Enhancing Insulating Performances of Presspaper by Introduction of Nanofibrillated Cellulose

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of Samples

2.2. SEM, FTIR, and XRD

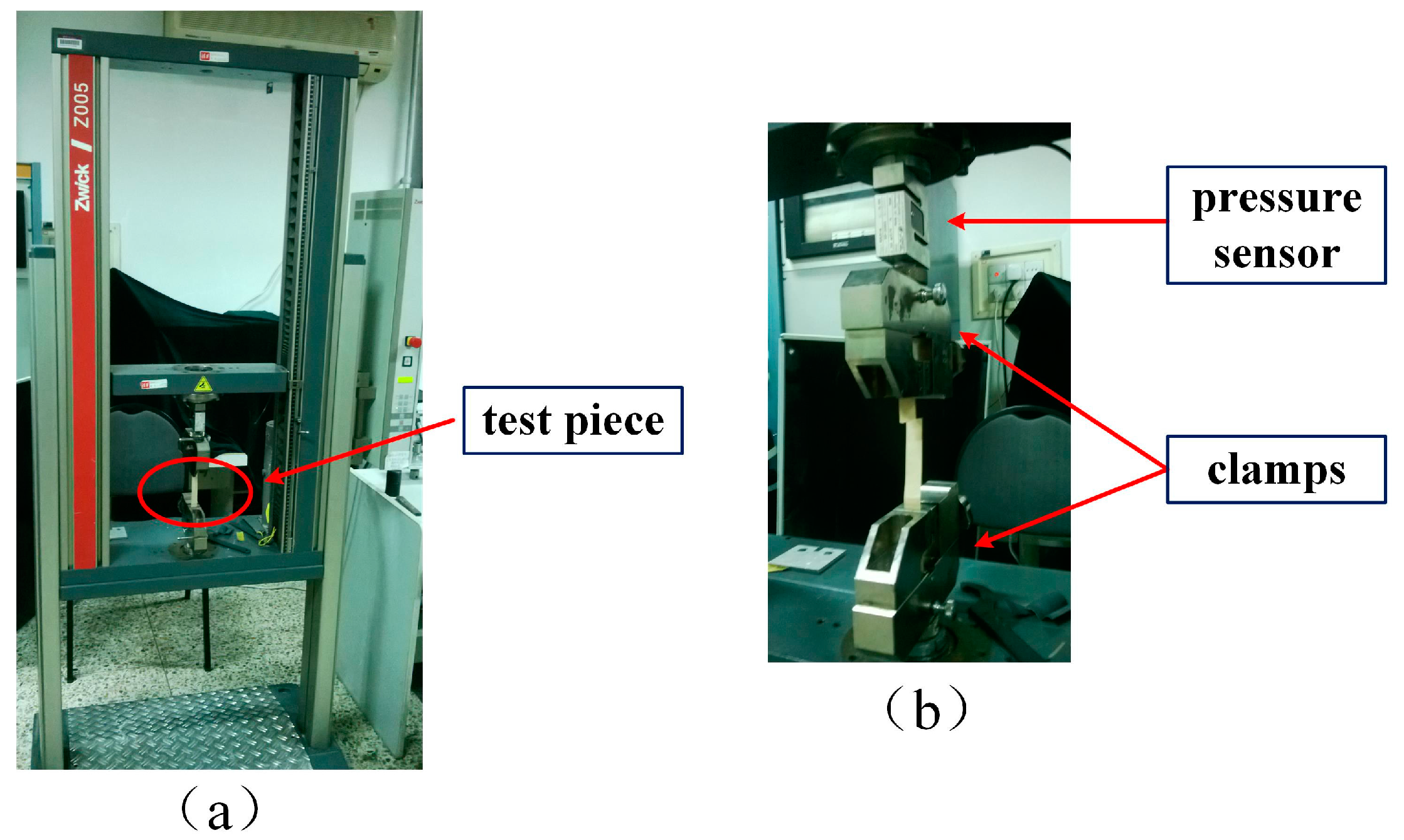

2.3. Tensile Strength

2.4. DC Volume Resistivity and Dielectric Response

2.5. Breakdown Behavior

2.6. Thermal Properties

3. Results and Discussion

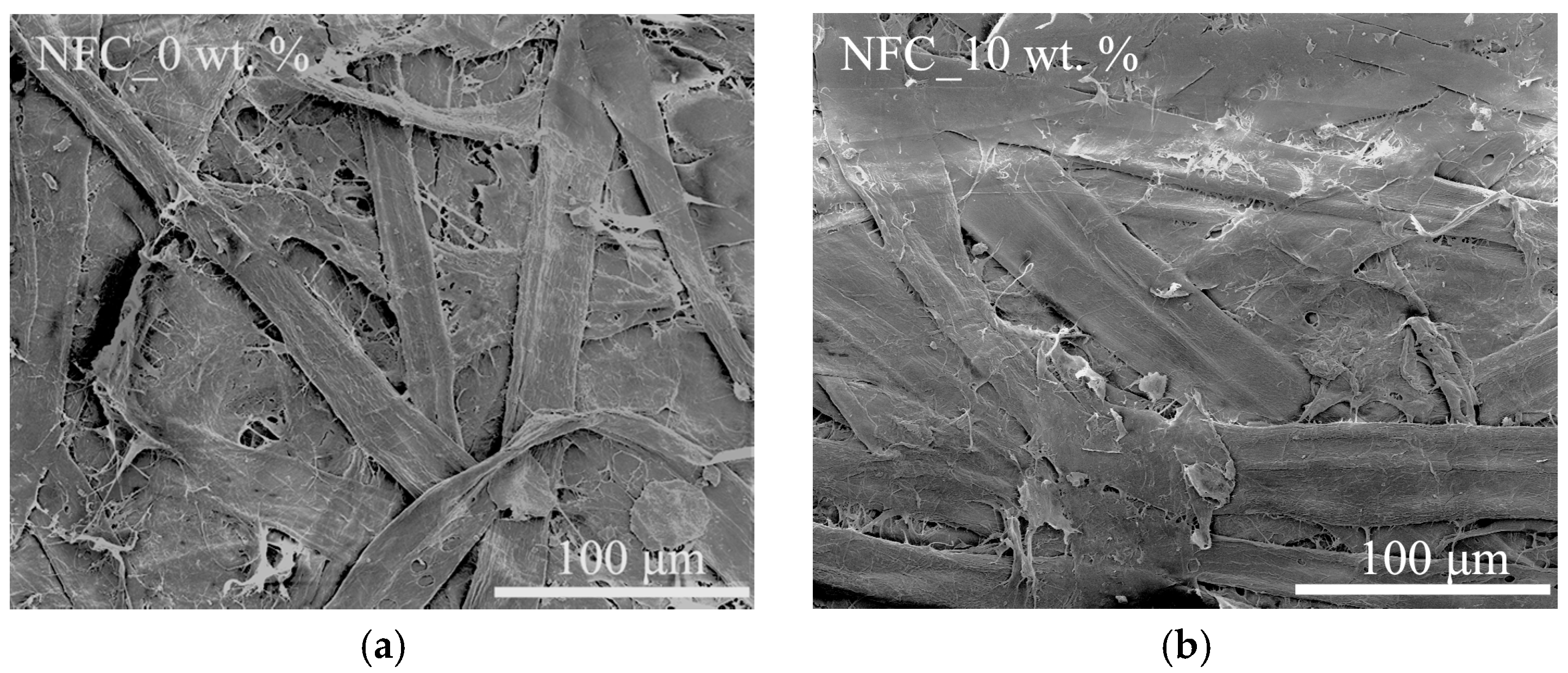

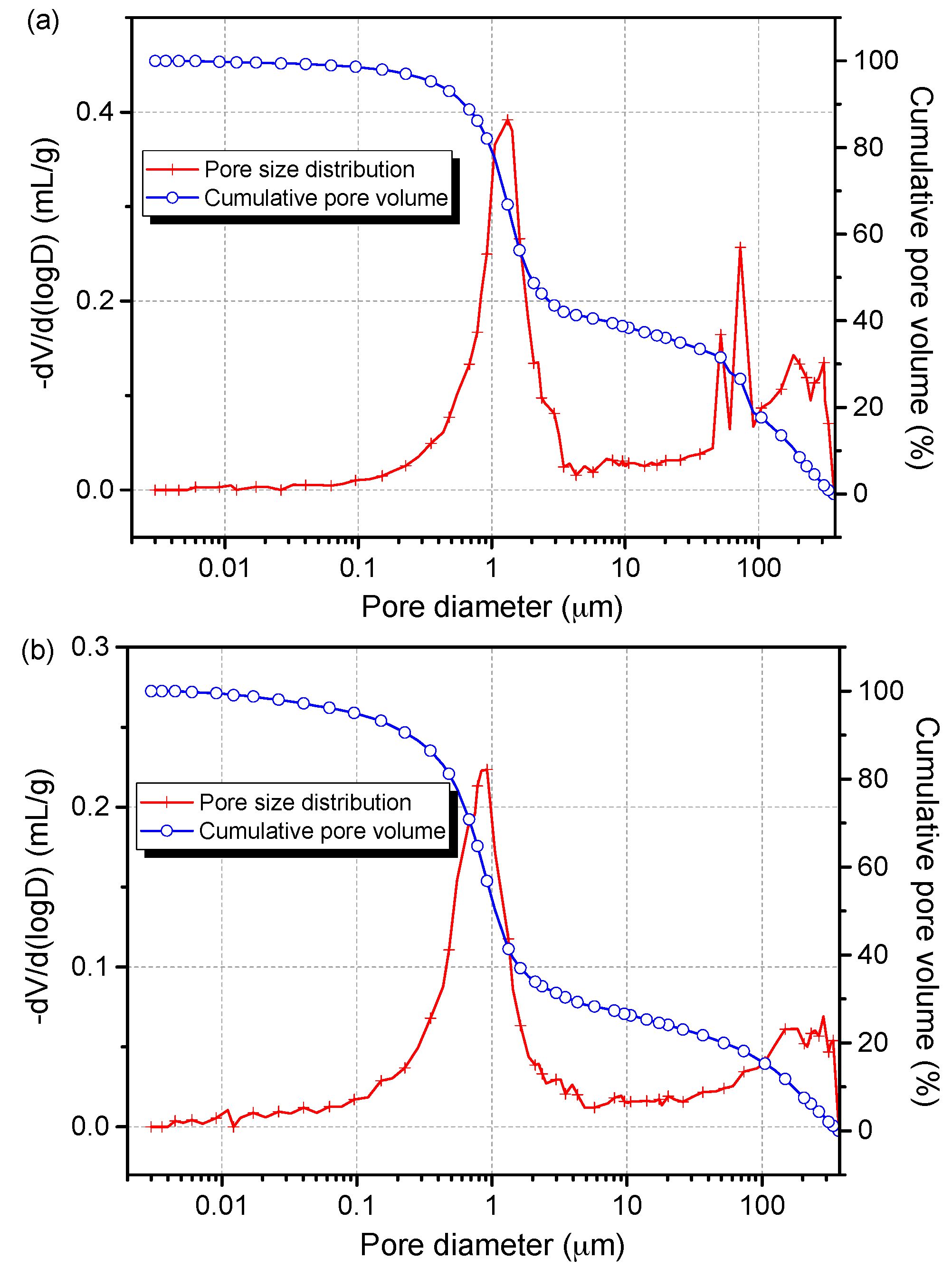

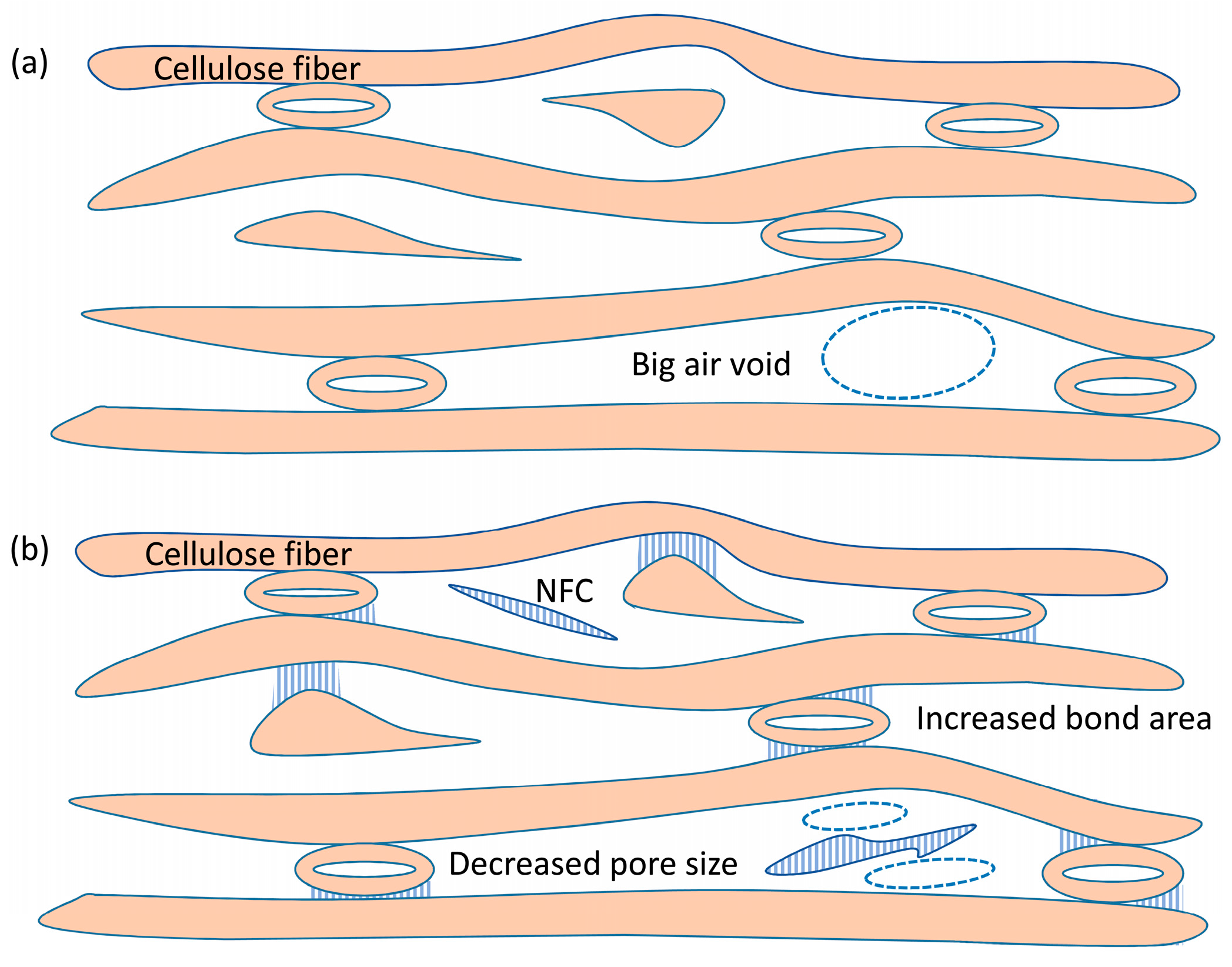

3.1. Morphology Property and Pore Size Distribution

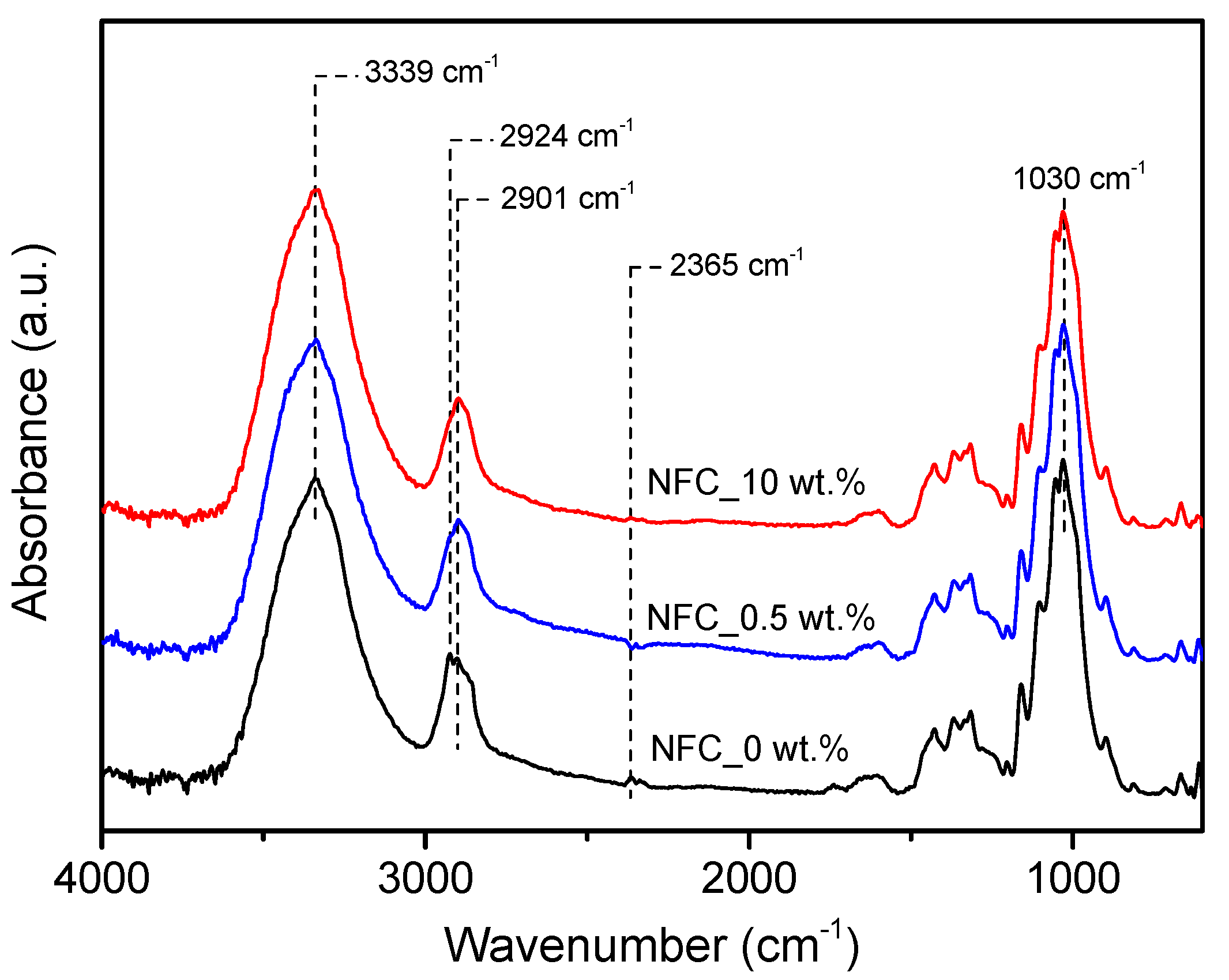

3.2. FTIR and XRD

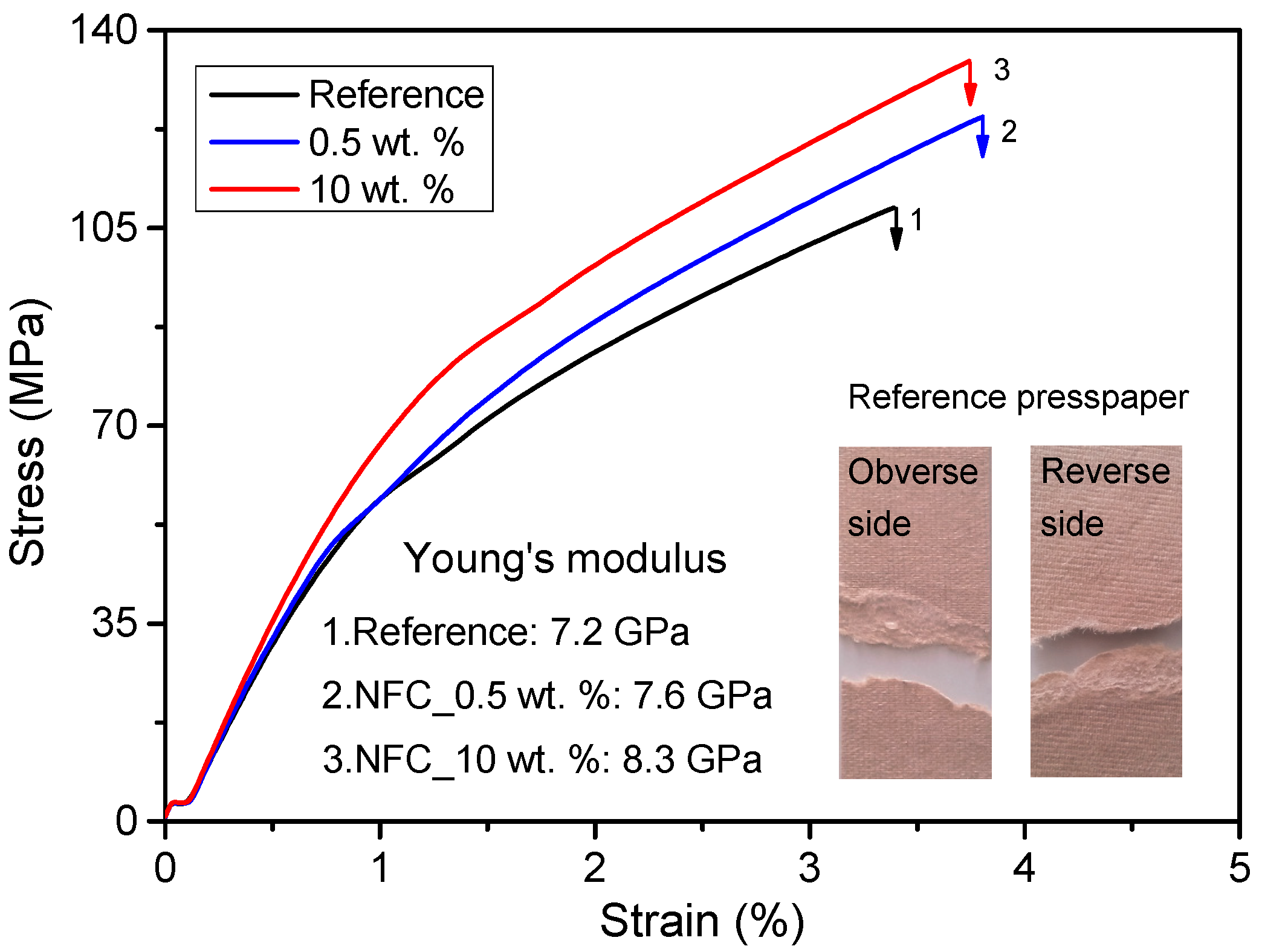

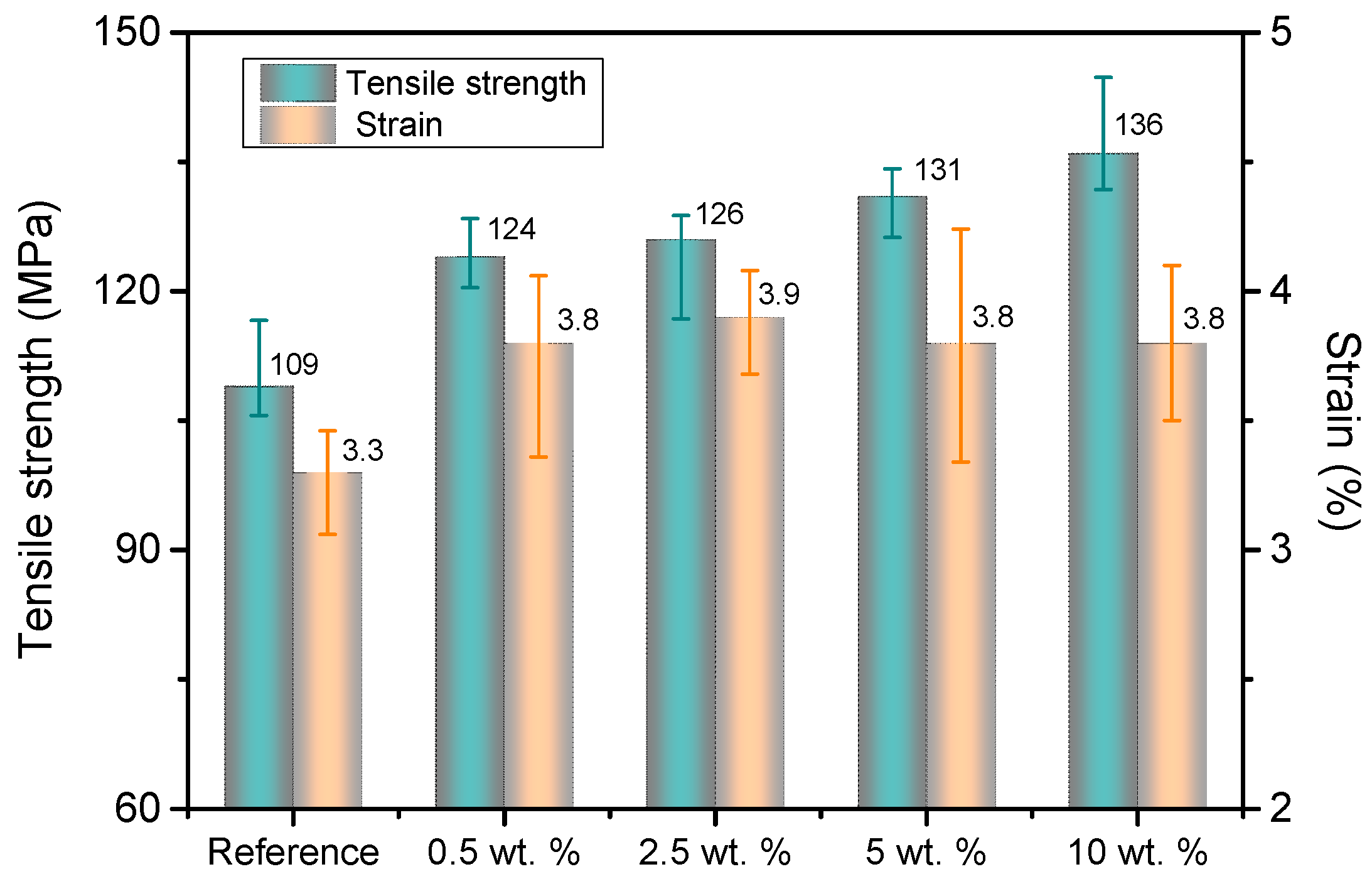

3.3. Mechanical Strength

3.4. Volume Resistivity and Dielectric Response

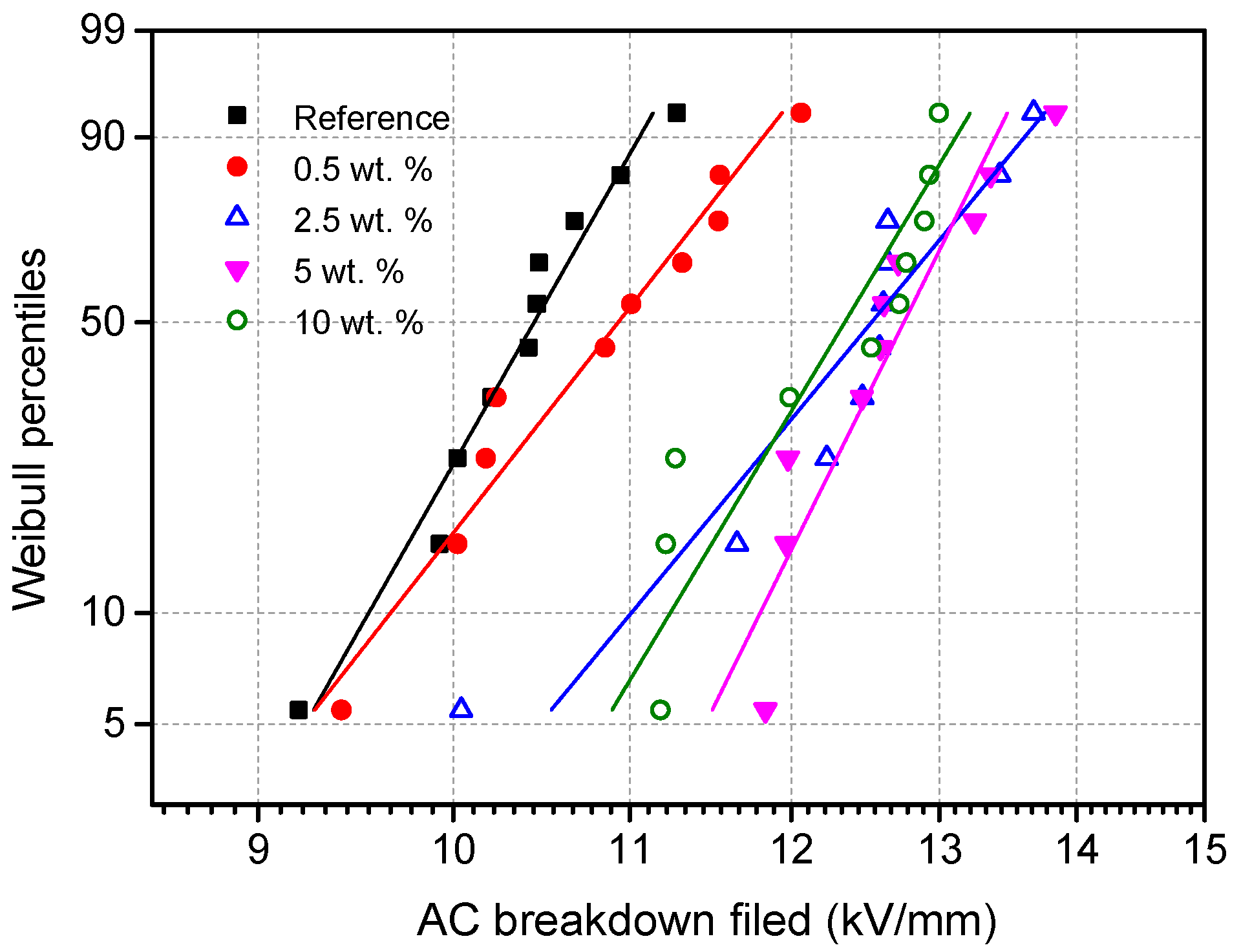

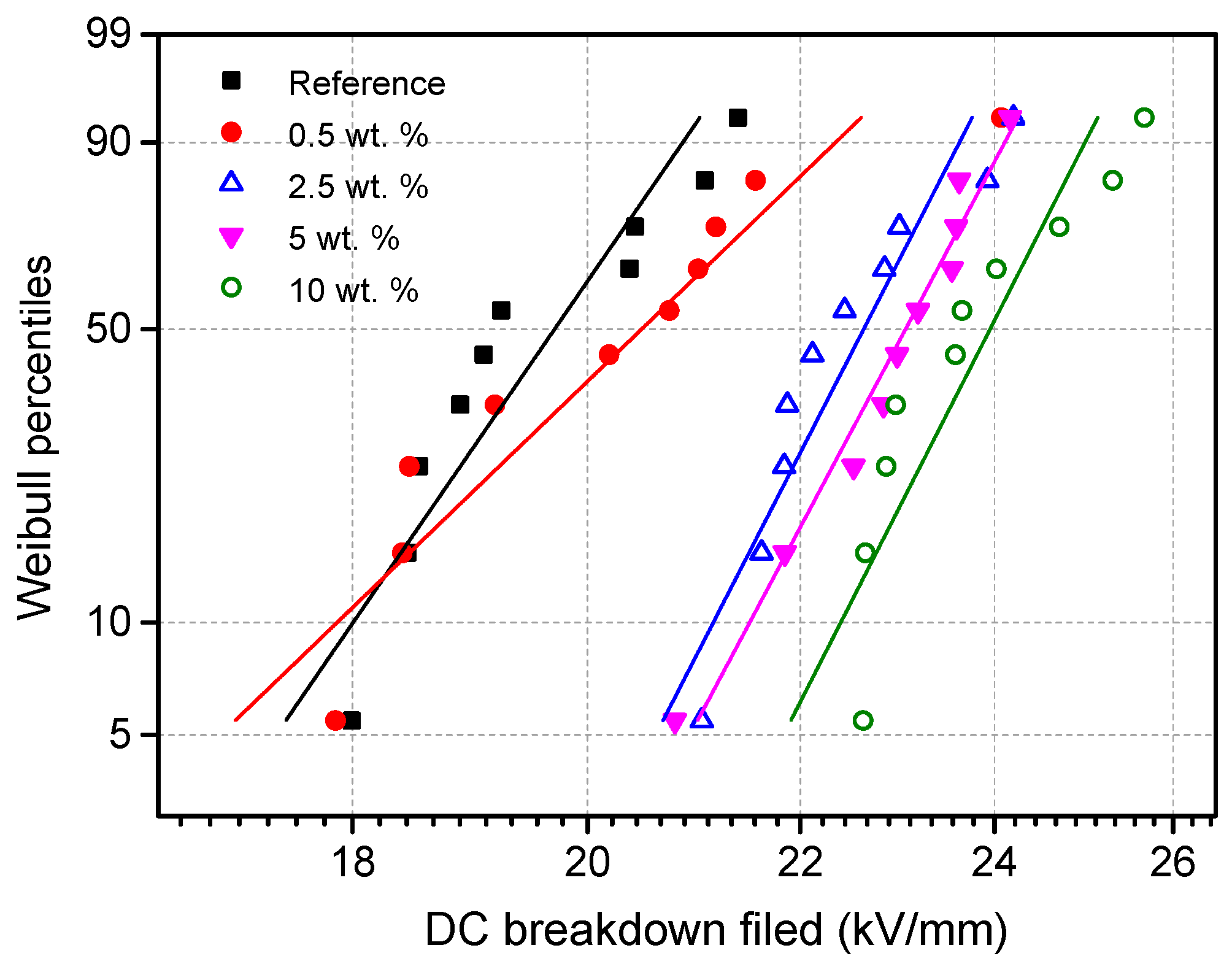

