Annual Assessment of Large-Scale Introduction of Renewable Energy: Modeling of Unit Commitment Schedule for Thermal Power Generators and Pumped Storages

Abstract

:1. Introduction

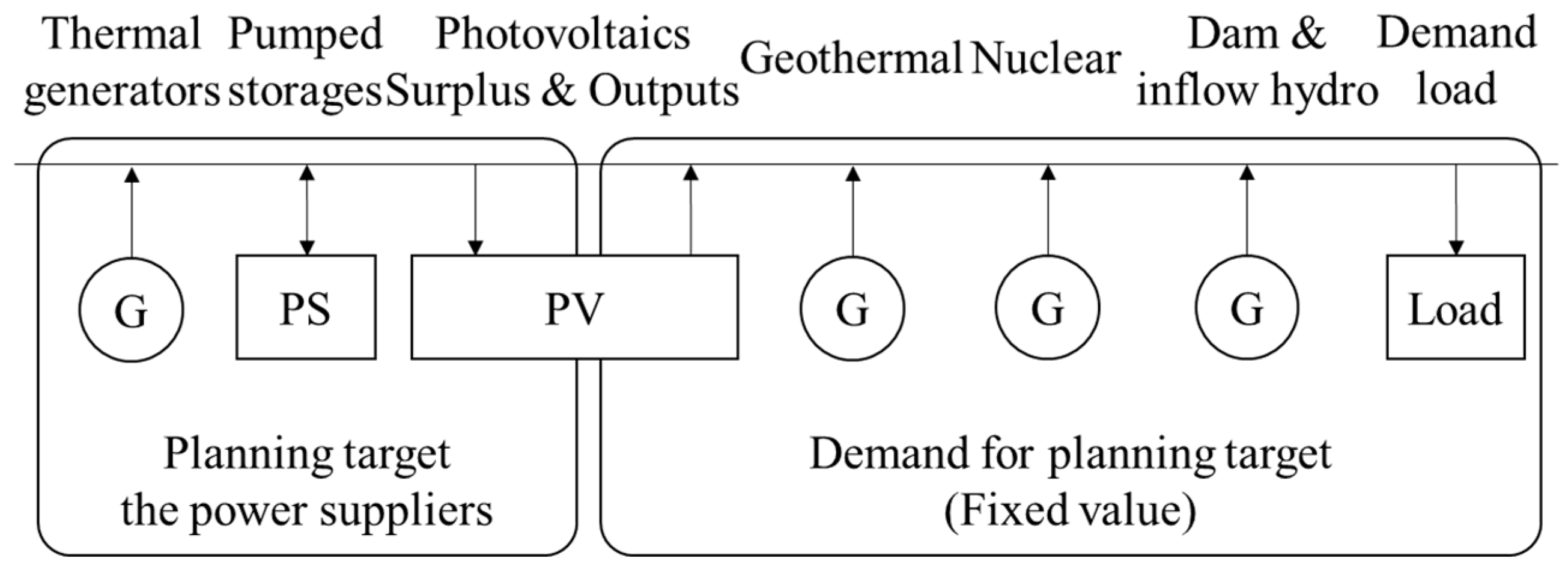

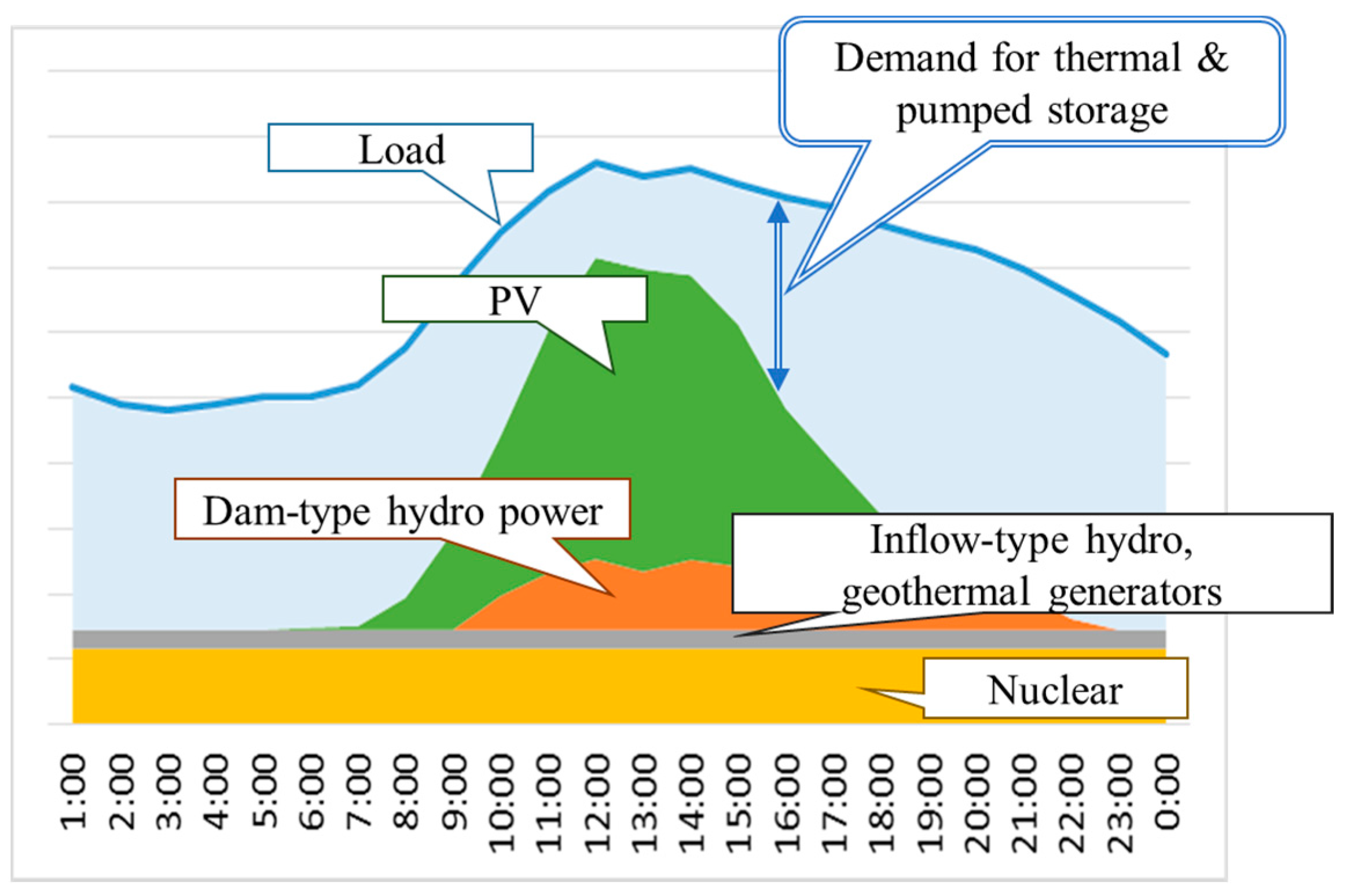

2. Generator Operation Model

