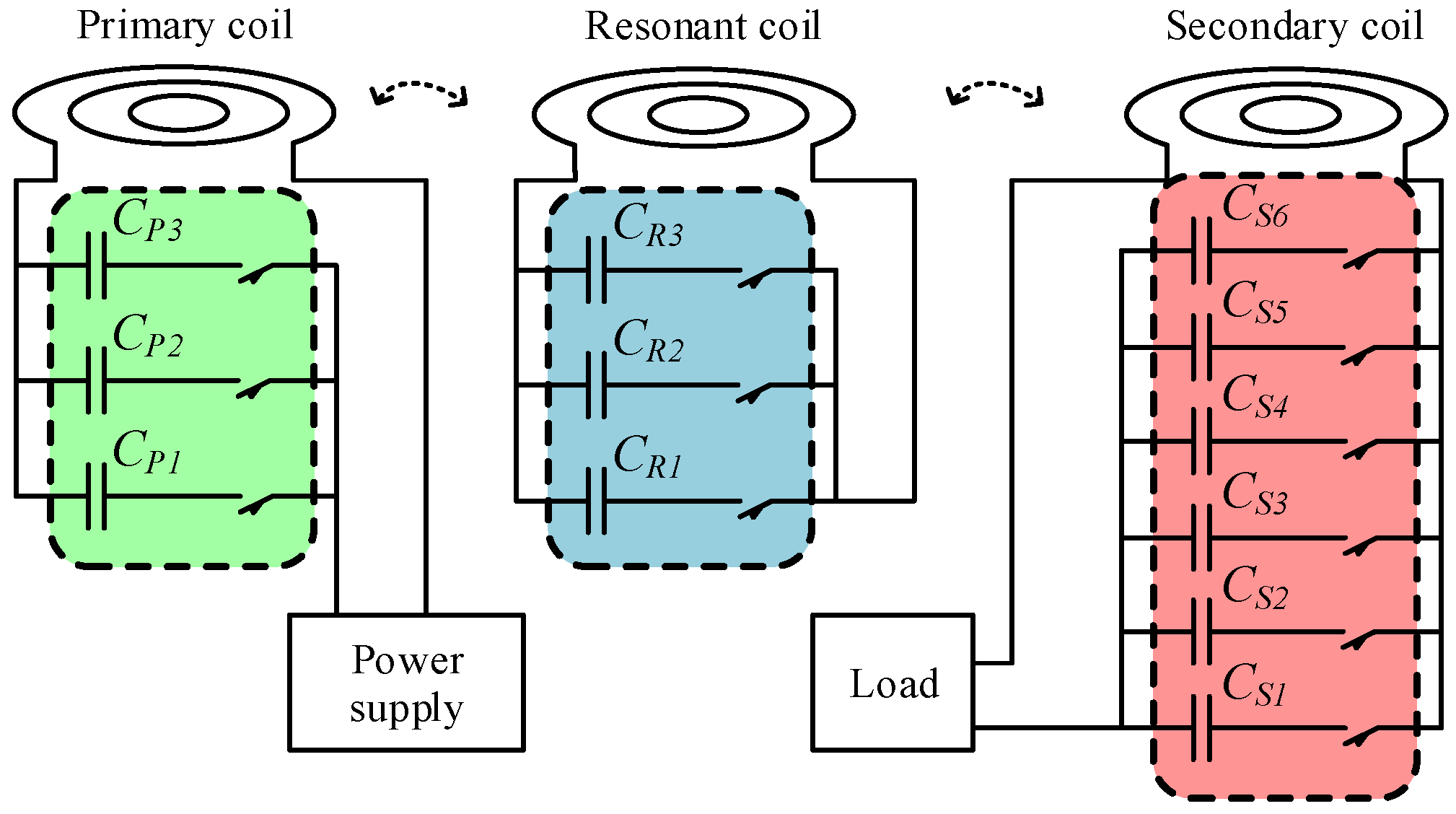

5. Selective Resonant Circuits

5.1. Selective Wireless Power Transfer

5.2. Energy Encryption

5.3. Online Load Identification

6. Development Trends

- (1)

- To develop targeted WPT for electric machines without requiring any energy storage, power electronic circuitry or sensory circuitry in the machine side.