3.5. Breakdown Behavior

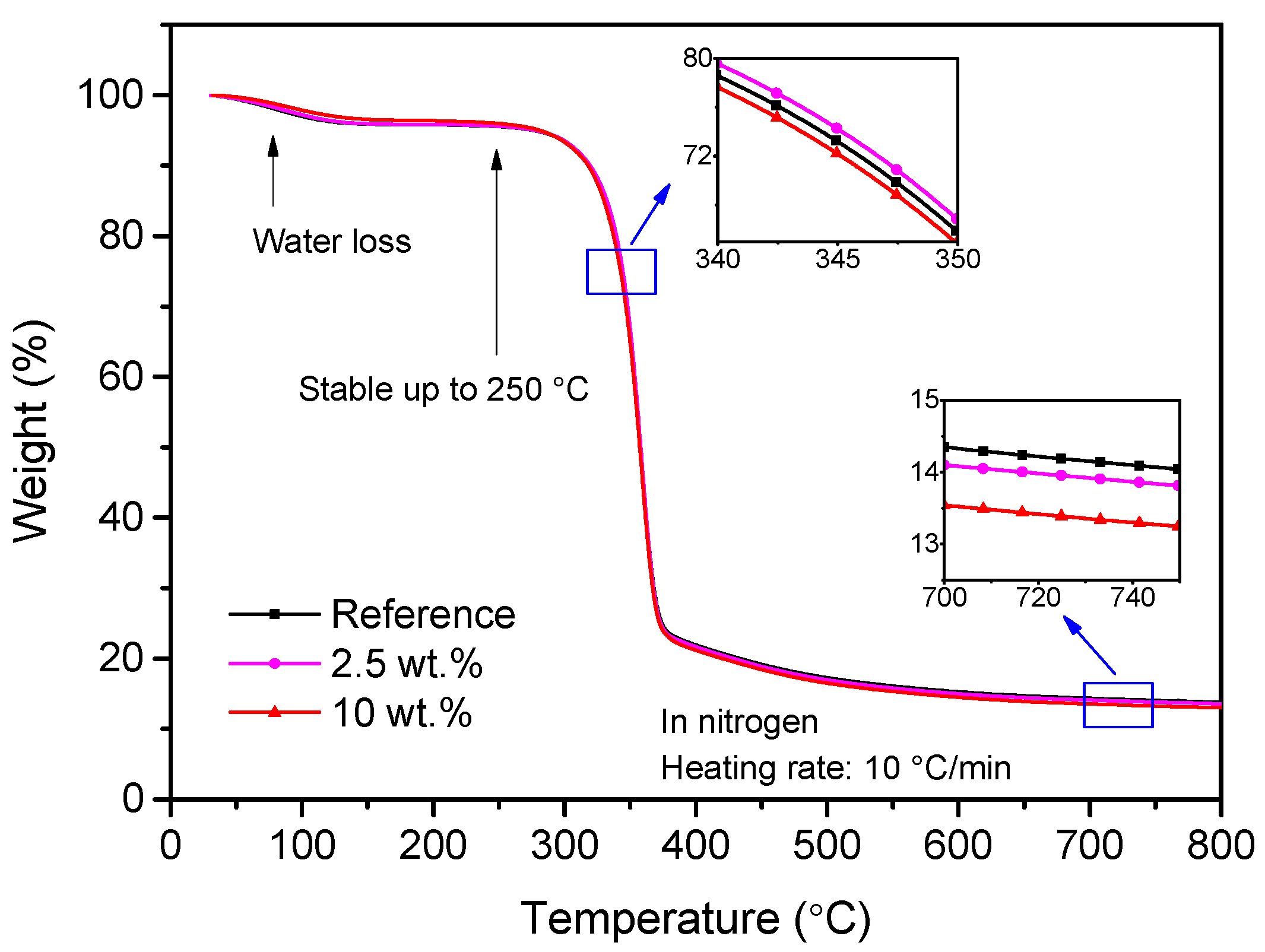

3.6. Thermal Properites

4. Conclusions

- (1)

- Presspaper modified by NFC has an increased density and inter fiber bond area. Porosities of reference presspaper and presspaper modified by 10 wt % NFC are 32.5% and 22.6%, respectively. Average pore diameter of reference presspaper is 2 μm. That of presspaper containing 10 wt % NFC is 1 μm. The effect of NFC on chemical functional groups and crystallinity is negligible when NFC content is no more than 10 wt %.

- (2)

- Presspaper modified by 10 wt % NFC has better mechanical and DC breakdown performances than presspaper containing other NFC contents.

- (3)

- Mechanical properties of nanomodified presspaper are improved due to the increased density and inter fiber bond strength. Tensile