2.1. Overview

2.2. Modeling and System Conditions

2.2.1. Objective Function

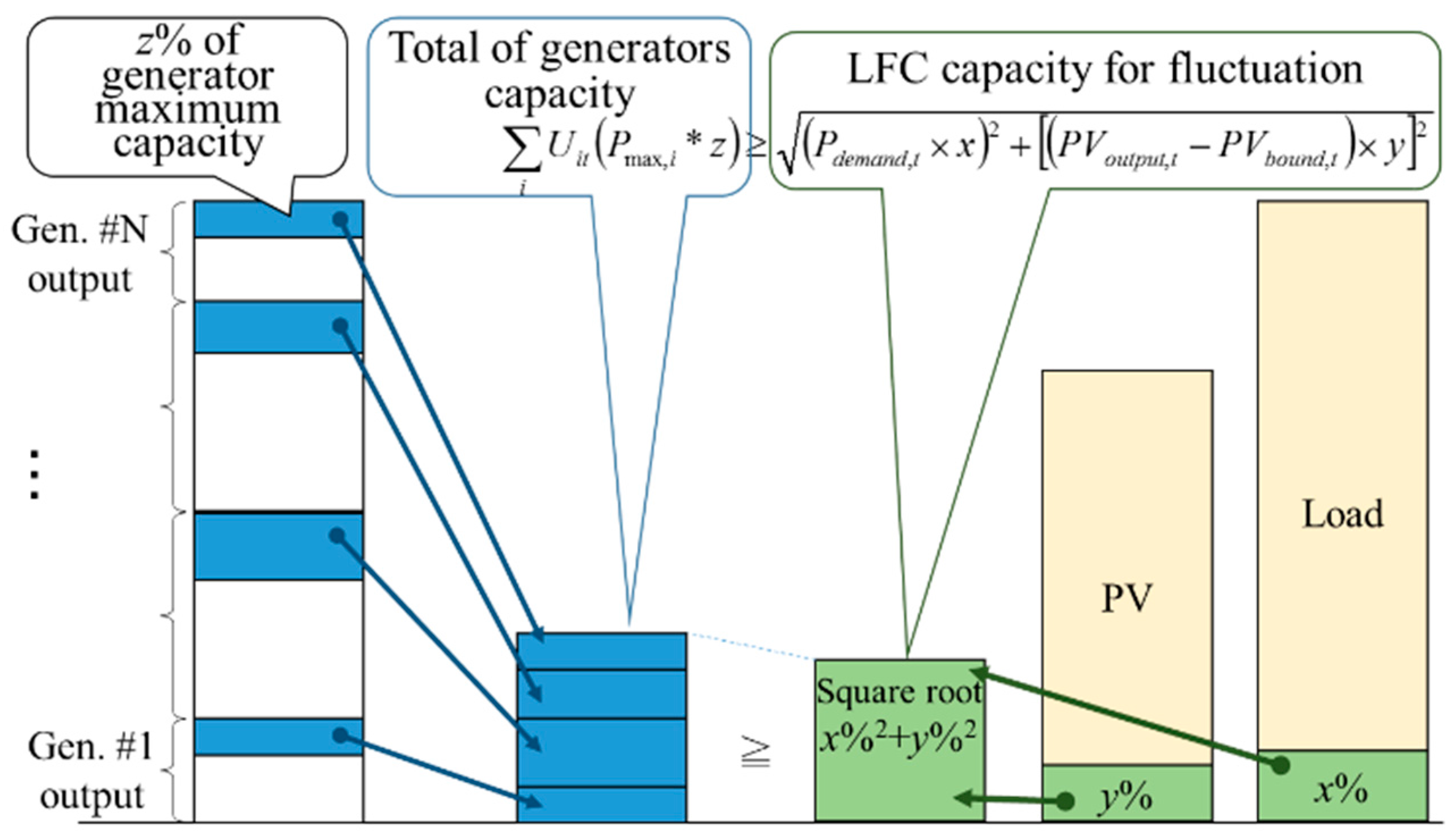

2.2.2. Operating Conditions of Power System

2.2.3. Mechanical Constraint of Generator

2.2.4. Operating Limitations of Pumped Storage

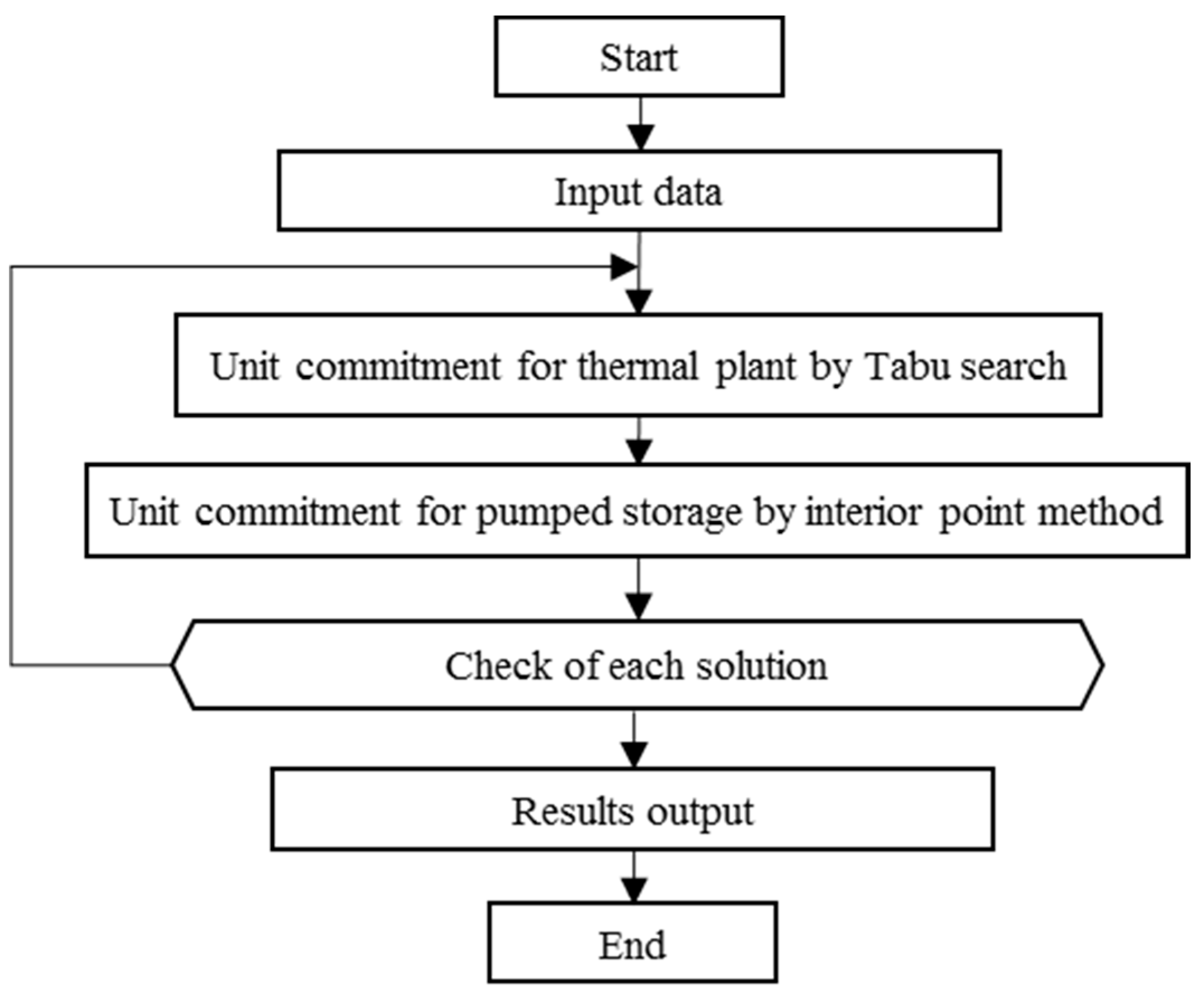