- (2)

- To devise optimized compensation networks or auxiliary circuits, aiming to suppress the power crosstalk between the targeted and nontargeted receivers.

- (3)

- To utilize the parasitic capacitance in the coil to realize the resonant circuit, hence achieving high resonant frequencies for long-distance WPT.

- (4)

- To design high-frequency inverters up to the MHz range while retaining low switching loss, simple gate-driving requirement and reasonable cost.

- (5)

- To develop high-power high-efficiency bidirectional inverters for WPT, hence realizing V2G operation without physical contacts.

- (6)

- To integrate wireless power transfer and wireless information transfer into the same channel to form the wireless power and information transfer (WPIT), hence manipulating power and control simultaneously.

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Covic, G.A.; Boys, J.T. Inductive power transfer. Proc. IEEE 2013, 101, 1276–1289. [Google Scholar] [CrossRef]

- Li, Y.; Mai, R.; Lin, T.; Sun, H.; He, Z. A novel wpt system based on dual transmitters and dual receivers for high power applications: Analysis, design and implementation. Energies 2017, 10, 174. [Google Scholar] [CrossRef]

- Jang, Y.J.; Jeong, S.; Lee, M.S. Initial energy logistics cost analysis for stationary, quasi-dynamic, and dynamic wireless charging public transportation systems. Energies 2016, 9, 783. [Google Scholar] [CrossRef]

- Wu, R.; Li, W.; Luo, H.; Sin, J.K.; Yue, C.P. Design and characterization of wireless power links for brain–machine interface applications. IEEE Trans. Power Electron. 2014, 29, 5462–5471. [Google Scholar] [CrossRef]

- RamRakhyani, A.K.; Mirabbasi, S.; Chiao, M. Design and optimization of resonance-based efficient wireless power delivery systems for biomedical implants. IEEE Trans. Biomed. Circuits Syst. 2011, 5, 48–63. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Chau, K.T.; Zhang, Z.; Qiu, C.; Li, W.; Ching, T. Wireless power transfer and fault diagnosis of high-voltage power line via robotic bird. J. Appl. Phys. 2015, 117, 17D521. [Google Scholar] [CrossRef]

- Han, W.; Chau, K.T.; Zhang, Z. Flexible induction heating using magnetic resonant coupling. IEEE Trans. Ind. Electron. 2016, 64, 1982–1992. [Google Scholar] [CrossRef]

- Zhang, Z.; Chau, K.T. Homogeneous wireless power transfer for move-and-charge. IEEE Trans. Power Electron. 2015, 30, 6213–6220. [Google Scholar] [CrossRef]

- Hwang, K.; Cho, J.; Kim, D.; Park, J.; Kwon, J.K.; Kwak, S.I.; Park, H.H.; Ahn, S. An autonomous coil alignment system for the dynamic wireless charging of electric vehicles to minimize lateral misalignment. Energies 2017, 10, 315. [Google Scholar] [CrossRef]

- Shekhar, A.; Prasanth, V.; Bauer, P.; Bolech, M. Economic viability study of an on-road wireless charging system with a generic driving range estimation method. Energies 2016, 9, 76. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, X.; Dai, H. Design and control of a 3 kW wireless power transfer system for electric vehicles. Energies 2016, 9, 10. [Google Scholar] [CrossRef]

- Choi, S.Y.; Gu, B.W.; Jeong, S.Y.; Rim, C.T. Advances in wireless power transfer systems for roadway-powered electric vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 18–36. [Google Scholar] [CrossRef]

- Sato, M.; Yamamoto, G.; Gunji, D.; Imura, T.; Fujimoto, H. Development of wireless in-wheel motor using magnetic resonance coupling. IEEE Trans. Power Electron. 2016, 31, 5270–5278. [Google Scholar] [CrossRef]