strength of reference presspaper is 109 MPa, whereas that of presspaper modified by 10 wt % NFC is 136 MPa, resulting in a 25% increase.

- (4)

- Breakdown behaviors of nanomodified presspaper are also enhanced because of the increased density and decreased pore size. Increases in AC and DC breakdown strengths by adding 10 wt % NFC to softwood fibers are 19% and 21%, respectively. The introduction of NFC has negligible effect on thermal stability of presspaper.

- (5)

- NFC has a small effect on volume resistivity and dielectric response. The slightly lower volume resistivity and higher dielectric constant of NFC modified presspaper indicate that the corresponding oil impregnated nanomodified presspaper insulation will be more suitable for applications in DC power equipment.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ali, M.; Eley, C.; Emsley, A.M.; Heywood, R.; Xaio, X. Measuring and understanding the ageing of kraft insulating paper in power transformers. IEEE Electr. Insul. Mag. 1996, 12, 28–34. [Google Scholar] [CrossRef]

- Wei, Y.; Mu, H.; Zhang, G.; Chen, G. A study of oil-impregnated paper insulation aged with thermal-electrical stress: PD characteristics and trap parameters. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3411–3420. [Google Scholar] [CrossRef]

- Hollertz, R.; Wagberg, L.; Pitois, C. Effect of composition and morphology on the dielectric response of cellulose-based electrical insulation. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2339–2348. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, J.; Sha, Y.; Zhang, L.; Jin, F.; Huang, M. Electrical properties of oil-paper affected by water conductivity during paper-making process. High Volt. Eng. 2015, 41, 382–388. [Google Scholar]