3. Unit Commitment Schedule for Thermal Power Generators and Pumped Storages

3.1. Overview of Proposed Method

3.2. Operating Plan for the Thermal Power Generators

3.3. Operating Plan for Pumped Storage

3.4. Acceleration of Calculations

3.4.1. Simplification of Complex Limiting Conditions

3.4.2. Reducing the Number of Neighborhood Solutions in Tabu Search

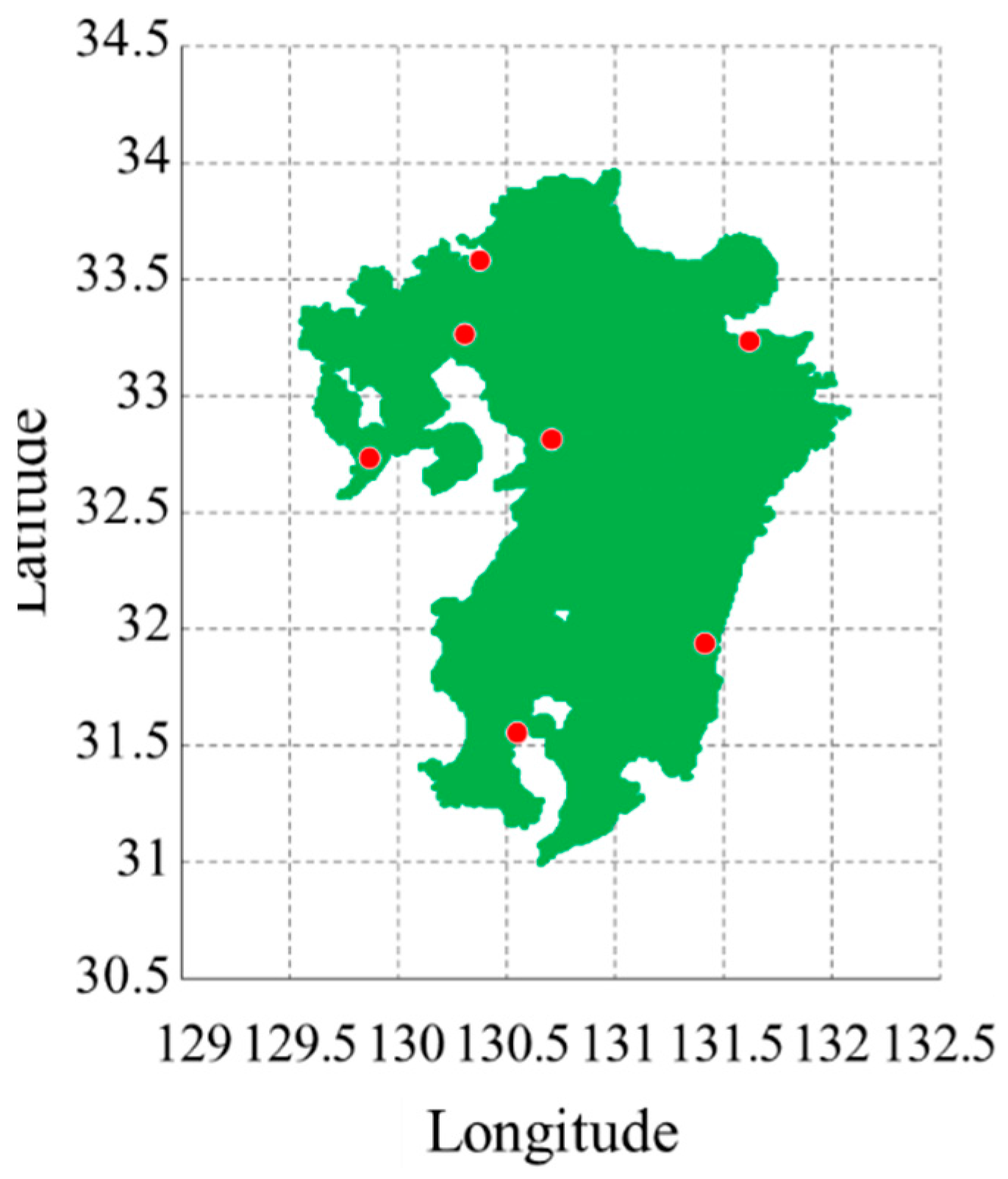

4. Area Selection and Example of Numerical Calculation

4.1. Conditions of Numerical Calculation

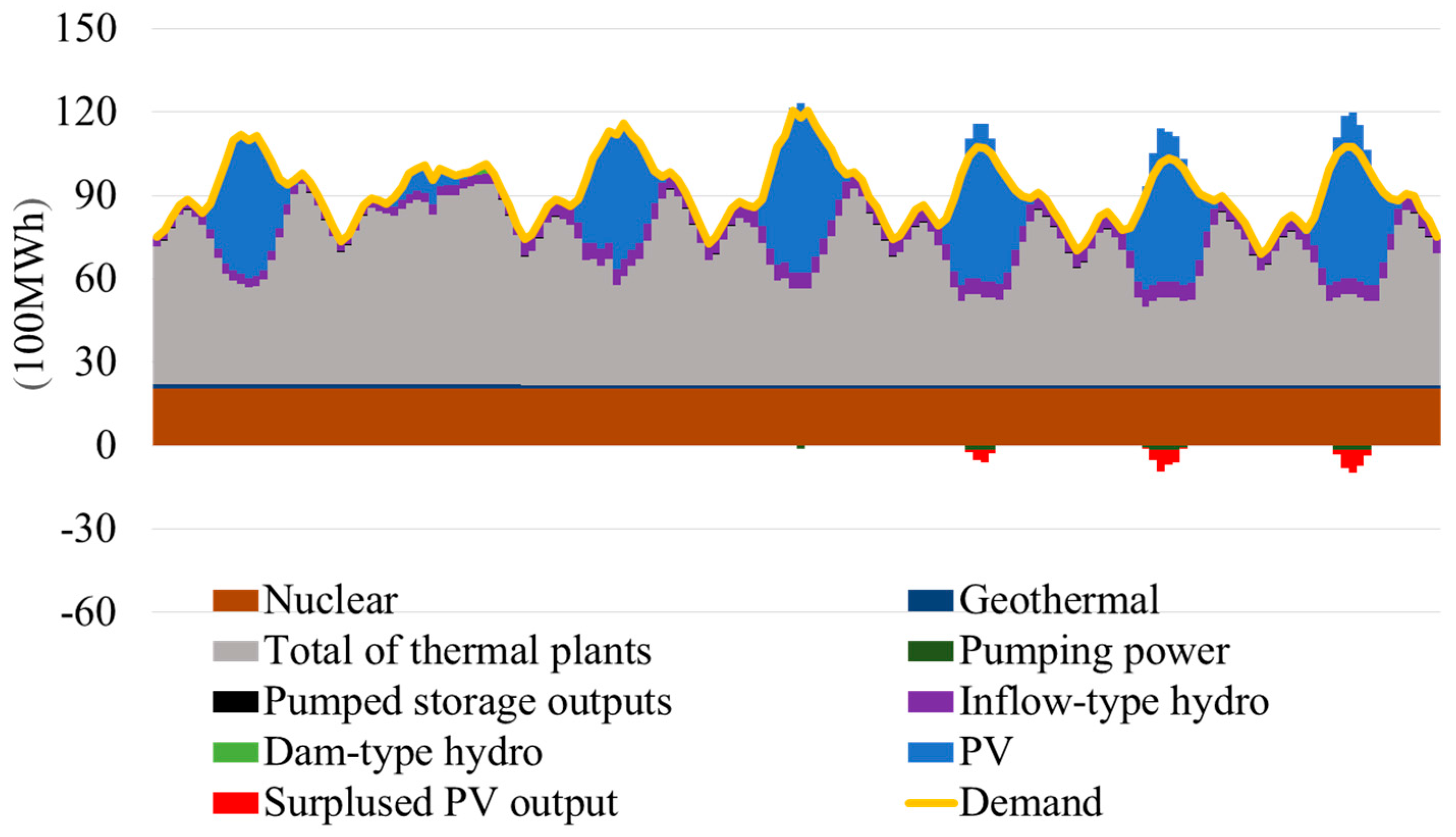

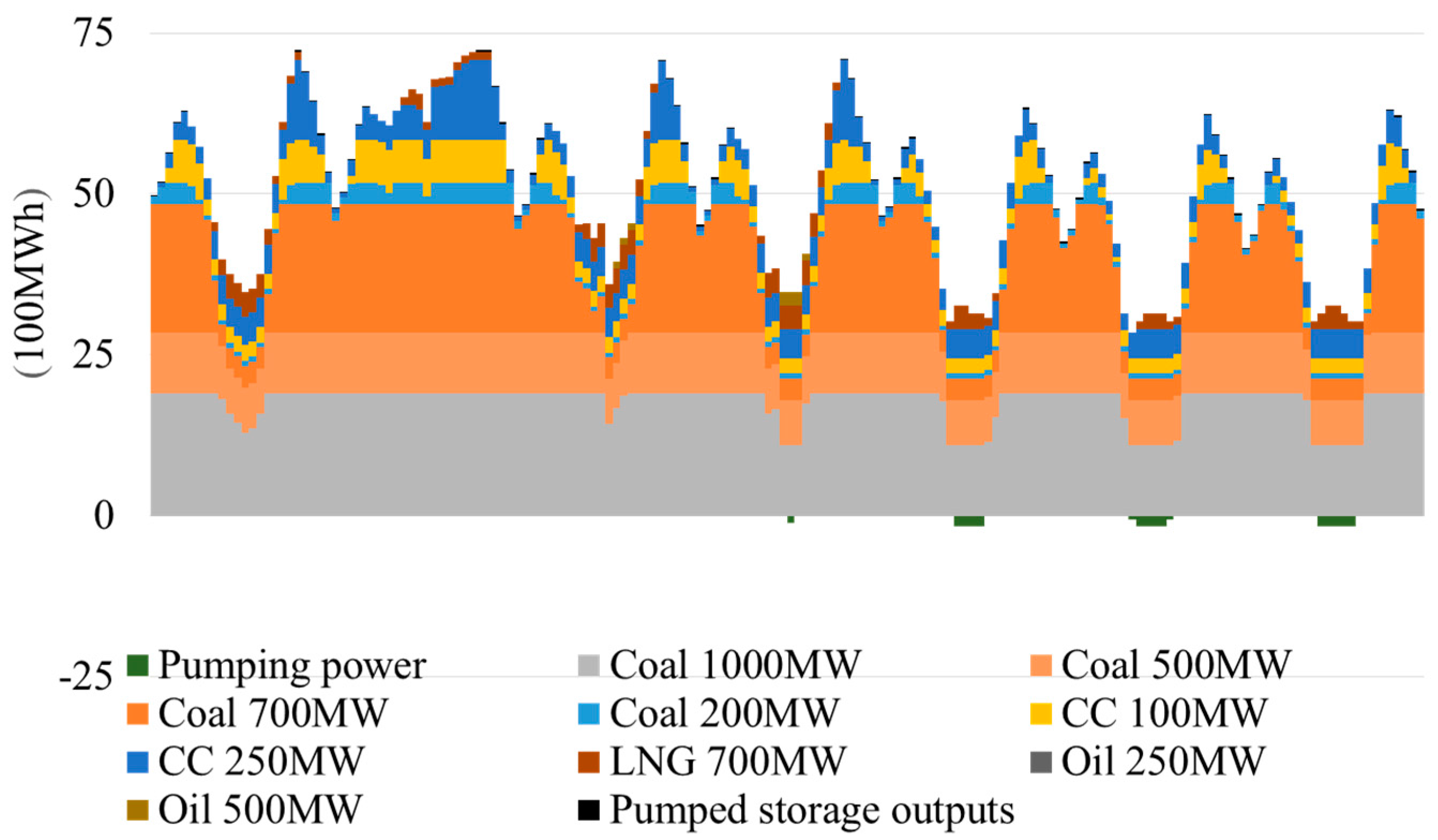