- Marian, V.; Allard, B.; Vollaire, C.; Verdier, J. Strategy for microwave energy harvesting from ambient field or a feeding source. IEEE Trans. Power Electron. 2012, 27, 4481–4491. [Google Scholar] [CrossRef]

- Lin, J.C. A new IEEE standard for safety levels with respect to human exposure to radio-frequency radiation. IEEE Antennas Propag. Mag. 2006, 48, 157–159. [Google Scholar] [CrossRef]

- Garnica, J.; Chinga, R.A.; Lin, J. Wireless power transmission: From far field to near field. Proc. IEEE 2013, 101, 1321–1331. [Google Scholar] [CrossRef]

- Jiang, C.; Chau, K.T.; Ching, T.W.; Liu, C.; Han, W. Time-division multiplexing wireless power transfer for separately excited DC motor drives. IEEE Trans. Magn. 2017. [Google Scholar] [CrossRef]

- Sample, A.P.; Meyer, D.T.; Smith, J.R. Analysis, experimental results, and range adaptation of magnetically coupled resonators for wireless power transfer. IEEE Trans. Ind. Electron. 2011, 58, 544–554. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, F.; Hofmann, H.; Liu, W.; Mi, C.C. A four-plate compact capacitive coupler design and LCL-compensated topology for capacitive power transfer in electric vehicle charging application. IEEE Trans. Power Electron. 2016, 31, 8541–8551. [Google Scholar]

- Zhang, Y.; Zhao, Z.; Chen, K. Frequency-splitting analysis of four-coil resonant wireless power transfer. IEEE Trans. Ind. Appl. 2014, 50, 2436–2445. [Google Scholar] [CrossRef]

- Zhang, W.; White, J.C.; Abraham, A.M.; Mi, C.C. Loosely coupled transformer structure and interoperability study for ev wireless charging systems. IEEE Trans. Power Electron. 2015, 30, 6356–6367. [Google Scholar] [CrossRef]

- Yoon, I.J.; Ling, H. Investigation of near-field wireless power transfer under multiple transmitters. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 662–665. [Google Scholar] [CrossRef]

- Nair, V.V.; Choi, J.R. An efficiency enhancement technique for a wireless power transmission system based on a multiple coil switching technique. Energies 2016, 9, 156. [Google Scholar] [CrossRef]

- Ahn, D.; Hong, S. A study on magnetic field repeater in wireless power transfer. IEEE Trans. Ind. Electron. 2013, 60, 360–371. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, C. Analysis and optimization of three-resonator wireless power transfer system for predetermined-goals wireless power transmission. Energies 2016, 9, 274. [Google Scholar] [CrossRef]

- Zhong, W.; Lee, C.K.; Hui, S.Y.R. Wireless power domino-resonator systems with noncoaxial axes and circular structures. IEEE Trans. Power Electron. 2012, 27, 4750–4762. [Google Scholar] [CrossRef]

- Mayordomo, I.; Dräger, T.; Spies, P.; Bernhard, J.; Pflaum, A. An overview of technical challenges and advances of inductive wireless power transmission. Proc. IEEE 2013, 101, 1302–1311. [Google Scholar] [CrossRef]

- Hui, S.Y.R.; Zhong, W.; Lee, C.K. A critical review of recent progress in mid-range wireless power transfer. IEEE Trans. Power Electron. 2014, 29, 4500–4511. [Google Scholar] [CrossRef]

- Barman, S.D.; Reza, A.W.; Kumar, N.; Karim, M.E.; Munir, A.B. Wireless powering by magnetic resonant coupling: Recent trends in wireless power transfer system and its applications. Renew. Sustain. Energy Rev. 2015, 51, 1525–1552. [Google Scholar] [CrossRef]

- Qiu, C.; Chau, K.T.; Ching, T.W.; Liu, C. Overview of wireless charging technologies for electric vehicles. J. Asian Electr. Veh. 2014, 12, 1679–1685. [Google Scholar] [CrossRef]