- Li, J.; He, Z.; Bao, L.; Yang, L. Influences of corrosive sulfur on copper wires and oil-paper insulation in transformers. Energies 2011, 4, 1563–1573. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Bao, L. Two factors failure model of oil-paper insulation aging under electrical and thermal multistress. J. Electr. Eng. Technol. 2014, 9, 957–963. [Google Scholar] [CrossRef]

- Huang, M.; Zhou, Y.; Chen, W.; Sha, Y.; Jin, F. Influence of voltage reversal on space charge behavior in oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 331–339. [Google Scholar] [CrossRef]

- Hollertz, R.; Wagberg, L.; Pitois, C. Novel cellulose nanomaterials: Towards usage in electrical insulation. In Proceedings of the IEEE 18th International Conference on Dielectric Liquids (ICDL), Bled, Slovenia, 29 June–3 July 2014; pp. 1–4. [Google Scholar]

- Abdelmalik, A.A.; Dodd, S.J.; Dissado, L.A.; Chalashkanov, N.M.; Fothergill, J.C. Charge Transport in thermally aged paper impregnated with natural ester oil. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2318–2328. [Google Scholar] [CrossRef]

- Baral, A.; Chakravorti, S. Compensating the effect of temperature variation on dielectric response of oil-paper insulation used in power transformers. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2462–2474. [Google Scholar] [CrossRef]

- Prevost, T.A.; Oommen, T.V. Cellulose insulation in oil-filled power transformers: Part I—History and development. IEEE Electr. Insul. Mag. 2006, 22, 28–35. [Google Scholar] [CrossRef]

- Tanaka, T.; Imai, T. Advances in nanodielectric materials over the past 50 years. IEEE Electr. Insul. Mag. 2013, 29, 10–23. [Google Scholar] [CrossRef]

- Andritsch, T.; Fabiani, D.; Ramirez Vazquez, I. Nanodielectrics-examples of preparation and microstructure. IEEE Electr. Insul. Mag. 2013, 29, 21–28. [Google Scholar] [CrossRef]

- Yuan, Y.; Liao, R. A novel nanomodified cellulose insulation paper for power transformer. J. Nanomater. 2014, 2014, 510864. [Google Scholar] [CrossRef]

- Liao, R.; Zhang, F.; Yuan, Y.; Yang, L.; Liu, T.; Tang, C. Preparation and electrical properties of insulation paper composed of SiO2 hollow spheres. Energies 2012, 5, 2943–2951. [Google Scholar] [CrossRef]

- Liao, R.; Lv, C.; Yang, L.; Zhang, Y.; Wu, W.; Tang, C. The insulation properties of oil-impregnated insulation paper reinforced with nano-TiO2. J. Nanomater. 2013, 2013, 373959. [Google Scholar] [CrossRef]

