Matching Relationship and Alternating Injection for Polymer Flooding in Heterogeneous Formations: A Laboratory Case Study of Daqing Oilfield

Abstract

:1. Introduction

2. Relationship between Polymer Molecular and Reservoir Permeability

2.1. The Measure of Polymer Molecular Size (Application of Light Scattering Theory)

2.2. The Relationship between Molecular Size and Polymer Parameters

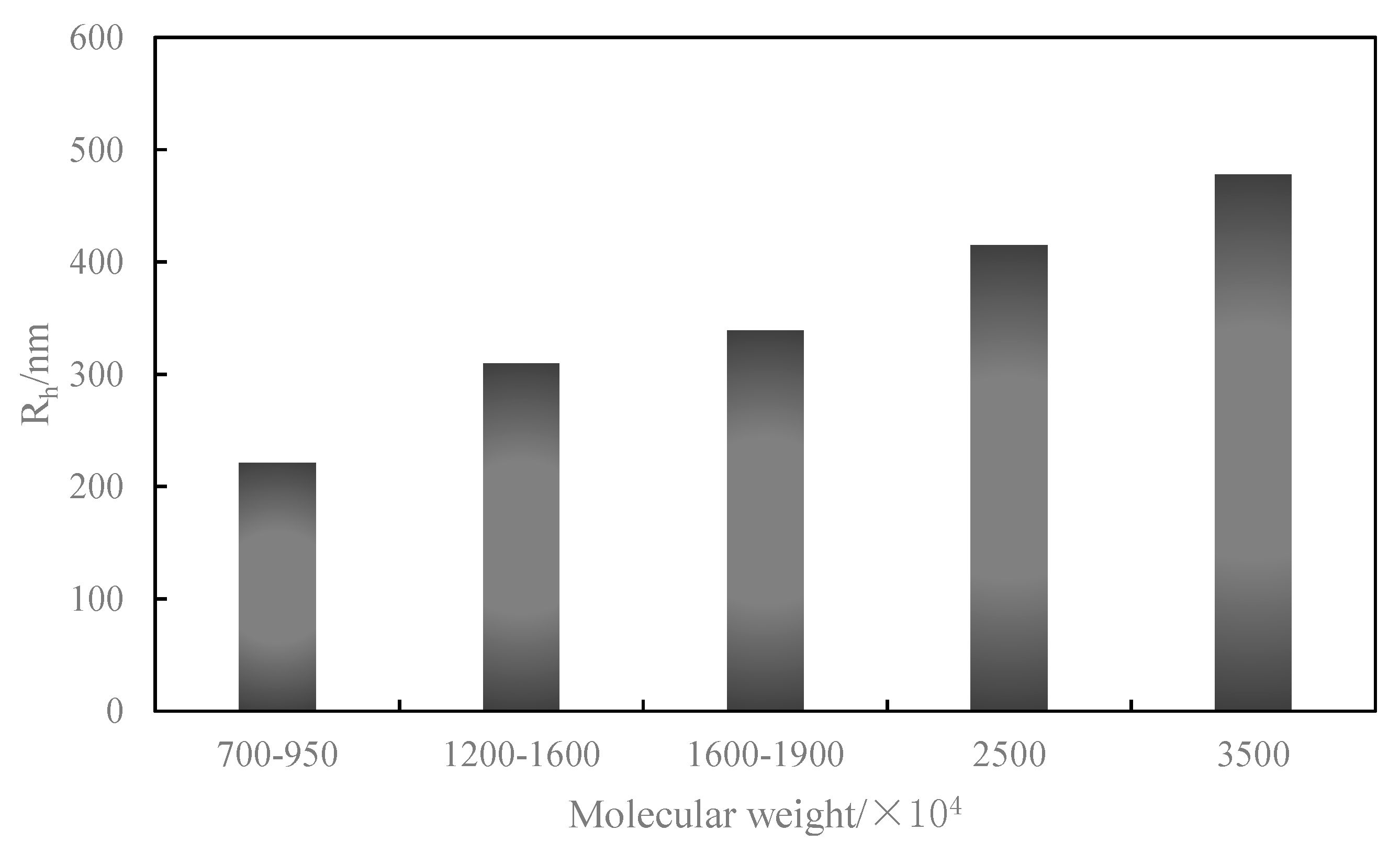

2.2.1. The Relationship between Rh and Polymer Molecular Weight