- Mi, C.C.; Buja, G.; Choi, S.Y.; Rim, C.T. Modern advances in wireless power transfer systems for roadway powered electric vehicles. IEEE Trans. Ind. Electron. 2016, 63, 6533–6545. [Google Scholar] [CrossRef]

- Musavi, F.; Eberle, W. Overview of wireless power transfer technologies for electric vehicle battery charging. IET Power Electron. 2014, 7, 60–66. [Google Scholar] [CrossRef]

- Khan, A.A.; Cha, H.; Ahmed, H.F. High efficiency single-phase AC-AC converters without commutation problem. IEEE Trans. Power Electron. 2016, 31, 5655–5665. [Google Scholar] [CrossRef]

- Sarnago, H.; Lucía, O.; Mediano, A.; Burdío, J.M. Efficient and cost-effective ZCS direct AC-AC resonant converter for induction heating. IEEE Trans. Ind. Electron. 2014, 61, 2546–2555. [Google Scholar] [CrossRef]

- Li, H.L.; Hu, A.P.; Covic, G.A. A direct ac–ac converter for inductive power-transfer systems. IEEE Trans. Power Electron. 2012, 27, 661–668. [Google Scholar] [CrossRef]

- Moghaddami, M.; Anzalchi, A.; Sarwat, A.I. Single-stage three-phase ac-ac matrix converter for inductive power transfer systems. IEEE Trans. Ind. Electron. 2016, 63, 6613–6622. [Google Scholar] [CrossRef]

- Wheeler, P.W.; Rodriguez, J.; Clare, J.C.; Empringham, L.; Weinstein, A. Matrix converters: A technology review. IEEE Trans. Ind. Electron. 2002, 49, 276–288. [Google Scholar] [CrossRef]

- Zhang, Y.; Ruan, X. Three-phase AC-AC converter with controllable phase and amplitude. IEEE Trans. Ind. Electron. 2015, 62, 5689–5699. [Google Scholar] [CrossRef]

- Ju, X.; Dong, L.; Huang, X.; Liao, X. Switching technique for inductive power transfer at high-regimes. IEEE Trans. Ind. Electron. 2015, 62, 2164–2173. [Google Scholar] [CrossRef]

- Del-Aguila-Lopez, F.; Pala-Schonwalder, P.; Molina-Gaudo, P.; Mediano-Heredia, A. A discrete-time technique for the steady-state analysis of nonlinear Class-E amplifiers. IEEE Trans. Circuits Syst. I Regul. Pap. 2007, 54, 1358–1366. [Google Scholar] [CrossRef]

- Liu, M.; Fu, M.; Ma, C. Low-harmonic-contents and high-efficiency Class E full-wave current-driven rectifier for megahertz wireless power transfer systems. IEEE Trans. Power Electron. 2017, 32, 1198–1209. [Google Scholar] [CrossRef]

- Pinuela, M.; Yates, D.C.; Lucyszyn, S.; Mitcheson, P.D. Maximizing DC-to-load efficiency for inductive power transfer. IEEE Trans. Power Electron. 2013, 28, 2437–2447. [Google Scholar] [CrossRef]

- Nagashima, T.; Wei, X.; Bou, E.; Alarcón, E.; Kazimierczuk, M.K.; Sekiya, H. Analysis and design of loosely inductive coupled wireless power transfer system based on class-e2 dc-dc converter for efficiency enhancement. IEEE Trans. Circuits Syst. I Regul. Pap. 2015, 62, 2781–2791. [Google Scholar] [CrossRef]

- Aldhaher, S.; Luk, P.C.; Bati, K.A.; Whidborne, J.F. Wireless power transfer using class e inverter with saturable dc-feed inductor. IEEE Trans. Ind. Appl. 2014, 50, 2710–2718. [Google Scholar] [CrossRef]

- Covic, G.A.; Boys, J.T.; Kissin, M.L.; Lu, H.G. A three-phase inductive power transfer system for roadway-powered vehicles. IEEE Trans. Ind. Electron. 2007, 54, 3370–3378. [Google Scholar] [CrossRef]