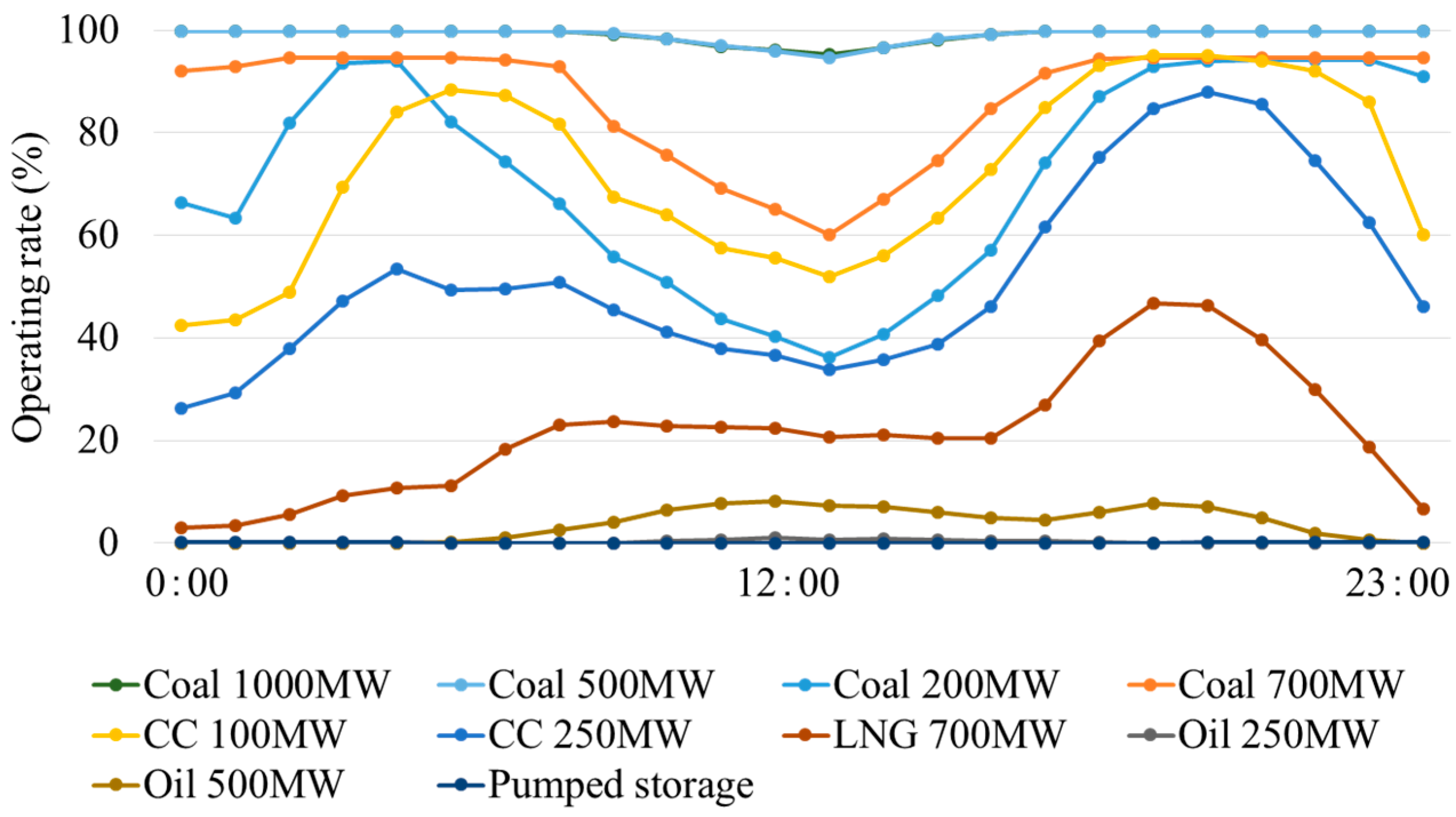

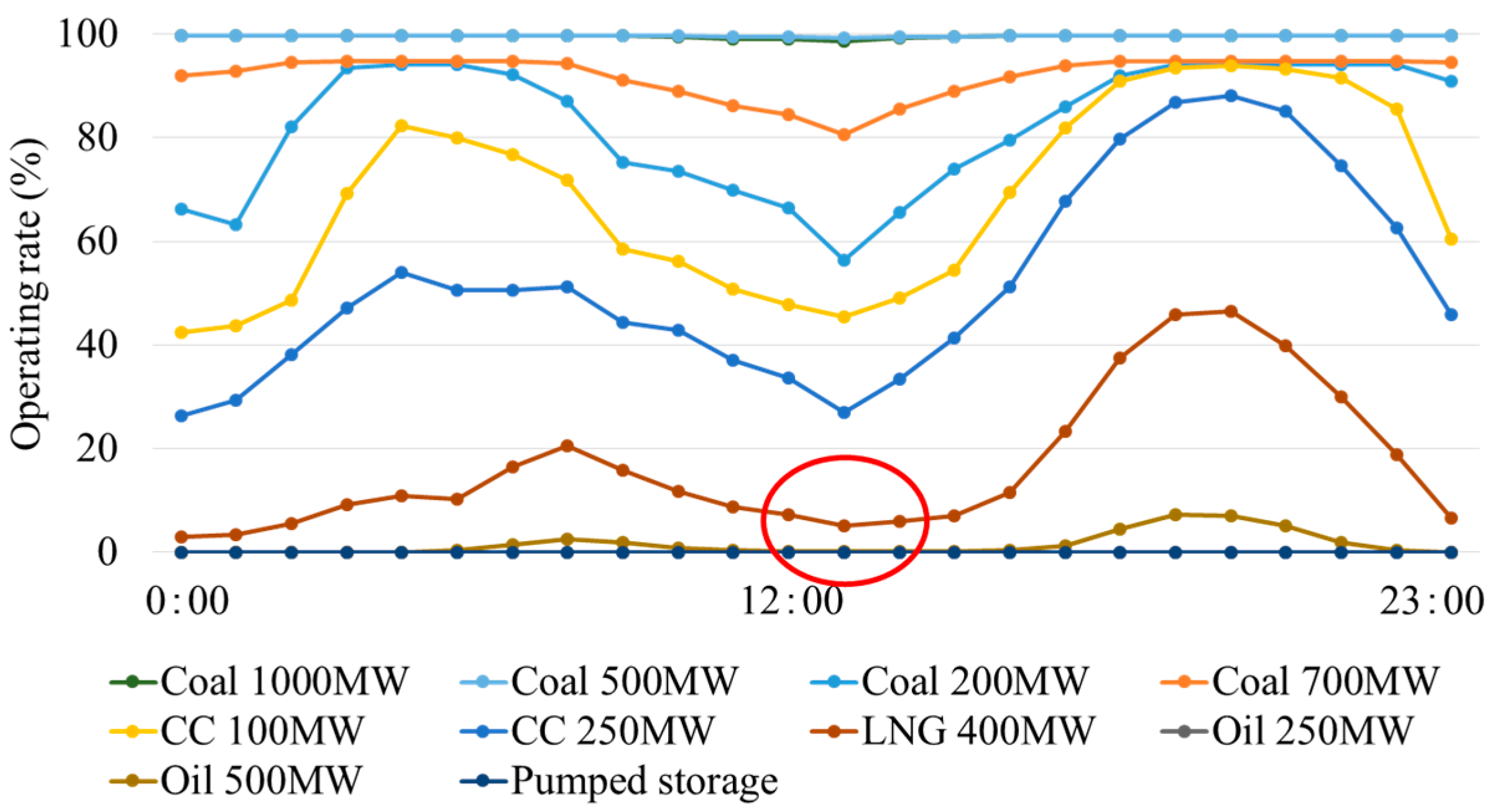

4.2. Numerical Results

5. Year-Round Evaluation by the Proposed Method

5.1. Explanation of Parameters

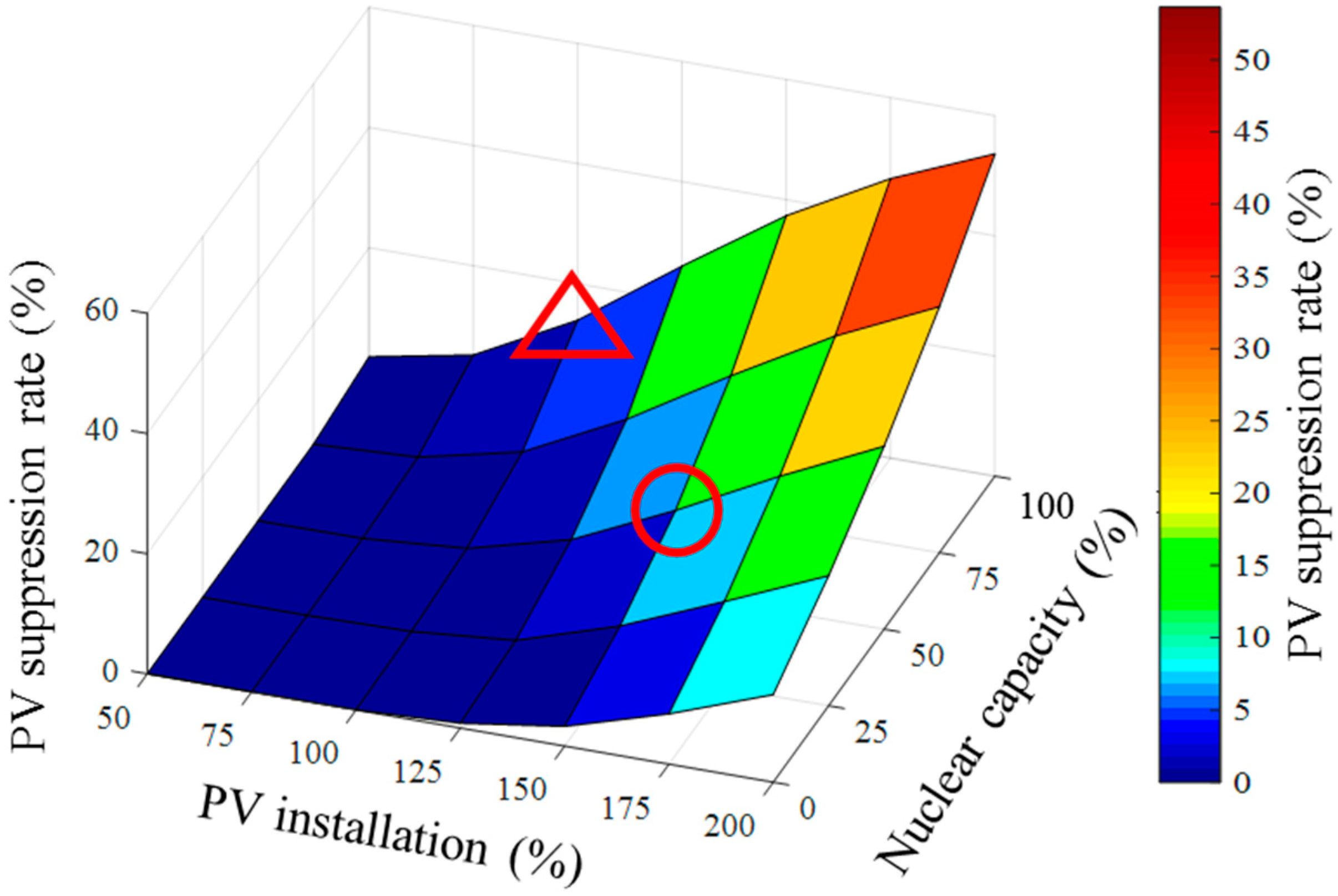

5.2. Impact of Nuclear Power Capacity and PV Introduction Amount onto the PV Surplus Rate