2.2.2. The Relationship between Rh and Polymer Concentration

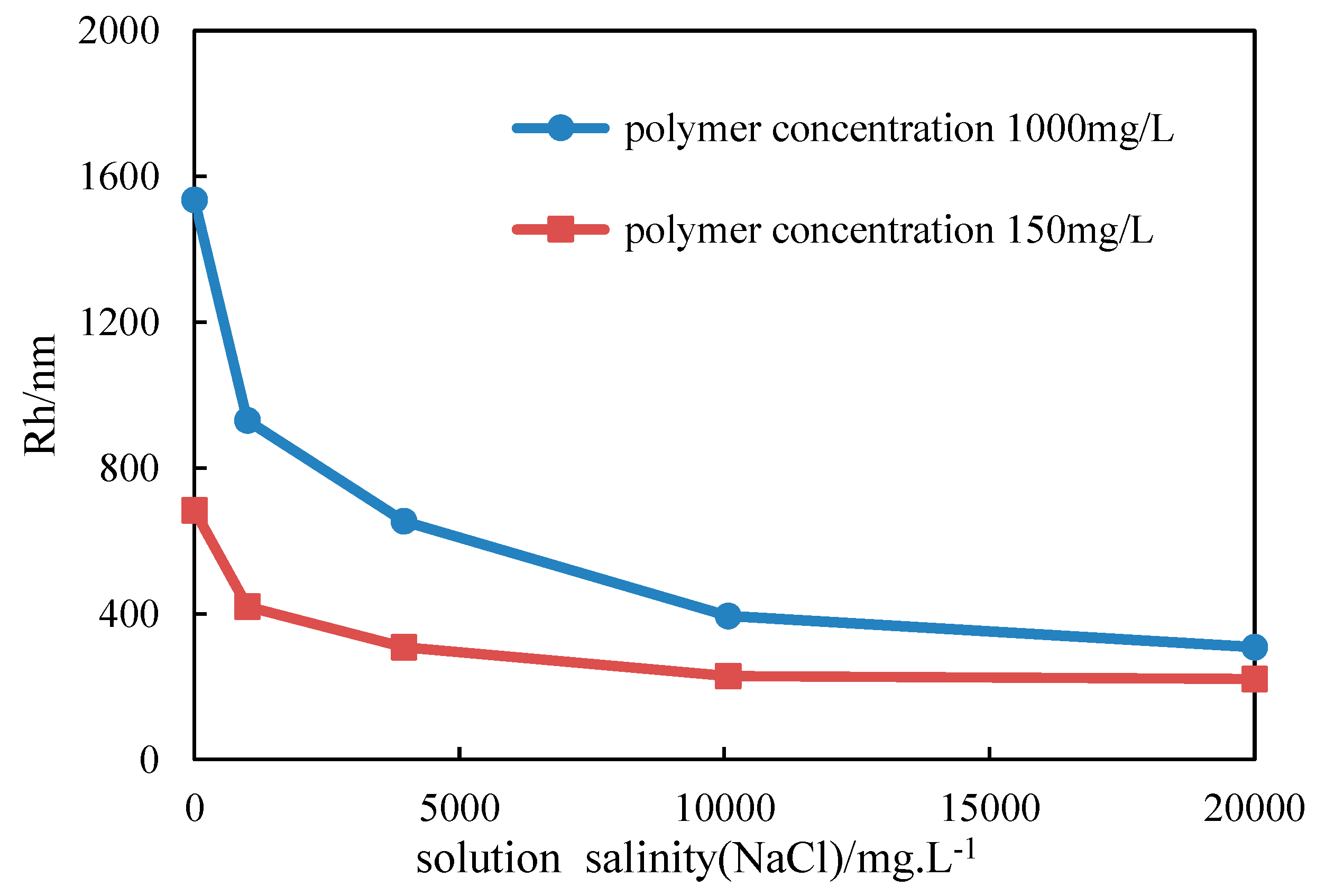

2.2.3. The Relationship between Rh and Salinity of Solution

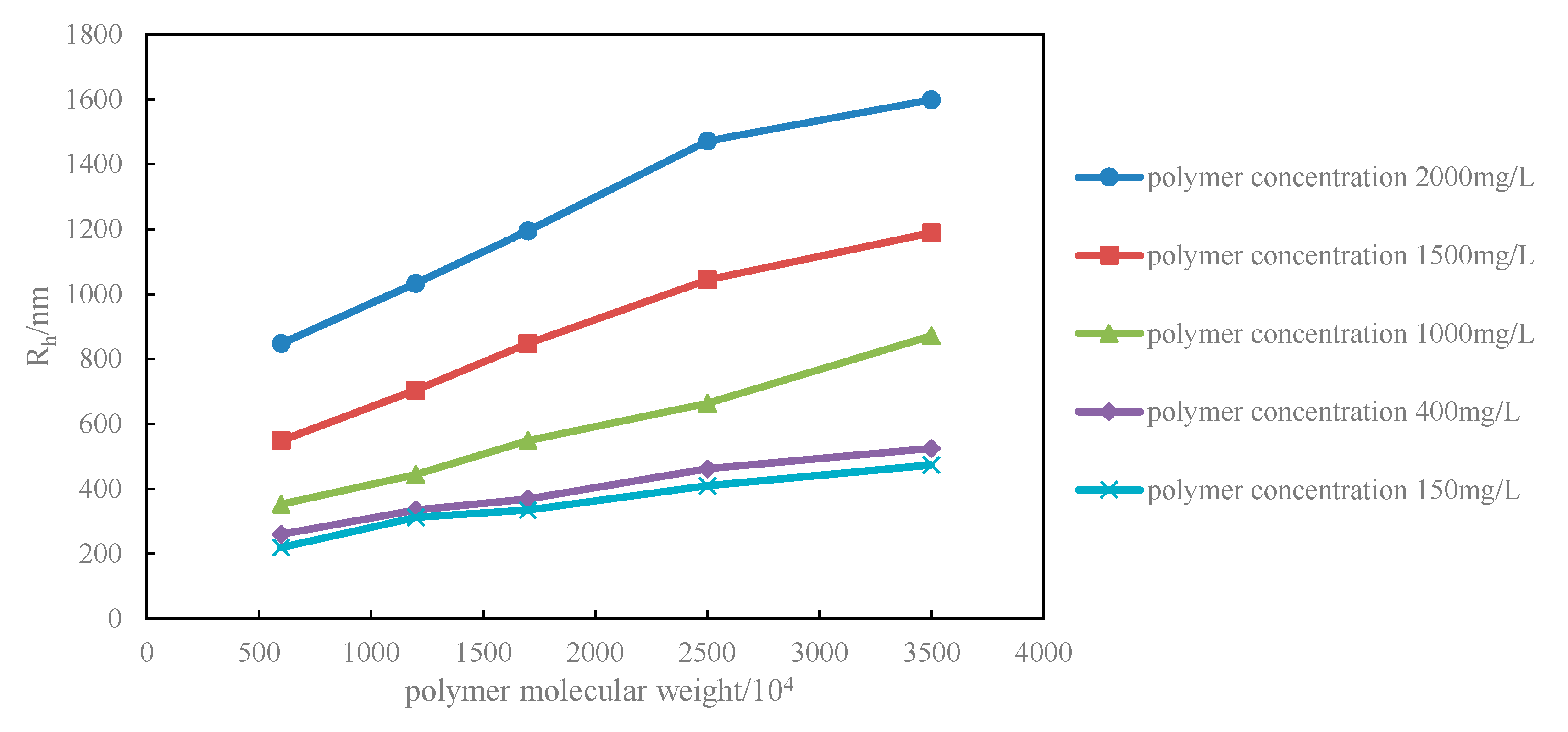

2.2.4. The Combined Impact of Polymer Concentration and Molecular Weight

2.3. Experimental Study on the Relationship between Polymer Concentration/Molecular Weight and Core Permeability

2.3.1. Experimental Design

2.3.2. Results and Discussion

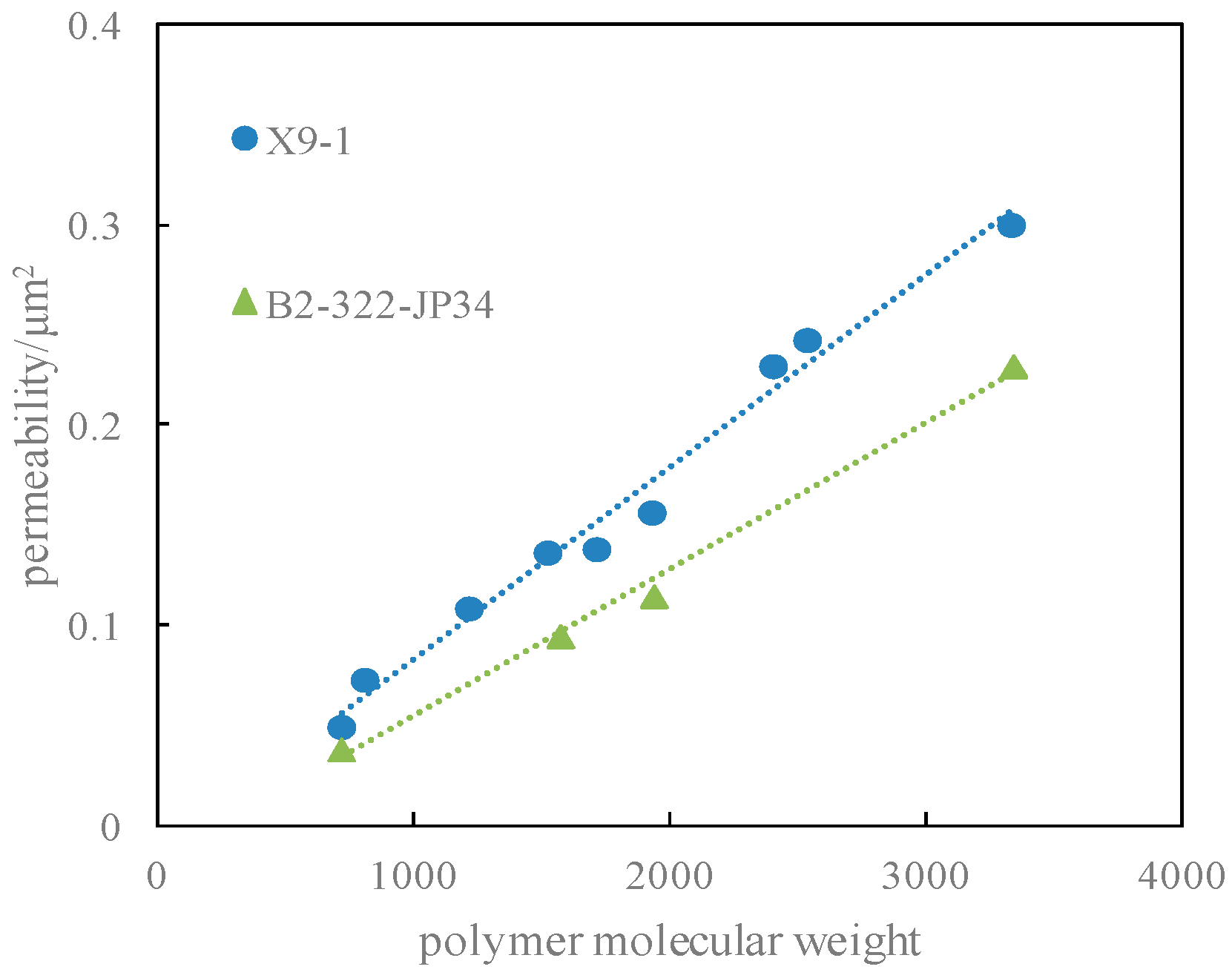