- Koizumi, H.; Kurokawa, K. Analysis of the class de inverter with thinned-out driving patterns. IEEE Trans. Ind. Electron. 2007, 54, 1150–1160. [Google Scholar] [CrossRef]

- Nagashima, T.; Wei, X.; Sekiya, H. Analytical design procedure for resonant inductively coupled wireless power transfer system with class-de inverter and class-e rectifier. In Proceedings of the 2014 IEEE Asia Pacific Conference on Circuits and Systems, Ishigaki, Japan, 17–20 November 2014. [Google Scholar] [CrossRef]

- Kaczmarczyk, Z. Modeling and analysis of Class EF and Class E/F inverters with series-tuned resonant networks. IEEE Trans. Ind. Electron. 2006, 53, 1584–1593. [Google Scholar] [CrossRef]

- Aldhaher, S.; Yates, D.C.; Mitcheson, P.D. Modeling and analysis of class ef and class E/F inverters with series-tuned resonant networks. IEEE Trans. Power Electron. 2016, 31, 3415–3430. [Google Scholar] [CrossRef]

- Aldhaher, S.; Mitcheson, P.D.; Yates, D.C. Load-independent Class EF inverters for inductive wireless power transfer. In Proceedings of the 2016 IEEE Wireless Power Transfer Conference, Knoxville, TN, USA, 4–6 October 2016. [Google Scholar] [CrossRef]

- Hao, H.; Covic, G.A.; Boys, J.T. A parallel topology for inductive power transfer power supplies. IEEE Trans. Power Electron. 2014, 29, 1140–1151. [Google Scholar] [CrossRef]

- Schonknecht, A.; De Doncker, R.W. Novel topology for parallel connection of soft-switching high-power high-frequency inverters. IEEE Trans. Ind. Appl. 2003, 39, 550–555. [Google Scholar] [CrossRef]

- Mai, Y.; Li, R.; Yang, M.; He, Z. Cascaded multi-level inverter based IPT systems for high power applications. J. Power Electron. 2015, 15, 1508–1516. [Google Scholar]

- Nguyen, B.X.; Vilathgamuwa, D.M.; Foo, G.; Wang, P.; Ong, A. A modified cascaded multilevel converter topology for high power bidirectional inductive power transfer systems with the reduction of switching devices and power losses. In Proceedings of the 2015 IEEE 11th International Conference on Power Electronics and Drive, Sydney, Australia, 9–12 June 2015; 2015; 15. [Google Scholar] [CrossRef]

- Abdolkhani, A.; Hu, A.P.; Tian, J. Autonomous polyphase current-fed push–pull resonant converter on ring coupled oscillators. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 568–576. [Google Scholar] [CrossRef]

- Abdolkhani, A.; Hu, A.P.; Covic, G.A.; Moridnejad, M. Through-hole contactless slipring system based on rotating magnetic field for rotary applications. IEEE Trans. Ind. Appl. 2014, 50, 3644–3655. [Google Scholar] [CrossRef]

- Liu, C.; Chau, K.T.; Wu, D.; Gao, S. Opportunities and challenges of vehicle-to-home, vehicle-to-vehicle, and vehicle-to-grid technologies. Proc. IEEE 2013, 101, 2409–2427. [Google Scholar] [CrossRef]

- Madawala, U.K.; Thrimawithana, D.J. A bidirectional inductive power interface for electric vehicles in V2G systems. IEEE Trans. Ind. Electron. 2011, 58, 4789–4796. [Google Scholar] [CrossRef]

- Neath, M.J.; Swain, A.K.; Madawala, U.K.; Thrimawithana, D.J. An optimal pid controller for a bidirectional inductive power transfer system using multiobjective genetic algorithm. IEEE Trans. Power Electron. 2014, 29, 1526–1531. [Google Scholar] [CrossRef]

- Swain, A.K.; Neath, M.J.; Madawala, U.K.D.J. Thrimawithana, A dynamic multivariable state-space model for bidirectional inductive power transfer systems. IEEE Trans. Power Electron. 2012, 27, 4772–4780. [Google Scholar] [CrossRef]