5.3. Effect of PV Introduction Amount

5.4. Impact of the Intensity of LFC Constraints

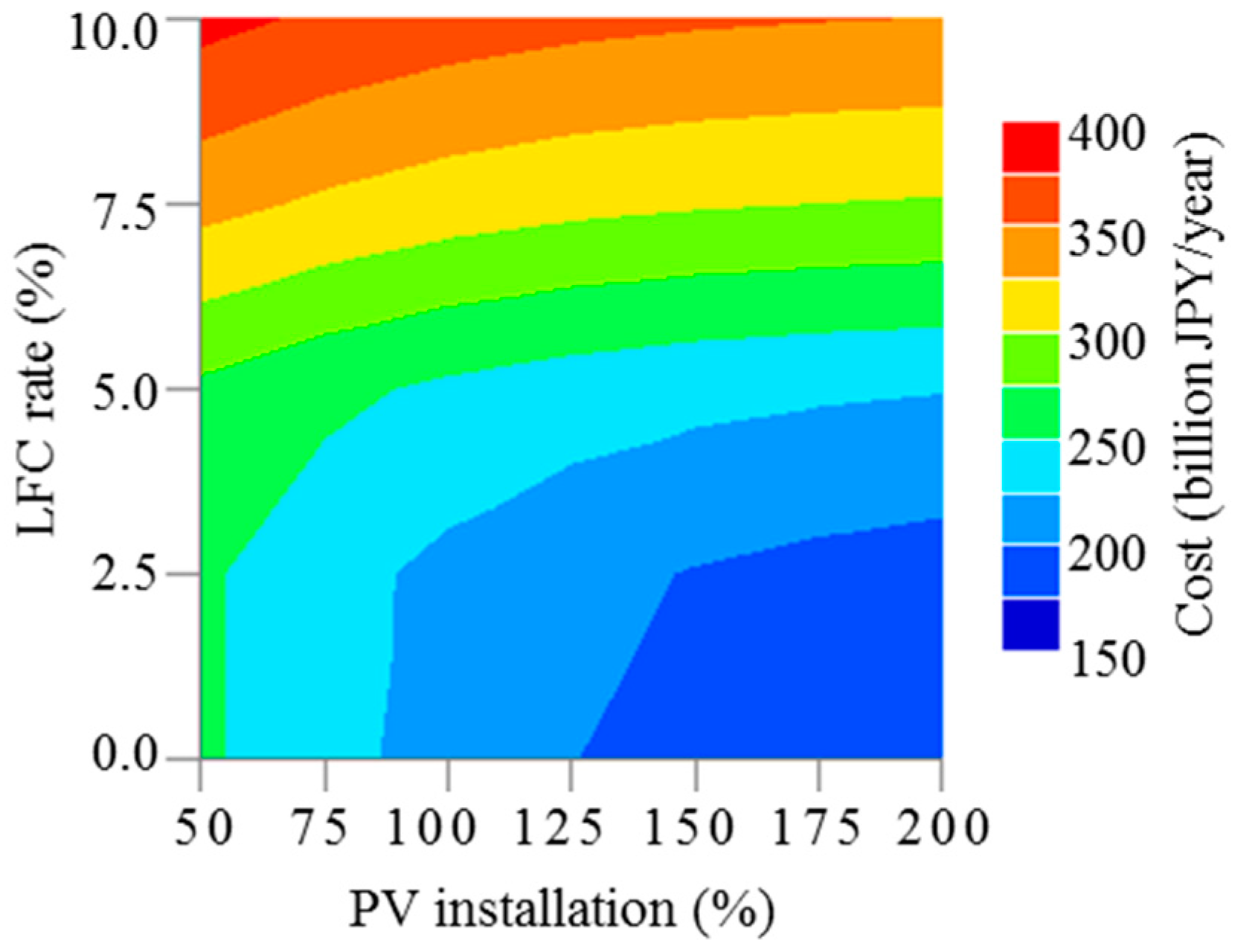

5.5. Impact of LFC Constraints on Operational Costs

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| aveC | average unit fuel cost by time period |