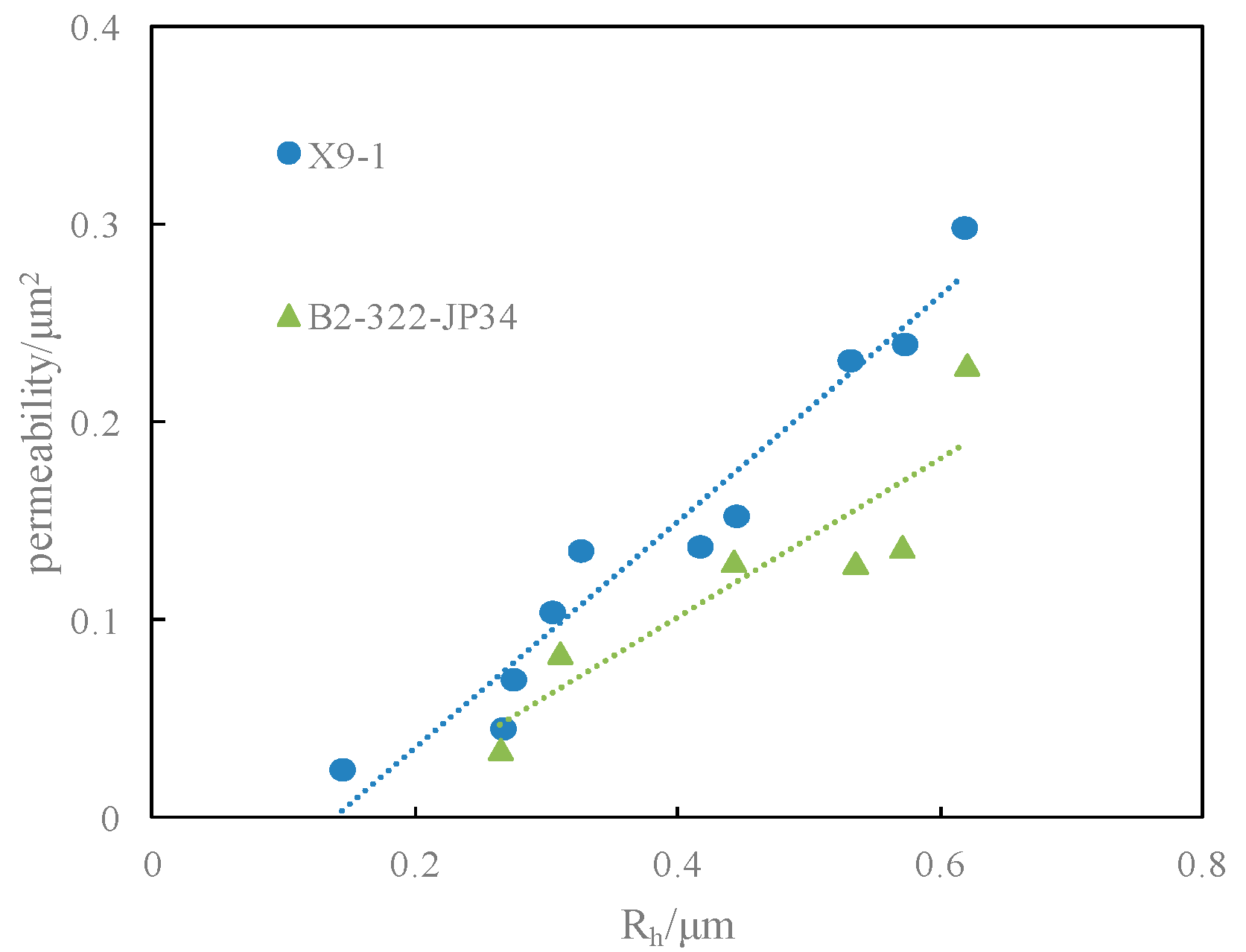

The Influence of Pore Structure

The Influence of Polymer Concentration

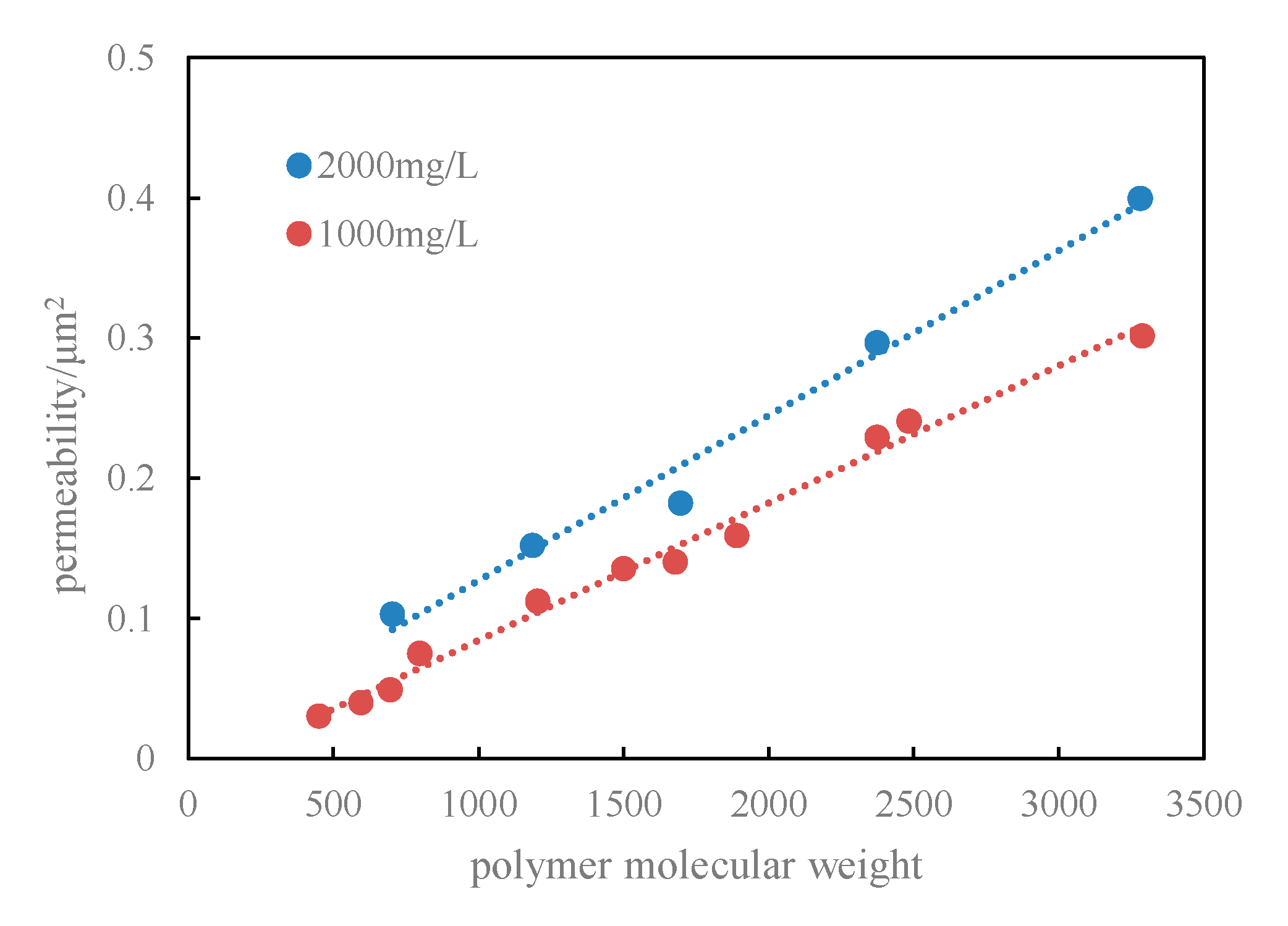

Synergetic Effects of Polymer MW and Concentration

3. Experimental Studies of Alternating Injection

3.1. Experiment Design

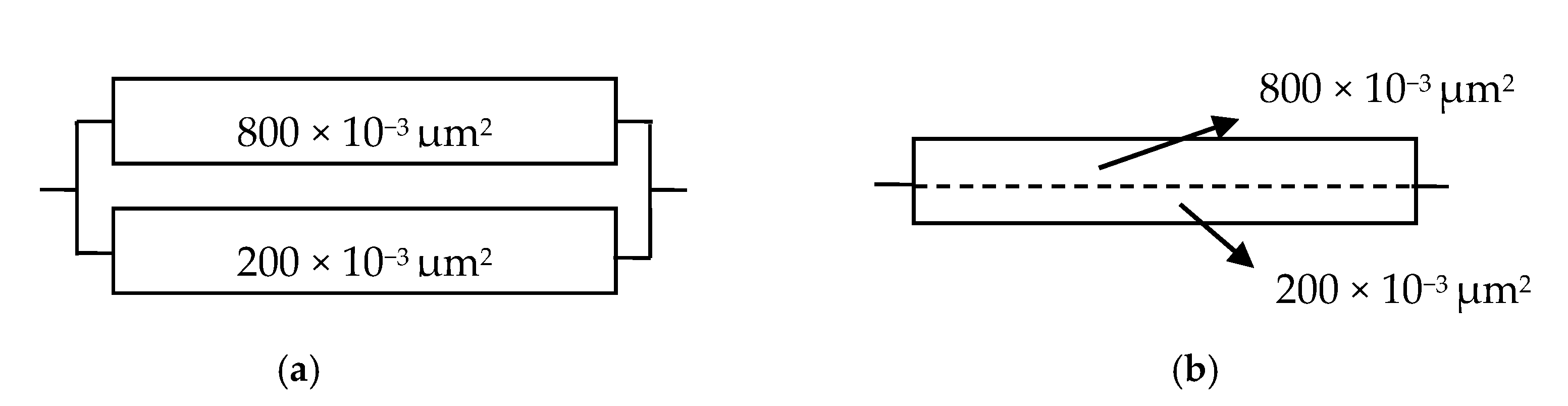

3.1.1. Experiment Conditions

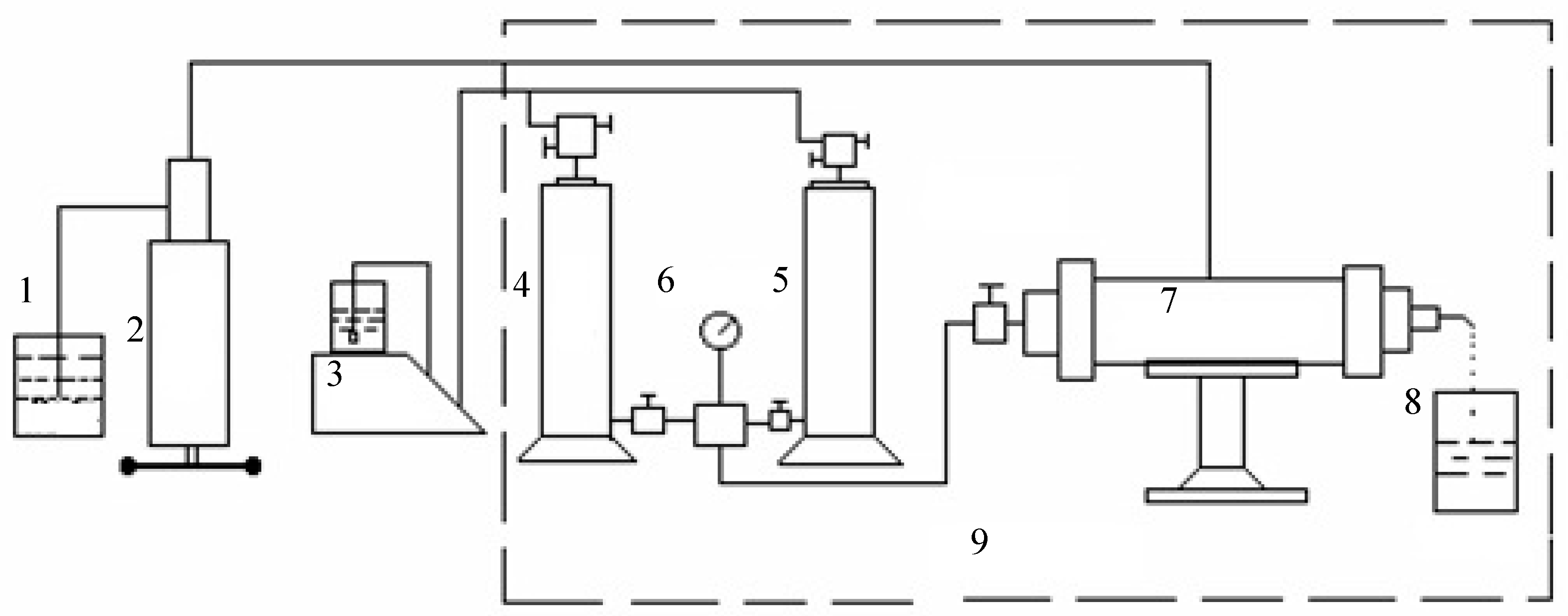

3.1.2. Experiment Setup

3.1.3. Experimental Procedures

- (1)

- Vacuumize the core and saturate with water, and calculate the water permeability;

- (2)

- Water should be flooded until the pressure is steady, calculate the diversion rates of high and low permeability layers, and calculate the permeability ratio and permeability of each layer;

- (3)

- Saturate the core with oil and calculate the oil saturation;

- (4)

- Water should be flooded until the water cut of the produced liquid is 98%, and calculate the efficiency of water flooding;

- (5)

- The core should be flooded with polymer slug combinations (MW: 2500 × 104 and 1700 × 104) for a total of 0.56 PV in divided-flow experiments, calculate the diversion rates of high and low permeability layers. Injected a total volume of 2.24 PV for the experiment in Section 3.2.2, match the polymer with MW of 2500 × 104 injected first, then polymer with MW of 1700 × 104.

- (6)

- Further, water is allowed to flood until the water cuts of the produced liquid reach 98%;

- (7)

- At the end of the experiment, calculate the efficiency of PF and the total efficiency.