- Wang, C.S.; Stielau, O.H.; Covic, G.A. Design considerations for a contactless electric vehicle battery charger. IEEE Trans. Ind. Electron. 2005, 52, 1308–1314. [Google Scholar] [CrossRef]

- Zhang, W.; Wong, S.C.; Chi, K.T.; Chen, Q. Analysis and comparison of secondary series-and parallel-compensated inductive power transfer systems operating for optimal efficiency and load-independent voltage-transfer ratio. IEEE Trans. Power Electron. 2014, 29, 2979–2990. [Google Scholar] [CrossRef]

- Boys, J.; Covic, G.; Green, A.W. Stability and control of inductively coupled power transfer systems. IEE Proc. Electr. Power Appl. 2000, 147, 37–43. [Google Scholar] [CrossRef]

- Zhang, W.; Wong, S.C.; Chi, K.T.; Chen, Q. Design for efficiency optimization and voltage controllability of series–series compensated inductive power transfer systems. IEEE Trans. Power Electron. 2014, 29, 191–200. [Google Scholar] [CrossRef]

- Imura, T.; Hori, Y. Maximizing air gap and efficiency of magnetic resonant coupling for wireless power transfer using equivalent circuit and neumann formula. IEEE Trans. Ind. Electron. 2011, 58, 4746–4752. [Google Scholar] [CrossRef]

- Jiang, W.X.; Chin, J.Y.; Li, Z.; Cheng, Q.; Liu, R.; Cui, T.J. Analytical design of conformally invisible cloaks for arbitrarily shaped objects. Phys. Rev. E 2008, 77, 066607. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Wang, L.; Guo, Y.; Liao, C.; Li, F. Applying LCC compensation network to dynamic wireless ev charging system. IEEE Trans. Ind. Electron. 2016, 63, 6557–6567. [Google Scholar] [CrossRef]

- Zhang, W.; Mi, C.C. Compensation topologies of high-power wireless power transfer systems. IEEE Trans. Veh. Technol. 2016, 65, 4768–4778. [Google Scholar] [CrossRef]

- Pantic, Z.; Bai, S.; Lukic, S.M. ZCS-compensated resonant inverter for inductive-power-transfer application. IEEE Trans. Ind. Electron. 2011, 58, 3500–3510. [Google Scholar] [CrossRef]

- Chen, L.; Liu, S.; Zhou, Y.C.; Cui, T.J. An optimizable circuit structure for high-efficiency wireless power transfer. IEEE Trans. Ind. Electron. 2013, 60, 339–349. [Google Scholar] [CrossRef]

- Wang, C.S.; Covic, G.A.; Stielau, O.H. Investigating an LCL load resonant inverter for inductive power transfer applications. IEEE Trans. Power Electron. 2004, 19, 995–1002. [Google Scholar] [CrossRef]

- Keeling, N.A.; Covic, G.A.; Boys, J.T. A unity-power-factor IPT pickup for high-power applications. IEEE Trans. Ind. Electron. 2010, 57, 744–751. [Google Scholar] [CrossRef]

- Zhong, W.; Hui, S.Y.R. Auxiliary circuits for power flow control in multifrequency wireless power transfer systems with multiple receivers. IEEE Trans. Power Electron. 2015, 30, 5902–5910. [Google Scholar] [CrossRef]

- Kim, Y.J.; Ha, D.; Chappell, W.J.; Irazoqui, P.P. Selective wireless power transfer for smart power distribution in a miniature-sized multiple-receiver system. IEEE Trans. Ind. Electron. 2016, 63, 1853–1862. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, T.; Zhao, Z.; He, F.; Chen, K.; Yuan, L. Selective wireless power transfer to multiple loads using receivers of different resonant frequencies. IEEE Trans. Power Electron. 2015, 30, 6001–6005. [Google Scholar] [CrossRef]