| C | start-up cost |

| CC | combined cycle |

| ELD | economic load dispatch |

| f | fuel cost |

| FIT | feed-in tariff |

| G | generator |

| LFC | load frequency control |

| LNG | liquefied natural gas |

| M | number of generators |

| MDT | minimum down time |

| MUT | minimum up time |

| P | power |

| Penalty | penalty coefficient |

| PS | pumped storage |

| PV | photovoltaic |

| RES | renewable energy source |

| U | start/stop condition (0 = stop, 1 = start) |

| WT | wind turbine |

| X | continuous time |

| x | LFC amount to respond demand fluctuation |

| y | LFC amount to respond PV fluctuation |

| z | generator rated output coefficient |

| Italics | |

| γ | limiting coefficient of changes in output |

| η | operational efficiency of pumped storage |

| Subscripts | |

| bound | suppression |

| demand | demand side |

| max | maximum |

| min | minimum |

References

- Zhang, J.; Hu, Z.; Zheng, Y.; Zhou, Y.; Wan, Z. Sectoral Electricity Consumption and Economic Growth: The Time Difference Case of China, 2006–2015. Energies 2017, 10, 249. [Google Scholar] [CrossRef]

- Aziz, M. Integrated Supercritical Water Gasification and a Combined Cycle for Microalgal Utilization. Energy Convers. Manag. 2015, 91, 140–148. [Google Scholar] [CrossRef]

- Ministry of Economy, Trade and Industry. Present Status and Promotion Measures for the Introduction of Renewable Energy in Japan. Available online: http://www.meti.go.jp/english/policy/energy_environment/renewable/ (accessed on 20 April 2016).

- Komiyama, R.; Fujii, Y. Assessment of Post-Fukushima Renewable Energy Policy in Japan’s Nation-Wide Power Grid. Energy Policy 2017, 101, 594–611. [Google Scholar] [CrossRef]

- Komiyama, R.; Fujii, Y. Assessment of Massive Integration of Photovoltaic System Considering Rechargeable Battery in Japan with High Time-Resolution Optimal Power Generation Mix Model. Energy Policy 2014, 66, 73–89. [Google Scholar] [CrossRef]

- Lotfy, M.E.; Senjyu, T.; Farahat, M.A.-F.; Abdel-Gawad, A.F.; Yona, A. A Frequency Control Approach for Hybrid Power System Using Multi-Objective Optimization. Energies 2017, 10, 80. [Google Scholar] [CrossRef]

- Erdinc, O.; Elma, O.; Uzunoglu, M.; Selamogullari, U.S.; Vural, B.; Ugur, E.; Boynuegri, A.R.; Dusmez, S. Experimental Performance Assessment of an Online Energy Management Strategy for Varying Renewable Power Production Suppression. Int. J. Hydrogen Energy 2012, 37, 4737–4748. [Google Scholar] [CrossRef]

- Barbour, E.; Wilson, I.A.G.; Radcliffe, J.; Ding, Y.; Li, Y. A review of pumped hydro energy storage development in significant international electricity markets. Renew. Sustain. Energy Rev. 2016, 61, 421–432. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.M. Pumped hydro energy storage system: A technological review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar] [CrossRef]

- Aziz, M.; Juangsa, F.B.; Kurniawan, K.; Budiman, B.A. Clean co-production of H2 and power from low rank coal. Energy 2016, 116, 489–497. [Google Scholar] [CrossRef]

- Aziz, M.; Zaini, I.N.; Oda, T.; Morihara, A.; Kashiwagi, T. Energy conservative brown coal conversion to hydrogen and power based on enhanced process integration: Integrated drying, coal direct chemical looping, combined cycle and hydrogenation. Int. J. Hydrogen Energy 2017, 42, 2904–2913. [Google Scholar] [CrossRef]

- Aziz, M.; Oda, T.; Mitani, T.; Watanabe, T.; Kashiwagi, T. Utilization of electric vehicles and their used batteries for peak-load shifting. Energies 2015, 8, 3720–3738. [Google Scholar] [CrossRef]

- Komiyama, R.; Fujii, Y. Assessment of Japan’s optimal power generation mix considering massive deployment of variable renewable power generation. Electr. Eng. Jpn. 2013, 185, 1–11. [Google Scholar] [CrossRef]

- Komiyama, R.; Ootsuki, T.; Fujii, Y. Optimal power generation mix considering hydrogen storage of variable renewable power generation. IEEJ Trans. Power Energy 2014, 134, 885–895. (In Japanese) [Google Scholar] [CrossRef]

- Ootsuki, T.; Komiyama, R.; Fujii, Y. Study on surplus electricity under massive integration of intermittent renewable energy source. IEEJ Trans. Power Energy 2015, 135, 299–309. (In Japanese) [Google Scholar] [CrossRef]

- Aihara, R.; Yokoyama, A. Optimal weekly operation scheduling of pumped storage hydro power plant considering optimal hot reserve capacity in a power system. Electr. Eng. Jpn. 2016, 195, 35–48. [Google Scholar] [CrossRef]

- Ashina, S.; Fujino, J. Simulation analysis of CO2 reduction scenarios in Japan’s electricity sector using multi-regional optimal generation planning model. J. Jpn. Soc. Energy Res. 2008, 29, 1–7. [Google Scholar]

- Shiraki, Y.; Ashina, S.; Kameyama, Y.; Moriguchi, Y.; Hashimoto, S. Simulation analysis of renewable energy installation scenarios in Japan’s electricity sector in 2020 using a multi-regional optimal generation planning model. J. Jpn. Soc. Energy Res. 2012, 33, 1–10. [Google Scholar]

- Ogimoto, K.; Kataoka, K.; Nonaka, S.; Makoto, H.; Nagao, I. Characteristic analysis of electricity demand and supply in massive renewable energy introduction. In Proceedings of the Energy and Resources Society, Energy System and Economic Environment Conference, Tokyo, Japan, 23–24 January 2014. [Google Scholar]