3.2. Results and Discussion

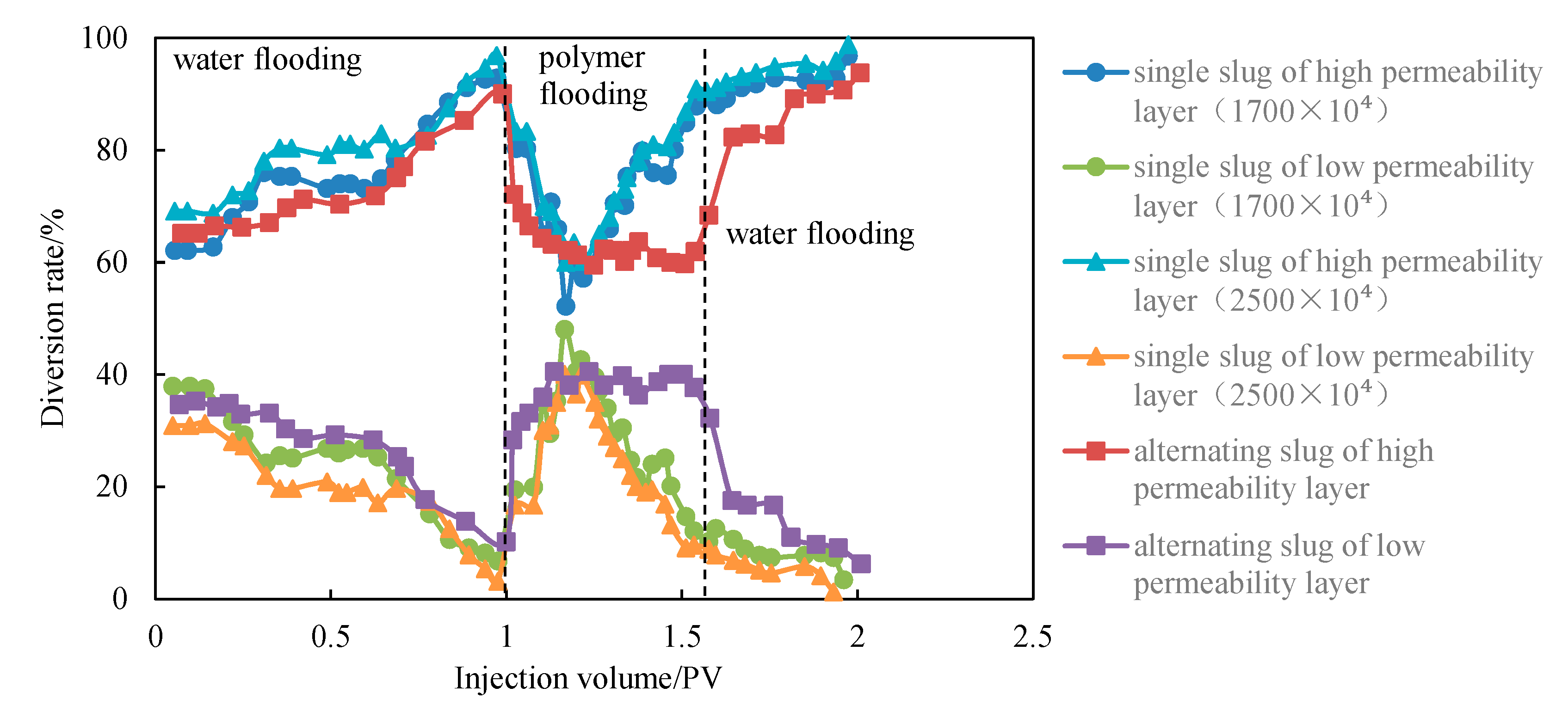

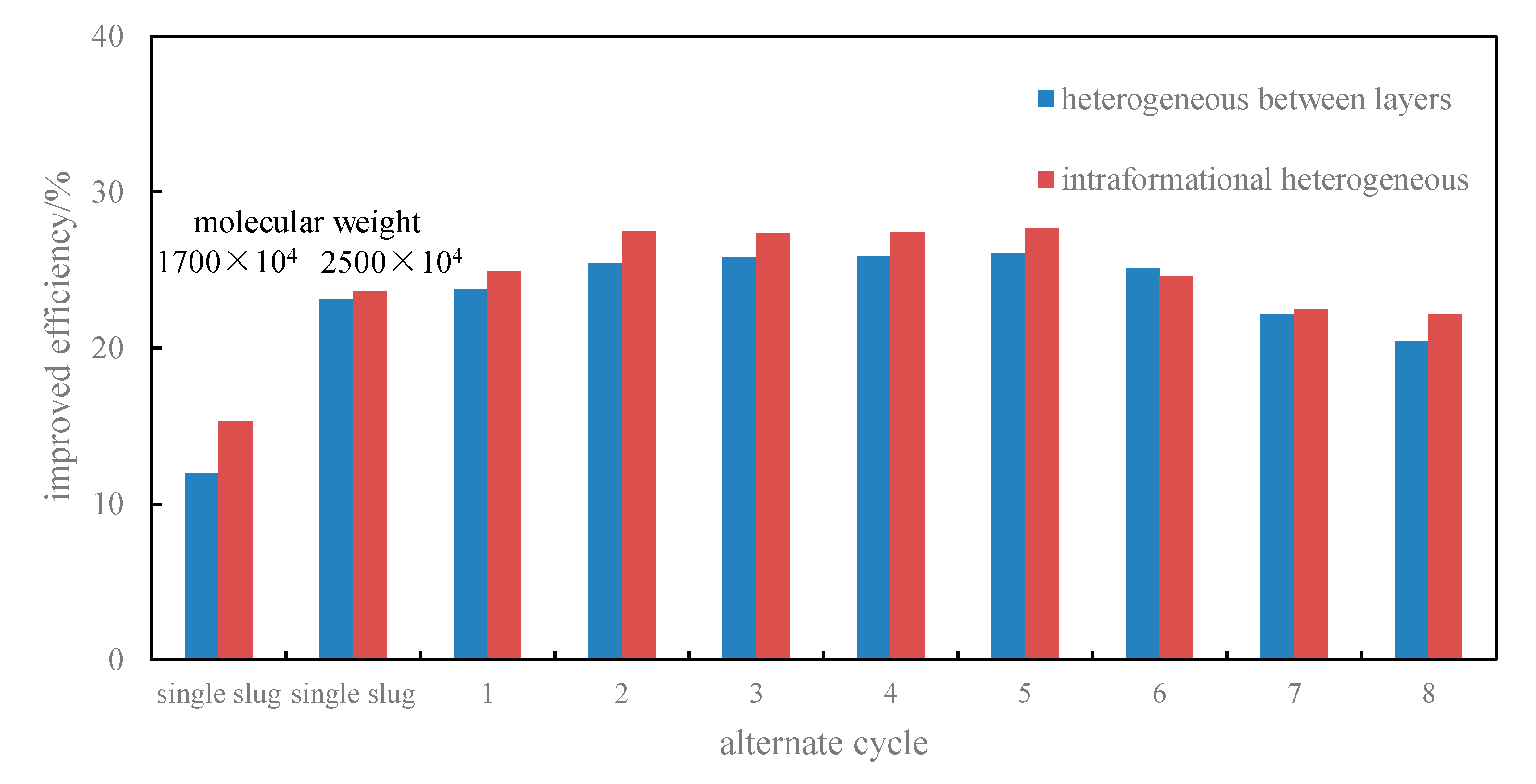

3.2.1. The Effects of Profile Inversion by Alternating Injection

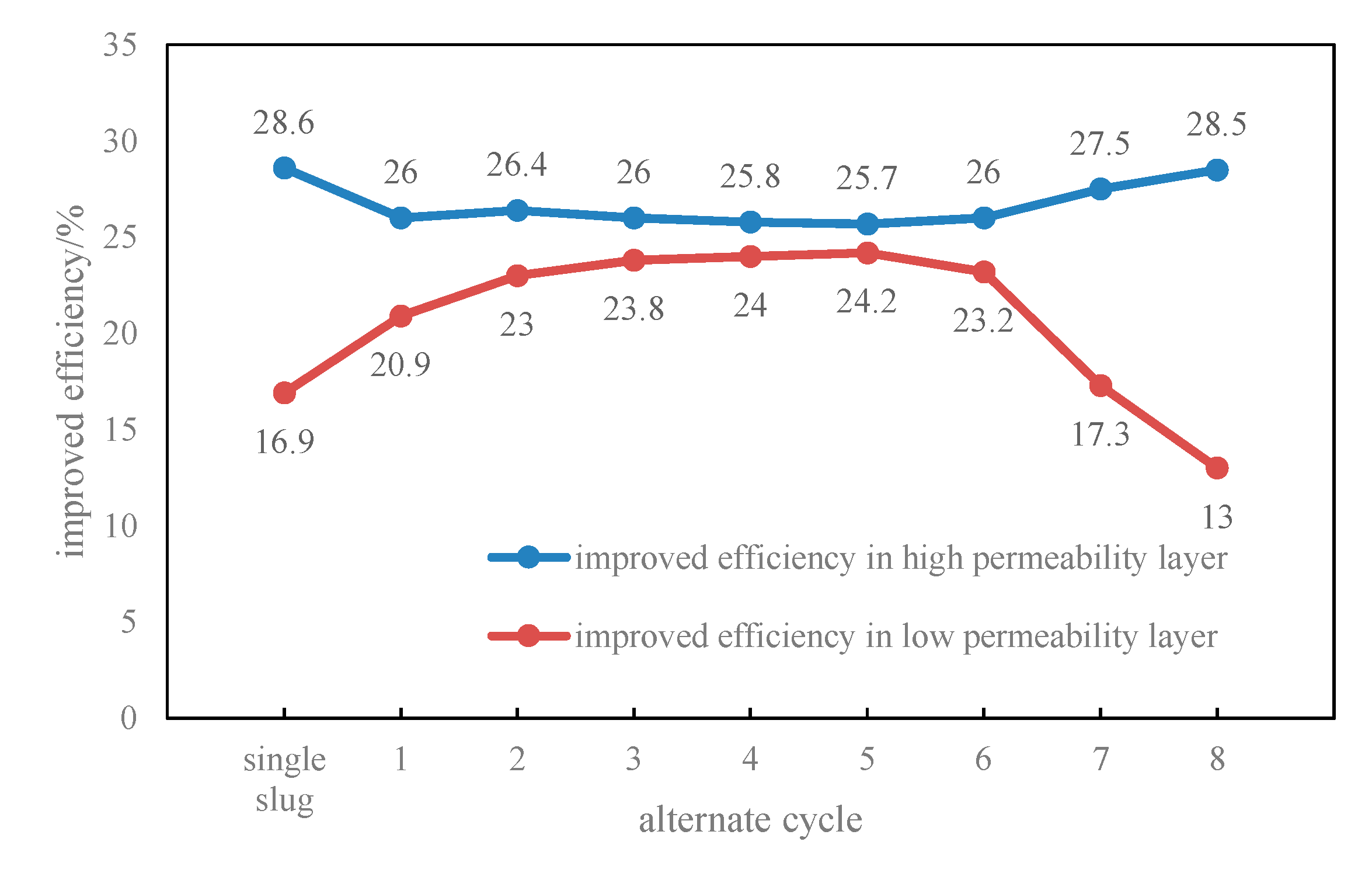

3.2.2. The Impacts of Alternate Cycles on Liquid Injection Profile

4. Conclusions

- (1)

- The Rh of polymer increases as the MW and concentration increases, and decreases as the solution salinity increases. It is proved from the core blocking test that the relationship between polymer and cores of the same permeability are different due to the pore structure.

- (2)

- In the PF experiments on heterogeneous cores, the alternating injection can significantly improve the efficiency of low permeability layers by an average of 4.27%, compared to single-slug injection. However, the alternating injection has very little effect on the high permeable layers.

- (3)

- The experiments verified that the alternating injection increases the efficiency of heterogeneous formation, mainly by improving the efficiency of low permeability layers and the water injection profile.