- Jiang, C.; Chau, K.T.; Liu, C.; Han, W. Wireless DC motor drives with selectability and controllability. Energies 2017, 10, 49. [Google Scholar] [CrossRef]

- Zhang, Z.; Chau, K.T.; Qiu, C.; Liu, C. Energy encryption for wireless power transfer. IEEE Trans. Power Electron. 2015, 30, 5237–5246. [Google Scholar] [CrossRef]

- Wang, Z.; Chau, K.T.; Liu, C. Improvement of electromagnetic compatibility of motor drives using chaotic PWM. IEEE Trans. Magn. 2007, 43, 2612–2614. [Google Scholar] [CrossRef]

- Neath, M.; Madawala, U.; Thrimawithana, D. Frequency jitter control of a multiple pick-up bidirectional inductive power transfer system. In Proceedings of the IEEE International Conference on Industrial Technology, Cape Town, Western Cape, South Africa, 25–28 February 2013; pp. 521–526. [Google Scholar]

- Wang, Z.H.; Li, Y.P.; Sun, Y.; Tang, C.S.; Lv, X. Load detection model of voltage-fed inductive power transfer system. IEEE Trans. Power Electron. 2013, 28, 5233–5243. [Google Scholar] [CrossRef]

- Su, Y.G.; Zhang, H.Y.; Wang, Z.H.; Hu, A.P.; Chen, L.; Sun, Y. Steady-state load identification method of inductive power transfer system based on switching capacitors. IEEE Trans. Power Electron. 2015, 30, 6349–6355. [Google Scholar] [CrossRef]

| Single-Phase AC-AC Converter | Three-Phase AC-AC Converter | DC Fed Energy Injection Converter | |

|---|---|---|---|

| Factors |

|

|

|

| Features |

|

|

|

| Type | Voltage Stress 1 | Power Level 2 | High Frequency Operation 3 | Control Difficulty | Switching Loss | Effective Cost |

|---|---|---|---|---|---|---|

| Single-phase AC-AC converter | Low | Low | Medium | Medium | Low | Medium |

| Three-phase AC-AC converter | Medium | Medium | Medium | High | Medium | Medium |

| DC fed energy injection converter | Low | Low | High | Medium | Low | Low |

| Class E resonant inverter | High | High | High | Low | Low | Low |

| Class D resonant inverter | Medium | Medium (half-bridge) High (full-bridge) | Medium | Low (half-bridge) Medium (full-bridge) | Medium 4 | Low |

| Class DE resonant inverter | Low | Medium | High | Medium | Low | Medium |

| Class EF2 resonant inverter | Low | Medium | High | Low | Low | Low |

| Current-fed push-pull resonant inverter | Medium | Medium | Medium | NA | Low | Low |

| Parallel resonant inverter | Medium | High | Medium | High | High | High |

| Cascaded resonant inverter | Medium | High | Medium | High | High | High |

| Topology | Reflected Resistance | Reflected Reactance | Secondary Quality Factor (QS) |

|---|---|---|---|

| SS | 0 | ||

| SP | |||

| PS | 0 | ||

| PP | |||

| LCC-S * | 0 | ||

| LCL-P * |

| Topology | Features | Topology | Features |

|---|---|---|---|

| SS topology |

| SP topology |

|

| PS topology |

| PP topology |

|

| LCC topology |

| LCL topology |

|

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, C.; Chau, K.T.; Liu, C.; Lee, C.H.T. An Overview of Resonant Circuits for Wireless Power Transfer. Energies 2017, 10, 894. https://doi.org/10.3390/en10070894

Jiang C, Chau KT, Liu C, Lee CHT. An Overview of Resonant Circuits for Wireless Power Transfer. Energies. 2017; 10(7):894. https://doi.org/10.3390/en10070894

Chicago/Turabian StyleJiang, Chaoqiang, K. T. Chau, Chunhua Liu, and Christopher H. T. Lee. 2017. "An Overview of Resonant Circuits for Wireless Power Transfer" Energies 10, no. 7: 894. https://doi.org/10.3390/en10070894