- Oommen, T.V.; Prevost, T.A. Cellulose insulation in oil-filled power transformers: Part II—Maintaining insulation integrity and life. IEEE Electr. Insul. Mag. 2006, 22, 5–14. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, Y.; Dong, L.; Zhou, Z.; Liu, R. Enhancement of mechanical and electrical performances of insulating presspaper by introduction of nanocellulose. Compos. Sci. Technol. 2017, 138, 40–48. [Google Scholar] [CrossRef]

- Missoum, K.; Belgacem, M.N.; Bras, J. Nanofibrillated cellulose surface modification: A review. Materials 2013, 6, 1745–1766. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665. [Google Scholar] [CrossRef] [PubMed]

- Boufi, S.; Gonzalez, I.; Delgado-Aguilar, M.; Tarres, Q.; Angels Pelach, M.; Mutje, P. Nanofibrillated cellulose as an additive in papermaking process: A review. Carbohydr. Polym. 2016, 154, 151–166. [Google Scholar] [CrossRef] [PubMed]

- Sehaqui, H.; Allais, M.; Zhou, Q.; Berglund, L.A. Wood cellulose biocomposites with fibrous structures at micro- and nanoscale. Compos. Sci. Technol. 2011, 71, 382–387. [Google Scholar] [CrossRef]

- Evangelina Vallejos, M.; Esteban Felissia, F.; Cristina Area, M.; Vanesa Ehman, N.; Tarres, Q.; Mutje, P. Nanofibrillated cellulose (CNF) from eucalyptus sawdust as a dry strength agent of unrefined eucalyptus handsheets. Carbohyd. Polym. 2016, 139, 99–105. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, I.; Boufi, S.; Angels Pelach, M.; Alcala, M.; Vilaseca, F.; Mutje, P. Nanofibrillated cellulose as paper additive in eucalyptus pulps. BioResources 2012, 7, 5167–5180. [Google Scholar] [CrossRef]

- Sehaqui, H.; Zhou, Q.; Berglund, L.A. Nanofibrillated cellulose for enhancement of strength in high-density paper structures. Nord. Pulp Pap. Res. J. 2013, 28, 182–189. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, L.; Zhou, Y.; Huang, M.; Sha, Y. Study on the suitability of bamboo fiber for manufacturing insulating presspaper. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3641–3651. [Google Scholar] [CrossRef]

- Orsolini, P.; Michen, B.; Huch, A.; Tingaut, P.; Caseri, W.R.; Zimmermann, T. Characterization of pores in dense nanopapers and nanofibrillated cellulose membranes: A critical assessment of established methods. ACS Appl. Mater. Interface 2015, 7, 25884–25897. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Fatah, I.Y.A.; Khalil, H.P.S.A.; Hossain, M.S.; Aziz, A.A.; Davoudpour, Y.; Dungani, R.; Bhat, A. Exploration of a chemo-mechanical technique for the isolation of nanofibrillated cellulosic fiber from oil palm empty fruit bunch as a reinforcing agent in composites materials. Polymers 2014, 6, 2611–2624. [Google Scholar] [CrossRef]

- Page, D.H. A theory for tensile strength of paper. Tappi 1969, 52, 674–681. [Google Scholar]

- Hubbe, M.A. Prospects for maintaining strength of paper and paperboard products while using less forest resources: A review. BioResources 2014, 9, 1634–1763. [Google Scholar] [CrossRef]

- Morgan, V.T. Effects of frequency, temperature, compression, and air pressure on the dielectric properties of a multilayer stack of dry kraft paper. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 125–131. [Google Scholar] [CrossRef]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; P. Peregrinus: London, UK, 1992. [Google Scholar]

- Sikorski, W.; Walczak, K.; Przybylek, P. Moisture migration in an oil-paper insulation system in relation to online partial discharge monitoring of power transformers. Energies 2016, 9, 1082. [Google Scholar] [CrossRef]

- Kohman, G.T. Cellulose as an insulating material. Ind. Eng. Chem. 1939, 31, 807–817. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, Y.; Zhou, Z.; Liu, R. Dramatically enhanced electrical breakdown strength in cellulose nanopaper. AIP Adv. 2016, 6, 1–7. [Google Scholar] [CrossRef]

- Kaplan, A.M.; Chekunaev, N.I.; Bezhikina, L.V.; Nikolskii, V.G. Composite papers with enhanced electrical strength. Compos. Sci. Technol. 1994, 51, 325–329. [Google Scholar] [CrossRef]

| Sample | Scale Parameter (kV/mm) | 90% Confidence Intervals | |

|---|---|---|---|

| Lower (kV/mm) | Upper (kV/mm) | ||

| AC Breakdown Tests | |||

| Reference | 10.6 | 10.3 | 10.9 |

| 0.5 wt % | 11.2 | 10.7 | 11.6 |

| 2.5 wt % | 12.8 | 12.4 | 13.2 |

| 5 wt % | 13.0 | 12.6 | 13.3 |

| 10 wt % | 12.6 | 12.2 | 12.9 |

| DC Breakdown Tests | |||

| Reference | 20.1 | 19.4 | 20.7 |

| 0.5 wt % | 21.0 | 20.0 | 22.0 |

| 2.5 wt % | 22.9 | 22.3 | 23.5 |

| 5 wt % | 23.4 | 22.9 | 23.8 |

| 10 wt % | 24.3 | 23.6 | 24.9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Zhou, Y.; Dong, L.; Zhou, Z.; Zeng, X. Enhancing Insulating Performances of Presspaper by Introduction of Nanofibrillated Cellulose. Energies 2017, 10, 681. https://doi.org/10.3390/en10050681

Huang J, Zhou Y, Dong L, Zhou Z, Zeng X. Enhancing Insulating Performances of Presspaper by Introduction of Nanofibrillated Cellulose. Energies. 2017; 10(5):681. https://doi.org/10.3390/en10050681

Chicago/Turabian StyleHuang, Jianwen, Yuanxiang Zhou, Longyu Dong, Zhongliu Zhou, and Xiangjun Zeng. 2017. "Enhancing Insulating Performances of Presspaper by Introduction of Nanofibrillated Cellulose" Energies 10, no. 5: 681. https://doi.org/10.3390/en10050681