- Lee, C.-W.; Lin, B.-Y. Application of hybrid quantum Tabu search with support vector regression (SVR) for load forecasting. Energies 2016, 9, 873. [Google Scholar] [CrossRef]

- Kusakana, K. Optimal scheduling for distributed hybrid system with pumped hydro storage. Energy Convers. Manag. 2016, 111, 253–260. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Li, Y.; Zhu, S.; Zhao, J. Techniques of applying wavelet de-noising into a combined model for short-term load forecasting. Int. J. Electr. Power Energy Syst. 2014, 62, 816–824. [Google Scholar] [CrossRef]

- Mantawy, A.H.; Abdel-Magid, Y.L.; Selim, S.Z. Unit commitment by tabu search. IEE Proc. Gener. Transm. Distrib. 1998, 45, 56–64. [Google Scholar] [CrossRef]

- Tang, F.; Zhou, H.; Wu, Q.; Qin, H.; Jia, J.; Guo, K. A Tabu Search Algorithm for the Power System Islanding Problem. Energies 2015, 8, 11315–11341. [Google Scholar] [CrossRef]

- Capitanescu, F.; Wehenkel, L. Experiments with the interior-point method for solving large scale Optimal Power Flow problems. Electr. Power Syst. Res. 2013, 95, 276–283. [Google Scholar] [CrossRef]

- Agency for Natural Resources and Energy. Electricity Survey Statistics. 2014. Available online: http://www.enecho.meti.go.jp/statistics/electric_power/ep002/xls/2014/2-5-H26.xls (accessed on 20 April 2016). (In Japanese)

- Usami, A.; Kawasaki, N. Development of the Technologies for Prediction of Real-Time PV Power Generation (III)—Integration of Elemental Technologies into a Proto-Type Model; CRIEPI Research Report: Yokosuka, Japan, 2012. (In Japanese) [Google Scholar]

- Ministry of Economy, Trade and Industry. Power Generator List (Kyushu). Available online: http://www.meti.go.jp/committee/sougouenergy/shoene_shinene/shin_ene/keitou_wg/pdf/003_s01_00.pdf (accessed on 20 April 2016).

- Ministry of Economy, Trade and Industry. Report on Analysis of Generation Costs, etc. for Subcommittee on Long-Term Energy Supply-Demand Outlook. Available online: www.meti.go.jp/english/press/2015/pdf/0716_01b.pdf (accessed on 11 April 2016).

- Research Institute of Innovative Technology for the Earth. Latest Estimate of Power Generation Costs by Power Source, and Cost-Benefit Analysis of Alternative Power Sources (Outline). Available online: https://www.rite.or.jp/system/global-warming-ouyou/download-data/E-PowerGenerationCost_estimates_20141020.pdf (accessed on 22 April 2016).

- Institute of Electrical Engineers. Standard Model of Electric Power System, Basic System Model. Available online: http://www2.iee.or.jp/ver2/pes/23-st_model/index020.html (accessed on 22 April 2016). (In Japanese).

- Agency for Natural Resources and Energy. Calculation Results of Total Connectable Capacity of Each company (interim) [Secretariat]. Available online: http://www.meti.go.jp/committee/sougouenergy/shoene_shinene/shin_ene/keitou_wg/pdf/003_09_00.pdf (accessed on 22 April 2016). (In Japanese)

- Kyushu Electric Power. Results of Equipment Utilization Rate of Domestic Nuclear Power Plants. Available online: http://www.kyuden.co.jp/nuclear_operation_kokunai.html (accessed on 22 April 2016). (In Japanese).

| Generator Class | ai | bi | ci | Start-Up Cost [M-JPY] | MUT [Time] | MDT [Time] | PGFi,min [MW] | PGFi,max [MW] | Number |

|---|---|---|---|---|---|---|---|---|---|

| Coal 1000 MW | 0.00005 | 1.1 | 120 | 1200 | 10 | 8 | 550 | 950 | 4 |

| Coal 700 MW | 0.0004 | 3.25 | 450 | 3000 | 5 | 8 | 110 | 665 | 3 |

| Coal 200 MW | 0.0005 | 5.0 | 100 | 2000 | 5 | 8 | 80 | 340 | 1 |

| Oil 500 MW | 0.00016 | 17.0 | 700 | 10,000 | 3 | 4 | 105 | 475 | 7 |

| Oil 250 MW | 0.0031 | 16.0 | 900 | 8000 | 3 | 4 | 105 | 360 | 2 |

| LNG 700 MW | 0.0009 | 8.6 | 400 | 6000 | 2 | 3 | 125 | 570 | 3 |

| CC 100 MW | 0.004 | 4.0 | 420 | 1000 | 1 | 1 | 40 | 110 | 6 |

| CC 250 MW | 0.006 | 5.0 | 400 | 2000 | 1 | 1 | 60 | 210 | 4 |

| CC 250 MW | 0.006 | 5.0 | 400 | 2500 | 1 | 1 | 70 | 230 | 3 |

| Pumped storage | 2350 | 1 | |||||||

| Total | 17,990 | 34 |

| Generator | Share | Number of Patterns | ||

|---|---|---|---|---|

| Nuclear | 0%, 25% | 50% | 75%, 100% | 5 |

| PV | 50%, 75% | 100% | 125%, 150%, 175%, 200% | 7 |

| LFC | 0%, 2.5% | 5% | 7.5%, 10% | 5 |

| LFC y (%) | PV Introduction Rate (%) | ||||||

|---|---|---|---|---|---|---|---|

| 50 | 75 | 100 | 125 | 150 | 175 | 200 | |

| 0.0 | 254 | 233 | 215 | 201 | 190 | 182 | 177 |

| 2.5 | 254 | 234 | 218 | 207 | 199 | 193 | 189 |

| 5.0 | 270 | 256 | 245 | 237 | 232 | 228 | 226 |

| 7.5 | 333 | 321 | 312 | 306 | 302 | 300 | 298 |

| 10.0 | 382 | 371 | 362 | 357 | 353 | 351 | 349 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitani, T.; Aziz, M.; Oda, T.; Uetsuji, A.; Watanabe, Y.; Kashiwagi, T. Annual Assessment of Large-Scale Introduction of Renewable Energy: Modeling of Unit Commitment Schedule for Thermal Power Generators and Pumped Storages. Energies 2017, 10, 738. https://doi.org/10.3390/en10060738

Mitani T, Aziz M, Oda T, Uetsuji A, Watanabe Y, Kashiwagi T. Annual Assessment of Large-Scale Introduction of Renewable Energy: Modeling of Unit Commitment Schedule for Thermal Power Generators and Pumped Storages. Energies. 2017; 10(6):738. https://doi.org/10.3390/en10060738

Chicago/Turabian StyleMitani, Takashi, Muhammad Aziz, Takuya Oda, Atsuki Uetsuji, Yoko Watanabe, and Takao Kashiwagi. 2017. "Annual Assessment of Large-Scale Introduction of Renewable Energy: Modeling of Unit Commitment Schedule for Thermal Power Generators and Pumped Storages" Energies 10, no. 6: 738. https://doi.org/10.3390/en10060738