- (4)

- The relationship of different regions in Daqing can be an important reference for PF design. During this study, the alternating injection proved to be effective in laboratory experiments. The alternating injection should be carried out as a field test and numerical simulation for further application.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yan, J.X. Practice and knowledge of polymer flooding technique applied in Shengli petroliferous province. Oil Gas Recovery Technol. 2002, 9, 1–3. [Google Scholar]

- Wang, D.M.; Cheng, J.C.; Wu, J.Z.; Wang, J. Application of polymer flooding technology in Daqing Oilfield. Acta Pet. Sin. 2005, 26, 74–78. [Google Scholar]

- Guo, W.K.; Cheng, J.C.; Liao, G.Z. Present Situation and Direction of Tertiary Recovery Technique in the Future in Daqing Oilfield. Pet. Geol. Oilfield Dev. Daqing 2002, 21, 1–6. (In Chinese) [Google Scholar]

- Xu, Z.S.; Niu, J.G.; Liao, G.Z. Application and experience of polymer flooding in Daqing oilfield. Pet. Geol. Oilfield Dev. Daqing 2000, 19, 13–16. (In Chinese) [Google Scholar]

- Han, P.H.; Dong, Z.L.; Zhang, Q.R. Determination of reasonable polymer amount in polymer flooding. Pet. Geol. Oilfield Dev. Daqing 1999, 18, 40–41. (In Chinese) [Google Scholar]

- Qian, G.B.; Xu, C.F.; Chen, Y.K.; Wang, X.G.; Liu, H.X.; Lian, G.H. Microscopic Mechanism of Polymer Flooding in Glutenite Reservoir of Lower Karamay Formation in East District-7(1), Karamay Oilfield. Xinjiang Pet. Geol. 2016, 37, 56–61. (In Chinese) [Google Scholar]

- Wang, D.; Wang, G.; Wu, W.; Xia, H.; Yin, H. The Influence of Viscoelasticity on Displacement Efficiency—From Micro to Macro Scale. In Proceedings of the 2007 Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar]

- Huh, C.; Pope, G.A. Residual Oil Saturation from Polymer Floods: Laboratory Measurements and Theoretical Interpretation. In Proceedings of the 2008 SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Lu, X.G.; Gao, Z.H.; Zhao, X.J.; Yan, W.H. Distribution regularities of remaining of oil in hetegeneous reservoirs after polymer flooding. Acta Pet. Sin. 1996, 4, 55–61. [Google Scholar]

- Li, J.; Wu, L.J.; Shao, Z.B. The technical points of polymer flooding in formation type II of Daqing oilfield. J. Oil Gas Technol. 2005, 27, 394–396. (In Chinese) [Google Scholar]

- Ma, P.P. The Influence of Hydrolysis Degree to Salt Tolerance of Zwitterionic Polymer. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2014. [Google Scholar]

- Jin, Z.P. Basic principles and application of laser light scattering detector. Mod. Instrum. 2006, 10, 49–53. [Google Scholar]

- Yang, X.Y. The study of polymer molecular size by dynamic light scattering method. Oil-Gas Field Surf. Eng. 2014, 33, 13. (In Chinese) [Google Scholar]

- Liu, J.; Zhang, L.J.; Gao, W.D.; Yue, X.A.; Wang, N. Adaptability study on polymer solution in low permeability layer. Pet. Geol. Recovery Effic. 2010, 17, 71–73. [Google Scholar]

- Wei, J.G.; Ma, Y.Y. Flow regular pattern experiment of polymer solution in porous medium. J. Petrochem. Univ. 2016, 29, 23–26. [Google Scholar]

- Sheng, J.; Leonhardt, B.; Azri, N. Status of polymer flooding technology. J. Can. Petroleum Eng. 2015, 54. [Google Scholar] [CrossRef]

- Cao, R.B.; Wang, X.L.; Han, P.H. Multi-slug alternative injection method and field application of polymer flooding. Pet. Geol. Recovery Effic. 2012, 19, 71–73. [Google Scholar]

| Group No. | Well Name | Sample No. | Layer | Porosity/% | Permeability/×10−3 μm2 | Throat Radius/µm | Pore Throat Ratio | Mainstream Throat Radius/µm | Structural Coefficient |

|---|---|---|---|---|---|---|---|---|---|

| A | X9-1 | 2-2 | SII | 26.90 | 83.6 | 6.23 | 42.71 | 6.98 | 1.90 |

| B2-322-JP34 | 15-1 | SII | 27.90 | 85.6 | 11.09 | 26.75 | 8.72 | 4.19 | |

| B | X9-1 | 6-2 | SIII | 26.72 | 244.2 | 7.13 | 46.12 | 6.71 | 0.76 |

| B2-322-JP34 | 15-2 | SIII | 28.06 | 225.7 | 7.27 | 43.99 | 16.14 | 1.38 | |

| C | X9-1 | 5-2 | SII | 27.80 | 437.0 | 11.26 | 29.79 | 8.86 | 0.45 |

| B2-322-JP34 | 10-2 | SII | 29.43 | 438.3 | 11.68 | 27.82 | 16.15 | 2.36 |

| Injection Pattern | Volume of Total Polymer Injection (PV) | Volume of One Slug (PV) | MW (×104) | Concentration (mg/L) | Viscosity (mPa·s) |

|---|---|---|---|---|---|

| Single-slug | 0.56 | / | 2500 | 2000 | 185 |

| Single-slug | 0.56 | / | 1700 | 1000 | 43.7 |

| Alternating slug | 0.56 | 0.28 | 2500 | 2000 | 185 |

| 0.28 | 1700 | 1000 | 43.7 |

| Injection Pattern | Volume of Total Polymer Injection (PV) | Volume of One Slug (PV) | MW (×104) | Concentration (mg/L) | Viscosity (mPa·s) |

|---|---|---|---|---|---|

| Single-slug | 2.24 | / | 2500 | 2000 | 185 |

| Single-slug | 2.24 | / | 1700 | 1000 | 43.7 |

| Alternating slug | 2.24 | 0.28 (4 times) | 2500 | 2000 | 185 |

| 0.28 (4 times) | 1700 | 1000 | 43.7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Shen, A.; Qiu, F.; Liang, S.; Wang, F. Matching Relationship and Alternating Injection for Polymer Flooding in Heterogeneous Formations: A Laboratory Case Study of Daqing Oilfield. Energies 2017, 10, 1018. https://doi.org/10.3390/en10071018

Liu S, Shen A, Qiu F, Liang S, Wang F. Matching Relationship and Alternating Injection for Polymer Flooding in Heterogeneous Formations: A Laboratory Case Study of Daqing Oilfield. Energies. 2017; 10(7):1018. https://doi.org/10.3390/en10071018

Chicago/Turabian StyleLiu, Songyuan, Anqi Shen, Feng Qiu, Shuang Liang, and Fengjiao Wang. 2017. "Matching Relationship and Alternating Injection for Polymer Flooding in Heterogeneous Formations: A Laboratory Case Study of Daqing Oilfield" Energies 10, no. 7: 1018. https://doi.org/10.3390/en10071018